Abstract

Over the last few decades, hot melt extrusion (HME) has emerged as a successful technology for a broad spectrum of applications in the pharmaceutical industry. As indicated by multiple publications and patents, HME is mainly used for the enhancement of solubility and bioavailability of poorly soluble drugs. This review is focused on the recent reports on the solubility enhancement via HME and provides an update for the manufacturing/scaling up aspects of melt extrusion. In addition, drug characterization methods and dissolution studies are discussed. The application of process analytical technology (PAT) tools and use of HME as a continuous manufacturing process may shorten the drug development process; as a result, the latter is becoming the most widely utilized technique in the pharmaceutical industry. The advantages, disadvantages, and practical applications of various PAT tools such as near and mid-infrared, ultraviolet/visible, fluorescence, and Raman spectroscopies are summarized, and the characteristics of other techniques are briefly discussed. Overall, this review also provides an outline for the currently marketed products and analyzes the strengths, weaknesses, opportunities and threats of HME application in the pharmaceutical industry.

Keywords: Hot melt extrusion, Process analytical technology tool, SWOT analysis, Poorly soluble drug, Polymer, Continuous manufacturing, Dissolution

Graphical Abstract

Introduction

Over many decades, the poor solubility of APIs has been a major obstacle for the development of more efficient drug delivery methods. To overcome this problem, various strategies were proposed in the literature (Alam et al., 2012; Goke et al., 2017; Wen et al., 2015). Among these strategies, hot-melt extrusion (HME) represents a complementary pharmaceutical manufacturing technology, which is widely used by industrial and academic researchers for mitigating the solubility issues of APIs.

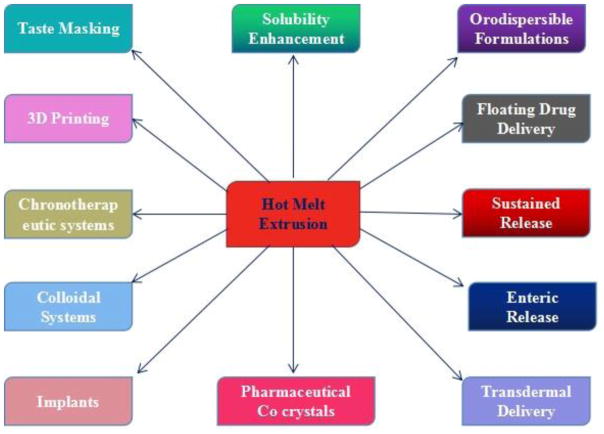

HME was first introduced in 1971 as a formulation technology platform for the pharmaceutical industry (El-Egakey et al., 1971). Since that time, not only HME was adopted by the industry, but it was also modified and customized for multiple applications (Langley et al., 2013). The versatility of HME for various drug delivery strategies such as transdermal applications (Qi and Craig, 2016), bio-adhesive functions (Palem et al., 2016), implants (Cosse et al., 2017), orodispersible formulations (Pimparade et al., 2017), pellets, gastroretentive systems (Vo et al., 2016) lipid nanoparticles (Bhagurkar et al., 2017; Patil et al., 2015), and other applications (Fig. 1) has made it a technology that is poised to shift the entire paradigm of pharmaceutical industry research and manufacturing. One of the most significant uses of HME is the improvement of the solubility of poorly soluble drugs obtained via advanced combinatory and high-throughput screening. The strengths, weaknesses, opportunities, and threats (SWOTs) of HME are listed in Table 1. Regardless of gaining popularity, HME faces challenges (perceived or real) from various issues such as thermal degradation of API and/or carrier at processing temperatures, recrystallization of API over time, and reproducibility of HME products. However, the above issues can be addressed by reducing the processing temperatures by use of plasticizers, reduction of residence time of materials during the extrusion process and drug melting point depression by co-crystallization, etc.

Fig. 1.

The various broad-spectrum applications of hot melt extrusion

Table 1.

S.W.O.T. analysis of pharmaceutical hot melt extrusion technology

| Strengths | Weaknesses |

|---|---|

|

|

| Opportunities | Threats |

|

|

HME can be considered an optimal technique for the processing of highly viscous materials without using any solvents and thus has been widely recognized as a green technology (Repka et al., 2008; Sarode et al., 2013). Its unique blending geometry promotes high-shear localized mixing while retaining the high throughput of the process. The HME screw configuration can be highly customized to tailor its shear level based on the formulation requirements (Haser et al., 2017; Morott et al., 2015). The continuous thinning, deformation, and elongation processes occurring in a very narrow space between the intermeshing elements facilitate the dissolution of drug molecules and/or their dispersion in a molten carrier (Haser et al., 2016). The high efficiency of distributive and dispersive mixing also allows contact between various chemical molecules at high frequencies without using any solvents that promote the formation of salt co-crystal species (Li et al., 2016; Liu et al., 2017). In addition, HME represents a high-throughput continuous process, which can be scaled up for industrial manufacture (Langley et al., 2013). The application of quality by design (QbD) and real-time monitoring techniques utilizing process analytical technology (PAT) strategies allows the development of HME as a continuous manufacturing (CM) platform (Islam et al., 2014; Tiwari et al., 2016), which can be used for more efficient and better controlled drug delivery (Chatterjee, 2012). This platform also offers many industrial benefits in the form of reduced labor, shorter operation times, lower investments, smaller facilities, and instrumentation (Bhagurkar et al., 2016). The concept of real-time release testing (RTRT) of pharmaceutical products proposed by the U.S. Food and Drug Administration (FDA) in 2004 promoted the use of process analytical tools for product development in the pharmaceutical industry. The resulting shift in the paradigm from batch testing to in-process testing (which improved the quality of product manufacturing) has been widely recognized and implemented. This article represents an integrated update of our previous review (Shah et al., 2013), which is written with an emphasis on the advances of HME for improved solubility and dissolution rates of poorly soluble drugs, thermodynamic aspects and mechanisms of drug/polymer solubilization, characterization techniques and its applicability as a CM technology for solid dispersions. This review also provides an overview of the current PAT tools employed in various pharmaceutical HME processes.

1. HME and solubilization enhancement

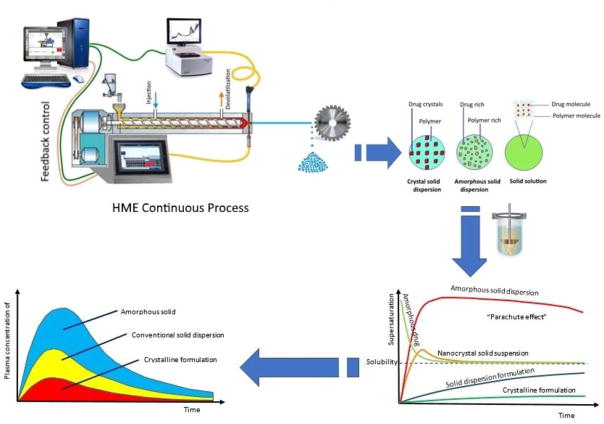

HME has been widely used to prepare amorphous solid dispersions for the improvement of solubility and dissolution rates of poorly soluble materials. During the melt extrusion process, the dissolution of APIs into the polymer matrix is accelerated under the influence of shear and heat. The amorphous solid dispersions produced via HME are expected to possess lower molecular mobilities and API molecules “freeze” inside a polymer matrix to inhibit the nucleation and crystallization processes (Baghel et al., 2016; Theil et al., 2017).

2.1. Thermodynamic phase diagram of a API/polymer binary mixture

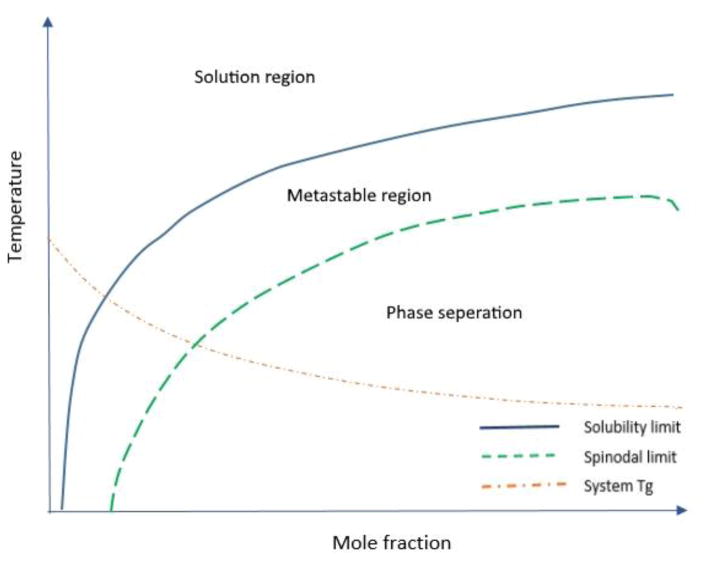

A typical phase diagram depicted in Fig. 2 exhibits various drug-polymer solubility and miscibility phases of the drug-polymer binary mixture corresponding to different temperatures and drug/polymer ratios. The solubility limit and spinodal curves divide the diagram area into three distinct regions (solution region, metastable region, and phase separation region) of the solid dispersion (Tian et al., 2014). In the solution region, the drug and polymer form a thermodynamically stable single-phase system. In the metastable region, amorphous APIs are miscible with polymers. Theoretically, systems in this region are not stable and exhibit a tendency to transform into a more stable state; however, the related evolution process may be very slow. Thus, they can be considered relatively stable systems under specific conditions or within a relatively short period. In the phase separation region, two different phases exist: a drug-rich phase and a polymer-rich phase. The glass transition temperature (Tg) line in the phase diagram further divides each of the described regions into two sub-regions, and the systems existing above this line can reach a steady state much faster than their counterparts. Three different types of relaxations (α, β, and γ), which are directly related to molecular mobility, strongly depend on temperature. In the regions below the Tg, only beta and gamma relaxations (which are weaker than alpha relaxations) can be observed.

Fig. 2.

Typical phase diagram of API/polymer binary mixture

2.2. API/polymer solubility and miscibility measurements

The solubility of a drug in a polymer matrix is a very important parameter that must be considered during polymer selection. Estimating the drug/polymer miscibility is a difficult task since reaching equilibrium usually takes a very long time. Therefore, the determination of the API/polymer solubility and miscibility can only be performed under certain assumptions (Qian et al., 2010). The most popular approach to the determination of the drug/polymer miscibility is the application of the Flory-Huggins theory for the dispersions of small molecules in a polymer matrix (Marsac et al., 2009; Marsac et al., 2006; Tian et al., 2014).

Using the lattice theory, the mixing free energy of an API/polymer blend can be calculated via the Flory–Huggins equation (Eq. 1):

| (1) |

where ϕ is the volume fraction, N is the molecular volume, χ is the Flory-Huggins interaction parameter, R is the molar ideal gas constant, and T is the temperature.

When studying solid dispersions, the Flory-Huggins equation is primarily utilized for constructing free energy phase diagrams of API/polymer blends. The free energy of mixing (ΔGmix) can be calculated at a specified temperature with respect to the interaction parameter. Experimentally, the latter can be obtained via a melting point depression method, which utilizes the following relationship between the melting point and the interaction parameters (Marsac et al., 2006; Tian et al., 2013):

| (2) |

where ϕ is the volume fraction; m is the ratio of the volume of a polymer chain to the drug molecular volume; Tm and Tm0 are the melting points of the drug crystals in the drug/polymer mixture and pure drug, respectively; R is the gas constant, and ΔH is the heat of fusion of the drug. The value of the left side of Eq. (2) can be determined via differential scanning calorimetry (DSC), and the magnitudes of ϕ and m can be calculated from the molecular weights and ratio between the drug and the polymer components. As a result, the Flory-Huggins interaction parameters are obtained and an API/polymer phase diagram can be plotted. One drawback of this method is that the melting point depression is not always detectable, especially when the Tg of polymer carriers is close to or higher than the melting point of APIs. The application of this method is also limited when APIs possess a high melting point because the thermal degradation of components might occur during experiments.

Another method for determining the API/polymer solubility is using the Hansen–Hildebrand solubility parameters (δ), which contains three components taken into account, namely dispersive interactions (δd), polar interactions (δp), and hydrogen bonding (δh) (Stefanis and Panayiotou, 2008; Stefanis and Panayiotou, 2012). The three-dimensional solubility parameter is the sum of squares of the partial solubility parameters:

| (3) |

| (4) |

where Fdi is the molar attraction constant corresponding to the dispersion component, Fpi is the molar attraction constant related to the polar component, Ehi is the hydrogen bonding energy, and V is the molar volume (Bellantone et al., 2012; Tian et al., 2014; Vay et al., 2011).

In general, if the difference between the solubility parameters of the drug and polymer is greater than 10.0 MPa1/2, their miscibility is extremely low; however, when the differential solubility parameter is below 7 MPa1/2, the drug and polymer are considered highly miscible (Ghebremeskel et al., 2007; Sarode et al., 2013). Solubility parameters can only be utilized to qualitatively estimate the cohesive properties of drug/polymer mixtures. They do not reflect the drug/polymer extent of miscibility, but can be used to calculate the interaction parameter (χ) in the Flory-Huggins equation. It should be noted that the calculation of solubility parameters is highly likely to pose errors since the concept is based on simple organic structures. The effects of long-range orders and interactions within the polymer chains are not considered.

The recently proposed perturbed-chain statistical associating fluid theory (PC–SAFT) was utilized for constructing the phase diagrams of various API/polymer blends (Prudic et al., 2014; Prudic et al., 2015). To apply this method, the residual Helmholtz energy must be calculated by considering the repulsion forces, van der Waals attraction forces, and hydrogen bonding of molecules. Each API or polymer molecule is described as a chain consisting of multiple spherical segments. The total interaction is simulated using the following ve pure-component parameters: segment number, segment diameter, dispersion-energy parameter, association-volume parameter, and association energy parameter. The solubility of APIs in polymers can be predicted assuming the thermodynamic solid–liquid equilibrium of pure API species in the API/polymer phase. Hence, the API solubility in a polymer can be calculated using the following equation:

| (5) |

where T and R are the temperature and universal ideal gas constant, respectively. , and are the API melting temperature, API fusion heat, and the difference in the heat capacity between the solid and liquid APIs, respectively (all these parameters can be determined by DSC). Therefore, a phase diagram can be constructed by estimating the API solubility in the polymer at different conditions (Rask et al., 2016). The application of PC–SAFT to construct drug/polymer phase diagrams is relatively new.

Although the described methods can be used for the prediction of API-polymer interactions; however, a gap exists between the prediction and reality. Therefore, the utilization of experimental methods such as DSC, various spectroscopic and microscopic techniques, and X-ray diffraction (XRD) is required to confirm the miscibility of the API and polymer (Sarode et al., 2013).

2.3. Solubilization and homogenization of drug molecules in a polymer matrix via HME

HME promotes the solubilization/dispersion of APIs in a polymer matrix and it depends on various parameters such as the formulation components (the compositions of the API and polymer and their ratio), process conditions (temperature, pressure, torque, and shear force), and equipment (type, screw configuration, feed rate, and other parameters). If the APIs are considered a solute, and the soft polymer matrix, a solvent, the dispersion of API species in the molten polymer is similar to the process of mixing small molecules with a liquid solvent. Thus, the described mixture can form a thermodynamically stable solution, metastable (supersaturated) molecular dispersion, or a suspension. The dispersion and solubilization of APIs in a polymer matrix are relatively slow processes because of the high viscosity of molten polymers. HME lowers the viscosity of a system, while the vigorous shear of screws improves its homogeneity. Furthermore, the effect of thinning and mixing at the micro-scale increases the effectiveness of melt extrusion. Based on the relative comparison between the operating temperature and the melting temperature of API, the process of melt extrusion can occur in two distinct regimes: solubilization regime and miscible regime (DiNunzio et al., 2012). For both regimes, the processing temperature preferably should significantly exceed the Tg of the carrier excipients. In the solubilization regime, the processing temperature is lower than the melting point of API; as a result, the drug molecules have to overcome molecular bonds within the bulk API crystal lattice before diffusing into the molten polymer matrix. If the drug/polymer ratio is greater than the solubility, only a fraction of API molecules can be dissolved, while the rest remains dispersed across the polymer matrix in the crystalline form. The kinetics of the solubilization process can be described by the Noyes Whitney equation:

| (6) |

where dM is the amount of API dissolved within the specified time interval (dt), dM/dt is the solubilization rate, D is the diffusion coefficient, A is the interphase area, h is the diffusion distance, C0 is the solubility of API in the polymer, and Ct is the bulk concentration of API in the polymer matrix.

All parameters of the Noyes–Whitney equation are affected by the melt extrusion process, which ultimately increases the API solubilization in the polymer matrix (Shah et al., 2013). The increase in the processing temperature increases solubility C0 and diffusivity D and decreases the melt viscosity of the molten polymer, thus facilitating the diffusion and API/polymer mixing processes. Additionally, the shear and blending processes decrease the boundary thickness h, bulk concentration Ct, and, in certain cases, increase the interphase area A. The applied shear force can be adjusted by modifying the screw design, screw speed, and feed rate. Increasing HME residence time and using micronized materials can further enhance the API solubilization in the polymer matrix (Li et al., 2015).

In the miscible regime, the processing temperature is higher than the melting point of API species; as a result, the latter are melted quickly inside the barrel and form a liquid phase during the melt extrusion process. The liquid API phase can be easily divided, kneaded, blended, and dispersed inside the molten polymer, which drastically increases the interphase area and thus promotes the solubilization process. When the drug/polymer ratio is higher than the drug solubility, the coexistence of two phases (the drug-rich and polymer-rich ones) is observed. Because of the stability concerns, the miscible regime is only applicable to the drugs with low melting points and very limited for the thermolabile APIs. It was found that along with the processing parameters, excipients also play a crucial role in the success of the HME process. Hence, the API/carrier solubility, melt viscosity, and thermal stability parameters must be considered during excipient screening.

A polymer, in which APIs are inherently soluble, always represent a good choice for a drug carrier since it enhances both the dissolution rate and degree of solubilization, owing to the high diffusivity (D) and solubility (C0) values. In addition, when the API is highly miscible with the polymer, the melting point of the drug is decreased (Djuris et al., 2013), which ultimately facilitates the HME process. However, carrier species should be soluble in water to ensure proper release of APIs from the matrix (Janssens and Van den Mooter, 2009). This criterion limits the range of materials with good carrier properties because the hydrophobic nature of APIs decreases their solubility in hydrophilic polymers. Additionally, a good carrier should possess reasonable melt viscosity and thermal stability values. Increasing the temperature lowers the torque, and thus facilitates the melt extrusion process. However, it is limited by the thermal stability concerns. Adding plasticizers can lower Tg and thus improve the processability of the formulations (Crowley et al., 2007), but it may accelerate the crystallization and phase separation processes during storage.

2. Manufacturing aspects

In our earlier review, basic aspects of the utilized HME equipment (including processing parameters and screw configurations) were discussed. This current review focuses on the recent updates on the manufacturing issues and specific issues related to the HME process (Maniruzzaman and Nokhodchi, 2017; Patil et al., 2016).

3.1 HME scale-up strategies

Generally, commercial production implies large-scale processing and a high throughput rate of materials. The process feasibility and preserving the key process parameters are critical for maintaining high quality of the product. Different scale-up strategies for HME include power scale-up, volumetric scale-up, and heat transfer scale-up (Dreiblatt, 2012).

3.1.1 Power scale-up

Specific energy (SE) input and specific torque are critical parameters that play a pivotal role in the successful scale-up implementation. The HME mechanical energy input can be expressed as (Munjal et al., 2006):

| (7) |

Here E is the mechanical energy, N is the real screw speed, τ is the real torque; Emax is the maximum mechanical energy of the system, Nmax is the maximal screw speed, and τmax is the maximal torque. The values of Emax, Nmax, and τmax are predetermined by the instrument design (Breitenbach, 2006). SE = E/Q, where Q is the true throughput of the process (which equals the feed rate of the starved feeding system).

3.1.2 Volume scale-up

Volumetric scale-up requires maintaining the same filling level and residence time distribution during the process. For the geometrically similar extruders, the target process throughput can be calculated using the following equation (Rothen-Weinhold et al., 2000):

| (8) |

where QT is the final process feed rate, QM is the initial process feed rate, DT is the screw diameter after scale-up, DM is the screw diameter before scale-up, NT is the screw speed after scale-up, and NM is the screw speed before scale-up.

3.1.3 Heat transfer scale-up

Melt extrusion depends on the heat transfer inside the barrel; thus, the surface area of heat transfer is equivalent to the barrel surface area. The scale-up for heat transfer can be described by the following equation (Munjal et al., 2006):

| (9) |

Here QT is the target throughput, QM is the initial throughput, DT is the target screw diameter, DM is the initial screw diameter, NT is the screw speed after scale-up, and NM is the screw speed before scale-up.

Recently, Agrawal et al. (2016) have performed the successful scale-up studies of an insoluble drug (compound X) by formulating an amorphous solid dispersion containing Kollidon® K12 (PVP K12) and Kollidon® VA64 (vinyl pyrrolidine-vinyl acetate co-polymer) polymers, utilized volumetric and power scale-up. In this study, a scale-up from a 9-mm extruder (with a batch size of 5–20 g) to a 16-mm or 18-mm clinical scale extruder with a minimum batch size of 500 g was performed. For successful scale-up, the geometric similarity between extruders is very important. Therefore, due to the difference in the geometries of the 16-mm and 18-mm extruders, feed rate estimation was conducted via the volumetric approach to ensure that both extruders exhibited the same values of specific energy. The melt pressure was greater inside the 16-mm extruder due to the differences in the die and screw designs (the latter had a large diameter due to the larger screw flight of 3 mm). The smaller shear force observed for the 18-mm extruder resulted in a low level of impurities as compared to those obtained for the 9-mm and 16-mm extruders. Hence, for successful scale-up, both the equipment geometry and screw design must be considered along with the scale-independent parameters.

3.2. Process parameters

The process parameters play a significant role in ensuring the quality and stability of HME products. This review discusses various process parameters reported in the literature.

3.2.1. Residence time

The residence time (RT) of the HME process characterizes the heat energy produced over a specific period during the material shear. If a given API/carrier system is thermolabile, downstream feeding can be used to narrow the residence time distribution (RTD) which avoids material degradation (Repka et al., 2012). The RT in a starved area (where the extruder operates at a feed rate capacity below the conveying capacity, and the screw is not completely filled with the material) can be obtained via the following equation (Hughey et al., 2010):

| (10) |

where Q is the net flow rate, Ls is the zone length, a is the open cross-section of the screw, f is the degree of filling, and z is the head length.

For the extruder with the completely filled screw, the mean RT is equal to

| (11) |

where Q is the net flow rate, Lf is the length of the completely filled zone, and a is the open cross-section of the screw (Stroyer et al., 2006).

The total RT is equal to the sum of the mean RTs of all zones (Wang et al., 2004):

| (12) |

RTD also plays an important role in maintaining the product stability. The increased RT exposes the material to heat and shear for a longer period, which can cause degradation affecting the product quality and performance (Gao et al., 2012).

Finally, RT is related to the filling properties of a material via the following equation (Gryczke et al., 2011):

| (13) |

where RT is the residence time in seconds, L/D is the extruder ratio, SV is the specific volume of the material, SG is the specific gravity of the material, % fill is the degree of filling expressed as a fraction, and Q is the throughput expressed in kg/h.

Li et al. (2015) investigated the effect of the API particle size (API milling) and HME process parameters (such as screw design and residence time) on the dissolution rate of acetaminophen (APAP) combined with Soluplus® (polyvinyl caprolactam–polyvinyl acetate–polyethylene glycol graft copolymer) at a Soluplus®/APAP ratio of 70/30. Extrusion was performed at a temperature of 100 °C, which was below the melting point of APAP (169–170 °C). These researchers reported an increased dissolution rate for the milled API, which was attributed to the greater area of interaction with Soluplus® and shortened diffusion path lengths. The dissolution of API was increased for the screw configuration with a high number of reverse elements because of the increased holdup volume resulting in a longer residence time (corresponding to an increment from 130 s to 180 s).

3.2.2. Viscosity

The basic factors affecting the HME process are represented by the mechanical properties of the blend as well as the thermoplasticity, deformation characteristics, and softness of the utilized materials. Viscosity is a specific parameter that maintains the value of the process torque within certain limits.

It was observed that the molecular weight (M.W.) and chain length of a polymer could significantly affect the product quality since these parameters were related to the rheological behavior of the polymer and its interactions in the molten state (Sperling, 2005). The viscosity of a polymer is proportional to its M.W.; thus, the polymers with high M.W. exhibit high melt viscosity.

Melt viscosity also depends on the Tg of a polymeric carrier. In particular, the melt viscosity of an amorphous carrier above Tg can be characterized by the William–Landel–Ferry (WLF) equation (Lu et al., 2003):

| (14) |

Here C1 and C2 are the constants, η is the melt viscosity at a processing temperature, and ηTg is the melt viscosity at Tg.

3.2.3. Temperature, screw design, and speed

The other important parameters of HME are the screw design, speed, and temperature of operation. The careful optimization of the processing conditions should be performed since these parameters directly influence the quality of the final product (Dong and Choi, 2008).

Huang et al. (2017) studied the effect of the processing conditions on the melt extrusion of amorphous dispersions of Gliclazide (GLZ) (M.P. = 180–182 °C) in Soluplus®, AffiniSol™, and PVP VA64 polymers. Extrusion was conducted in the temperature range of 100–160 °C at screw speeds of 100, 200, and 300 RPM. The results of thermogravimetric analysis (TGA) studies revealed that GLZ was stable at temperatures below 165 °C.

Overall, the selection of suitable scale up methods for HME depends on the quality and stability of the final product. In fact, the difference in geometry of the equipment could be a potential factor taken into consideration since it can influence the total energy introduced into the extruder (and thus the product). The scale-up strategy should be systematically studied to establish a relation between quality product attributes and extrusion parameters by understanding their effect on scale-independent system parameters. The relation between the scale independent parameters residence time distribution, maximum shear rate, specific energy, degree of fill and temperature inside the barrel affect quality product attributes irrespective of equipment model and scale. It is crucial to note that each system parameter is affected by multiple extrusion parameters, such as the change in the feed rate and screw configuration directly affect the shear generated within the process (Liu et al., 2012a; Markarian, 2012). It is critical to establish a feasible scale up approach to develop a quality product. However, the type of method selected depends on the physico-chemical properties of the API and the excipients utilized.

3. Role of polymers in solubilization

This section of the review is focused on the broad applicability of the polymers reported in the literature with a special emphasis on the recent case studies on solubility enhancement. HME facilitates the enhancement of the solubility and dissolution rate of poorly soluble API species by distributing them in a suitable polymeric carrier system. The mechanisms of the improvement of API solubility involve the alteration of the physicochemical properties of APIs to enhance their solubility, inhibit recrystallization, and improve their stability in the extrudates (Fousteris et al., 2013).

The mixing of the drug and polymer components during HME converts the crystalline API into its amorphous form and prevents further drug recrystallization via either the non-covalent bonding between the drug and the polymer chain or steric hindrance (Crowley et al., 2007). Since the drug had been previously dissolved in the water-soluble carrier, its solubility in the GI fluid was improved as compared to that in its native crystalline state, owing to Gibb’s free energy and absence of a lattice energy barrier (Terife et al., 2012).

Krupa et al. (2017) prepared the extrudates of poorly soluble Tadalafil species using Soluplus®, lactitol, and mannitol carriers with drug loadings of 10, 20 and 30%. The extrusion temperature ranged between 110 and 160 °C depending on the Tg of the carrier. The Soluplus® extrudates were smooth and semi-transparent at low drug loads and exhibited a “creamy” white appearance at higher loads, suggesting partial dissolution of the drug species in the polymeric matrix. The mannitol extrudates were rough and porous, indicating that the native crystal structure of the mannitol affected the total crystallinity of the extrudates. Both the disintegration and drug release processes proceeded faster in the case of porous mannitol extrudates, while the milling procedure promoted the release of Soluplus® extrudates due to the destruction of the polymeric network.

Thiry et al. (2017a) investigated the effect of polymeric systems on in-vitro drug release and in-vivo absorption of a poorly soluble drug itraconazole (ITZ). The studied amorphous solid dispersions of ITZ contained a combination of Soluplus®, Ac-Di-Sol®, and β-cyclodextrins (βCD). It was reported that Soluplus® in combination with other components exhibited enhanced solubility as compared to that of plain Soluplus®. The in-vivo studies revealed significant improvement in the absorption of the Soluplus®-Ac-Di-Sol® and Soluplus®-cyclodextrin mixtures as compared to that of the marketed product Sporanox®, which could be explained by the formation of stable Soluplus® micelles preventing the re-precipitation of drug molecules.

Martinez-Marcos et al. (2016) reported HME-enhanced solubility of the high melting point drug albendazole (M.P. = 208 °C) containing hydrophilic polymer PVP K12. During miscibility studies, they found that the drug completely melted at 216 °C, and the polymer at 145 °C. The drug loads of 1, 5 and 10% extruded in the temperature range of 70–145 °C at 100 RPM resulted in improved solubility as compared to that of pure drug (its supersaturation (spring effect) was achieved at a concentration of extrudates equal to 10% drug load). The observed solubility enhancement was due to the amorphous conversion of drug molecules within the extrudates as indicated by scanning electron microscopy (SEM), DSC, and powder X-ray diffraction (PXRD) studies. Although the drug dissolution improved significantly, its complete release was not observed, which indicated the role of the polymer in controlling the drug release process.

Kate et al. (2016) prepared a solid dispersion of atovaquone (M.P. = 220 °C), a highly lipophilic drug with very low solubility (<0.2 μg/mL) via HME to improve its bioavailability. Its formulations were obtained by using a combination of hydrophilic carriers (PVP K30, HPMC E5, and PVP VA64) and surfactants/solubilizers (Tween 80®, Gelucire® 44/14, Poloxamer 188, Soluplus®, PEG 400, and PEG 6000) in the temperature range of 110–160 °C. In the dissolution studies, media containing a 40% isopropyl alcohol solution buffered to pH = 8 exhibited the highest rate of drug release for PVP VA 64 at a ratio between the drug and the polymer equal to 1:2. The authors reported that reduction in the glass transition temperature of PVP VA64 was observed after the addition of surfactants (such as Tween 80® and PEG 6000). These researchers reported the improved absorption profile characterized by an 8-fold dose reduction in an anti-malarial efficacy study, which provided various insights into the selection of hydrophilic polymers and surfactants for the improvement of drug solubility. These data demonstrated that one’s choice of polymer combinations as well as surfactant selection can solve a solubility problem with a very low soluble drug (<0.2 μg/mL).

Wang et al. (2015) formulated a solid dispersion to improve the solubility and bioavailability of Ginkgo biloba extract (GE) with a Kollidon® VA64/Kolliphor® RH40 in a ratio of 85:15 using hot melt techniques. The extrusion procedure was performed in the temperature range of 120–125 °C at a speed of 100 RPM and drug load of 25%. Both the DSC and XRD studies confirmed the amorphous conversion of GE, and its dissolution in 250 mL of 0.1 N HCl solution showed that the solubility of the solid dispersion of GE was significantly improved by a factor of 2–3 after 120 min, compared to pure GE and its corresponding physical mixture. This study illustrates an example of solubilizing plant extracts with melt extrusion techniques and proper selection of polymers.

Similarly, Fu et al. (2016) prepared an amorphous solid dispersion of nisoldipine (M.P = 151 °C) in Kollidon® VA64 at an extrusion temperature of 153 °C and ratio of 1:10 to improve the solubility and stability of the amorphous dispersion. Among the various formulations, the maximum dissolution (100% after 1 h) was achieved at a ratio between the drug and polymer equal to 1:10. Both the DSC and PXRD studies confirmed the absence of crystalline nisoldipine species in the final formulation, while stability testing conducted at temperatures of 40 °C and 60 °C and relatively humidity (RH) of 0% for up to 10 days showed no recrystallization. Furthermore, the stress studies conducted at a higher RH of 92.5% for 10 days revealed a shift in the carbonyl wavelength to a lower value, indicating the destruction of H bonds.

HME was also explored as a method for the development of co-amorphous systems containing heat- and shear-sensitive molecules. Lenz et al. (2017) studied the feasibility of the extrusion process for the enhancement of the solubility of indomethacin (IND, M.P. = 160 °C) by forming an arginine (AGN)-based co-amorphous system with and without copovidone (CP). Extrusion was conducted in the temperature range of 120–200 °C and different heating zones at a speed of 50–100 RPM. The resulting amorphous dispersions exhibited a common Tg of around 70 °C and a second Tg value at 116–117 °C corresponding to the phase separation of AGN and IND. Drug release testing performed under non-sink conditions demonstrated a higher solubility profile (by almost a factor of 2) and preservation of the supersaturated state for the copovidone-containing melt extrusion formulations indicating the effect of copovidone on the obtained co-amorphous system.

Pawar et al. (2017) developed a solid crystalline suspension of the poorly soluble Efavirenz drug (M.P. = 139 °C) using xylitol and mannitol as crystalline carriers. Extrusion was performed at the melting point of Efavirenz (138–140 °C) and screw speed of 100 RPM. Both the DSC and XRD studies confirmed the crystallinity of the obtained formulations, and Fourier transform infrared (FTIR) chemical imaging revealed the uniform distribution of API species in the hydrophilic carrier. The dissolution studies performed in 1000 mL of the 0.1 N HCl solution containing 0.2% of sodium lauryl sulfate (SLS) showed significant improvement in the drug release rates of the xylitol formulations as compared to that of pure drug. Regardless of the polyol structure, the drug release rate was improved by the hydrophilic environment provided by the crystalline carrier. The stability studies conducted for up to 12 months showed no significant differences in the drug release patterns of the mannitol-based formulations; however, the xylitol-based formulations were found to be unstable.

Lipid micro-domains (LMD) represent a novel technique for the preparation of solid dispersions, in which lipid molecules are adsorbed on the carrier surface. As a result, the lipid structure becomes disrupted by the disorder of the lipid chains, leading to the formation of a new microstructure. This newly created microstructure can accommodate drug molecules, producing a solid dispersion. Adler et al. (2016) fabricated LMDs using β-carotene (βC) drug, stearic acid (STA) used as acidic lipid and plasticizer interacting with the inorganic carrier Neusilin® US2 (aluminum magnesium silicate) and HPC polymer utilized for controlling the drug release rate. Extrusion was performed at a temperature of 160 °C and speed of 50 RPM for the most favorable formulation of 70/10/20% (HPC/STA/Neusilin® US2). The analysis of the extrudates showed that the interaction of STA with 5–20% Neusilin®US2 was proportional to the degree of the amorphous conversion of STA. The attenuated total reflectance FTIR studies revealed that the presence of βC did not disturb the interactions between STA and Neusilin® US2 species. The authors reported higher amorphousness and stability of the obtained drug due to the restricted movement of its molecules across the lipid chain structure.

Another approach to producing stable amorphous dispersions is to prepare solid solutions. In these solutions, the drug species are homogenously dispersed across the polymer matrix in a metastable state, which prevents the recrystallization of API. Fule et al. (2016) prepared a solid solution of artesunate (M.P. = 145–149 °C), a poorly soluble drug containing Soluplus® along with a combination of surfactants such as PEG 400, Lutrol F 127, TPGS, and Lutrol F 68. Both the DSC and XRD studies showed no signs of crystallization in the obtained extrudates, and the FTIR spectra revealed no changes in the system functionality even in the presence of surfactants. The observed significant enhancement of solubility occurred due to the structural disorder of the amorphous system and short-range intermolecular attractions. The results of in-vivo studies showed improved permeation through the GI membrane due to the presence of surfactants. After accelerated testing at 40 °C/75% RH for 6 months, the formulations were physically stable and maintained good content uniformity. Thus a “metastable” solid solution can be stabilized within an extrudate with selection of appropriate matrices.

Thiry et al. (2017b) investigated ternary inclusion complexes of cyclodextrin to improve the solubility of poorly soluble ITZ by HME. The studied cyclodextrins (CD) were β-cyclodextrin (βCD), randomly methylated β-cyclodextrin (Rameb®), sulfobutylether-β-cyclodextrin (Captisol®), methyl-β-cyclodextrin (Crysmeb®), and hydroxypropyl-β-cyclodextrin (HPβCD) mixed with Soluplus® (SL) at a molar ratio of 1:1. Their extrusion was performed at a temperature of 180 °C and screw speed of 100 RPM. The observed shifts of the cyclodextrin FTIR peaks centered at 3300 cm−1 and DSC results confirmed the formation of a complex containing ITZ, CD, and SL species. The in-vitro release studies demonstrated a significantly higher solubility of all the obtained ternary cyclodextrin complexes as compared to that of pure drug. This phenomenon can be attributed to the high hydrophilicity of cyclodextrin along with the stabilizing effect of SL on the ternary complex. Many of the studies discussed above suggest the improvement of drug solubility and bioavailability, which is schematically illustrated in Fig. 3.

Fig. 3.

Schematic representation of various possible dispersions in the HME process

4. Characterization of HME-produced systems

The characterization, quality and stability of the extrudates of poorly soluble drugs prepared by HME can be predicted via physicochemical, thermal characterization and microscopic studies. However, the recent introduction of PAT tools facilitated the inline quantification, characterization, and monitoring of both the HME process and resulting products. The various characterization methods reported in the literature include DSC, PXRD, FTIR, Raman spectroscopy, nuclear magnetic resonance (NMR) spectroscopy, isothermal micro-calorimetry (IC), TGA, hot stage microscopy (HSM), SEM, and polarized light microscopy (PLM) techniques. Finally, the process efficiency and performance of the obtained product can be evaluated via content uniformity and in vitro dissolution studies. The above-mentioned physicochemical and thermal characterization methods are extensively discussed in earlier reviews (Maniruzzaman et al., 2012; Patil et al., 2015; Shah et al., 2013); therefore, this review provides updates for those recent reports with a special emphasis on the in vitro dissolution studies and PAT tools.

5.1. Physico-chemical characterization of extrudates

5.1.1. PXRD

The PXRD technique is used to determine whether the drug in polymer system is in the crystalline or amorphous state. The kinetics of crystallization investigated at various temperature and humidity conditions provides important information regarding product stability. Lu et al. (2016) developed an amorphous solid dispersion of felodipine in Soluplus® via HME at drug loads of 10, 20, and 30% w/w. At a drug load of 10%, its complete conversion into an amorphous system was reported. Similar results for the amorphous conversion in solid solutions were reported for a poorly soluble azithromycin dihydrate using Soluplus® and Kollidon® VA64 carriers (Jaiswar et al., 2016). Maddineni et al. (2015) produced a solid dispersion of poorly soluble nifedipine drug (M.P. = 172–174 °C) via HME using Kollidon® VA64 at temperatures below the M.P. of the drug (115–130 °C).

5.1.2. FTIR and near-infrared spectroscopy

FTIR is one of the most efficient vibrational spectroscopy techniques used for examining the drug-polymer interactions in physical mixtures and processed extrudates. It provides data describing the presence or absence of interactions in the system, which facilitates the selection of excipients for the final formulations. The type of interactions between the molecules represents the type of chemical bonding in the final product, which may affect the solubility properties of the formulation. Djuris et al. (2013) reported a study on the miscibility of carbamazepine (CBZ) and Soluplus® via FTIR. The absence of the API characteristic peaks in the FTIR spectra recorded for extrudates and appearance of a new peak at 1034 cm−1 indicate a high probability of hydrogen bond formation between the drug and the polymer. The obtained results were further confirmed by DSC and XRD studies. Nevertheless, the FTIR studies of the HME-based solid solution of artesunate in the water-soluble Soluplus® and Kollidon® VA64 polymers did not exhibit any changes in molecular stretching (although slight shifts of specific peaks were observed) and the resulting molecular dispersions significantly improved the dissolution properties of artesunate (Fule et al., 2016). Li et al. (2016) engineered a co-crystal suspension of ibuprofen and isonicotinamide via HME using xylitol as a molecular matrix carrier. The presence of an additional FTIR peak centered at 3317.93 cm−1 can be attributed due to the formation of supramolecular heteromeric synthon between the N pyridine group of isonicotinamide and the OH group of ibuprofen.

5.1.3. NMR spectroscopy

NMR spectroscopy is used to characterize the physical state of a component (crystalline or amorphous) based on the spin energy transitions in pure API, a physical mixture, or a formulation. It is frequently utilized for evaluating the stability of drug–polymer complexes by analyzing additional peaks and proton de-shielding (Hanafy et al., 2009; Stuart, 2005). NMR can also provide valuable information on the structural similarity of impurities and structural comparison of the unknown impurities with the known ones. Yang et al. (2016) analyzed the crystallinity and amorphous character of clotrimazole–PVP solid dispersions via NMR spectroscopy using cross polarizing and magic angle spinning techniques. They reported shorter spin relaxation time (SRT) of the cryo-milled samples, which indicated the presence of a crystalline component along with the amorphous one, while the broad C13 peaks obtained for the HME extrudates confirmed the complete amorphous conversion of API.

5.2. Thermal characterization

Thermal analysis provides information on the state of the drug in a dispersion system and is closely related to the dissolution behavior and stability of the final product (Stankovic et al., 2015).

5.2.1. DSC

DSC is a destructive technique that is used for the qualitative and quantitative analysis of thermal events in a physical mixture or final formulation. The observed melting transitions allow characterization of the crystallinity of the tested product. The selected temperature range strongly depends on the individual thermal properties (M.P./Tg) of the drug and polymers (Guo et al., 2014). Medarevic et al. (2016) reported absence of drug peaks in the physical mixture of carbamazepine and poloxamers which was attributed to the gradual dissolution of carbamazepine in the molten polymer during DSC scanning. It was hypothesized that after the temperature reached the melting point of the drug, its remaining quantity was very low to produce a detectable melting endotherm on the DSC curve.

Lamm et al. (2016) examined the phase transition properties of D-α-tocopherol polyethylene glycol 1000 succinate (TPGS 1000) mixed with copovidone via modulated DSC (mDSC) and reported melting point depression due to the difference in the melting points of the mixture components. Keating et al. (2017) formulated the dispersions of isoniazid (M.P=171°C) with Soluplus® and Eudragit® EPO for taste masking applications. From the DSC characterization of the produced extrudates, they observed that Soluplus® formed amorphous dispersions at drug loadings up to 20%, while Eudragit® EPO produced crystalline dispersions. Puri et al. (2017) evaluated the crystalline properties of the griseofulvin-maltodextrin extrusion-molded tablets at 40 °C/75% RH and observed that they are instable. Similarly, Genina et al., 2017 studied the distribution of ibuprofen and carvedilol in mesoporous silica and Soluplus® via DSC.

5.2.2. Thermogravimetric Analysis

Prior to HME processing, the elucidation of the thermal behavior of APIs and other excipients is required (Morott et al., 2015). This facilitates to determine the safe processing temperature range, in which a formulation can be extruded without any undesirable thermal events (Juluri et al., 2016; Tiwari et al., 2016; Vo et al., 2017). The Tg of the obtained extrudates represented the degree of solubility of the API in a specific carrier. Cifuentes et al. (2017) studied the effect of Mg content on the stability of poly-L-lactic acid/magnesium (PLA/Mg) composites. The TGA of the formulation revealed that the degree of degradation of the PLA–Mg composites was dependent on the Mg content.

5.3. Microscopic characterization

Microscopy is the most widely used method for studying the morphological characteristics of extrudates (such as surface morphology, crystalline/amorphous nature, and particle size).

5.3.1. SEM

SEM is utilized to observe the surface morphology, porosity of extrudates and surface changes during release studies (Almeida et al., 2011; Stankovic et al., 2013). Jaiswar et al. (2016) formulated a solid solution of azithromycin, which exhibited shiny appearance and the absence of crystallinity indicating good miscibility between the drug and carrier species. Lu et al. (2016) reported that after increasing drug load from 10% to 50%, the resulting formulations contained few crystalline particles indicating incomplete amorphous conversion of the drug, which was confirmed by its solubility data. Puri et al. (2017) observed that the morphological changes of the tablet surface observed during the stability studies were related to the moisture uptake by the tablet matrix and its subsequent effect on the formulation.

5.3.2. HSM

HSM represents another HME microscopic characterization tool, which visually provides information about the observed thermal events as a function of time and temperature. It can be utilized for studying the dissolution of drug and polymer species in the molten state and provides good preformulation input for the HME process and subsequent experimental design. HSM can serve as a complimentary technique to DSC since it characterizes the melt behavior of the material tested at a specific temperature (Li et al., 2006). Pawar et al. (2017) studied the crystalline dispersion of efavirenz in a carrier matrix using HSM. Djuris et al. (2013) investigated the effect of temperature on the recrystallization of API in carbamazepine-Soluplus® solid dispersions through HSM.

5.4. In vitro dissolution testing

Drug dissolution testing is an important tool that allows evaluation of the performance of extrudates. During HME, drug molecules are blended, sheared, and melted with hydrophilic polymers; therefore, the assessment of drug solubilization in the presence of polymers represents a significant parameter of the characterization of extrudates.

The dissolution testing of poorly soluble drugs is an important task that must be performed to develop a suitable, discriminating, and validated dissolution model of the correlation between the processes occurring in vitro and in vivo. According to the literature, the utilized dissolution media are characterized by different volumes and pH values. In most of the studies, surfactants (such as Tween 80® and SLS ones) were added to the dissolution media. In this review, various dissolution media used for the characterization of HME products are highlighted to provide an insight into the selection of suitable dissolution conditions. Table 2 lists different types of dissolution media and equipment as well as the testing times utilized for the release studies of several poorly soluble drugs.

Table 2.

In vitro dissolution conditions of selected poorly soluble drugs

| Drug | Carrier | Official dissolution media (USP 40) | Dissolution Conditions | Ref |

|---|---|---|---|---|

| Tadalafil | Soluplus®, Mannitol and Lactitol | 0.5% SLS, 1000 mL, type II, 50RPM | USP type II, 0.1 % SLS simulated gastric fluid, 900 mL, 50 RPM, DT: 2 h | (Krupa et al., 2017) |

| Indomethacin-Arginine | Copovidone | 1 volume of pH 7.2 phosphate buffer mixed with 4 volumes of water, 750 mL, type I, 100RPM (Indomethacin) and 0.1 N hydrochloric acid, 900 mL, type II, 100 RPM (Arginine USP 40 Dietary supplements) | USP type II, Non-sink dissolution medium (pH 4.5 phosphate buffer) or at pH 1.2 (using HCl)), 900 mL, 50 RPM, DT: 24 h | (Lenz et al., 2017) |

| Efavirenz | Xylitol and mannitol | 2.0% (w/v) SLS in water, 1000 mL, type II, 50RPM | USP type II, 0.2% SLS in 1000 mL of 0.1 N HCl, 50 RPM, DT: 1.5 h | (Pawar et al., 2017) |

| Itraconazole | Soluplus®/βCD and Ac- Di-Sol® | Not Available | USP type II, Biphasic dissolution media 400 mL of HCl and 0.1 M and 400 mL of octanol; 50 RPM, DT: 6 h | (Thiry et al., 2017a) |

| Felodipine | HPMC K15M + HPC | pH 6.5 phosphate buffer with 1% SLS, 500 mL, type II, 50 RPM | USP type II, 1% SLS in 0.1 N HCl, 900 mL, DT: 12 h | (Vo et al., 2017) |

| Azithromycin sulphate | Soluplus® and Kollidon® VA 64 | pH 6.0 sodium phosphate buffer, 900 mL,; type II, 50 RPM | USP type II, phosphate buffer pH 6 and water, 900 mL, 50 RPM, DT:1h | (Jaiswar et al., 2016) |

| Nisoldipine | Kollidon® VA 64 | Not Available | USP type II, distilled water, 900 mL, 50 RPM, DT: 1 h | (Fu et al., 2016) |

| Ibuprofen and isonicotinamide | Soluplus®, Eudragit® EPO, Xylitol | pH 7.2 phosphate buffer, 900mL, type II, 50 RPM, (Ibuprofen) Isonicotinamide - Not Available | USP type II, 600 mL of deionized water, 75 RPM, DT: 8 h | (Li et al., 2016) |

| Artesunate | Soluplus® and Kollidon® VA 64 | Not Available | Type I, 1000 mL of water, 50 RPM, DT: 2 h | (Fule et al., 2016) |

| Atovaquone | PVP K30, HPMC E5, PVP-VA64 and tween 80, Gelucire® 44/14, poloxamer 188, Soluplus®, PEG 400 and 6000 | Not Available | USP type II, 40% isopropyl alcohol buffered to pH 8, 900mL and multi media studies in pH 1.2 (with 1 % tween 80) and 6.8 media; 900 mL, DT: 2 h | (Kate et al., 2016) |

| Nifedipine | Kollidon® VA 64 | Simulated gastric fluid TS (without pepsin), 900 mL, type II, 50RPM | USP type II, pH 6.8 phosphate buffer with 1% w/v SLS, 900 mL, DT: 2 h | (Maddineni et al., 2015) |

| Suvorexant | PVP VA | Not Available | USP type II, 900 mL with 0.4% sodium dodecyl sulfate, DT: 1 h | (Kesisoglou et al., 2015) |

| Ginkgo biloba extract | Kollidon® VA64/Kolliph or ® RH40 | 0.1 N hydrochloric acid, 500 mL, type II, 75 RPM (Dietary Supplements USP 40) | USP type II, 250 mL of 0.1N HCl, 250 mL; 100 RPM, DT: 2 h | (Wang et al., 2015) |

| Naproxen | Eudragit®L 100-55, HPMC AS LF, HPMCP-HP-50, Tri ethyl cellulose | pH 7.4 phosphate buffer;900mL, type II, 50 RPM | USP type II, 750 mL of a 0.1 N solution of HCl followed by addition of 250 mL Na3PO4.12H2O (0.2 M) to make up to pH 6.8 (for naproxen); demineralized water (for Esomeprazole); 100RPM, DT: 10 h and 2 h for naproxen and esomeprazole | (Vynckier et al., 2015) |

| Ibuprofen | HPMC, Neusilin® and PEG 2000 | pH 7.2 phosphate buffer, 900mL; type II;50 RPM | USP type II, 900 mL of both 0.1 M HCl (pH 1.2) and 0.2 M dihydrogen-sodium-orthophosphate (pH adjusted with NaOH to 6.8), DT: 2 h | (Maniruzzaman et al., 2015) |

| Lornoxicam | Soluplus® | Not Available | USP type II, 900 mL phosphate buffer of pH 6.2, DT: 1 h | (Fule et al., 2014) |

| Olanzapine | PVP-VA/PVPK30/Soluplus® | 0.1N HCl; 900mL, type II, type II, 50RPM | USP type II, 900 mL of phosphate buffer pH 6.8, DT: 2 h | (Pina et al., 2014) |

| Osthole | PVP-VA or Eudragit® E PO or HPMC E5 or Soluplus® | Not Available | Chinese Pharmacopeia dissolution type II, 900 mL of pH 4.5 acetate buffer with 0.05% Tween 80, DT: 2 h | (Yun et al., 2014) |

| Felodipine | Soluplus® | pH 6.5 phosphate buffer with 1% SLS, 500mL, type II, 50 RPM | USP type II, pH 6.8 phosphate buffer and pH 6.8 phosphate buffer with pre-dissolved Soluplus®, 500ml, 100 RPM, DT: 12 h | (Lu et al., 2016) |

5.6. Micromeritics

Most commonly, extrudates are milled and formulated in the form of tablets or capsules. Before this procedure, the micromeritics of extrudate blends must be evaluated to achieve a clear understanding of the powder/granule behavior. Various traditional compendium methods are typically used for the evaluation of powder flow characteristics (including the angle of repose, bulk density, tapped density, Carr’s index, compressibility index, and Hausner ratio) (Shah et al., 2008). This evaluation can help to determine the most suitable dosage form for the milled extruded material flowing from a hopper.

5. HME and PAT tools

This section provides an overview of the current PAT tools for pharmaceutical HME, their advantages, disadvantages, and applications as summarized in Tables 3 & 4. Since each tool has specific applications, it is difficult to suggest a universal PAT method. Hence, the information provided in this section may help the reader to select an appropriate tool for their specific needs.

Table 3.

The various process analytical technology (PAT) tools for real time analysis of solid dispersions using HME processes

| PAT Tool | Advantages | Disadvantages | Application | Site of Probe | Analys is type | Ref |

|---|---|---|---|---|---|---|

| UV/VIS Spectroscopy | Cost Effective Technique | Low count rate results in error, Limited to Polymer and Food Industry | Residence Time Distribution, Particle size analysis, Quantification | Die | Inline | (Becker et al., 2017; Wang et al., 2008) |

| NIR Spectroscopy (Transmittance & Reflectance) | Noninvasive, Nondestructive, Fast, Continuous, No sample preparation | Data Pretreatment or Chemometrical Data analysis is needed | Molecular Interaction, Hydrogen Bonding, Quantification of API | Die | Inline/Online | (Apruzzese et al., 2003; Jamrogiewicz, 2012; Luypaert et al., 2007; Roggo et al., 2007; Tumuluri et al., 2004) |

| MIR Spectroscopy Attenuated Total Reflection (ATR) | Noninvasive, Nondestructive, Little or No sample preparation | Limited radiation path length & Penetration depth length, Polymer Industry | High density polymer blend composition, Residence Time Distribution | Modified Barrel or Special Gear pump flow cell | Online (Special adaptor) | (Coates et al., 2003; Haberstroh et al., 2002) |

| Raman Spectroscopy | Nondestructive, Minor sample preparation | Low signal intensity, Fluorescence due to impurities, Risk of sub sampling | Molecular interaction, API Quantification, Composition of Polymer or melt blends | Die | Inline | (Coates et al., 2003; Gala and Chauhan, 2015; Saerens et al., 2014a) |

| Fluorescence Spectroscopy | Quantification less than 1% w/w, Improved peak resolution and recording speed | Limited to developmental stage | Melt temperature measurements, Residence Time Distribution, simultaneous quantification of two APIs | Die | Inline | (Cogdill et al., 2007; Sievers, 1972; Zhong et al., 2011) |

| Parsum Probe | Can measure particles up to 20000/s & Wide particle size range 50–6000um | Not suitable for particle size less than 50um | Particle size analysis in Melt granulation | Die (Adaptor) | online | (Huang et al., 2010) |

Table 4.

Promising PAT tools for prospects in Pharmaceutical HME

| PAT Tool | Principle | Site & Type of Analysis | Applications | Advantages | Limitations | Ref |

|---|---|---|---|---|---|---|

| Terahertz Spectroscopy | Electromagnetic wave, Terahertz radiation 0.1 THz to 10 THz | Die & Inline | Differentiate Crystal Forms, Intermolecular Bonding, Refractive Index Measurement, | Insensitive to Thermal Interferences | High Cost, Complex System | (Strachan et al., 2004; Zeitler et al., 2006) |

| Ultrasonic Spectroscopy | Hi frequency acoustical wave | Die, Barrel & Inline or Online | API Quantification, Residence Time Distribution, Particle Size Distribution, Crystal Size Distribution, | Good Penetrability, Easy to change wavelength of ultrasonic wave | Probe adapter required | (Li et al., 2004; Shukla et al., 2010; Stelzer et al., 2013) |

| Dielectric Spectroscopy | Electric Field and measures energy associated with dipole orientation. | Die & Inline | Melt Rheology and Quantification | Useful to analyse physical/chemical structures of organic materials | Limited depth penetration measures at surface | (Gottwald and Scheler, 2005) |

| NMR Spectroscopy | Magnetic field | Next to Die & Online | Monitor API and Polymer interaction, Different polymorphs | Sensitive with small amounts of API | High temperature decreases magnetic field | (Gottwald and Scheler, 2005) |

| Rheometry | Capillary, Rotational & Oscillatory | Between screw and die & Inline/On line | Measures Viscosity, and linear viscoelastic behaviour, Reaction kinetics, Melt strength | Thermal degradation is also noted with reduction in viscosity | High shear rates influence morphology of product | (Covas et al., 2004; Rajan et al., 2010) |

Process analytical testing can be performed in-line, on-line, at-line, and off-line. The in-line and on-line measurements are useful for CM, which involves the direct real-time analysis of the entire process (here the word “in-line” represents the direct analysis of the studied process, and the word “on-line” – the analysis of the sample). The at-line and off-line analyses are typically used in batch-type manufacturing (“at-line” involves the examination of the removed sample at proximity, whereas “off-line” is the analysis of the removed sample performed in a different laboratory) (Saerens et al., 2014a). A conventional HME setup consists of an extruder connected to ancillary equipment to monitor the torque, screw speed, and melt pressure as well as the die and barrel temperatures. In general, the HME process involves the feeding of a physical mixture (containing an API, a polymer, and excipients) through the extruder hopper into the extruder barrel fixed with a specific screw design and maintained at a desired temperature. Both the thermal heat and shear generated in rotating screws melt the powder blend and convey it towards the die to produce the final extrudate. Over the decades, the obtained extrudates have been analyzed using various offline characterization techniques such as DSC, TGA, FTIR, and PXRD.

Typically, off-line testing is expensive, time consuming, and requires random sampling, which makes it a batch-type manufacturing process and therefore contradicts the interests of the pharmaceutical industry. The CM ability of the HME-coupled PAT tools converted them into an important technology that satisfies the requirement of the FDA to conduct real-time monitoring of product quality attributes. It also allows visualization of the material behavior and thus the development of high-quality HME products. The currently available PAT tools can provide a better understanding of the manufacturing process on-line and control its various processing parameters such as temperature, pressure, screw speed, and feed rate.

The spectroscopic PAT tools utilized in pharmaceutical HME include NIR, mid-infrared (MIR), Raman, and fluorescence spectroscopies. These tools can be integrated by using the probe in the barrel or die of extruder to monitor the process, detect molecular changes in the raw material characteristics and perform API quantification. However, the data obtained by these techniques are very complex and must be interpreted appropriately to draw meaningful conclusions. It was reported that multivariate data analysis (MVA) was utilized for processing such complex data to optimize the related process parameters. It should be noted that the PAT tools equipped with MVA reduce the process errors and provide a quality product (Challa and Potumarthi, 2013).

The vibrational NIR, MIR, and Raman spectroscopy techniques utilized in HME are fast, continuous, non-invasive, and non-destructive tools, which can analyze molecular interactions to better understand the nature of hydrogen bonding in solid dispersions. Saerens et al. (2012) reported the use of NIR for the in-line characterization of metoprolol tartarate extrudates with Kollidon® SR. The obtained information about molecular interactions suggested partial conversion of the API into an amorphous form, which was further confirmed by other analytical techniques. Khorasani et al. (2016) used near-infrared spectroscopy chemical imaging (NIR-CI) during HME and 3D printing to characterize the spatial distribution of the present components. The obtained data were analyzed using the NIR-CI technique complemented with the multivariate curve resolution-alternating least squares method, which could predict the spatial distribution of the drug in polymeric films. Saerens et al. (2011) reported the in-line analysis of the metoprolol tartarate concentration in a polymer matrix and related molecular interactions, which was performed by inserting a Raman probe into the die of the extruder. Chiu et al. (1997) reported the in-line measurements of melt viscosity using a viscometer at different screw speeds and temperatures. The obtained results were compared with the corresponding off-line data; they indicated that the utilized method was more suitable for the use in pharmaceutical HME.

The following PAT tools utilized in the polymer industry can serve as potential tools for pharmaceutical HME: terahertz spectroscopy, ultrasonic spectroscopy, dielectric spectroscopy, NMR spectroscopy, and rheometry (Hitzer et al., 2017; Maniruzzaman and Nokhodchi, 2017; Saerens et al., 2012; Saerens et al., 2014b). The use of PAT tools in HME represent a future strategy; however, the quality of the obtained product depends on the proper understanding of the process, accurate assessment of the melt temperature, and viscosity of the system, which can be determined using different probes. A thorough understanding of the various PAT tools described in this review may suggest a strategy for the optimization of the CM process.

6. Innovative applications of HME for solubility enhancement

The industrial use of HME technology is clearly stimulated by the availability of various types of pharmaceutical products in the global market (Tiwari et al., 2016). Apart from the development of traditional dosage forms, HME techniques have been further explored for various novel opportunities such as foam extrusion, co-crystallization, nano-systems, and reactive extrusion.

7.1. Pharmaceutical foam extrusion

HME is one of the most effective approaches to formulating solid dispersions for the enhancement of the dissolution and solubility properties of poorly soluble drugs. Sometimes, the processability and stability concerns limit the application of the HME technology. Supercritical and pressurized CO2-assisted extrusions are excellent approaches to improving both the extrusion processing window and stability of formulations. The presence of CO2 in a molten polymer lowers the viscosity of the resulting polymer blends (Nalawade et al., 2006) that allow their extrusion at lower temperatures and torque, while increasing the stability of the formulation. In addition, the injected CO2 acts as a temporary plasticizer during the melt extrusion process and is not present in the final product (Verreck et al., 2005). Therefore, the Tg of the system can be maintained sufficiently high that benefits the physical stability of formulations during storage. Furthermore, CO2 acts as a blowing agent and creates an internal porous foam structure of the extrudate, which increases the total surface area and ultimately improves the drug dissolution properties (Nagy et al., 2012; Verreck et al., 2006). Foam extrusion also facilitates the extrudate milling process because of its porous internal structure and low physical strength. This is especially helpful for minimizing the heat generated during milling that significantly softens the formulation and makes it particularly sticky inside the milling equipment (Ashour et al., 2016).

Foam extrusion is also exploited to develop floating drug delivery systems. Owing to its low density, the foam strand can be cut into pellets or mini-tablets to formulate buoyance dosage forms, which are able to prolong their residence time inside the stomach. Low boiling point solvents (Vo et al., 2016) and sodium bicarbonate (Fukuda et al., 2006; Vo et al., 2017) can be utilized as foaming agents, based on phase transition phenomena and thermal degradation, respectively. The floating dosage forms can be utilized to formulate controlled release drug delivery systems of narrow absorption window drugs.

7.2. Melt extrusion of co-crystals

Pharmaceutical co-crystals are crystalline molecular complexes that are largely formed by the hydrogen bonding between therapeutic molecules and co-formers (Williams et al., 2013). Co-crystals may exhibit entirely different physical properties as compared to those of the corresponding pure components. Their formation can potentially improve the solubility, stability, bioavailability, and mechanical properties of the active drug (Smith et al., 2011). Co-crystals are mainly formed via solvent-based crystallization and solid-based techniques. Recently, HME has been used as a promising technology for producing pharmaceutical co-crystals because of its scalability, absence of solvents, and cost effectiveness.

During the HME process, the high shear at a microscale continuously divide and blend the drug and co-former phases that facilitate a close contact between the API and co-former molecules and the formation of co-crystal bonds. In addition, the use of melt extruders enables varying temperature profiles, shear force, and residence time, which represent critical productivity parameters of the co-crystallization process. The ibuprofen and nicotinamide (1:1) co-crystals was successfully prepared via melt extrusion technology (Dhumal et al., 2010). The results obtained at high shear, high temperatures (above the formulation eutectic point), and low screw speed (long residence time) produced almost 100% pure co-crystals. The studied co-crystals were physically stable for a period of 6 months under ambient conditions.

The corresponding processes can be completed in a single step via HME, in which API, co-former, and polymer species are fed into the extruder barrel simultaneously or separately at different feed zones. In general, co-crystals can be formed in situ and dispersed in polymer matrices during the extrusion process (Li et al., 2016; Liu et al., 2012b). The formation of co-crystals reduces the melting point of the entire system, which allows reduction of the HME processing temperature. However, the effect of the co-former on the re-crystallization, stability, and moisture absorption of the obtained dispersion need to be investigated thoroughly. Hot melt twin-screw extrusion is an effective, environmentally friendly, and scalable technique for the continuous production of co-crystals (Boksa et al., 2014).

7.3. Nanocrystal solid dispersions formulated by melt extrusion

Reducing the size of API particles to the micro- or nano-scale and thus increasing their specific surface area is a well-established approach to the enhancement of the dissolution and apparent solubility of poorly soluble drugs (Blagden et al., 2007; Merisko-Liversidge and Liversidge, 2011). It can be achieved by drastically increasing the specific surface area and related energy of the system (Müller et al., 2001). As compared to amorphous solid dispersions, nanomaterials are more thermodynamically stable since drugs can exist in a lower energy state. However, they possess some limitations that are related to particle aggregation, morphological instability, and poor wettability. It is well known that aggregation occurs more often to high surface area materials, which results in an increase in the particle size and decrease in the free surface energy (Brough and Williams, 2013). To overcome these drawbacks, nanomaterials can be incorporated into solid dispersions. Engineering nanoparticles usually require the removal of a large amount of solvents prior to formulating various dosage forms. The corresponding processes are typically complex, time-consuming, less controllable, and difficult to scale-up.

Solid dispersions loaded with nanocrystals have been prepared in three steps, including the preparation of a nanosuspension, suspension injection, and solvent devolatilization. Aqueous nanosuspensions are obtained by dispersing powder nanomaterials (Khinast et al., 2013), wet ball milling (Baumgartner et al., 2014), or high-pressure homogenization (Ye et al., 2016) to form a nanosuspension in water. In the second step, the prepared nanosuspension is slowly injected into the extruder barrel to blend with the molten carrier. Presently, only Soluplus® has been used as a carrier for this application. In the last step, the utilized solvent is eliminated via devolatilization through the port located at the end of the barrel. Inside the barrel, the molten mass is continuously thinned on the screw surface that dramatically enhances its surface area and thus accelerates the evaporation process. This devolatilization technique shows promise for successful production of selected solid dispersions.

7.4. Melt extrusion of amorphous APIs

Converting APIs from the crystalline to the amorphous form is a widely used approach to enhance the dissolution and solubility of poorly soluble drugs. It has been reported that HME can be successfully used to formulate amorphous solid dispersions, in which amorphous drugs are dispersed inside a polymer matrix to enhance their physical stability. However, high processing temperatures limit the applications of this technique (especially for high melting point or heat-sensitive drugs).

A feasible solution to the problem is converting crystalline APIs to an amorphous form before extrusion. Since their values of Tg are usually lower than the corresponding melting points, the use of amorphous materials facilitates the extrusion process by conducting it at lower temperatures in the miscibility regime, which results in faster mixing of API species with the molten carrier. Among many polymorphic transformation techniques, solvent evaporation methods such as rotary evaporation, spray drying, and low-pressure evaporation are easy to perform in the laboratory and scale up.

In a study utilizing this approach, pre-engineered ITZ amorphous microparticles were used as a starting material for the extrusion process (Miller et al., 2007). The amorphous microparticles were prepared using a flash evaporation method, in which the solvent devolatilized under low pressure. The obtained amorphous solid dispersion flakes were milled into microparticles via ball milling before feeding into an extruder containing a low melting point polymer (polyethylene oxide) used as a second carrier. The properties of the amorphous micro-particles were preserved after extrusion and exhibited improved dissolution and bioavailability. In another study, a new compound was transformed from the crystalline to an amorphous state via a simple solvent evaporation method (Lakshman et al., 2008). The resulting amorphous drug served as a plasticizer during the melt extrusion process with the polymer carrier. The final product was characterized by higher solubility and bioavailability as compared to those of the crystalline API. The amorphous nature of API particles in the solid dispersion was preserved after the stability study with a duration of 12 months.

Despite the promising results reported in the published studies, the production of amorphous APIs prior to HME via solvent evaporation poses a risk of environmental pollution that makes the HME technique “less green”. Moreover, it raises a question whether the HME integration is necessary or not, since polymeric carriers can be introduced into the formulation to produce stable amorphous solid dispersions using solvent evaporation techniques.

7.5. Pre-emulsified extrusion of lipid nanoparticles

The hot melt extruder, which simultaneously provides heat and mechanical shear, can be utilized as a continuous emulsifying tool. The supplied solid contents of the formulations are melted inside the first several zones of the extruder barrel before mixing with the aqueous phase that is injected through the middle port of the barrel. The application of shear inside the twin-screw extruder forms a crude emulsion, which is subsequently transferred to a homogenizer for further particle size reduction. The emulsifying effect of the extruder can be optimized by establishing an appropriate temperature pattern for different zones, customizing the screw configuration, and varying the screw speed. Although the size of the final products is determined during the homogenization stage, the preparation of a suitable crude emulsion significantly contributes to the quality of the final product (Mehnert and Mader, 2001). By conjugating the extruder with a high-pressure homogenizer, a continuous process for the preparation of solid lipid nanoparticles loaded with fenofibrate was proposed (Patil et al., 2015). A solid lipid dispersion with particle sizes below 200 nm was obtained that significantly enhanced the solubility and oral bioavailability of fenofibrate. In another study, the combination of a sonication probe with an extruder was used to fabricate lipid nanoparticles loaded with lidocaine (Bhagurkar et al., 2017). The resulting lipid nanosuspension was formulated to a topical gel for cutaneous pain management, whose drug release profile exhibited extended characteristics governed by the lipid matrix. Although the emulsifying efficiency of the extrusion process is not as effective as that of high-speed homogenizers or colloidal mills, it can be a viable approach to the integration of continuous manufacturing processes.

7.6. Pharmaceutical reactive extrusion

The term “reactive extrusion” has been used in polymer science for several decades. It is considered an efficient method for continuous polymerization and chemical modification of polymers (Tzoganakis, 1989). HME produces heat and leads to microscale homogenization simultaneously; hence, it can be potentially used for melting/softening compounds and blending them together at a molecular level, and thus facilitates chemical reactions without using solvents. Therefore, melt extrusion is considered an environment friendly, green, and continuous process.