Abstract

In the present study, the GAB and moisture migration rate models were used to predict the shelf life of paprika under domestic (40 °C and 90% RH) and industrial (5, 10, 15 and 20 °C with 70% RH) storage conditions. The correlations between physicochemical characteristics and moisture content of paprika were developed to estimate the stability of the paprika. The estimated shelf life of low moisture paprika (4.40% dry basis) was found to be 101 and 31 days in HDPE and LDPE packages, respectively when stored in domestic condition. In industrial storage condition, the shelf life prediction was 5.47 years in HDPE and 1.68 years in LDPE packages. The first order kinetic models of extractable color (ASTA) and degree of caking described the quality degradation of paprika during storage. The relative humidity and temperature of the storage environment were significant parameters affecting the stability of paprika. The shelf life of paprika can be extended by storage at or below monolayer moisture content and low temperature.

Keywords: Water activity, Shelf life, Paprika, Quality alterations, Degradation kinetics

Introduction

Red pepper (Capsicum annuum L.) is extensively cultivated and consumed throughout the world. India plays a major role in the production, export as well as consumption of red pepper. In 2014, world’s red pepper (dry) production was 3.81 million tons, and India recorded the highest contribution of 39.07% (FAOSTAT 2016). Paprika (pulverized or ground product of dried red pepper) has been utilized to enhance or change the color of food (Topuz et al. 2009). It is an excellent source of phytochemicals and antioxidants which delays the aging process as well as plays a major role in the protection of the body from cancer-causing components (Vega-Gálvez et al. 2009). The surface color of paprika is a key quality attribute which determines the market price and overall quality (Ladrón de Guevara et al. 2002). The quality of paprika deteriorates due to unhygienic post-harvest practices. Therefore, the paprika produced under unhygienic conditions becomes contaminated with dust, insects, animal waste, pathogenic microorganisms, and filth (FDA 2013). Production of paprika from the naturally dried red pepper is most likely to be contaminated with aflatoxins due to the unsatisfactory drying process (Ozilgen et al. 2013). The storage of paprika at high temperature and humid condition also results in microbial growth, and such storage condition is favorable for aflatoxin contamination (Sudha et al. 2013). The poor hygienic conditions during post-harvest and processing practices result in contamination and occurrence of aflatoxins (Arimboor et al. 2015). Hence paprika with higher microbial load is a major reason for concern and the recent decline in the export from the India (Nathawat et al. 2013). The quality of paprika is dependent on moisture content which affects pigment stability and degradation of Vitamin C and E during processing (Ramesh et al. 2001). Also, the water activity plays a major role in the stability of extractable color (ASTA) and microbial growth of paprika during storage (Topuz 2008). To maintain the overall quality of paprika during longer storage periods without additional antioxidants necessitates the storage under industrial controlled conditions (Pérez-Gálvez et al. 2009). In addition, for microbial and physical stability of product necessitates storage at low moisture content i.e., at or below monolayer moisture (Téllez-Pérez et al. 2015; Won et al. 2015). The different kinetic models have been reported in the literature to predict quality deterioration during processing and storage (Patras et al. 2011).

The variation in physicochemical characteristics with a moisture content of product provides a valuable data. Porosity and bulk density are primary considerations in designing of drying, aeration, and storage systems. The product smoothness during material handling and storage stability is affected by the hygroscopicity and degree of caking, which transform the powder into adhesive and agglomerated material (Oliveira et al. 2014). Besides, in India, the paprika is stored or kept for several months under different conditions at different places by farmers, traders, and shopkeepers. Therefore, to predict the shelf life of paprika for long storage periods (from post-harvest processing to consumption) necessitates moisture dependent correlations. Experimental data collection for 2 years at a laboratory may not have repeatability due to a drastic change in climatic conditions throughout the country. Hence, the study on changes in different physicochemical characteristics of paprika in the laboratory under different moisture conditions is required for the development of correlations. Using developed correlations which are based on actual experimental work in the laboratory and different storage conditions that prevail in the Indian farm to consumer chain, it is possible to predict the changes in important quality parameters. However, the data on sorption behavior, shelf life and quality degradation kinetics of paprika under different storage condition has not been reported in the literature. Therefore, the present research work on shelf life estimation of paprika using sorption modeling and quality degradation (extractable color and degree of caking) was undertaken.

Materials and methods

Raw material

The freshly prepared paprika (pulverized product of red pepper) var. Byadgi with an initial moisture content (IMC) of 6.74% db was procured from M/S Kabbur Spices, Karnataka (India) and used as a raw material in the study. The paprika was composed of 70.1% fine sized powder (10-30 ISS sieve), followed by 29.6% medium-sized powder (40-100 ISS sieve) and 0.3% coarse size powder (200 ISS sieve). The average particle size (Dp) of paprika was 0.458 mm. The paprika was wetted by a known quantity of double distilled water, to obtain predetermined moisture content (6.93, 10.81, 14.75, 18.65, and 23.05% db). Thoroughly mixed samples were packed in high-density polyethylene (HDPE) bags and conditioned for 3 days at 5 °C temperature in the refrigerator. Prior to each experiment, sample bags were removed and kept in ambient for 2 h (Staack et al. 2008a). The hot air oven method at 105 °C suggested by Guo and Zhu (2014) was used to measure the moisture content (MC) of the paprika.

Water activity (aw) measurement and modeling sorption phenomena

The aw of paprika was measured by using water activity meter (Rotronic-HC2-Aw, Rotronic Measurement Solutions., Switzerland). To determine the monolayer moisture content of paprika, the aw and equilibrium moisture content data were fitted to following equation suggested by Guggenheim–Anderson–de Boer, which is also known as GAB model:

| 1 |

where M is moisture content (MC) of the sample (db), aw is the water activity of a sample, M0 is monolayer moisture content (db), Km is a molecule multilayer factor, and Cg is the Guggenheim constant. The coefficients of second order polynomial equation (b1, b2, and b3) were found by fitting the data between aw and aw/M. The constants of GAB model were calculated using following equations (Patel and Sutar 2016):

| 2 |

| 3 |

where b1 = Km/M0(1/Cg − 1), b2 = 1/M0(1 − 2/Cg) and b3 = (1/M0CgKm) with following solution for constants of GAB model:

| 4 |

| 5 |

| 6 |

Physical characteristics of paprika

Physical characteristics of paprika at five moisture levels (6.93, 10.81, 14.75, 18.65, and 23.05% db) were determined by the standard methods available in the literature.

Density and porosity

Paprika was filled in a cylinder of known volume (1000 mL) from a height of 15 cm above the cylinder to determine the bulk density (ρb). The cylinder was filled at the constant rate without any manual compaction (Işıklı and Yılmaz 2014). A gas pycnometer (Smart Instruments Company Pvt Ltd., India) was used to measure true density (ρt) of the sample using helium as an inert gas. Bulk porosity of paprika was determined by the following relationship given by Singh et al. (2010):

| 7 |

where ε is bulk porosity (%), ρt is the true density (kg m−3), and ρb is the bulk density (kg m−3).

Surface color

The colorimeter (Hunterlab, Colorflex EZ, USA) was used to measure the surface color of paprika and color values were expressed in CIE color system. The L (brightness or whiteness), a (greenness or redness) and b (blueness or yellowness) coordinates were recorded using D65/10° setting (Daylight 65 illuminant/10° observer). Furthermore, the following equations were used to determine the total color difference (∆E), the color intensity (chroma, C) and hue angle (h°).

| 8 |

| 9 |

| 10 |

where L, a and b are respective values at different moisture content. The L*, a*, and b* are values of the fresh paprika sample. The C value varies from a low (dull) to high (vivid) color, and it is related to saturation of color. The h° is an angular component of polar presentation, such as red-purple, yellow, bluish-green, and blue at an angle of 0°, 90°, 180° and 270°, respectively.

Hygroscopicity

The hygroscopicity (HG) of paprika at different moisture levels was measured using a procedure given by Sablani et al. (2008). The HG (absorbed moisture per 100 g dry solids) was estimated using following equation:

| 11 |

where Mi (%, wb) is the free moisture content of sample before exposure to 79.5% RH, Δm is the increase in mass of sample (g) when conditioned in the air of 79.5% RH to attain equilibrium moisture content, and W is the initial weight of the sample (g).

Degree of caking (DC)

The percent DC of paprika was estimated using the method described by Mahdavi et al. (2016). After the hygroscopicity measurement, the sample was dried in hot air oven (102 ± 2 °C) for an hour. The sample was weighed (w1, grams) and shaken for five minutes in 600 μ sieve. The weight of the paprika (w2, grams) left on the sieve was measured. The ratio of ‘w2’ and ‘w1’ estimated the DC as:

| 12 |

Chemical characteristics of paprika

The effect of moisture content on extractable color, red/yellow (R/Y) pigment ratio, browning index, pH, and ascorbic acid content was studied. All measurements were taken in triplicate to report the average values.

Extractable color (EC)

The EC was determined using American Spice Trade Association (ASTA) recommended AOAC method with little modifications (AOAC-Method-971.26 2000). The 0.1 g of paprika was extracted with 20 mL acetone for three-hours by using a water bath (axially shaken at 140 rpm) at 25 °C. Further, the extract was diluted five times with acetone, and spectrophotometer (Model: AU 2701, Systronics India Ltd.) measured the absorbance of diluted extract at 460 nm. The following equation calculated the extractable color:

| 13 |

where EC is the extractable color (ASTA units), W is the sample weight (g) in dry basis, If is the instrument correction factor, and A is the extract absorbance. The factor ‘If’ was obtained by dividing the theoretical absorbance of the standard color solution by its real absorbance at 460 nm. The standard color solution comprised 0.001 M potassium dichromate and 0.09 M ammonium cobalt (II) sulfate hexahydrate.

Red/yellow (R/Y) pigment ratio

The absorbance by extract (in acetone) was measured at 470 and 455 nm for red and yellow pigments, respectively by using spectrophotometer (Topuz et al. 2009).

Browning index (BI)

Lee et al. (1991) suggested a method for measurement of BI in red pepper products. The water-soluble pigments from paprika (0.1 ± 0.001 g) extracted with distilled water after axially shaking at 25 °C for 2 h were centrifuged at 25 °C and 8000 rpm for 8 min. Filtration of supernatant removed suspended particles on Whatman Grade 4 (20–25 μm) filter paper. The spectrophotometer was used to measure the absorbance of filtrate at 420 nm. The moisture content of the paprika was compensated for converting absorbance on the dry weight of 0.1 g of the sample (Topuz et al. 2009).

pH and ascorbic acid

pH of the paprika sample at different moisture levels was determined by AOAC-Method-981.12 (2000). Ascorbic acid (AA) content (mg AA retained/g dry matter) was determined using quantifiable discoloration of 2,6-dichlorophenol indophenol by the titrimetric method as given in AOAC-Method-967.21 (2000).

Shelf life prediction of paprika under domestic and industrial storage

The shelf life was predicted at domestic (40 °C and 90% RH) and industrial storage conditions (5, 10, 15, and 20 °C with 70% RH) in HDPE (high-density polyethylene) and LDPE (low-density polyethylene) packages. The domestic storage condition (40 °C and 90% RH) was chosen as representative of unfavorable actual environmental conditions for food storage (Surkan et al. 2009). Whereas, industrial storage conditions (5, 10, 15, and 20 °C with 70% RH) were chosen with little modifications as the stability of paprika without supplementary antioxidants can be maintained at industrial controlled conditions (Pérez-Gálvez et al. 2009). Further, the prediction of the shelf life of paprika with two different IMC’s was made based on commercial and theoretical assumptions. In the first instance, the IMC of paprika was considered less than monolayer moisture content (M0), and in the second case, IMC was equal to (approx.) average moisture content of commercially available paprika. The literature shows the water activity of 0.55 as the upper limit for unaccepted change in ASTA color of paprika and aflatoxin level (Rhim and Hong 2011; Sahar et al. 2015). The corresponding moisture content of paprika at 0.55 aw was 10.50% db. The maximum industrial storage temperature in shelf life prediction was limited to 20 °C as the ascorbic acid content and surface color are preserved for longer durations if paprika stored at temperatures below 20 °C (Pérez-Gálvez et al. 2009).

The following equation can express the change in moisture content of paprika (dM/dθp) during storage period (θp) at a temperature (Tp):

| 14 |

where Wp is the dry weight of packed paprika (kg), Rhp is the relative humidity of storage (fraction), kg is the packaging material permeability (kg water m−2 d−1 Pa−1), bp and lp are width and length of the package (m), respectively and 2bplp (m2) is the surface area of packaging material. aw is the water activity (fraction) and M is the moisture content (% db), θp is storage periods in days (d), Tp is the temperature of storage environment (°C) and P*p is the saturation vapor pressure of water (Pa) at temperature Tp (°C). For prediction of the shelf life of paprika in days, the formula based on Eq. 14 as follows:

| 15 |

where θps is the shelf life of the paprika (d), Mpi and Mpc are the initial and critical moisture contents of paprika (% db), respectively. The Mpi should normally be near to monolayer moisture M0 of the product (Jena and Das 2012).

Quality degradation kinetics of paprika

The degree of caking indicating product smoothness during storage and is affected by moisture content, which results in a powder with decreased quality and functionality (Oliveira et al. 2014). Also, the extractable color (ASTA) is one of the important quality attributes of paprika specified by ASTA. Therefore, the extractable color degradation and caking of paprika under different storage conditions are required to study. The kinetics of change in quality parameters mentioned above were estimated using first order reaction. The first-order kinetic equation as follows:

| 16 |

where C is the EC and DC values at any given storage time t, C0 is the initial values of EC and DC, and k is degradation rate constant.

Statistical analysis

The ANOVA was done using Analysis ToolPak-VBA of Microsoft Excel (MS Office 2016) to study the effect of MC on different physicochemical characteristics.

Results and discussion

Effect of MC on aw and estimation of GAB constants

The water activity (aw) plays a major role in microbial and storage stability of the product (Staack et al. 2008b). Table 1 gives the means and standard deviations of aw within the experimental range of moisture content (6.93–23.05% db). The aw of paprika increased significantly (p < 0.01) from 0.420 to 0.783 with an increase in MC. The change in water activity was 86% due to increase in MC from 6.93 to 23.05% db. The water activity of paprika might have changed due to change in the water vapor pressure because of conditioning. The correlation between water activity and moisture content of paprika as follows:

| 17 |

where aw is the water activity of sample (fraction) and M is the moisture content (% db).

Table 1.

The mean and standard deviation of various physicochemical characteristics of paprika at different levels of moisture content

| Physical Characteristics | Moisture content (% db) | ||||

|---|---|---|---|---|---|

| 6.93 | 10.81 | 14.75 | 18.65 | 23.05 | |

| ρb, kg m−3 | 453.33 (± 1.95) |

416.33 (± 0.58) |

409.33 (± 2.31) |

401.33 (± 1.53) |

398.00 (± 2.00) |

| ρt, kg m−3 | 1266.93 (± 1.27) |

1291.33 (± 4.76) |

1314.70 (± 2.52) |

1348.20 (± 6.68) |

1359.60 (± 6.65) |

| ε, % | 64.22 (± 0.19) |

67.76 (± 0.09) |

68.86 (± 0.18) |

70.23 (± 0.21) |

70.73 (± 0.29) |

| L | 37.01 (± 0.02) |

34.62 (± 0.01) |

31.81 (± 0.02) |

29.56 (± 0.01) |

28.80 (± 0.01) |

| a | 34.12 (± 0.01) |

34.39 (± 0.01) |

33.94 (± 0.04) |

32.15 (± 0.05) |

30.24 (± 0.01) |

| b | 36.47 (± 0.07) |

36.32 (± 0.03) |

34.67 (± 0.29) |

30.59 (± 0.02) |

26.29 (± 0.03) |

| C | 49.94 (± 0.05) |

50.02 (± 0.03) |

48.52 (± 0.21) |

44.38 (± 0.03) |

40.07 (± 0.01) |

| h° | 46.90 (± 0.06) |

46.56 (± 0.02) |

45.61 (± 0.24) |

43.58 (± 0.05) |

41.01 (± 0.04) |

| ΔE | 0.05 (± 0.03) |

2.41 (± 0.01) |

5.51 (± 0.09) |

9.69 (± 0.02) |

13.64 (± 0.02) |

| HG | 5.49 (± 0.06) |

5.69 (± 0.04) |

5.85 (± 0.03) |

6.01 (± 0.00) |

6.19 (± 0.00) |

| DC | 6.86 (± 0.05) |

8.21 (± 0.01) |

11.85 (± 0.06) |

14.46 (± 0.06) |

15.34 (± 0.04) |

| EC (ASTA) | 107.03 (± 1.62) |

83.10 (± 2.22) |

80.56 (± 0.05) |

75.17 (± 0.38) |

70.96 (± 0.48) |

| R/Y ratio | 1.0105 (± 0.0007) |

1.0037 (± 0.0019) |

1.0013 (± 0.0014) |

1.0018 (± 0.0005) |

1.0076 (± 0.0089) |

| BI | 0.1633 (± 0.0038) |

0.1492 (± 0.0016) |

0.1473 (± 0.0015) |

0.1461 (± 0.0019) |

0.1444 (± 0.0006) |

| pH | 5.02 (± 0.01) |

5.04 (± 0.01) |

5.06 (± 0.01) |

5.08 (± 0.01) |

5.09 (± 0.01) |

| AA | 0.43 (± 0.02) |

0.43 (± 0.02) |

0.43 (± 0.02) |

0.43 (± 0.02) |

0.44 (± 0.02) |

| aw | 0.4199 (± 0.007) |

0.5948 (± 0.002) |

0.6873 (± 0.002) |

0.7530 (± 0.002) |

0.7832 (± 0.004) |

Data in parentheses represent standard deviation

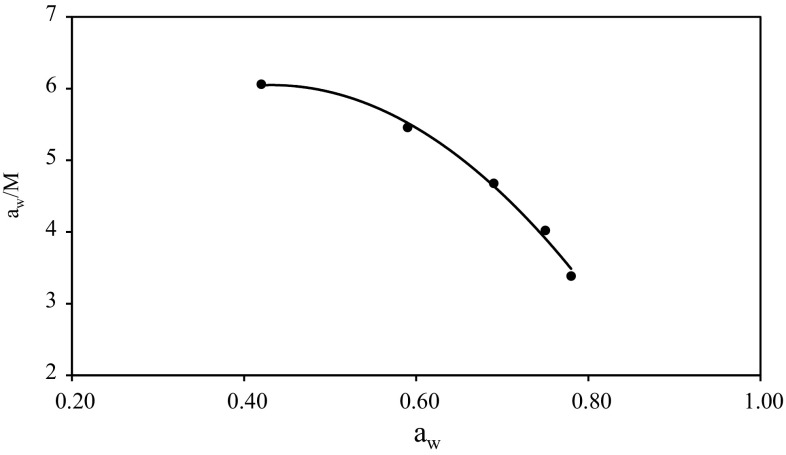

The second order polynomial equation fitting to a plot of aw/M vs. aw (Fig. 1) obtained the coefficients (Eq. 18). Further Eqs. 4, 5 and 6 were used to estimate GAB model constants Km, M0, and Cg, respectively. The Km, M0, and Cg were found to be 1.0320, 0.0442 and 10.4401, respectively. The calculated M0 was 4.42 (% db), which is an in-between range of monolayer moisture content (3.84–7.69% db) for Indian red pepper during adsorption reported by Kaleemullah and Kailappan (2007) using different sorption models. However, the present M0 (4.42% db) was less than the monolayer moisture content (8.16% db) reported by Carbonell et al. (1986). The change in monolayer moisture content is due to alterations in free polar surface sites and porous microstructure due to different drying methods (Téllez-Pérez et al. 2015). The literature shows that in the prediction of shelf life the initial moisture content should be near to monolayer moisture content (Jena and Das 2012). The second order polynomial equation obtained is given below:

| 18 |

where M is the moisture content of paprika (% db), and aw is water activity (fraction) of the product.

Fig. 1.

Plot of aw/M versus aw for coefficients of second order polynomial equation

Variations in physical characteristics with moisture content

Table 1 gives the mean and standard deviations of various physical characteristics of paprika at different levels of moisture content. Also, ANOVA showed the variance in the quality characteristics due to change in moisture content.

Bulk density (ρb)

The ρb of conditioned paprika reduced from 453.33 to 398.00 kg m−3 with a rise in moisture content (p < 0.01). The decrease in ρb of paprika indicates the increase in the volume of conditioned sample at a faster rate compared to increase in mass of sample due to the addition of moisture (Kenghe et al. 2013). The change in bulk density was 12.20%. The correlation developed for bulk density of paprika is given below:

| 19 |

where ρb is the bulk density (kg m−3), and M is the moisture content (% db) of the product.

True density (ρt)

The ρt increased from 1266.93 to 1359.60 kg m−3 with moisture content (p < 0.01). The percent change in true density was 7.31% during moisture change from 6.93 to 23.05 (% db). The rise in true density of paprika with moisture may be due to a larger increase in the volume of conditioned sample in comparison to mass. The correlation between true density and moisture content is as follows:

| 20 |

where ρt is the true density (kg m−3), and M is the moisture content (% db).

Bulk porosity

The bulk porosity significantly (p < 0.01) changed linearly from 64.22 to 70.73% with a rise in MC. The results showed that percent rise in bulk porosity was 10.13%. The extent of the increase in bulk porosity may be due to change in ρb and ρt with moisture content (Singh et al. 2010). The following equation gives the correlation between bulk porosity and moisture content:

| 21 |

where ε is the bulk porosity (%) and M is the moisture content (% db).

Surface color

The L, a, and b values decreased from 37.01 to 28.80, 34.12 to 30.24 and 36.47 to 26.29, respectively with the rise in moisture content. The values of L, a, b, ΔE, hue angle (h°) and chroma (C) showed significant (p < 0.01) change in moisture content. Overall color change (ΔE) of the paprika was increased linearly from 0.05 to 13.64. The chroma values decreased from 49.94 to 40.07 with an increase in moisture which indicates the degree of saturation of color and correlation with browning during storage (Lee et al. 1991). The h° values were decreased linearly from 46.90 to 41.01 with an increase in moisture. The correlations for L, a, b, ΔE, h°, and C is as follows:

| 22 |

| 23 |

| 24 |

| 25 |

| 26 |

| 27 |

where L, a, and b are coordinates of CIE color system, ΔE is an overall change in surface color, C is Chroma value, h° is the hue angle and M is the moisture content (% db).

Hygroscopicity (HG)

The HG of paprika increased linearly from 5.493 to 6.185 g 100 g−1 of dry paprika. The moisture content of paprika significantly (p < 0.01) affected HG. The HG shows the ability of paprika to absorb moisture from the humid air. Powder with less HG and low moisture content considered as a good product (Rigon and Noreña 2016). The hygroscopic behavior is also assigned to the granulation, as the food product with fine particles have a greater surface of contact and hence a more number of active sites (Oliveira et al. 2014). The developed correlation for HG is as follows:

| 28 |

where HG is the hygroscopicity (absorbed moisture in g per 100 g dry solids), and M is the moisture content (% db).

Degree of caking (DC)

The DC of paprika increased linearly from 6.86 to 15.33% with the rise in moisture content from 6.93 to 23.05 (% db). The paprika was significantly caked (p < 0.01) with elevation in moisture content. The DC of paprika was found to be increasing with increase in hygroscopicity. The following equation gives the correlation between DC and moisture content:

| 29 |

where DC is the degree of caking (%) and M is the moisture content (% db).

Alterations in chemical characteristics of paprika

The mean and standard deviations of various chemical characteristics (extractable color, R/Y pigment ratio, BI, ascorbic acid content, and pH) at different moisture content are given in Table 1. ANOVA was done to find the effect of moisture content on chemical characteristics.

Extractable color

The extractable color (EC) represents total carotenoid contents in paprika (Topuz et al. 2009). The EC was significantly affected by moisture content (p < 0.01). The percent change in extractable color was 33.70%. The ASTA values changed from 107.03 to 70.96 followed by a change in overall surface color (ΔE) from 0.05 to 13.64. The following equation represents the correlation between EC and moisture content:

| 30 |

where EC is the extractable color (ASTA), and M is moisture content (% db).

Red/yellow pigment ratio

Table 1 gives the mean and standard deviation of R/Y at different moisture contents. The value of R/Y was almost same (p > 0.01) during an experimental range of moisture content. The non-significant change was due to the proportional decrease in absorbance by both the red and yellow pigments in paprika at 470 and 455 nm, respectively during moisture increment from 6.93 to 23.05 (% db). Absorbance by red pigment at 470 nm decreased from 0.702 to 0.470. The yellow pigment at 455 nm showed reduced absorbance from 0.695 to 0.466.

Browning index

The BI is considered as another quality criterion to judge the paprika. The BI decreased from 0.1633 to 0.1444 with the rise in MC. BI of paprika was significantly affected by moisture content (p < 0.01). The non-enzymatic browning in paprika may be due to Maillard reactions between sugar and amino acids resulting in a change in the BI (Lee et al. 1991). The correlation between the BI and moisture content is as follows:

| 31 |

where BI is the browning index and M is moisture content (% db).

pH and ascorbic acid

The pH of paprika changed significantly (p < 0.01) due to moisture content. It may be due to dilution of acidity in paprika. The non-significant (p > 0.01) change in AA was observed during an experimental range of moisture content. The linear relationship between pH and moisture content of paprika is as follows:

| 32 |

where pH is the hydrogen ion concentration to specify acidity of paprika and M is the moisture content (% db).

Shelf life prediction of paprika under domestic and industrial storage conditions

The shelf life of paprika under different conditions was predicted using Eq. 15. The surface area of the pouch was 0.0276 m2. The water vapor permeability of HDPE and LDPE pouch was 1.04 × 10−11 and 3.38 × 10−11 kg water m−2 day−1 Pa−1, respectively. The dry solids content in 80 g of paprika was 76.48 g in the first case (IMC, 4.40% db which is less than M0) and 75.20 g in the second instance (IMC, 6.0% db which is higher than M0). Under the domestic condition the shelf life of paprika having 4.40% db IMC was found to be 101 and 31 d when stored in HDPE and LDPE packages, respectively. In the case of industrial storage condition (5 °C and 70% RH), the predicted shelf life of the same product was 5.47 years in HDPE and 1.68 years in LDPE packages. Whereas the paprika having 6.0% db IMC under a domestic condition showed shelf life of 73 d in HDPE and 22 d in LDPE packages. Under industrial condition (5 °C and 70% RH), the same product shows 3.97 and 1.22 years shelf life in HDPE and LDPE packages, respectively. Table 2 gives the predicted shelf life in days (d) for different storage conditions.

Table 2.

Predicted shelf life of paprika for different storage and packaging conditions

| Storage conditions | HDPE (IMC, 4.40% db) | LDPE (IMC, 4.40% db) | |

|---|---|---|---|

| T (°C) | RH (%) | Shelf life, d | Shelf life, d |

| Domestic | |||

| 40 | 90 | 101 | 31 |

| Industrial | |||

| 20 | 70 | 743 | 229 |

| 15 | 70 | 1019 | 314 |

| 10 | 70 | 1417 | 436 |

| 5 | 70 | 1998 | 615 |

| Storage conditions | HDPE (IMC, 6.0% db) | LDPE (IMC, 6.0% db) | |

|---|---|---|---|

| T (°C) | RH (%) | Shelf life, d | Shelf life, d |

| Domestic | |||

| 40 | 90 | 73 | 22 |

| Industrial | |||

| 20 | 70 | 539 | 166 |

| 15 | 70 | 739 | 227 |

| 10 | 70 | 1028 | 316 |

| 5 | 70 | 1449 | 446 |

Quality degradation kinetics of paprika during storage

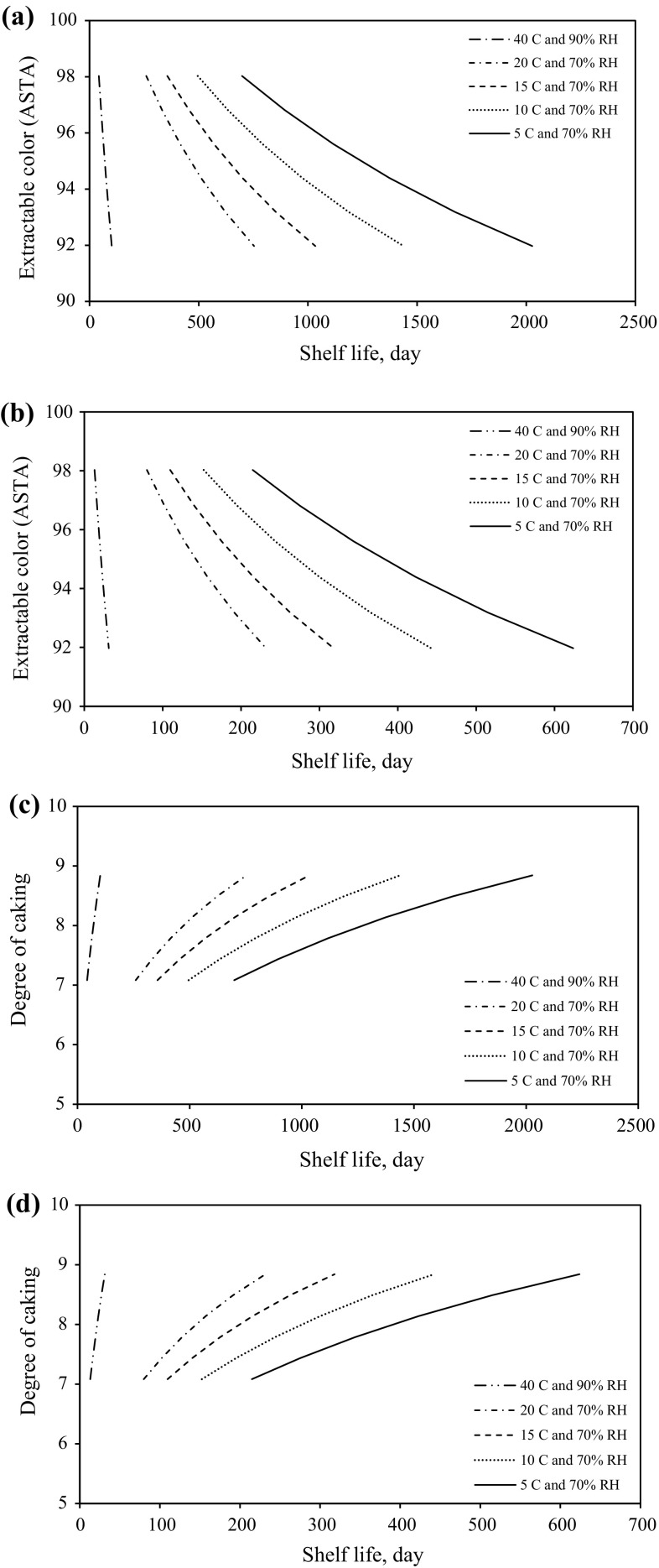

Table 3 gives the degradation rate constants (k, day−1) with a coefficient of determination (R2) for extractable color and degree of caking under different storage conditions. The change in moisture content of paprika in the first case (IMC < M0) and the second instance (IMC, 6.0% db) up to considered critical moisture content of 10.5% db with respect to time (shelf life) was predicted using Eq. 15. Further, the corresponding degree of caking and extractable color values at different moisture content were predicted using developed correlations as given in Eqs. 29 and 30, respectively. During this kinetics study, degradation rate constants were negative for extractable color and positive for the degree of caking. The negative value of rate constant indicates the color loss during the storage. A similar result for a reduction in extractable color (ASTA) during storage is reported in the literature (Topuz et al. 2009). In the first instance of storage condition (IMC < M0), Fig. 2a, b show the predicted extractable color values for HDPE, and LDPE packed paprika, respectively. The second case of storage (IMC at 6.0% db) shows the similar trend.

Table 3.

Degradation rate constants with coefficient of determination (R2) for extractable color (ASTA) and degree of caking under different storage conditions

| Storage conditions | HDPE (IMC, 4.40% db) | LDPE (IMC, 4.40% db) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ASTA | Degree of caking | ASTA | Degree of caking | ||||||

| T (°C) | RH (%) | k | R2 | k | R2 | k | R2 | k | R2 |

| Domestic | |||||||||

| 40 | 90 | − 0.0011 | 0.99 | 0.0038 | 0.99 | − 0.0012 | 0.99 | 0.0122 | 0.99 |

| Industrial | |||||||||

| 20 | 70 | − 0.0001 | 0.99 | 0.0004 | 0.98 | − 0.0001 | 0.99 | 0.0014 | 0.98 |

| 15 | 70 | − 0.000094 | 0.99 | 0.0003 | 0.98 | − 0.0001 | 0.99 | 0.0011 | 0.98 |

| 10 | 70 | − 0.000067 | 0.99 | 0.0002 | 0.98 | − 0.000078 | 0.99 | 0.0008 | 0.98 |

| 5 | 70 | − 0.000048 | 0.99 | 0.0002 | 0.98 | − 0.000075 | 0.99 | 0.0005 | 0.98 |

| Storage conditions | HDPE (IMC, 6.0% db) | LDPE (IMC, 6.0% db) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ASTA | Degree of Caking | ASTA | Degree of Caking | ||||||

| T (°C) | RH (%) | k | R2 | k | R2 | k | R2 | k | R2 |

| Domestic | |||||||||

| 40 | 90 | − 0.0035 | 0.99 | 0.0041 | 0.99 | − 0.0038 | 0.99 | 0.0133 | 0.99 |

| Industrial | |||||||||

| 20 | 70 | − 0.0004 | 0.99 | 0.0005 | 0.98 | − 0.0005 | 0.99 | 0.0017 | 0.98 |

| 15 | 70 | − 0.0003 | 0.99 | 0.0004 | 0.98 | − 0.0004 | 0.99 | 0.0012 | 0.98 |

| 10 | 70 | − 0.0002 | 0.99 | 0.0003 | 0.98 | − 0.0003 | 0.99 | 0.0009 | 0.98 |

| 5 | 70 | − 0.0002 | 0.99 | 0.0002 | 0.98 | − 0.0002 | 0.99 | 0.0006 | 0.98 |

Fig. 2.

a, b represents predicted extractable color (ASTA) of HDPE and LDPE packed paprika, respectively at different storage conditions, c, d represents predicted degree of caking of HDPE and LDPE packed paprika, respectively at different storage conditions

Figure 2c, d show the predicted degrees of caking of HDPE and LDPE packed paprika (IMC < M0), respectively. In the second case of storage (IMC = 6.0% db), the degree of caking followed a similar pattern. These results showed the degradation rate constants (k) were high in LDPE packed paprika compared to HDPE packed paprika and decreased with a decrease in storage temperature. Also, the storage temperature influenced the extractable color and rate of moisture migration (permeability of packaging material).

Conclusion

GAB and moisture migration models were found suitable for the prediction of the shelf life of paprika under different storage conditions. The extension of the shelf life of paprika is possible by storage at M0 and low temperature. The quality degradation can be controlled by decreasing storage temperature and using low permeable packaging material. The water activity, true density, bulk porosity, overall color change, hygroscopicity, the degree of caking and pH of paprika significantly increased with moisture content from 6.93 to 23.05 (% db). The bulk density, L, a and b parameters of surface color, chroma value, hue angle, extractable color, and the browning index significantly decreased with increase in moisture content. The R/Y pigment ratio and ascorbic acid content remain unchanged at measured moisture levels.

Acknowledgements

The authors are thankful to Ministry of Food Processing Industries (MoFPI) and Ministry of Human Resource Development (MHRD), Government of India for their financial support to this research work.

References

- AOAC-Method-967.21 (2000) Official method of analysis, Gaithersburg, MD, USA: Association of Official Analytical Chemists (No. 967.21 Ascorbic acid in vitamin preparation and juices)

- AOAC-Method-971.26 (2000) Official method of analysis, Gaithersburg, MD, USA: Association of Official Analytical Chemists (No. 971.26 Colour (Extractable) in spices spectrophotometric method)

- AOAC-Method-981.12 (2000) Official method of analysis, Gaithersburg, MD, USA: Association of Official Analytical Chemists (No. 981.12 pH of acidified foods)

- Arimboor R, Natarajan RB, Menon KR, Chandrasekhar LP, Moorkoth V. Red pepper (Capsicum annuum) carotenoids as a source of natural food colors: analysis and stability—a review. J Food Sci Technol. 2015;52:1258–1271. doi: 10.1007/s13197-014-1260-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carbonell J, Pinaga F, Yusa V, Pena J. The dehydration of paprika with ambient and heated air and the kinetics of colour degradation during storage. J Food Eng. 1986;5:179–193. doi: 10.1016/0260-8774(86)90024-5. [DOI] [Google Scholar]

- FAOSTAT (2016) Food and Agricultural Organisation of United Nations (FAO). Retrieved from: http://www.fao.org/faostat/en/#data/QC. Accessed 28 Dec 2016

- FDA (2013) Draft risk profile: pathogens and filth in spices. Retrieved from :http://www.fda.gov/downloads/Food/FoodScienceResearch/RiskSafetyAssessment/UCM367337.pdf. Accessed 12 July 2015

- Guo W, Zhu X. Dielectric properties of red pepper powder related to radiofrequency and microwave drying. Food Bioprocess Technol. 2014;7:3591–3601. doi: 10.1007/s11947-014-1375-x. [DOI] [Google Scholar]

- Işıklı ND, Yılmaz İ. Some physical properties of sun-dried Berberis fruit (Berberis crataegina) J Food Sci Technol. 2014;51:104–110. doi: 10.1007/s13197-011-0469-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jena S, Das H. Shelf life prediction of aluminum foil laminated polyethylene packed vacuum dried coconut milk powder. J Food Eng. 2012;108:135–142. doi: 10.1016/j.jfoodeng.2011.06.036. [DOI] [Google Scholar]

- Kaleemullah S, Kailappan R. Monolayer moisture, free energy change and fractionation of bound water of red chillies. J Stored Prod Res. 2007;43:104–110. doi: 10.1016/j.jspr.2005.12.001. [DOI] [Google Scholar]

- Kenghe RN, Nimkar PM, Shirkole SS. Moisture dependent physical properties of lathyrus. J Food Sci Technol. 2013;50:856–867. doi: 10.1007/s13197-011-0428-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ladrón de Guevara RG, Gonzalez M, García-Meseguer MJ, Nieto JM, Amo M, Varón R. Effect of adding natural antioxidants on colour stability of paprika. J Sci Food Agric. 2002;82:1061–1069. doi: 10.1002/jsfa.1158. [DOI] [Google Scholar]

- Lee DS, Chung SK, Kim HK, Yam KL. Nonenzymatic browning in dried red pepper products. J Food Qual. 1991;14:153–163. doi: 10.1111/j.1745-4557.1991.tb00056.x. [DOI] [Google Scholar]

- Mahdavi SA, Jafari SM, Assadpoor E, Dehnad D. Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. Int J Biol Macromol. 2016;85:379–385. doi: 10.1016/j.ijbiomac.2016.01.011. [DOI] [PubMed] [Google Scholar]

- Nathawat N, Joshi P, Chhipa BG, Hajare S, Goyal M, Sahu M, Singh G. Effect of gamma radiation on microbial safety and nutritional quality of Kachri (Cucumis callosus) J Food Sci Technol. 2013;50:723–730. doi: 10.1007/s13197-011-0380-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oliveira DM, Clemente E, da Costa JMC. Hygroscopic behavior and degree of caking of grugru palm (Acrocomia aculeata) powder. J Food Sci Technol. 2014;51:2783–2789. doi: 10.1007/s13197-012-0814-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ozilgen S, Bucak S, Ozilgen M. Improvement of the safety of the red pepper spice with FMEA and post processing EWMA quality control charts. J Food Sci Technol. 2013;50:466–476. doi: 10.1007/s13197-011-0371-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patel J, Sutar P. Acceleration of mass transfer rates in osmotic dehydration of elephant foot yam (Amorphophallus paeoniifolius) applying pulsed-microwave-vacuum. Innov Food Sci Emerg Technol. 2016;36:201–211. doi: 10.1016/j.ifset.2016.06.018. [DOI] [Google Scholar]

- Patras A, Brunton NP, Tiwari B, Butler F. Stability and degradation kinetics of bioactive compounds and colour in strawberry jam during storage. Food Bioprocess Technol. 2011;4:1245–1252. doi: 10.1007/s11947-009-0226-7. [DOI] [Google Scholar]

- Pérez-Gálvez A, Dm Hornero-Méndez, MaI Mínguez-Mosquera. Stability of paprika without supplementary antioxidants during storage under industrial controlled conditions. J Agric Food Chem. 2009;57:4718–4723. doi: 10.1021/jf804058m. [DOI] [PubMed] [Google Scholar]

- Ramesh M, Wolf W, Tevini D, Jung G. Influence of processing parameters on the drying of spice paprika. J Food Eng. 2001;49:63–72. doi: 10.1016/S0260-8774(00)00185-0. [DOI] [Google Scholar]

- Rhim J-W, Hong S-I. Effect of water activity and temperature on the color change of red pepper (Capsicum annuum L.) powder. Food Sci Biotechnol. 2011;20:215–222. doi: 10.1007/s10068-011-0029-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rigon RT, Noreña CPZ. Microencapsulation by spray-drying of bioactive compounds extracted from blackberry (Rubus fruticosus) J Food Sci Technol. 2016;53:1515–1524. doi: 10.1007/s13197-015-2111-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sablani SS, Shrestha AK, Bhandari BR. A new method of producing date powder granules: physicochemical characteristics of powder. J Food Eng. 2008;87:416–421. doi: 10.1016/j.jfoodeng.2007.12.024. [DOI] [Google Scholar]

- Sahar N, Arif S, Iqbal S, Afzal QUA, Aman S, Ara J, Ahmed M. Moisture content and its impact on aflatoxin levels in ready-to-use red chillies. Food Addit Contam Part B. 2015;8:67–72. doi: 10.1080/19393210.2014.978395. [DOI] [PubMed] [Google Scholar]

- Singh K, Mishra H, Saha S. Moisture-dependent properties of barnyard millet grain and kernel. J Food Eng. 2010;96:598–606. doi: 10.1016/j.jfoodeng.2009.09.007. [DOI] [Google Scholar]

- Staack N, Ahrne L, Borch E, Knorr D. Effect of infrared heating on quality and microbial decontamination in paprika powder. J Food Eng. 2008;86:17–24. doi: 10.1016/j.jfoodeng.2007.09.004. [DOI] [Google Scholar]

- Staack N, Ahrne L, Borch E, Knorr D. Effects of temperature, pH, and controlled water activity on inactivation of spores of Bacillus cereus in paprika powder by near-IR radiation. J Food Eng. 2008;89:319–324. doi: 10.1016/j.jfoodeng.2008.05.010. [DOI] [Google Scholar]

- Sudha S, Naik M, Ajithkumar K. An integrated approach for the reduction of aflatoxin contamination in chilli (Capsicum annuum L.) J Food Sci Technol. 2013;50:159–164. doi: 10.1007/s13197-011-0471-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Surkan S, Albani O, Ramallo L. Influence of storage conditions on sensory shelf life of yerba mate. J Food Qual. 2009;32:58–72. doi: 10.1111/j.1745-4557.2008.00236.x. [DOI] [Google Scholar]

- Téllez-Pérez C, Sobolik V, Montejano-Gaitán JG, Abdulla G, Allaf K. Impact of swell-drying process on water activity and drying kinetics of Moroccan pepper (Capsicum annum) Drying Technol. 2015;33:131–142. doi: 10.1080/07373937.2014.936556. [DOI] [Google Scholar]

- Topuz A. A novel approach for color degradation kinetics of paprika as a function of water activity. LWT Food Sci Technol. 2008;41:1672–1677. doi: 10.1016/j.lwt.2007.10.004. [DOI] [Google Scholar]

- Topuz A, Feng H, Kushad M. The effect of drying method and storage on color characteristics of paprika. LWT Food Sci Technol. 2009;42:1667–1673. doi: 10.1016/j.lwt.2009.05.014. [DOI] [Google Scholar]

- Vega-Gálvez A, Di Scala K, Rodríguez K, Lemus-Mondaca R, Miranda M, López J, Perez-Won M. Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian) Food Chem. 2009;117:647–653. doi: 10.1016/j.foodchem.2009.04.066. [DOI] [Google Scholar]

- Won Y-C, Min SC, Lee D-U. Accelerated drying and improved color properties of red pepper by pretreatment of pulsed electric fields. Drying Technol. 2015;33:926–932. doi: 10.1080/07373937.2014.999371. [DOI] [Google Scholar]