Abstract

Liquid chromatography (LC) coupled with mass spectrometry (MS) is widely used for the determination of mycotoxins in cereals and cereal-based products. In addition to the regulated mycotoxins, for which official control is required, LC–MS is often used for the screening of a large range of mycotoxins and/or for the identification and characterization of novel metabolites. This review provides insight into the LC–MS methods used for the determination of co-occurring mycotoxins with special emphasis on multiple-analyte applications. The first part of the review is focused on targeted LC–MS approaches using cleanup methods such as solid-phase extraction and immunoaffinity chromatography, as well as on methods based on minimum cleanup (quick, easy, cheap, effective, rugged, and safe; QuEChERS) and dilute and shoot. The second part of the review deals with the untargeted determination of mycotoxins by LC coupled with high-resolution MS, which includes also metabolomics techniques to study the fate of mycotoxins in plants.

Electronic supplementary material

The online version of this article (10.1007/s00216-017-0750-7) contains supplementary material, which is available to authorized users.

Keywords: Fungal secondary metabolites, Liquid chromatography–tandem mass spectrometry, Liquid chromatography–high-resolution mass spectrometry, Metabolomics, Validation

Introduction

Cereals and cereal-based products are the most important commodities in human nutrition. The health benefits of whole grain cereal products are currently widely recognized and understood because of the presence of a broad range of bioactive compounds [1]. Whole grain cereals are a rich source of carbohydrates, oils, proteins, vitamins, and minerals. The increasing demand for cereals and products thereof is reflected also by the fact that the world cereal production has reached its maximum level, exceeding 2.609 × 109 tonnes in 2016, having increased steadily in the last 8 years [2]. Although it is estimated that it is possible to maintain present food consumption levels by increasing overall food supplies in quantitative terms, providing quality food that is nutritious and free from contaminants is becoming a very challenging task. Among food contaminants, mycotoxins can have serious consequences in terms of both human and animal health as well as huge economic impacts [3].

Mycotoxins are toxic products of secondary metabolism of microscopic filamentous fungi. These ubiquitous microorganisms are able to colonize various agricultural commodities either before harvest or under postharvest conditions, thus causing, in addition to mycotoxin contamination, a serious loss of harvest yield and quality of the infested commodity. According to the European Commission [4], it has been estimated that 5–10% of global production is lost annually because of mycotoxin contamination. However, in a recent survey on mycotoxin contamination, more than 80% of samples were contaminated with at least one mycotoxin and 45% contained more than one secondary metabolite of fungi [5]. Currently, there are approximately 100,000 described fungal species. The number of the most commonly occurring species in foods/feeds and indoor environments is estimated to be around 175 [6]. The most toxigenic species belong mainly to three fungi genera: Fusarium, Aspergillus, and Penicillium [7–10]. These fungi can produce a wide range of mycotoxins differing not only in their chemical structures but also in the mode of toxicological actions. However, the health risk to humans and animals is currently attributed to only a limited number of them. With regard to high incidences of contamination (and thus possible dietary exposures) and their toxicity, aflatoxins (AFs) (from Aspergillus), ochratoxins (from Aspergillus and Penicillium), trichothecenes, fumonisins B (FBs), and zearalenone (ZEN) (from Fusarium) are of greatest concern. Their toxic effects range from various effects on the liver, kidney, hematopoietic system, immune system, and fetal and reproductive systems to significantly contributing to carcinogenetic and mutagenic developments [11, 12]. The effect of mycotoxin exposure differs greatly. The susceptibility of animals and humans to the toxicological effects of mycotoxins differs with species, age, nutrition, length of exposure, and other factors. Evaluation of adverse health effects is complicated by exposure to various co-occurring mycotoxins, which may lead to additive, synergic, or antagonist toxic effects [13].

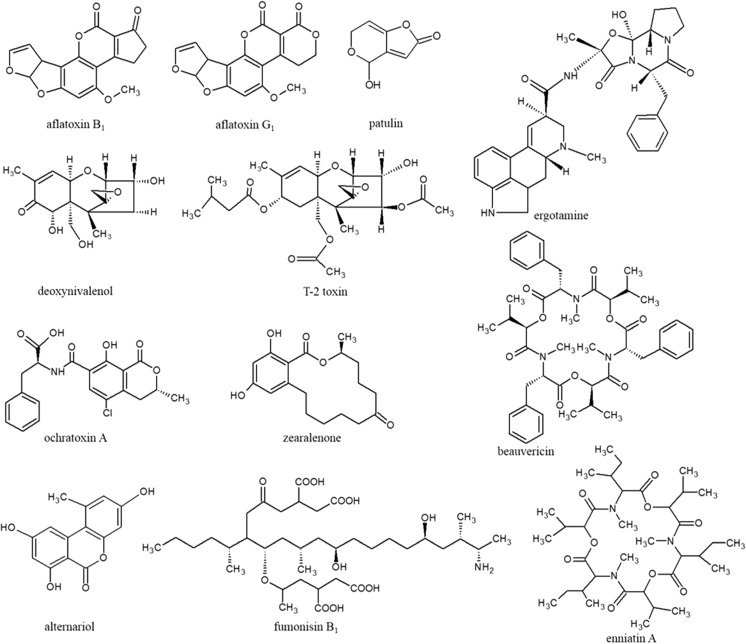

With regard to the health hazards attributed to mycotoxins and their impact on consumers (and farm animals), many countries have set up regulations for their control in the food and feed chain. On the world scale, the Joint FAO/WHO Expert Committee on Food Additives has assessed the toxicity of various mycotoxins and related health risks. In the European Union (EU), scientific opinions on the risk assessment of mycotoxins have been issued by the European Food Safety Authority (EFSA), which advises the European Commission Directorate-General for Health and Food Safety. Currently, only maximum levels for AFs, deoxynivalenol (DON), ZEN, ochratoxin A (OTA), FBs, and patulin in various foodstuffs have been set in EU countries [14, 15]. The chemical structures of some EU-regulated mycotoxins and other toxicologically important mycotoxins are depicted in Fig. 1. The establishment and acceptance of new regulatory limits is a long-term and complex process consisting of the evaluation of occurrence data that are important for overall risk assessment, availability, and understanding of toxicological data. To obtain such information, advanced analytical methods are required in both research and official control laboratories for reliable and accurate determination of mycotoxins. The determination of mycotoxins in cereals and cereal-based products is a challenging task because of their low occurrence levels and the complexity of the matrices [13].

Fig. 1.

Chemical structures of the most important mycotoxins belonging to the group of Aspergillus toxins (aflatoxin B1, alfatoxin G1, ochratoxin A, patulin), Fusarium toxins (deoxynivalenol, T-2 toxin, zearalenone, fumonisin B1, beauvericin, enniatin A), Alternaria toxins (alternariol), ergot alkaloids (ergotamine), and Penicillium toxins (patulin, ochratoxin A)

In the past, the analytical methods were more focused on routine analysis (i.e., mainly methods for a single analyte/matrix or groups of structurally related mycotoxins in a respective matrix had been developed). These methods were usually based on specific sample preparation protocols followed by traditional chromatographic separation. Primarily liquid chromatography (LC) coupled with ultraviolet/diode array detection and fluorescence detection, was used, but detection by mass spectrometry (MS) was rarely used. Gas chromatography with either electron capture detection or MS was used in routine determination of mycotoxins (e.g., trichothecenes) after time-consuming and laborious derivatization [16]. However, ongoing developments in the field of LC–MS technology have led to the availability of high-throughput instrumentation meeting the current demands of scientists and regulatory authorities for mycotoxin detection. The use of LC–MS in the determination of low molecular weight contaminants and residues at trace levels has significantly increased during the past two decades. Because of the unique features of this technique, LC–MS became a tool of choice to deal with a number of analytical challenges related to chemical food and feed safety testing in both research and routine commercial laboratories. In the field of mycotoxin determination there is a clear trend toward the use of multiple-analyte methods based on ultrahigh-performance LC (UHPLC) coupled with MS with various mass analyzers. LC–MS-based workflows provide significantly higher selectivity and sensitivity, increased confidence in the identification of analytes, and wider analyte/matrix scope as compared with traditional methods using conventional detectors [17]. LC–MS also facilitates the use of streamlined sample preparation procedures that save time and labor and reduce the overall costs associated with mycotoxin testing. State-of-the-art LC–MS methods for the determination of mycotoxins may largely differ in terms of analyte scope depending on the intended use of the resulting data. Although some of the available methods focus exclusively on mycotoxins with regulatory limits in place, others may allow (semi)quantitative or qualitative analysis of hundreds of mycotoxins, metabolites, or degradation products in a single analytical run. Having a large analyte scope usually results in the need for compromises in terms of the method performance characteristics achieved for the respective compounds. Besides targeted applications, LC–MS also plays an invaluable role in metabolomics-based studies dealing with the discovery and elucidation of new toxins or metabolites, as discussed in detail later in this review.

Currently, there are a wide range of LC-compatible MS instruments available on the market. A detailed overview and discussion of the advantages and disadvantages of current MS systems allowing measurements in low, medium and (ultra)high mass resolving power modes was provided in several recent comprehensive reviews [18, 19]. From the available studies, the MS detectors used in mycotoxin analysis include triple quadrupole (QqQ), ion trap, time-of-flight (TOF), and orbital ion trap mass analyzers, as well as hybrid systems that combine two types of analyzers. The latter group includes quadrupole–linear ion trap (QLIT), double quadrupole–TOF (QqTOF), quadrupole–orbital ion trap quadrupole–Orbitrap; Q–Orbitrap, and linear ion trap–orbital ion trap systems. The distribution of the LC–MS techniques applied in mycotoxin determination from 2012 to 2016 is depicted in Fig. 1.

In the past 10 years, several review articles on the occurrence and determination of mycotoxins have been published [11, 13, 16, 20–24]. Moreover, new developments and updates in this field are covered on a yearly basis in World Mycotoxin Journal [25–28].

This review thus provides insight into LC–MS-based methods for the determination of co-occurring mycotoxins. The aim is not to give a comprehensive overview of all published methods, but rather to focus on LC–tandem MS (MS/MS) targeted approaches and on untargeted analysis using LC–high-resolution MS (HRMS), including application of these approaches in the analysis of cereals and cereal-based food products. The advantages and limitations of both methods are critically assessed.

Requirements and guidance for quantification and proper validation

Basic validation of an analytical method is a crucial part of the overall process of implementation of a new method. It must demonstrate that the analytical method complies with the criteria applicable for the relevant performance characteristics (i.e., it confirms that the method is suitable for the intended applications and provides reliable results). In the EU, only general guidelines on the performance of analytical methods and the interpretation of results are laid down in Commission Decision 2002/657/EC [29]. This document gives the specification of individual performance characteristics that have to be evaluated during method validation. According to the in-house validation approach, specificity, trueness, recovery, repeatability, reproducibility, decision limit (CCα), detection capability (CCβ), calibration curve (linearity), and ruggedness should be evaluated (Table 1). Strict guidelines on how to perform the experiments for the evaluation of the individual performance characteristics are also given here. Additionally, the term “confirmatory method” has been established. Any confirmatory method has to provide full information on the chemical structure of an analyte. Furthermore, an internal standard, preferably isotope labeled, should be used. Therefore, LC–MS/MS and LC–HRMS are recommended as the techniques of first choice.

Table 1.

Overview of performance characteristics of an analytical method defined in Commission Decision 2002/657/EC

| Performance characteristic | Definition |

|---|---|

| Accuracy | The closeness of agreement between a test result and the accepted reference value. It is determined by determining trueness and precision |

| Detection capability (CCβ) | The smallest content of the substance that may be detected, identified, and/or quantified in a sample with an error probability of β. For mycotoxins with no legislation limit, the detection capability is the lowest concentration at which a method is able to detect truly contaminated samples with a statistical certainty of 1-β. For mycotoxins with a legislation limit, the detection capability is the concentration at which the method is able to detect the legislation limit concentration with a statistical certainty of 1-β. β error means the probability that the tested sample is truly noncompliant, even though a compliant measurement has been obtained (false compliant decision) |

| Decision limit (CCα) | The limit at and above which it can be concluded with an error probability of α that a sample is noncompliant. α error means the probability that the tested sample is compliant, even though a noncompliant measurement has been obtained (false noncompliant decision) |

| Precision | The closeness of agreement between independent test results obtained under stipulated (predetermined) conditions. The measure of precision is usually expressed in terms of imprecision and computed as the standard deviation of the test results. Less precision is determined by larger standard deviation |

| Recovery | The percentage of the true concentration of a substance recovered during the analytical procedure. It is determined during validation if no certified reference material is available |

| Repeatability | The precision under repeatability conditions. Repeatability conditions means conditions where independent test results are obtained with the same method on identical test items in the same laboratory by the same operator using the same equipment |

| Reproducibility | The precision under reproducibility conditions. Reproducibility conditions means conditions where test results are obtained with the same method on identical test items in different laboratories with different operators using different equipment. Participation in ring trials is needed |

| Ruggedness | The susceptibility of an analytical method to changes in experimental conditions that can be expressed as a list of the sample materials, analytes, storage conditions, and environmental and/or sample preparation conditions under which the method can be applied as presented or with specified minor modifications. For all experimental conditions that could in practice be subject to fluctuation, any variations that could affect the analytical result should be indicated. |

| Specificity | The ability of a method to distinguish between the analyte being measured and other substances. This characteristic is predominantly a function of the measuring technique described, but can differ according to the class of the compound and the matrix |

| Trueness | The closeness of agreement between the average value obtained from a large series of test results and an accepted reference value. Trueness is usually expressed as bias |

LC separation should be done with the appropriate LC column. The minimum acceptable retention time of the analyte of interest has to be at least twice the retention time corresponding to the dead volume of the column and has to match that of the calibration standard. The width of the retention time window should correspond to the resolving power of the chromatographic system. Moreover, the relative retention time of the analyte should match that of the calibration standard with a tolerance of ±2.5%.

MS detection should be done by use of MS techniques such as recording of full mass spectra or selected-ion monitoring (SIM), as well as MS/MS techniques such as selected-reaction monitoring (SRM). In HRMS the resolution should typically be greater than 10,000 for the entire mass range (according to the 10% valley definition [30]). In the full scan, the presence of all diagnostic ions (protonated and deprotonated molecules, characteristic fragment ions, and isotope ions) with a relative intensity of more than 10% in the reference spectrum of the calibration standard is obligatory. For SIM and SRM, a protonated or deprotonated molecule should preferably be one of the diagnostic ions selected. The diagnostic ions selected should not exclusively originate from the same part of the molecule. The signal-to-noise ratio for each diagnostic ion should be higher than 3:1. For the interpretation of data, a system of identification points should be used. In the case of mycotoxins, a minimum of three identification points are required per analyte. That means that two precursor ion to product ion transitions or one precursor ion and one product ion are required per analyte when low-resolution MS/MS or accurate mass HRMS is used, respectively [29].

The trueness of a quantitative confirmatory method has to be verified either by the repeated analysis of a certified reference material or, if this is not available, through the recovery of additions of a known amount of the analyte to a blank matrix. The analytical standards and certified reference materials for mycotoxins are supplied by two companies (Romer Labs and Sigma-Aldrich) [31, 32]. The guideline ranges for the deviation of the experimentally determined recovery corrected mean mass fraction from the certified value are -50% to +20% for mass fraction below 1 μg/kg, -30% to +10% for mass fraction between 1 and 10 μg/kg, and -20% to +10% for mass fraction above 10 μg/kg [29]. The precision of a quantitative confirmatory method expressed as the interlaboratory coefficient of variation (CV) for the repeated analysis of a reference or fortified material under reproducibility conditions (definition in Table 1) should not exceed the level calculated by the Horwitz equation: CV = 2(1-0.5logC), where C is the mass fraction. For instance, the CV for a mass fraction of 100 μg/kg should not exceed 23% [29]. The trueness and precision of the analytical methods intended for the official control of mycotoxins are laid down in Commission Regulation (EC) No 401/2006 [33]. Participation in interlaboratory testing is an efficient tool to demonstrate a sufficient level of method trueness.

A drawback of both aforementioned European Commission decision and regulation is that the LC–MS methods counting more than 100 mycotoxins are not considered. Therefore, the performance of some validation experiments for such a high number of analytes is not feasible. For instance, to find a blank material free of a broad spectrum of mycotoxins is almost impossible, the definition of matrix effects and their evaluation is missing, the term “recovery” is not exactly specified, and the determination of the limit of detection (LOD) and limit of quantification (LOQ) by the spiking of 20 replicates at one level for various matrices is not feasible for hundreds of analytes because of the cost of analytical standards. Moreover, the availability of isotopically labeled standards (as it is recommended they be used) and certified reference materials on the market is also limited. Therefore, in practice, guidance document SANTE 11945/2015 [34] designed for multiresidue determination of pesticides was very useful also for validation of LC–MS methods for multiple determination of mycotoxins. Briefly, matrices are grouped on the basis of water/sugar/fat content, and for each group one representative matrix should be validated. Sensitivity, mean recovery (extraction efficiency), precision, and LOQ have to be evaluated in the method validation. The spiking experiments have to be performed on a minimum of five replicates at two different levels (a low level to check the sensitivity and a higher level). The method LOQ is defined as the lowest validated spiking level meeting the method performance acceptability criteria [mean recovery of 70–120% with a relative standard deviation (RSD) of 20% or less]. The criteria for LC–MS in this document do not differ from those specified in Commission Decision 2002/657/EC. To ensure the accuracy of the results generated, a quality control is recommended to be introduced in the laboratory. In practice, most of laboratories regularly participate in proficiency ring trials.

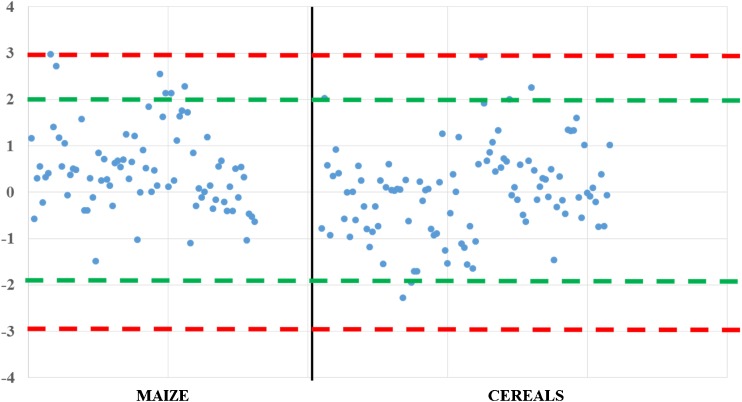

Proficiency testing is an effective procedure for quality assurance and performance verification in chemical analysis laboratories, ensuring that laboratory validation and within-laboratory procedures are working satisfactorily. The individual laboratory performance is expressed in terms of the z score in accordance with ISO 13525:2015 [35] and is calculated as z = (χlab - χassigned)/σp, where χlab is the mean of the two measurement results reported by a participant, χassigned is the assigned value (robust mean), and σp is the standard deviation for proficiency assessment derived from the truncated Horwitz equation. The z scores obtained are interpreted as follows: |z| ≤ 2 is an acceptable result, 2 < |z| ≤ 3 is considered a questionable result, and |z| > 3 is an unacceptable result. An example of the z scores obtained by the “dilute and shoot” multimycotoxin LC–MS/MS method [36] in routine proficiency testing organized by the Bureau Interprofessionnel des Études Analytique (BIPEA) is displayed in Fig. 2.

Fig. 2.

An example of the z score compilation obtained by the multimycotoxin liquid chromatography–tandem mass spectrometry method in proficiency testing organized by the Bureau Interprofessionnel des Études Analytique (BIPEA). Green lines borders of acceptable range of z scores, red lines borders of questionable range of z scores, area outside red lines unacceptable values

Currently, several proficiency testing schemes for mycotoxins are available in Europe, such as those from FAPAS (UK), BIPEA (France), Dienstleistung Lebensmittel Analytik (Germany), DUCARES (Netherlands), LGC Standards Proficiency Testing (UK), and Test Veritas (Italy). A detailed list of these schemes is available from [37]. However, most proficiency testing schemes organized by the aforementioned providers are focused on only a single mycotoxin or mycotoxins belonging to the same group. The first multimycotoxin proficiency testing scheme was organized by the Institute of Sciences of Food Production of the National Research Council of Italy in 2011. Since then, several other multimycotoxin proficiency testing schemes has been organized. The results of these trials have been summarized by De Girolamo et al. [38].

LC–MS/MS-based approaches intended for the targeted determination of mycotoxins

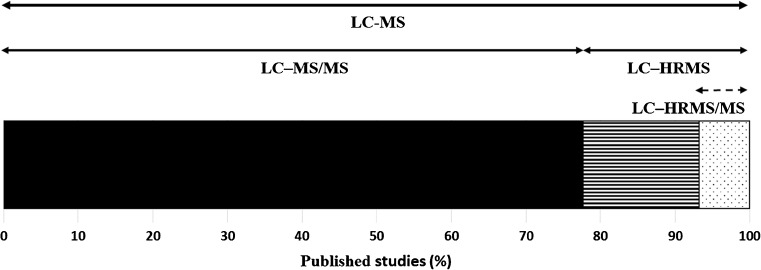

Almost 80% of all published LC–MS studies on mycotoxins since 2012 used methods based on LC–MS/MS (Fig. 3). The term “targeted” analysis implies that only “known” mycotoxins can be determined. In targeted mycotoxin determination, the complexity of the analyzed matrix and the range of “target mycotoxins” are the most important factors in determining a suitable instrument to be used for that particular application. A detailed description of the analytical methods discussed in the following text is given in Table 2.

Fig. 3.

An overview of use of liquid chromatography (LC)–mass spectrometry (MS) instruments in studies focused on mycotoxin analysis published between 2012 and 2016. LC–MS/MS covers studies using instruments equipped with triple quadrupole, quadrupole–linear ion trap, and ion trap mass analyzers; LC–high resolution MS (HRMS)/MS covers studies using instruments equipped with quadrupole–time of flight or quadrupole–orbital ion trap mass analyzers

Table 2.

Detailed description of the setup of some liquid chromatography (LC)–mass spectrometry (MS) methods for mycotoxin determination

| Reference | Extraction | Cleanup | Analytes | Matrix | LC–MS instrument | LC conditions | MS conditions |

|---|---|---|---|---|---|---|---|

| [39] | CH3CN–H2O (84:16, v/v) | MycoSep 226 AflaZON+, MycoSep 227 (both Romer Labs) | NIV, DON, FUS-X, 3ADON, 15ADON, DAS, HT2, T2, ZEN | Maize | QTRAP MS/MS instrument (Sciex) coupled to 1100 series LC system (Agilent Technologies) | Aquasil RP-18 column (100 mm × 4.6 mm, 3 μm) + C18 guard column; 25 °C, flow rate 1000 μL/min, injection volume 25 μL; eluent A H2O–CH3OH (80:20, v/v), eluent B H2O–CH3OH (10:90, v/v), both containing 5 mM NH4CH3COO-; gradient 0.5 min 0% eluent B, linear gradient to 100% eluent B to 4.5 min, 100% eluent B to 7 min, 7.1 min 0% eluent B, reequilibration 3 min, total run 10 min | APCI± MRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), dwell time 100 ms, polarity switching (2 periods) |

| [40] | CH3CN–H2O (84:16, v/v) | MycoSep 226 AflaZON+ | AFs, NIV, DON, 3ADON, 15ADON, FUS-X, HT2, T2, ZEN, OTA, STER, CIT, verruculogen | Various foods and feed | Quattro Ultima QqQ instrument (Micromass) coupled to Acquity UHPLC system (Waters) | UPLC BEH C18 (100 mm × 2.1 mm, 1.7 μm); 35 °C, flow rate 300 μL/min, injection volume 5 μL; eluent A ESI+ 10 mM NH4CH3COO-, ESI− 0.1% 0.1% (v/v) aqueous NH3, eluent B CH3OH; gradient initially 20% eluent B, linear increase to 5.5 to 85% eluent B, 100% eluent B within 0.3 min, reequilibration for 2 min at 20% eluent B, total run 10 min | ESI+, ESI−, MRM, 2 chromatographic runs, monitoring of 2 transitions (1 quantifier and 1 qualifier) |

| [41] | 2-step extraction: (1) PBS; (2) 70% CH3OH | AOZFDT2 (VICAM) | AFs, OTA, FBs, DON, ZEA, T2, HT2 | Maize | QTRAP MS/MS (Sciex) instrument coupled to 1100 micro LC system (Agilent Technologies) | Gemini C18 column (150 mm × 2 mm, 5 μm) + Gemini C18 guard column (4 mm × 2 mm, 5 μm); 40 °C, flow rate 200 μL/min, injection volume 20 μL; eluent A H2O, eluent B CH3OH, both containing 0.5% CH3COOH and 1 mM NH4CH3COO-; gradient 3 min at 20% eluent B, jump to 40% eluent B, linear increase to 63% eluent B within 35 min, 63% eluent B for 11 min, reequilibration at 20% eluent B for 10 min, total run 59 min | ESI+, ESI−, dMRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), time window of 1 MRM 0.8 min, cycle time 0.55 s |

| [42] | CH3CN–H2O–CH3COOH (79.5:20:0.5, v/v/v). Evaporation and redissolution in PBS before IAC | Myco6in1+ (VICAM) | AFs, OTA, FBs, DON, ZEN, T2, HT2 | Barley, maize breakfast cereals, peanuts | QTRAP 4500 instrument (Sciex) coupled to a Prominence UFLC XR chromatography system (Shimadzu) | Acquity UPLC HSS T3 end-capped C18 column (100 mm × 2.1 mm, 1.7 μm), 40 °C, flow rate 400 μL/min, injection volume 10 uL; eluents A H2O, eluent B CH3OH, both containing 5 mM NH4CH3COO-; gradient 5% eluent B increased to 50% eluent B in 1 min, linear increase to 100% eluent B within 6 min, 100% eluent B to 8 min, at 8.1 min initial conditions 5% eluent B, reequilibration at 5% eluent B for 2 min, total run 10 min | ESI± MRM, 2 periods, monitoring of 2 transitions (1 quantifier and 1 qualifier), dwell time 50 ms, polarity switching (2 periods) |

| [43] | 2-step extraction: (1) H2O; (2) CH3OH. Evaporation and redissolution in PBS before IAC | Myco6in1+ (VICAM) | AFs, OTA, FBs, DON, ZEN, T2, HT2, NIV | Maize, durum wheat, corn flakes, maize crackers | QTRAP MS/MS instrument (Sciex) coupled to 1100 micro LC system (Agilent technologies) | Gemini C18 column (150 mm × 2 mm, 5 μm) + Gemini C18 guard column (4 mm × 2 mm, 5 μm); 40 °C, flow rate 200 μL/min, injection volume 20 μL; eluent A H2O, eluent B CH3OH, both containing 0.5% CH3COOH and 1 mM NH4CH3COO-; gradient 3 min at 20% eluent B, jump to 40% eluent B, linear increase to 63% eluent B within 35 min, 63% eluent B for 11 min, reequilibration at 20% eluent B for 10 min, total run 59 min | ESI± MRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), dwell time 100 ms, polarity switching (2 periods) |

| [44] | NaCl + H2O–CH3OH (30:70, v/v). Dilution with PBS before IAC | OCHRAPREP + DZT MS-PREP, AOF MS-PREP + DZT MS-PREP, AFLAOCHRA PREP + DZT MS-PREP (R-Biopharm) | OTA + DON, ZEN, T2, HT2; AFs, FBs, OTA + DON, ZEN, T2, HT2; AFs, OTA + DON, ZEN, T2, HT2 | Wholemeal bread, maize and maize-based products including infant foods, oat-based muesli | Acquity TQD tandem QqQ MS instrument (Waters) | Gemini C18 column (150 mm × 2 mm, 5 μm), 40 °C, flow rate 300 μL/min, injection volume 20 μL; eluent A H2O–CH3OH (95:5, v/v), eluent B H2O–CH3OH (98:3, v/v), both containing 0.5% HCOOH and 1 mM NH4HCOO-; gradient 20% eluent B for 0.1 min, to 10 min linear increase to 90% eluent B, 90% eluent B to 15 min, reequilibration at 20% eluent B, total run 20 min | ESI+ MRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), 6 acquisition periods, dwell times from 0.1 to 0.27 s |

| [45] | QuEChERS | AFs, FBs, NIV, DON, 3ADON, 15ADON, FUS-X, HT2, T2, ZEN, OTA, DAS, NEO | Rice, corn, wheat, rye, oat, barley, infant cereals, soya, corn gluten | QTrap 4000 instrument (Sciex) coupled to 1100 series LC system (Agilent Technologies) | Zorbax Bonus-RP column (150 mm × 2.1 mm, 3.5 μm) + Zorbax RB C8 guard column (12.5 mm x 2.1 mm, 3.5 μm), flow rate 250 μL/min, injection volume 40 μL; eluent A 0.15% (v/v) HCOOH + 10 mM NH4HCOO-, eluent B 0.05% HCOOH (v/v) in CH3OH; gradient: 0% eluent B at 1 min, linear increase to 100% eluent B until 15 min, 100% eluent B for 5 min, reequilibration at 0% eluent B for 5 min, total run 25 min | ESI± MRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), 3 acquisition periods | |

| [46] | QuEChERS | AFs, FBs, DON, HT2, T2, ZEN, OTA | Wheat, maize, rice | Micromass Quattro Micro QqQ coupled to Alliance 2695 system (Waters) | Atlantis RP C18 column (150 mm × 2.1 mm, 5 μm), 30 0°C, flow rate 300 μL/min, injection volume 20 μL; eluent A H2O–CH3OH (90:10, v/v), eluent B H2O–CH3OH (10:90, v/v), both containing 5 mM NH4CH3COO-; gradient 20% eluent B for 0.1 min, until 10 min linear increase to 90% eluent B, 90% eluent B to 15 min, reequilibration at 20% eluent B, total run 20 min | ESI± MRM, monitoring of 2 transitions (1 quantifier and 1 qualifier), 3 acquisition periods | |

| [47] | QuEChERS, dilute and shoot | 38 mycotoxins and 288 pesticides | Apple baby food, wheat flour, paprika, black pepper, sunflower seed | QTRAP 5500 instrument (Sciex) coupled to Acquity UHPLC system (Waters) | Acquity UPLC HSS T3 end-capped C18 column (100 mm × 2.1 mm, 1.8 μm), 40 °C, flow rate 350–700 μL/min, injection volume 3 μL; ESI+ eluent A: H2O, eluent B: CH3OH, both containing 0.2% HCOOH + 5 mM NH4HCOO-; ESI− eluent A H2O, eluent B CH3OH, both containing 0.2% HCOOH + 5 mM NH4HCOO-; gradient: 10% eluent B with flow rate 350 μL/min increased to 50% eluent B in 1 min, linear increase to 100% eluent B within 10 min and simultaneous increase of flow rate to 550 μL/min, flow rate 0.7 μL/min at 100% eluent B, reequilibration for 2.5 min at 10% eluent B at 450 μL/min, total run 15.5 min | ESI+, ESI−, dMRM, time window for 1 MRM 0.8 min, cycle time 0.55 s | |

| [48] | Dilute and shoot | No | 39 mycotoxins | Wheat, maize | QTRAP 4000 instrument (Sciex) coupled to 1100 series LC system (Agilent Technologies) | Gemini C18 column (150 mm × 2 mm, 5 μm) + Gemini C18 guard column (4 mm × 2 mm, 5 μm); 40 °C, flow rate 1000 μL/min, injection volume 5 μL; eluent A CH3OH–H2O–CH3COOH (10:89:1, v/v/v), eluent B CH3OH–H2O–CH3COOH (97:2:1, v/v/v), both containing 5 mM NH4CH3COO-; gradient 2 min at 100% eluent A, linear increase to 100% eluent B within 12 min, held at 100% eluent B for 3 min, reequilibration at 100% eluent A for 4 min, total run 19 min | ESI+, ESI−, dMRM, dwell time 100 ms, pause time 5 ms |

| [36] | Dilute and shoot | No | 295 analytes | Apple puree, hazelnut, maize, green pepper | QTRAP 5500 instrument (Sciex) coupled to 1290 series LC system (Agilent Technologies) | Gemini C18 column (150 mm × 2 mm, 5 μm) + Gemini C18 guard column (4 mm × 2 mm, 5 μm); 40 °C, flow rate 1000 μL/min, injection volume 5 μL; eluent A CH3OH–H2O–CH3COOH (10:89:1, v/v/v), eluent B CH3OH–H2O–CH3COOH (97:2:1, v/v/v), both containing 5 mM NH4CH3COO-; gradient: 2 min at 100% eluent A, linear increase to 50% eluent B within 3 min, linear increase zo 100% eluent B within 9 min, hold at 100% eluent B for 4 min, reequilibration at 100% eluent A for 2.5 min, total run 20.5 min | ESI+, ESI−, dMRM, MRM window ±27 s for positive mode, ±42 s for negative mode, scan time 1 s |

| [49] | Raw extract, SIDA | No | AFs, FBs, DON, HT2, T2, OTA, ZEN | Maize, cereal-based products | 6490 triple-quadrupole instrument coupled to 1290 series UHPLC system (both Agilent Technologies) | Zorbax RRHL Eclipse Plus C18 column (100 mm × 2.1 mm, 1.8 μm); 30 °C, flow rate 350 μL/min, injection volume 3 μL; eluent A H2O–HCOOH (99.9:0.1, v/v), eluent B CH3OH–HCOOH (99.9:0.1, v/v) both containing 5 mM NH4HCOO-; gradient: 0.5 min at 30% eluent B, linear increase to 100% eluent B in 7.5 min, hold at 100% eluent B for 1.5 min, at 9.6 min back to 30% eluent B, reequilibration at 30% eluent B for 2 min, total run 11.5 min | ESI±, dMRM, monitoring of 2 transitions (1 quantifier and 1 qualifier) |

| [50] | CH3CN–H2O (84:16, v/v), SIDA | Bond Elut Mycotoxin SPE cartridges (Agilent Technologies) | NIV, DON, FUS-X, DON-3-Glc, 3ADON, 15ADON, HT2, T2, ENNs, BEA, ZEN | Barley, malt, oat, wheat, maize | QTRAP 4000 instrument (Sciex) coupled to LC-20A Prominence system series LC system (Shimadzu) | Hydrosphere RP-C18 column (100 mm × 3 mm, 3 μm) + C18 guard column; 40 °C, flow rate 200 μL/min, injection volume 10 μL; eluent A H2O–HCOOH (99.9:0.1, v/v), eluent B CH3OH–HCOOH (99.9:0.1, v/v); gradient ESI− 2 min at 10% eluent B, linear increase to 99% eluent B in 6 min, hold at 99% eluent B for 7.5 min, for 2 min back to 10% eluent B, reequilibration at 10% eluent B for 9.5 min, total run 25 min; ESI+ 2 min at 10% eluent B, linear increase to 87% eluent B in 6 min, hold at 87% eluent B for 7 min, increase to 100% eluent B in 5 min, hold at 100% eluent B for 3.5 min, for 2 min back to 10% eluent B, reequilibration at 10% eluent B for 9.5 min, total run 34.5 min | ESI−, ESI+, dMRM, 2 single chromatographic runs, monitoring of 2 transitions (1 quantifier and 1 qualifier) |

| [51] | CH3CN–H2O (84:16, v/v), evaporation, reconstitution in CH3OH and H2O | SPE (Oasis HLB columns) | AFs, OTA, DON, ZEN, T2, HT2 | Wheat flour, barley flour, crisp bread | Accela HPLC system, Exactive HRMS instrument (Thermo Fisher Scientific); 1100 micro-LC system (Agilent Technologies), QTRAP instrument (Applied Biosystems) | Kinetex C18 column (100 mm × 2.1 mm, 2.6 μm); 40 °C, flow rate 200 μL/min, injection volume 20 μL; eluent A H2O, eluent B CH3OH, both containing 0.5% CH3COOH and 1 mM NH4CH3COO-; gradient 10% eluent B start, until 4 min linear increase to 40% eluent B, 60% eluent B in 27 min, keep for 5 min, reequilibration at 10% eluent B for 7 min, total run 20 min | HESI-II (heated-electrospray, ESI+, HCD fragmentation (in-source fragmentation) |

| [52] | QuEChERS (2 g sample, 10 mL 0.1% HCOOH in H2O, 3 min shaking, 10 mL CH3CN, 3 min shaking, 4 g MgSO4, 1 g NaCl, shaking) | No additional cleanup | 3ADON, 15ADON, DON, DON-3-Glc, FUS-X, NIV, HT2, T2, DAS, NEO, AFs, OTA, FBs, STER, ZEN, penitrem A, BEA, Alternaria toxins, ergot alkaloids | barley | Accela HPLC system, Exactive HRMS instrument (Thermo Fisher Scientific) | Acquity UPLC HSS T3 column (100 mm × 2.1 mm, 1.8 μm); 40 °C, flow rate 300 μL/min, injection volume 5 μL; eluent A H2O with 5 mM NH4HCOO- and 0.1% HCOOH, eluent B CH3OH; gradient: start with 5% eluent B, increase to 50% eluent B in 6 min, increase to 95% eluent B within 4 min, keep until 15 min of the run, reequilibration at 5% eluent B for 3 min | HESI-II, ESI+/ESI− |

| [53] | QuEChERS (2 g sample, 10 mL 0.1% HCOOH in H2O, 3 min shaking, 10 mL CH3CN, 3 min shaking, 4 g MgSO4, 1 g NaCl, 0.5 trisodium citrate dihydrate, shaking) | No additional cleanup | 3ADON,15ADON, DON, DON-3-Glc, FUS-X, NIV, HT2, T2, DAS, NEO, AFs, OTA, FBs, STER, ZEN, mycophenolic acid, MON, BEA, Alternaria toxins, ergot alkaloids, culmorins | malting barley | Acquity UHPLC system (Waters), Q-Exactive system (Thermo Fisher Scientific) | Atlantis T3 column (100 mm × 2.1 mm, 3 μm); 30oC, flow rate 300 μL/min, injection volume 2 μL; eluent A CH3CN–H2O–CH3COOH (95:4.9:0.1, v/v/v), eluent B H2O–CH3COOH (99.9:0.1, v/v), both containing 5 mM NH4CH3COO-; gradient 5% eluent A start for 1 min, increase to 15% eluent A in 14 min, increase to 100% eluent A in next 15 min, kept at 100% eluent A for 3 min, reequilibration for 4.4 min | HESI-II (positive, negative) |

15ADON 15-acetyldeoxynivalenol, 3ADON 3-acetyldeoxynivalenol, AFs aflatoxins, APCI atmospheric pressure chemical ionization, BEA beauvericin, CIT citrinin, DON-3-Glc deoxynivalenol 3-glucoside, DAS diacetoxyscirpenol, dMRM dynamic multiple-reaction monitoring, DON deoxynivalenol, ENNs enniatins, ESI electrospray ionization, FBs fumonisins B, FUS-X fusarenon X, HCD high-energy collisional dissociation, HPLC high-performance liquid chromatography, HRMS high-resolution mass specrometry, HT2 HT-2 toxin, IAC immunoaffinity chromatography, MON moniliformin, MRM multiple-reaction monitoring, NEO neosolaniol, NIV nivalenol, OTA typo in ocratoxin A, PBS phosphate-buffered saline, QqQ triple quadrupol, QuEChERS quick, easy, cheap, effective, rugged, and safe, SIDA stable isotope dilution assay, SPE solid-phase extraction, STER sterigmatocystin, T2 T-2 toxin, UFLC ultrafast liquid chromatography, UHPLC ultrahigh-performance liquid chromatography, UPLC ultraperformance liquid chromatography, ZEA zearalanol, ZEN zearalenone

In MS/MS, the generation of analyte ions is followed by the selection of suitable precursor ions, and collision-induced dissociation (fragmentation) to form product ions that are further detected. LC–MS/MS techniques using a QqQ (and QLIT) mass spectrometer are the most frequently used approach in targeted mycotoxin determination. QqQ systems are typically operated in multiple-reaction monitoring (MRM) mode based on recording two or more precursor ion to product ion transitions. In contrast to the poor performance in full-scan mode, the use of MRM data acquisition provides a significant gain in both sensitivity and selectivity. The excellent sensitivity of QqQ analyzers when operating in SRM mode makes it possible to achieve low microgram per kilogram detection levels [54]. The average number of mycotoxins cited in the most recently published studies was about 30. Such methods cover a range of well-established mycotoxins, for which analytical standards are available (e.g., trichothecenes, enniatins, AFs B, Alternaria toxins, FBs, and ergot alkaloids). The matrices of interest are typically cereals, nuts, seeds, or baby food, but also more complex and problematic matrices such as spices, fruits, herbs, or food supplements are tested. Although MS/MS is generally considered to be a very selective technique especially for problematic matrices, in the case of challenging matrices the MS/MS signal might be overestimated and lost because of the complexity of some samples, which can finally result in false positive findings. In LC–MS methods, positive-mode electrospray ionization (ESI) is almost exclusively used to couple high-performance LC (HPLC) or UHPLC and MS detection. In theory, QqQ mass spectrometers can simultaneously detect a large number of targeted analytes. However, to achieve low LOQs compliant with the regulatory level and have an acceptable number of points per chromatographic peak to ensure accurate and reproducible quantification, the number of simultaneously recorded MRM transitions is limited. This is because of the need for sufficient dwell times for the recording of the respective MRM transitions. Faster instrument electronics and improved design of the collision cell significantly shorten the minimum dwell times that need to be used for each precursor ion–product ion pair monitored. The rapid multimethods that fully exploit the potential of the state-of-the-art QqQ/QLIT instruments are capable of the simultaneous analysis of up to 300 mycotoxins, their metabolites, or other related food contaminants depending on the length of the chromatographic run [36, 49, 55]. Such multimycotoxin methods are considered to be semiquantitative methods, since no pure analytical standards are available on the market and only in-house purified standards are used for quantification. This brings up a significant disadvantage associated with the use of QqQ MS detectors that do not allow nontargeted analysis (e.g., mycotoxin metabolites), as the detection conditions need to be typically optimized for each analyte with the use of a standard.

The main difficulty in LC–MS analysis of complex matrices is matrix effects. Components of the sample matrix can cause suppression (in most cases) or enhancement of the analyte signal during the ionization process and thus affect accurate quantification of analytes, leading to incorrect results, when pure solvent standards are used. A review dealing with matrix effects in LC–MS/MS methods was published in 2010 [56]. Matrix effects are a complex phenomenon. Their extent is dependent on many factors. First, the chemical structure and polarity of the analyte of interest play an important role. Furthermore, the matrix type and the relative concentrations of the components competing for the charges in the MS interface are also significant. Therefore, the entire sample preparation procedure and the chromatographic and MS conditions have to be optimized to decrease the matrix effects to a minimum [56]. Ion suppression might be caused by the presence of matrix compounds that are co-eluted with the target analytes and that reduce the ionization efficiency as well as affect the reproducibility and accuracy of the method [57]. Huge differences in the extent of matrix effects are not only seen for different matrices; high deviations between individual samples of one matrix type are also observed [58, 59]. Matrix effects were present also after highly extensive immunoaffinity cleanup [41, 42].

Standard addition is often used in routine analysis. It is applied in single-analyte methods rather than in multiple-analyte determination as it is laborious and costly because of the high consumption of analytical standards and double the number of LC runs [60]. The last and currently most frequently used approach is isotopically labeled internal calibration. Stable isotopically labeled standards share the same chemical and physical properties as the target analytes, but are still distinct by their different molecular masses. Additionally, they are not present in naturally contaminated samples. The principle of the use of isotopically labeled standards is that of the dilution of naturally abundant isotopic distribution. Therefore, this procedure is called “stable isotope dilution assay” (SIDA). The basic SIDA principle is to transfer the concentration of the analyte into an isotopologue ratio, which has to be stable during all analytical steps. Therefore, the first prerequisite for an internal standard is stable labeling. As carbon–carbon and nitrogen–carbon bonds are very unlikely to be cleaved, mainly labels consisting 13C and 15N are used for preparation of the isotopically labeled standards for mycotoxins. In contrast, losses of 18O and 2H can occur if these labels are at labile positions. For instance, 18O in carboxyl moieties can be exchanged in acidic and basic solutions. As a concern, deuterium (2H) is susceptible to “protium–deuterium exchange” if it is activated by an adjacent carbonyl group or aromatic systems. Moreover, chromatographic shifts caused by the isotope effect are more common in the case of deuterated standards than in the case of 13C- and 15N-labeled ones. Therefore, 13O and 2H labeling are less common in mycotoxin quantification using SIDA [61].

The following paragraphs highlight examples of currently used approaches for LC–MS/MS determination of mycotoxins in cereals and products thereof. The methods range from those intended for official control to multiclass methods used in research for both screening and quantitative purposes. In addition, how to cope with determination of conjugated mycotoxins will also be part of this section.

Most of the methods discussed have been developed for the determination of EU-regulated mycotoxins in various matrices to fulfill the strict requirements of EU legislation (e.g., low LODs for AFB1 and OTA in processed cereal-based food and baby food for infants and young children) [42, 44, 62, 63]. Therefore, to minimize the amount of undesirable matrix co-extracts (further discussed later), purification steps are usually required during sample preparation, especially in the case of complex matrices such as cereal-based products. Typical cleanup strategies involve commercially available solid-phase extraction (SPE) cartridges or immunoaffinity columns (IACs). However, despite the use of highly sensitive LC–MS instrumentation, achieving trace detection levels of some analytes in more than 200 multidetection methods is impossible when compromises have to be made with regard to both sample preparation and LC–MS/MS conditions. These methods rely on the injection of raw extracts [43, 64], “dilute and shoot” approaches [36, 47], or different modifications of the “quick, easy, cheap, effective, rugged, and safe” (QuEChERS) approach [48, 62, 64, 65].

Strategies to eliminate matrix effects in (multi)mycotoxin determination

Solid-phase extraction

Cleanup techniques in mycotoxin analysis were last critically reviewed in 2008 [16]. For multitoxin analysis, mainly SPE cartridges are used. Nowadays, there are plenty of these from different manufacturers available on the market. For example, multifunctional columns, MycoSep®, containing a mixture of charcoal, ion-exchange resins, and other exchange materials are available for various combinations of mycotoxins or single mycotoxins [OTA, moniliformin, nivalenol (NIV)] [66]. Use of MycoSep® columns has become a routine purification step especially for trichothecenes since the 1990s [66, 67]. The procedure involves extraction with aqueous acetonitrile and passing the extract through the SPE column, and preconcentration of the analytes of interest. Matrix co-extracts are retained on the column packing, and the analytes of interest pass to the supernatant. No washing step is required. One of the first pioneering LC–MS/MS methods using MycoSep® 226 for purification of maize samples before simultaneous detection of Fusarium mycotoxins [NIV, DON, fusarenon X (FUS-X), 3-acetyldeoxynivalenol (3ADON), 15-acetyldeoxynivalenol (15ADON), diacetoxyscirpenol, HT-2 toxin (HT2), T-2 toxin (T2), and ZEN] was published in 2005 [39]. Although MycoSep® 227 was also tested and satisfactory recoveries were obtained for most of the trichothecenes, 50% retention of NIV and complete retention of ZEN on the column packing was observed. MycoSep® 226, designed for a broader range of polarities, increased the recovery rate for ZEN. However, more matrix components that also passed through the column caused high signal suppression, which resulted in a recovery of 30% for ZEN. Therefore, the addition of an internal standard (zearalanol) was used for ZEN quantification. The low recovery (50%) obtained for NIV was within the manufacturer’s specification. The method performance characteristics summarized in the electronic supplementary material show that because of MycoSep-based purification, low LODs can be achieved without highly sensitive state-of-the-art LC–MS/MS systems having to be used. An in-house validation of another method including MycoSep® 226 was done for 17 mycotoxins, including AFs and trichothecenes, in various foods and feed [40]. Special attention was paid to the selection of proper eluents, the chromatographic column, and MS/MS conditions to achieve the highest possible sensitivity. The LOQs below 0.01 μg/kg for AFs, low intraday and interday precision (RSD below 10%), and high recoveries (70–110%) (see the electronic supplementary material) achieved passed the criteria of the official methods for mycotoxin determination in baby food [40].

Recently, MycoSpinTM 400 for multimycotoxin LC–MS/MS analysis (optimized for most of the EU-regulated mycotoxins) in a spin format became available. So far, it has been applied to the purification of maize-based silages [68]. The manufacturer claims that highly accurate results are achieved by use of 13C-labeled standards [66]. Dispersive magnetic SPE might be an attractive technique as an alternative to classic SPE in the future [96]. However, compared with a classic on-column SPE, dispersive magnetic SPE requires the same time for a single extraction. The mechanism occurring in magnetic SPE is analogous to that in classic on-column SPE. The dispersion of the magnetic nanoparticles into the solution containing mycotoxins ensures a continuous and dynamic contact with the adsorbent surface, leading to more efficient analyte retention. The separation of the magnetic material with the adsorbed analytes from the solution is then realized by application of a magnet outside the vessel, avoiding centrifugation or filtration steps. Finally, after washing, analytes are eluted from the magnetic material by a proper solvent mixture. So far, only one study on the use of dispersive magnetic SPE in mycotoxin determination (AFs, ZEN, and OTA) in cereals has been published [96].

Immunoaffinity columns

IACs provide an even more specific cleanup compared with SPE cartridges. The principle is based on antibodies that entrap an analyte of interest. The matrix co-extracts are removed by washing, and “pure analyte” is released from the antibody with use of an organic solvent. IAC cleanup should provide a purified sample completely free of the matrix, which allows the use of a solvent calibration curve for quantification. However, as discussed later [41, 42], ion suppression/enhancement (caused by the IAC sorbent) has been observed. In the past, IACs were mainly designed for one or two toxins. However, legislative requirements led to the development of IACs for multiple regulated toxins; for example, AFLAOCHRA PREP® (AFs and OTA), AO ZON PREP® (AFs, OTA, and ZEN), and DZT MS-PREP® (DON, ZEN, HT2, and T2). The only IAC that covers most of the EU-regulated mycotoxins is Myco6in1+ (VICAM) containing antibodies for AFs, OTA, FBs, DON, ZEN, NIV, T2, and HT2. Although, the application of IACs is a preferred and selective tool for sample cleanup, the sample extraction and handling procedure recommended by the manufacturer is very laborious and time-consuming, and produces large volumes of solvent waste. Special attention has to be paid to the extraction solvent, elution rate, and column capacity to achieve optimal recoveries of targeted analytes [41, 42]. In addition, column capacity may be hindered as a result of antibody cross-reactivity (affinity for other structurally related toxins). This, on the other hand, is a big advantage in the determination of conjugated mycotoxins (discussed later). An LC–MS/MS method for simultaneous determination of AFs, OTA, and Fusarium mycotoxins in maize using multifunctional IACs (AOZFDT2TM) was developed and validated in-house [41]. Despite the laborious cleanup and long chromatographic gradient (59 min), matrix effects were observed (i.e., significant suppression for AFB1 and AFG1 and a slight suppression for OTA). Although no matrix effects were observed for DON, T2, HT2, FBs, and ZEN, the study authors decided to use matrix-matched standards for quantification. When validated for maize, at EU maximum permitted levels, the method showed satisfactory performance in terms of recovery and repeatability (see the electronic supplementary material). The application of these IACs in analysis of maize-based cereals, barley, and peanuts was documented in another study [42]. The sample preparation procedure was markedly simplified, and the compatibility of several extraction solvents with the IACs was tested. Assessment of matrix effects confirmed the ion suppression observed for AFs and OTA [41] and showed significant ion enhancement for FBs. The follow-up evaluation on the “IAC solvent” calibration curve (when standards were prepared in solvent obtained from passing through the IAC) revealed that the ion suppression/enhancement was mainly caused by compounds flushed from the IAC packing. Therefore, “IAC solvent” standards can be used for quantification instead of matrix-matched calibration, and so this approach allows the use of one calibration for various matrices [42].

Other measures were taken to enhance the method; for example, changing from HPLC to UHPLC decreased the chromatographic run time from 59 to 10 min. Similarly, the sample preparation procedure [41] was simplified, and the modified method was validated for maize, durum wheat, corn flakes, and maize crackers [43]. Full in-house validation was performed for 12 mycotoxins at three levels (see the electronic supplementary material). Another option in determining multiple mycotoxins using IAC cleanup more efficiently is to use different IACs in tandem (i.e., the first column is connected below the glass vessel and the second column is connected below the first one). Thus sample loading, washing, and elution is achieved for two columns simultaneously. The use of columns in tandem offers a range of desired combinations of mycotoxins in accordance with EU regulations, so analytical cleanup can focus on target mycotoxins known to co-occur in specific matrices. OCHRAPREP® and DZT MS-PREP® columns have been used in tandem for analysis of wholemeal bread, AOF MS-PREP® and DZT MS-PREP® IACs have been combined for analysis of a range of maize and maize-based products, including infant foods, and AFLAOCHRA PREP® and DZT MS-PREP® columns have been combined for the analysis of oat-based muesli containing dried fruit and nuts [44].

In summary, immunoaffinity chromatography is still the most powerful cleanup method for up to six mycotoxins especially when used before LC-based (no MS) detection [62, 63]. Because of recent trends leading to the use of LC–MS/MS, it is no longer necessary in laboratories with sophisticated instrumentation. However, IACs are often used in LC–MS/MS when low LODs are required (e.g., OTA and AFB1 in baby food) [64].

LC–MS/MS with limited cleanup or without cleanup

The availability of sensitive LC–MS instruments that are less prone to matrix effects has led to the development and application of so-called multiple-analyte approaches. Hence, a clear trend toward the determination of a range of different mycotoxin classes can be observed, both in the literature and in research and routine laboratories. Because of the broad physicochemical properties of mycotoxins, a compromise, using nonspecific, minimal cleanup (if needed), has to be used to avoid a discrimination of some analytes during sample preparation processing.

QuEChERS approach

As a minimal cleanup, the QuEChERS approach is being used in multiclass analysis [69]. This approach was developed for multipesticide analysis, for very fast extraction and purification. The key principle is the partitioning of an acetonitrile–water mixture induced by addition of inorganic salts. While the analytes are largely transferred into an organic phase, more polar matrix impurities are left in an aqueous layer. Nevertheless, use of such a basic cleanup for multiresidue analysis in complex matrices leads inevitably to matrix effects, and thus affects sensitivity adversely. For this reason, LC–MS/MS methods including QuEChERS-based protocols are generally inefficient for the detection of AFs and OTA in baby foods at the EU limits. Hence, for these specific metabolites in baby foods, a multiresidue approach is often abandoned in favor of dedicated methods making use of specific cleanup with IACs [64] or a combination with another cleanup technique is used [41, 42, 45, 46, 64].

The original QuEChERS method for determination of pesticide residues consists of several steps: (1) extraction with acetonitrile, (2) partitioning step with magnesium sulfate (MgSO4) and sodium chloride (NaCl), (3) addition of an internal standard, (4) dispersive SPE—aliquot purified with MgSO4 and SPE sorbents [e.g., primary–secondary amine (PSA) salts, C18, C8], and (5) addition of an analyte protectant and adjustment of the pH. The implementation of the QuEChERS method in mycotoxin determination required some modifications depending on the spectrum of the analytes and the character of the matrix. For instance, PSA used for the removal of polar matrix components caused significant loss of FBs [45], and/or addition of water before acetonitrile extraction was needed for low water content matrices to increase the recovery yields [45, 47].

The QuEChERS-like approach was used for the development of an LC–MS/MS method for 17 mycotoxins in cereals for human consumption and infant cereals [45]. Besides the aforementioned modifications, the extraction was done with acidified acetonitrile to increase recoveries for FBs. Direct analysis of the extract after the partitioning step resulted in significant matrix effects, and thus insufficient sensitivity (especially for AFs). Several dispersive solid-phase extraction (SPE) sorbents were tested (SPE, Oasis HLB, Carbograph 4, C18, or dispersive SPE with both PSA and C18 modified silica gel). Finally, a simple defatting step with n-hexane followed by a two-step sequential reconstitution in aqueous methanol was shown to be the best adaptation for all analyte–matrix combinations. Although the performance characteristics of the method fulfilled the EU legislation criteria [33], it is not appropriate for official control of infant cereals. The maximum EU legislation level for AFB1 is 0.1 μg/kg but the LOQ was 1 μg/kg. The current method was applied in the analysis of more matrices (cereals, cocoa, oil, spices, infant formula, coffee, and nuts) and validated. Matrix effects were successfully corrected by 13C-labeled standards. To achieve lower LOQs for AFs and OTA in baby food, an additional cleanup step (immunoaffinity chromatography) was applied [64]. Positive identification of mycotoxins in the matrix was conducted according to the confirmation criteria defined in Commission Decision 2002/657/EC [29], while quantification was performed by isotopic dilution using 13C-labeled mycotoxins as internal standards. The LOQs were at or below the maximum levels set by Commission Regulation (EC) No 1881/2006 [14] for all regulated mycotoxin–matrix combinations. In particular, the inclusion of an immunoaffinity chromatography step allowed LOQs as low as 0.05 and 0.25 μg/kg to be achieved in cereals for AFs and OTA, respectively [64].

Another QuEChERS modification followed by LC–ESI-MS/MS was introduced for the determination of EU-regulated mycotoxins in wheat, maize, and rice [46]. Water soaking and acidified acetonitrile extraction with a mixture of magnesium sulfate, sodium chloride, sodium citrate tribasic dihydrate, and sodium citrate dibasic sesquihydrate (4:1:1:0.5) was followed by dispersive SPE with a mixture of magnesium sulfate and C18 sorbent. Purified extract was evaporated and reconstituted in aqueous methanol. The validation data obtained are summarized in the electronic supplementary material. It is worth noting that the greatest matrix effects were observed for maize.

“Dilute and shoot” approach

“Dilute and shoot” and the injection of raw extract, without any cleanup, is now commonly performed in multiresidue LC–MS analysis [47, 48, 65]. The dilute and shoot LC–MS/MS-based method is considered a pioneering method in the field of multimycotoxin determination [48]. Simple extraction with a mixture of acetonitrile–water–acetic acid (79:20:1, v/v/v) further diluted 1:1 with acetonitrile–water–acetic acid (20:79:1, v/v/v) was used in the determination of 39 mycotoxins, including conjugated metabolites, in cereals. Although the MS/MS parameters for most of the analytes could have been optimized in both polarities (i.e., analytes give the MS/MS signal in negative ionization mode as well as in positive ionization mode), some analytes (moniliformin, NIV, ZEN 14-glucoside) gave no or very weak signals in the positive mode. Because of the high number of analytes, the determination was performed in two chromatographic runs (positive and negative) to avoid losses in sensitivity caused by polarity switching. The method was validated for wheat and maize. Ion suppression effects caused by co-eluted matrix components were negligible in the case of wheat, whereas significant signal suppression for 12 analytes was observed in maize. The apparent recoveries were within the range of (100 ± 10)% for half of the analytes; in extreme cases the apparent recovery dropped to 20%. As an example of an analyte with low apparent recovery, FB1 (34%) can be given. Apparent recovery of 113% was observed for a common contaminant of maize, ZEN. Nevertheless, this was caused by matrix effects rather than low extraction recovery, and can thus be compensated by the use of matrix-matched standards. The method performance characteristics for some analytes are given in the electronic supplementary material. The method has been continuously extended to include 331 bacterial, plant, and fungal metabolites, and has been fully validated for 295 analytes in maize and three other matrices [36]. To successfully acquire as many MRM transitions with acceptable sensitivity and repeatability in a reasonable time, the method was transferred onto the next generation of a QTRAP instrument (QTRAP 5500). As no guidelines are available for multidetection of mycotoxins, the validation procedure was performed according to SANTE 11945/2015 [34], and the trueness of the method was demonstrated with use of samples from organized ring trials. With regard to the apparent recovery in maize, 62% of 295 analytes matched the acceptable recovery range of 70–120% laid down in SANTE 11945/2015 at the highest spiking level. At the levels close to the LOQ, 57% of the analytes fulfilled this criterion. The extent of matrix effects was strongly dependent on the analyte–matrix combinations. No matrix effects were observed for 45% analytes at the highest spiking level and 35% of analytes at the lowest spiking level. The repeatability of the method was acceptable (RSD ≤ 20%) for 95% of the analytes. The trueness of the method was proved by participation in ring trials. The calculated z scores were satisfactory for all maize samples analyzed (i.e., between −2 and 2) and also for a broad variety of different matrices, which proves that the method provides accurate results also for other “nonvalidated” matrices.

A critical assessment of extraction methods in the simultaneous analysis of 288 pesticides and 38 mycotoxins was performed in another study [47]. Three extraction procedures were performed for wheat and other matrices: aqueous acetonitrile extraction followed by a modified QuEChERS approach, aqueous acetonitrile extraction, and pure acetonitrile extraction. Different eluent modifiers were used for positive-mode ESI and negative-mode ESI measurements to obtain high sensitivity and sharper peak shape. For positive-mode ESI, two to four times higher responses were observed in the presence of ammonium formate for most of the analytes. Extraction with pure acetonitrile was not efficient in terms of recoveries, whereas the QuEChERS approach and extraction with aqueous methanol showed satisfactory recoveries within the range of 70–120% with RSD less than 20% [34] for most of the analyte–matrix combinations. Although the QuEChERS-like method resulted in lower LOQ and more consistent results, the recoveries were lower in particular for polar analytes [DON 3-glucoside (DON-3-Glc), NIV, T2 tetraol] because of the partitioning step. Finally, QuEChERS-like extraction was chosen as the most suitable approach for the analytes tested [47].

SIDA methods

The correction of matrix effects in LC–MS/MS methods using limited sample cleanup can be done with SIDAs; however, this approach also has its limitations. Although the spectrum of commercially available isotopically labeled standards is getting broader, it is still mainly limited to EU-regulated mycotoxins or to those considered by EFSA. Moreover, the cost of these internal standards is far greater than that of those of natural origin, which significantly increases the cost of the analysis [56]. A review of the application of SIDA in mycotoxin analysis was published in 2008 by Rychlik and Asam [61]. Therefore, the following discussion is focused on a few examples of SIDA applications in multimycotoxin LC–MS/MS methods.

A UHPLC–MS/MS method for the determination of all EU-regulated mycotoxins in maize and cereal-based products was developed [70]. The accuracy was enhanced by the application of 13C-labeled compounds for each of the target analytes before UHPLC–MS/MS analysis. The simple raw-extract-injection technique was validated as a confirmatory method according to Commission Decision 2002/657/EC [29]. The trueness of the method was verified by the measurement of 12 test materials from different providers with well-defined analyte concentrations.

Method performance parameters were evaluated for maize (see the electronic supplementary material). The sample preparation consisted of two extraction steps: (1) extraction with acetonitrile–water–formic acid (80:19:0.1, v/v/v); (2) extraction of the residue with acetonitrile–water–formic acid (20:79.9:0.1, v/v/v). Both extracts were combined and centrifuged, and the raw extract was fortified with a mixture of labeled standards in a ratio of 4:1 (v/v) before injection. A drawback of this procedure is that more matrix compounds are extracted because of the high water content of the second extraction solvent. However, the use of internal standards efficiently compensated for all matrix effects for all target analytes.

An 11.5-min UHPLC gradient elution using methanol and water containing 5 mM ammonium formate and 0.1% formic acid provided a capacity factor k′ of the first analyte eluted (DON) of more than 1 (actually 1.5), and acceptable resolution and peak shape for all analytes, which fulfills the Commission Decision 2002/657/EC criteria [29]. The MS detection was performed using the dynamic MRM mode and fast polarity switching. Dynamic MRM is a technique that monitors the analytes only around the expected retention time, and thus decreases the number of co-occurring MRM transitions, allowing both the cycle time and the dwell time to be optimized for the highest sensitivity, accuracy, and reproducibility. Fast polarity switching needs less than 0.5 s for switching between positive and negative modes, which reduces the losses in sensitivity. As the method fulfilled all the European Commission criteria, it is suitable for routine analysis of maize for official control [33].

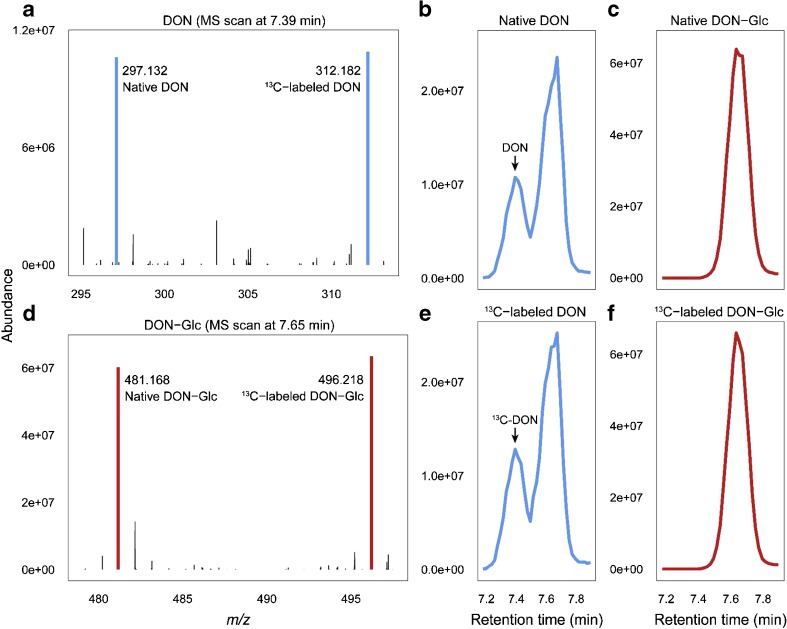

A combination of SIDA and SPE cleanup was used in the determination of EU-regulated and EFSA-recommended mycotoxins in cereals. Moreover, conjugated forms of DON (DON-3-Glc, 15ADON, 3ADON) were included [50]. Isotopically labeled standards of 3ADON, T2, enniatins, and beauvericin were prepared in-house. For the 13C-labeled equivalents of 15ADON and DON-3-Glc, 13C-labeled 3ADON and 13C-labeled DON, respectively, were used for correction. Similarly to the previous study [70], internal standards were added to the raw extract, which then underwent SPE cleanup using Bond Elut Mycotoxin cartridges (Agilent Technologies). Special attention had to be paid to the chromatographic separation of DON and DON-3-Glc because of in-source fragmentation of DON-3-Glc. To avoid decreases in sensitivity, the analysis was performed in two single chromatographic runs (positive-mode ESI and negative-mode ESI). Detailed information about the method performance characteristics obtained with use of SIDA is given in the electronic supplementary material. The mycotoxins for which 13C-labeled standards were not available were evaluated by matrix-matched calibration of potato starch. The accuracy was confirmed by analysis of commercially available reference materials and samples from interlaboratory testing. This method was later applied to beer [71]. Although satisfactory recoveries were achieved, the LOQ of 20 μg/L for DON-3-Glc is too high for beer control, where common levels of DON-3-Glc are usually lower than 20 μg/L. To achieve a lower LOD and LOQ, the method needs to be optimized further (i.e., use of any cleanup, change of the chromatographic gradient, or use of a more sensitive LC–MS/MS instrument).

A dilute and shoot method for the LC–MS/MS determination of multiple mycotoxins (AFs, OTA, FBs, ZEN, DON, T2, and HT2) in wines and beers has been developed and validated. Separation was accomplished by UHPLC with an analysis time of less than 10 min. Mycotoxins were detected by dynamic MRM in positive-mode ESI. To reduce matrix effects, 13C-labeled mycotoxin standards were added to the sample extracts before LC–MS/MS analysis. With external calibration, the recoveries were 18−148% for white wines, 15−118% for red wines, and 20−125% for beers, at three spiking levels. The 13C-labeled internal standards compensated for matrix effects effectively, with overall recoveries of 94−112% for white wines, 80−137% for red wines, and 61−131% for beers, with greater recoveries for FBs, at three spiking levels. The RSD was less than 20% for all analytes in the wines and beers. This method was applied in a survey of domestic and imported wines and beers for the determination of OTA, and was extended to include other mycotoxins [72].

LC–MS for the determination of masked mycotoxins

Masked mycotoxins (also conjugated by plants), which are plant metabolites of mycotoxins, are a well-known and significant subgroup of these natural contaminants. Research on these derivatives has expanded tremendously, especially within the last 10 years, during which time their forms, occurrence, and principles of origin and metabolization in plants have been continuously elucidated. As a result, the development of analytical methods to measure these metabolites has progressed. The topic of masked mycotoxins was comprehensively reviewed by Berthiller et al. [73].

First, the terminology used in the field of masked mycotoxins should be clarified. The term “masked mycotoxins” refers to a specific group of mycotoxin metabolites that are created by plants as their defense against various xenobiotics. The masked mycotoxins can be further subdivided into the two categories of conjugated and bound mycotoxins. Conjugated mycotoxins can be extracted from samples (plants, cereals, food) and detected by further described analytical strategies. In contrast, bound mycotoxins cannot be extracted directly from samples of interest since they are covalently or noncovalently attached to polymeric carbohydrate or protein structures and have to be released from the matrix by chemical or enzymatic treatment first [74].

Regarding analytical methods, basically there are two possible strategies for testing, direct and indirect, depending on the particular analytes and the available laboratory equipment. In the field of direct methods, which cover the soluble forms of these metabolites, the LC–MS approaches are the techniques of choice for accurate, fast, and specific analysis of masked mycotoxins. Unfortunately, for most of the masked mycotoxins analytical standards are not commercially available, and thus in-house purified standards have to be prepared first. This production is laborious and time-consuming.

Since masked mycotoxins tend to be more polar than their parent toxins (glycosylated, sulfated, acetylated forms), their determination can be done easily by an analytical procedure developed for the determination of native forms of mycotoxins. This means, as also previously demonstrated by several authors, that the best recovery of masked mycotoxins can be obtained through extraction with acidified acetonitrile–methanol and water mixtures, which is the procedure widely applied in multimycotoxin analysis. From the available published methods and protocols, it is clear that acetonitrile–water mixtures ranging from 80% to 84% acetonitrile, simple or acidified with 1% acetic acid, are the most versatile extraction solvents, yielding sufficient recoveries (mostly above 70% regardless of the type of matrix) of various masked trichothecenes (DON-3-Glc, T2 glucoside, HT2 glucoside, NIV glucoside) or ZENs (ZEN 14-glucoside, ZEN 14-sulfate). Although several studies dealt with various cleanup strategies, it was uniquely determined that neither SPE cartridges nor IACs are suitable for their analysis, since only very low recoveries (less than 50%) are commonly obtained [73].

Generally, the dilute and shoot strategy has been proven to provide the best recoveries and data repeatability. In contrast, the QuEChERS approach provides significantly lower recoveries of masked forms compared with the parent compounds. In the case of the QuEChERS approach, analytes are typically not transferred into the acetonitrile phase because of their polar character, which also causes retention problems in SPE cartridges. Chromatographic separation can be easily achieved by use of traditional C18 columns, although methods based on hydrophobic interaction LC could also be advantageous.

Problems as a result of the lack of analytical standards can be avoided by the application of indirect methods when primary hydrolysis (enzymatic, acetic, and basic) of conjugated mycotoxins is required before analysis [73]. The significant disadvantage of these methods is the impossibility of complete hydrolysis of conjugates and its confirmation, which results in problematic quantification and underestimation of results.

High-resolution (LC–HRMS) approaches for the targeted determination of mycotoxins

Currently, the use of HRMS is gaining increasing interest in both research and routine laboratories. Advanced HRMS instruments combine crucial features such as increased selectivity and mass resolution, lower cost, and relatively easy maintenance. HRMS is provided by two types of analyzers, TOF and Orbitrap analyzers, with resolving power of 10,000–100,000 and 140,000–240,000 (full width at half maximum defined at m/z), respectively. In contrast to MS/MS, HRMS techniques can overcome all the limiting factors of SIM/MRM analyte detection, thus representing an appropriate alternative to the use of QqQ instruments for targeted as well as nontargeted compound detection. Generally, HRMS measurements have enhanced performance in terms of confirmatory capabilities compared with MS/MS measurements. Especially when one is dealing with complex sample matrices, adequate mass resolution is essential, and the absence of noise can cause a significant decrease of the signal-to-noise ratio [47]. The use of accurate mass measurement permits full spectral data acquisition for all ions, does not rely on fragmentation of analytes, which means that it can overcome the problems caused by production of transitions (nonspecific transitions and stable adducts), and allows retrospective data mining of the chromatogram to look for additional compounds of interest, predominantly metabolites. Overall, HRMS analyzers operate in full-scan mode, and thus allow target, posttarget, and nontarget analysis in a single run without time-consuming optimization of MRM conditions for each compound. The analysis of accurate mass reduces matrix interferences within one mass unit of the target analytes that are normally detected in QqQ systems; however, sole measurement of accurate mass for analyte identification can lead to false positive results or misidentifications.

A new generation of hybrid instruments, quadrupole–TOF (QTOF) and Q–orbital ion trap (Q Exactive) instruments, combine the benefits of high-performance quadrupole selection of precursor ions with those of high-resolution mass detection. Furthermore, the use of these systems also allows higher selectivity in comparison with targeted QqQ systems and simultaneously allows retroactive processing of samples for other untargeted compounds of interest. To collect MS/MS data for nontargeted compounds either a data-dependent acquisition (DDA) strategy or a data-independent acquisition (DIA) strategy can be used. In DDA, a limited number of ions with highest abundance detected in the full MS scan are isolated and fragmented in a product ion scan experiment. The approach based on DIA involves sequential isolation of windows across a mass range for MS/MS. The cycle is repeated throughout the LC run ensuring that product ion spectra of all ions are recorded. Moreover, the DIA approach allows the use of fragment ions for quantification [75]. Application of DIA and DDA in analysis of mycotoxins was demonstrated in several recent studies [76, 77].

Finally with respect to Commission Decision 2002/657/EC [29] for HRMS measurements, each ion earns two identification points, so quantification with the molecular ion and confirmation with one product ion gives enough points to confirm any substance. The advantages and disadvantages of LC–HRMS approaches over targeted LC–MS/MS are summarized in Table 3.

Table 3.

Comparison, advantages and drawbacks of mass spectrometry (MS) instrumentation

| MS technique | Analyzer | Pros | Cons | |

|---|---|---|---|---|

| LRMS(/MS) | QqQ, IT, QLIT | High sensitivity and selectivity in MRM mode Wide linear dynamic range Robust gold standard instrumentation Lower purchase costs |

Number of simultaneously detected analytes in MRM mode is limited Poor/moderate sensitivity in full MS mode Need to optimize detection conditions for each analyte Screening without reference standard not usually possible |

|

| HRMS(/MS) | TOF, QTOF | High sensitivity and selectivity in full MS mode Postacquisition data interrogation for nontargeted analytes Identification of unknowns is possible |

Narrower dynamic range compared with LC–MS(MS/MS) instruments High purchase cost |

Lower mass resolving power and mass accuracy compared with Orbitrap systems |

| Orbitrap, Q–Orbitrap | Acquisition speed limited at high mass resolving power settings | |||

HRMS high resolution mass spectrometry, LC liquid chromatography, LRMS low-resolution mass spectrometry, MRM multiple-reaction monitoring, QLIT quadrupole–linear ion trap, Q–Orbitrap quadrupole–Orbitrap, QqQ triple quadrupole, TOF time of flight