Abstract

Ultrafast laser systems are becoming more widespread throughout the research and industrial communities yet eye protection for these high power, bright pulsed sources still require scrupulous characterization and testing before use. Femtosecond lasers, with pulses naturally possessing broad-bandwidth and high average power with variable repetition rate, can exhibit spectral side-bands and subtly changing center wavelengths, which may unknowingly affect eyewear safety protection. Pulse spectral characterization and power diagnostics are presented for a 80 MHz, Ti+3:Sapphire, ≈ 800 nm, ≈40 femtosecond oscillator system. Power and spectral transmission for 22 test samples are measured to determine whether they fall within manufacturer specifications.

Keywords: Femtosecond lasers, Laser Safety, retinal injury, eyewear protection, optical density, ultrafast

I. Introduction

With the advent of femtosecond and shorter pulsed lasers, eyewear protection has become increasingly more demanding because of the naturally broadband nature of these sources. High average power, often in the multi-Watt range, can achieve peak powers with irradiance levels on the order of TW/cm2 to even PW/cm2, making interaction with materials highly nonlinear.1 Many earlier studies using nanosecond sources2 and <200 fs lasers1,3,4 investigated the efficacy of commercial eyewear “M-rated” mode-locked laser protection.5,6 But for high peak power cases of concern here, absorbing filter materials such as organic dyes may exhibit saturation and concomitant increased transmission if the irradiance (referred to as peak fluence throughout with units W/cm2) exceeds certain thresholds. When required protective eyewear is employed, it is often assumed that the manufacturer’s specifications may be adequate, but these specifications are typically obtained using extremely low power, DC light sources and standard spectrophotometric measurement rather than the high power lasers themselves.6 Because of these potentially high peak power laser fluence output conditions, specified eyewear filter optical densities (OD = −log10(T) where T is the transmitted power ratio integrated across the laser spectrum) and wavelength coverage may be suspect and needs to be tested under actual working environmental conditions to achieve established laser safety eyewear standards (see specifically ANSI Z136.1-2014 Section 4.4.4.2.3 pp 40–44 and Section 8. pp 62–68).5 According to the Laser Institute of America protective eyewear calculator7 the recommended optical density (OD) required for the laser oscillator used in this study (covering the range 750 nm to 850 nm) should be 2.7 or higher.

In order to address potentially dangerous eye safety situations when employing ultrafast lasers, detailed determination of the laser system’s output properties and protective eyewear characterization is required. Herein, as a first evaluation, we elected to perform careful quantitative spectral and power measurements for a typical high-repetition rate, near transform-limited femtosecond Titanium Sapphire oscillator system. Test samples were graciously provided by several “unidentified” laser safety eyewear manufacturers and results referred to by arbitrary sample names (letters A through V) to keep their origins unknown. We report measured sample ODs for spectrally characterized laser output and test filter transmission spectra and compare measured OD values to those provided by the supplier.

II. Experimental

A. Ti+3:Sapphire Femtosecond Oscilllator

The Kerr-lens modelocked output of a standard linear cavity designed oscillator (Kapteyn-Murnane Lasers, Inc.8) contains a nominally 5 % transmission output coupler (broadband centered at 800 nm but with slowly varying 3 % to 4 % transmission wells on either side), double prism intracavity group velocity compensation and rear broadband high reflector without any intracavity tuning elements or slits. The sapphire rod is collinearly excited by a diode-pumped, 527 nm continuous wave (CW) laser (Coherent Verdi V) at 3.5 W output. Under these excitation conditions, the Ti+3:Sapphire oscillator typically generates 170 mW CW output (not mode-locked) and 140 mW to 470 mW average power when modelocked (depending on center wavelength) with <10 nJ/pulse at 81.5 MHz repetition rate. Wavelength tuning is achieved, after CW power optimization, stable modelocking and warmup (center wavelength can shift to lower wavelength by up to 25 nm over the course of an hour) by slightly twisting the prism nearest the laser rod. This enabled tests at various output center wavelengths ranging from 780 nm to 850 nm and bandwidth conditions ranging from ca. 26 nm to 40 nm FWHM (full-width at half maximum). Pulsewidths, as measured by autocorrelation, typically fall within the 40 fs to 80 fs FWHM range depending on spectral bandwidth. Laser output average power was measured with a calibrated thermopile 10 W power head and analog meter (LaserProbe, Inc. Model Rk-3100 with ± 5% uncertainty power specification). Beam profiles and diameters (see Figure S1 in Supplemental Information) at full-width half maximum (FWHM) were obtained at several sample positions (e.g., 2 mm and 10 mm beam diameters) with a large format (7.1 × 11.3 mm) Mako model G-234B 1216×1936 pixel CMOS camera acquired and analyzed using Labview software.8

B. Low Fluence OD Measurements

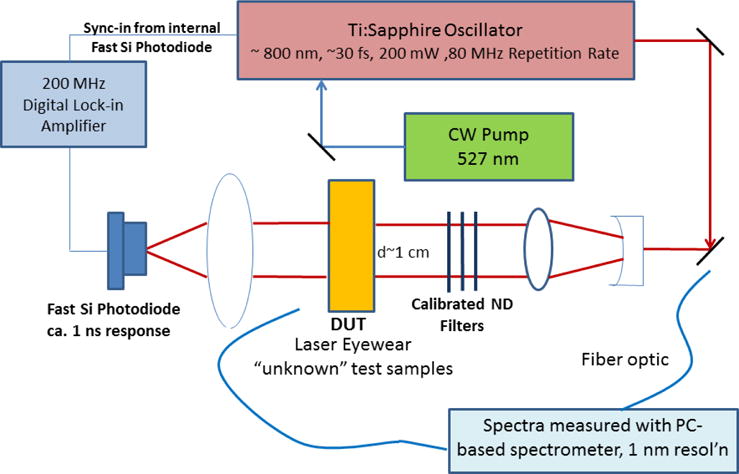

Measurements were conducted with direct output beam on the test sample (diameter ≈ 2 mm) and at low irradiance. Low irradiation was achieved by negative lens beam expansion (to ≈ 1.5 cm diameter) before the sample yielding values of <100 kW/cm2 at that position. By employing a fast, DC-biased silicon photodiode to detect transmitted power and a second intracavity monitor diode to synchronously trigger a high-frequency lock-in amplifier (Stanford Research Systems Model 844), direct measurement of optical densities (OD) of standard neutral density filters and eyewear test samples with up to six decades of dynamic range was readily achieved. Once a set of standard glass neutral density filters were analyzed (each having OD < 1), the total system response range was extended to ≈ OD ≤ 9 by adding these calibrated neutral density filters in the incident laser beam. Detection system linearity was checked by swapping filters and making measurements over several decades of signal. A schematic of the optical layout used in this study is shown in Figure 1:

Figure 1.

Optical layout of apparatus employed to measure laser eyewear sample transmission at low peak power input fluence from a femtosecond modelocked Ti:Sapphire oscillator. Expander/collimator optics used with ≈ 1 cm beam diameter at sample.

Laser spectra were recorded with a PC-based spectrometer (Avantes Model AvaSpec-2048-USB2, 2 nm FWHM resolution and wavelength uncertainty ± 0.05 nm specification) using a fiber-optic input coupler and 10 ms acquisition averaging to measure the incident laser spectrum and in-line transmitted spectrum after each sample. Table entries are noted in cases where OD precluded spectral measurement. Optical densities were measured by first obtaining the averaged diode voltage from the lock-in amplifier and using neutral density filters where necessary to keep the voltage within the linear regime. The eyewear filter was then inserted in the sample position and new voltage recorded. The OD for the filter was then ascertained according to the definition OD = −log10(Vsample/Vno sample) where V is the lock-in averaged detected voltage. When possible, multiple measurements on different days at the same center wavelength but different powers were accumulated and the average value reported (k=2 type B error analysis). From the collected dataset, OD values were reproducible to within ± 20%. In several cases with high irradiance exposure (direct collimated beam), samples with both intrinsically high and even low OD exhibited damage (sample burn or distortion with changing transmission) and this is noted in the Results section, Table I below.

Table I.

Representative accumulated data for laser eyewear test samples A – V with laser oscillator tuned to various center wavelengths, bandwidths, output power and impinging beam diameter. The maximum attainable system optical density (Max System OD) is also noted for each set of laser conditions.

| Center Wavelength (nm) | 847 | 850 | 792 | 789 | 800 | 800 | 800 | 800 | ||||

| Bandwidth (nm FWHM) | 42.5 | 37 | 35.1 | 32.7 | 26.2 | 26.2 | 26.2 | 26.2 | ||||

| Average Power (mW) | 238 | 229 | 128 | 125 | 470 | 400 | 420 | 375 | ||||

| Max System OD | 6.42 | 6.41 | 6.40 | 6.41 | 8.88 | 9.02 | 8.82 | 9.07 | ||||

| Beam Diameter (mm) | 2 | 10 | 10 | 10 | 15 | 15 | 15 | 2.5 | ||||

| Sample | ODa | d (mm)b | OD | Damc | OD | OD | OD | OD | OD | OD | OD | Damc |

| A | >7 | 3.2 | Infd | Inf | 8.88 | 9.07 | ||||||

| B | >7 | 3.2 | Inf | Inf | 8.9 | 9.07 | ||||||

| C | 7+ | 3.5 | Inf | Inf | 7.21 | 7.78 | ||||||

| D | 7+ | 7.0 | Inf | Inf | 7.37 | 7.52 | 7.83 | |||||

| E | 7+ | 3.5 | Inf | Inf | 8.88 | 9.07 | ||||||

| F | 2 | 3.2 | 4.83 | 3.28 | 3.27 | 4.32 | 3.5 | Y | ||||

| G | 7+ | 3.0 | 2.31 | Y | 5 | 7.62 | 7.38 | Y | ||||

| H | 5+ | 2.0 | 0.49 | 1 | 1.13 | 1.23 | ||||||

| I | 2.0 | Inf | Inf | 8.89 | 8.18 | Y | ||||||

| J | >7 | 6.2 | Inf | Inf | 8.9 | 8.15 | ||||||

| K | >6 | 3.4 | Inf | Inf | 8.9 | 8.68 | 7.92 | |||||

| L | >6 | 4.0 | Inf | Inf | 8.9 | 8.88 | ||||||

| M | 7+ | 3.0 | 2.35 | Y | 2.2 | 5.49 | 8.42 | 7.38 | Y | |||

| N | 5+ | 3.0 | 1.93 | Y | 1.84 | 3.93 | 5.31 | 5.53 | 5.44 | |||

| O | 5+ | 3.2 | 1.08 | 1.05 | 2.81 | 3.14 | 3.16 | |||||

| P | 7+ | 3.0 | Inf | Y | Inf | Inf | 8.9 | 9.05 | Y | |||

| Q | 6+ | 3.2 | Inf | Y | Inf | Inf | 8.89 | 8.85 | Y | |||

| R | 7+ | 3.0 | Inf | Y | Inf | 5.65 | 7.24 | 7.44 | Y | |||

| S | 4.3 | 6.4 | 4.77 | 4.73 | 3.04 | 5.11 | Y | |||||

| T | >7 | 2.0 | 2.5 | 5.13 | 7.91 | 5.91 | Y | |||||

| U | 7+ | 2.0 | 7.46 | 8.11 | 7.33 | Y | ||||||

| V | 2.0 | 7.53 | 7.86 | 7.47 | Y |

Optical Density at 800 nm from Manufacturer either with sample or extracted from website

No filter thickness provided on supplier’s websites so nominal measured thickness (d) supplied

“Y” in Dam columns signifies damage to sample was observed (discoloration or distortion) during the course of several seconds of exposure under the experimental conditions specified in the preceding column

“Inf” = infinity; signifies measured OD exceeds the system dynamic range maximum value

C. Investigated Laser Eyewear Filter Samples

Five laser eyewear suppliers provided multiple samples of their suggested filters for either 800 nm pulsed or CW laser protection with highest OD. They were supplied as round cut samples (with varying 25 mm to 75 mm diameters as either flats or concave format) or oblong flat rectangles and were apparently composed of colored plastic or glass several millimeters thick. In a very few cases, the samples appeared to employ optical dielectric coatings on a glass substrate material. Several samples from each type were also provided for testing and randomly labeled for identification during test. In addition, two pairs of laser eyewear protection chosen specifically for use in the NIST femtosecond laser test facility were similarly measured to directly compare OD values to manufacturer’s specifications. Each filter type was assigned an arbitrary alphabetic descriptor (A through V) for identification and to report measurement results below. Specifications for these samples are tabulated with OD measurements made using the above methodology. As checks, test sample transmission spectra were obtained with a Perkin-Elmer Lambda-2 UV-Visible spectrometer (2 nm resolution with OD uncertainty of ± 0.01, but values OD > 3 were not reliably attainable with this instrumentation).

III. Summarized Test Results

To provide an example for experiments performed on a sample, we first chose to examine actual laser eyewear purchased for use in the Ti:Sapphire laser lab (e.g., test sample “T”). Optical density values supplied by the manufacturer over three wavelength ranges were provided and compared to measured OD values at specified laser output center wavelengths. The measured laser and transmitted spectral results are summarized in Figure S2 (see Supplemental Information) where it is shown that the stated protection is OD > 4 for 755 nm to 855 nm while it is OD > 7 for 780 nm to 840 nm. Actual measured OD’s are >5 for center wavelengths at 800 nm and 792 nm, but OD = 2.5 at 847 nm laser output. These results suggest care must be taken when the laser spectral output is greater than ≈ 840 nm. It was also found that the eyewear sustained damage when the laser was center-wavelength tuned to 800 nm with 238 mW output in the direct 2 mm beam (corresponding to 7.6 W/cm2 average power and 1.9 MW/cm2 peak pulse irradiance) impinged on the sample for a few seconds.

Findings for filter sample labeled “N” are presented in Figure S3 which has similar color hue as the laser eyewear discussed above. In this test case, the supplier quotes OD > 5 for the wavelength range 785 nm to 818 nm. We measured OD > 4 for center wavelengths 800 nm and 792 nm, but OD = 2 at 847 nm. These two samples clearly exhibit lower OD for wavelengths > 840 nm suggesting extreme care must be taken when the Ti:Sapphire system emits radiation in the higher wavelength region. Sample “O” which appears similar to “N” consistently yielded even lower OD values for the same wavelength ranges.

Experimental details and results for measurements made during several different days and conditions for the designated samples are summarized in Table I:

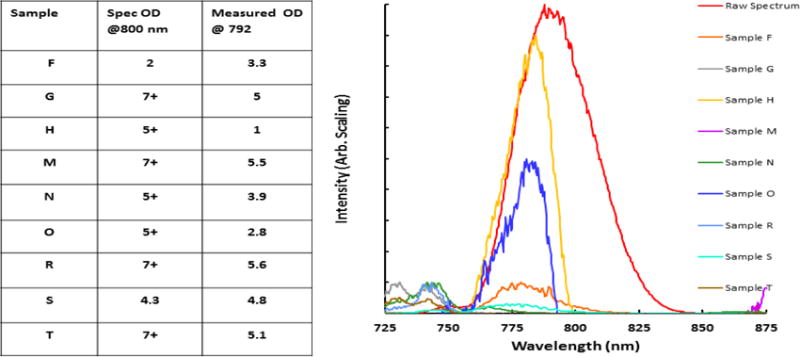

To provide the reader with a more concrete set of sample transmission spectra, please refer to Figure 2. For those samples listed in Table I which yielded “infinite” OD values, no transmission spectra could be obtained. However, several of the filters with lower than the manufacturer’s OD specification (at 800 nm) are shown with transmission spectra for each in Figure 2. As is evident from the spectra, these sample filters transmit power at wavelengths lower than 800 nm and so yield measured OD values below specification even when the laser is tuned only 8 nm lower than 800 nm. There is also evidence of power transmission for wavelengths below 750 nm, which is hard to detect in the raw laser spectrum. These results clearly indicate that laser eyewear filters require scrupulous testing prior to use with < 100 femtosecond, broadband laser sources.

Figure 2.

Transmission spectra (arb. Intensity scaling for clarity) for several test samples listed at left compared to the laser output spectrum (red). The specified OD values supplied by the commercial filter sources (Spec OD) are compared to those measured directly suggesting the measured densities are lower because of inherent pulse spectral width and side-bands outside the 800 nm specification.

IV. Discussion

In general, several of the examined test samples fared extremely well and did not transmit appreciable power across the measured laser output tuning wavelengths, powers and bandwidths. It is promising to find that, within our measurement capabilities, samples A–E, I–L and P–R yielded actual measured OD > 7 across the tuning wavelengths and even under the highest fluence conditions (direct output beam). One would conclude that these filters, if employed as laser eyewear for the Ti:Sapphire oscillator used in this test, would be more than satisfactory protection against eye damage under all test and deployment scenarios similar to the test conditions. Our study was restricted to the wavelength region near 800 nm, so use of these filters for wavelengths far beyond the 745 nm to 850 nm range, where Ti:Sapphire lasers can operate, require further testing.

The measured OD’s for several filter samples were inexplicably low. For example, samples M, N, O and T exhibited very low OD values across the tested spectral range (OD < 3) and were especially small (see filter “O” and Figure S2) for the longer (red) wavelength ranges. In these cases, the measured low OD values suggest these filters are not appropriate for protective safety use.

However, as can be found in the summary Table I, there were also many instances where test samples exhibited damage during exposure to the direct laser output beam, but only for the smallest beam diameters (2 mm and 2.5 mm). Under these highest peak power conditions, the average energy flux for both cases is estimated to be ca 7.6 W/cm2 with a peak pulse fluence of ca 1.8 × 106 W/cm2 and ≈ 1.1 × 106 W/cm2 for the 2 mm and 2.5 mm diameters, respectively. In both cases, these are extremely high pulse peak fluences, which are potentially able to damage absorbing materials (e.g., dyes dispersed in polymers) or attain non-linear saturable absorption or bleaching in organic systems. In two cases, the measured OD becomes much lower after damage (e.g., arising from dye bleaching or permanent decomposition) for highest input fluence compared to similar laser output conditions at lower fluence (see, for example, samples M and N at 847 nm and T at 800 nm). There does not appear to be a correlation between the measured OD for each sample at low fluence and whether a filter can incur damage. Several filters with high OD were also found to damage with direct exposure (see 800 nm, 2.5 mm diameter column) but may also increase OD after damage (e.g., filter S at 800 nm). Thus, even when a direct output beam impinges the filter directly on a rather large subset of these samples, it is possible to damage the eyewear and change the effective optical density if they are exposed for several seconds without movement.

The measured OD values presented in Table I are obtained by integrating overall output wavelengths and power generated by the laser. In our case, the laser oscillator exhibits weak but observable side-bands that can penetrate through laser eyewear and potentially induce retinal damage. These predominantly arise from the specific transmission characteristics of the output coupler. In our system, the output coupler is specified to be ≈ 5% transmitting at 800 nm, but this value decreases to either side of this center wavelength, thus producing spectral sidebands. Filter transmission is increased for shorter and longer wavelength sidebands (e.g., <770 nm and > 830 nm) as found for most of the tested samples. Thus, it is very important that the spectral content of the ultrafast laser source be carefully examined to properly choose an appropriate filter for the conditions of a particular application.

V. Conclusions

We directly measured the transmission properties and optical densities (ODs) for a set of test filters chosen by laser eyewear manufacturers for ≈ 800 nm Ti:Sapphire laser protection. It was demonstrated that the specific laser output characteristics, especially spectral content, determine the transmission properties of these test samples. In several cases, the measured OD for the filter was several units lower than specifications (e.g., sample H is specified as OD 5+ but measured to be OD 0.5). This arises from the naturally broadband spectra and possible sideband generation when employing femtosecond laser sources.

In this work, a generic Ti:Sapphire femtosecond oscillator was selected as the source because it generates relatively low average power (<500 mW) but with up to 45 nm bandwidth (FWHM) corresponding to transform-limited pulse durations less than 80 fs. Even with the laser running ostensibly near the 800 nm center wavelength (with center wavelength ranging from 789 nm to 850 nm), measured ODs for the test samples varied considerably and in several cases were several OD units lower than the manufacturer’s specifications. In static exposure conditions, some of the filter materials exhibited damage and showed increased transmission (lower OD) than under very low fluence conditions. Among the samples tested, there appears to be a trend that the absorption/dissipation mechanisms in glass filters are better able to accommodate the employed femtosecond pulse widths and fluences, but this by no means implies that all glass filters are optimal nor does it imply that all polycarbonate filters are unable to accommodate all femtosecond pulse conditions. This was a representative sampling of filters and should not be construed to be fully comprehensive. In some cases, if some of these test filters were to be employed as protective eyewear, they may not meet recommended ANSI Z136 standards (OD > 2.12 for 80 MHz; 800 nm 1 nJ/pulse at 100 fs/pulse duration)7 since the transmitted peak power could lead to retinal damage.

We conclude that in order to provide adequate eye protection in femtosecond laser labs and commercial environments, utmost care must be made to analyze the specific spectral content of the laser source. Once obtained, an appropriate filter or eyewear should be selected to provide the maximum protection for that particular laser source. It is impractical for laser eyewear manufacturers to establish their own femtosecond laser-based test facilities which cover all possible output conditions of ultrafast systems. Since each laser source may be different, the output spectrum may be tuned or vary during warm-up or modified for new applications, we strongly suggest wherever possible, that filter materials should be directly tested by the end user for the application and conditions in question.

As a follow-on to this study, work is in progress to examine the transmission characteristics and nonlinear behavior (absorption saturation or damage) of these same filter materials under much higher peak fluence conditions. We will examine the irradiance dependence with the oscillator system in more detail and employ a kilohertz regeneratively amplified Ti:Sapphire laser system running at ≈ 80 fs output pulse duration (with ~20 nm FWHM bandwidth) to measure the same filter set under single and multi-pulse conditions. This scenario will help ascertain whether the filters retain high optical density after damage or exhibit saturable absorption by the active medium during short-pulse excitation.

Supplementary Material

Figure S1: Beam profiles (image and x, y cuts) with extracted diameters (FWHM in mm) obtained by using a 1216×1936 pixel CMOS camera at sample positions with ca. 2 mm and 10 mm beam diameter. S2: Description of employed laboratory eyewear with vendor specifications, measured OD values and spectra at various laser center wavelengths; Figure S3: Similar descriptions for Test Sample N.

Acknowledgments

We wish to thank the five anonymous laser eyewear manufacturers for graciously providing test samples for this study. Per NIST’s requirement for anonymity, we do not identify any sources or materials but demonstrate to the laser community that different eyewear filters exhibit varying degrees of protection depending on the ultrafast laser source used and its specific output characteristics. Special thanks to Leon Lu and Jared Wahlstrand for helping make beam profile measurements. We also thank the NIST Office of Safety, Health and Environment (OSHE) and NIST Scientific and Technical Research and Services (STRS) for supporting this work.

References

- 1.Stolarski J, Hayes K, Thomas R, Noojin G, Stolarski D, Rockwell B. Laser eye protection bleaching with femtosecond exposure,” in Laser and Noncoherent Light Ocular Effects: Epidemiology, Prevention, and Treatment III. In: Stuck Bruce E, Belkin Michael., editors. Proceedings of SPIE. Vol. 4953. 2003. [Google Scholar]

- 2.Stolarski DJ, Stolarski J, Noojin GD, Rockwell BA, Thomas RJ. Reduction of protection from laser eyewear with ultrashort exposure,” in Laser-Tissue Interaction XII: Photochemical, Photothermal, and Photomechanical. In: Duncan Donald D, Jacques Steven L, Johnson Peter C., editors. Proceedings of SPIE. Vol. 4257. 2001. [Google Scholar]

- 3.Lenner M, Fiedler A, Spielmann C. Reliability of laser safety eyewear in the femtosecond regime. Optics Express. 2004;12:1329–1334. doi: 10.1364/opex.12.001329. [DOI] [PubMed] [Google Scholar]

- 4.Schirmacher A, Sutter E, Werhahn O, Siegner U, Nevejina-Sturhan A. Investigation of the irradiance-dependent spectral transmittance of laser filters in the nanosecond- and femtosecond-pulse regime in the wavelength range between 700 and 800 nm. J Laser Applications. 2005;17:191–197. [Google Scholar]

- 5.See ANSI Z136.1; Laser Applications and Safety. Laser Institute of America; 2014. American National Standard for Safe Use of Lasers. Order #02029460. (2014) [Google Scholar]

- 6.See European EN 207 and EN 60825 Personal Protection Equipment, Laser Safety Standards: http://www.hse.gov.uk/foi/internalops/oms/2009/03/om200903app3.pdf

- 7.See: https://www.lia.org/evaluator/od.php for free use of the calculator.

- 8.Certain commercial equipment or materials are identified in this paper to adequately specify the experimental procedures. In no case does the identification imply recommendation or endorsement by NIST, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Figure S1: Beam profiles (image and x, y cuts) with extracted diameters (FWHM in mm) obtained by using a 1216×1936 pixel CMOS camera at sample positions with ca. 2 mm and 10 mm beam diameter. S2: Description of employed laboratory eyewear with vendor specifications, measured OD values and spectra at various laser center wavelengths; Figure S3: Similar descriptions for Test Sample N.