Abstract

The most common solid tumors show intrinsic multidrug resistance (MDR) or inevitably acquire suchwhen treated with anticancer drugs. In this work, we describe the discovery of a peripherally restricted, potent, competitive NMDA receptor antagonist 1l by a structure-activity-study of the broad-acting ionotropic glutamate receptor antagonist 1a. Subsequently, we demonstrate that 1l augments the cytotoxic action of sorafenib in murine hepatocellular carcinoma (HCC) cells. The underlying biological mechanism was shown to be interference with the lipid signaling pathway, leading to reduced expression of MDR transporters and therebyan increased accumulation of sorafenib in the cancer cells. Interference with lipid signaling pathwaysby NMDA receptor inhibition is a novel and promising strategy for reversing transporter-mediated chemoresistance in cancer cells.

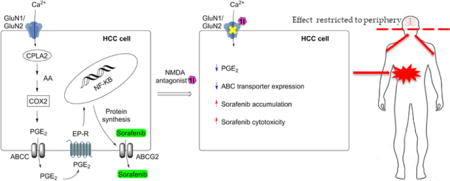

Graphical abstract

Introduction

Over time, solid tumors inevitably acquire resistance against anticancer therapy - a phenomenon known as multi-drug resistance (MDR).1 But more devastatingare cancers, such as hepatocellular carcinoma (HCC), which exertsintrinsic drug-resistance.2 A key mechanism underlyingMDR is increased expression of ATP-binding cassette (ABC) transporters, whichexpel a broad range of chemotherapeutic agents from the cancer cells.3 According to current knowledge, the principal ABC transporters responsible for chemoresistance in humans areATP-binding cassette subfamily B member 1 (ABCB1, Pgp), ATP-binding cassette subfamily G member 2 (ABCG2, BCRP) and ATP-binding cassette subfamily C (ABCC, MRP).4–7 In regard to HCC, these transporters are responsible for expelling the first line HCC drug sorafenib from the cancer cells.8–10 The general strategy to reverseMDR has been to co-administer ABC transporter inhibitors with anticancer drugs.11 However, several complications limit the use of ABC transporter inhibitors, amongst them the fact that ABC transporters are also present in normal cells, leading to undesired drug accumulation.11 Thus, a change of strategy is needed to overcome ABC transporter-mediated chemoresistance.

One such strategy is to down-regulate efflux transporter expression by alternating the cell lipid signaling pathwayby blocking theN-methyl-D-aspartate (NMDA) receptors.12 NMDA receptors are a subclass of ionotropic glutamate receptors (iGluRs), which also comprises the α-amino-3-hydroxy-5-methyl-4-isoxazolepropionic acid (AMPA) receptors and the kainic acid (KA) receptors.13 NMDA receptor activation increases calcium entry, whichactivates cytoplasmic phospholipase A2 (cPLA2), leading to increased production of arachidonic acid (Figure 1).14,15 This fatty acid is further converted to the proinflammatory lipid, prostaglandin-E2 (PGE2) and actively transported into the extracellular space by ABCC transporters, where it binds to the prostaglandin E receptors (EP-Rs), leading to NF-κB activation and creating a positive feedback loop creating an inflammation microenvironment.12,14 It has been shown that NF-κB activation results in increased cancercell survival and proliferationas well aschemoresistance due to elevated ABC transporterand CYP enzyme expression.12,16,17

Figure 1.

Activation of the lipid signaling pathway by GluN1/GluN2A receptor and the creation of transporter mediated drug resistance. NMDA binding to the GluN1/GluN2A receptor allows the influx of Ca2+ into the cell, which leads to cPLA2 activation and the release of arachidonic acid (AA) from phospholipids. Arachidonic acid is metabolized to PGE2, which is transported by ABCC transporters out of the cell allowing the PGE2 binding to EP-R. The EP-R activation leads to nuclear translocation of NF-κB followed by ABCG2 protein transcription and MDR.12,14–17

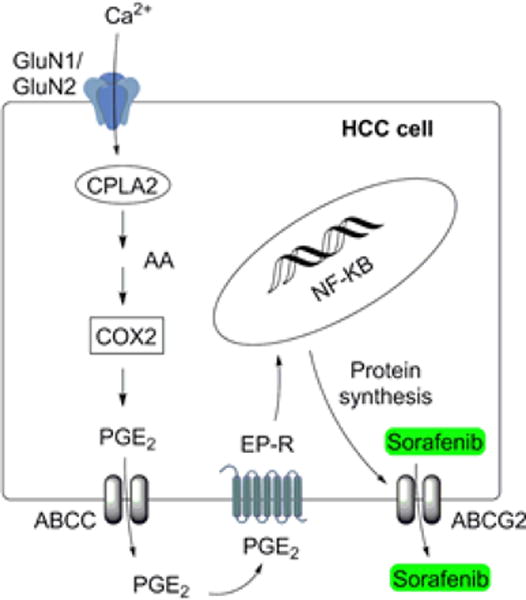

NMDA receptors are over-expressed on the cell membrane of many types of cancer cells, including HCC.18 The non-competitive NMDA receptor antagonist MK-801 (Figure 2) has previously been shown to augment the antiproliferative efficacy of antiestrogens in melanoma cells19 and suppress the growthof HCC cells.20 The antiproliferative effect of MK-801 in HCC cells was shown to be mediated through the FOXO/XTNIP pathway, which is not connected to pro-inflammatory lipid signaling. Moreover, the impact of NMDA receptor antagonists on transporter expression, anticancer drug accumulation, and efficacy in cancers has not been studied. Most importantly, a competitiveNMDA receptor antagonist for use as an augmentative drug for the treatment of peripheral solid tumors must notbe capable ofcrossing the blood-brain barrier (BBB), as this would otherwise lead tosevere adverse effects, including psychosis.21

Figure 2.

Chemical structures of Glu, selective un-competitive NMDA receptor antagonist MK-801, selective competitive NMDA receptor antagonists D-AP5, (R)-CPP, and competitive iGluR antagonist 1a, including published analogs 1b,c with relevanceto SAR study reported herein.

In the present study, we report the design and synthesis of the novel peripherally acting potent NMDA receptor antagonist 1l. We describe the ability of 1l to modulate the cPLA2 activation-dependent lipid signaling pathway, downregulate ABC transporter expression andthereby augmentthe cytotoxic efficacy of the anticancer drug sorafenib in murine HCC cells.

Results and Discussion

The two commonly studied competitive NMDA receptor antagonists which do not penetrate the BBB are D-AP5 and (R)-CPP (Figure 2). Both are amino acid analogs and highly polar with calculated partition coefficient values in octanol:water (cLogP(o/w)) well below zero (−1.7 and −2.2, respectively). Incomparisonwith recommended cLogP(o/w) values of −0.4 to 5.622 for oral bioavailability, we believed that these NMDA receptor antagonists were not attractive candidates for this study.

We therefore turned to the previously reported non-selective iGluR antagonist 1a (Figure 2 and Table 1).23 The fact that 1a does not penetrate the BBB in mouse in situ brain perfusion and that its cLogP(o/w) value is calculated at 1.3, makes it an attractive starting point for the purpose of developing orally available, peripherally restricted, competitive NMDA receptor antagonist.22

Table 1.

Binding affinities of 1a-n at native AMPA, KA and NMDA receptors (rat synaptosomes), and cloned homomeric receptors GluK1-3.

| Cmpd No |

|

AMPA IC50 (μM) |

KA IC50 (μM) |

NMDA Ki (μM) |

GluK1 Ki (μM) |

GluK2 Ki (μM) |

GluK3 Ki (μM) |

|---|---|---|---|---|---|---|---|

| 1a23 |

|

51 | 22 | 6.0 | 4.3 | >100 | 8.1 |

| 1b24 |

|

2.0 | 1.4 | 1.0 | 4.8 | 10–100 | 0.87 |

| 1c24 |

|

>100 | >100 | >100 | 126 | >1000 | 78 |

| 1d |

|

>100 | >100 | >100 | >100 | >100 | >100 |

| 1e |

|

>100 | >100 | >100 | >100 | >100 | >100 |

| 1f |

|

>100 | >100 | >100 | – | – | – |

| 1g |

|

>100 | >100 | >100 | >1000 | >1000 | >1000 |

| 1h |

|

>100 | >100 | >100 | >100 | >100 | >100 |

| 1i |

|

>100 | >100 | >100 | >1000 | >1000 | >100 |

| 1j |

|

>100 | >100 | 35 [ 4.46 ± 0.04] |

– | – | – |

| 1k |

|

> 100 | 59 [4.23 ± 0.05] |

4.6 [5.34 ± 0.04] |

12 ± 0.5 |

>100 | 11 ± 0.97 |

| 1l |

|

>100 | >100 | 0.63 [6.22 ± 0.10] |

154 ± 13 |

>100 | 131 ± 13 |

| 1m |

|

>100 | >100 | 17 [4.78 ± 0.04] |

>100 | >100 | >100 |

| 1n |

|

>100 | >100 | 0.62 [6.22 ± 0.07] |

> 100 | > 100 | > 100 |

–: not tested. Radioligands: AMPA, [3H]AMPA; KA, [3H]KA; NMDA, [3H]CGP-39653; GluK1, [3H]SYM2081; GluK2 and GluK3, [3H]KA. Data are mean values of three to six individual experiments performed in triplicate. For AMPA and KA: pIC50 values with SEM in brackets. For NMDA: pKi values with SEM in brackets.

We have previously reported a first structure-activity-relationship (SAR) study on 1a, which disclosed the 4-position on the aryl ring as a hotspot for induction of KA receptor subtype selectivity (compound 1b, Figure 2 and Table 1). Also, it was seen that simple lipophilic substituents in the 5-position did not lead to any significant improvement in receptor selectivity or higher affinity (structures not shown).24 The 3-carboxylic acid functionality was displaced with a phosphonic acid group, compound 1c (Figure 2), which led to a significant reduction in binding affinity at the iGluRs (Table 1).24

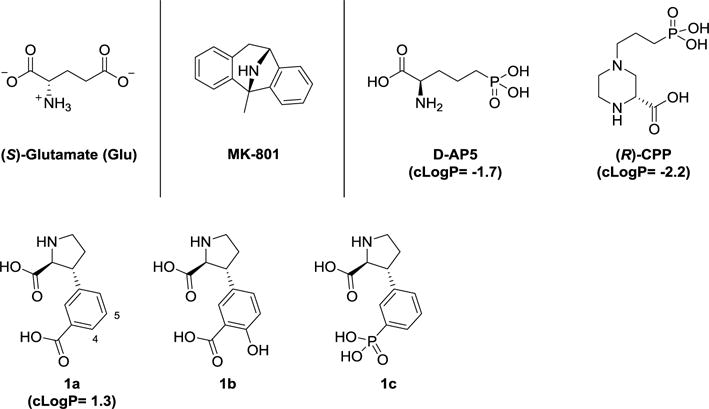

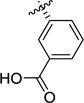

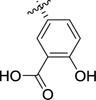

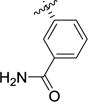

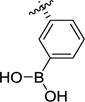

Withthis SAR information in hand, we set out to investigate two strategies with the aim of improving iGluR class selectivity. Firstly, we wanted to substitute the 3-carboxylic acid functionality with different functional groups (analogs 1d-j). While it is well-accepted that the γ-carboxylate functionality in Glu is mandatory for agonist activity at the iGluRs,13 it remains an open question if non-ionizable distal functional groups can stabilize the NMDA receptor in itsopen antagonist state. Based on synthetic tractability, the following seven analogs were thus designed: 3-chloro (1d), 3-trifluoromethyl (1e), 3-amino (1f), 3-cyano (1g), 3-carbamido (1h), 3-boronic acid (1i), and 3,4-dihydroxy (1j). The synthesis of 1d-j was carried out by a stereoselective rhodium(I)-catalyzed addition of an arylboronic acid to protected enone 224 as the key step (Scheme 1).25 Hereby, the 2,3-trans stereochemistry on the proline ring was set, and subsequent functional group transformations in accordance with earlier reported strategies (1d-f; Scheme 2), (1g,h; Scheme 3), (1i;Scheme 4) and (1j; Scheme 5), gave the free amino acids 1d-j ready for pharmacological evaluation.23,24

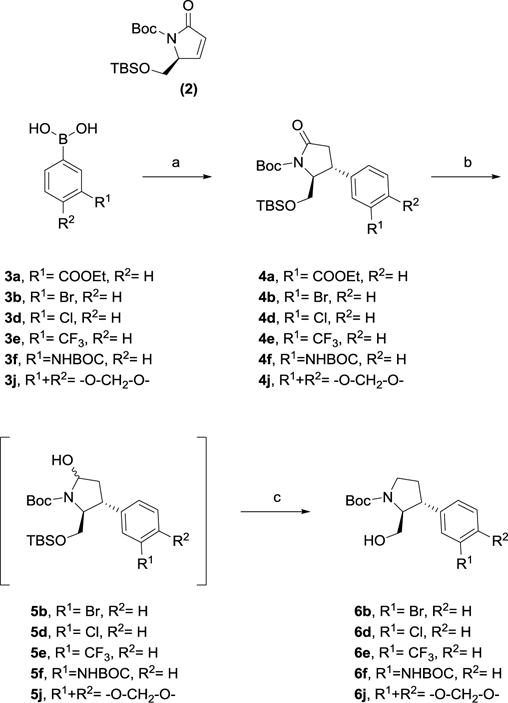

Scheme 1.

Synthesis of key alcohol intermediates 6b,d-f,j via rhodium(I)-catalyzed 1–4 addition of respective boronic acids 3a,b,d-f,j to enone 2.

Reagents and conditions. a) [Rh(cod)Cl]2, H2O, Cs2CO3, enone 2, THF or dioxane, rt (52–67%). b) LiBEt3H, THF, −78°C. c) HSiEt3, BF3•Et2O, DCM, −78°C (31–78%).

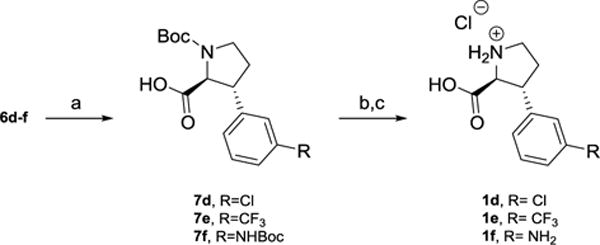

Scheme 2.

Synthesis of1d-f from alcohols6d-f, respectively

Reagents and conditions. a) RuCl3•xH2O, NaIO4, EtOAc:MeCN:H2O (49–86%). b) TFA, DCM, rt. c) 1 M HCl (12–78%).

Scheme 3.

Synthesis of 3-cyano analog 1gfrom alcohol 6b, and3-carbamido analog 1h from7g.

Reagents and conditions. a) TBSCl, imidazole, DMF, rt (73%, three steps from 4b). b) Zn(CN)2, Pd2(dba)3, dppf, DMA, 120°C. c) TBAF, THF, rt (71%, two steps). d) RuCl3•xH2O, NaIO4, EtOAc:MeCN:H2O (76%). e) TFA, DCM, rt. f) 1 M HCl (81%, two steps). g) 30% H2O2, K2CO3, EtOH/H2O, rt (66%). h) TFA, DCM, rt. i) 1 M HCl (59% after three steps).

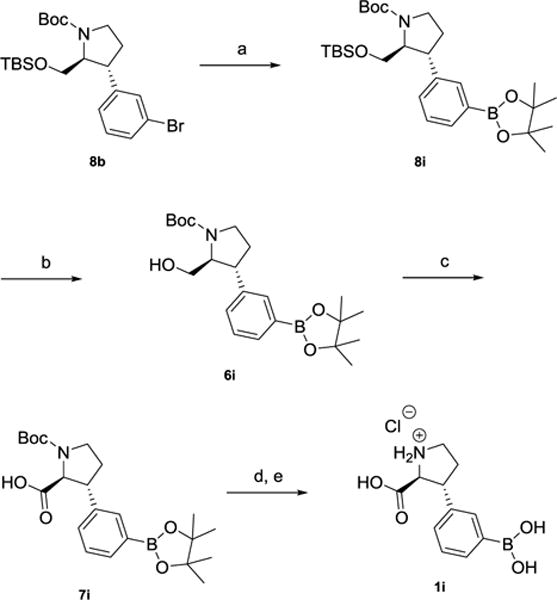

Scheme 4.

Synthesis of 3-boronic acid analog 1i, starting from bromine8b

Reagents and conditions. a) KOAc, Pd2(dba)3, dppf, DMF (61%). b) TBAF, THF, rt (60%). c) RuCl3•xH2O, NaIO4, EtOAc:MeCN:H2O (65%). d) TFA, DCM, rt. e) 1 M HCl (40%, two steps).

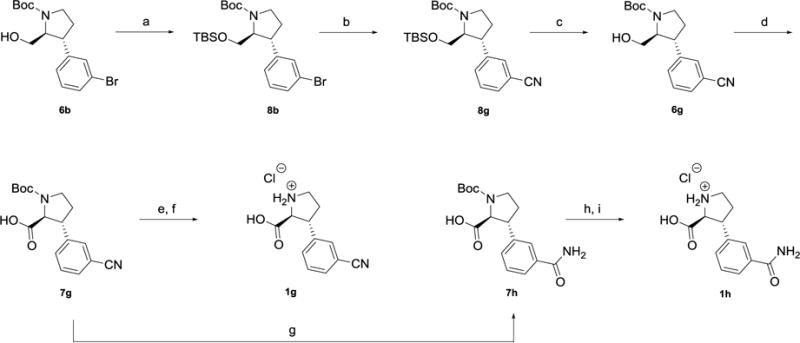

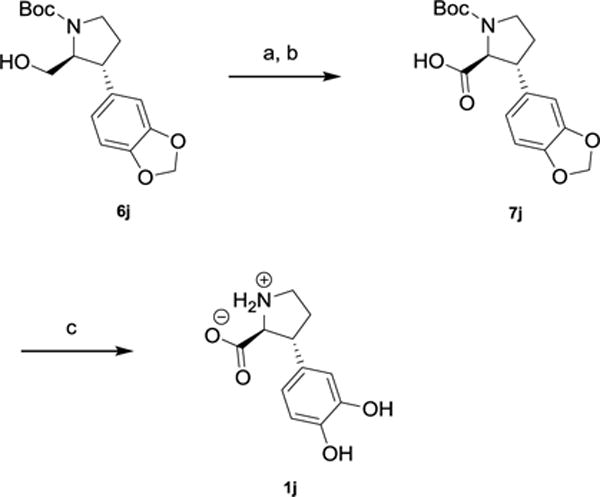

Scheme 5.

Synthesis of 1j from alcohol 6j.

Reagents and conditions. a) IBX, DMSO, rt. b) NaClO2, NaH2PO4, 2-methyl-2-butene, tert-BuOH/H2O, rt (66%, two steps). c) BBr3, DCM (8% after recrystallization from MeOH).

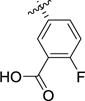

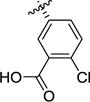

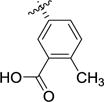

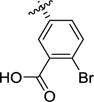

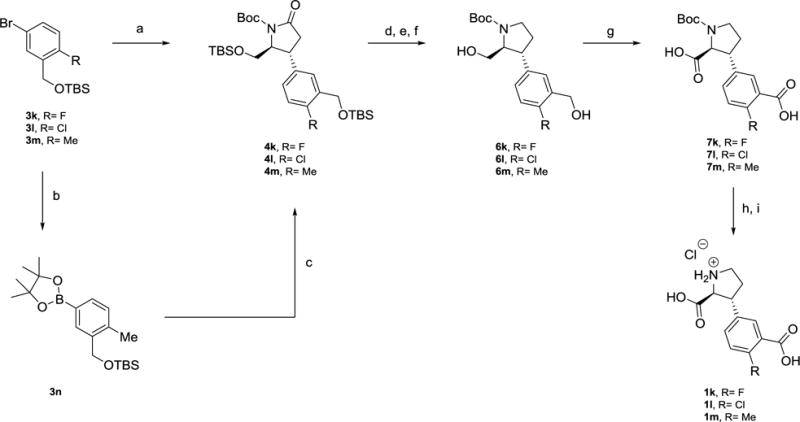

The second series of analogs, compounds 1k-n, aimed to further explore the impact of substituents in the4-position of the aryl ring. We have previously shown that introduction of a 4-hydroxy group (analog 1b) resulted in generally enhanced affinity for iGluRs with a 10-fold improvement for the GluK3 subunit (Table 1).24 Given the hydrogen bond donor and acceptor abilities of the 4-hydroxyl group, three new analogs were designed to address the influence of these features: 4-fluoro (1k), 4-chloro (1l) and 4-methyl (1m). For 1k and 1l, the syntheses were based on the stereoselective conjugate addition of an in situ formed aryl cuprateto enone 2,24,26 whereas for 1m, the afore applied protocol of rhodium(I)-catalyzed addition of a boronic ester to enone 2 was used (Scheme 6). Subsequent functional group transformations to obtain the free amino acids 1k-m followed the strategy for comparable analogs previously reported by us.23,24

Scheme 6.

Synthesis of 1k-lvia copper(I) catalyzed addition to enone 2, and 1m via rhodium(I) catalyzed addition to enone 2.

Reagents and conditions. a) for 3k,l: n-BuLi, CuCN, then enone2, Et2O, −78 to −42°C (46% and 73%). b) for 3m: (Bpin)2, KOAc, (PPh3)2PdCl2 (quant). c) [Rh(cod)Cl]2, H2O, Cs2CO3, enone 2, rt (41%). d) for 4k,l: LiBEt3H, THF, −78°C, then HSiEt3, BF3•Et2O, DCM, −78°C. e) for 4m: BH3•SMe2, THF, reflux. f) TBAF, THF, rt. (20% and 49%). g) RuCl3•xH2O, NaIO4, EtOAc:MeCN:H2O (20–97%). h) TFA, DCM, rt. i) 1 M HCl (56–60%).

Binding affinities of the synthesized amino acids 1d-n were determined at native AMPA, KA and NMDA receptors (rat synaptosomes) and cloned rat homomeric subtypes GluK1-3 and results summarized in Table 1. The 3-chloro, 3-trifluoromethyl, 3-amino and 3-cyano analogs, 1d-g respectively, all showed insignificant binding affinity for any of the iGluRs (IC50 or Ki>100 μM). Furthermore, 3-carbamido analog 1h and 3-boronic acid analog 1i did not display notable binding affinities for native iGluRs nor for homomeric GluK1-3 receptors (IC50 or Ki>100 μM). Finally, the 3,4-dihydroxy analog 1j was a weak binder at the NMDA receptors (Ki = 35 μM). While these results were all together disappointing, the affinity profiles for the 4-substituted analogs 1k-m were in contrast exciting. In comparison with the 4-hydroxy analog 1b, the 4-fluoro analog 1k displayed first steps towards selectivity for the NMDA receptors by showing a lower affinity for native AMPA and KA receptors as well as for homomeric GluK1-3 receptors. This trend was boosted significantly for 4-chloro analog 1l, which proved to be selectivefor native NMDA receptors with submicromolarbinding affinity (Ki = 0.63 μM). Also for 4-bromo analog 1n,27 full selectivity for NMDA receptors was observed with binding affinity similar to 1l (Ki = 0.62 μM). In contrast to this important finding, the binding affinity for native NMDA receptors dropped 30-fold for the 4-methyl analog 1m.

The cLogP(o/w) of 1l and 1n were calculated at 1.9 and 2.1, respectively, placing both analogs in the recommended cLogP intervalof −0.4 to 5.6 for good bioavailability.22 Given that an aryl bromide is a less attractive functional group in compounds for biological administration compared to an aryl chloride, compound 1l was selected for further functional studies at NMDA receptors.

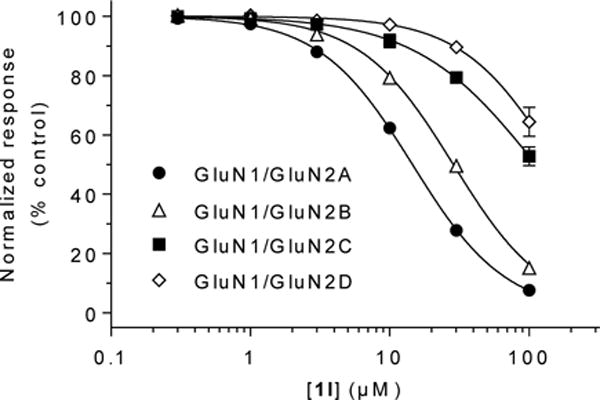

Functional characterization of 1l at NMDA receptor subtypes

Compound 1l was next evaluated in a functional assay at the four NMDA receptor subtypes, GluN1/GluN2A-D (Figure 3 and Table 2). At all four subtypes, 1l was found to be a competitive antagonist with Kivalues of 4.7, 10, 24 and 41 μM, respectively, and the selectivity profile of 1l was similar to D-AP5 (Ki values of 0.39, 2.8, 5.9 and 21, respectively28).

Figure 3.

Concentration-inhibition data for1lat recombinant NMDA receptor subtypes GluN1/GluN2A-D. Responses were measured using two-electrode voltage-clamp electrophysiology and were activated by co-application of 100 μM glycine and GlutoXenopusoocytes expressing recombinant NMDA receptors subtypes. 10 μM Glu was used for GluN1/GluN2A, 3 μM Glu for GluN1/GluN2B and GluN1/GluN2C, and 1 μM Glu for GluN1/GluN2D receptors. Data are mean ± SD (error bars are mostly contained within the symbols). See Table 2 for IC50 and estimated Ki values.

Table 2.

Inhibition of recombinant NMDA receptor subtypes by 1l. IC50 values for inhibition of current responses activated by co-application of 100 μM glycine and GlutoXenopusoocytes expressing recombinant rat GluN1/GluN2A-D NMDA receptors. Responses were activated by Glu concentrations 2- to 3-fold higher than the EC50 at the respective NMDA receptor subtypes; 10 μM Glu was used for GluN1/GluN2A, 3 μMGlu for GluN1/GluN2B and GluN1/GluN2C, and 1 μM Glu for GluN1/GluN2D receptors. Ki values were estimated using the Cheng-Prusoff relationship29 andpreviouslydetermined Glu EC50 values30. IC50 and Ki values are mean ± SEM, nH is the Hillslope, and N is the number of oocytes.

| IC50(μM) | nH | Estimated Ki (μM) | N | |

|---|---|---|---|---|

| GluN1/GluN2A | 15 ± 1 | 1.3 | 4.7 ± 0.1 | 7 |

| GluN1/GluN2B | 29 ± 1 | 1.3 | 10 ± 1 | 5 |

| GluN1/GluN2C | 110 ± 8 | 1.0 | 24 ± 2 | 4 |

| GluN1/GluN2D | 170 ± 10 | 1.3 | 41 ± 3 | 7 |

Pharmacokinetics of Compound 1l in Mice

With the attractive pharmacological profileof 1l in hand, we turned to determine its pharmacokinetics and brain permeation. The pharmacokinetic analysis was performed by 10 mg/kg i.p. injection at five time points between 10 and 240 min. The apparent pharmacokinetic parameters, area under the concentration-time curve from time zero to 240 min (AUC0-240 min), the maximum concentration after dosing (Cmax), time to reach Cmax (tmax) and elimination half-life (t½β) in plasma, liver and brain, calculated from the in vivo data are presented in Table 3. The compound was absorbed from the injection site and concentrations above the Ki value were detected from both plasma and liver. The Kpliver/plasma value was 0.19. Importantly, compound 1l did not exhibit BBBpermeation and was detected only at 30 and 60 min time points with concentrations of 0.3 and 0.1 nmol/g, respectively. We confirmed the poor BBBpermeationusing an in situ mouse brain perfusion technique. The brain concentration of compound 1l followingperfusion with 100 μM of the compound was below the detection limit of our analytical method (5 pmol/g). Moreover, there were no observable changes in the behavior of the mice after 1l injection. This supports our findings from the in vivo pharmacokinetic experiments that 1l is a fullyperipherally restricted NMDA receptor antagonistsuitable for affecting peripheral tumors. In addition to hepatocellular carcinoma, NMDA receptor expression has been reported to be elevated in colon, prostate and breast cancers compared to healthy tissues.18 Moreover, the lack of pharmacological effect in the CNS provides the possibility to utilize the compound as a research tool for investigating the role of peripheral NMDA receptors in other diseasesand/or conditions such as chronic pain.

Table 3.

Pharmacokinetic parameters of compound 1l in plasma, liver and brain calculated from in vivo data after a single dose of 10 mg/kg i.p. in mice.

| Plasma | Liver | Brain | |

|---|---|---|---|

| AUC(0–240min) (nmol/g×min) | 3020 | 575 | 13 |

| Cmax (nmol/g) | 43.4 | 8.7 | 0.3 |

| tmax (min) | 15 | 30 | 30 |

| t½β (min) | 30 | 36 | ND |

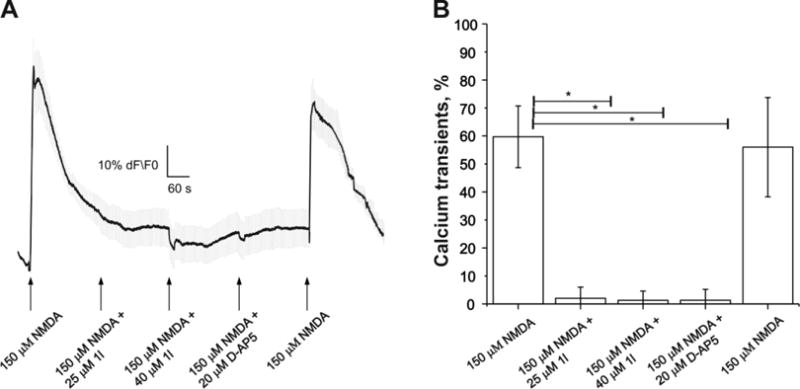

The ability of compound 1l to inhibit NMDA receptor expressed in murine HCC cells

With compound 1l in hand, we proceeded to studies ofits in vitro efficacy in mice. First, we confirmed the expression of the GluN1 NMDA receptor subunit in the murine HCC cell line by Western immunoblotting (data not shown). In order to assess the function of NMDA receptors in the murine HCC cell culture we used calcium imaging (Figure 4). To compare the abilities of 1l and D-AP5 to inhibit NMDA to activation, we measured the intracellular Ca2+ transients induced by 150 μM NMDA alone and in presence of the compound 1l (25 and 41 μM) or D-AP5 (20 μM). Both compounds were able to inhibit NMDA activation significantly in the murine HCC cells suggesting their ability to antagonise the lipid signaling pathway in cancer cells.

Figure 4.

Ca2+ transients via NMDA receptors in murine HCC cells. A) Ca2+ transients in HCC cells activated by NMDA applications (15 s) with and without NMDA receptor antagonists (1l and D-AP5). B) Histogram showing percentage of induced Ca2+ transients in a response to NMDA application and absence of the activation while applied together with 1l at 25 μM 41 μM concentration and D-AP5 at 20 μM concentration. Quantitative data were expressed as mean ± SEM (n=5). The statistical significance was assessed with the Student-paired t test or Mann-Whitney t test for non-parametric data. Statistically significant differences were set at *P < 0.05.

Ability of compound 1l to decrease PGE2 concentration in murine HCC cells

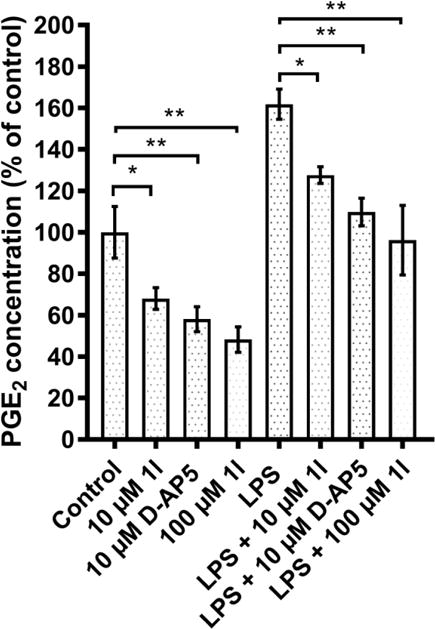

The ability of compound 1l to decreasethe extracellular PGE2 concentration in murine HCC cells was investigated by incubating the cells in 24-well plates for 24 h with 100 μM 1l. In addition, the PGE2 concentration wasmeasured from HCC cells with lipopolysaccharide (LPS) induced inflammation using the same compound 1l concentration and incubation time (Figure 5). Compound 1l significantly decreased the PGE2 concentration in both the presence and absence of LPS, confirming that the compound is able to interfere with the synthesis of PGE2. This inhibition of PGE2 production will reducethe proinflammatory lipid signaling pathway in HCC cells, which has been suggested to down-regulateABC transporters in cancer cells.12,14–16

Figure 5.

The effect of compound 1l and D-AP5 on PGE2 levels in HCC cells. Compounds 1l and D-AP5 at 10 μM and compound 1l at 100 μM reduced the concentration of PGE2 after 24 h incubation to 68± 5 %, 58 ± 6 % and 48 ± 6%, respectively. The addition of LPS (2.5 μg/mL) increased the PGE2 concentration to 162 ± 7 % %, and the addition of compounds 1l and D-AP5 at 10 μM as well as compound 1l at 100 μM prevented the effect of LPS, reducing the PGE2 concentrations to 127 ± 4 %, 110 ± 7 and 96 ± 17, respectively. The data is presented as mean ± SEM, n=3. The statistical significance of differences in PGE2 concentrations between treatments was determined using One-way ANOVA and Tukey`s test. (*P < 0.05, **P< 0.01).

Effect of the compound 1l on transporter expression in mouse HCC cells

Expression levels of Abcb1, Abcg2, Abcc2 and Abcc4 as well as Slc7a5 and Slc2a1 in HCC cells was determined by selected/multiple reaction monitoring (SRM/MRM) analysis in liquid chromatography-tandem mass spectrometry (LCMS-MS),31 following administration of 10 μM 1l and compared to control. Compound 1l reduced the expression levels of Abcb1 and Abcg2 transporters in the crude membrane fraction by 39% and34%, respectively (Table 4). Abcc4 protein expression was reduced by 14%, but the reduction was not statistically significant and, Abcc2 protein expression was below the lower limit of quantification. Interestingly, the expression of Slc2a1 and Slc7a5 transporter proteins was decreased by 42% and 24%, respectively. However, the difference in the case of Slc7a5 was not statistically significant. In all, these findings evidence that NMDA receptor antagonism results in downregulation of ABC transporter expression in HCC cells. In addition, the expression of the two investigated nutrient transporters was reduced significantly. In order to further study the significance of the transporter downregulation, we investigated the cell accumulation of transporter probes and sorafenib.

Table 4.

TheABC transporter expression levels in mouse HCC cell crude membrane fraction measured by SMR/MRM analysis.

| Protein expression level (fmol/μg of total protein)

|

||||||

|---|---|---|---|---|---|---|

| Abcb1 (Pgp) | Abcg2 (Bcrp) | Abcc2 (Mrp2) | Abcc4 (Mrp4) | Slc2a1 (Glut1) | Slc7a5 (Lat1) | |

| Control | 0.64 ± 0.08 | 1.88 ± 0.04 | a | 0.31 ± 0.04 | 22.7 ± 0.84 | 7.55 ± 0.28 |

| 10 μM 1l | 0.39± 0.06* | 1.24± 0.13** | a | 0.27 ± 0.04 | 13.2± 0.53*** | 5.72± 1.61 |

below the lower limit of quantification; The statistical difference between compound 1l-treated cells and the control cells was determined using unpaired two-tailed t-test (*P < 0.05, **P< 0.01, ***P< 0.001). Data are presented as mean ± SEM (n=4).

Ability of NMDA receptor antagonist 1l to alterthe cell accumulation of transporter probes and sorafenib

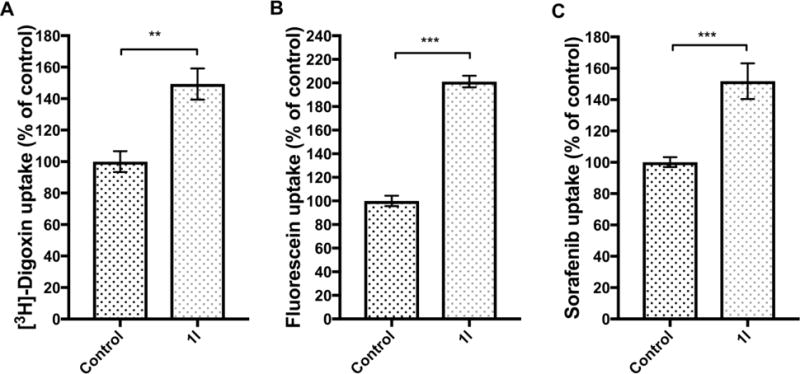

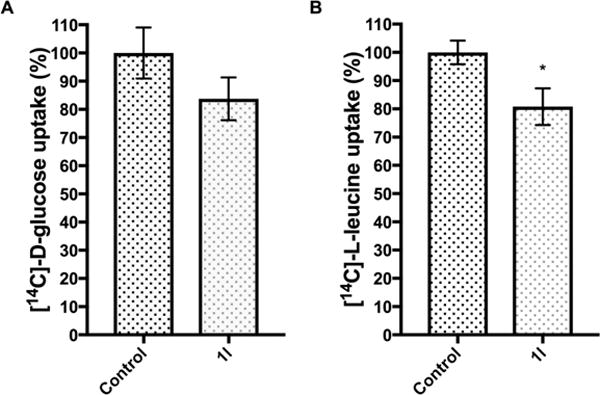

To investigatethe ability of compound 1l to reverse ABC transporter mediated MDR and decrease the uptake of essential nutrients in murine HCC cells, we determined the intracellularaccumulation of known ABC transporter substrates:Abcb1 probe [3H]-digoxin,32 Abcc1-5 probe fluorescein,33 Abcb1 and Abcg2 substrate sorafenib (Figure 6) as well as Slc7a5 substrate [14C]-L-leucine and Slc2a1 substrate [14C]-D-glucose (Figure 7).8–10 The cells were incubated with or without 10 μM of compound 1l in the growth medium for 24 h. Accumulation of theefflux probes in the cells was significantly increased after incubating the cells with compound 1l. In addition, the cell uptake of [14C]-L-leucine was reduced significantly. Therefore, the data provides evidence that the reduced transporter expression levels are significant enough to lead to reduced transporter activity. The riskof compound 1l to interfere with transporter function was minimized by washing the cells before uptake experiments. Thus, the increased cell accumulation of transporter probes is not likely due to compound 1l acting as a transporter inhibitor, but as a modulator of transporter expression.

Figure 6.

The effect of compound 1l on cell accumulation of efflux probes [3H]-digoxin, fluorescein and sorafenib. The incubation of the HCC cells with 10 μM compound 1l increased the cell accumulation of (A) [3H]-digoxin, (B) fluorescein and (C) sorafenib to 149 % ±10 %, 201 % ±9 % and 152 % ± 11 %, respectively. The analyte concentrations are normalized by the amount of protein in each sample. The statistical difference between compound 1l-treated cell and the control cells was determined using unpaired two-tailed t-test (**P< 0.01, ***P < 0.001). Data are presented as mean ± SEM (n=3).

Figure 7.

The effect of compound 1l on cell accumulation of Slc2a1 and Slc7a5 transportersubstrates [14C]-D-glucose and [14C]-L-leucine. The incubation of the HCC cells with 10 μM compound 1l reduced the cell accumulation of (A)[14C]-D-glucose and (B)[14C]-L-leucineto 84 % ±8 % and 81 % ±6 %, respectively. The analyte concentrations are normalized by the amount of protein in each sample. The statistical difference between compound 1l-treated cell and the control cells was determined using unpaired two-tailed t-test (*P< 0.05). Data are presented as mean ± SEM (n=4).

Effect of compound 1l on sorafenib cytotoxicity in mouse HCC cells

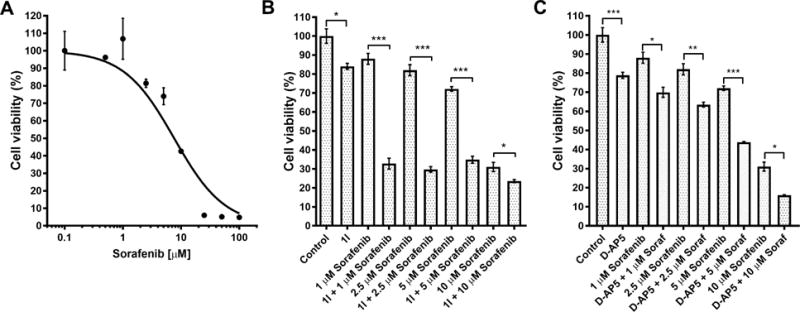

Thehalf maximal inhibitory concentration (IC50) value of sorafenib on HCC cell viability was investigated at 72 h using concentration range from 0.1 to 200 μM (Figure 8A) The effect of 1l on HCC cell proliferation and the possible potentiating effect on sorafenib cytotoxicity were evaluated by incubating the HCC cells for 72 h atdifferent sorafenib concentrations with and without a 100 μM concentration of 1l (Figure 8B). Interestingly, 1l significantlyaugmented the efficacy of sorafenib at 1, 2.5 and 5 μM concentrations. At 10 μM sorafenib concentration, NMDA receptor antagonist 1l also augmentedsorafenib efficacy, although the effect was less pronounced. On its own the NMDA antagonist 1l was only able to reduce HCC cell proliferation slightly. In addition, D-AP5 had potentiating effect on sorafenib cytotoxicity at all sorafenib concentrations investigated (Figure 8C). Previously it was shown that at above 100 μM concentrations a non-competitive NMDA receptor antagonist has antiproliferative effects on HCC cells affecting the FOXO/TXNIPpathway. Therefore, the antiproliferative effect of 1l alone is likely mediated via the same pathway. However, as sorafenib exerts its effect through the RAF/MEK/ERK pathway,34 the potentiating effect of 1l is more likely mediated through the lipid signaling pathway and downregulation of efflux transporter expression.

Figure 8.

A) Concentration-dependent antiproliferative efficacy of sorafenib in HCC cells after 72 h. IC50 value was 7.4 ± 1.7 μM. Ability of compound 1l to potentiate the cytotoxic efficacy of sorafenib in mouse HCC cells. B) The potentiating effect of compound 1l on sorafenib antiproliferative efficacy in murine HCC cells. Compared to sorafenib effect alone, the cell viability was further reduced in the presence of 100 μM compound 1lfrom 88 ± 3 % to 33 ± 3 %,82 ± 3 % to 30 ±2 %, 72 ± 1 % to 35 ±2 % and from 31 ± 2 % to 24 ± 1 %, at 1 μM, 2.5 μM, 5 μM and 10 μM sorafenib, respectively. Compound 1l at 100 μM without sorafenib was able to reduce the cell viability to 84 ± 2 %. C) The potentiating effect of D-AP5 on sorafenib antiproliferative efficacy in murine HCC cells. The cell viability wasreduced to 70 ± 3 %, 63 ± 1 %, 44 ± 1 % and 16 ± 1 %, in combination of 100 μM D-AP5and1 μM, 2.5 μM, 5 μM and 10 μM sorafenib, respectively. D-AP5 at 100 μM without sorafenib was able to reduce the cell viability to 79 ± 2 %. The remaining viability is presented as mean ± SEM (n = 3˗6). The statistical difference between groups were determined by one-way ANOVA followed by Tukey`s multiple comparison test (*P< 0.05,**P < 0.01,***P < 0.001).

Conclusion

Starting from the broad-acting iGluR antagonist 1a, we have developed apotent and selective competitive NMDA receptor antagonist, compound 1l, which action is restricted to peripheral tissues and which displays good drug-like properties. Application of 1l to murine HCC cells reduced the intracellular concentration of PGE2 and thereby interferedwith the proinflammatory lipid signaling pathway resulting in downregulation of MDR transporters. It was subsequentlyshown that 1l augmentscell accumulation of MDR transporter substrates and that cell accumulation of the HCC anti-cancer agentand ABC transporter substrate sorafenib was significantly increased leading to augmentedcytotoxic efficacy. Another important finding was the significant downregulation of nutrient transporters, which are essential for the rapid growth of cancer cells. In summary, this proof-of-conceptstudy demonstrates that competitive NMDA receptor antagonistsrepresenta novel and promisingstrategy to reverseMDRinperipheral solid tumors, such as HCC.

Experimental Section

Chemistry

All reagents were obtained from commercial suppliers and used without further purification. Dry solvents were obtained differently. THF was distilled over sodium/benzophenone. Et2O was dried over neatly cut sodium. All solvents were tested for water content using a Carl Fisher apparatus. Water - or air sensitive reactions were conducted in flame dried glassware under nitrogen with syringe-septum cap technique. Purification by DCVC (dry columnvacuum chromatography) was performed with silica gel size 25–40μm (Merck, Silica gel 60). For TLC, Merck TLC Silica gel F254 plateswere used with appropriatespray reagents: KMnO4 or Molybdenum blue. 1H NMR and 13C NMR spectrawere obtained on a Varian Mercury Plus (300 MHz) and a Varian Gemini 2000 instrument (75 MHz), respectively, unless otherwise noted. Dioxane was used as internal reference for NMR spectra run in D2O. Preparative HPLC was performed using either a Spectraseries UV100 detector with a JASCO 880-PU HPLC pump and an XTerra®Prep MS C18 (10μm, 10×300 mm) column or an Agilent Prep HPLC system, equipped with a 1100 series pump, a 1200 seriesmultiplewavelength detector, and aZorbax 300 SB-C18 (21.2 × 250 mm,7 μm) column. LC-MS was performed using an Agilent 1200 HPLCsystem coupled to an Agilent 6400 triple quadrupole mass spectrometer equipped with an electrospray ionizationsource. A Zorbax Eclipse XDB-C18 (4.6 × 50 mm) column and gradients of 10% aqueous acetonitrile + 0.05% formic acid (buffer A) and 90% aqueous acetonitrile + 0.046% formic acid (buffer B) were employed. Optical rotation was measured using a Perkin-Elmer 241 spectrometer, with a Na lamp at 589 nm. Melting points were measured using anautomated melting point apparatus, MPA100 OptiMelt (SRS) and are uncorrected. Compounds were dry either under high vacuum or freeze dried usinga Holm & Halby, Heto LyoPro 6000 freeze drier. Compounds for pharmacological characterization were all with a purity of >95%, determined by HPLC (254 nM).

(2S,3R)-2-Carboxy-3-(3-chlorophenyl)pyrrolidin-1-ium chloride (1d)

Acid 7d (120 mg, 0.37 mmol, 1.0 equiv) was dissolved in a 1:1 mixture of TFA:DCM (7.2 mL). The reaction mixture was allowed to stir for 1 hour at rt, then evaporated to dryness under reduced pressure. The solid was dissolved in 1M HCl (2 mL) and evaporated to dryness (3×) to give the crude product, which was recrystallized from MeOH/CHCl3 to afford the title compoundas white needles (17 mg, 18%).1H NMR (CDCl3) δ (two rotamers) 9.64 (br s, 1H), 7.27–7.22 (m, 3H), 7.15–7.13 (m, 1H), 4.40 (d, J = 5.5 Hz, 0.4H), 4.25 (d, J = 6.5 Hz, 0.6H), 3.79–3.44 (m, 3H), 2.38–2.28 (m, 1H), 2.06–1.96 (m, 1H), 1.49 (s, 4H), 1.42 (s, 5H).13C NMR (CDCl3) δ (two rotamers) 177.6, 175.7, 155.2, 153.7, 142.9, 142.4, 134.6, 130.1, 127.5, 127.4, 127.1, 125.2, 81.2, 80.1, 65.4, 64.9, 49.4, 47.5, 46.1, 45.9, 32.7, 32.2, 28.3, 28.2. MS (m/z) calcd. for C11H13ClNO2 [M+H]+ 226.1, found 226.1..Mp: decomposition.

(2S,3R)-2-Carboxy-3-(3-(trifluoromethyl)phenyl)pyrrolidin-1-ium chloride (1e)

Compound 7e (135 mg) was dissolved in a 1:1 mixture TFA:DCM (7.0 mL). The reaction mixture was allowed to stir for 1h at rt, then the solvent was evaporated under reduced pressure. The crude was dissolved in HCl 1M (30 mL) and the solvent was evaporated to afford the corresponding HCl salt (63 mg) as a white solid. The compound was recrystallized from MeOH/CHCl3 to afford the title compound as a white powder (51 mg, 46%). 1H NMR (CDCl3) δ (two rotamers) 9.64 (br s, 1H), 7.27–7.22 (m, 3H), 7.15–7.13 (m, 1H), 4.40 (d, J = 5.5 Hz, 0.4H), 4.25 (d, J = 6.5 Hz, 0.6H), 3.79–3.44 (m, 3H), 2.38–2.28 (m, 1H), 2.06–1.96 (m, 1H), 1.49 (s, 4H), 1.42 (s, 5H). 13C NMR (CDCl3) δ (two rotamers) 177.6, 175.7, 155.2, 153.7, 142.9, 142.4, 134.6, 130.1, 127.5, 127.4, 127.1, 125.2, 81.2, 80.1, 65.4, 64.9, 49.4, 47.5, 46.1, 45.9, 32.7, 32.2, 28.3, 28.2. MS (m/z) calcd. forC12H13F3NO2 [M+H]+295.06, found 295.1. [α]25D +58.9 (c= 0.38, MeOH). Mp: 180.7–182.5 °C.

(2S,3R)-3-(3-Aminophenyl)pyrrolidine-2-carboxylic acid dihydrochloride (1f)

Acid 7f (41 mg, 0.101 mmol, 1 equiv) was dissolved in a 1:1 mixture TFA:DCM (2.0 mL). The reaction mixture was allowed to stir for 1.5h at rt, then the solvent was evaporated under reduced pressure. The oily residue was dissolved in 1M HCl (10 mL) and the solvent was evaporated (3×) to give the crude product, which was recrystallized from MeOH/CHCl3 to afford the title compound as a white solid (22 mg, 78%).1H NMR (MeOD) δ 7.58 – 7.31 (m, 3H), 7.31 (d, J = 7.2 Hz, 1H), 4.45 (d, J = 9.1 Hz, 1H), 3.77 – 3.58 (m, 2H), 3.57 – 3.42 (m, 1H), 2.66 – 2.49 (m, 1H), 2.36 – 2.17 (m, 1H).13C NMR (CDCl3) δ 168.5, 144.4, 140.6, 131.18, 131.17, 124.8, 118.6, 66.7, 49.6, 46.8, 34.4. MS (m/z) calcd. for C11H15N2O2 [M+H]+ 207.1, found 207.1.[α]25D +62.7° (c= 0.22, MeOH). Mp: decomposition.

(2S,3R)-3-(3-Cyanophenyl)pyrrolidine-2-carboxylic acid hydrochloride (1g)

Acid 7g (65 mg, 0.205 mmol, 1 equiv) was dissolved in a 1:1 mixture of TFA:DCM (2.0 mL). The reaction mixture was allowed to stir for 3 hours at rt, then the solvent was evaporated under reduced pressure. The oily residue was dissolved in HCl 1M (10 mL) and evaporated to dryness (3×) to afford the title compound as a white solid (42 mg, 81%). 1H NMR (D2O) δ 7.82 (t, J = 1.6 Hz, 1H), 7.78 – 7.70 (m, 2H), 7.59 (t, J = 7.8 Hz, 1H), 4.44 (d, J = 9.9 Hz, 1H), 3.80 – 3.68 (m, 2H), 3.57 (ddd, J = 11.8, 10.3, 6.9 Hz, 1H), 2.61 (dtd, J = 10.5, 7.1, 3.3 Hz, 1H), 2.35 – 2.22 (m, 1H).13C NMR (D2O+dioxane) δ 171.4, 140.3, 133.4, 132.5, 132.1, 130.5, 120.0, 112.3, 65.41, 48.0, 46.4, 33.4. LC-MS (m/z) calcd. for C12H13N2O2 [M+H]+ 217.10, found 217.0. Mp: 210.8–212.9 °C.

(2S,3R)-3-(3-Carbamoylphenyl)-2-carboxypyrrolidin-1-ium chloride (1h)

H2O2 (4.23 mmol, 0.43 mL of 30% solution in H2O, 6 equiv.) was added dropwise to a solution of 7g (223 mg, 0.71 mmol, 1.0 equiv.) and K2CO3 (390 mg, 2.82 mmol, 4 equiv.) in EtOH:H2O (1:1,4.86 mL). The reaction mixture was stirred at rt for 70 min, then slowly acidified with 1M HCl. The aqueous phase was extracted with EtOAc (3 × 10 mL) and the combined organic layers washed with brine (10 mL), dried over MgSO4 and concentrated to give a pale yellow solid. The crude was dissolved in DCM (5.8 mL) and TFA (5.8 mL) was added. The reaction mixture was stirred for 2 hours at rt. The solvent was evaporated and the oily residue was dissolved in 1M HCl and evaporated to dryness (3 × 10 mL). The crude pink solid was recrystallized from H2O/Acetone to afford the title compound as a white solid (95 mg, 59% over two steps).1H NMR (D2O) δ 7.85 (d, J = 1.6 Hz, 1H), 7.83 – 7.77 (m, 1H), 7.70 – 7.65 (m, 1H), 7.59 (t, J = 7.7 Hz, 1H), 4.38 (d, J = 9.7 Hz, 1H), 3.77 – 3.67 (m, 2H), 3.64 – 3.52 (m, 1H), 2.61 (dtd, J = 13.9, 7.1, 3.4 Hz, 1H), 2.39 – 2.25 (m, 1H).13C NMR (D2O) δ 173.4, 172.3, 139.9, 134.1, 132.2, 130.1, 127.4, 127.2, 66.1, 48.7, 46.3, 33.7. LC-MS (m/z) calcd. for C12H15N2O3 [M+H]+ 235.1, found 235.1. Mp: decomposition.

(2S,3R)-3-(3-Boronophenyl)pyrrolidine-2-carboxylic acid hydrochloride (1i)

To a solution of 7i (50 mg, 0.120 mmol, 1.0 equiv.) in acetone (9.4 mL) was added 0.1M NH4OAc (27.7 mg, 0.36 mmol, 3.0 equiv, in H2O) and NaIO4 (76.8 mg, 0.36 mmol, 3 equiv). The reaction mixture was stirred for 48 hours at rt. Acetone was removed under reduced pressure and the aqueous layer diluted with 2M NaOH (4 mL) and washed with EtOAC, The aqueous phase was then acidified with 1M HCl until pH~3 and extracted with EtOAc (4 × 5 mL). The combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to dryness. The crude product was dissolved in DCM (1.0 mL) and TFA (1.0 mL) and the reaction mixture stirred for 2.5h at rt. The solvents were evaporated and the oily residue was dissolved in 1M HCl and evaporated to dryness (3 × 10 mL) to give an off-white solid, which was recrystallized from H2O/acetone to give the title compound as an off-white solid (13 mg, 43% over two steps).1H NMR (D2O) δ 7.80 – 7.72 (m, 2H), 7.58 – 7.46 (m, 2H), 4.41 (d, J = 9.8 Hz, 1H), 3.75 – 3.65 (m, 2H), 3.56 (ddd, J = 11.7, 10.3, 6.9 Hz, 1H), 2.57 (dtd, J = 13.9, 7.1, 3.4 Hz, 1H), 2.38 – 2.20 (m, 1H).13C NMR (D2O+dioxane) δ 171.4, 137.9, 133.1, 132.6, 130.1, 128.7, 65.2, 48.2, 45.8, 33.1. LC-MS (m/z) calcd. for C11H15BNO4 [M+H]+ 236.1, found 236.1. Mp: decomposition.

(2S,3R)-3-(3,4-Dihydroxyphenyl)pyrrolidine-2-carboxylic acid (1j)

In a flame-dried flask a solution of 7j (70 mg, 0.21 mmol, 1.0 equiv) in dry DCM (3 mL) was cooled to 0°C. A 1M solution of BBr3 (in DCM) (0.53 mL, 0.522mmol, 2.5 equiv) was added dropwise and the reaction mixture was allowed to stir 3hat rt. The reaction mixture was quenched with H2O (1 mL) and the solvent evaporated. The crude product was purified by prep. HPLC and then recrystallized from MeOH to afford the title compound as a white solid (3.8 mg, 8% yield).1H NMR (CDCl3) δ 6.89 - 6.94 (m, 2H), 6.79 - 6.86 (m, 1H), 4.02 (d, J = 9.03 Hz, 1H), 3.54 - 3.62 (m, 1H), 3.36 - 3.51 (m, 2H), 2.43 (dtd, J = 3.64, 6.73, 13.52 Hz, 1H), 2.09 - 2.23 (m, 1H). MS (m/z) calcd. for C11H13NO4 [M+H]+ 224.09, found 224.1.

(2S,3R)-2-Carboxy-3-(3-carboxy-4-fluorophenyl)pyrrolidin-1-ium chloride (1k)

Acid 7k (85 mg, 0.24 mmol, 1 equiv) was dissolved in a 1:1 mixture TFA:DCM (4.66 mL). The reaction mixture was allowed to stir for 2h at rt, then the solvent was evaporated under reduced pressure. The oily residue was dissolved in HCl 1M (10 mL) and the solvent was evaporated (3×) to afford the title compound as a white solid (42 mg, 60%). 1H NMR (D2O, 400 MHz) δ 7.97 (dd, J = 6.9, 2.6 Hz, 1H), 7.69 (ddd, J = 8.6, 4.6, 2.5 Hz, 1H), 7.31 (dd, J = 11.0, 8.6 Hz, 1H), 4.36 (d, J = 9.7 Hz, 1H), 3.77 – 3.66 (m, 2H), 3.57 (ddd, J = 11.8, 10.2, 6.9 Hz, 1H), 2.59 (dtd, J = 13.9, 7.0, 3.3 Hz, 1H), 2.29 (dtd, J = 13.4, 10.4, 8.2 Hz, 1H).13C NMR (D2O) δ 172.0, 168.4, 162.5, 160.8, 135.34, 135.31, 135.2, 135.1, 131.5, 119.2, 119.1, 118.2, 118.1, 67.2, 65.9, 47.8, 46.3, 33.5. MS (m/z) calcd. for C12H13FNO4 [M+H]+ 254.1, found 254.1. Mp: 196.8→dec.

(2S,3R)-3-(3-Carboxy-4-chlorophenyl)pyrrolidine-2-carboxylic acid hydrochloride (1l)

Diacid 7l (190 mg, 0.514 mmol, 1 equiv) was dissolved in a 1:1 mixture TFA:DCM (10 mL). The reaction mixture was allowed to stir for 2 hours at rt, then the solvent was evaporated under reduced pressure. The oily residue was dissolved in 1M HCl (10 mL) and the solvent was evaporated (3 times) to afford the corresponding HCl salt (135 mg). The crude product was recrystallized from H2O/acetone to afford the title compound as an off-white solid (89 mg, 56%). 1H NMR (D2O) δ 7.85 (d, J = 1.8 Hz, 1H), 7.68 – 7.49 (m, 2H), 4.37 (d, J = 9.7 Hz, 1H), 3.71 (ddd, J = 11.8, 9.2, 5.1 Hz, 2H), 3.62 – 3.52 (m, 1H), 2.60 (dtd, J = 13.9, 7.1, 3.4 Hz, 1H), 2.35 – 2.23 (m, 1H). 13C NMR (D2O) δ 171.9, 170.7, 138.3, 132.6, 131.9, 131.8, 131.7, 130.3, 65.7, 47.8, 46.2, 33.4. MS (m/z) calcd. for C12H13ClNO4 [M+H]+ 270.0, found 270.0. Mp 239.4–241.3 °C.

(2S,3R)-3-(3-Carboxy-4-methylphenyl)pyrrolidine-2-carboxylic acid hydrochloride (1m)

A solution of NaIO4 (638 mg, 2.98 mmol, 8.2 equiv) and RuCl3·xH2O (4.5 mg, 0.022 mmol, 0.06 equiv) in H2O (4.5 mL) was added to a solution of 6m (117 mg, 0.36 mmol) in MeCN:EtOAc (1:1, 5.2 mL) cooled to 0 °C. The reaction mixture was stirred for 30 min and then filtered through celite and the filter cake washed with EtOAc. The aqueous layer was extracted with EtOAc and the combined organic layers were washed with brine, dried over MgSO4 and concentrated to give the corresponding di-acid, which was used without further purification. The diacid 7m was dissolved in a 1:1 mixture of TFA:DCM (6.0 mL), and the reaction mixture allowed to stir for 2.5h at rt, then the solvent was evaporated under reduced pressure. The oily residue was dissolved in 1M HCl (10 mL) and evaporated to dryness (3×). The crude product was purified by preparative HPLC (0 to 40% B in A) and then evaporated with 1M HCl (3 × 1 mL) to afford the title compound, as a white solid (21 mg, 20% over two steps). 1H NMR (600 MHz, D2O) δ 7.78 (d, J = 2.0 Hz, 1H), 7.45 (dd, J = 7.9, 2.1 Hz, 1H), 7.29 (d, J = 7.9 Hz, 1H), 4.39 (d, J = 9.8 Hz, 1H), 3.69 – 3.61 (m, 2H), 3.51 (ddd, J = 11.7, 10.2, 6.9 Hz, 1H), 2.50 (dtd, J = 10.5, 7.1, 3.2 Hz, 1H), 2.44 (s, 3H), 2.25 – 2.17 (m, 1H). 13C NMR (151 MHz, D2O) δ 171.54, 170.63, 139.15, 135.72, 132.31, 131.28, 130.16, 129.04, 64.56, 47.25, 45.81, 32.82, 20.04. MS (m/z) calcd. for C13H16NO4 [M+H]+ 250.3, found 250.3. Mp: decomposition.

(2S,3R)-3-(3-Carboxy-4-bromophenyl)pyrrolidine-2-carboxylic acid hydrochloride (1n)

1H NMR (600 MHz, D2O) δ 7.67 (d, J = 8.3 Hz, 1H), 7.63 (d, J = 2.3 Hz1H), 7.36 (dd, J = 8.3, 2.4 Hz, 1H), 4.18 (d, J = 9.4 Hz, 1H), 3.61–3.54 (m, 1H), 3.48–3.43 (m, 1H), 2.51–2.46 (m, 1H), 2.21–2.14 (m, 1H). 13C NMR (600 MHz, D2O) δ 171.9, 171.6, 138.6, 134.8, 134.2, 131.4, 128.8, 118.4, 65.6, 47.5, 45.6, 32.8, MS (m/z) calcd. forC12H12BrNO4 [M+H]+312.9 & 314.9, found 313.9 & 315.9. Mp:250.1–257.3 °C.

5-Bromo-2-methylbenzyl)oxy)(tert-butyl)dimethylsilane (3m)

To a flame-dried round bottom flask was charged with5-bromo-2-methylphenyl)methanol35 (4.34 g, 21.6 mmol), anhydrous DMF (50 mL), imidazole (4.41 g, 64.8 mmol), TBSCl (6.51 g, 43.2 mmol) and DMAP (264 mg, 2.16 mmol). The reaction mixture was stirred for 16h at rt and subsequently diluted with EtOAc. The resulting mixture was washed twice with 1M HCl, twice with brine, dried over MgSO4, filtered and concentrated in vacuo. The crude product was purified by consecutive flash chromatography (heptane:EtOAc, 2:1 and 5:1), to provide title compound as a clear oil (4.63 g, 68%). 1H NMR (600 MHz, CDCl3) δ 7.56 (d, J = 2.0 Hz, 1H), 7.27 (dd, J = 8.0, 2.2 Hz, 1H), 6.98 (d, J = 8.0 Hz, 1H), 4.65 (s, 2H), 2.19 (s, 3H), 0.95 (s, 9H), 0.11 (s, 6H). 13C NMR (151 MHz, CDCl3) δ 141.60, 133.72, 131.50, 129.77, 129.30, 119.78, 62.76, 26.09, 18.56, 18.16, −5.17. Rf 0.84 (heptane:EtOAc, 1:1).

tert-Butyldimethyl((2-methyl-5-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)benzyl)oxy)silane (3n)

A dry, Ar-filled 20 mL vial was charged with bromine 3m (419 mg, 1.33 mmol), (Bpin)2 (354 mg, 1.40 mmol), KOAc (394 mg, 4.06 mmol) and (PPh3)2PdCl2 (46.9 mg, 66.5 μmol). The vialwas then evacuated and backfilled with Ar, followed by addition of degassed dioxane (13.2 mL). The vial was capped with a screw cap and stirred for 16h at 100 °C. The reaction mixture was then diluted with EtOAc and washed three times with H2O. The organic partition was washed with brine, dried over MgSO4, filtered through celite and evaporated. The crude product was purified by DCVC (heptane:EtOAc, 10:1) to yield the title compound (407 mg, contains 5 mol% PPh3) which was used without further purification.1H NMR (600 MHz, CDCl3) δ 7.76 (s, 1H), 7.62 (dd, J = 7.4, 1.0 Hz, 1H), 7.15 (d, J = 7.5 Hz, 1H), 4.70 (s, 2H), 2.34 (s, 3H), 1.33 (s, 12H), 0.93 (s, 9H), 0.09 (s, 6H). 13C NMR (151 MHz, CDCl3) δ 139.94, 138.40, 134.16, 134.03, 129.75, 83.71, 64.14, 26.11, 25.01, 19.19, 18.57, −5.11. Rf 0.54 (heptane:EtOAc, 10:1).

(2S,3R)-tert-Butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-3-(3-(ethoxycarbonyl)phenyl)-5-oxopyrrolidine-1-carboxylate (4a)

[Rh(cod)Cl]2 (37.6 mg, 0.076 mmol, 0.05 equiv), (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (500 mg, 1.53 mmol, 1.0 equiv) and (3-(ethoxycarbonyl)phenyl)boronic acid (3a, 474 mg, 2.44 mmol, 1.6 equiv) were placed in a 50 mL flask which was evacuated and backfilled with N2. Degassed dioxane (13.0 mL) was added and to the stirred clear solution, 1M NaOH (2.44 mL, 1.6 equiv, degassed water) was added dropwise. The reaction mixture was stirred at rt for 4.5 hours. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 15 mL). The combined organic layers were washed with brine (1 × 20 mL), dried over MgSO4 and concentrated to give 743 mg. The crude product was purified by flash chromatography (heptanes:EtOAc, 9:1) to afford the title compound as an off-white solid (382 mg, 52%). 1H NMR (CDCl3) δ 7.95 (dt, J = 7.4, 1.6 Hz, 1H), 7.87 (s, 1H), 7.39 (tt, J = 4.6, 3.3 Hz, 2H), 4.38 (q, J = 7.1 Hz, 2H), 4.09 (dt, J = 4.0, 2.1 Hz, 1H), 4.01 (dd, J = 10.6, 3.9 Hz, 1H), 3.82 (dd, J = 10.5, 2.2 Hz, 1H), 3.54 (dt, J = 9.6, 2.4 Hz, 1H), 3.17 (dd, J = 17.9, 9.6 Hz, 1H), 2.53 (dd, J = 17.9, 2.8 Hz, 1H), 1.53 (s, 9H), 1.39 (t, J = 7.1 Hz, 3H), 0.91 (s, 9H), 0.08 (s, 3H), 0.07 (s, 3H). 13C NMR (CDCl3) δ 173.7, 166.4, 150.0, 144.6, 131.4, 130.6, 129.4, 128.5, 128.0, 83.3, 66.6, 63.7, 61.3, 40.1, 38.8, 28.2, 26.0, 18.3, 14.5, -5.3. LC-MS (m/z) calcd. for C25H39NO6Si [M+H]+ 478.2, found 378.2 [(M+H)-Boc]+. Rf 0.25 (heptanes:EtOAc, 8:2).

(2S,3R)-tert-Butyl 3-(3-bromophenyl)-2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxopyrrolidine-1-carboxylate (4b)

To a solution at rt of (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (1.0 g, 3.05 mmol, 1.0 equiv) and (3-bromophenyl)boronic acid (3b, 981 mg, 4.89 mmol, 1.6 equiv) in degassed THF (26.3 mL) under nitrogen was added [Rh(cod)Cl]2 (75.3 mg, 0.153 mmol, 0.05 equiv). A 1M NaOH (4.9 mL, 1.6 equiv) solution was then added dropwise and the reaction mixture stirred at rt for 4 hours. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 15 mL). The combined organic layers were washed with brine (1 × 20 mL), dried over MgSO4 and concentrated to give 1.56 g. The crude product was purified by flash chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a white solid (803 mg, 54%). 1H NMR (CDCl3,400 MHz) δ 7.40 (ddd, J = 7.9, 1.9, 1.0 Hz, 1H), 7.34 (t, J = 1.8 Hz, 1H), 7.21 (t, J = 7.8 Hz, 1H), 7.14 – 7.09 (m, 1H), 4.06 (dt, J = 3.9, 2.0 Hz, 1H), 3.99 (dd, J = 10.5, 3.9 Hz, 1H), 3.80 (dd, J = 10.5, 2.2 Hz, 1H), 3.42 (dt, J = 9.6, 2.2 Hz, 1H), 3.14 (dd, J = 17.9, 9.6 Hz, 1H), 2.50 (dd, J = 17.9, 2.6 Hz, 1H), 1.53 (s, 9H), 0.91 (s, 9H), 0.08 (s, 3H), 0.07 (s, 3H). 13C NMR (CDCl3, 400 MHz) δ 173.6, 150.0, 146.6, 130.8, 130.5, 129.9, 125.0, 123.2, 83.4, 66.6, 63.8, 39.94, 38.7, 28.2, 26.0, 18.3, −5.3, −5.4. Rf 0.21 (heptanes:EtOAc, 9:1).

(2S,3R)-tert-Butyl-2-(((tert-butyldimethylsilyl)oxy)methyl)-3-(3-chlorophenyl)-5-oxopyrrolidine-1-carboxylate (4d)

To a solution of (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (500 mg, 1.53 mmol, 1.0 equiv) and (3-chlorophenyl)boronic acid (3d, 382 mg, 2.44 mmol, 1.6 equiv) in THF:H2O (9:1, 15 mL) under nitrogen at rt, was added [Rh(cod)Cl]2 (37.6 mg, 0.076 mmol, 0.05 equiv). Then, NaOH 1M (2.5 mL, 1.6 equiv) was added dropwise and the reaction mixture was stirred at rt for 4.5h. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 15 mL). The combined organic layers were washed with brine (1 × 20 mL), dried over MgSO4 and concentrated to give 690 mg. The crude product was purified by flash chromatography (heptanes:EtOAc, 4:1) to afford the title compound as a white solid (387 mg, 58%). 1H NMR (CDCl3) δ 7.55–7.38 (m, 4H, Ar-H), 4.09 (m, 1H, CH-N), 4.01 (m, 1H), 3.83 (dd, J = 10.5, 2.3 Hz, 1H), 3.54 (dt, J = 9.5, 2.3 Hz, 1H), 3.20 (dd, J = 17.9, 9.7 Hz, 1H), 2.53 (dd, J = 17.8, 2.5 Hz, 1H), 1.54 (s, 9H), 0.92 (s, 9H), 0.09 (s, 3H), 0.08 (s, 3H). 13C NMR (CDCl3) δ 173.3, 149.8, 145.1, 131.3 (q, J =32 Hz, C-CF3), 129.7, 129.4, 124.0 (q, J =3.7 Hz, C-Ar), 123.9 (q, J =270 Hz, CF3), 123.6 (q, J = 3.7, C-Ar), 83.3, 66.3, 63.3, 39.8, 38.7, 28.0, 25.8, 18.1, −5.5, −5.6. LC-MS (m/z) calcd. for C22H35ClNO4Si [M+H]+ 440.2, found 340.1 [(M+H)-Boc]+. [α]25D −26.5 (c= 0.27, MeOH). Mp: 71.4–73.9 °C. Rf 0.29 (heptanes:EtOAc, 9:1).

(2S,3R)-tert-Butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-3-(3-(trifluoromethyl)phenyl)pyrrolidine-1-carboxylate (4e)

To a solution of (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (1.0 g, 3.053 mmol, 1 equiv) and commercially available (3-(trifluormomethyl)phenyl)boronic acid (3e, 928 mg, 4.89 mmol, 1.6 equiv) in THF:H2O (9:1, 30.0 mL) under nitrogen at rt, was added [Rh(cod)Cl]2 (75.3 mg, 0.153 mmol, 0.05 equiv). Then, NaOH 1M (5.0 mL, 1.6 equiv) was added dropwise and the reaction mixture was stirred at rt for 4 hours. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 20 mL). The combined organic layers were washed with brine (1 × 30 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a white solid (727 mg, 56%). 1H NMR (CDCl3) δ 7.55–7.38 (m, 4H), 4.09 (m, 1H), 4.01 (m, 1H), 3.83 (dd, J = 10.5, 2.3 Hz, 1H), 3.54 (dt, J = 9.5, 2.3 Hz, 1H), 3.20 (dd, J = 17.9, 9.7 Hz, 1H), 2.53 (dd, J = 17.8, 2.5 Hz, 1H), 1.54 (s, 9H), 0.92 (s, 9H), 0.09 (s, 3H), 0.08 (s, 3H).13C NMR (CDCl3) δ 173.3, 149.8, 145.1, 131.3 (q, J =32 Hz), 129.7, 129.4, 124.0 (q, J =3.7 Hz), 123.9 (q, J =270 Hz), 123.6 (q, J = 3.7 Hz), 83.3, 66.3, 63.3, 39.8, 38.7, 28.0, 25.8, 18.1, −5.5, −5.6. LC-MS (m/z) calcd. for C23H35F3NO4Si [M+H]+ 474.2, found 374.1 [(M+H)-Boc]+. [α]25D -26.4 (c= 0.32, MeOH). Mp: 95.3–96.9 °C. Rf 0.29 (heptanes:EtOAc, 9:1).

(2S,3R)-tert-Butyl 3-(3-((tert-butoxycarbonyl)amino)phenyl)-2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxopyrrolidine-1-carboxylate (4f)

[Rh(cod)Cl]2 (37.6 mg, 0.076 mmol, 0.05 equiv), (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (500 mg, 1.53 mmol, 1.0 equiv) and 3-(tert-butoxycarbonylamino)boronic acid (3f, 579 mg, 2.44 mmol, 1.6 equiv) were placed in a 50 mL flask which was evacuated and backfilled with N2. Degassed dioxane (13.0 mL) was added followed by dropwise addition of 1M NaOH (2.44 mL, 1.6 equiv, degassed water). The reaction mixture was stirred at rt for 3.5h. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 15 mL). The combined organic layers were washed with brine (1 × 20 mL), dried over MgSO4 and concentrated to give 743 mg. The crude product was purified by flash chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a pale yellow oil (471 mg, 59% yield). 1H NMR (CDCl3) δ 7.19 - 7.30 (m, 3H), 6.82 - 6.90 (m, 1H), 6.49 (s, 1H), 4.07 - 4.12 (m, 1H), 4.02 (dd, J = 3.51, 10.54 Hz, 1H), 3.80 (dd, J = 1.88, 10.67 Hz, 1H), 3.43 (td, J = 1.88, 9.54 Hz, 1H), 3.15 (dd, J = 9.54, 17.82 Hz, 1H), 2.50 (dd, J = 2.26, 17.82 Hz, 1H), 1.52 (s, 9H), 0.91 (s, 9H), 0.08 (s, 3H), 0.07 (s, 3H).13C NMR (CDCl3) δ 174.1, 152.6, 149.9, 145.4, 138.9, 129.7, 120.7, 117.2, 116.6, 83.0, 80.7, 66.6, 63.8, 40.2, 38.9, 28.3, 28.1, 25.8, 18.2, −5.5. LC-MS (m/z) calcd. for C27H45N2O6Si [M+H]+ 521.3, found 365.2 [(M+H)-Boc -t-Bu]. [α]25D −19.8 (c= 0.55, MeOH). Rf 0.28 (heptanes:EtOAc, 8:2).

(2S,3R)-tert-Butyl 3-(benzo[d][1,3]dioxol-5-yl)-2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxopyrrolidine-1-carboxylate (4j)

[Rh(cod)Cl]2 (112.9 mg, 0.229 mmol, 0.05 equiv) was added to a solution of (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (1.50 g, 4.58 mmol, 1.0 equiv) and benzo[d][1,3]dioxol-5-ylboronic acid (1.22 g, 7.33 mmol, 1.6 equiv) in THF (39.0 mL) under nitrogen at rt. Aqueous 1M NaOH (7.5 mL, 1.6 equiv) was then added dropwise and the reaction mixture was stirred at rt for 4h. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 30 mL). The combined organic layers were washed with brine (1 × 50 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a white solid (1.38 g, 67%). 1H NMR (CDCl3) δ 6.75 (d, J = 8.0 Hz, 1H), 6.68 (d, J 1.8 Hz, 1H), 6.64 (dd, J = 8.0, 1.8 Hz, 1H), 5.95 (s, 2H), 4.03 (m, 1H), 3.98 (m, 1H), 3.78 (dd, J = 10.4, 2.1 Hz, 1H), 3.37 (dt, J = 9.5, 2.3 Hz, 1H), 3.12 (dd, J = 17.8, 9.5 Hz, 1H), 2.47 (dd, J = 17.8, 2.8 Hz, 1H), 1.53 (s, 9H), 0.91 (s, 9H), 0.08 (s, 3H), 0.07 (s, 3H). 13C NMR (CDCl3) δ 173.9, 149.8, 148.2, 146.6, 138.1, 119.3, 108.5, 106.7, 101.1, 83.0, 66.9, 63.5, 40.2, 38.5, 28.1, 25.8, 18.2, −5.5. LC-MS (m/z) calcd. for C23H36NO6Si [M+H]+ 450.2, found 350.1 [(M+H)-Boc]+. [α]25D -25.6 (c= 0.42, MeOH). Mp: 106.6–107.6 °C. Rf 0.36 (heptanes:EtOAc, 8:2).

(2S,3R)-tert-Butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-3-(3-(((tert-butyldimethylsilyl)oxy)methyl)-4-fluorophenyl)-5-oxopyrrolidine-1-carboxylate (4k)

A flamed-dry round-bottomed flask was charged with a solution of tert-BuLi in pentane (8.98 mL, 15.265 mmol, 5.0 equiv.) and cooled to −78 °C. A solution of bromine 3k (2.44 g, 7.634 mmol, 2.5 equiv.) in dry Et2O (25 mL) was added dropwise and the clear, yellow solution was stirred at −78 °C for 10 minutes. A suspension of CuCN in dry Et2O (2.5 mL) was added portion wise at −78 °C. The resulting suspension was stirred at −78 °C for 5 minutes and then at −42 °C for 10 min (clear solution), after which it was re-cooled to −78 °C. Enone 2 was dissolved in dry Et2O (3.0 mL) and added dropwise to the cuprate mixture at −78 °C, which resulted in a color change to bright dark red. The temperature was raised to −42 °C and the reaction mixture was stirred at this temperature for 1 hour. The brown solution was quenched by addition of a freshly prepared sat. NaHCO3 (5 mL), allowed to warm up to rt and then transferred to a separating funnel with water (15 mL) and EtOAc (15 mL). The organic layer was separated and the aqueous layer was extracted with EtOAc (2 × 15 mL). The combined organic layers were washed with brine (1 × 15 mL), dried over anhydrous MgSO4, filtered and evaporated in vacuo to dryness. The crude product was purified by column chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a pale yellow oil (793 mg, 1.40 mmol, 46% yield). 1H NMR (CDCl3) δ 7.30 (dd, J = 6.8, 2.3 Hz, 1H), 7.04 (ddd, J = 7.5, 4.9, 2.5 Hz, 1H), 6.95 (dd, J = 9.6, 8.5 Hz, 1H), 4.77 (s, 2H), 4.04 (dd, J = 3.9, 2.0 Hz, 1H), 3.99 (dd, J = 10.4, 4.0 Hz, 1H), 3.79 (dd, J = 10.4, 2.1 Hz, 1H), 3.45 (dt, J = 9.6, 2.3 Hz, 1H), 3.13 (dd, J = 17.9, 9.6 Hz, 1H), 2.49 (dd, J = 17.9, 2.7 Hz, 1H), 1.52 (s, 9H), 0.94 (s, 9H), 0.91 (s, 9H), 0.11 (s, 3H), 0.11 (s, 3H), 0.08 (s, 3H), 0.07 (s, 3H). 13C NMR (CDCl3) δ 173.9, 159.8, 158.1, 150.0, 140.12, 140.10, 129.2, 129.1, 126.64, 126.61, 126.25, 126.19, 115.6, 115.4, 83.2, 66.9, 63.7, 59.1, 59.0, 40.3, 38.3, 28.2, 26.1, 26.0, 18.6, 18.3, −5.17, −5.20, −5.3. Rf 0.32 (heptanes:EtOAc, 9:1).

(2S,3R)-tert-Butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-3-(3-(((tert-butyldimethylsilyl)oxy)methyl)-4-chlorophenyl)-5-oxopyrrolidine-1-carboxylate (4l)

A flamed-dry round-bottomed flask was charged with a solution of tert-BuLi in pentane (8.98 mL, 15.265 mmol, 5.0 equiv) and cooled to −78 °C. A solution of 3l (2.56g, 7.63 mmol, 2.5 equiv) in dry Et2O (25 mL) was added dropwise and the clear, yellow/orange solution was stirred at −78 °C for 10 minutes. A suspension of CuCN in dry Et2O (2.4 mL) was added portion wise at −78 °C. The resulting suspension was stirred at −78 °C for 5 minutes and then at −42 °C for 10 min (clear solution), after which it was re-cooled to −78 °C. Enone 2 was dissolved in dry Et2O (3.0 mL) and added dropwise to the cuprate mixture at −78 °C, which resulted in a color change to bright dark red. The temperature was raised to −42 °C and the reaction mixture was stirred at this temperature for 1 hour. The brown solution was quenched by addition of a freshly prepared sat. NaHCO3 (5 mL), allowed to warm up to rt and then transferred to a separating funnel with water (15 mL) and EtOAc (15 mL). The organic layer was separated and the aqueous layer was extracted with EtOAc (2 × 15 mL). The combined organic layers were washed with brine (1 × 15 mL), dried over anhydrous MgSO4, filtered and evaporated in vacuo to dryness. The crude product was purified by column chromatography (heptanes:EtOAc, 9:1) to afford the title compound as a low-melting white solid (1.31 g, 73%). 1H NMR (CDCl3) δ 7.39 (d, J = 2.3 Hz, 1H), 7.26 (d, J = 8.2 Hz, 1H), 7.01 (dd, J = 8.2, 2.3 Hz, 1H), 4.77 (s, 2H), 4.04 (dt, J = 3.9, 2.0 Hz, 1H), 4.00 (dd, J = 10.4, 3.9 Hz, 1H), 3.78 (dd, J = 10.4, 2.0 Hz, 1H), 3.45 (dt, J = 9.6, 2.3 Hz, 1H), 3.14 (dd, J = 17.9, 9.6 Hz, 1H), 2.50 (dd, J = 17.9, 2.8 Hz, 1H), 1.52 (s, 9H), 0.96 (s, 9H), 0.90 (s, 9H), 0.13 (s, 3H), 0.13 (s, 3H), 0.07 (s, 3H), 0.06 (s, 3H). 13C NMR (CDCl3) δ 173.7, 150.0, 143.1, 139.6, 130.2, 129.6, 125.9, 125.8, 83.2, 66.7, 63.7, 62.4, 40.1, 38. 6, 28.2, 26.1, 26.0, 18.6, 18.4, −5.1, −5.2, −5.34, −5.35. Rf 0.47 (heptanes:EtOAc, 8:2).

tert-Butyl (2S,3R)-2-(((tert-butyldimethylsilyl)oxy)methyl)-3-(3-(((tert-butyldimethylsilyl)oxy)methyl)-4-methylphenyl)-5-oxopyrrolidine-1-carboxylate (4m)

[Rh(cod)Cl]2 (23.2 mg, 0.047 mmol, 0.05 equiv), (S)-tert-butyl 2-(((tert-butyldimethylsilyl)oxy)methyl)-5-oxo-2,5-dihydro-1H-pyrrole-1-carboxylate (2) (300 mg, 0.92 mmol), tert-butyldimethyl((2-methyl-5-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)benzyl)oxy) silane (3n) (532 mg, 1.47 mmol) and Cs2CO3 (477 mg, 1.46 mmol) were placed in a 25 mL flask which was evacuated and backfilled with Ar. Degassed, anhydrous THF (8.9 mL) was added, followed by addition of degassed H2O (21 μL, 1.1 mmol). The reaction mixture was stirred at rt for 24 hours. The reaction mixture was diluted with H2O and the aqueous phase was extracted with EtOAc (3 × 15 mL). The combined organic layers were washed with brine, dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptane:EtOAc, 10:1 to 5:2) to afford the title compound as a pale yellow oil (211 mg, 41% yield). 1H NMR (400 MHz, CDCl3) δ 7.24 (d, J = 1.4 Hz, 1H), 7.09 (d, J = 7.8 Hz, 1H), 7.00 (dd, J = 7.7, 2.0 Hz, 1H), 4.68 (s, 2H), 4.11 – 4.05 (m, 1H), 4.01 (dd, J = 10.5, 3.8 Hz, 1H), 3.79 (dd, J = 10.5, 2.0 Hz, 1H), 3.46 – 3.41 (m, 1H), 3.13 (dd, J = 17.9, 9.6 Hz, 1H), 2.53 (dd, J = 17.8, 2.8 Hz, 1H), 2.25 (s, 3H), 1.52 (s, 9H), 0.94 (s, 9H), 0.91 (s, 9H), 0.11 (s, 3H), 0.10 (s, 3H), 0.08 (s, 3H), 0.07 (s, 3H). 13C NMR (101 MHz, CDCl3) δ 174.29, 150.02, 141.83, 139.94, 134.14, 130.65, 124.93, 124.83, 82.97, 67.01, 63.70, 63.41, 40.18, 38.57, 28.19, 26.08, 25.97, 18.52, 18.32, 18.26, −5.14, −5.15, −5.38, −5.40. Rf 0.43 (heptane:EtOAc, 5:1).

(2S,3R)-tert-Butyl 3-(3-chlorophenyl)-2-(hydroxymethyl)pyrrolidine-1-carboxylate (6d)

In a flame dried flask a solution of 4d (368 mg, 0.84 mmol, 1.0 equiv) in dry THF (2.2 mL) was cooled to −78 °C. LiBEtH3 1 M (1.0 mL, 1.00 mmol, 1.2 equiv) was added via syringe dropwise and the reaction mixture was stirred for 1h, then quenched with NaHCO3 sat. sol. (3 mL) and warmed to rt. The aqueous phase was extracted with EtOAc (3 × 5 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 5d as a colorless oil was which was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal 5d (0.84 mmol, 1.0 equiv) in dry DCM (2.6 mL) was cooled to −78 °C. HSiEt3 (0.27 mL, 1.670 mmol, 2 equiv) and BF3·Et2O (0.23 mL, 1.837 mmol, 2.2 equiv) were added sequentially via syringe and the reaction mixture stirred for 6 hours. The reaction mixture was quenched with sat. NaHCO3 (4 mL) and warmed to rt. The mixture was diluted with DCM and the organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 2:1) to afford the title compounds as a colorless gummy oil (154 mg, 59% over two steps). 1H NMR (CDCl3) δ 7.31–7.26 (m, 3H, Ar-H), 7.16–7.14 (m, 1H, Ar-H), 3.94 (m, 1H, CH-N), 3.78 (m, 1H), 3.67 (m, 1H), 3.40 (m, 1H), 3.05 (broad s, 1H), 2.20 (m, 1H), 1.97 (m, 1H), 1.54 (s, 9H). 13C NMR (CDCl3) δ 156.5, 143.0, 134.5, 130.0, 127.6, 127.2, 125.7, 80.5, 66.7, 65.5, 47.2, 46.8, 32.6, 28.4. MS (m/z) calcd. for C16H23ClNO3 [M-H]+ 312.14, found 212.1 [(M+H)-Boc]+. [α]25D −13.1 (c= 0.92, MeOH). Rf 0.49 (heptanes:EtOAc, 1:1 + 1% AcOH).

(2S,3R)-tert-Butyl 2-(hydroxymethyl)-5-oxo-3-(3-(trifluoromethyl)phenyl)pyrrolidine-1-carboxylate (6e)

In a flame dried flask a solution of 4e (500 mg, 1.06 mmol, 1.0 equiv) in dry THF (2.8 mL) was cooled to −78 °C. 1M LiBEtH3 (solution in THF) (1.27 mL, 1.27 mmol, 1.2 equiv) was added via syringe dropwise and the reaction mixture was stirred for 40 minutes, then was quenched with NaHCO3 sat. sol. (3 mL) and warmed to rt. The aqueous phase was extracted with EtOAc (3 × 10 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 5e as a colorless oil which was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal 5e (1.06 mmol, 1 equiv) in dry DCM (3.3 mL) was cooled to −78 °C. HSiEt3 (0.34 mL, 2.11 mmol, 2 equiv) and BF3·Et2O (0.29 mL, 2.315 mmol, 2.2 equiv) were sequentially added via syringe and the reaction mixture was stirred for 6h. After the complete consumption of the substrate the reaction was quenched with sat. NaHCO3 (4 mL) and warmed to rt. The mixture was diluted with DCM and the organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated to give 371 mg (crude). The crude was purified by flash chromatography (heptanes:EtOAc, 2:1) to afford the title compound as a colorless gummy oil (286 mg, 78% yield over two steps). 1H NMR (CDCl3) 7.49–7.39 (m, 4H), 4.94 (br s, 1H, OH), 3.92 (br s, 1H), 3.75–3.58 (m, 3H), 3.35 (ddd, J = 11.2, 8.9, 6.8, 1H), 3.04 (m, 1H), 2.18 (br s, 1H), 1.99–1.89 (m, 1H), 1.46 (s, 9H). 13C NMR (CDCl3) δ (two rotamers) 156.3, (154.3), (143.9), 142.1, 130.9 (q, J = 31.5 Hz, C-CF3), 130.8, 129.1, 124.1, 123.9 (q, J = 272.2 Hz, CF3), 123.8, 80.4, (80.1), 66.6, (65.6), 65.0, (62.5), 47.1, 46.7, (46.2), (32.6), 31.7. MS (m/z) calcd. for C17H23F3NO3 [M+H]+ 346.2, found 246.1 [(M+H)-Boc]+. [α]25D −10.3 (c= 0.43, MeOH). Rf 0.23 (heptanes:EtOAc, 2:1).

(2S,3R)-tert-Butyl 3-(3-((tert-butoxycarbonyl)amino)phenyl)-2-(hydroxymethyl)pyrrolidine-1-carboxylate (6f)

In a flame dried flask a solution of 4f (371 mg, 0.71 mmol, 1.0 equiv) in dry THF (1.86 mL) was cooled to −78 °C. 1M LiBEtH3 (solution in THF) (1.7 mL, 1.72 mmol, 2.4 equiv) was added via syringe dropwise and the reaction mixture was stirred for 1h, then was quenched with sat. NaHCO3 (3 mL) and warmed to rt. The aqueous phase was extracted with EtOAc (3 × 5 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 4f as a colorless oil which was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal 4f (0.714 mmol, 1 equiv) in dry DCM (2.2 mL) was cooled to −78 °C. HSiEt3 (0.23 mL, 1.43 mmol, 2.0 equiv) and BF3·Et2O (0.27 mL, 2.14 mmol, 3.0 equiv) were sequentially added via syringe and the reaction mixture was stirred for 5h. After the complete consumption of the substrate the reaction was quenched with NaHCO3 sat. sol. (4 mL) and warmed to rt. The mixture was diluted with DCM and the organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 2:1) to afford the title compound as a colorless oil (110 mg, 31% over two steps).1H NMR (CDCl3) δ 7.39 (s, 1H), 7.21 (t, J = 7.8 Hz, 1H), 7.12 (d, J = 8.1 Hz, 1H), 6.89 (d, J = 7.6 Hz, 1H), 6.57 (s, 1H), 3.90 (d, J = 6.8 Hz, 1H), 3.79 – 3.68 (m, 2H), 3.60 (dd, J = 11.5, 6.7 Hz, 1H), 3.39 – 3.27 (m, 1H), 2.92 (s, 1H), 2.14 (dtd, J = 9.1, 6.5, 2.8 Hz, 1H), 1.96 (dtd, J = 12.4, 10.1, 8.1 Hz, 1H), 1.51 (s, 9H), 1.49 (s, 9H).13C NMR (CDCl3) δ 152.8, 141.1 (b), 139.0, 129.4, 122.3, 117.7, 117.4, 80.7, 80.6, 67.0, 48.0, 47.2, 32.9, 28.6, 28.5. MS (m/z) calcd. for C21H32N2O5 [M+H]+ 392.23, found 293.1 [(M-Boc) +H]+. [α]25D −8.6 (c= 0.31, MeOH). Rf 0.16 (heptanes:EtOAc, 2:1).

(2S,3R)-tert-Butyl 3-(3-cyanophenyl)-2-(hydroxymethyl)pyrrolidine-1-carboxylate (6g)

Under nitrogen atmosphere, TBAF (1.74 mmol, 3 equiv,1.74 mL of 1M solution in THF) was added to a solution of 8g (242 mg, 0.581 mmol, 1 equiv) in dry THF (5.6 mL). The reaction mixture was stirred at rt for 2h, then diluted with water (10 mL) and sat. NaHCO3 (10 mL). The aqueous layer was extracted with EtOAc (2 × 10 mL) and the combined organic layers were washed with brine, dried over MgSO4 and concentrated. The crude product was purified by column chromatography (heptanes:EtOAc, 1:1) to give the title compound as a pale yellow oil (202 mg, 63% yield over two steps). 1H NMR (CDCl3) δ 7.51 – 7.34 (m, 4H), 4.78 (br s, 1H), 3.86 (br s, 1H), 3.73 – 3.54 (m, 3H), 3.33 (ddd, J = 11.1, 8.8, 6.8 Hz, 1H), 3.01 (bs, 1H), 2.17 (m, 1H), 1.95 – 1.81 (m, 1H), 1.43 (s, 9H). 13C NMR (CDCl3) δ 156.2, 154.2, 144.6, 142.9, 132.0, 131.1, 130.7, 129.6, 118.6, 112.7, 80.6, 80.3, 66.5, 65.5, 64.9, 62.4, 46.9, 46.8, 46.3, 32.5, 31.7, 28.4. Rf 0.21 (heptane:EtOAc, 1:1).

(2S,3R)-tert-Butyl 2-(hydroxymethyl)-3-(3-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)pyrrolidine-1-carboxylate (6i)

Under nitrogen atmosphere, TBAF (1.311 mmol, 3 equiv, 1.31 mL of 1M solution in THF), was added to a solution of 9 (226 mg, 0.437 mmol, 1 equiv) in dry THF (5.3 mL). The reaction mixture was stirred at rt for 2.5h, then was diluted with sat. NaHCO3 (10 mL). The aqueous layer was extracted with EtOAc (3 × 10 mL) and the combined organic layers were washed with brine, dried over MgSO4 and concentrated. The crude product was purified by column chromatography (heptanes:EtOAc, 2:1) to give the title compound as a colorless oil (106 mg, 63%). 1H NMR (CDCl3) δ 7.72 – 7.63 (m, 2H), 7.32 – 7.29 (m, 2H), 3.96 (bs, 1H), 3.72 (m, 2H), 3.59 (dd, J = 11.5, 6.7 Hz, 1H), 3.33 (td, J = 10.5, 6.5 Hz, 1H), 2.89 (bs, 1H), 2.10 (bs, 1H), 2.04 – 1.89 (m, 1H), 1.48 (s, 9H), 1.33 (s, 12H). 13C NMR (CDCl3) δ 156.9, 139.9, 133.9, 133.7, 130.7, 129.6, 128.2, 83.9, 80.5, 67.1, 66.0, 48.0, 47.2, 33.1, 28.5, 24.9. LC-MS (m/z) calcd. for C17H23N2O3 [M+H]+ 302.17, found 203.1 [(M+H)-Boc]+. Rf 0.17 (heptanes:EtOAc, 2:1).

(2S,3R)-tert-Butyl 3-(benzo[d][1,3]dioxol-5-yl)-2-(hydroxymethyl)-5-oxopyrrolidine-1-carboxylate (6j)

In a flame dried flask a solution of 4j (687 mg, 1.53 mmol, 1.0 equiv) in dry THF (4 mL) was cooled to −78 °C. 1M LiBEtH3 (THF solution) (1.83 mL, 1.834 mmol, 1.2 equiv) was added via syringe dropwise and the reaction mixture was stirred for 45 minutes, then was quenched with NaHCO3 sat. sol. (4 mL) and warmed to rt. The aqueous phase was extracted with EtOAc (3 × 10 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 5j as a colorless oil, which was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal (1.53 mmol, 1 equiv) in dry DCM (4.8 mL) was cooled to −78 °C. HSiEt3 (0.49 mL, 3.06 mmol, 2 equiv) and BF3·Et2O (0.42 mL, 3.37 mmol, 2.2 equiv) were added sequentially via syringe and the reaction mixture was stirred for 6h. The reaction was quenched with sat. NaHCO3 (4 mL) and warmed to rt. The mixture was diluted with DCM and the organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 2:1) to afford the title compound as a pale yellow oil (334 mg, 69% yield over two steps).1H NMR (CDCl3) δ 6.69 – 6.64 (m, J = 4.7, 3.2 Hz, 2H), 6.61 (dd, J = 8.0, 1.6 Hz, 1H), 5.85 (s, 2H), 3.82 – 3.58 (m, 3H), 3.53 (dd, J = 11.4, 6.0 Hz, 1H), 3.26 (ddd, J = 11.0, 9.4, 6.7 Hz, 1H), 2.88 – 2.73 (m, 1H), 2.05 (br s, 1H), 1.89 – 1.72 (m, 1H), 1.42 (s, 9H).13C NMR (CDCl3) δ (two rotamers) 156.4, 154.4, 147.9, 146.4, 136.7, 134.7, 120.7, 120.4, 108.2, 107.5, 100.9, 80.3, 80.0, 66.9, 66.0, 65.2, 62.4, 47.3, 46.8, 46.4, 32.8, 32.0, 28.3. MS (m/z) calcd. for C17H24NO5 [M+H]+ 322.16, found 222.1 [(M+H)-Boc]+. [α]25D −18.3 (c= 1.2, MeOH). Rf 0.38 (heptanes:EtOAc, 2:1).

(2S,3R)-tert-Butyl 3-(4-fluoro-3-(hydroxymethyl)phenyl)-2-(hydroxymethyl)pyrrolidine-1-carboxylate (6k)

In a flame dried flask a solution of 4k (793 mg, 1.40 mmol, 1.0 equiv) in dry THF (4.3 mL) was cooled to −78 °C. LiBEtH3 1 M (1.68 mL, 1.675 mmol, 1.2 equiv) was added via syringe dropwise and the reaction mixture was stirred for 1h, then quenched with sat. NaHCO3 (5 mL). The aqueous phase was extracted with EtOAc (3 × 10 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 5k as a colorless oil, which was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal (1.40 mmol, 1.0 equiv) in dry DCM (4.43 mL) was cooled to −78 °C. HSiEt3 (0.44 mL, 2.79 mmol, 2 equiv) and BF3·Et2O (0.38 mL, 3.07 mmol, 2.2 equiv) were added sequentially via syringe and the reaction mixture stirred for 5h at −78 °C. The reaction mixture was quenched with sat. NaHCO3 (5 mL), warmed to rt and diluted with DCM. The organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated. The crude was dissolved in dry THF under N2 atmosphere at rt and 1M TBAF (THF solution) (1.02 mL, 1.02 mmol, 3 equiv) was added dropwise. The reaction mixture was allowed to stir overnight, then quenched with sat. NaHCO3 (5 mL) and portioned between EtOAc (10 mL) and H2O (10 mL). The layers were separated and the aqueous layer was extracted with EtOAc (2 × 10 mL). The combined organic layers were washed with brine (1 × 10 mL), dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 2:3) to afford the title compound as a colorless oil (92 mg, 20% over three steps). 1H NMR (CDCl3,400 MHz) δ 7.35 – 7.26 (m, 1H), 7.08 (ddd, J = 7.7, 5.0, 2.4 Hz, 1H), 6.95 (dd, J = 9.7, 8.4 Hz, 1H), 5.13 (br s, 1H), 4.68 (s, 2H), 3.95 – 3.53 (m, 4H), 3.31 (td, J = 10.4, 6.4 Hz, 1H), 2.90 (br s, 1H), 2.22 – 2.05 (m, 1H), 1.89 (ddd, J = 12.6, 10.5, 8.2 Hz, 1H), 1.47 (s, 9H). 13C NMR (CDCl3, 600 MHz) δ 160.3, 158.6, 156.8, 154.7, 138.3, 136.6, 128.6, 128.5, 128.13, 128.10, 115.5, 115.4, 80.7, 67.1, 66.1, 65.6, 62.8, 58.94, 58.91, 47.2, 47.1, 46.7, 46.5, 33.0, 32.3, 28.5. MS (m/z) calcd. for C17H25FNO4 [M+H]+ 326.2, found 226.1 [(M-Boc) +H]+. Rf 0.18 (heptanes:EtOAc, 1:1).

(2S,3R)-tert-Butyl 3-(4-chloro-3-(hydroxymethyl)phenyl)-2-(hydroxymethyl)pyrrolidine-1-carboxylate (6l)

In a flame dried flask a solution of 4l (1.31 g, 2.24 mmol, 1 equiv) in dry THF (6.85 mL) was cooled to −78 °C. LiBEtH3 1 M (2.69 mL, 2.69 mmol, 1.2 equiv) was added via syringe dropwise and the reaction mixture was stirred for 1h, then quenched with sat. NaHCO3 (6 mL) and warmed to rt. The aqueous phase was extracted with EtOAc (3 × 10 mL) and the combined organic layers were washed with brine (10 mL), dried over MgSO4 and concentrated to give the corresponding hemiaminal 5l as a colorless oil was used in the next step without further purification.

In a flame dried flask a solution of the crude hemiaminal 5l (2.24 mmol, 1 equiv) in dry DCM (7.1 mL) was cooled to −78 °C. HSiEt3 (0.71 mL, 4.476 mmol, 2 equiv) and BF3·Et2O (0.62 mL, 4.94 mmol, 2.2 equiv) were sequentially added via syringe and the reaction mixture was stirred for 5h at −78 °C. After the complete consumption of the substrate the reaction was quenched with sat. NaHCO3 (4 mL) and warmed to rt. The mixture was diluted with DCM and the organic phase was separated, washed with sat. NH4Cl (5 mL), dried over MgSO4 and concentrated to give 1.12 g. The crude product was dissolved in dry THF under N2 atmosphere at rt and 1M TBAF-THF solution (6.7 mL, 6.71 mmol, 3 equiv) was added dropwise. After 2h, the reaction mixture was quenched with sat. NaHCO3 (5 mL), EtOAc (10 mL) and H2O (10 mL). The layers were separated and the aqueous layer extracted with EtOAc (2 × 10 mL). The combined organic layers were washed with brine (1 × 10 mL), dried over MgSO4 and concentrated to dryness. The crude product was purified by flash chromatography (heptanes:EtOAc, 2:1 → 3:2) to afford the title compounds as a colorless oil (370 mg, 49% over three steps).1H NMR (CDCl3) δ 7.37 (d, J = 1.9 Hz, 1H), 7.25 (d, J = 8.2 Hz, 1H), 7.04 (dd, J = 8.2, 2.2 Hz, 1H), 4.69 (s, 2H), 4.00 – 3.48 (m, 6H), 3.41 – 3.24 (m, 1H), 2.92 (s, 1H), 2.12 (dtd, J = 9.4, 6.4, 2.9 Hz, 1H), 1.89 (dq, J = 12.3, 9.7 Hz, 1H), 1.47 (s, 9H).13C NMR (CDCl3) δ 156.7, 139.9, 139.0, 130.9, 129.5, 127.5, 127.5, 80.7, 66.8, 65.5, 62.3, 47.2, 47.0, 32.8, 28.5. MS (m/z) calcd. for C17H25ClNO4 [M+H]+ 342.1, found 242.1 [(M-Boc) +H]+. Rf 0.25 (heptanes:EtOAc, 6:4).

tert-Butyl (2S,3R)-2-(hydroxymethyl)-3-(3-(hydroxymethyl)-4-methylphenyl)pyrrolidine-1-carboxylate (6m)

Compound 4m (211 mg, 0.037 mmol) was dissolved in dry THF (3.1 mL) and dimethylsulfide borane complex (0.11 mL, 10.5 M in THF) was added dropwise. The reaction mixture was refluxed for 2.5h, after which it was allowed to cool down to rt and diluted with Et2O, quenched with sat. NH4Cl and the organic portion separated. The organic partition was washed with brine, dried over MgSO4, filtered through celite and concentrated in vacuo. The crude product was dissolved in THF (4.7 mL) and treated with TBAF (1M, 2.24 mL) at rt for 23h. The mixture was diluted with EtOAc and washed consecutively with NH4Cl (1M), H2O, brine and dried over MgSO4. The solution was concentrated under reduced pressure and purified by flash column chromatography (heptane:EtOAc, 10:1 −> EtOAc) to provide the title compound as a colorless syrup (117 mg, 97%). Two rotamers.1H NMR (400 MHz, CDCl3) δ 7.25 (s, 1H), 7.11 – 7.07 (m, 1H), 7.06 – 7.01 (m, 1H), 4.68 – 4.50 (m, 2H), 3.99 – 3.84 (m, 1H), 3.72 (m, 2H), 3.65 – 3.55 (m, 1H), 3.38 – 3.26 (m, 1H), 2.87 (m, 1H), 2.30 – 2.25 (m, 3H), 2.15 – 2.05 (m, 1H), 2.00 – 1.86 (m, 1H), 1.49 (s, 9H). 13C NMR (101 MHz, CDCl3) δ 156.93, 139.42, 130.66, 128.87, 126.69, 126.45, 114.21, 80.66, 67.02, 65.78, 63.11, 47.56, 47.22, 33.00, 28.57, 18.27. Rf 0.05 (heptane:EtOAc, 10:1).

(2S,3R)-1-(tert-Butoxycarbonyl)-3-(3-chlorophenyl)pyrrolidine-2-carboxylic acid (7d)

A solution of NaIO4 (434 mg, 2.03 mmol, 4.1 equiv) and RuCl3·xH2O (3.1 mg, 0.015 mmol, 0.03 equiv) in H2O (6.2 mL) was added to a solution of 6d (154 mg, 0.494 mmol, 1 equiv) in MeCN:EtOAc (1:1, 7.0 mL) cooled to 0 °C. The reaction mixture was stirred for 30 min then filtered through celite and the filter cake washed with EtOAc. The aqueous layer was extracted with EtOAc and the combined organic layers were washed with brine, dried over MgSO4 and concentrated. The crude product was purified by flash chromatography (heptanes:EtOAc, 1:1 +1% AcOH) to afford the title compound as an off-white solid (138 mg, 86%). 1H NMR (CDCl3) δ (two rotamers) 9.64 (br s, 1H), 7.27–7.22 (m, 3H), 7.15–7.13 (m, 1H), 4.40 (d, J = 5.5 Hz, 0.4H), 4.25 (d, J = 6.5 Hz, 0.6H), 3.79–3.44 (m, 3H), 2.38–2.28 (m, 1H), 2.06–1.96 (m, 1H), 1.49 (s, 4H), 1.42 (s, 5H).13C NMR (CDCl3) δ (two rotamers) 177.6, 175.7, 155.2, 153.7, 142.9, 142.4, 134.6, 130.1, 127.5, 127.4, 127.1, 125.2, 81.2, 80.1, 65.4, 64.9, 49.4, 47.5, 46.1, 45.9, 32.7, 32.2, 28.3, 28.2. LC-MS (m/z) calcd. for C16H21ClNO4 [M+H]+ 326.12, found 226.0 [(M+H)-Boc]+. [α]25D +40.5 (c= 0.55, MeOH). Rf 0.27 (heptanes:EtOAc, 1:1 +1% AcOH). Mp: decomposition.

(2S,3R)-1-(tert-Butoxycarbonyl)-3-(3-(trifluoromethyl)phenyl)pyrrolidine-2-carboxylic acid (7e)

A solution of NaIO4 (380.6 mg, 1.78 mmol, 4.1 equiv) and RuCl3·xH2O (2.7 mg, 0.013 mmol, 0.03 equiv) in H2O (5.45 mL) was added to a solution of 6e in MeCN:EtOAc (1:1, 6.2 mL) cooled to 0 °C. The reaction mixture was stirred for 30 min then was filtered through Celite and the filter cake was washed with EtOAc. The aqueous layer was extracted with EtOAc and the combined organic layers were washed with brine, dried over MgSO4 and concentrated to give the title compound as a colorless sticky oil (95 mg, 61%). 1H NMR (CDCl3) δ (two rotamers) 9.26 (br s, 1H), 7.55–7.44 (m, 4H), 4.43 (d, J = 5.8 Hz, 0.4H), 4.27 (d, J = 6.5 Hz, 0.6H), 3.81–3.52 (m, 3H), 2.42–2.31 (m, 1H), 2.10–1.99 (m, 1H), 1.50 (s, 4H), 1.42 (s, 5H).13C NMR (CDCl3) δ (two rotamers) 177.4, 175.4, 155.3 153.7, 141.8, 141.3, 131.1 (q, J = 33.0 Hz, C-CF3), 130.4, 130.3, 129.4, 129.3, 124.2, 124.1, 123.9 (q, J = 272.2 Hz, CF3), 123.8, 123.7, 81.3, 81.1, 65.4, 65.0, 49.5, 47.6, 46.1, 45.9, 32.8, 32.3, 28.3, 28.1.[α]25D +27.9 (c= 0.64, MeOH). Rf 0.26 (heptanes:EtOAc, 1:1 + 1% AcOH).

(2S,3R)-1-(tert-Butoxycarbonyl)-3-(3-((tert-butoxycarbonyl)amino)phenyl)pyrrolidine-2-carboxylic acid (7f)