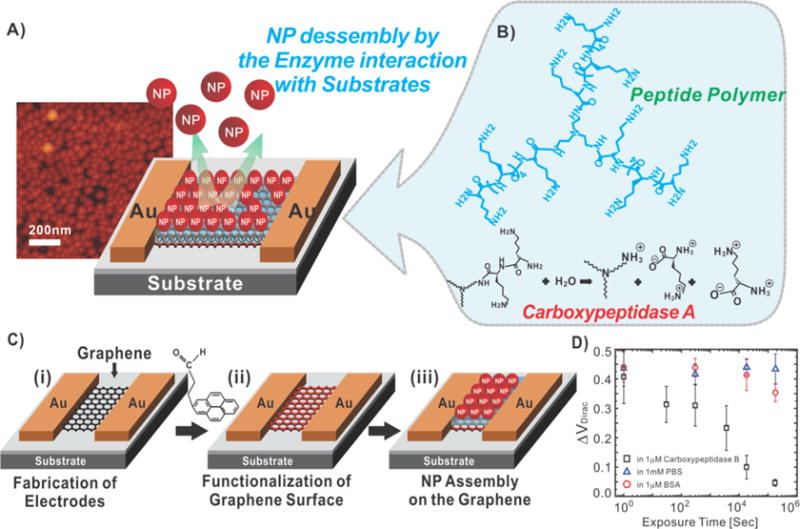

Graphical abstract

1. INTRODUCTION

Graphene is composed of single-atom thick sheets of sp2 bonded carbon atoms that are arranged in a perfect two-dimensional (2D) honeycomb lattice. Because of this structure, graphene is characterized by a number of unique and exceptional structural, optical, and electronic properties.1 Specifically, these extraordinary properties include, but are not limited to, a high planar surface area that is calculated to be 2630 m2 g−1,2 superior mechanical strength with a Young’s modulus of 1100 GPa,3 unparalleled thermal conductivity (5000 W m−1 K−1),4 remarkable electronic properties (e.g., high carrier mobility [10 000 cm2 V−1 s−1] and capacity),5 and alluring optical characteristics (e.g., high opacity [~97.7%] and the ability to quench fluorescence).6 As such, it should come as no surprise that graphene is currently, without any doubt, the most intensively studied material for a wide range of applications that include electronic, energy, and sensing outlets.1c Moreover, because of these unique chemical and physical properties, graphene and graphene-based nanomaterials have attracted increasing interest, and, arguably, hold the greatest promise for implementation into a wide array of bioapplications.7

In the last several years, numerous studies have utilized graphene in bioapplications ranging from the delivery of chemotherapeutics for the treatment of cancer8 to biosensing applications for a host of medical conditions9 and even for the differentiation and imaging of stem cells.10 While promising and exciting, recent reports have demonstrated that the combination of graphene with nanomaterials such as nanoparticles, thereby forming graphene–nanoparticle hybrid structures, offers a number of additional unique physicochemical properties and functions that are both highly desirable and markedly advantageous for bioapplications when compared to the use of either material alone (Figure 1).11 These graphene–nanoparticle hybrid structures are especially alluring because not only do they display the individual properties of the nanoparticles, which can already possess beneficial optical, electronic, magnetic, and structural properties that are unavailable in bulk materials, and of graphene, but they also exhibit additional advantageous and often synergistic properties that greatly augment their potential for bioapplications.

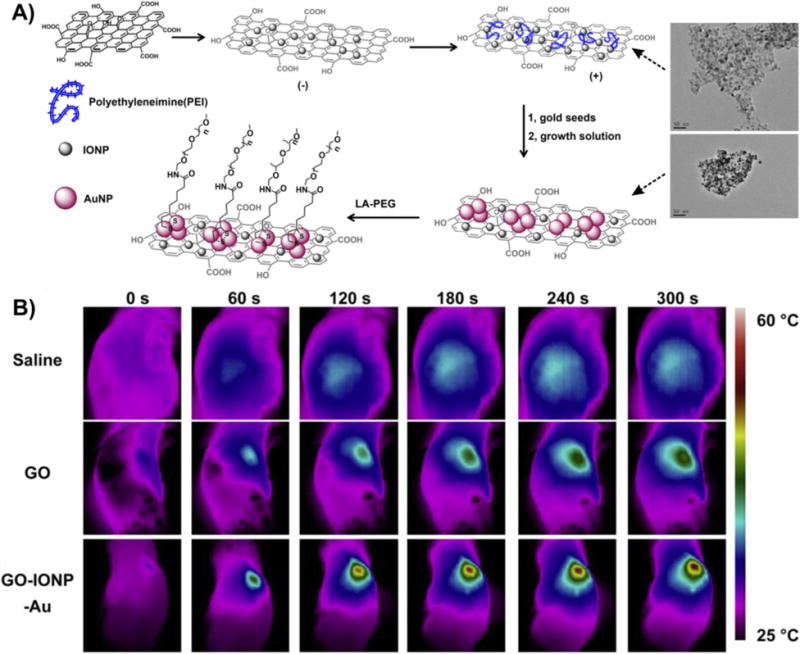

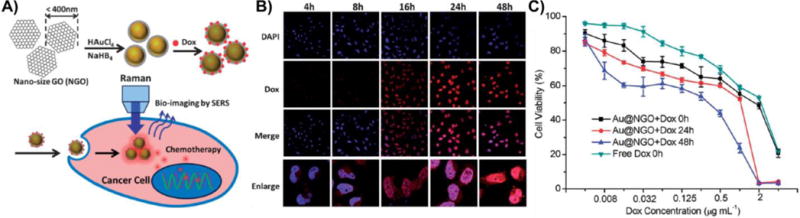

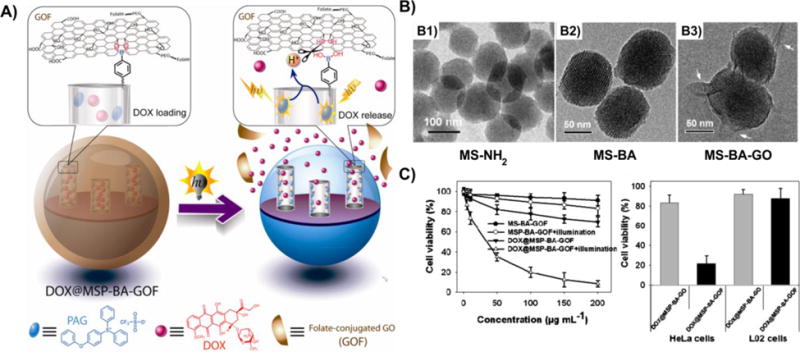

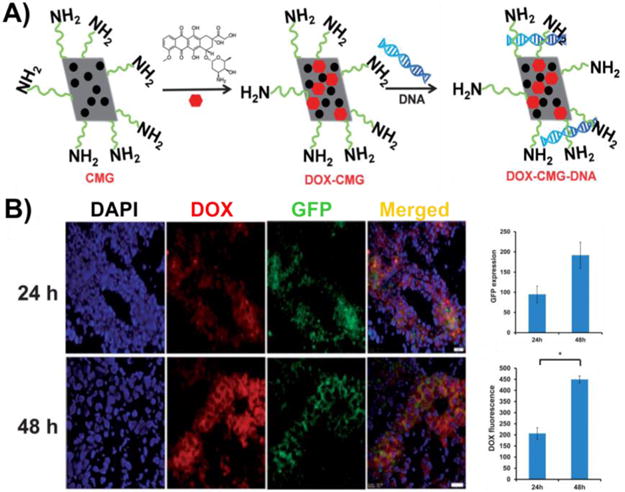

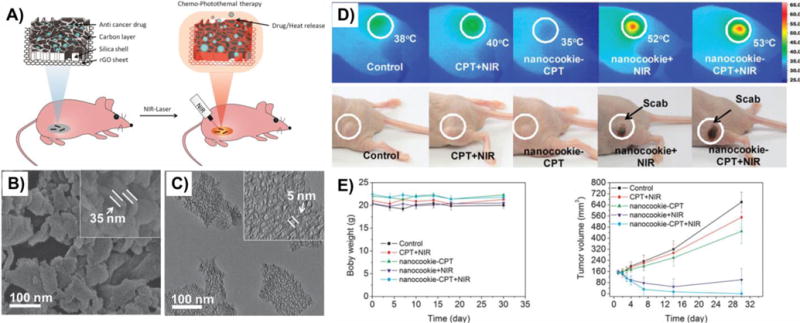

Figure 1.

Graphene nanoparticle hybrids exist in two forms, as graphene–nanoparticle composites and graphene-encapsulated nanoparticles, and can be used for various bioapplications including biosensors, photothermal therapies, stem cell/tissue engineering, drug/gene delivery, and bioimaging. Panel (A) reprinted with permission from ref 110. Copyright 2012 Wiley. Panel (B) reprinted with permission from ref 211. Copyright 2013 Elsevier. Panel (C) reprinted with permission from ref 244. Copyright 2013 Wiley.

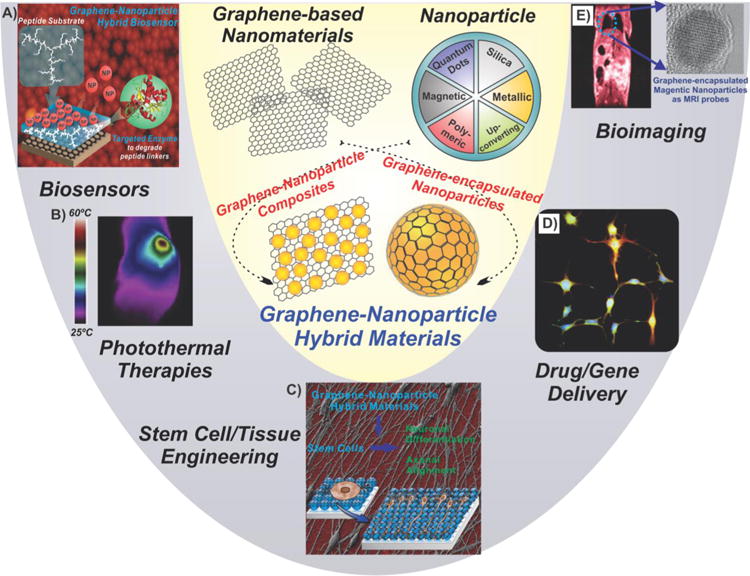

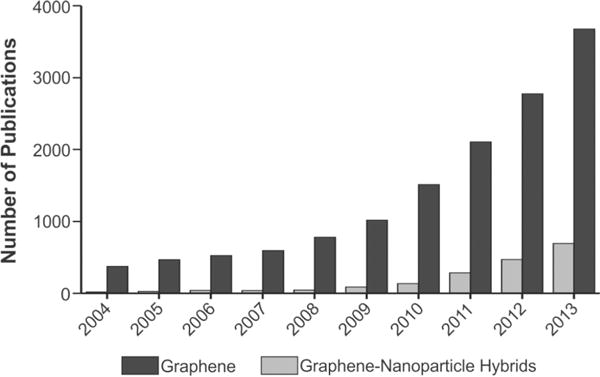

In general, these graphene–nanoparticle hybrid materials can be categorized into two classes (Figure 2). They can exist as (1) graphene–nanoparticle composites, where the nanoparticles decorate or are grown on graphene sheets (Figure 2A and B), or (2) graphene-encapsulated nanoparticles wherein the nanoparticle surface is wrapped or coated with graphene (Figure 2C and D). In particular, graphene–nanoparticle hybrid structures can be synthesized by combining graphene or its derivatives, graphene oxide (GO) and reduced graphene oxide (rGO), with various types of nanoparticles including, but not limited to, quantum dots (QDs), metal (e.g., noble metal and magnetic), metal oxide, or silica nanoparticles (SiNPs), depending on the final functional properties that are desired. By combining these unique and robust materials, a striking synergy can often be achieved. For instance, the decoration of metal or metal oxide nanoparticles on graphene surfaces has been shown to have implications on the charge transfer behavior in graphene through the modification of the local electronic structure.12 As a result, this type of composite material can show improved performance as catalysts. On the other hand, in sensing applications, the combination of nanoparticles, which have excellent conductivity and catalytic properties, with graphene materials allows for the enhancement of achievable sensitivity and selectivity over either graphene or nanoparticle-based sensors alone.11a,13 Finally, by combining graphene with nanoparticles, it is possible to deliver cargo (e.g., small molecule drugs, nucleic acids, etc.) to target cells (e.g., cancer cells or stem cells) while enabling complementary multifunctionalities such as imaging (e.g., surface-enhanced Raman spectroscopy [SERS] or magnetic resonance imaging [MRI]) and hyperthermia (e.g., using near-infrared [NIR] radiation).14

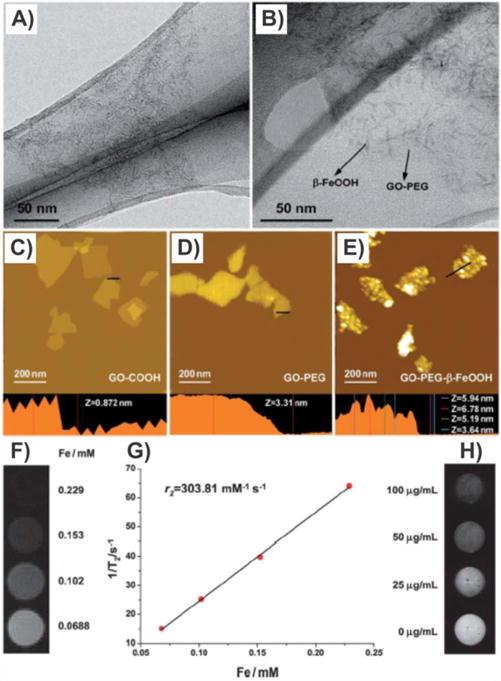

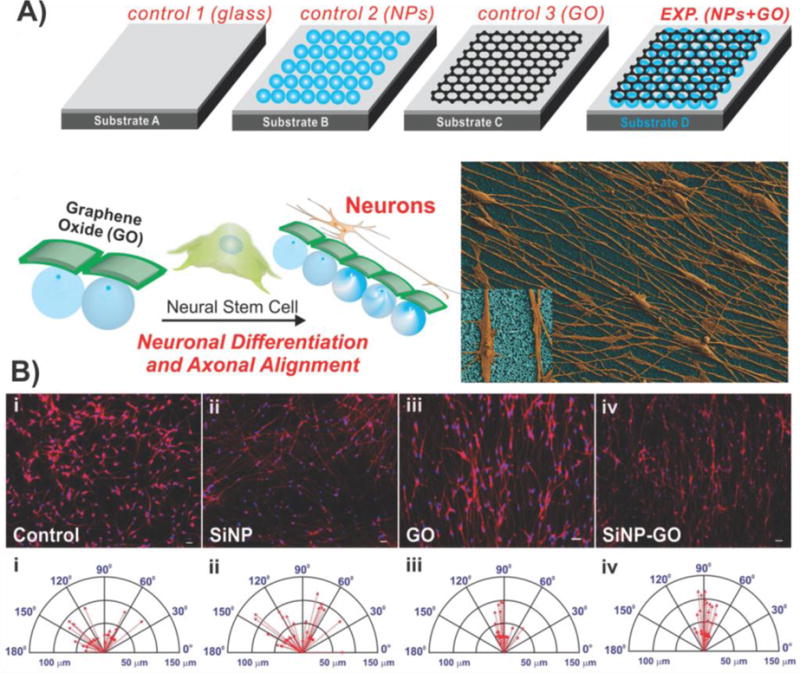

Figure 2.

Graphene–nanoparticle hybrid structures. Panels (A) and (B) show graphene-nanoparticle composites wherein nanoparticles are decorated on the surface of graphene sheets. Panel (A) reprinted with permission from ref 146. Copyright 2011 Elsevier. Panel (B) reprinted with permission from ref 102. Copyright 2010 American Chemical Society. Panels (C) and (D) show graphene-encapsulated nanoparticles wherein nanoparticles are wrapped by graphene. Panel (C) reprinted with permission from ref 112. Copyright 2012 American Chemical Society. Panel (D) reprinted with permission from ref 104. Copyright 2010 Wiley.

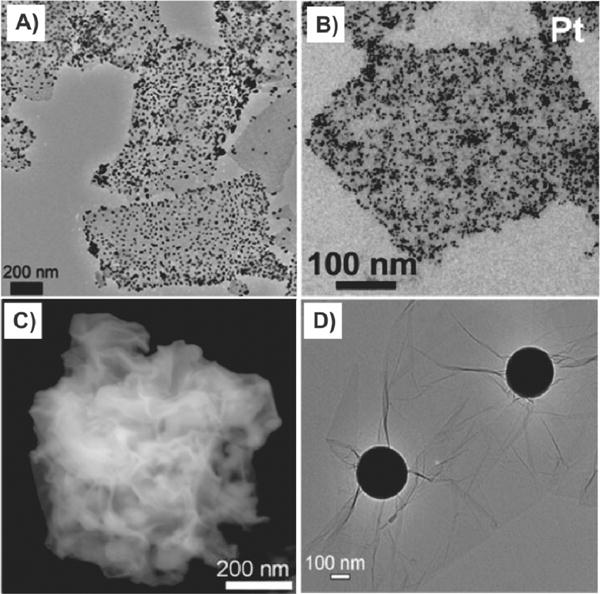

In this Review, we will systematically discuss graphene–nanoparticle hybrid materials in terms of their synthesis, characterization, and implementation to a host of bioapplications. While there are already numerous excellent reviews that cover graphene synthesis, its chemical and physical properties, and its bioapplications,1,15 graphene–nanoparticle hybrid materials and their implementation into bioapplications is a relatively new area that has not been comprehensively reviewed. Moreover, graphene–nanoparticle hybrid materials are gaining significant traction in the field of graphene research, where, in 2013, approximately 20% of all papers published on graphene involved the synthesis and application of graphene–nanoparticle hybrid materials (Figure 3). Thus, we present the first complex work covering all modes and methods for the synthesis of graphene–nanoparticle hybrid materials, its unique chemical and physical properties, and, most importantly, its utilization for bioapplications. Specifically, we will focus on graphene–nanoparticle hybrid materials for biosensing, multifunctional drug delivery, imaging, as well as for the control of stem cell differentiation with particular emphasis on the advantages and differences that are conferred by the use of graphene–nanoparticle hybrid materials over conventional methods in each area. We will also discuss trends, future directions, and any controversies that exist in the field. As a result, we hope that this Review will inspire interest from various disciplines and highlight an up and coming field wherein graphene–nanoparticle hybrid structures can bring significant advantages to a wide variety of bioapplications.

Figure 3.

The number of publications utilizing graphene–nanoparticle hybrid materials is increasing (numbers were obtained from PubMed).

2. SYNTHESIS AND CHARACTERIZATION OF GRAPHENE–NANOPARTICLE HYBRID MATERIALS

Because of the many unique and advantageous properties of graphene and its derivatives, GO and rGO, a significant amount of effort has been invested in utilizing these materials either by themselves, or in combination with other interesting nanomaterials such as nanoparticles. As mentioned previously, graphene–nanoparticle hybrid materials can be broadly categorized into two main classes on the basis of their structural morphology. They can exist as (1) graphene–nanoparticle composites, where nanoparticles are decorated or grown on sheets of graphene or its derivatives, and (2) graphene-encapsulated nanoparticles wherein nanoparticles are wrapped by graphene or its derivatives. The main difference between these two classes can be found in the relative size ratio that exists between the diameter of the nanoparticles and the lateral dimensions of the graphene sheets. Specifically, when the diameter of the nanoparticles is in the range of a few nanometers to about a hundred nanometers, the nanoparticles are generally small in comparison to the graphene sheets and can easily be decorated onto the sheets, thereby forming graphene–nanoparticle composites. On the other hand, when the size of the nanoparticles is larger and becomes more comparable with the graphene sheets, the small 2D sheets can be wrapped around the nanoparticles resulting in graphene-encapsulated nanoparticles. In this section, we will begin by briefly describing the primary methods used to produce graphene, GO, and rGO. This will be followed by an in-depth analysis of the various methods that have been developed for the synthesis of graphene–nanoparticle hybrid structures, with particular emphasis on the properties and characteristics that result from these different procedures.

2.1. Graphene and Graphene Oxide

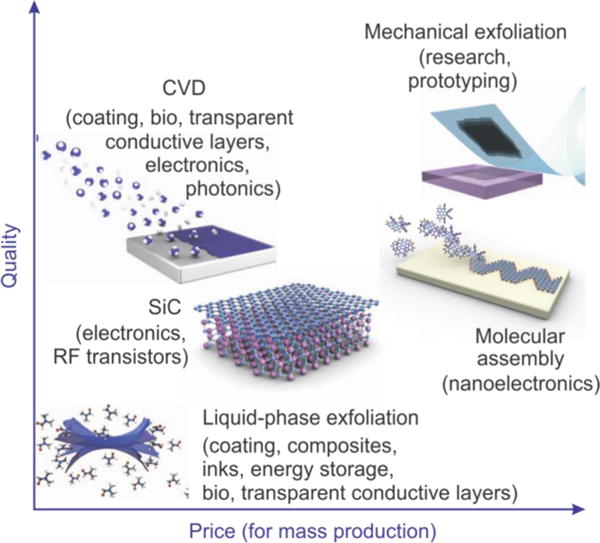

Graphene sheets can be obtained using a number of procedures; however, there are three primary methods, which include: (1) mechanical exfoliation, (2) chemical vapor deposition (CVD) onto metal or Si substrates, and (3) the chemical, electrochemical, or thermal reduction of GO (Figure 4). For the mass-production of graphene, the CVD method is the most effective and can be used to fabricate large areas of graphene while limiting the number of defects.16 Consequently, graphene that is obtained using the CVD method can have a carrier mobility that reaches values as high as ~2000–4000 cm2 V−1 s−1.17 On the other hand, mechanical exfoliation using the Scotch tape method or by rubbing lithographically patterned pillars with “tipless” atomic force microscopy (AFM) cantilevers can be used to generate very high-quality graphene with a carrier mobility that reaches ~10 000 cm2 V−1 s−1 at room temperature.18 Using this method, the physical limit of the graphene sheets that are produced has lateral dimensions on the order of tens to hundreds of micrometers. However, mechanical exfoliation has poor reproducibility and is not amenable to large-scale fabrication.1c Finally, the reduction of GO has also been demonstrated to be a relatively economical and facile technique for the production of graphene and will be explained in more detail below; however, it has been reported that the quality of these graphene (rGO) sheets, in terms of electrical conductivity, is generally lower than that produced using the other two methods described.19 As such, overall, the reduction method is a better fit for the mass-production of small graphene sheets, while the CVD method is more efficient for the mass-production of high-quality graphene. Hence, the application for which graphene is being synthesized must first be considered before the appropriate synthesis method can be selected (Figure 4).

Figure 4.

Methods for the mass-production of graphene. There are several choices depending on the particular application, each with differences in terms of size, quality (e.g., presence of defects and impurities), and price. Reprinted with permission from ref 1c. Copyright 2012 Nature.

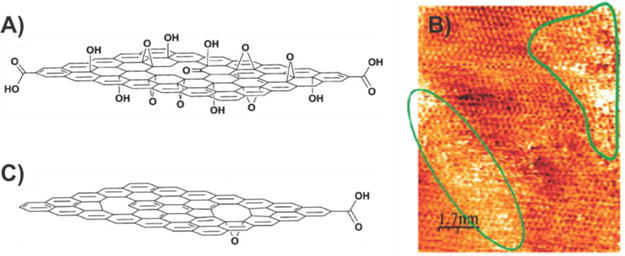

On the other hand, GO has many distinct characteristics that greatly differentiate it from those of graphene due to the presence of numerous oxygen-containing hydroxyl and epoxy groups on the basal plane, along with smaller quantities of carboxyl, carbonyl, phenol, lactone, and quinone that are present at the edges,20 which collectively act to inhibit electron transfer (Figure 5A and B). Specifically, GO films are hydrophilic and typically insulating with an energy gap in the electron density of states and a sheet resistance of about 1012 Ω sq−1 or higher.21 However, similar to graphene, GO exhibits excellent electronic, thermal, electrochemical, and mechanical properties and is flexible, transparent, and also biocompatible due to its hydrophilic nature. In terms of its fabrication, GO is most commonly produced using the Brodie, Staudenmaier, and Hummer methods or some variation of these methods.19b,22 All three methods involve the oxidation of graphite to various levels resulting in the formation of hydrophilic groups on the surface. In particular, a combination of potassium chlorate (KClO3) and nitric acid (HNO3) is typically used to oxidize graphite in the Brodie and Staudenmaier methods, while potassium permanganate (KMnO4) and sulfuric acid (H2SO4) are used in the Hummer method.23 After the oxidation process, the resulting product is then exfoliated to obtain one- or multilayered GO sheets with ultrasonication being the most commonly used procedure.

Figure 5.

Structure of graphene oxide and reduced graphene oxide. (A) Chemical structure of GO. (B) Scanning tunneling microscope (STM) image of a GO monolayer on a highly oriented pyrolytic graphite substrate. Oxidized regions are marked by green contours. Panel (B) reprinted with permission from ref 5b. Copyright 2007 American Chemical Society. (C) Chemical structure of rGO. Panels (A) and (C) reprinted with permission from ref 24. Copyright 2010 Wiley.

Finally, as mentioned above, rGO can be obtained from GO through chemical, electrochemical, or thermal reduction, which removes the oxygen-containing branches from the basal planes and edges of the GO sheets (Figure 5C).22,24 As a consequence, the electrical conductivity of GO (as well as its thermal stability) can be restored close to the levels found in graphite. Specifically, the electrical conductivity of rGO has been reported to fall within the range of 200–42 000 Sm−1.19a,25 However, this depends significantly on the parameters used during reduction, including the type of reducing agent, duration of reduction, temperature, annealing time, and annealing temperature. Moreover, while the specific capacitance of rGO is significantly higher than that of GO, the transparency and dispersibility of rGO are significantly reduced when compared to pure GO sheets. To form rGO from GO, hydrazine, hydroquinone, ascorbic acid (AA), and sodium borohydride are commonly used to remove the hydroxyl groups from GO. Electrochemical tools can also be used to fabricate rGO. For instance, this can be accomplished using either acidic (e.g., sulfuric acid) or nonacidic solutions such as Na-phosphate-buffered saline (PBS), K-PBS, NaOH, and KCl in the presence of a constant reduction potential or sweeping potential.26 Finally, thermal reduction is also a well-known method for the removal of oxygen functional groups from the surface of GO. In this method, oxygen functional groups are removed in the form of water, carbon dioxide, and carbon monoxide by placing the GO sample in a preheated furnace at 1000–1100 °C for 30–45 s in the absence of air.27 However, chemical and electrochemical methods tend to be preferred as they can be performed under more mild conditions.

2.2. Graphene–Nanoparticle Composites

Graphene–nanoparticle composites, wherein sheets of graphene, GO, or rGO, are decorated with nanoparticles that are a few nanometers to a couple hundred nanometers in diameter,28 can be obtained by anchoring various types of nanoparticles to the surface of graphene sheets through both in situ (e.g., growing the nanoparticles on the graphene surface) and ex situ (e.g., attaching premade nanoparticles to the graphene surface) methods. GO and rGO are especially promising templates for this purpose as the presence of defects and oxygen functional groups on their surfaces allows for the nucleation, growth, and attachment of various metal (e.g., Au,29 Ag,30 Pt,31 etc.) and metal oxide nanoparticles (e.g., Fe3O4,32 TiO2, 33 ZnO,34 SnO2,35 Cu2O,36 MnO2,37 NiO,38 etc.). The resulting graphene–nanoparticle composites are then able to offer numerous unique and advantageous properties for various applications depending on the particular characteristics possessed by the nanoparticles used to form the composites. For example, graphene–nanoparticle composites can confer excellent catalytic activity, enhancements in mass transport, and a significantly higher effective surface area.20b As such, recent efforts in this area have not only focused on methods to form graphene–nanoparticle composites while preserving the excellent properties of graphene but also on precisely tuning the physicochemical features that are present. In this section, we will give a comprehensive review of the different methods that are available for the preparation of graphene–nanoparticle composites including various in situ (e.g., reduction, hydrothermal, and electrochemical) and ex situ methods (Table 1). We will specifically focus on the distinct characteristics and properties that each technique imparts on the resulting graphene–nanoparticle composite.

Table 1.

Summary of the Different Methods Used To Prepare Graphene–Nanoparticle Composites

| method | typical NPs | key characteristics | key refs |

|---|---|---|---|

| reduction | metal NPs, especially noble metals | (1) one-pot synthesis; (2) highly efficient and easy to perform; (3) can be difficult to control the size and morphology of the NPs; however, can be addressed by using microwave-facilitated reduction | 30, 39–55 |

| hydrothermal | metal oxide NPs, QDs | (1) can create NPs with high crystallinity and narrow size distribution; (2) high temperature and long reaction times can partially or completely reduce GO on its own | 56–76 |

| electrochemical | metal NPs, especially noble metals | (1) simple, fast, and green technique; (2) low cost, easy to miniaturize and automate, and is highly stable and reproducible; (3) pulse current can be adjusted to control density, size, and morphology of NPs; also allows for simultaneous reduction of GO | 78–84 |

| ex situ | inorganic NPs, especially noble metals | (1) NPs are synthesized in advanced; this allows for precise control of the size, shape, and density of the NPs that are used to form hybrids; (2) ex situ methods include covalent or noncovalent interactions such as van der Waals interactions, hydrogen bonding, π–π stacking, or electrostatic interactions | 86–103 |

2.2.1. Reduction Methods To Form Graphene–Nanoparticle Composites

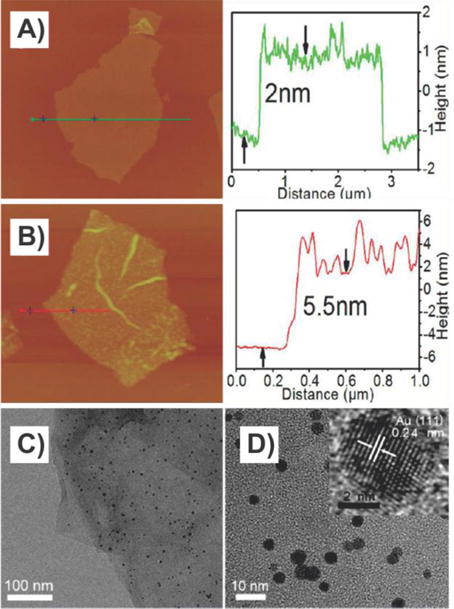

Graphene–metal nanoparticle composites are most frequently fabricated via the reduction of metallic salts (e.g., HAuCl4, AgNO3, and K2PtCl4) using chemical agents such as ethylene glycol, sodium citrate, and sodium borohydride.30,39 More specifically, the negatively charged functional groups that exist on the surface of GO allow for the nucleation of positively charged metallic salts, resulting in the growth of metal nanoparticles on the GO surface. By utilizing this method to form rGO–metal nanoparticle composites, it is possible to preserve the excellent electrical properties of graphene. Moreover, by controlling the density of oxygen-containing groups on the GO and rGO surface, one can easily tune the density of nanoparticles formed on the resulting graphene–nanoparticle composites. In general, to form graphene–metallic nanoparticle composites in situ via reduction, a one-step method is used wherein the metal precursor and GO sheets are mixed in an aqueous solution and then reduced simultaneously (Figure 6). This reaction is similar to conventional nanoparticle synthesis methods and follows three steps: (1) reduction, (2) nucleation, and (3) nanoparticle growth. More specifically, the functionalities that exist on the GO and rGO surface, such as alcohols, carbonyl groups, and acids, are responsible for the attachment of free metal ions through electrostatic interactions. Subsequently, the addition of a reducing agent promotes the reduction of the attached metal ions, thereby enabling the growth of metal nanoparticles on the GO and rGO surfaces.40 While this method is highly efficient and easy to perform, the size and morphology of the metal nanoparticles on the resulting composite can be difficult to control, resulting in samples that are decorated with nanoparticles that have a wide size distribution.41

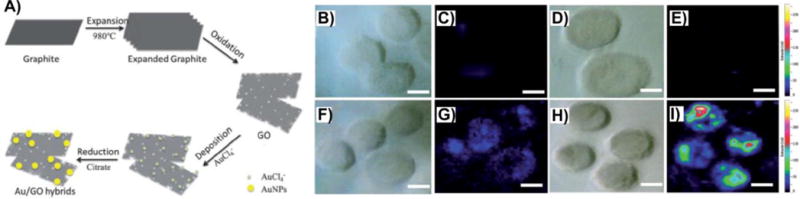

Figure 6.

Graphene–nanoparticle composite composed of GO sheets decorated with AuNPs. (A) AFM image of a single GO sheet and (B) a GO sheet decorated with 3.5 nm AuNPs. The corresponding curves on the right side show the thicknesses of the GO sheet and the GO/AuNP sheet. (C and D) TEM images of the GO/AuNP sheet with different magnifications. Inset of (D) shows a high-resolution TEM image of a single AuNP. Reprinted with permission from ref 41. Copyright 2013 American Chemical Society.

To date, the reduction technique has been used primarily for the preparation of graphene–noble metal nanoparticle composites. Noble metal nanoparticles, especially gold (AuNP) and silver nanoparticles (AgNPs), are among the most extensively studied nanomaterials and have led to the development of numerous biotechniques and applications including diagnostics, imaging, drug delivery, and other therapeutics.42 Noble metal nanoparticles are of particular interest because of their unique and unusual properties such as high biocompatibility and optical properties (e.g., surface plasmon resonance), which can easily be tuned to the desired wavelength according to their shape (nanoparticles, nanoshells, nanorods, etc.), size, and composition.43 In addition, when combined with graphene as a composite, graphene–noble metal nanoparticle hybrids are able to exhibit SERS as well as enhanced catalytic potential.44 To this end, numerous methods have been used to fabricate graphene–AuNP composites, which are currently the most commonly prepared and utilized graphene–nanoparticle composite. Briefly, graphene–AuNP composites can be attained by mixing HAuCl4 precursor with exfoliated GO and sodium citrate, resulting in gold precursors anchoring to the surface of GO via electrostatic interaction. Afterward, the gold precursors are reduced using NaBH4 to form AuNPs.45 Similarly, graphene–AgNP composites can be obtained by mixing GO with AgNO3, followed by reduction with NaBH4.46 Finally, graphene decorated with platinum or palladium nanoparticles has also been produced by mixing graphene with chloroplatinic acid (H2PtCl6) or tetrachloropalladic acid (H2PdCl4), followed by reduction with ethylene glycol, respectively.47 In terms of the characteristics that are imparted by the formation of graphene–noble metal nanoparticle composites, Subrahmanyam et al. recently studied the interaction between noble metal nanoparticles and graphene utilizing Raman spectroscopy.47a Specifically, they reported that the decoration of graphene with noble metal nanoparticles results in electronic interactions that give rise to significant changes in the ionization energies of the metals as well as in their charge-transfer interaction and, subsequently, the Raman spectrum of the graphene sheets.

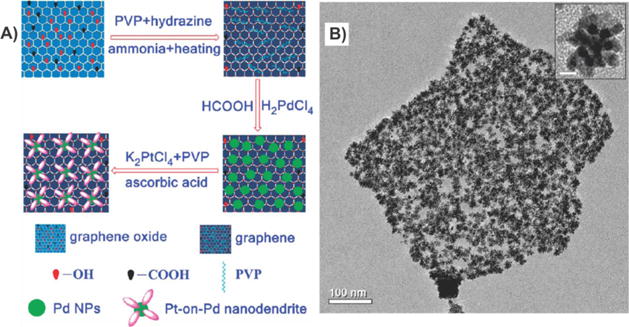

On the other hand, graphene–nanoparticle composites containing bimetallic nanoparticle hybrids can also be obtained utilizing a two-step reduction process. By fabricating such a structure, not only can synergism be achieved between the different nanoparticle species that are present but also between the bimetallic nanoparticles and graphene.48 For example, the reduction of H2PdCl4 by formic acid, followed by the addition of K2PtCl4 and reduction by AA, yielded a graphene–PtPd bimetallic nanoparticle composite structure (Figure 7).49 The resulting bimetallic hybrid composite showed much higher catalytic activity than conventional graphene–platinum nanoparticle (PtNP) hybrid structures and PtPd bimetallic catalysts. This can be attributed to a combination of the increased surface area of Pt in bimetallic nanoparticles, which is an essential factor in improving catalytic activity, as well as their better dispersion on graphene nanosheets that have a high surface area.50 Similarly, Yang et al. described the preparation of another bimetallic nanoparticle hybrid wherein GO was decorated with PtCo bimetallic nanoparticles.48b In this case, ethylene glycol-functionalized GO sheets were loaded with PtCo bimetallic nanoparticles by the addition of H2PtCl6 and CoCl2 at room temperature, followed by reduction with NaBH4. Similar to the graphene–PtPd bimetallic nanoparticle composites, the resulting graphene–PtCo bimetallic nanoparticle composite also exhibited good stability, resistance to degeneration, and an especially high catalytic activity as compared to other PtNPs and graphene–PtNP composites, presumably for the same reasons as mentioned for graphene PtPd composites.

Figure 7.

Graphene–bimetallic nanoparticle composites. (A) Procedure to fabricate graphene nanosheet/Pt-on-Pd bimetallic nanodendrite hybrids. (B) TEM images of the graphene–bimetallic nanoparticle composites. Inset of (B) shows the Pt-on-Pd bimetallic nanodendrites at a higher magnification. Reprinted with permission from ref 49. Copyright 2010 American Chemical Society.

Finally, as an alternative to the traditional reduction methods used to prepare graphene–nanoparticle composites, microwaves can also be used as a source of energy that facilitates the process.51 For instance, graphene and its derivatives were decorated with metal (e.g., Au,51 Ag,52 and Pt53) and metal oxide (e.g., Co3O4 and MnO2) nanoparticles,54 in the presence or absence of reducing agents and stabilizing molecules, with the help of rapid microwave irradiation. The main advantage of microwave irradiation is the uniform and rapid heating of the reaction mixture, thereby reducing the barrier to reduction, nucleation, and ion incorporation.55 Hence, nanoparticles with a very small size and narrow size distribution can be obtained.

2.2.2. Hydrothermal Methods To Form Graphene–Nanoparticle Composites

The hydrothermal method is also commonly used to synthesize inorganic nanoparticles that have a high crystallinity and narrow size distribution on graphene sheets. Moreover, this method allows for the formation of nanoparticles on graphene without the need for postannealing and calcination.11b In general, the process involves the use of high temperatures and pressures, which induce the growth of nanocrystals and, at the same time, reduce GO to rGO. However, while the high temperature and long reaction times can partially or completely reduce GO on its own, in most cases, reducing agents are added to ensure the complete reduction of GO.11b,56

Graphene–metal oxide nanoparticle composites (e.g., ZnO,57 TiO2,58 Fe3O4,59 SnO2,60) are, by far, the most common hybrids synthesized using the hydrothermal method. Specifically, metal oxide nanoparticles can provide the graphene–metal oxide nanoparticle hybrids with a number of advantages such as a higher capacitance, which depends on the nanoparticle structure, size, and crystallinity, while suppressing agglomeration and the restacking of graphene.61 Moreover, graphene–metal oxide nanoparticle composites result in enhanced electron conductivity, shortened ion paths, and a significant increase in the available surface area when compared to graphene alone, which altogether lead to higher electrochemical activity.11c For example, in 2012, Park et al. reported the one-pot synthesis of rGO–SnO2 nanoparticle composites, wherein the resulting composites exhibited outstanding cycling performance and could be used as an electrode.60b In their study, a hydrothermal synthesis assisted by hydrazine, which promoted the complete reduction of GO to rGO, was utilized. The resulting composites exhibited a first discharge capacity of 1662 mA h g−1, which rapidly stabilized and remained at 626 mA h g−1 even after 50 cycles when cycled at a current density of 100 mA g−1, whereas the capacity of pure SnO2 nanoparticles decreases continuously. This could be attributed to the lack of aggregation in the rGO-supported SnO2 composites and the uncontrolled aggregation of the pure SnO2 nanoparticles. On the other hand, Ren et al. reported the synthesis of graphene–magnetic nanoparticle (MNP) composites. In particular, these graphene–MNP composites exhibited excellent electrical conductivity and mechanical strength while possessing the magnetic properties of the attached MNPs.62 In this case, a one-step hydrothermal method was performed, wherein anhydrous FeCl3 provided the source of iron, and ethylene glycol (or a bisolvent of diethylene glycol and ethylene glycol) was used as the reductant and solvent. Consequently, Fe3O4 nanoparticles with a diameter of 7 nm were densely and uniformly deposited on the rGO sheets. Moreover, the reduction of GO by this process was comparable to that achieved by conventional methods. For example, the D/G intensity ratio of rGO in the aforementioned hybrids was 2.30:1, which is similar to the ratio typically obtained for pristine graphene (2.45:1), indicating the recovery of the sp2 domain in the carbon network.62

In addition, various chalcogenide QDs such as CdS,63 ZnS,64 Cu2S,65 MoS2,66 Sn3S4,67 and CdTe68 have been successfully immobilized on graphene utilizing hydrothermal methods. These semiconductor nanostructures have attracted intense interest due to their fundamental importance as well as their enormous potential in optoelectronic, magnetic, and catalytic applications.69 Specifically, for biological applications, QDs provide a high quantum yield (0.1–0.8 [visible], 0.2–0.7 [NIR] vs 0.5–1.0 [visible], 0.05–0.25 [NIR] for organic dyes),70 high molecular extinction coefficients (~10–100× that of organic dyes),71 broad absorption with narrow symmetric photoluminescence spectra (full-width at half-maximum ~25–40 nm) spanning from ultraviolet (UV) to NIR, high resistance to photobleaching, and exceptional resistance to photo- and chemical degradation.72 Moreover, because of their size-tunable fluorescence emission and the broad excitation spectra, QDs have a significant advantage over molecular dyes. However, these semiconductor nanoparticles are limited by their tendency to aggregate, resulting in a reduction in the surface area that is available for subsequent applications. In terms of the fabrication of rGO–sulfide nanocomposites, the sulfur sources often act as a reducing agent for GO. Zhang et al. recently reported the synthesis of graphene–CdS nanoparticle composites wherein a facile one-step hydrothermal approach was utilized to simultaneously form CdS nanoparticles and reduce GO (Figure 8).73 By combining these two excellent materials in a single composite, the graphene–CdS nanoparticle composites were able to serve as promising visible-light-driven photocatalysts, whose excellent photoactivity could be attributed to the integrative effect of the enhanced light absorption intensity, high electron conductivity of graphene, which significantly prolonged the lifetime of photogenerated electron–hole pairs, and its significant influence on the morphology and structure of the samples (e.g., the density and size of the nanoparticles could be controlled during synthesis).

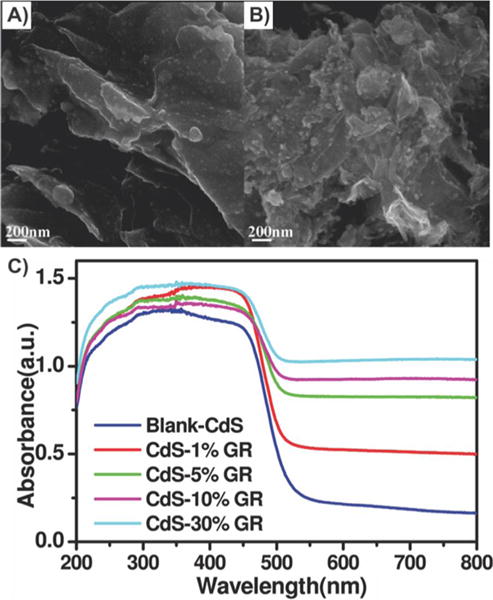

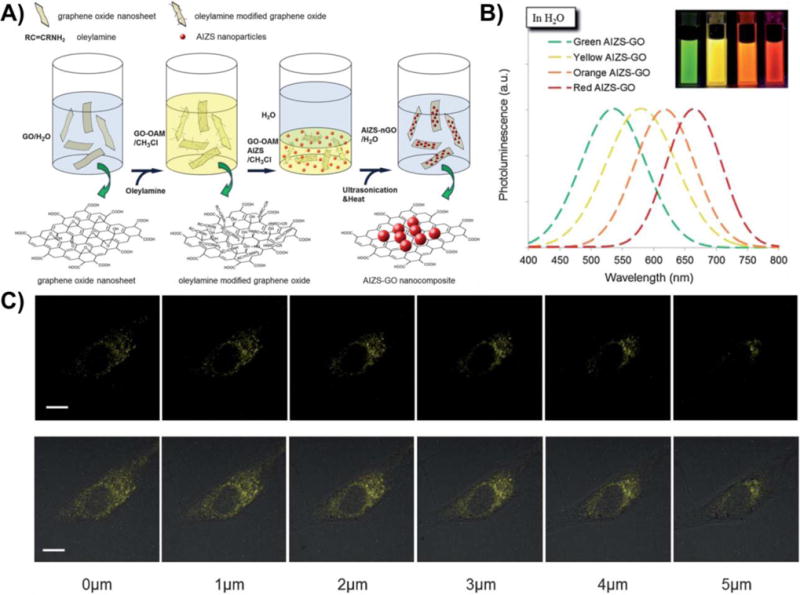

Figure 8.

Graphene–quantum dot composites. SEM images of the as-prepared samples of (A) CdS–5% graphene, (B) CdS–30% graphene, and (C) UV–vis diffuse reflectance spectra of the samples of blank-CdS and Cd-GR nanocomposites with different weight addition ratios. Reprinted with permission from ref 73. Copyright 2011 American Chemical Society.

Finally, there have also been some reports utilizing hydrothermal methods for the preparation of rGO–noble metal nanoparticle composites (Figure 9).74 In the case of graphene–AuNPs, a solution of HAuCl4·3H2O and NaOH was mixed with GO.75 Subsequently, the solution was sonicated at a frequency of 40 kHz and heated to 180 °C. The resulting graphene–AuNP composites had AuNPs with a narrow size distribution in the range of 2 or 18 nm, with and without sonication, respectively. Graphene–Pt or –Pd nanoparticle composites can also be prepared by a similar method using H2PtCl6·6H2O and PdCl2, respectively.75 Moreover, graphene–bimetallic nanoparticle hybrid composites have been reported using the hydrothermal method. For instance, platinum–ruthenium nanoparticles with a mean size of 2.17 nm were decorated on graphene nanosheets, and it was found that the size and morphology of these nanoparticles could easily be controlled by modifying the synthesis temperature and the initial materials used.76

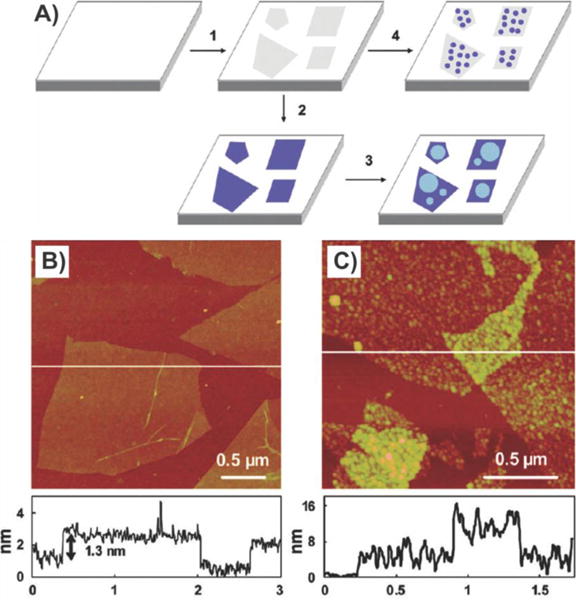

Figure 9.

Hydrothermal methods to synthesize graphene–AgNP composites. (A) (1) GO is adsorbed on the APTES-modified SiOx substrate. (2) GO is reduced, and rGO is obtained. (3) Growth of Ag particles by heating the rGO substrate in 0.1 M AgNO3 at 75 °C for 30 min. (4) Growth of AgNPs by heating the GO substrate in 0.1 M AgNO3 at 75 °C for 30 min. (B) Tapping mode AFM topographic image and height profile of a single layer of GO adsorbed on an APTES-modified SiOx substrate. (C) SEM image of Ag particles grown on a rGO surface. Reprinted with permission from ref 74b. Copyright 2009 American Chemical Society.

2.2.3. Electrochemical Methods To Form Graphene–Nanoparticle Composites

Electrochemical deposition is a simple, fast, and green technique that can be used to form graphene–nanoparticle composites while preventing the contamination of the synthesized materials. In addition, it is low cost, easy to miniaturize and automate, and is highly stable and reproducible.77 As such, by utilizing electrochemical deposition, the size and shape of the nanoparticles that are deposited can be precisely controlled by simply altering the conditions of electrochemical deposition. In particular, electrochemical deposition methods have been developed extensively for the fabrication of graphene–inorganic nanoparticle composites with the vast majority of composites formed using this method being noble metals such as Au,78 Ag,79 Pt,80 as well as bimetallic metals.

In a typical electrochemical deposition experiment, there are three steps wherein (1) the graphene sheets are first assembled onto an electrode, (2) the graphene-coated electrode is then immersed in an electrolytic solution containing metallic precursors, and (3) a potential is applied. For the formation of graphene–AgNP composites, Golsheikh and co-workers recently reported an electrochemical deposition method wherein the resulting nanoparticles fell within a very narrow size distribution with a mean size of 20 nm.79 In this case, a solution containing silver–ammonia [Ag(NH3)2OH] and GO was exposed to cyclic voltammetry (CV), which was performed using a three-electrode system that consisted of an indium tin oxide (ITO) working electrode, a platinum foil counter electrode, and a saturated calomel electrode (SCE) reference electrode (scanning between −1.5 and 0 V at a rate of 25 mV s−1). Fisher et al. also utilized electrochemical tools to fabricate graphene–PtNP composites wherein PtNPs were decorated on multilayered graphene petal nanosheets (MGPNs).80b According to their report, a three-electrode system, wherein the MGPNs acted as the working electrode, Pt gauze as the auxiliary electrode, and Ag/AgCl as the reference electrode, was dipped in a solution containing H2PtCl6·6H2O and Na2SO4. Utilizing this method, the density, size, and morphology of the PtNPs could be precisely controlled by simply adjusting the intensity of the pulse current. In particular, this allowed for the simultaneous reduction of GO and H2PtCl6 to rGO and PtNPs, respectively, without the need for any other reagents or thermal treatment.

As for graphene–nanoparticle composites composed of non-noble metal nanoparticles, Wu et al. recently deposited Cu nanoparticles on rGO and, more interestingly, investigated the mechanism underlying their electrochemical deposition (Figure 10).81 In their study, the nucleation of Cu on rGO was achieved using an electrolyte solution containing CuSO4 in a conventional three-electrode system, wherein the rGO electrode, a Pt mesh, and an Ag/AgCl electrode were used as the working, counter, and reference electrodes, respectively (Figure 10A). To fundamentally study the nucleation of Cu on rGO via electrochemical deposition, the authors used CV, Tafel plots, and chronoamperometry. From CV, it was inferred that Cu deposition on rGO electrodes initiated at a more positive potential of 0.105 V (vs Ag/AgCl) as compared to that found for glassy carbon and pencil graphite. On the other hand, the Tafel plot confirmed that the rate-determining step for Cu deposition on rGO was mass transport and, finally, that nucleation on rGO occurred either instantaneously or progressively depending on the initial concentration of the electrolyte (e.g., instantaneously at higher concentrations [50 mM] and progressively at lower concentrations [10 mM]).

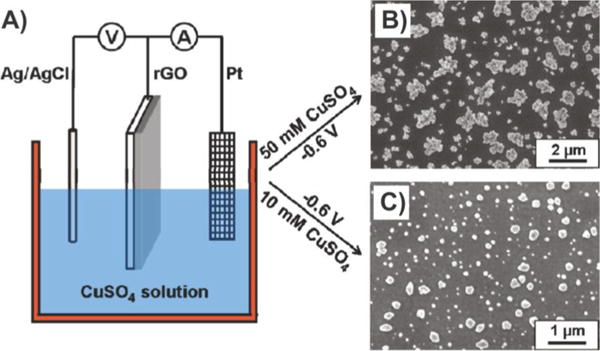

Figure 10.

Electrochemical deposition of Cu nanoparticles on rGO. (A) Electrochemical experiments were performed by an electrochemical workstation (CHI600C, CH Instrument Inc., U.S.) in a conventional three-electrode electrochemical cell. The rGO electrode, a Pt mesh, and an Ag/AgCl (3 M NaCl) electrode were used as the working, counter, and reference electrodes, respectively. (B) SEM image of Cu electrodeposited on a rGO electrode in 50 mM CuSO4 solution at −0.6 V. (C) SEM image of Cu electrodeposited on a rGO electrode in 10 mM CuSO4 solution at −0.6 V. Reprinted with permission from ref 81. Copyright 2011 American Chemical Society.

Last, although the vast majority of research efforts has concentrated on the electrochemical deposition of metal nanoparticles on graphene sheets, there have also been several reports of the electrochemical deposition of metal oxide nanoparticles onto graphene. For instance, Wu et al. deposited Cl-doped n-type Cu2O nanoparticles, which are abundant and nontoxic nanoparticles that have a direct band gap of ca. 2.0 eV,82 on rGO electrodes resulting in a carrier concentration of up to 1 × 1020 cm−3.83 Specifically, to deposit Cl–Cu2O nanoparticles on rGO, a solution of CuSO4, CuCl2, and lactic acid was added to a three-electrode system where the rGO electrode, a Pt mesh, and SCE were used as the working, counter, and reference electrodes, respectively. The deposition used a potentiostatic process (potential of −0.4 V, charge density of 2 C cm−2) at a temperature of 60 °C. Similarly, ZnO nanorods could also be deposited on rGO films using a solution containing ZnCl2 and KCl as the supporting electrolyte in a conventional three-electrode system where an rGO-polyethylene terephthalate electrode, a Pt mesh, and a SCE were used as the working, counter, and reference electrodes, respectively.84

2.2.4. Ex Situ Methods To Form Graphene–Nanoparticle Composites

Graphene–nanoparticle composites can also be produced by the ex situ assembly of nanoparticles onto the graphene surface. In this method, the nanoparticles are synthesized in advance and then later attached to the surface of the graphene sheets via linking agents that can utilize either covalent or noncovalent interactions including van der Waals interactions, hydrogen bonding, π–π stacking, or electrostatic interactions. Although this method requires more time and steps to complete, it can offer a number of advantages when compared to in situ growth. For instance, ex situ methods result in a significantly narrower size distribution as well as better control over the size, shape, and density of the nanoparticles that decorate the graphene sheets while utilizing self-assembly.85

For the covalent attachment of nanoparticles, GO rather than rGO is preferred due to the large amount of oxygen-containing groups on its surface, which can facilitate linkage with other functional groups. A variety of nanoparticles have been attached to graphene using this method. Fan et al. covalently attached MNPs to GO by first modifying the Fe3O4 nanoparticles with tetraethyl orthosilicate and (3-aminopropyl)triethoxysilane (APTES), thereby introducing amino groups on its surface.86 Next, these amino groups were reacted with the carboxylic groups on the surface of GO with the aid of 1-ethyl-3-(3-(dimethylamino)propyl)carbodiimide (EDC) and N-hydroxysuccinimide (NHS), resulting in the formation of GO-Fe3O4 nanoparticle composites. Moreover, they demonstrated that the GO could subsequently be reduced to rGO using NaBH4 as the reducing agent. Similarly, cadmium sulfide (CdS) QDs have been immobilized covalently on GO nanosheets.87 In this case, amino-functionalized CdS QDs were first prepared by modification of the kinetic trapping method.88 Next, GO nanosheets were aceylated with thionyl chloride to introduce acyl chloride groups on its surface. To covalently bond the QDs to the GO nanosheets, an amidation reaction between the amino groups on the QDs and the acyl chloride groups on the GO surface was performed. Finally, noble metal nanoparticles such as AuNPs have also been covalently attached to graphene. Specifically, Ismaili and co-workers demonstrated the light-activated covalent formation of AuNPs on rGO.89 In this study, 4 nm AuNPs were modified with a 3-aryl-3-(trifluoromethyl)-diazirine functionality. Correspondingly, upon irradiation with wavelengths above 300 nm and in the presence of rGO, the terminal diazirine group lost nitrogen to generate a reactive carbene that could then undergo addition or insertion reactions with the functional groups on graphene leading to covalent linkage.

Alternatively, nanoparticles can be attached to graphene sheets via noncovalent bonds including van der Waals interactions, hydrogen bonding, π–π stacking, and electrostatic interactions. Among these noncovalent bonds, π–π stacking and electrostatic interactions have been the most widely used. For π–π stacking, generally, aromatic compounds are attached to the nanoparticle surface, which enables their attachment to graphene via π–π stacking. For example, derivatives of the pyrene molecule as well as pyrene-functionalized block copolymers have provided an effective way for the noncovalent functionalization of carbon nanomaterials including graphene.90 In particular, pyrene groups have the ability to interact strongly with the basal plane of graphene via π–π stacking. For example, 1-pyrenebutyric acid (PBA) is one of the simplest pyrene-containing molecules that are attached to a carboxyl group. Resultantly, graphene sheets functionalized with PBA become negatively charged allowing for the attachment of positively charged nanoparticles via electrostatic interaction.91 The use of pyrene-containing molecules has been reported for various nanoparticles. Examples include PBA, which was used to form graphene–AuNP hybrids,29c and pyrene-grafted poly(acrylic acid), which was used to form graphene–CdSe nanoparticle hybrids.92 Pyridine is another aromatic structure that has also seen significant use in anchoring nanoparticles such as Au44b,93 and CdSe94 nanoparticles to the basal planes of GO/rGO sheets via π–π stacking. Importantly, pyrene- or pyridine-modified graphene sheets have a high loading capacity for nanoparticles, and the amount of nanoparticle that assembles on the graphene sheets can easily be modulated by controlling the feeding weight ratio of both components.29c

DNA molecules, which contain both purine and pyrimidine bases, have also been used to mediate the fabrication of graphene–nanoparticle composites. In particular, DNA is able to interact with graphene via π–π stacking interactions as well as the surface binding model wherein DNA electrostatically interacts with graphene basal planes, which is similar to what is observed between single-stranded DNA (ssDNA) and CNTs.95 For instance, Liu et al. developed a strategy wherein thiolated DNA oligos (d(GT)29SH) were first adsorbed onto GO sheets (DNA–GO) and then reduced by hydrazine to obtain DNA–rGO sheets.96 Consequently, the addition of a large excess of 6 nm AuNPs to a solution containing either DNA–GO or DNA–rGO resulted in the formation of GO–AuNP and rGO–AuNP composites, respectively. Similarly, Wang et al. fabricated GO–AuNP and GO–AgNP composites by first functionalizing AuNPs or AgNPs with DNA via didentate capping ligands and then assembling them onto GO via π–π stacking interactions.97

As mentioned previously, electrostatic interactions are also commonly used to modify graphene with various nanoparticles as it provides a facile and scalable method to form composite structures in a controlled manner while avoiding conglomeration. GO and rGO have an inherent negative charge as a result of the ionization of the oxygen functional groups on their surface. As such, they can be decorated with positively charged inorganic nanoparticles through electrostatic interactions. For instance, graphene–metal oxide nanoparticle composites (e.g., rGO–Fe3O4 nanoparticle composites98 and GO–MnO2 nanoparticle composites99) have been formed by mixing positively charged metal oxide nanoparticles with negatively charged graphene nanosheets.98 Similarly, graphene–noble metal and other inorganic nanoparticles have also been prepared in this way. To this end, Lu et al. noncovalently decorated GO sheets with positively charged aerosol Ag nanocrystals that were synthesized from an arc plasma source using an electrostatic force-directed assembly technique.100 Moreover, reports have decorated graphene with APTES-modified Si nanoparticles.101 Specifically, while the amine functional groups of APTES can function to reduce GO and form covalent bonds with rGO, APTES can also help disperse rGO and Si nanoparticles due to polar–polar interactions.

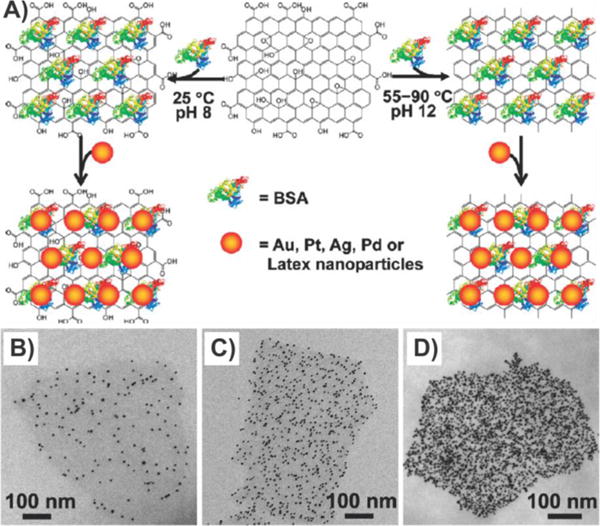

Finally, Deng and co-workers utilized a novel nontoxic synthetic method wherein bovine serum albumin (BSA) was utilized for the fabrication of graphene–nanoparticle composites that could be composed of various types of nanoparticles (Au, Pt, Pd, Ag, and polystyrene beads).102 In this study, the use of BSA not only effectively reduced GO to rGO, but also acted as a stabilizer to induce the attachment of nanoparticles onto the graphene surface (Figure 11A). Specifically, BSA–GO/rGO conjugates were first obtained via the adsorption of BSA onto the basal planes of GO/rGO. Afterward, the nanoparticles were mixed in a solution containing the BSA–GO/rGO conjugates overnight to form the final graphene–nanoparticle composites. Moreover, the density of nanoparticles on the graphene–nanoparticle composites could be controlled by simply changing the concentration of BSA and NaCl during assembly (Figure 11B–D). Similarly, Wang et al. recently reported an inexpensive and unique green synthetic method for the production of Ag–GO nanocomposites that utilized glucose as both the reducing and the stabilizing agent, eliminating the need for toxic reduction agents.103 In particular, Wang and co-workers demonstrated that AgNPs could be directly reduced from silver ions on GO in a glucose solution.

Figure 11.

Protein-induced reduction and decoration of GO for the assembly of multiple nanoparticles. (A) General scheme depicting the BSA protein-based decoration and reduction of GO, leading to a general nanoplatform for nanoparticle assembly. (B) TEM images of AuNP decorated BSA–GO with well-controlled densities of AuNPs. (B and C) AuNP densities were varied by increasing the concentrations of BSA from 0.5 mg/mL (B) to 20 mg/mL (C), during the preparation of BSA–GO. NaCl was omitted for the samples in (B) and (C). (D) AuNP density was further increased (in comparison with (C)) by adding 0.1 M NaCl to the assembly system as in (C). Reprinted with permission from ref 102. Copyright 2010 American Chemical Society.

2.3. Graphene-Encapsulated Nanoparticles

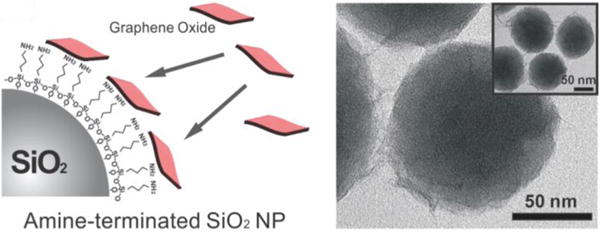

Because of the flexible and 2D sheet-like nature of graphene and its derivatives, these sheets can easily be used to wrap or encapsulate nanoparticles that range in diameter from 100 nm to several hundreds of nanometers and even micrometers (Figure 12). rGO sheets are the most frequently utilized carbon material for the encapsulation of nanoparticles due to their slightly hydrophilic nature and the ease with which small fractions of rGO can be fabricated. In particular, methods used to fabricate graphene-encapsulated nanoparticles typically utilize noncovalent bonds. For instance, the most frequently used method to encapsulate nanoparticles with rGO consists of endowing the surface of the nanoparticle with a positive charge (e.g., by coating with APTES), resulting in the strong attachment of rGO via electrostatic interaction.101b,104 By controlling the size of cracked rGO, a variety of nanomaterials such as polymer as well as inorganic, metals, and metal oxide nanoparticles can be encapsulated by graphene/rGO to enhance their properties as well as to obtain additional advantages.

Figure 12.

Fabrication process for graphene-coated NPs. Schematic diagram of GO assembly on amine-functionalized NPs and TEM image of NPs coated with GO (inset: zoomed-out TEM image of NPs coated with GO). Reprinted with permission from ref 101b. Copyright 2011 Wiley.

In terms of its benefits, the encapsulation of nanoparticles with graphene endows similar enhancements in electrical, electrochemical, and optical properties that were observed for graphene–nanoparticle composites. However, due to the characteristically strong negative charge of rGO, the encapsulation of small nanoparticles with rGO also results in the suppression of aggregation, which is a major issue in many nanoparticle-based bioapplications.96,105 Moreover, because of the high degree of contact that exists between graphene and the encapsulated nanoparticle, which is significantly greater than that seen in graphene–nanoparticle composites, graphene-encapsulated nanoparticles are very stable, thereby limiting the degree of exfoliation of the nanoparticles from graphene or vice versa.11c

Numerous reports have demonstrated the encapsulation of metal oxide nanoparticles with graphene. For example, Yang et al. reported rGO-encapsulated cobalt oxide nanoparticles (Co3O4). These rGO-encapsulated Co3O4 nanoparticles exhibited a very high reversible capacity (1000 mA h g−1) over 130 cycles, which was superior to normal cobalt oxide nanoparticles used for capacitors.104 In particular, using alternating current impedance measurements (30 cycles), Nyquist plots were obtained wherein the diameter of the semicircle for rGO-encapsulated Co3O4 electrodes in the high–medium frequency region was much smaller than that of bare Co3O4 electrodes. This suggested that the rGO-encapsulated Co3O4 electrodes possessed lower contact and charge-transfer impedances. Feng and co-workers also reported graphene-encapsulated TiO2 nanospheres for efficient photocatalysis due to their high specific surface area (133 m2 g−1). Specifically, the resulting hybrid material was much more efficient at decomposing rhodamine B (91%) than normal TiO2 (65%) due to the presence of graphene, which was beneficial for the separation of photogenerated electrons and holes.106 Similarly, the performance of tin oxide (SnO2) nanoparticles was also improved by encapsulation of individual aggregates with graphene, resulting in excellent performance including a charge capacity of 700 mA h g−1 at the current density of 0.1 A g−1 and 423 mA h g−1 after a 10-fold increase in the current density to 1 A g−1 in the 0.005–2 V voltage window.107 Finally, Lin and coworkers recently created rGO-encapsulated amine-functionalized Fe3O4 MNPs that were used to support Pt catalysts.108 Specifically, after the Fe3O4 nanoparticles were functionalized with APTES and coated with rGO, PtNPs were uniformly anchored by a polyol reduction reaction and the GO was simultaneously reduced to rGO. Resultantly, the electrochemical activity of the catalyst for methanol oxidation was significantly improved. The authors claimed that this was due to the accessibility of the PtNPs on the graphene surface and the greatly enhanced electronic conductivity of the underlying rGO-encapsulated Fe3O4 nanoparticles.

Others have focused on encapsulating metal nanoparticles with graphene. For instance, Zhang et al. recently reported an interesting material, a “graphene-veiled gold nanostructure”. In this study, they used graphene as a passivation nanosheet to prevent metal–molecule chemical interactions and to control the spatial resolution of molecules to achieve sensitive SERS signals from analytes of interest.16 Kawasaki and co-workers have also reported graphene-encapsulated cobalt nanomagnets, wherein the cobalt nanoparticles were first functionalized with benzylamine groups.109 These 30 nm graphene-encapsulated nanoparticles had a high specific surface area of 15 m2 g−1 and a high strength saturation magnetization of 158 emu g−1, which led to efficient extraction of analytes by magnetic separation for surface-assisted laser desorption/ionization mass spectrometry (affinity SALDI-MS) analysis.

In addition to the above examples, our group recently reported a method to convert nonconducting silicon oxide nanoparticles into conducting rGO-encapsulated nanoparticles, which could then be used as the “bridging-material” in a field-effect transistor (FET)-based biosensor.101b,110 Specifically, SiO2 nanoparticles were functionalized with APTES thereby imparting them with a positive surface charge, which allowed for encapsulation with rGO via electrostatic interaction (Figure 12). In doing so, we were able to prevent aggregation while maintaining a high electrical conductivity and enhanced surface area for the detection of cancer markers. Similarly, Zhou et al. also encapsulated Si nanoparticles with rGO via electrostatic interaction, again using APTES.111 As a consequence of encapsulation, the Si nanoparticles exhibited less aggregation and destruction than pristine SiNPs and acted as an outstanding electrode, exhibiting high reversible capacity (902 mA h g−1 after 100 cycles at 300 mA g−1). On the other hand, pristine SiNPs exhibited an initial discharge capacity of 3220 mA h g−1, which dropped to 13 mA h g−1 after only 50 cycles.

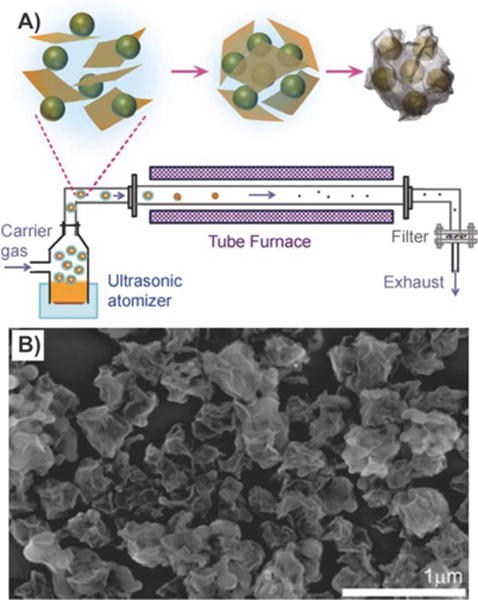

Finally, while electrostatic interaction has been the most commonly used method to form graphene-encapsulated nanoparticles, Luo et al. reported an innovative method to fabricate graphene-encapsulated nanoparticles via a facile and scalable, capillary-driven aerosol droplet method. Specifically, in a typical experiment, Si nanoparticles in an aqueous suspension were directly added to a dispersion of micrometer-sized GO sheets. Nebulization of the colloidal mixture resulted in the formation of aerosol droplets, which were blown through a preheated tube furnace at 600 °C with a N2 carrier gas (Figure 13A). As a result, during the process of evaporation, the amphiphilic GO sheets migrated to the surface of the droplets to form a shell, and as the droplets evaporated further, the GO shell collapsed forming a “crumpled” shell around the Si nanoparticles (Figure 13B).112

Figure 13.

Crumpled graphene-encapsulated Si nanoparticles. (A) Schematic drawing illustrating aerosol-assisted capillary assembly of crumpled-graphene-wrapped Si nanoparticles. Aqueous dispersion of GO and Si particles was nebulized to create a mist of aerosol droplets, which were passed through a preheated tube furnace. During evaporation, GO sheets first migrated to the surface of the droplets and then tightly wrapped the Si particles upon complete evaporation. (B) SEM image showing the crumpled capsules of graphene-wrapped Si. Reprinted with permission from ref 112. Copyright 2012 American Chemical Society.

3. GRAPHENE–NANOPARTICLE HYBRID MATERIALS FOR BIOSENSING APPLICATIONS

Biosensors are analytical devices that utilize biological sensing elements to detect and/or quantify a particular target analyte or family of analytes. As such, biosensors are applicable to and are important for virtually every conceivable analytical task in the biomedical field, which can range from applications in medical diagnostics to drug discovery, food safety, environmental monitoring, and defense.

In general, biosensors are composed of two fundamental elements: a receptor and a transducer. The receptor consists of any material, either organic or inorganic, that can interact with a target analyte or family of analytes. On the other hand, the transducer converts the recognition event that occurs between the analyte and the receptor (e.g., the binding of an enzyme to its substrate, binding between an antibody and its target protein, or reduction/oxidation of an electroactive biomolecule by the sensing electrode) into a measurable signal that can come in many forms including, but not limited to, electronic, electrochemical, and optical signals. In terms of its performance, biosensors are evaluated on the basis of sensitivity to the target(s), limit of detection (LOD), linear and dynamic ranges, reproducibility or precision of its response, and selectivity.113 Other parameters that are often compared and useful include the sensor’s response time (e.g., the amount of time needed for the sensor response to reach 95% of its final value after introduction of the analyte(s)), operational and storage stability, ease of use, and portability. Moreover, the ideal biosensor should be reusable, thereby allowing for several consecutive measurements to be made.

Graphene–nanoparticle hybrids are particularly well-suited for biosensing applications. As mentioned previously, graphene possesses numerous unique and advantageous physicochemical properties including an extremely high surface area, excellent electrical properties, high mechanical strength, advantageous optical properties (e.g., transparent and can quench fluorescence), and is relatively easy to functionalize and mass produce. As such, there has been significant effort invested in utilizing this material for the development of biosensors.9a,114 Moreover, nanoparticles have also been widely investigated in the field of biosensing due to the exquisite sensitivity that nanomaterials can offer for this type of application.115 Specifically, because of the diameter of nanoparticles (e.g., 1–100 nm scale), these nanomaterials can display unique physical and chemical features (e.g., quantum size effect, surface effect, and macro-quantum tunnel effect). As such, nanoparticles can be used to enhance achievable sensitivities by amplifying the obtained signal as well as increasing the available surface area for analyte binding.

By combining these two excellent and unique modalities as graphene–nanoparticle hybrids, a number of advantageous properties are attained for biosensing applications. In particular, it has been observed that graphene acts as an excellent material with which to immobilize nanoparticles and enhance their stability (e.g., preventing aggregation). Moreover, the combination of graphene with nanoparticles can increase the available surface area for analyte binding as well as improve their electrical conductivity and electron mobility, thereby enhancing the achievable sensitivity and selectivity.11a In particular, the field of graphene–nanoparticle hybrid materials for biosensing applications can be generally divided into three classes based on the underlying mechanism of detection. These classes include (1) electronic, (2) electrochemical, and (3) optical sensors, with each class having its own advantages and disadvantages. As such, in this section, we will give a comprehensive review of recent work that has been conducted on the development of graphene–nanoparticle hybrid biosensors. In particular, we will focus primarily on the use of graphene–nanoparticle hybrid materials in electronic (e.g., FET), electrochemical, and optical biosensors, with emphasis on how they compare to current gold standards and their achievable sensitivities and selectivities for various biomolecules (Table 2).

Table 2.

Summary of the Different Detection Mechanisms Discussed

| type | common NPs | LOD | advantages | key refs |

|---|---|---|---|---|

| FET | Au, Pt, SiO2 | aM–pM | (1) enhanced surface area for detection; (2) can preserve the electrical properties of graphene by conjugating the probe on the nanoparticle | 124, 127, 128, 130 |

| electrochemical | Au, Pt, Cu | pM–μM | (1) immobilization of biomolecules; (2) catalyze electrochemical reactions; (3) act as a reactant | 137, 140, 143–146, 148–152 |

| FRET | QD, UCNP, Au, Ag | pM–nM | (1) GO is superquenching, which can result in double-quenching (e.g., with Au or Ag) | 156, 162, 163, 165 |

| SERS | Au | nM | (1) dual enhancement of Raman signals via chemical and electromagnetic enhancement | 174–179, 181 |

3.1. Electronic Sensors

As compared to the other methods that are available for biosensing applications, nanomaterial-based electronic biosensing offers significant advantages, such as high achievable sensitivities, high spatial resolution for localized detection, easy miniaturization, facile integration with standard semiconductor processing, and label-free, real-time detection that can be achieved in a nondestructive manner.116 In particular, these electronic sensors primarily utilize the principle of FETs to convert the biological recognition event to a measurable electronic signal. In a standard FET device, current flows along a semiconductor path (the channel) that connects two electrodes (the source and the drain). The conductance of the channel between the source and the drain is then switched on and off by a third electrode (the gate) that is capacitively coupled to the device through a thin dielectric layer.116,117 Specifically, in FET-based biosensors, the channel is in direct contact with the sensing sample, which enhances the achievable sensitivity as any single biological event that occurs at the channel surface could result in a variation in the surface potential thereby modulating the channel conductance.118

Currently, FET sensors that are composed of Si nanowires or carbon nanotubes (CNTs) are the most heavily investigated.118,119 FET sensors that utilize either of these materials exhibit exceptional performance with their achievable LOD falling in the range of picomolar (pM) to femtomolar (fM); however, the achievable sensitivity of devices that use these materials is limited by the rarity of binding events that occur between the probe and its target molecule due to the scarcity of available binding sites on the surface of the materials.116 Moreover, the use of Si nanowires is expensive. On the other hand, while CNT sensors represent a significantly cheaper option, the reproducibility of CNT-based devices in terms of their fabrication and electrical properties is considered a significant limiting factor.120 As such, graphene-based materials have a major advantage in FET sensing applications in that graphene has an extremely high surface-to-volume ratio, which increases the likelihood of binding events. In particular, graphene-based FET biosensors are able to compete with CNT and Si nanowire-based FET sensors with an ultrasensitive LOD down to a similar (pM to fM) and potentially lower range.121 More specifically, because of this high surface-to-volume ratio, any analytes that adsorb onto the graphene surface could potentially alter its electronic properties (e.g., the conductivity can be altered when an analyte is adsorbed due to doping or a change in the carrier mobility of graphene). In addition, by utilizing graphene–nanoparticle hybrid materials it is possible to further push this limit to the attomolar (aM) range for biomolecule detection by utilizing the synergism that occurs in these unique structures, wherein the combination of two materials results in additional surface area for analyte binding as well as signal amplification and enhanced electrical conductivity. For instance, Zhang et al. determined that the covalent linkage of AuNPs to GO could enhance the electronic conductivity when compared to GO alone.122 Similarly, Dinh and colleagues reported that the formation of rGO–AgNPs decreased the sheet resistance from 10.93 kΩ sq−1 (for rGO) to 270 Ω sq−1.123

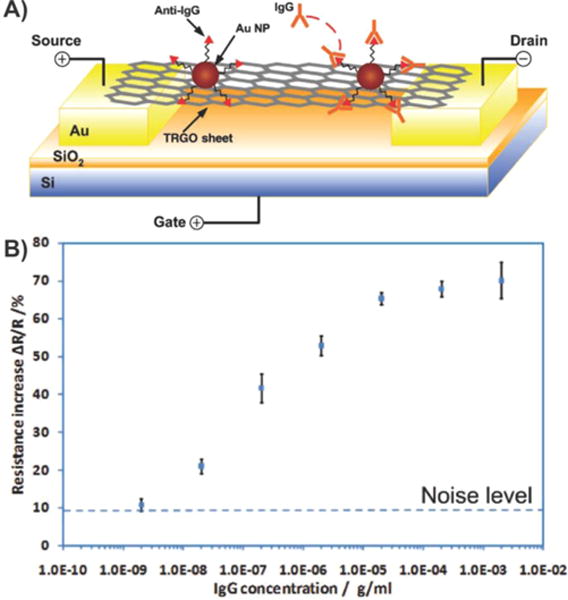

Demonstrations utilizing graphene–nanoparticle hybrid-based FET biosensors have focused on exploiting variations of a single mechanism. Specifically, studies have shown that by conjugating the detection probe (e.g., antibody) to the nanoparticle and then using these nanoparticle–probe conjugates to form graphene–nanoparticle composites, one can preserve the superb electrical properties of graphene. In these cases, the formation of the graphene–nanoparticle hybrid generally occurs via electrostatic interaction and van der Waals binding. As such, as long as detection probe conjugation does not significantly affect the charge of the nanoparticles, graphene–nanoparticle composites can be formed without any steric hindrance. One popular FET-based biosensing application that has utilized this concept is for the detection of proteins. Protein detection is particularly important as proteins play an essential role in all biological functions. As such, they are at the center of almost all pathological conditions, and the majority of disease markers are composed of proteins. Chen et al. reported the first graphene–AuNP hybrid sensor for the detection of proteins.124 In this case, thermally reduced GO sheets (TRGO) (e.g., a few layers with a thickness of 3–6 nm) were decorated with 20 nm AuNPs, which were covalently conjugated to anti-immunoglobulin G (IgG) antibodies (Figure 14A). Upon introduction of the target protein (e.g., IgG), FET and direct current was measured resulting in a LOD of approximately 13 pM (Figure 14B), which is among the best LODs when compared to carbon nanomaterial-based protein sensors including CNTs,125 graphene, and GO.126 This sensor also showed excellent selectivity when exposed to samples containing mismatched protein such as immunoglobulin M (IgM) or horseradish peroxidase (HRP). In particular, when 0.8 mg mL−1 IgM and 0.2 mg mL−1 HRP were introduced to the sensor using the exact procedure as that used for IgG, the sensor response was 15.3% and 12.4%, respectively, which was significantly lower than that from the complementary IgG (68.0%). Last, it was observed that binding of the IgGs to their anti-IgGs resulted in local geometric deformations and an increase in the number of scattering centers across the sheet, thereby reducing the mobility of holes and, subsequently, the conductivity of the TRGO sheets.

Figure 14.

Protein detection using thermally reduced graphene oxide (TRGO) sheets decorated with gold nanoparticle–antibody conjugates. (A) Schematic of a TRGO FET. Anti-IgG is anchored to the TRGO sheet surface through AuNPs and functions as a specific recognition group for IgG binding. The electrical detection of protein binding is accomplished by FET and direct current measurements. (B) Sensor sensitivity (relative resistance change, %) versus IgG concentration. Dashed line represents the noise level from the buffer solution. Reprinted with permission from ref 124. Copyright 2010 Wiley.

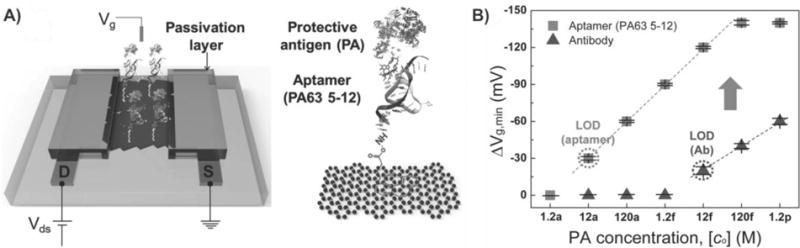

Besides preserving the excellent electrical properties of graphene, graphene–nanoparticle composites also exhibit additional advantages such as increasing available surface area for the binding of target analyte, enhanced stability, and also amplified transduction signals.127 For example, Kwon et al. reported a novel liquid-ion gated FET using large-scale graphene micropattern nanohybrids decorated with closely packed conducting polymer nanoparticles for the detection of HIV.127a Specifically, this closely packed nanoparticle array was composed of 20 nm carboxylated polypyrrole nanoparticles that were covalently modified with HIV-2 gp36 antigen and provided an enlarged surface area and stable sensing geometry. Therefore, the authors could detect the HIV biomarker at concentrations as low as 1 pM, which is better than any biosensor that has been reported for this particular purpose. Moreover, this biosensor exhibited excellent mechanical flexibility and durability. On the other hand, Kim and coworkers demonstrated that, in addition to preserving the superb electrical properties of graphene and increasing available surface area, graphene–nanoparticle hybrids could also be designed to amplify the transduction signal, thereby further increasing the achievable LOD by a full order of magnitude.127b In this work, the authors fabricated a FET biosensor that had networked channels of chemically reduced GO nanosheets, which were modified with aptamers specific for the detection of anthrax toxin (e.g., protective antigen) (Figure 15A). Briefly, in their design, the source/drain electrodes were formed on a networked film composed of rGO nanosheets using a shadow mask to prevent the deposition of polymeric residues during photolithography. Next, passivation of the electrodes was achieved with a 200 nm thick Al2O3 layer and direct pasting with PDMS, which minimized local work function modulation and isolated the leakage current between the electrode and electrolytes. In this way, Kim et al. achieved an ultralow LOD of 12 aM in 10 μM PBS. Furthermore, by utilizing secondary aptamer-conjugated AuNPs, they were able to achieve an even lower LOD of 1.2 aM (Figure 15B). This was attributed to the ability of the secondary aptamer-conjugated AuNPs to further amplify the transduction signal. As for the achievable selectivity, the authors exposed their sensor to a PBS solution containing carcinoembryonic antigen (CEA). The results showed no shift in voltage and no change in current, indicating that no CEA binding occurred.

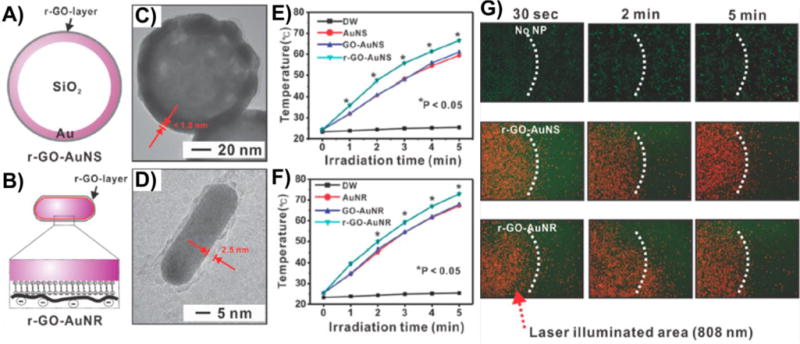

Figure 15.

Electronic graphene–nanoparticle composite sensor utilizing aptamers to detect anthrax toxin. (A) Schematic illustration of the aptamer-immobilized graphene FET for detection of protective antigen (PA). (B) Vg,min shift (ΔVg,min) versus PA concentration in PBS solutions with different probe molecules. The ΔVg,min value was obtained by calculating the difference in the charge neutrality point, Vg,min, as a reference for the device with no binding of PA. Reprinted with permission from ref 127b. Copyright 2013 Wiley.

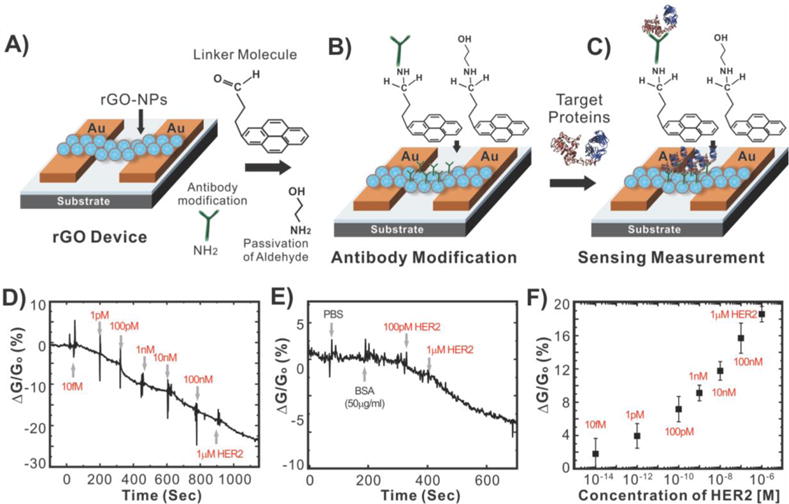

As a variation of the above-mentioned mechanism, encapsulating nanoparticles with graphene can also enhance the surface-to-volume ratio that is available for the capture of target analyte in FET sensors while enhancing stability. Recently, our group developed an rGO encapsulated nanoparticle-based FET sensor for the sensitive and selective detection of proteins (Figure 16).101b In particular, we sought to detect human epidermal growth factor receptor 2 (HER2) and epidermal growth factor receptor (EGFR), which are both known to be overexpressed in breast cancers.128 To this end, individual silicon oxide nanoparticles (100 nm diameter) functionalized with APTES were coated with a thin layer of rGO (5 nm thick) due to the electrostatic interaction that could occur between the negatively charged GO sheets and the positively charged silicon oxide nanoparticles. Arrays of rGO nanoparticles (rGO-NP) were then patterned to form channels between gold electrodes, which occurred through a self-assembly process upon centrifugation of the device with a solution containing rGO–NPs (Figure 16A). Finally, the rGO–NPs were functionalized with monoclonal antibodies against HER2 or EGFR (Figure 16B). Specifically, this was accomplished using a well-established process where the rGO surface was functionalized with 4-(pyren-1-yl)butanal via π–π stacking. Next, the aldehyde groups were coupled to the amine groups of the HER2 or EGFR antibodies through reductive amination and unreacted aldehyde groups were blocked using ethanolamine. In this way, we were able to preserve the electrical properties of the rGO by not conjugating the antibodies directly to the rGO surface while increasing the available surface area available for detection over rGO alone. Using this device, we were able to achieve a detection limit as low as 1 pM for HER2 and 100 pM for EGFR (Figure 16D–F). In addition, we demonstrated the highly selective nature of our biosensor in the presence of other proteins such as BSA (50 μg mL−1), which did not induce a change in conductance.

Figure 16.

Real-time detection of cancer marker, HER2, using a graphene-encapsulated nanoparticle-based FET biosensor. (A) The preparation of the rGO–NP device. (B) Surface functionalization of rGO for immobilizing the antibody. (C) Measuring conductance of the devices when the target protein is introduced. (D) The sensitivity of the biosensor (relative conductance change, %) in response to the concentration of HER2 with VDS (voltage drain to source) = 1 V and Vg (gate voltage) = 0 V. (E) The selectivity of the biosensor in response to PBS buffer, BSA with 50 μg mL−1, and HER2 (100 pM and 1 μM). (F) Sensor sensitivity (relative conductance change, %) as a function of the HER2 concentration with VDS = 1 V and Vg = 0 V. All experiments were performed multiple times (sample number, n = 30) to collect statistical data (with error bars) and confirm the reproducibility and robustness of the biosensing system. Reprinted with permission from ref 101b. Copyright 2011 Wiley.

Finally, besides proteins, the detection of specific nucleic acids (e.g., DNA or RNA) has garnered significant attention as it can be utilized for various bioapplications including, but not limited to, pathogen identification, the recognition of genetic mutations, and forensic analysis.129 For instance, Yin and coworkers reported a PtNP-decorated rGO FET where a thiolated DNA probe was attached to the PtNPs via Pt–S bonding.130 Specifically, a large, continuous, few-layer thick film of GO was fabricated via the Langmuir–Blodgett method and subsequently reduced with high temperature annealing in an Ar/H2 atmosphere at 1000 °C. To form graphene–nanoparticle composites, the PtNPs were directly synthesized on the rGO film by immersion of the rGO in an ethanolic solution of PtCl4 followed by light irradiation. It was found that this graphene–nanoparticle composite-based FET, when modified with probe DNA, was able to detect the real-time hybridization of target DNA in PBS with a calculated detection limit of 2.4 nM. Moreover, the sensor exhibited good selectivity. For instance, when 1 μM of noncomplementary DNA was added to the sensing chamber, there was no obvious change in the conductance.

Overall, the performance of hybrid electronic sensors depends strongly on graphene morphology (e.g., wrinkles, folds, number of layers), the number of graphene sheets, the level of graphene reduction, and the interface that exists between the nanoparticles and graphene, which can all influence the electrical properties of the device. In particular, the morphology (e.g., wrinkles, folds, number of layers) of graphene should be free of defects and, as such, hinges on the synthesis method used. On the other hand, the nanoparticle–graphene interface is highly susceptible to modulations by adsorbed species, and the Schottky barrier of the interface has been shown to significantly change device conductance.124 In particular, smaller sized nanoparticles can be distributed more uniformly on graphene materials and provide more contact area than bigger sized nanoparticles, resulting in an improvement in electrical properties.123

3.2. Electrochemical Sensors

Electrochemical sensors are, by far, the largest group of sensors and provide an especially attractive means with which to analyze the content of a biological sample due to the direct conversion of a biological recognition event to an electrical signal. A typical electrochemical sensor consists of a sensing (or working) electrode that has a biological recognition element and a counter electrode that are separated by a layer of electrolytes. Electrochemical biosensors can be divided into two main categories based on the nature of their biological recognition process: (1) affinity-based sensors and (2) catalytic sensors. Affinity sensors rely on the selective binding interaction that occurs between a biological component such as an antibody, enzyme, nucleic acid, or a receptor (e.g., immunosensor or DNA hybridization biosensor) and its target analyte, which results in the production of a measurable electrical signal. On the other hand, catalytic sensors generally incorporate nanoparticles or enzymes that recognize the analyte of interest and produce electroactive species. The amount of analyte that is either reduced or oxidized at the sensing electrode would then correlate with the concentration of the target analyte present. In particular, various forms of voltammetry (e.g., linear sweep, differential pulse, squarewave, stripping) and amperometry are commonly used for the electrochemical detection of biomolecules.131

Graphene is an ideal material for electrochemical biosensors as it is an excellent conductor of electrical charge.9a Moreover, because of its high surface area, graphene can facilitate a large number of defects and thus electroactive sites.132 The electrochemical behavior of graphene is also excellent and comparable to other carbon-based materials including CNTs and graphite where recent reports have even demonstrated that graphene-based electrochemical sensors have superior performance when compared to CNTs due to the presence of more sp2-like planes and edge defects on the surface of graphene.133

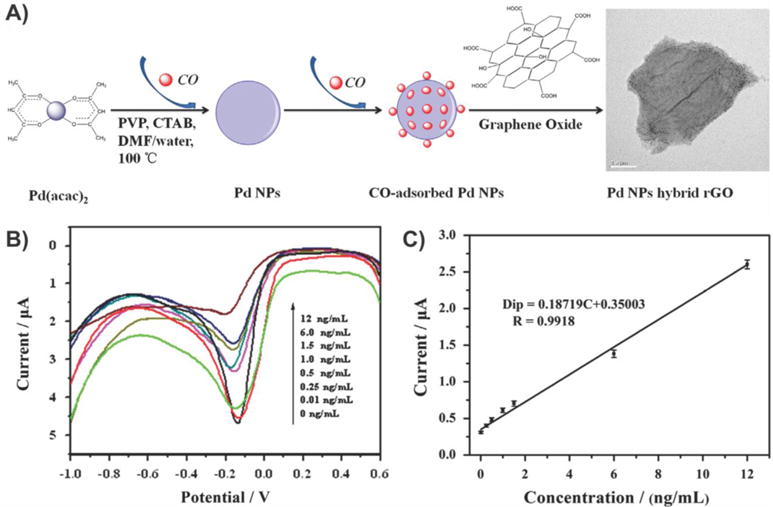

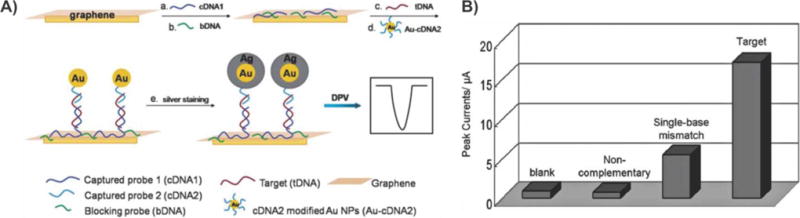

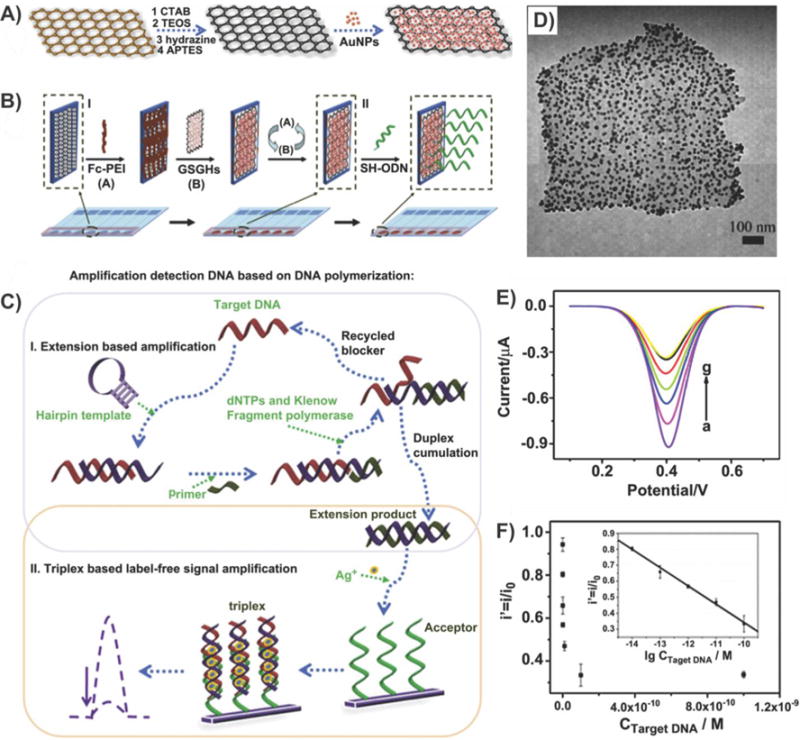

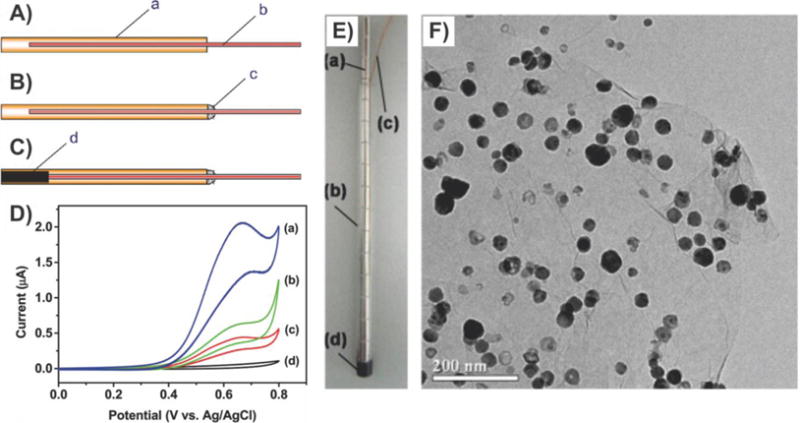

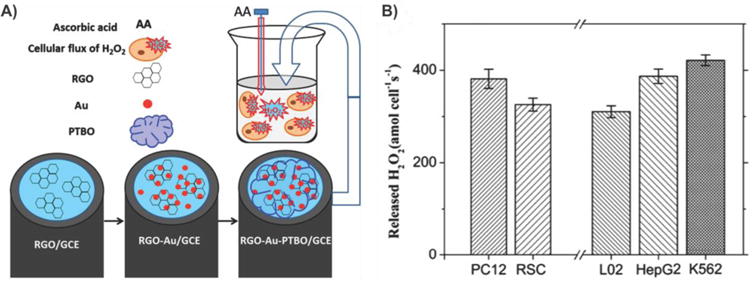

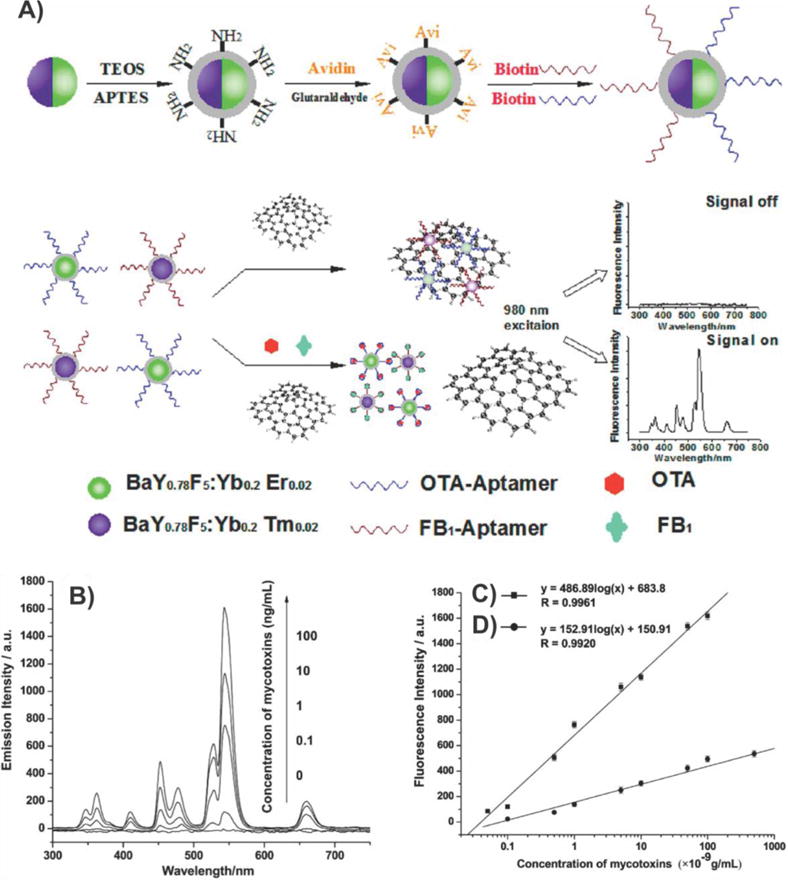

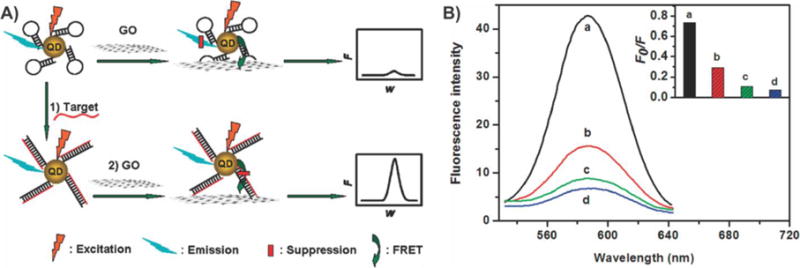

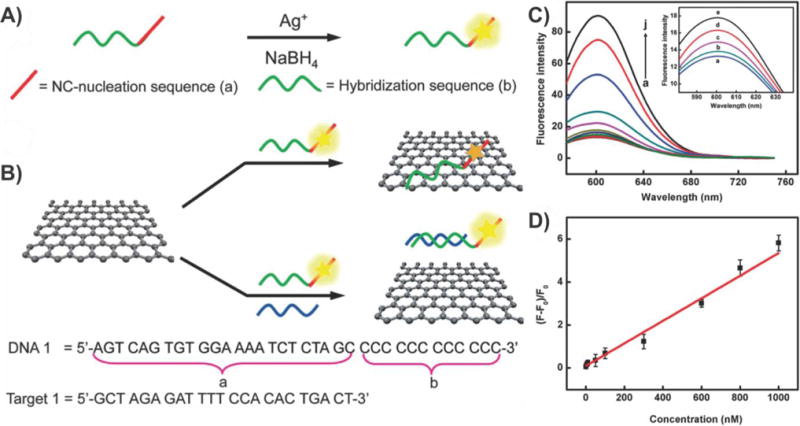

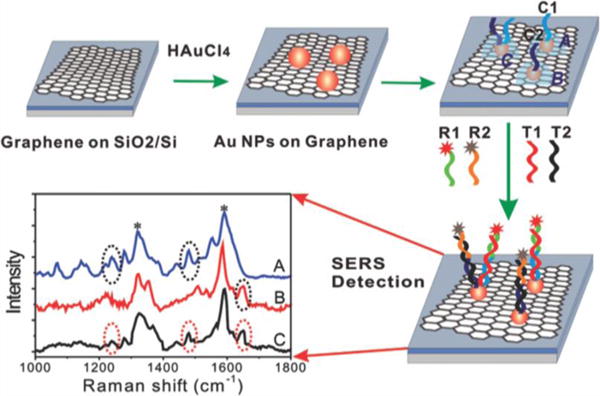

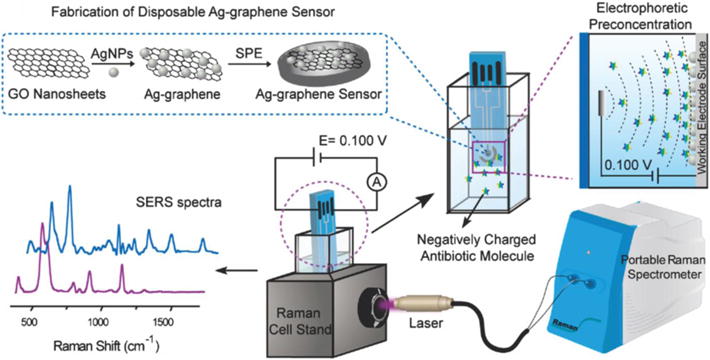

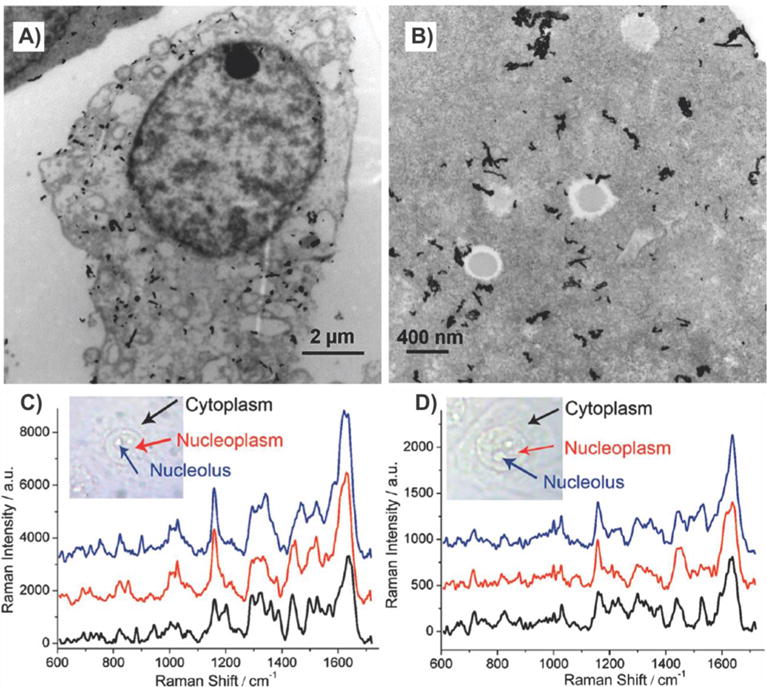

While graphene exhibits great promise, graphene–nanoparticle hybrid structures have recently gained increasing attention for their applicability to electrochemical sensing. In particular, various types of nanoparticles, including metal nanoparticles such as Au and Pt, metal oxide nanoparticles, and semiconductor nanoparticles, are already widely used for electrochemical sensing applications.115a,134 These nanoparticles can have different roles in electrochemical sensing platforms; for example, they can function to (1) immobilize biomolecules, (2) catalyze electrochemical reactions, or (3) act as a reactant. As such, by incorporating graphene–nanoparticle hybrid structures, one can impart unique and advantageous properties to electrochemical biosensors resulting in the exhibition of the advantages provided by the individual nanoparticle and graphene components as well as synergy from the hybrid. For example, graphene sheets that are decorated with nanoparticles can help overcome the poor utilization coefficient of aggregated nanoparticles.48d In certain cases, by decorating graphene with nanoparticles, one can also efficiently improve the electron transfer that occurs between the analyte and the electrode.135 Finally, similar to the strategy that was used in some hybrid FET sensors, instead of immobilizing the sensing biomolecules directly to graphene, which is often difficult and can negatively affect electrical properties, graphene–nanoparticle hybrids can be formed wherein the sensing biomolecules are first immobilized on the nanoparticles prior to decoration onto graphene. As a result, this can enhance the achievable sensitivity of graphene–nanoparticle hybrid electrochemical sensors.