Abstract

A research study was conducted to assess the effectiveness of cool coat in reducing heat strain among workers exposed to heat in a steel plant located in south India. The study consists of assessing heat strain of workers exposed to heat in a steel plant by measuring physiological reactions of workers such as pulse rate and core body temperature with and without cool coat. The coal coat taken for this study was procured from M/s Yamuna Industries, Noida. Out of 140 employees exposed to heat hazard, 101 employees were examined in this study. Study was done in important production units in steel plant having heat hazard. Workers were interviewed and examined and information regarding thermal comfort was collected. First, the heat strain was assessed when the workers were not using cool coats. The air temperature was measured at all hot zone workplaces and found in the range of 34 0 C to 39.4 0 C (Mean: 36.54 0 C & S.D: 1.54). Physiological response such as core body temperature, pulse rate and blood pressure of workers exposed to heat hazard were measured before & after work to know the heat strain sustained by workers when they were working. Maximum core body temperature after work was found to be 39.3 0 C (Mean; 38.52 & S.D; 0.7). Maximum pulse rate of workers after work was found to be 120 beats/minute (Mean; 94.96 beats/minute, S.D: 13.11). The study indicate core body temperature of workers was found more than the permissible exposure limit prescribed by ACGIH, indicating the heat strain sustained by workers is significant, whereas the pulse rate and blood pressure was found normal & not exceeded the limits. Second, with cool coat, the heat strain was assessed among 10 workers selected from the 101 employees. Core body temperature was measured before and soon after work, The core body temperature recorded soon after work was in the range of 35.5 - 37.20C (Mean 36.36, SD= 0.52), indicating a drop in the core body temperature. In this study, a core body temperature rise in the range of 1 0 -1.4 0 C was noticed when the employees were not wearing cool coats. Whereas, with the usage of cool coat a rise in core body temperature was not found and in many coat wearing workers a drop in core body temperature (0.2 to 0.9 0 C) was noticed. Employees revealed that the cool coats was comfortable to use and provided the thermal comforts. The study concluded that the cool coat taken for this study was found effective in reducing the heat strain.

Keywords: Air temperature, blood pressure, cool coat, core body temperature, exposure limits, heat stress, heat strain, hydro folic, pulse rate

INTRODUCTION

Steel making is basically a high temperature process. Steel workers are exposed to heat stress, particularly during the hot summer months. The local climate (where the study steel plant is located) is hot and humid and temperatures go up to 42°C in summer. High levels of heat stress are found in the steel industry, especially at hot rolling areas, casting platforms, and near furnaces. In a previous study conducted at this plant, the thermal stress with Wet bulb globe temperature (WBGT) levels of 28°C to 34°C was found at many production areas. At WBGT levels over 30°C, the risk of incurring heat illness progressively increases with the level of risk being higher for heavier physical work. Excessive heat strain in the workplace can lead to heat-related illnesses ranging from headache, nausea, and vomiting to severe forms of heat stroke, which, if untreated, can lead to death.[1]

Heat stress can cause safety problems by impairing a worker's ability to work safely. Heat can lead to accidents resulting from slipperiness of sweaty palms and accidental contact with hot surfaces. Heat causes dizziness and may also affect mental alertness, increasing the risk of accidents. Fogging of eye glasses can briefly obscure vision presenting a safety hazard.

Physiological responses to heat

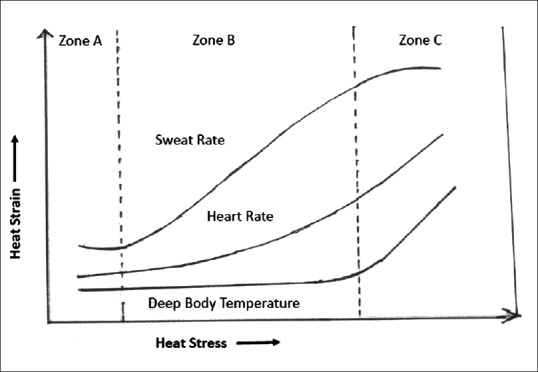

Heat strain is the response of the body to heat exposure. It is a series of physiological responses to heat stress.[2] Environmental heat stress (air temperature, humidity) combined with physical work causes heat strain among steel workers.[3] Heat strain is defined as “the physiological impact of heat stress on the body, as expressed in terms of changes in core body temperature and compensating changes in the activity of physiological systems (heart rate, sweat rate, skin blood flow).” Figure 1 shows the interaction between heat stress and heat strain. It is evident that environmental heat stress increases the sweat rate, core body temperature and pulse rate among employees exposed to heat hazard.

Figure 1.

Relationship between Heat stress and Heat strain – Source: WHO 1969

Pulse rate

Pulse rate, typically measured in beats/minute, provides a guide to stress on the body. It can be used as an effective measure of heat strain due to the manner in which the body responds to increased heat loads. Blood circulation is adjusted to move blood around the body to dissipate heat, which inturn results in an increased pulse rate.

In humans, the heart rate is highly variable, however, in most average adults, a rate of 60–80 beats/minute is common. Under thermal stress, higher than normal pulse rates are observed.

Core body temperature

Humans are warm blooded and biochemistry functions at an optimum temperature level (near 37°C). Deviation of a few degrees from this temperature can have serious consequences. When the body is unable to cope with the hot environment, the body's heat gain exceeds the body's capability to lose heat. As a result, the inner body temperature rises increasing the risk of heat-related illnesses.[4] Thus, core body temperature is a very good indicator of heat strain on the body. Because the humans are highly variable, the only way to determine the true thermal strain is to measure individual response to heat hazard. In a hot environment, deep body temperature is measured and monitored as the best single gauge of heat strain. Konz recommends multiple measures such as heart rate and sweat rate in addition to deep body temperature.

Protective clothing

To protect from heat hazard, protective clothing is widely used for performing jobs in hot environment. However, clothing affects heat exchange between the body and the environment. Heavy clothing such as heat resistant suits, fail to breathe and does not allow the body to cool off by air circulation and affect sweat evaporation processes. Such clothing significantly increases the risk of heat illness. Hence, protective clothing should ensure that sweat can be evaporated off the skin to obtain the cooling effect. The protective clothing (breathable and hydro folic) developed by M/s Yamuna Industries, Noida was selected for this study.

Objective of the study

The objective of this research was to study the effectiveness of cool coat (Trade name: Cool magic) in reducing heat strain sustained by workers in a steel plant. The study consisted of assessing heat strain of workers exposed to heat hazard by measuring the physiological reactions of workers, such as core body temperature, heart rate and blood pressure with and without using cool coat for determining its effectiveness of cool coat. The ambient temperature was also measured to know the extent of heat hazard at workplace.

MATERIALS AND METHODS

Workers and job profile

This study was carried out in a steel plant located in south India. A cross-sectional study was conducted by selecting employees of different age groups working in production departments such as blast furnaces, basic oxygen furnaces, continuous casters, and rolling mills. The workers were all males in the age group of 25–55 years.

Work profile

All study participants were industrial workers habitually exposed to heat stress in a hot environment in production units such as blast furnace cast house, basic oxygen furnace, rolling mill area, and continuous casting machines.

The factory works continuously in three shifts of 8 hours each. Posting of a worker in a particular section was of a permanent nature. The shifts changed on rotation every week. The clothing ensemble consisted of long thick cotton trousers and long-sleeved shirts, safety boots, safety helmets, and face protection. Workforce was mobile. The workers worked intermittently for 1–2 hours, three times, with lunch break and rest. The workers were relatively well informed about the safety issues related to working in a hot environment.

Work load

Work consisted of tap hole launder preparation, lancing of oxygen at blast furnace, mold level monitoring in casting platform of continuous casting machine, gas cutting of hot blooms, hot punching, etc. These jobs fall under the category of light-to-moderate physical work (approximately 240 kcal/h).

Questionnaire

Information such as age, height, weight, exposure period, task carried out, availability of cool rest room, drinking water, and type of clothing with respect to heat hazard problems was collected from all employees in a proforma designed for the purpose.

Body bass index

Because heat strain is influenced by obesity and age, the information regarding age, weight, and height of workers exposed to hot environment were collected and body mass index (BMI) was calculated. All workers who participated in this study were examined in the factory occupational health center, periodically. Each worker was interviewed and examined.

Assessment of heat strain

Measurement of core body temperature

It is the temperature of body's internal organs. A clinical thermometer (Make: MC 246) was used by placing it below the tongue to measure pyrogenic changes in body temperature.

Measurement of pulse rate (heart rate) and blood pressure

Pulse rate of employees exposed to heat hazard was measured before the start of work and soon after work. The instrument used was automatic blood pressure monitor OMRON HEM-7113. This instrument measures blood pressure (systolic and diastolic) and pulse rate simultaneously and shows the values in digital format'. The workers were considered for high blood pressure when there was persistent elevation of systolic blood pressure to a level of 140 mm/Hg and diastolic pressure at a level of 90 mm/Hg or higher (Young and Laffrey 2006).

Measurements of air temperature at the workplace was done using OMRON MC-246 thermometer. Three measurements were taken at each workplace and the average temperature was recorded.

Statistical analysis

Data from completed questionnaire and field results were entered in Microsoft Excel spread sheets and analyzed with the help of MINITAB statistical software package. Mean and standard deviation and coefficient of correlation were used for statistical analysis. Frequency distribution, tables, and percentage were used to summarize the data in tabular format.

Heat strain limits

The results obtained with respect to body core temperature and pulse rate were compared with permissible exposure limits recommended by American Conference of Governmental Industrial Hygienists (ACGIH).

As per the ACGIH exposure limits, one or more of the following measures may mark excessive heat strain and an individual's exposure to heat stress should be discontinued when any of the following occurs:

Sustained (several minutes) pulse rate is in excess of 180 bpm (beats/minute) minus the individual's age in years (e.g., 180 – age)

Body core temperature is greater than 38.5°C for medically selected and acclimatized personnel or not greater than 38°C for nonacclimatized workers

When there is symptom of sudden and severe fatigue, nausea, dizziness, or light headedness.

The limits of heat strain are to be followed to monitor exposure to heat stress on an individual basis. The limits represent time to cease exposure and allow for recovery.

RESULTS

Assessment of heat strain without coat

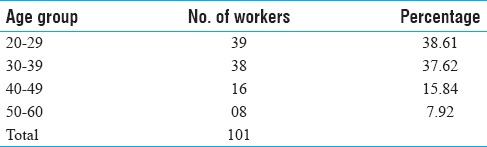

Age group of target group employees

Table 1 shows that the participants were from all age groups. However, the maximum number of workers were in the age group of 20–29 and 30–39 (total 76.23%). Age is one of the important factors while determining heat strain. Older a person is the more likely he will suffer from the effect of heat; particular consideration should be given to individuals over 45 years of age. It is not advisable to post persons over 50 years of age for strenuous jobs in hot environment British Occupational Hygiene Society (BOHS). However, 8% of workers in the age group of 50–60 years were working in the hot environment. For these employees, there is a need to monitor the body core temperature, heart rate, rest pause, etc., at the workplace.

Table 1.

Age group of target group employees

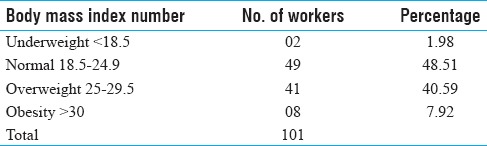

Weight and physical fitness

Susceptibility to heat varies from person to person. Body weight and physical fitness are important factors for assessing heat strain. Those who are overweight and physically weak are more likely to experience the ill effects of heat. Table 2 shows the details of height, weight and BMI of target group employees.

Table 2.

Classification of body mass index of workers exposed to hot work

Nearly 48.5% of target group employees were classified as overweight and obese. These employees require greater energy to perform a task. Hence, higher metabolic heat is produced in the body. Bigger the person, lower is the surface area to mass ratio, and the person's ability to dissipate heat is reduced. Fat is a good insulator, which means that fatter the person he is the less heat tolerant he is. It is established that persons with BMI of more than 30 have less heat intolerance, and there is a risk of heat stroke for such workers when they work in hot environment (SIMRAC- Hand book of Occupational health practice -2001, Editor: Dr. A.J. Keil block). Persons with obesity having BMI of more than 30 need to be closely monitored at the workplace where heat hazards exist.

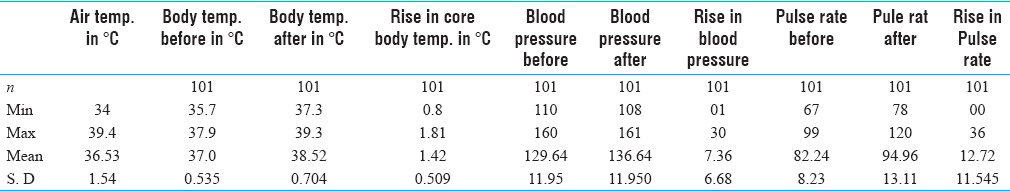

Core body temperature, pulse rate and blood pressure

Table 3 shows the air temperature at workplace and details of body temperature, pulse rate, and blood pressure of workers measured, individually, during work in hot environment.

Table 3.

Details of body temperature, pulse rate of workers exposed to heat hazard, and air temperature

Air temperature

Air temperature was measured at all workplaces having heat hazard. Air temperature is important in the assessment of thermal stress as it affects the convection of heat transfer from an individual. The minimum air temperature recorded at workplace was 34°C and the maximum was 39.4°C (Mean air temperature: 36.53°C and standard deviation: 1.54). Air temperature exceeding 35°C can increase the heat load on the body. Air temperature indicates that there is a significant heat stress for employees working in hot environment.

Core body temperature

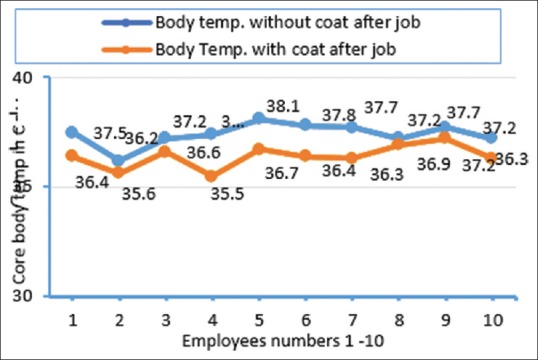

Core body temperature was measured before and soon after work. Table 3 shows the core body temperature of workers before start of work which was in the range of 35.7°C to 37.9°C (Mean 37.0°C and standard deviation: 0.535). The core body temperature measured soon after work was in the range of 37.3°C to 39.3°C (Mean 38.52°C and standard deviation: 0.704). The maximum core body temperature rise was 1.81°C. The rate of increase in core body temperature is a potential factor in the development of heat illnesses (Hales JRS, Richard DAB-1988). The commonly recommended limits for industrial hyperthermia are 38°C or an increase of ±1°C. The limits for core temperature of body recommended by ACGIH is 38.5°C for medically selected and acclimatized personnel or not greater than 38°C for nonacclimatized workers. It was found during the study that 53 workers out of 101 (52.47%) reached core body temperatures of more than 38.5°C. This indicates more than 50% of the employees working in hot environment were suffering from significant heat strain at workplace. The core body temperature rise of up to 1.81°C indicates that the heat loss from the body was not adequate. Figure 2 shows the graph indicating core body temperature with and without coat.

Figure 2.

Core Body temperature with and without cool coat

Pulse rate

Pulse rate is as an effective measure of heat strain. Pulse rate indicates reaction to heat much sooner than body temperature response. Table 3 shows the pulse rate of workers before start of work and soon after work. Pulse rate before start of work was found in the range of 67 to 99 beats/min (Mean: 82.24 and standard deviation: 8.23) and pulse rate soon after work was found in the range of 78 to 120 beats/min (Mean: 94.96 and standard deviation: 13.11). For three employees, increase in pulse rate was found more than 30 beats/min.

The limit with respect to pulse rate (sustained for several minutes) during work is 180 beats/min minus the individual's age in years (ACGIH: 2007 TLV BEI book). The pulse rates shown in Table 3 indicate that no employee crossed the exposure limits recommended by ACGIH.

Blood pressure

Out of 101 target group workers, eight were found with hypertension in the range of 140/90 to 161/89. The remaining did not have hypertension problems. Increase in blood pressure during moderate to heavy work at any workplace is a common phenomenon. Similar rise in blood pressure was also found among workers working in hot environment. No association between hypertension and hot environment was found in this study.

Medical reports of target group

No cases of heat stroke were reported to the 24-hour on-site medical centre for the past 10 years. Only skin rashes and superficial burns were reported when workers were in contact with hot surfaces.

Workers feedback

Feedback of employees with respect to heat-related illnesses was obtained. According to the feedback obtained from the workers through questionnaire, the following are the heat-related problems faced by employees:

Workers in basic oxygen furnace, blast furnace cast house, and continuous casting sections complained of eye strain due to exposure to intense, yellow infrared radiations from the furnace and molten metal. Usage of goggles to protect eyes against radiant heat was found to be only 40%

10% of workers complained of mild headache while working in hot environment

Five out of 101 target group workers experienced vomiting symptoms, occasionally, during attending hot work jobs

Nearly 50% of employees complained of discomfort with respect to usage of helmet, face shield, shoes, and thick cotton uniform while working in hot environment. They suggested to provide cool coats for thermal comfort.

Assessment of heat strain among employees with cool coat

A study was conducted to assess the effectiveness of cool coat to combat heat hazard in the industry by measuring core body temperature. The cool coat used for this study was procured from M/s Yamuna industries, Noida. The cool coat was developed for use of employees exposed to heat hazard to reduce heat strain sustained by workers during work.

The details of cool coat taken for the research study

How it works?: Cool coat (cool magic) works on the concept of evaporative cooling. When the wearer puts on the water soaked coat, water from cool magic garment starts evaporating, which eventually carries hot vapor from the body (passed through inner breathable fabric to outside) keeping the person cool.

This protective clothing acts as a water barrier between the skin and the atmospheric temperature. Figure 3 shows the picture of cool coat.

Figure 3.

Cool Coat

Structure of cool coat

Cool coat is a three-layered quilted apparel with a magnificent ability to hold water

The inner layer is a breathable waterproof fabric

The middle layer is a felt that has the capacity to withhold water many times its own weight

The outer fabric is a highly breathable fabric with hydrophilic property which easily allows the water to absorb to the middle layer and helps in faster evaporation when exposed to hot environment

All the three layers are held together through quilting/ultrasonic sealing making a composite fabric suitable for garment making.

Preparing cool coat for trial

Water was taken in a bucket and the cool coat was immersed in the water

Cool coat was submerged in the water for 3–5 min

The cool coat was removed and squeezed gently to remove the excess water;

Extra water in the jacket was wiped out with a cotton cloth

Then the garment was ready for field study.

Research methods used

Ten employees in the age group of 28–50 years were selected from production departments where heat hazard exists. Their main job included punching of hot billets, tap hole opening in the blast furnace cast house, gas cutting of hot blooms, and oxygen lancing for removal of jam of solidified molten slag and metal

First, the body temperature of employees was measured before starting the hot job and soon after completion of job. In these cases, cool coat was not used

Next, the body temperature of employees was measured before starting hot job and cool coat was served for use. Soon after the completion of job, the body temperature was measured with cool coat in use

The employee's feedback was obtained regarding thermal comforts and effectiveness of cool coat in reducing heat strain.

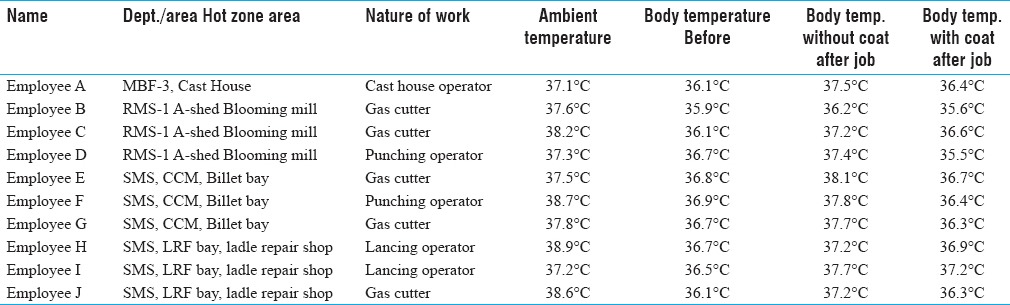

The readings obtained during field study are given in Table 4.

Table 4.

Heat strain results before and after use of cool coat

Research findings

Ambient temperature: The ambient temperature at the workplaces measured was in the range of 37°C to 38.7°C. This indicates there was enough heat hazard at workplace where the trials were conducted

Work rest regime for employees under trial was 75% work and 25% rest. The work load for jobs such as hot punching, gas cutting, coke injection, cast house work, etc., was classified as moderate

-

Body temperature readings;

Rise in body temperature indicates the heat strain sustained by employees, whereas drop in core body temperature makes the wearer feel cool

- When cool coat was not used: Core body temperature rise during work was found in the range of 1–1.4°C. This indicates that employees were subjected to heat strain.

- With usage of cool coat: There was no rise in core body temperature. In fact, the core body temperature decreased by 0.2–0.9°C.

-

Employees feedback

- Employees who used this coat were found to be comfortable while carrying out hot jobs

- Employees felt happy to use cool coat during trial because it ensures cooling effect while working in hot environment.

CONCLUSION

In this study, it was found that air temperature in many areas exceed 35°C, indicating heat stress in working environment. Heat stress is a potential health problem in a steel plant. This study indicates a rise in core body temperature of workers (up to 1.4°C) in hot environment, which is a potential risk factor in causing heat illnesses. However, a drop in core temperature (0.2–0.9°C) was noticed when workers used cool coat. Gradual decrease in skin temperature does not hamper body metabolism. Body metabolism performs better in cool condition, which leads to long and healthy life. This study indicated that the cool coat used was found effective in arresting core body temperature rise and in thermal comfort to workers.

However, engineering control measures, such as installation of thermal barriers, improving ventilation, and provision of A/C rooms are suggested for protection of employees from heat stress. Close monitoring of core body temperature and pulse rate is essential. Shortening the work period in shifts to avoid hyperthermia, intermittent rest, and provision of cool drinking water are also suggested.

It is suggested to provide cool coat to employees exposed to heat stress from the safety and health points of view. The use of cool coat prevents health disorders such as heat cramp, heat stroke, and heat strain at the workplace and also minimizes accidents occurring to employees due to heat exposure. This cool coat can also be used by outdoor workers in construction, mining, and agriculture sectors.

Study limitations

Measurement of core body temperature: In this study, for measurement of core body temperature, a clinical thermometer was used by placing it below the tongue. For accurate measurement, inserting a thermometer 8–12 cm into the rectum is suggested.[5] However, this method generally meets with resistance from workers and their cooperation is difficult to get.

Assessment of heat strain: In this research work, two important indicators core body temperature and pulse rate, are measured and considered for assessment of heat strain. It is suggested to consider other parameters such as sweat rate, dehydration and heart rate recovery for accurate assessment.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Ravichandran B., Krishnamurthy V., Raghavan S., Rajan B.K., Rajmohan H.R. Assessment of Thermal environment in an integrated iron & steel plant of south India. Thermal Environment & noise intensity levels in steel manufacturing. 2006;12(3):159–166. [Google Scholar]

- 2.Rodahl K, Guthe T. Environmental Ergonomics – sustaining human performance in harsh environments. London: Taylor & Francis; 1988. Physiological limitations of human performance in hot environments, with particular reference to work in heat exposed industry; p. 37. [Google Scholar]

- 3.Minard D, Gold R. Industrial. Vol 32. Hygienist Association; 1971. smith. P.H. farrier, B. Lambiotte. Physiological Evaluation of Industrial Heat stress; pp. 17–28. [DOI] [PubMed] [Google Scholar]

- 4.Derrick John Brake, BE (Hons), MBA, Graham peter bates, MB, ChB, MPH, PhD. Deep body temperatures in industrial workers under thermal stress. Indian journal of Environment medicine. 2002 Feb;Volume 44(Number 2) doi: 10.1097/00043764-200202000-00007. [DOI] [PubMed] [Google Scholar]

- 5.Tranter M, Abut GA. The assessment of metabolic rate, core body temperature & hydration status during underground coal mining. Proceedings of the 1998 safety institute of Australia Annual conference, Gold coast. SIA. 1998:293–303. [Google Scholar]