Abstract

Traditional cell culture and animal models utilized for preclinical drug screening have led to high attrition rates of drug candidates in clinical trials due to their low predictive power for human response. Alternative models using human cells to build in vitro biomimetics of the human body with physiologically relevant organ-organ interactions hold great potential to act as “human surrogates” and provide more accurate prediction of drug effects in humans. This review is a comprehensive investigation into the development of tissue-engineered human cell-based microscale multi-organ models, or multi-organ microphysiological systems for drug testing. The evolution from traditional models to macro- and microscale multi-organ systems are discussed in regards to the rationale for recent global efforts in multi-organ microphysiological systems. Current advances in integrating cell culture and on-chip analytical technologies, as well as proof-of-concept applications for these multi-organ microsystems are discussed. Major challenges for the field, such as reproducibility and physiological relevance, are discussed with comparisons of the strengths and weaknesses of various systems to solve these challenges. Conclusions focus on the current development stage of multi-organ microphysiological systems and new trends in the field.

Keywords: microphysiological systems, body-on-a-chip, drug development, functional readouts, PBPK

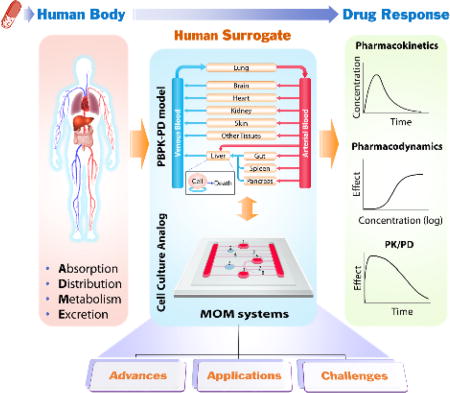

Multi-organ microphysiological (MOM) systems are in vitro microscale cell culture analog of the human body (Body-on-a-chip). Tissue engineered single organ models are interconnected to reproduce complex multi-organ interactions. Such biomimetics of the human body can potentially serve as “human surrogates” to simulate human responses to drugs, providing pharmacokinetic and pharmacodynamic information.

1. Introduction

The current paradigm of pharmaceutical innovation has rendered drug development a lengthy and increasingly expensive process. It takes an average of more than 10 years to develop and bring a safe and effective new treatment to bedside.[1] The average cost for a new drug to reach market has been more than doubling every decade for the last forty years,[1] and has recently estimated to be $2.6 billion per drug.[2] The escalating R&D cost burden is inevitably passed on to patients, and partially contributes to the spiraling price of new drugs.[3] The impetus behind this rising R&D cost is the high drug attrition rate during clinical trials, the most expensive stage in drug development. Around 90% (95% for oncology) of drug candidates selected through preclinical studies fail clinical development mainly due to unexpected safety issues or lack of efficacy.[4,5] New strategies for preclinical screening that can better predict clinical outcomes are an urgent need to expedite drug development and to do so at sustainable prices.

1.1. Current models

Current preclinical drug screening relies heavily on in vitro cell culture models and animal models to project drug responses in humans. While conventional two-dimensional (2D) cell culture models can be easily established in automation-friendly, multi-well microtiter plates and can facilitate high throughput screening (HTS), the screening accuracy is limited. These simplified 2D models in many cases do not capture the in vivo three-dimensional (3D) cell microenvironment and tissue structure that support authentic cell and organ functions. Most importantly, they fail to reproduce complex multi-organ interactions and dynamic drug process that take place in a living animal. Animal models, on the other hand, can provide valuable information on in vivo drug process and responses. Yet, they not only are expensive and time-consuming, raise ethical issues, but have shown disappointingly low predictive power for human drug responses due to cross-species discrepancies between human and experimental animals.[4,6]

1.2. Emerging alternative models

In recognizing the problems with current cell and animal models, the field of drug development, including regulatory agencies, pharmaceutical, and chemical companies, is actively searching for new methodologies, aiming to develop a realistic “human surrogate” that will reduce animal usage and offer more accurate and cost-effective prediction of human responses. Ideally, a human surrogate should recapitulate the dynamic in vivo drug process of absorption, distribution, metabolism and excretion (ADME), reproduce the pharmacokinetics (PK) and pharmacodynamics (PD), and ultimately project the time course of pharmacological response (PK/PD) to guide drug candidate screening and dose selection for clinical trials (Figure 1). The goal for the human surrogate development for drug screening is not to build a perfect mini-human or to replicate a human body, but simply to provide a better predictive model than animal models. Increasing the success of clinical trials from 10% to even 20–30% would reduce drug development costs tremendously.

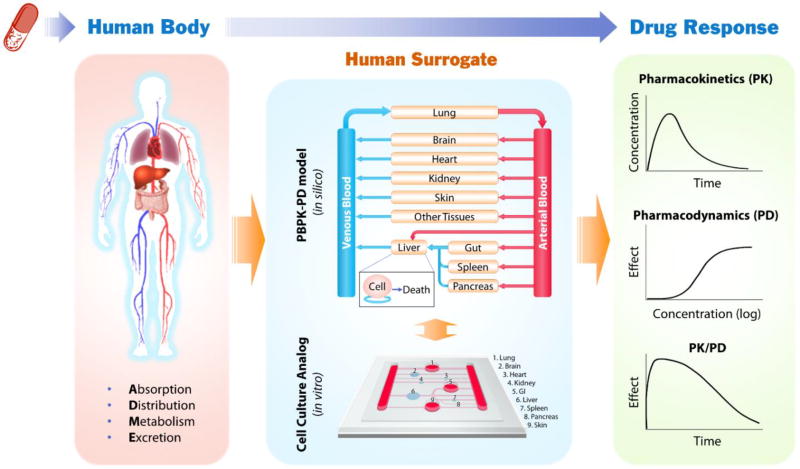

Figure 1.

Schematic diagram illustrating how in vitro cell culture analog (CCA) combined with PBPK-PD modeling can serve as human surrogates and contribute to improving the accuracy and efficiency of preclinical prediction of drug response in human. Drugs entering the human body undergo a dynamic process of drug absorption, distribution, metabolism and excretion (ADME), and elicit various responses. PBPK-PD models and CCAs are mathematical and physical representation of the human body, respectively. They model the human body as a series of interconnected compartments representing different organs or tissues to simulate drug process and responses. The two types of models are complementary. PBPK models can guide the design of CCAs to improve their physiological relevance, while data from CCAs can be used to reduce the number of adjustable parameters in PBPK models. Comparison of CCA results with PBPK simulation results can lead to improvement or validation of CCA models that aims to reproduce the pharmacokinetics (PK, the time course of drug and metabolite concentrations in the body) and pharmacodynamics (PD, the pharmacological effect of a drug, described as a function of concentration), and ultimately project the time course of pharmacological response (PK/PD).

A promising technology that has gained increasing recognition is a mathematical approach, physiologically based pharmacokinetic (PBPK) modeling. PBPK modeling takes a bottom-up approach that integrates known biological mechanisms with all available compound data.[7] It treats the human body as a series of interconnected compartments representing single organs or tissues with great similarity (Figure 1). The contents within a compartment are considered homogenous. The compartments are reactors, absorbers, or holding tanks, where the concentration of drugs or metabolites can be described by differential equations. Such mathematical models can reflect organ-organ interactions and the dynamic exposure of tissues to drugs, allowing one to predict the pharmacokinetics for a given dose scenario. PBPK models combined with PD models can be potent tools in predicting dynamic drug effects under normal and disease conditions. A rodent PBPK model with five tissue compartments (“lung”, “fat”, “kidney”, “liver”, and “other tissues”) built to describe naphthalene uptake and metabolism in vivo, solely based on the then-current knowledge of naphthalene circulation and biotransformation, as well as physiological and in vitro kinetic parameters, accurately predicted naphthalene responses in animals under various routes of administration, pretreatments and doses.[8] The value of PBPK modeling for predicting human drug responses, however, has not been fully exploited, mainly due to the limited quantitative knowledge of human cell metabolism and a large body of unknown biological mechanisms. Most current PBPK models are either empirical descriptions or more mechanistic with a great number of adjustable parameters, which diminish their predictive power.[7]

In contrast to PBPK modeling’s mathematical representation of the human body, cell culture based multi-compartmental, multi-cellular bioreactors have been proposed as the physical analog of a living system to incorporate organ-organ interactions into in vitro drug testing.[9,10] An early proof-of-concept experiment was conducted in a three-chamber system using naphthalene as a model drug.[11] Simply by interconnecting all cell culture flasks/bottles and providing continuous medium circulation among them, a cell culture based multi-organ model (also called cell culture analog, CCA) with “liver”, “lung”, and “other tissues” chambers recapitulated the toxic effects of naphthalene on lung cells due to the formation of cytotoxic naphthalene oxide in the liver chamber and its circulation to the lung chamber.[11] Such interconnected multi-compartmental CCA models are powerful tools for studying remote actions of compounds with reactive metabolites[11] and other soluble ligand mediated crosstalks among tissues[12], which are usually missing in the traditional cell culture models. Connected cultures of hepatocytes, endothelial cells and adipocytes in the multi-compartment bioreactors (MCB) under circulating perfusion exhibited modified glucose and lipid metabolic profiles as compared to static individual cultures.[12–14] Intestinal and liver cell co-culture in consecutively perfused bioreactors mimicked the intestinal absorption and first-pass liver metabolism of the prodrug phenacetin,[15,16] and indicated synergistic intestinal and liver metabolism in response to paracetamol.[17] The CCA models also offer great flexibility for focusing on specific subsets of organs, creating “knockout models” or changing the cell number or cell metabolic/functional states of specific organ chambers to pursue mechanistic interrogation or mimic pathological conditions, which are usually complicated to achieve with living animals.

Human CCA models hold the potential to simulate human drug responses including those from drug actions of unknown mechanisms that cannot be predicted by PBPK modeling. They are also powerful platforms to generate quantitative knowledge of human cell metabolism and help reduce the number of adjustable parameters in a PBPK model. Meanwhile, PBPK models of the human body can guide the design of CCA models, thus making them more physiologically relevant, and help extrapolate the results from CCA models for clinical trials. Combining the strength of PBPK modeling and human CCA models can be a potent approach to develop realistic human surrogates for drug development.

1.3. New opportunities for developing multi-organ microphysiological systems

The explosive growth in the fields of stem cell technology, 2D and 3D cell culture, microfabrication, and microfluidics since the beginning of the 21st century has brought unprecedented opportunities for developing in vitro microscale biomimetics of the human body as a promising “human surrogate” for the next generation drug screening. The success in generating human induced pluripotent stem cells (hiPSCs) from adult somatic cells[18–20] and differentiating them in vitro into a variety of specific organ cell types, including neurons,[21–23] cardiomyocytes,[24,25] hepatocytes,[26] pancreatic cells,[27] lung and airway epithelial cells,[28] brain microvascular endothelial cells[29] and intestinal cells,[30] offers new possible cell sources for building in vitro human tissue biomimetics. Compared to cell lines, human iPSC derived cells exhibit phenotypes closer to their in vivo counterparts, and the available cell number is potentially unlimited, in contrast to primary cells. Such techniques also allow creation of patient and disease specific cells for personalized drug screening models.[31,32] With the advent of novel biomaterials that mimic native cell microenvironment[33,34] and 3D biofabrication technologies[35,36] that can create cell spheroids or clusters with 3D organization, in vitro re-creation and maintenance of functional organ mimetics has become realistic. Several miniaturized organotypic models of human organs, including the brain,[37] heart,[38] kidney,[39] and liver,[40] have been developed and demonstrated with some organ level functions. Development of micro/nanofabrication technologies and biological microelectromechanical systems (BioMEMS) allows creation of miniaturized bioreactors with interface feature size close to the cell emulating the native cell niche, microarchitectures mimicking tissue structures, as well as in situ microbiosensors.[41] Recent development in microfluidics enables precise microscale fluid control and allows the creation of desired fluidic connections among microscale organ models in mimicking in vivo blood circulation.[42,43] With all these advances in technologies, new global efforts have been mounted to build the next generation drug testing tool, namely, tissue-engineered human cell-based microscale multi-organ models. These multi-organ microphysiological systems (MOMs), also known as microCCA[44,45] or body-on-a-chip (BOC),[41,46–48] are gaining momentum in recent years and hold great potential to better identify drug candidates for clinical trials.

1.4. Focus of the current review

There have been many comprehensive reviews on the design, construction and applications of tissue engineered microphysiological systems (MPS) for single organs or specific diseases.[41,49–59] This review will focus on microscale multi-organ systems with total fluid and tissue volume smaller than 1/10,000 of the human body (~6.5 mL).[60] We will review the current available multi-organ integration platforms, on-chip analytical technologies, and the proof-of-concept applications in drug testing and disease modeling. We will also evaluate different models in terms of their strength and weakness, and focus on discussing several critical challenges that the field is facing and possible strategies as well as future directions.

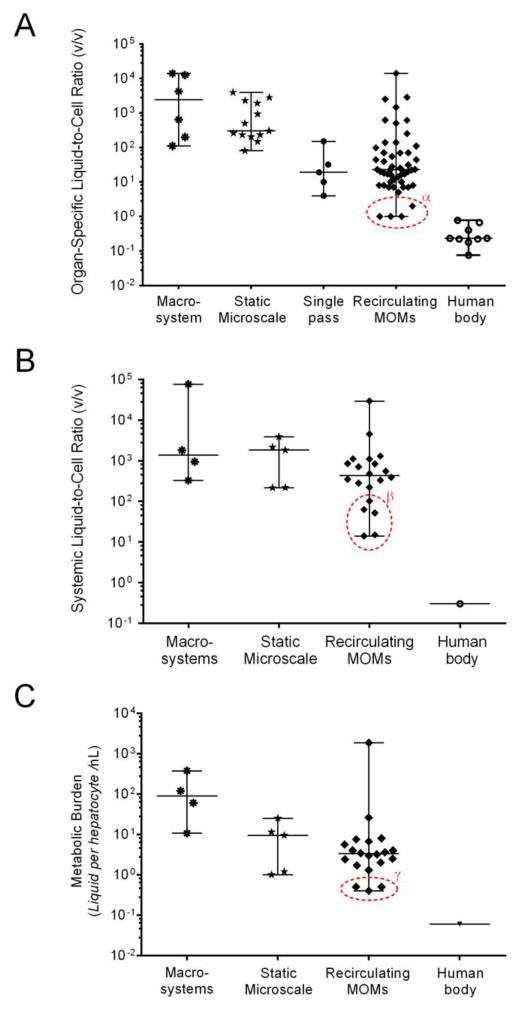

2. Advances in multi-organ integration platforms

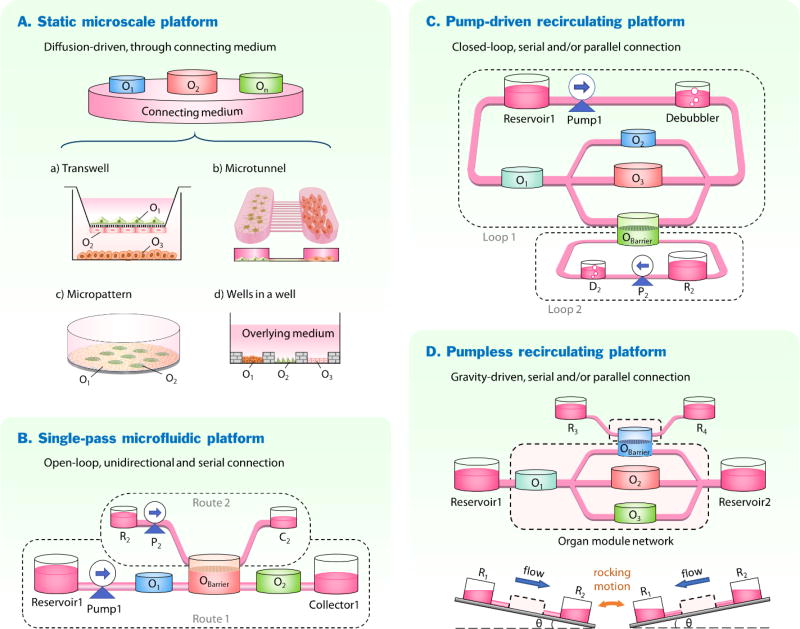

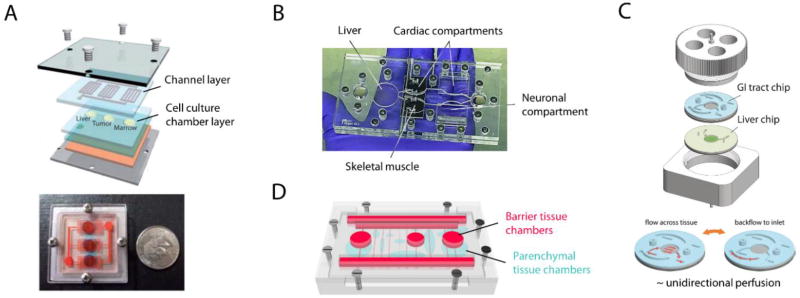

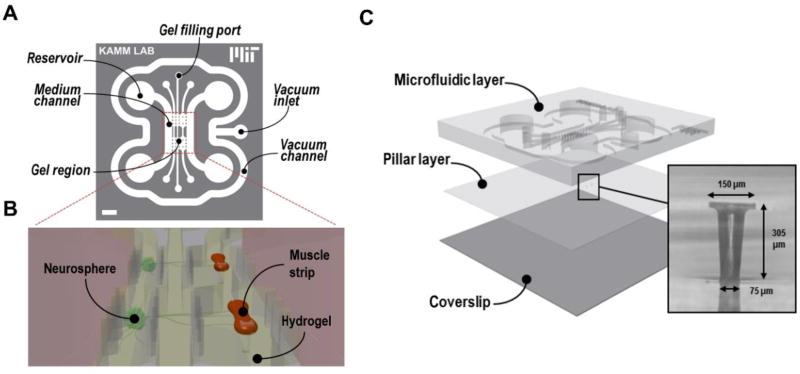

To establish organ-organ interactions in vitro, fluidic connections among organ models are often required. Based on how various organ models are fluidically interconnected, the current integration platforms can be categorized into four major types (Figure 2): i) static microscale platforms, ii) single-pass microfluidic platforms, iii) pump-driven recirculating microfluidic platforms, and iv) pumpless recirculating microfluidic platforms. We will discuss each type of platform by focusing on their approaches to integration, representative models, and their advantages vs. disadvantages. More detailed applications of different platforms will be discussed in Section 4. Challenges that are common for all platforms will be discussed in Section 5.

Figure 2.

Integration platforms for recreating organ-organ interactions in vitro. (A) Static microscale platform presented in four major forms: a) transwell platform; b) microtunnel platform; c) micropattern platform; d) wells-in-a-well platform. (B) Single-pass microfluidic platform connects all organ modules in series in one fluid route (route 1), or with additional routes (e.g., route 2) if barrier tissues are involved. (C) Pump-driven recirculating platform interconnects organ modules in serial and/or parallel in a closed-loop circuit (loop 1). Separate fluidic pools or loops (e.g. loop 2) are needed for barrier tissues. (D) Pumpless recirculating platforms utilize gravity-driven flow and a rocking motion to drive fluid through the organ module network, in which organ modules are connected in serial and/or parallel. On, organ module; Pn, pump; Rn, reservoir; Cn, medium collector; Dn, debubbler. n represents the index of a specific module.

2.1. Static microscale platforms

Static microscale platforms achieve organ-organ interactions mainly through direct physical contact among tissues and/or passive diffusion of soluble ligands, cell metabolites or cellular components via a common medium connecting all organ compartments. Four major forms of static multi-organ MPS are presented below and their advantages and disadvantages are discussed (Figure 2A).

2.1.1. Transwell platform

The transwell platform is a long-established static system for multi-compartmental, multi-cellular co-culture. It was first developed by Dr. Stephen Boyden for leukocyte migration analysis in 1960s.[61] In such a system, a transwell, which is a cylindrical insert with a thin porous polymeric membrane bottom, is placed in a traditional cell culture well, dividing the well into an upper and a lower compartments (Figure 2A (a)).[62,63] It compartmentalizes different organ models while allowing inter-organ medium exchange, cellular contact and even cell migration through micropores of various dimensions. The transwell system accommodates up to three different organs that can be easily analyzed and retrieved individually. The platform is particularly useful for systems involving barrier tissues. With open access to both compartments, drug absorption through a barrier tissue (such as the intestinal wall, the skin, vasculature, and the blood brain barrier) constructed on the porous membrane can be easily evaluated by monitoring the concentrations of test drugs or their metabolites in both donor and receiving compartments over time.

2.1.2. Microtunnel platform

In contrast to a transwell’s vertical connection through micropores, the microtunnel platform creates horizontal ties among organ chambers with microfabricated fluid tunnels (Figure 2A (b)). Inter-organ medium exchange through the microtunnels by diffusion is generally not efficient due to the great length and small cross-sectional area of the fluid path. The resulting biochemical gradient established across the microtunnels, however, can be effective in guiding cell migration or directional growth of cellular projections (such as axons and neurites) with their cell bodies restrained within the organ chambers. The microtunnel platform is therefore often used to create connections between the neural system and other organs, such as muscle[64] or tumors[65].

2.1.3. Micropattern platform

The micropattern platform creates multi-organ co-culture in a single compartment with different organ cells spatially separated using cell micropatterning techniques (Figure 2A (c)).[66] Different types of cells are often selectively attached to or removed from 2D culture substrate with regional (patterned) surface modification that tunes cell attachment,[67,68] or encapsulated in different hydrogels patterned in 3D configuration.[69] Different organ cell interactions are mainly mediated by diffusion through the overlying medium, and sometimes also by physical contact with neighboring cells. The cell micropatterning allows easy allocation of different organ cells for optical interrogation. Selective retrieval of live cells is also possible for further cell/molecular analysis.[70] Yet the spatial constraints based on the differential properties of initially patterned surface or scaffold can gradually lose effectiveness after cells produce their own extracellular matrix and modify their surroundings. Analysis of individual organs in a long-term multi-organ co-culture could be challenging using this platform.

2.1.4. Wells-within-a-well platform

The wells-in-a-well concept modifies the micropattern platform by using physical barriers instead of surface or 3D micropatterning to separate various organ cells (Figure 2A (d)). The integrated discrete multiple organ cell culture (IdMOC) system developed by Li and coworkers represents the first commercial use of the “wells-within-a-well” platform for multi-organ co-culture.[71] The IdMOC plates consist of large co-culture wells with each containing multiple small wells. Each small inner well serves as an isolated culture compartment for individual organs. Different organs can be cultured in organ-specific medium till they are all ready for co-culture. Multi-organ co-culture is initiated by filling up the large co-culture wells above all inner wells with a common medium. Crosstalk among organ compartments is driven by diffusion of soluble cell metabolites through the overlying medium. The IdMOC plates support multi-organ co-culture of up to 6 different organ models. The plates were adapted from conventional multiwell culture plate format and can be easily compatible with automated liquid handling and imaging systems to achieve high-throughput multi-organ drug testing.

2.1.5. Summary

In general, static microscale multi-organ integration platforms are easy to construct and operate, and can recreate basic organ-organ connections in vitro. There are usually no moving parts or forced convection of fluids in the system. The platforms are either commercially available (the transwells and the IdMOC plates) or require minimal microfabrication. The organ compartments are often open for direct access where macroscale cell culture and liquid handling techniques can easily be applied. The horizontal arrangement of multiple organ compartments in most static microsystems, including microtunnel, micropattern and wells-within-a-well models, facilitates optical interrogation, while the transwell platform supports multi-organ models with barrier tissues. The organ-organ interactions in the static systems rely on diffusion and/or physical contact that are mostly established based on biochemical gradients among organ compartments.

Any disturbance to the gradients in the system could lead to outcome variations or unrepeatable results. More importantly, inter-organ communication through the common medium is less controllable in terms of specificity, directionality and extent, unlike the in vivo circulation system with specific perfusion order and rate for different organs.

2.2. Single-pass microfluidic platforms

Single-pass microfluidic platforms integrate different organ models by applying open-loop sequential medium perfusion through all organ units in a single fluid route, or multiple separate ones if barrier tissues are included (Figure 2B). The organ-organ interactions in such systems are mostly unidirectional. Drugs and drug metabolites from upstream organ models are carried along and can act on the downstream organ units while there is no feedback route to the upstream organs. This lack of feedback eliminates the detection of a potentially important route of inter-organ interactions.

Multi-organ microfluidic platforms often take modular approaches to integration. van Midwoud et al. constructed a single-pass multi-organ platform made of polydimethylsiloxane (PDMS) through serial tubing connection of multiple microfluidic biochips previously designed for continuous organ slice perfusion (Figure 3A).[72,73] Each biochip unit adopted a transwell-like structure, where a polycarbonate porous membrane was integrated to divide cylindric microchambers into upper and lower chambers and support organ slices. The medium was perfused using a syringe pump through the porous membrane, around the organ slice, and then passed to the downstream biochip to convey unidirectional organ interactions. Loskill et al. proposed a configurable multi-organ platform, µOrgano, which used Lego®-like plug-and-play connectors for rapid and reliable transformation between discrete single-organ mode and integrated multi-organ mode (Figure 3B).[74] This modular platform decouples the single-organ culture platforms from the multi-organ integration platform, and thus can reduce the complexity of multiple organoid preparation. The demonstration of the above microfluidic integration platforms has so far been limited to single-pass, single-route perfusion for parenchymal tissues (or barrier tissues without consideration of their barrier function).

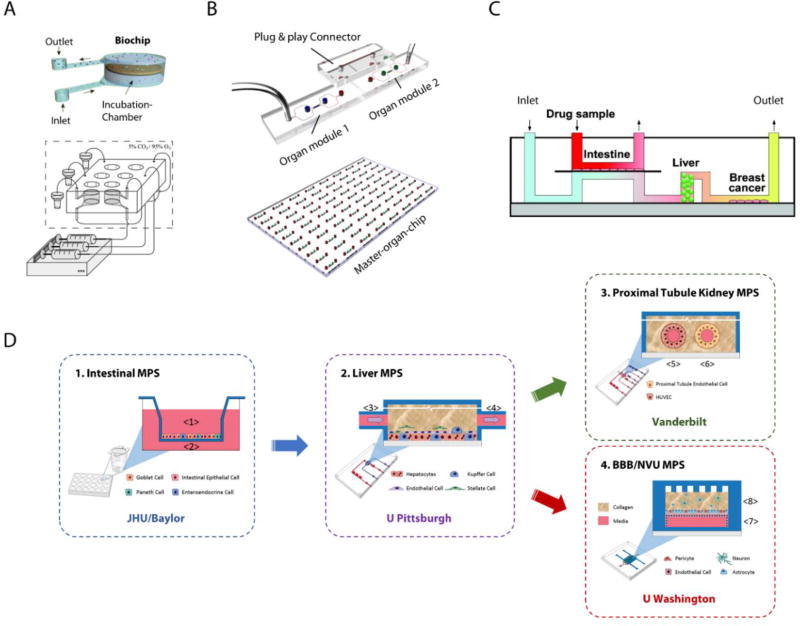

Figure 3.

Representative single-pass MOM systems. (A) A liver-intestine MOM based on serially connected biochips designed for tissue slice perfusion. Reproduced with permission.[73] Copyright 2010, Royal Society of Chemistry. (B) µOrgano, a modular multi-organ platform using Lego®-like plug&play connectors for inter-organ connection. Adapted under the terms of the CC-BY-4.0 license.[74] Copyright 2015, Loskill et al. (C) An intestine-liver-tumor MOM with both systemic and intestinal perfusion. Reproduced with permission.[75] Copyright 2010, American Chemical Society. (D) A functionally coupled microphysiological system with multiple organ modules constructed at physically distant laboratories and connected through medium transfer in a physiological order. Adapted under the terms of the CC-BY-4.0 license.[77] Copyright 2017, Vernetti et al.

Integration of functional barrier tissues into multi-organ MPS requires multiple separate microphysiological fluid pools or routes. Imura et al. constructed an intestine-liver-tumor microsystem with both apical and basal side perfusion of the intestine tissue driven by two syringe pumps (Figure 3C).[75] A porous membrane was sandwiched between two microfluidic channels made in PDMS to support the intestine tissue culture at the interface of the dual fluid circuits. This enabled quantitative evaluation of intestine absorption through apical drug administration and both-side sampling. The systemic perfusion through “intestine” (basal), “liver” and “tumor” chambers also allowed testing of liver metabolism and the anti-cancer effects of drugs after intestinal absorption and metabolism. Imura and coworkers extended the platform by adding infusion inlets along the apical microchannel before passing through the intestine chamber. Such modification enabled sequential mixing of drug samples with infused artificial gastric juice, neutralization buffer, and artificial intestinal juice, and thus allows additional testing on the stability of drugs throughout the digestion process.[76]

Aside from the physical integration of various organ models, a special form of the single-pass MOMs using “functional coupling” has been demonstrated through a multi-laboratory collaboration (Figure 3D).[77] Individual organ units were constructed separately in four physically distant laboratories. Organ-organ connections were established by transporting medium effluent from one organ module to the next in a physiological order. A liver-muscle model and a four-organ model of intestine, liver, blood brain barrier/neurovascular unit, and kidney were built in such form as proof-of-concept microsystems to model drug ADME process. The integration strategy of “functional coupling” could potentially combine the expertise from different laboratories and include the most sophisticated single organ modules into a multi-organ system. The physical decoupling allowed to construct individual organ models on different microfluidic platforms and culture them in their optimized medium at organ-specific perfusion rate. Yet the results would not be in real-time or dynamic. The extra intermediate steps to connect distant organ modules could bring additional administrative and logistic costs and raise a major concern about to which extent the inter-organ communication can be preserved and recreated after transportation. Cell metabolites and other soluble ligands that could act on downstream organ modules may have lost or compromised their bioactivity during the prolonged process, especially those reactive intermediates. Overall, functional coupling could be a practical strategy for constructing pilot multi-organ models to gain valuable insights for future designs before a universal platform and a common medium are developed to physically integrate all organ modules. Yet it would be difficult to adopt for industrial drug screening in its current format.

In summary, the single-pass microfluidic platforms for multi-organ integration feature open-loop sequential fluid transfer across organ modules through connecting tubing, microfluidic channels, or transportation. The controlled fluid flow allows more reliable mass transfer of cell metabolites among organ models than that in systems solely depend on diffusion. The continuous perfusion of fresh medium and drug sample solutions gives constant nutrient supply, waste removal and a steady dose of drug. Such multi-organ models could be useful in providing a qualitative evaluation of drug pharmacodynamics. Yet their ability to simulate in vivo pharmacokinetics and drug effects is largely limited due to the oversimplified series perfusion architecture and the lack of reciprocal organ-organ interactions.

2.3. Recirculating microfluidic platforms

Recirculating multi-organ platforms connect individual organ compartments with circulating culture media that mimic the blood flow in the body (Figure 2C–D). Such closed-loop perfusion facilitates reciprocal organ interactions that are usually missing in the single-pass perfusion systems. Cell metabolites released from one organ chamber are distributed by circulation and can act on other organ units until clearance. The closed-loop medium circulation also allows simulation of the dynamic exposure of organ cells to drugs and drug metabolites over time, producing valuable pharmacokinetic information.

2.3.1. Pump-driven recirculating MOMs for parenchymal tissues

In 2004, the Shuler group, which had previously demonstrated the CCA models in macroscale, combined the CCA concept with microfabrication technologies to develop a three-compartment microscale CCA (µCCA) model based on a 2.5 cm × 2.5 cm silicon chip with etched microchannels and microchambers.[78] The medium was recirculated through the chip using a peristaltic pump. The group extended this silicon chip based platform to four-chamber models to integrate more parenchymal organs,[44,79,80] and later introduced 3D cell culture in hydrogels into the µCCA platform to better mimic the 3D structure of parenchymal tissues (Figure 4A).[81] These µCCA models were designed based on PBPK models, which incorporated better physiological relevance into the systems. The dimensions of the on-chip microfluidic channels and microchambers were specifically devised and coupled with the pump flow rate based on proportional scaling of the organ volumes and perfusion rates in human. Such systems maintained in vivo organ size ratios and physiological fluid residence time in the corresponding organ chambers. The silicon base for these early models enabled creation of miniaturized fluidic channels and organ chambers, which required hundreds to thousands fold fewer cells and media than the macroscale counterpart,[11] and provided near-physiological level liquid-to-tissue ratios in organ compartments.[78] It also allowed integration of microscale features for local fluidic control, such as using micropillar arrays for rapid and even flow distribution in organ chambers.[78]

Figure 4.

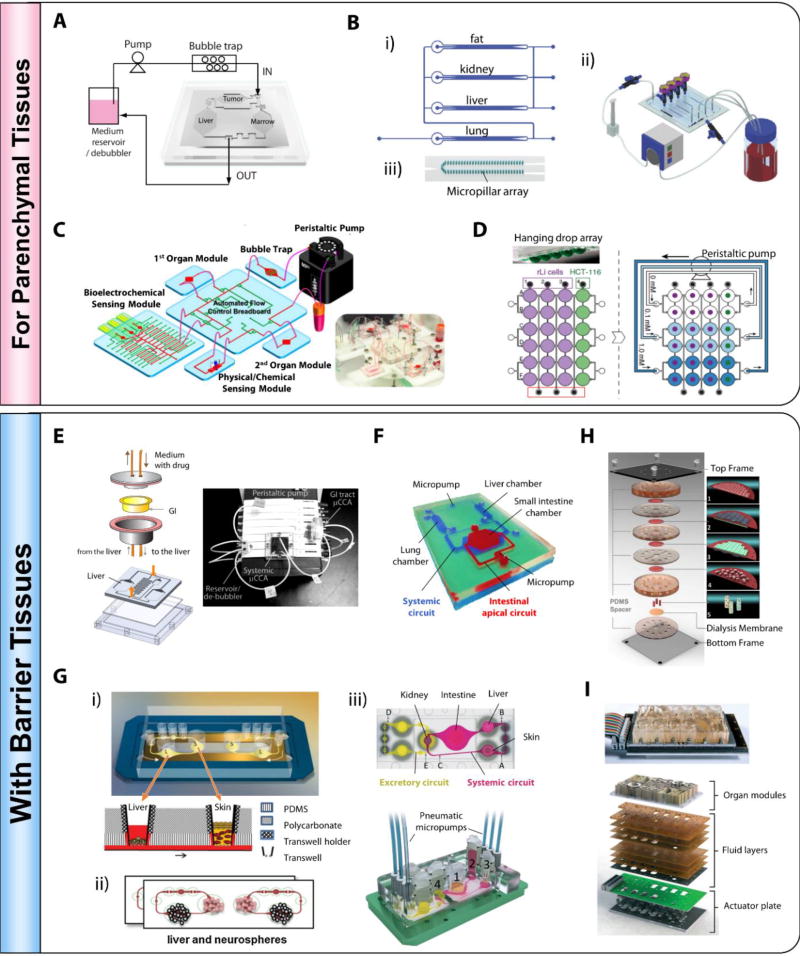

Representative pump-driven recirculating MOM systems demonstrated for parenchymal tissues (A–D) and with barrier tissues (E–F). (A) A liver-marrow-tumor 3-organ µCCA with 3D hydrogel cell culture. Adapted and reproduced with permission.[81] Copyright 2009, Royal Society of Chemistry. (B) A 4-organ MOM with compartmentalized microenvironment. Reproduced with permission.[83] Copyright 2009, Royal Society of Chemistry. (C) A modular MOM system integrated with a flow-controlling breadboard, an on-chip bubble trap, and multiple biosensors. Adapted from Zhang et al.[84] Copyright 2017, Zhang et al. (D) A liver-tumor MOM based on open channels and hanging drop arrays. Reproduced with permission.[85] Copyright 2014, Nature Publishing Group. (E) A 5-compartment, liver-GI 2-organ MOM. Photograph of the system reproduced with permission.[87] Copyright 2009, John Wiley and Sons. (F) A dual-layer, stirrer-based micropump driven liver-intestine-lung MOM.[90] Photo provided by courtesy of Dr. Teruo Fujii. G) Transwell compatible, pneumatic pump driven MOM systems. i) A liver-skin MPS; Reproduced with permission.[92] Copyright 2013, Royal Society of Chemistry. ii) A liver-neurosphereo MPS; Reproduced with permission.[94] Copyright 2015, Elsevier. iii) A four-organ MOM with systemic and excretory circuits. Adapted under the terms of the CC-BY-3.0 license.[42] Copyright 2015, Royal Society of Chemistry. H) A multilayer MOM mimicking the ADME process of oral drugs.1) Caco-2 cell layer; 2) Human umbilical vein endothelial cells (HUVEC) (grey) and hepatocyte (green) layers; 3) Hepatocyte (green) and HUVEC (grey) layers; 4) MCF-7 cell layer; 5) Lung, heart, adipose tissues. Adapted under the terms of the CC-BY-4.0 license.[95] Copyright 2016, Nature Publishing Group. (I) An integrated MOM platform driven by electromagnetically actuated micropumps. Reproduced with permission.[96] Copyright 2016, Royal Society of Chemistry.

In contrast to the serial connection in all single-pass platforms to achieve inter-organ communications, the perfusion through different organ models in a recirculating MOM can be serial,[82] parallel,[80] or combined. The four-compartment µCCA of “lung”, “liver”, “fat”, and “other tissues” developed by Viravaidya et al. adopted a perfusion architecture mimicking the blood circulation.[79] The “liver”, “fat”, and “other tissues” chambers were connected in parallel, and together connected in series with the “lung” chamber, a medium reservoir and a peristaltic pump. A similar perfusion network was used for a 4-organ recirculating MOM of “fat”, “kidney”, “liver” and “lung”, presented by Zhang et al. (Figure 4B).[83] The volumes and the perfusion rates in this 4-organ system, however, were not customized for each organ compartment, leaving the system less physiologically relevant despite the in vivo-like connections among organs. The system integrated four micropillar arrays to confine hydrogel immobilized 3D cell cultures within the organ chambers, and allow peri-chamber perfusion through microchannels defined by the micropillars (Figure 4B (iii)). Such micropillar arrays combined with the hydrogel encapsulation approach protected cells from direct exposure to shear stress from medium perfusion.

To construct more sophisticated recirculation architecture for multi-organ systems, a fluid breadboard based modular approach has recently been proposed.[84] The automated flow control breadboard made of PDMS was integrated with on-chip microchannels and program controllable pneumatic valves and could be used to manage fluid circulation among organ models, on-chip analytical modules, bubble traps, and reservoirs (Figure 4C). The platform was demonstrated with a two-organ model of “liver” and “heart” connected in series. It holds the potential of integrating multiple organ modules and handling complexed fluid network with features of in vivo-like perfusion architecture and organ-specific perfusion rates.

A unique, open channel based multi-organ microfluidic platform has also been developed.[85] Frey et al. transformed an array of hanging drops, commonly used for the 3D culture of cell spheroids or microtissues, into multiple parallel multi-organ microsystems using a multi-channel peristaltic pump and a reconfigurable microfluidic network interconnected through open channels between neighboring hanging drops (Figure 4D). By filling and establishing perfusion through one dimension of the 2D microchannel network, cells from different organs were loaded and cultured in columns of the hanging drop network. Multi-organ units were then created in rows by switching the perfusion to the second dimension of the network. Such a platform supports the 3D culture and analysis of both individual organ units and multi-organ sets, and can flexibly switch between the two modes. The multiple parallel multi-organ sets on chip also allow simultaneous testing of several drugs or drugs at different doses. Yazdi et al. further made the system more compact with built-in pneumatic chambers for flow control.[86] The hanging drop array based design can potentially create an integrated, high throughput platform for recirculating MOM systems. These open-channel based systems usually do not have the problem of bubble formation that occurs in most closed channel microfluidic systems, yet they face a major issue of medium evaporation at rates varying with the surrounding environment. Additional compensating flow is often required. In addition, the current proof-of-concept multi-organ system adopted the simplest serial fluidic network architecture to connect all the different organ chambers, which were perfused at the same flow rate. It is not straightforward whether such a platform can be extended to incorporate in vivo-like circulation structure with parallel branches and organ-specific perfusion rates or accommodate functional barrier tissues.

2.3.2. Pump-driven recirculating MOMs with functional barrier tissues

Barrier and parenchymal organ models are usually constructed on different platforms. Unlike parenchymal organ models established in confined microchambers or hanging drops, models of barrier tissues, such as intestine, lung and skin, are often constructed on microporous membranes that separate the apical and basal space of the barrier. Incorporating barrier tissues into multi-organ microfluidic systems often involves integration of the different platforms for barrier and non-barrier tissues.

Mahler et al. took a simple modular approach for integration by keeping barrier and parenchymal organ models on their own platforms and interlinking them with tubing (Figure 4E).[87] They created a 5-compartment MOM by combining a previously developed transwell-based gastrointestinal (GI) tract model[88] and a four-chamber silicon µCCA. The system provided systemic and intestine apical dual circulation and can be used to model the absorption, metabolism and toxicity of oral drugs and supplements.[87,89] Such modular multi-organ systems are usually less compact than single-chip integrated systems, yet they require minimum adaptation for both barrier and parenchymal organ models.

Kimura et al. proposed a single-chip, dual-layer design for barrier tissue integration (Figure 4F). They constructed a three-organ recirculating microsystem of “liver”, “small intestine” and “lung”.[90] The barrier tissue (small intestine) chamber and the apical fluid circuit were created in the upper PDMS layer, while the parenchymal tissue chambers (liver, and lung, treated as a non-barrier tissue) and the systemic (basolateral) circuit were built in the lower layer. A microporous membrane was sandwiched in between as the interface of the two circuits. To better reproduce the interactions between small intestine and liver, the system preserved many physiological parameters for both organs, such as organ size ratio and perfusion rate, as well as systemic perfusion structure. The built-in stirrer-based micropumps also made the system compact and self-contained (no fluid or gas loops required outside of the device[91]).

Wagner et al. from the Marx group utilized transwell inserts to host barrier tissues and developed a multi-compartment microfluidic platform that could accommodate transwell inserts and provide recirculating perfusion with an on-chip pneumatic pump (Figure 4G (i)).[92] A proof-of-concept system with two organ compartments was demonstrated with liver microtissues and skin biopsy. With a transwell insert installed in the skin compartment, this microfluidic device established the air-liquid interface required for skin tissue culture and supported stable co-culture of the liver and skin tissues for up to 28 d. The group later used the same platform to build liver-skin, liver-neurosphere, and liver-intestine microsystems with 3D cultured liver microtissues, skin biopsies, neurospheres, and intestine constructs (Figure 4G (ii)).[93,94] They endothelialized the microfluidic channels in the liver-skin model to mimic the in vivo vasculature, and observed interactions between endothelial cells and the liver microtissues. These co-cultures were stable and maintained on chip for up to 14 d. The same group further developed a four-organ MOM system of “intestine”, “liver”, “skin”, and “kidney” on a modified device with two recirculating fluid circuits (Figure 4 G (iii)).[42] The chip included a second microfluidic channel layer for the excretory circuit and a sandwiched microporous membrane between the two channel layers to support kidney proximal tubule epithelial cell culture. The microsystem maintained cell viability and tissue structure for 28 d and established a stable gradient of glucose among the three fluid pools representing the intestine lumen, the blood circulation and the kidney excretory circuit. Such a platform can potentially be used to simulate the ADME profile of drug candidates. Overall, these transwell compatible microfluidic systems provide a reliable platform for long-term co-culture of multiple organ models including barrier tissues, and thus can potentially support drug testing with repeated doses.

An et al. proposed a unique vertical stacking structure for constructing MOM systems (Figure 4H).[95] The presented microsystem included cell and tissue models representing intestine, vasculature, liver, heart, lung and adipose tissues, a dialysis membrane representing the kidney, and three recirculating fluid loops representing intestinal lumen, systemic circulation and kidney excretory circuit. Four polycarbonate microporous membranes and the dialysis membrane were sandwiched between six vertically stacked PDMS microchannel or microchamber layers to support barrier and non-barrier tissue culture and serve as permeable interface between microchannels and microchambers. It should be noted that, different from the microfluidic MOMs previously discussed, the transfer of cell metabolites among different organ models in this system depended mainly on diffusion driven by the gradients established between the three fluid circuits. The system was used to simulate the ADME process and toxicity of several oral drugs. The microsystem established interconnections among multiple organ models, yet it had little physiological resemblance in terms of the circulation structure, organ volume and perfusion rate. The testing results were more qualitative than quantitative and should be interpreted with appropriate caution.

More integrative platforms are emerging.[96–99] They usually consist of an organ module layer, a fluidic layer, and a flow control layer embedded with arrays of pneumatic or electrically actuated micropumps (Figure 4I). These integrative MOM boards often provide flexibility of fluid circuit configuration and sophisticated onboard fluid control. They are also featured with scalability and portability attractive for industrial adoption. Coppeta et al. demonstrated both isolated individual organ recirculation and inter-organ recirculation for multiple pairs of airway-liver cultures on a single board, which were maintained with function for 2 weeks.[96] It should be noted, though, that these highly integrative MOM boards have limited flexibility to customize organ chambers for physiologically relevant representation of different organs. Fluid reconfiguration and control also often requires excessive fluid in the system which could dilute drugs and metabolites in the system.

2.3.3. Pumpless recirculating microfluidic platforms

Unlike above discussed recirculating multi-organ platforms that all rely on active fluid pumping to move medium among organ models, Sung et al. proposed a novel microfluidic platform that combined passive gravity-driven flow and a rocking motion to recirculate medium on chip.[100] A proof-of-concept model of three organ compartments representing liver, tumor and bone marrow was created on a 4 cm × 4 cm chip (Figure 5A). All fluidic components, including three organ microchambers, two reservoirs, and interconnecting microchannels, were built on chip with no external fluid or gas loops. The medium recirculation was achieved by positioning the entire chip on a titling rocker platform to create gravity-induced flow through the on-chip fluidic network and switching the tiling direction periodically. Such pumpless microfluidic platform provides reciprocating circulation of medium rather than a closed-loop unidirectional perfusion as in vivo. Yet the difference in the recirculation mode causes little deviation in pharmacokinetic profiles of drugs.[100] The resulting bidirectional flow did not show adverse effects on the metabolism of the liver tissue reconstructed from primary cells.[101] The pumpless platform was further applied to construct a four-organ MOM with cardiac, muscle, neuronal and liver modules with functional readouts (Figure 5B).[43] This recirculating platform maintained the co-culture viable and functional over a 14 d period.

Figure 5.

Representative pumpless recirculating MOM systems. Self-contained, integrated MOMs that support co-culture of 2 to 13 organs have been demonstrated on pumpless microfluidic platforms. (A) A liver-tumor-marrow three-organ MOM. Reproduced with permission.[100] Copyright 2010, Royal Society of Chemistry. (B) A palm-sized 4-organ MOM system with integrated electrical activity and contractile force sensors for non-invasive functional monitoring.[43] (C) A modular microsystem that approximates unidirectional perfusion and supports the co-culture of GI tract epithelium and 3D primary liver construct with in situ TEER measurement capacity.[104] (D) A whole-body microphysiological system that considers explicitly thirteen organs.[105]

To accommodate barrier tissues, such as the intestine and endothelial layers, which can be effected by bidirectional flows, a “step chamber” has been introduced to minimize the bidirectional shear stress in the pumpless systems.[102,103] Passive valves were also used to approximate unidirectional perfusion in the organ chambers (Figure 5C).[104]

The Shuler group later developed a whole-body model based on the pumpless microfluidic platform, which considered explicitly thirteen organs (Figure 5D).[105] This body-on-a-chip device was designed based on a PBPK model. Organ chamber volumes and perfusion rates were scaled down proportionally to keep in vivo organ size ratios and physiological fluid resident time. To accommodate barrier tissues, they incorporated microporous membranes and adopted a layered design to separate barrier and non-barrier tissue cultures. A proof-of-concept demonstration was performed with 3D cultured cells from five different organs. The microfluidic platform maintained the co-cultures at high viability and liver functionality over a seven-day period. Their work demonstrated the feasibility of constructing and operating a physiologically relevant whole-body microphysiological system (with a large number of organ compartments) for a sustained period with the capability of measuring cellular functions.

Overall, the pumpless recirculating MOM systems are highly integrated, self-contained, and relatively easy and cost-effective to construct and maintain. With all fluidic components (microchambers, microchannels and reservoirs) built on chip requiring no external fluid or gas loops, these microsystems can be compact and stackable,[91] and thus hold great potential for relatively high throughput application in pharmaceutical industries. The gravity-driven passive flow system keeps the MOM systems free of air bubbles, which commonly occurs in a closed-channel recirculating systems and affects or interrupts their operation. The pumpless feature makes the MOMs easy to set up and maintain and can support reliable, long-term operation. The open reservoir design also provides easy access for liquid sampling. Current pumpless MOMs are all based on PBPK models that incorporate human physiological parameters. By designing microfluidic channel dimension and the tilting angle, desired organ-specific perfusion rates can be achieved. A price for this highly-integrated fluid system is losing some flexibility of flow network reconfiguration. Once the pumpless device is fabricated, the ratio of flow through different channels has been fixed, although the total flow rate can be adjusted by changing the tilting angle. The reservoirs required for reciprocal recirculation also increase the total volume of the fluid system resulting in higher systemic liquid-to-tissue ratio.

2.3.4. Summary

Recirculating multi-organ microfluidic platforms allow re-creation of the reciprocal organ-organ interactions that are missing in single-pass platforms. Different organ modules can be connected in parallel or in more complex circuits while still achieving organ-organ interactions. Without being limited to serial circuits, it is possible to create in vivo-like circulation architecture and provide differential perfusion over various organ modules. However, most of current recirculating MOMs are still at the stage of establishing reciprocal connections among organ modules. Many still used the simplest single serial circuit to connect all modules. PBPK model based µCCAs and the pumpless MOMs show greater physiological relevance by incorporating physiological parameters into designs of the microchambers, microchannels and the perfusion networks.

3. Advances in on-chip analytical technologies for MOMs

To construct reliable multi-organ MPS and perform drug testing, it is crucial to maintain desired cell microenvironment (such as pH, temperature, and oxygen level) and constantly assess cell responses in terms of viability, metabolism, and functionality. Integration of on-chip analytical technologies into MOMs often enables in situ non-invasive real-time monitoring of those important systemic and cellular parameters. Online biosensors and bioanalytical assays using electrical, electromechanical, electrochemical, and optical signals to extract physical, chemical, and biological information from in vitro culture systems have been developed and initially demonstrated in single-organ models. We will focus on major on-chip analytical technologies that have currently been integrated into MOMs.

3.1. Monitoring cellular microenvironment

Important physicochemical factors such as pH, dissolved oxygen, and temperature, as well as specific biochemical factors strongly affect cell function, behavior and growth.[106] In vitro cell culture aims to reproduce to some extent the complex in vivo microenvironment by controlling these physicochemical and biochemical parameters.[107] Monitoring of these parameters is crucial in MOM systems to provide reproducible conditions during in vitro culture.

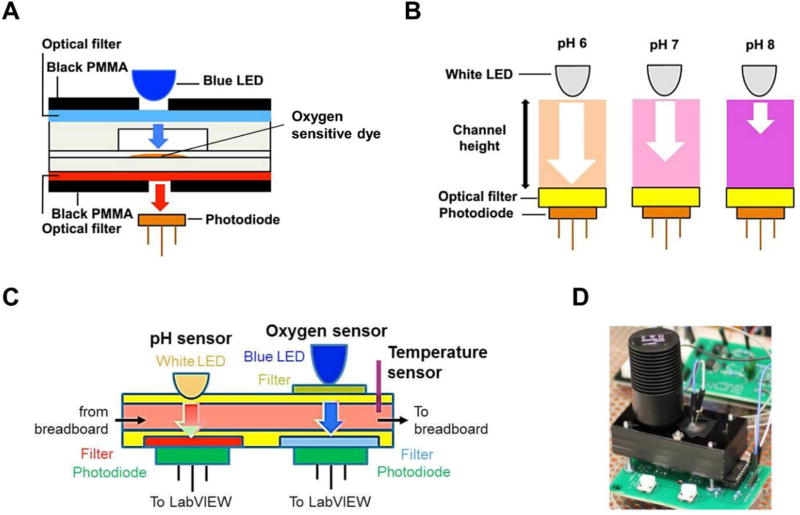

Oxygen is a key element in the behavior, function and energy metabolism of cells.[108] Maintaining desired levels of dissolved oxygen is essential to provide optimal culture conditions. Approaches using electrochemical and luminescent optical sensors have been developed for dissolved oxygen measurement. Optical methods are usually preferred in body-on-a-chip applications for their non-invasive nature and good signal stability over extended periods of time.[109] Fluorescence quenching of oxygen sensitive dyes is often utilized for oxygen sensing.[110] Sin et al. integrated a dissolved oxygen fluorometric sensor in a 3-chamber µCCA, which detected the fluorescence quenching of a ruthenium complex upon collision with oxygen molecules.[78] The ruthenium complex was immobilized in resin based particles and further encapsulated into a PDMS patch integrated in the µCCA chip. The patch was excited by a blue silicon LED, and the fluorescent emission was measured with a photodiode module. This in situ real-time monitoring approach indicated that the µCCA chip achieved adequate oxygen levels for culture. Zhang et al. incorporated an optical multi-analyte sensing module for in-line monitoring of pH and dissolved oxygen into a multi-organ microsystem.[84] The oxygen sensing used a similar setup as described above (Figure 6A).[111] The pH sensor utilized a silicon photodiode to quantify optical absorbance of the culture medium containing a pH-sensitive dye phenol red (Figure 6B). These sensors combined with a temperature probe allowed monitoring three key aspects of the microenvironment of the multi-organ platform (Figure 6C–D).

Figure 6.

Working principle of dissolved oxygen and pH measurement using optical sensors. (A) Measurement of dissolved oxygen is based on the luminescent quenching of an oxygen sensitive dye. A blue LED is used to excite the dye and a photodiode measures the changes in luminescent intensity. Reproduced with permission.[111] Copyright 2016, AIP Publishing. (B) Measurement of pH is based on the detection of light absorbed by phenol red containing cell culture media. Reproduced with permission.[111] Copyright 2016, AIP Publishing. (C) Schematic diagram showing the pH, dissolved oxygen and temperature sensors within a microfluidic module. Adapted from Zhang et al., 2017.[84] Copyright 2017, Zhang et al. (D) Photograph of the oxygen and pH sensing module. Reproduced with permission.[111] Copyright 2016, AIP Publishing.

3.2. Evaluating cell viability, morphology and functionality

Application of MOM systems requires effective readouts to assess the effects of a specific challenge. Cell viability and morphological analyses are the most commonly used approaches for evaluating cell response. Applications for drug bioavailability and efficacy testing often require more in-depth information on the functional state of cells and organs. Functional measurements of organ-specific parameters, such as cell metabolism, contractile force, electrical activity, and barrier permeability, produce a more sensitive evaluation of drug responses and provide insight into the underlying mechanisms.[91] Ideally, on-chip analytical technologies for integration into MOMs should provide non-invasive evaluation of these parameters to minimize any potential alteration of the system and allow live-cell monitoring throughout the culture period.

3.2.1. Cell morphology and viability

Imaging techniques such as light and fluorescence microscopy are a key tool in modern cell biology. A simple approach to monitor cell morphology in multi-organ systems is by developing optical transparent MOM systems with a size scale that allows visual inspection using standard optical microscopy. Materials such as PDMS, poly(methyl methacrylate) (PMMA), and glass with high optical transparency have been widely used in multi-organ systems.[112] Combined with automated imaging systems and cell viability indicators, transparent MOMs allow real-time in situ high-throughput analysis of cell morphology and viability. For example, Oh et al. developed a high-throughput approach to monitor long-term growth of liver (HepG2/C3A) and cancer (MES-SA) cells in multiple µCCA chips using a portable epi-fluorescence based optical microscope system that fitted into a standard cell culture incubator to image a large number of cells simultaneously.[113]

3.2.2. Cell metabolism

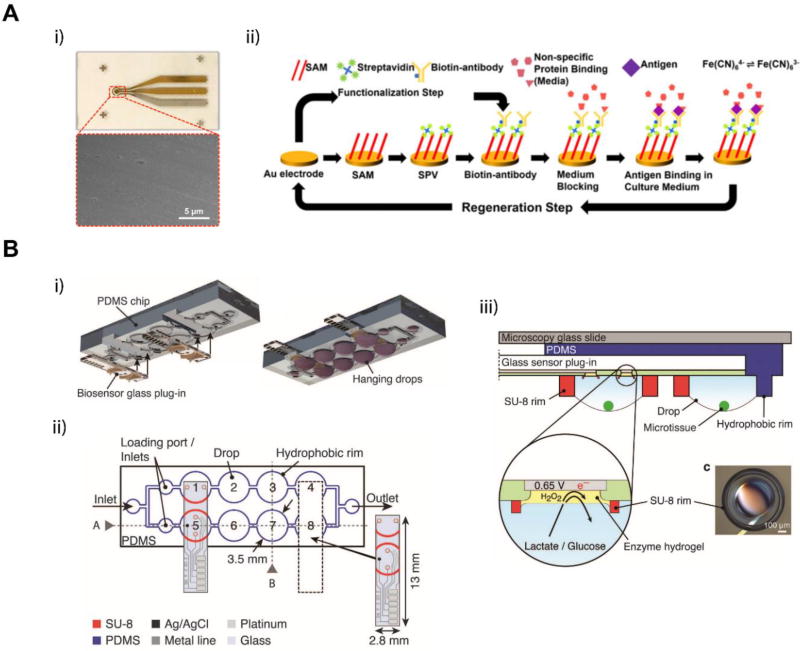

Cell metabolites secreted into the culture medium are often used to assess cell status during in vitro culture. They are useful functional markers for evaluating cell and organ response to physical or chemical challenges. Detection and quantification of these biomarkers with miniaturized on-chip biosensors using minimal sample volumes are desired in MOM systems. Much effort has been devoted to adapting macroscale biosensors for on-chip applications. Zhang et al. integrated electrochemical immunobiosensors in a liver-heart MOM system for continuous monitoring of the liver biomarkers albumin and glutathione S-transferase α (GST-α), and the cardiac specific marker creatine kinase (CK-MB) (Figure 7A).[84] The electrochemical sensors used biotinylated antibodies attached to the functionalized surface of microfabricated gold electrodes for antigen detection. The immunobiosensor module could also be regenerated using a cleaning mechanism (Figure 7A ii). This approach allows for continuous monitoring of cell secreted biomarkers through extended periods of time. Misun et al. incorporated in situ biosensing electrodes for monitoring lactate secretion and glucose consumption into a previously developed open channel, hanging drop array based MOM platform (Figure 7B).[85,114] The chip design allowed for plug-and-play usage of the biosensing electrodes, which could improve operation as the sensors could be calibrated off-chip and inserted before use or when needed during the culture period.

Figure 7.

On-chip biosensors integrated in MOM systems for cell metabolite detection. (A) Electrochemical immune biosensor. Adapted from Zhang et al., 2017.[84] Copyright 2017, Zhang et al. i) Photograph of a microelectrode set and SEM image of the working electrode surface. ii) Schematic showing the functionalization and regeneration process of the electrode. SAM, self-assembled monolayer; SPV, streptavidin. (B) Schematics of the microfluidic hanging-drop network and the plug-in biosensor chip. Adapted under the terms of the CC-BY-4.0 license.[114] Copyright 2016, Misun et al. i) 3D exploded view of the device and the plug-in biosensors. ii) 2D schematic of the hanging drop chip. The dashed lines represent the slot where the biosensor electrode is inserted. iii) Schematic and working principle of the enzyme-based biosensor. A hydrogel containing either glucose oxidase (GOx) or lactate oxidase (LOx) transforms glucose or lactate to produce hydrogen peroxide, which is electrochemically detected on the Pt surface at 0.65 V vs. Ag/AgCl.

3.2.3. Contractile force

Skeletal, cardiac and smooth muscle tissues are specialized for contraction, generating contractile forces. Functional readouts on muscle contractility are often desired when assessing a compound’s toxicity and efficacy on muscle tissues due to their superior sensitivity.[115] Traditional in vitro measurement approaches for muscle contractility often involve invasive and complex setups that are difficult to apply to microscale systems.[116,117] Novel miniaturized biosensors combined with non-invasive recording systems are being developed and incorporated into microphysiological systems.[118]

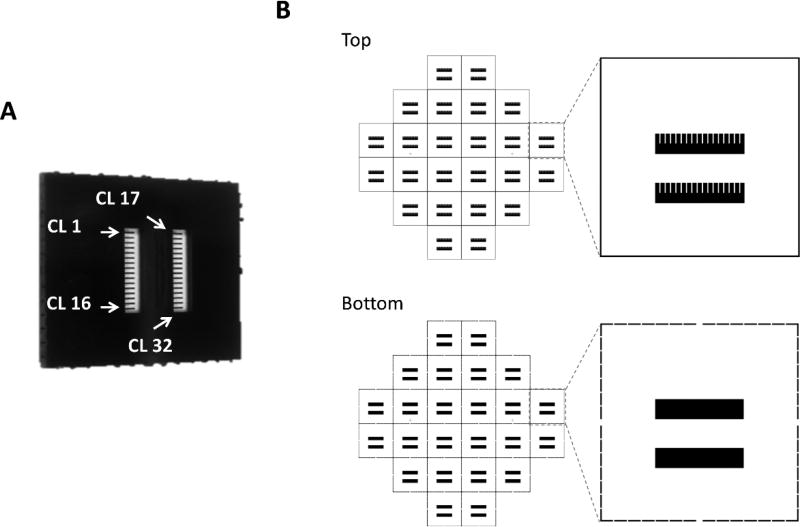

Adoption of silicone microcantilevers, originally developed for microelectromechanical systems (MEMS), has enabled on-chip biomolecular recognition[119] and force sensing[115] at micro- and nanoscale. Mechanical forces generated from myocytes cultured on the cantilever surface are transferred to the cantilever beam causing bending of the silicone cantilever. Based on this, the Hickman group developed a microcantilever array chip (Figure 8A) and an optical recording system (Figure 9A) to measure contractile force from cardiac or skeletal muscle cells.[43,120–126] The microcantilever chips with 32 parallel microcantilever beams were microfabricated from silicon-on-insulator wafers using photolithography (Figure 8B), and were surface modified to facilitate the anchorage of muscle cells.[126] Bending of the microcantilever beam due to muscle tissue contraction was non-invasively detected through a photodetector that measured changes in the deflection of a laser beam directed at the tip of the cantilever (Figure 9A–B). The contractile force was then calculated through the Stoney equation considering the mechanical properties of the cantilever and the geometry of the system.[123,124] Recently, Oleaga et al. has incorporated this technology into a pumpless four-organ MOM system (Figure 5B), and demonstrated and validated the use of biomechanical readouts on muscle tissues for drug testing in a multi-organ setting.[43] The system integrated two silicon microcantilever array chips as the on-chip biosensors to analyze changes in contractility of either human stem cell (hSC)-derived cardiomyocytes or skeletal muscle cells in response to drugs. This microcantilever based approach allows comprehensive measurement of peak force, time to fatigue and other characteristics that are difficult to quantify in in vitro systems.

Figure 8.

Design and fabrication of microcantilever chips for contractile force measurement. (A) Photograph of a silicon cantilever chip (1 cm × 1 cm). The chip contains 32 microcantilevers. Arrows indicate the position of cantilever 1, 16, 17 and 32. CL: cantilever. Reproduced with permission.[126] Copyright 2017, Springer Science+Business Media New York. (B) Schematics of the top and bottom photomasks for fabricating 24 cantilever chips on a single 4-inch wafer.

Figure 9.

Cardiac functional analysis with human cells using a microelectrode array (MEA) and microcantilever based system. (A) Diagram of the cantilever-based force measurement system. (B) Top: Phase contrast micrograph and immunocytochemistry micrograph of aligned human cardiomyocytes on the microcantilever chip. Bottom: Example traces of deflection and torsional force produced by the myocyte contractions. (C) Schematics of the patterning process on MEA. (D) Top left: Phase contrast micrograph of MEA with patterned human-derived cardiomyocytes. Top right: Immunostaining micrograph showing that human derived cells differentiated to cardiomyocytes. Bottom: Rhythm generation recorded by the MEA electrodes. Scale: The inter-electrode distance on the MEA is 200 µm. Reproduced with permission.[125] Copyright 2015, Elsevier.

Compliant micropillar based approaches have also been used for contractile force measurement.[127,128] Uzel et al. utilized PDMS micropillars to assess the force generation of muscle strips in a neuromuscular junction (NMJ) model (Figure 10).[128] Motoneurons derived from photosensitized mouse embryonic stem cells (mESCs) were optically excited to fire action potentials and further trigger muscle contraction. The contraction of a muscle strip anchored to a pair of PDMS micropillars was quantified by imaging-based automated tracking of the muscle strip deformation and micropillar deflection, and was converted to the contractile force based on the stress-strain characteristics of PDMS. The integration of these force sensors allowed for a non-invasive and quantitative characterization of muscle contraction due to neural excitation and NMJ function.

Figure 10.

Schematics of the neuromuscular MOM using integrated compliant micropillars to measure force generation from muscle strips. (A) Two-dimensional scheme of the chip design. B) Three-dimensional view showing the coculture of neurospheres and hydrogel embedded muscle bundles attached to the micropillars. C) Exploded view of the system showing the position of the micropillar layer. Adapted under the terms of the CC BY-NC 4.0 license.[128] Copyright 2016, Uzel et al.

3.2.4. Electrical activity

Measurement of the electrical activity provides information on the functionality of electrical conductive tissues, such as cardiac, muscle and nervous tissues. Techniques such as patch clamp and microelectrode arrays (MEA) have been developed to study the electrical activity of conductive tissues at the micro and meso scale.[129,130] While the patch clamp has greatly extended our knowledge of the electrophysiology of those tissues, it is an invasive, time-consuming, labor-intensive and skill-demanding technique that is difficult to integrate into MOM systems.[131] MEA based technologies, on the other hand, provide a non-invasive and high-throughput solution for monitoring the electrical activity of conductive tissues in microphysiological systems.[132,133]

MEAs allow detection of field potentials generated by cells in close proximity to substrate-integrated electrodes.[132,134,135] Based on that, the Hickman group designed a custom MEA (cMEA) chip for in vitro recording of the electrical activity of cardiac cells first demonstrated in a single organ system (Figure 9C–D).[125,136] With cells directly cultured on the MEA surface, this approach also allows to monitor cell networks and study signal propagation. Combined with cell patterning techniques, MEA recording can provide in-depth functional information, such as QT intervals, conduction velocity, in addition to beat frequency.[125,136,137] The cMEA chips have recently been incorporated into a pumpless multi-organ system to provide non-invasive functional readouts of cardiac and neuronal electrical activity (Figure 5B).[43] Integration of MEA and microcantilever chips into a same MOM system, enabling electrical and mechanical readouts, allows for comprehensive functional evaluation as well as mechanistic interrogation of organ response to challenges by compounds and drugs.

3.2.5. Barrier function

Barrier tissues, such as skin, GI tract and blood brain barrier, play an important role in regulating drug bioavailability and distribution in the body. Establishing and maintaining barrier functions in those tissue models in vitro are critical for multi-organ systems to reproduce in vivo pharmacokinetics. Transepithelial/transendothelial electrical resistance (TEER) is a commonly used indicator for barrier integrity. Non-invasive measurement of TEER can be conducted with electrodes on both sides of the cellular layer to measure the electrical resistance across the barrier.[138,139] This approach has been applied using microfabricated on-chip thin-film electrodes to monitor the barrier integrity of in vitro microfluidic models of intestine, lung alveolar epithelium, and blood brain barrier.[140,141] Circular Ag/AgCl pellet electrodes have also been integrated into organ chambers on a pumpless platform to measure the barrier properties of a blood-brain barrier model based on co-culture of brain microvascular endothelial cells and astrocytes cells.[103] The in-line electrode system provided comparable readouts to the commonly used chopstick electrode system designed for transwells. The same setup has recently been incorporated into a GI-liver model to monitor the barrier function of the GI tract cell layer over a 14 d culture period.

3.3. Summary

The continual development of MOM systems will require incorporating biosensor technology to monitor cell microenvironment and functionality in real time, non-invasively to move beyond acute evaluations of drugs and toxins to chronic assessment. Some effort has been done in incorporating non-invasive technologies that allow in situ monitoring of different organ modules but this work is still in its infancy and will be a major hurdle to overcome to enable more mainstream use of this technology. Several approaches have been used either by incorporating the biosensors inside the main platform system or by developing the biosensors as separate modules as indicated in the previous section and while these systems are functional their incorporation into multi-organ systems remains a challenge.

4. Applications for multi-organ microphysiological systems

Main applications of MOM systems are toward toxicity testing of compounds and industrial chemicals, drug efficacy evaluation, as well as modeling of diseases that involve multiple organs. NCATS at NIH and DARPA recently funded a $150,000,000 program for grants in this important area. Many proof-of-concept applications have been demonstrated on different platforms.

4.1. Toxicity assay and drug efficacy testing

One of the main areas of application of MOM systems is for the pharmaceutical, chemical and cosmetic industries to assess the potential toxicological hazard and effects of diverse compounds.[142,143] With multiple interconnected organ models, MOM systems hold the potential to simulate the dynamic in vivo ADME process of diverse substances,[144] and predict compound toxicity and drug efficacy. Systems with functional readouts could at the same time provide long-term evaluation of compounds that can currently only be done in animals.

4.1.1. Hepatic metabolism and Bioactivity

Liver models are the most commonly included module in a MOM system due to the essential role of liver in drug metabolism. Various compounds can undergo biotransformation in the liver that modifies their bioactivity. Prodrugs are transformed to active forms through enzymatic activation, while some toxins can be detoxified by hepatocytes. Therefore, a great number of MOM systems that includes the liver model have been developed to test the effects of drug and drug metabolites.

Metabolism-dependent, organ-specific toxicity

Dual-organ MOM systems combining models of the liver and another organ, such as heart, lung, and kidney, are used to test organ-specific toxicity of drugs and drug metabolites in addition to hepatotoxicity.

Cardiotoxicity is one of the main reasons of drug attrition during preclinical and clinical studies as well as post-approval withdraw.[145] Zhang et al. developed a liver-heart MOM system on the fluid breadboard based modular platform with on-chip electrochemical immunobiosensors and a mini-microscope to evaluate the side effects of an anti-cancer prodrug, capecitabine, and an anti-inflammatory drug, acetaminophen.[84] Capecitabine induced enhanced cell death in heart organoids (prepared from human iPSC-derived cardiomyocytes) in the present of liver organoids (prepared from human primary hepatocytes), likely due to the enzymatic bioactivation of capecitabine by hepatocytes into cardiotoxic 5-fluorouracil (5-FU). In contrast, 2 d exposure to acetaminophen resulted in dose-dependent hepatoxicity indicated by increased GST-α secretion and decreased albumin production and cell viability, and only slight changes in cardiac CK-MB secretion and beating rate. This demonstrates that a live-heart MOM system can be a useful tool to detect metabolism-dependent cardiotoxicity and hepatotoxicity of drug candidates.

Nephrotoxicity is another common adverse drug effect that could lead to significant clinical syndromes, such as acute kidney injury. Biotransformation of xenobiotics through the liver into more water-soluble compounds favors their disposal through the kidneys.[146,147] The kidney’s blood filtration process extracts these xenobiotic compounds and metabolites from the blood stream, which are concentrated in the kidney microenvironment.[148] This combined with constantly high levels of renal blood flow makes the kidney especially poised as a target for toxicity. Liver-kidney MOMs have been applied to investigate liver metabolism-dependent nephrotoxicity. Choucha-Snouber et al. established a liver-kidney system on a pump-driven recirculating MOM platform to test the nephrotoxicity of an anti-cancer prodrug ifosfamide.[82] Kidney cells (MDCK) proliferation was significantly inhibited in response to ifosfamide exposure in liver-kidney models constructed with HepaRG hepatocytes, but not with HepG2/C3A cells. This is mainly due to the much higher expression levels of cytochrome P450 (CYP)3A4 and CYP2B6 in HepaRG cells, which are involved in biotransformation of ifosfamide into nephrotoxic chloroacetaldehyde.

Other organ models, such as the lung and skin, have also been integrated with the liver models for toxicological studies. A liver-lung µCCA developed by Viravaidya et al. demonstrated liver metabolism dependent naphthalene toxicity towards lung epithelial cells.[44] A liver-fibroblast model built on the IdMOC platform showed that the presence of hepatocytes modified the viability of fibroblasts in response to 4-aminophenol and cyclophosphamide treatment through diffusible metabolites after liver detoxification or activation of the drugs,[149] while the cytotoxic effects of aflatoxin B1 were only limited to the liver compartment after the metabolic activation with no toxicant diffused to outside of the liver cells.[150] Liver-skin models using HepaRG hepatocyte spheroids and skin biopsies were built on the transwell compatible, pneumatic micropump-driven recirculating MOM platform, and used to study chronic toxicity of repeated dosing of troglitazone for up to 9 days.[92,93] The study showed that repeated exposure to troglitazone induced hepatotoxicity with an increase of LDH activity and CYP3A4 in a dose dependent manner.

Efficacy and toxicity of anti-cancer drugs

Oncology drug development has the lowest clinical success rate among all therapeutic areas, with only 5.1% of candidates entering Phase I eventually get FDA approval.[4] Clinical safety concerns on serious adverse events and lack of efficacy are two primary causes of failure in clinical trials.[151] To assess the efficacy as well as toxicity of an anti-cancer treatment in vitro, MOM systems that integrate models of the liver, tumor, and other organs have been developed.

Efficacy of anti-cancer drugs and drug metabolites can simply be evaluated using dual liver-cancer models. Frey et al. constructed a liver-colon cancer model with HCT-116 colon cancer spheroids and rat liver cells using the hanging drop array-based platform, and demonstrated the anti-cancer effects of 5-FU and liver-bioactivated cyclophosphamide (CP), indicated by inhibited cell growth of HCT-116 cells.[85] Lee et al. developed a liver-tumor model with HepG2 and HeLa cells on the pumpless recirculating platform to investigate the anti-cancer activity of a flavonoid, luteolin, which was found metabolized by liver cells into more potent tumor-killing metabolites in a concentration dependent manner.[152] This dual organ system also revealed significantly weaker anti-cancer activity than that predicted by a 96-well plate study, likely due to the simultaneous liver metabolism and tumor growth inhibition in the MOM system, versus the sequential presence of those two activities using the multiwell plate platform.

More organ models, in addition to the liver and cancer, have been integrated into MOM systems to simultaneously evaluate the efficacy and toxicity of anti-cancer therapeutics. Two heart-liver cancer MOM systems have been developed to test a chemotherapeutic drug, doxorubicin.[84,99] They were constructed on either the fluid breadboard based platform or an integrative pneumatic pump-driven recirculating platform, using HepG2/C3A hepatocellular carcinoma cells and primary or iPSC-derived human cardiomyocytes. Both systems captured the anti-cancer effects of doxorubicin indicated by decreased albumin secretion, cell proliferation and viability of the liver cancer cells. These models also detected significant cardiotoxicity from doxorubicin treatment, likely due to the cardiotoxic liver metabolite doxorubicinol. Sung et al. designed a liver-colon cancer-marrow three-organ µCCA to study the drug effects of 5-FU, its oral prodrug, Tegafur, and a combination of Tegafur with uracil.[81] The µCCA were built with 3D hydrogel cultures of colon cancer cells (HCT-116), liver (HepG2/C3A) and myeloblast (Kasumi-1) cells, and demonstrated the anti-cancer effects of 5-FU and liver-bioactivated Tegafur and their cytotoxicity towards myeloblasts. Administration of Tegafur with uracil to the system enhanced the anti-cancer effects by inhibiting 5-FU degradation. Sung et al. later reinvented the 3-organ system using a pumpless platform, and combined with a PK-PD model to study the dose responses to 5-FU from all three cell types.[100]

With increased number of organs incorporated into the basic liver-cancer model, MOM systems can also be used to evaluate the differential multi-organ toxicity beyond the anti-cancer effect of cancer therapeutic drugs. Li et al. constructed a 6-organ MOM on the wells-within-a-well IdMOC platform using cocultures of MCF-7 breast cancer cells and primary human cells from five major organs, including liver (hepatocytes), kidney (renal proximal tubule cells), lung (small airway epithelial cells), central nervous system (astrocytes) and vasculature (aortic endothelial cells).[71] This multi-organ coculture system demonstrated the anti-cancer effect of tamoxifen as well as its differential cytotoxicity on primary cells from various organs.

Multidrug resistant (MDR) cancers are especially challenging to treat. While current MDR modulators all come with various side effects, combining chemotherapeutics with a mixture of MDR modulators with different side effects may generate useful treatment strategies. In a proof-of-concept study, Tatosian et al. used a 4-chamber µCCA with liver (HepG2/C3A), bone marrow (MEG-01), uterine cancer (MES-SA), and MDR uterine cancer (MES-SA/DX-5) to test drug combinations that selectively attack MDR cancer cells.[80] The study identified a combination of a chemotherapeutic, doxorubicin and two MDR modulators, cyclosporine and nicardipine that provided optimal efficacy with acceptable side effects.

Chronic drug toxicity and efficacy testing with functional readouts

Chronic testing of drug efficacy and side-effects are often needed in preclinical screening, while most of current MOM systems developed have been focused on acute studies, due to the challenge of long-term maintenance of multi-organ co-cultures and many destructive, end-point assays they use. Increasing the lifespan of multi-organ systems is critical to enable the feasibility of performing repeated dose and chronic studies of xenobiotics. MOM systems that support long-term multi-organ co-cultures, and provide non-invasive functional readouts are desired for chronic applications. In a landmark investigation, Oleaga et al. used a four-organ MOM to test the effects of doxorubicin, atorvastatin, valproic acid, acetaminophen and a control compound N-acetyl-m-aminophenol in human cardiac (iPSC-derived cardiomyocytes), liver (HepG2/C3A), skeletal muscle (human skeletal muscle) and neurons (human motoneurons) in a recirculating serum-free medium.[43] The co-cultures were maintained for up to 14 days. Results obtained upon drug exposure in the multi-organ system showed a good correlation with results observed in the literature. Doxorubicin at 5uM induced hepatotoxicity, cardiotoxicity and a decrease in cardiac and skeletal muscle functionality while atorvastatin showed myotoxicity, neurotoxicity, hepatotoxicity and reduction in muscle functionality. Exposure to valproic acid at 2 mM affected the liver compartment with a reduction in viability and urea production while showing neuroprotective effects. Exposure to an overdose concentration of 5 mM acetaminophen decreased liver viability while preserving cardiac viability and functionality. The multi-organ platform was later extended by the Hickman group for up to 28 days in vitro, which maintained organ function, and demonstrated the potential of this platform for further chronic studies.

4.1.2. GI absorption and metabolism of oral drugs

Oral drug delivery is the most commonly used route of drug administration due to its convenience and low cost. Orally delivered drugs need to go through the GI system, where they are selectively absorbed and metabolized before entering the hepatic portal vein. GI absorption and the subsequent liver metabolism, also called first-pass metabolism, play an important role in determining the bioavailability of an oral drug and its bioactive metabolites in the systemic blood circulation. GI tract models are, therefore, often integrated with liver models into a MOM system to simulate this process and to predict oral drug bioavailability.[42,62,63,73,75,76,87,89,90,93,102,104]