Abstract

Statement of the Problem:

The clinical success of ceramic depends on the quality of the bond between the zirconia and resin cement.

Purpose:

In the present study, the effects of universal and conventional MDP-containing primers were evaluated on the shear bond strength of zirconia ceramic and nanofilled composite resin.

Materials and Method:

Thirty blocks of zirconia ceramic (6mm×2mm) were prepared. Then the inner surfaces were air-abraded and divided into three groups (n= 10) as follows: untreated with primer (control group, I); All- Bond Universal (group II) and Z-Prime Plus (group III). The specimens in each group were bonded with Variolink N cement to cylinders of composite resin Z350XT. After 24 hour water storage, the shear bond strength test was performed with a universal testing machine at a crosshead speed of 1mm/ min and bond strength values (MPa) were calculated and analyzed with one-way ANOVA and post hoc Tukey tests (p< 0.05). The failure mode of each specimen was evaluated under a stereomicroscope and representative specimens were analyzed by scanning electron microscopy (SEM).

Results:

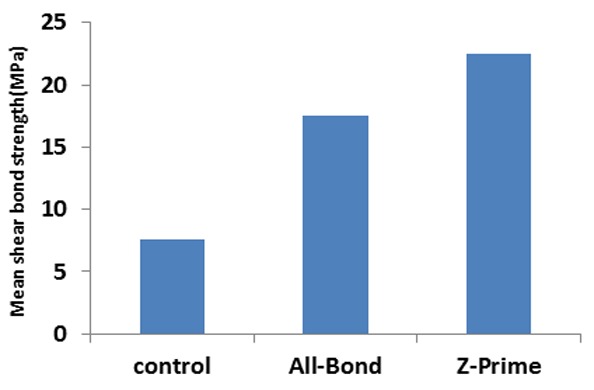

The mean shear bond strength values (MPa) were 7.58±1.62, 17.51±1.34 and 22.45±3.60 in groups I, II and III, respectively. These results indicated that the shear bond strength were significantly higher in groups II and III compared to the control group (p< 0.001). Chemical pre-treatment of zirconia with Z- Prime Plus revealed significantly higher bond strength than the All-Bond Universal adhesive (p< 0.002). All the failure modes were adhesive in the control group (I) and when using primer treatment, mixed failures occurred in 40% and 50% of specimens in groups II and III, respectively.

Conclusion:

Treatment with both primers resulted in higher bond strength values compared to the control group. The use of Z-Prime Plus treatment in combination with air-abrasion procedure resulted in the highest bond strength.

Keywords: Zirconia , Strength , Adhesives , Primer , Composite

Introduction

Zirconia is a silica-free ceramic, which is commonly used in dentistry, due to its natural appearance and superb properties such as low thermal conduction, biocompatibility, chemical stability, translucency, fluorescence and thermal expansion similar to the tooth structure.[1-3] To achieve a bond with zirconia which has high hardness and crystallinity, different techniques have been proposed to prepare the zirconia surface in order to create micromechanical retentive areas and surface roughness and increase the bond strength between the ceramic and resin cement.[4-6]

To achieve a strong bond, one of the most commonly used and effective techniques is air abrasion with aluminum oxide particles.[7-9] Another commonly used technique for preparation of ceramic surfaces is the application of different primers regarding their ease of application and reasonable cost and moreover, no special tools are required for their application. Primers containing 10-methacryloxydecyl dihydrogen phosphate (MDP) and phosphate monomers are primers that improve the bond strength to zirconia.[10-12] Several studies by Tanis et al.[9] Shine et al.,[13] Wang et al.[14] and Ahn and Young[10] reported that the combined use of MPD primer and air- abrasion improved the bond strength of zirconia ceramic. In addition, based on the findings of a systematic review by Tzanakakis et al.,[5] it was concluded that the air abrasion was mandatory for durable resin bonding to zirconia ceramic and the adhesive monomers are necessary for chemical bonding.

Recently, a new group of adhesives, referred to as multi-mode universal adhesives, have been marketed, which are used with both self-etch and etch-and-rinse adhesives.[15] Since the conventional and commonly used systems require several steps, use of universal adhesives simplifies the preparation of the surface of restorations and teeth, saving time. Some studies have mentioned that these universal bonding agents not only can form a favorable bond with tooth structures, but also they can bond to other substrates such as resins, metals and other indirect restorations, including zirconia ceramics and lithium disilicate.[16-18] In addition, it is stated that the universal adhesives contain a new type of MDP. The multi-mode universal adhesives are used for strong and durable adhesion to silica-based ceramics such as feldspathic porcelains and glass ceramics; they are also used frequently for high-strength ceramics restorations.[18-19] These universal adhesives increase the bond strength of ceramics that can be etched (glass-containing) and those that cannot be etched (glass-free).[14,20] A number of researchers have evaluated the effects of universal adhesives on the bond strength of ceramics, especially that of zirconia. However, there is still insufficient data available on the effects of these adhesives.

Composite resins can be used to restore the large defected vital or nonvital teeth and can be used as a base for crown or bridge restorations such as zirconia .The bond strength between composite core-resin cement and resin cement-zirconia affects the long-term clinical success of the ceramic restoration.[20] Various factors affect the bonding of the composite restorations including surface roughness, cement type, type of composite resin, and time after repairing.[2,21] Since the morphology, size and the amount of filler particle play a role in the final properties of composite restorations; nanofilled composite resins were introduced with higher filler content and a filler size of 0.1‒100 µm, which resulted in an improvement in the properties of composite restorations, including resistance to abrasion, diametral tensile strength, and microhardness.[22-23] The nanofilled composite restorations have a unique nature that is attributed to their mechanical strength which is similar to that of microhybrid composite resins and their smooth surface similar to that of microfilled composite resins during their clinical service.[23-24] It has been recommended to use nanofilled composites for both anterior and posterior restorations.[23]

Several important factors, including the bond strength between the resin core‒resin cement and ceramic, the cementation technique, cement type and the surface characteristics of ceramics, including zirconia, play a role in the long-term success of ceramic restorations in the clinic.[25-26] A high bond strength between zirconia and resin cement results in better marginal adaptation, retention and high resistance to fracture. In previous studies, the effects of different primers, the type of cement, the cementation technique, and the surface characteristics of zirconia on bond strength have been evaluated. However, no data is available on the effect of changes in zirconia surface with the use of different primers on the bond strength between resin cement and nanofilled composite resin cores. In the present study, the effects of two types of primer, universal and conventional, containing MDP, were evaluated on the bond strength of zirconia ceramics.

Materials and Method

In the present study, zirconia ceramics (DDcube X2, Dental Direct Materials, Germany) were used. The imes-icore (CORiTEC340i, Germany) device was used to cut ceramic blocks into disc shapes measuring 6mm in diameter and 2mm in thickness.[27] All of the 30 discs prepared were subjected to an air abrasion procedure with 50μm Al2O3 particles at low pressure 2 bar1 for 10 seconds, using a sandblasting device (JNBP-2, Jianian Futong Medical Equipment Co. Ltd., Tianjin, China) followed by rinsing for 3 minutes with distilled water in an ultrasonic cleaner device and drying with an air syringe. Then the samples were assigned to three groups (n=10). The inner surfaces of the ceramic samples, after this stage, were considered as the controls in the group I with no application of the primer. In the group II, the ceramic samples were prepared with All-Bond Universal (Bisco, USA) primer; in the group III, they were prepared with Z-Prime Plus (Bisco, USA) primer. Experimental materials and their characteristics were showed in Table 1. For preparation of the composite resin cylinders, first acrylic resin blocks, measuring 2×3cm and 1cm in thickness, were prepared and then cylindrical cavities were prepared at their center, measuring 6mm in diameter and 3mm in depth. Then, Z350XT composite resin was placed in the cavities in two 1.5mm layers using the incremental technique and each layer was light-cured for 40 seconds using an LED light-curing unit (Demi Plus, Kerr, Switzerland) at a light intensity of 1200mw/ cm2 and a wavelength of 470nm. In the group I, the ceramic samples were prepared without the application of primer, considered as the control group. The ceramic samples in the group II were prepared using All-Bond Universal primer. The primer was used in two separate layers with the use of a disposable microbrush for 10 seconds for each layer on the intaglio surface of the samples by scrubbing, followed by drying with an air syringe for 10 seconds and light-curing for 10 seconds. In the group III, Z-Prime Plus primer was applied in two layers by a disposable microbrush to the intaglio surface of the samples in order to wet the bonding surface homogeneously, followed by drying with an air syringe for 5 seconds. The ceramic samples in each group (6mm× 2mm) were cemented to the composite resin cylinders (6mm×3mm) with Variolink N (Ivoclar, Vivadent) resin cement. The base and catalyst of the cement were carefully mixed on a paper pad with the use of a spatula at a ratio of 1:1. The cement was placed on the intaglio surfaces of the ceramics, which were bonded to the mounted composite resin cylinders with light pressure for a few seconds. Extra cement was removed with disposable microbrush and light cured for 40 seconds from the top surface. All specimens were stored in distilled water at 37ºC for 24 hours in an incubator (ES 250 Nuve, Turkey), individually for each group. Subsequently, the prepared samples underwent shear bond strength tests in a universal testing machine (Zwick/Roell Zo20 Germany), using the knife-edge blade of the machine at a crosshead speed of 1mm/minute until fracture occurred.[4,9,17,28] Then the mean values of fracture (MPa) were recorded.

Table 1.

Experimental materials and their characteristics

| Material | Composition | Manufacturer |

|---|---|---|

| Zirconia ceramic | ZrO2%+HfO2>90%,Y2O3<10%Al2O3<0.1%,other oxide<0.005% | DDcube X2, Dental Direct |

| Materials, Germany | ||

| Z-Prime Plus | BPDM, HEMA, ethanol, MDP | Bisco Inc., Schaumburg, IL |

| All-Bond Universal | HEMA, ethanol, MDP,Bis-GMA,water,initiator | Bisco Inc., Schaumburg, IL |

| Variolink N | Bis-GMA, UDMA, TEGDMA, Bis-EMA(6), PEGDMA, silica filler, zirconia filler, zirconia/silica cluster filler | Ivoclar Vivadent, Schaan, Liechtenstein |

| Barium glass, ytterbiumtrifluoride, Ba-Al-fluorosilicate glass, spheroidmixed oxide, initiators, stabilizers , pigments | ||

| Z350XT (Dentin A1) | Bis-GMA, UDMA, TEGDMA, Bis-EMA(6), PEGDMA, silica filler, zirconia filler, zirconia/silica cluster filler | 3M ESPS, USA |

Data were analyzed with one-way ANOVA, followed by post hoc Tukey tests using SPSS 22 (pl< 0.05). The failure modes (adhesive, cohesive and mixed) were evaluated under a stereomicroscope (BS-3060C, China) at magnification of 40×. These failure modes are classified as cohesive failure that is referred to a complete fracture within the ceramic or within the composite resin, adhesive failure which means fracture between the ceramic (or composite resin) and resin cement, and finally mixed fracture which indicates fracture involving at least two materials.[20]

After fractures occurred, two samples from each group were randomly selected and were mounted for gold- sputtered aluminum plates on a device (EMITEC-H, K450X, England) then the samples were evaluate under a scanning electron microscopy (VEGA11, TESCA-M, Czech Republic) at different magnification (from 500× to 3000×) and a high voltage of 15KV.

Results

The means and standard deviations for shear bond strength (MPa) for all the groups are presented in Table 2.

Table 2.

Mean Shear bond strength Values (MPa) and Standard Deviation (SD)

| Group | n | Mean Shear bond Strength ± SD |

|---|---|---|

| I | 10 | 7.57± 1.62A |

| II | 10 | 17.51± 1.34B |

| III | 10 | 22.45±3.60C |

Different letters show that mean shear bond strength were statistically different, Tukey HSD test

One- way ANOVA showed that the interaction between two different primers and zirconia ceramic was statistically significant than the control groups (pl< 0.001). The use of both primers after air-abrasion was more effectiveness than the control group (pl< 0.001) (Figure 1).

Figure1.

Mean shear bond strength values (MPa) in all groups according to different MDP-containing primers

HSD Tukey test showed statistically significant differences between the two primers (pl< 0.002). The Z- Prime Plus treatment yielded the best results and the bond strength values were significantly higher than the All-Bond group (pl< 0.002). Multiple comparisons for all the tested groups are presented in Table 3.

Table 3.

Multiple Comparisons for all tested groups with Tukey HSD test

| Multiple comparison (p Values) | |

|---|---|

| Group I vs II | (pl< 00.01) |

| Group I vs III | (pl< 00.01) |

| Group II vs III | (pl< 0.002) |

The mean difference is significant at the 0.05 level

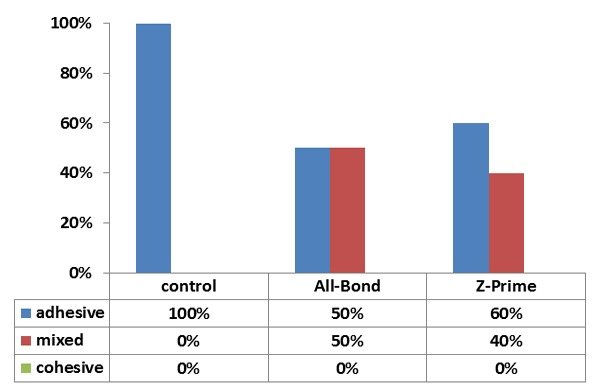

The distribution of failure modes in all the groups are presented in Figure 2. All the failure at the zirconia surface in the control group (I) were adhesive failures. In contrast, when primers were used for treatment, mixed failure modes occurred (50% in the group II and 40% in the group III). The results exhibited a high percentage of adhesive failures in Z-Prime Plus group (60%), with 40% of mixed failures. In the All-Bond group, adhesive and mixed failures were equal (50%). No cohesive failures were observed in the all groups.

Figure2.

Failure mode distributions in all groups (%)

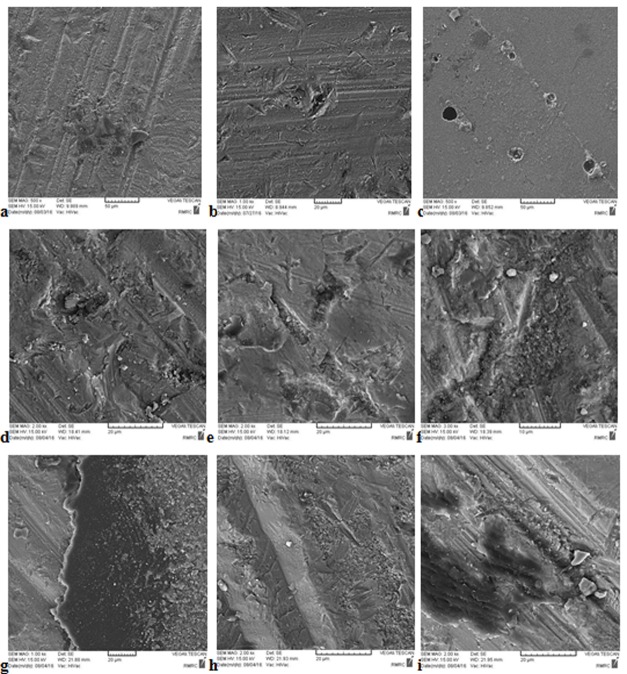

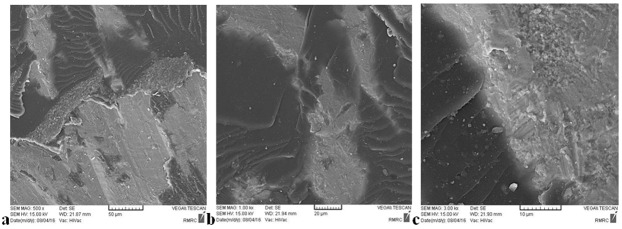

The SEM images of zirconia surfaces in all the groups are presented in Figure 3. The relative degree of the remaining resin cement could be seen. In addition, the specimens treated with MDP-containing primers exhibited mixed failures and a characteristic corrugation appearance (Figure 4).

Figure3.

Scanning electron micrographs (500× to 3000× original magnification) of zirconia ceramic specimens: a ,b, c: control surface without any primer treatment ; air-abraded surface of zirconia with 50 μm Al2O3 in fig c; d, e, f: surface treatment with Z-Prime Plus; g, h, i: surface treatment with All-Bond Universal. The relative degree of the resin cement remaining can be seen in fig d-i.

Figure4.

Scanning electron micrographs (500× to 3000× original magnification) of zirconia ceramic specimens under mixed failures in groups of II and III. It is notable a unique corrugated appearance.

Discussion

The high bond strength between the zirconia ceramic and resin cements can be one of the main reasons for the clinical success of the restoration.1 Based on the results of past studies, one of the most commonly used tests for assessment the bond strength is the shear-bond strength test;[5,15] thus in the present study, the effects of different MDP-primers on zirconia ceramic were evaluated with shear bond strength test. The trimming technique of specimens that is required for the tensile tests is time-consuming and it is expected to cause adhesive defects. It might stress the zirconia interface and affect the bond strength values[20,29] but the shear test does not require trimming the samples and is simpler to carry out than the tensile test; however, the shear bond strength has been questioned for nonhomogeneous stress distribution at the interface.[29]

In the present study, all the specimens were subjected to an air-abrasion procedure because various studies have shown that this mechanical surface treatment improves bond strength between the resin and zirconia ceramic by increasing the bonding surface area, surface roughness and wettability, thus resulting in the flow of the resin cement onto the zirconia surfaces.[8-9,30] In addition, this procedure removes organic contaminants from the zirconia surface for chemical bonding[5,8] However, some studies have reported that air-abrasion process can produce micro cracks in zirconia and influence the properties of zirconia negatively;[9,20] therefore, researchers have recommended that the zirconia ceramic should be air- abraded at low pressure with small particle sizes of aluminum oxide.[7,20] As a result, in the current study, the zirconia discs were air-abraded at a low pressure of 2 bar, using a powder with a particle size of 50μm to avoid surface damage. It has been reported that the air-abrasion process is a crucial factor for improving bond strength to zirconia ceramic but it has a limited and insufficient effect. The best adhesion to zirconia ceramic can be acquired by using primers containing a phosphate-based functional monomer, especially 10-MDP; [12-13,15,20,31] therefore in the present study, both of the primers were tested contained MDP monomer but it seems they are not equally effective.[20] According to the result of this study, both Z-Prime Plus and All-Bond Universal primers showed significantly higher bond strength than the control group (with no primer application). However, Z-Prime Plus treatment exhibited the highest bond strength and significantly higher bond strength values than All-Bond Universal treatment because Z-Prime Plus contains conventional MDP and carboxylic monomers that can interact with the layer of the zirconia oxide at the interface chemically. [32] The interfacial forces might improve the wettability and chemical bonding to zirconia ceramics; increasing the interlocking between the resin cement and zirconia surfaces. [9,32] In addition, MDP has an amphiphilic construction; the vinyl group, as the hydrophobic end, can copolymerize with the resin monomer and the phosphate group as the hydrophilic end can interact with the hydroxyl groups on the zirconia surface, improving the chemical affinity. [10,33] It seems that the synergistic effect between acidic MDP and carboxylic monomer is the most likely reason for having the highest bond strength values. [17] Z-Prime Plus was compatible with many resin cements, too.[5]

The results of several previous studies were similar to those of the present study. [5-6,12,14,26] Magne et al.[31] showed that the Z-Prime Plus treatment increased the shear bond strength to zirconia ceramic with different resin-based cements. Similar results were reported by Zandparsa et al. [12] and Shine et al.;[13] the combined use of Z-Prime Plus primer and air- abrasion improved the bond strength of zirconia ceramic. In addition, Yi and et al. [32] reported that the Z-Prime Plus treatment after air-abrasion process produced the highest, the strongest and the most durable bond strength between zirconia ceramic and resin cements, followed by Monobond Plus and silane primer treatment after cojet, consistent with the results of the present study. However, according to a study by Inokoshi et al.,[20] pre-treatment of zirconia with Clearfil Ceramic Primer or Monobond Plus yielded the best results; they explained that these primers contained silane monomer and low bonding values were registered for Z-Prime Plus, in contrast to the results of the present study. The bond strength values that they recorded for Z-Prime Plus were somewhat unexpected and were inconsistent with the more acceptable bond strength by other researchers, which they had also mentioned. They prepared micro-specimens for tensile test and assigned random values of 0 and 10 MPa for pretesting failure of samples. This might have affected the bond strength values in their study.[20] Kim et al.[15] reported that the silane could not contribute to chemical bonding to zirconia ceramic because there is no silica in the zirconia structure. In addition, they found that the All-Bond Universal and Single-Bond Universal adhesive exhibit significantly higher bond strength than the primers containing conventional MDP.[15] That is in contrast to the results of the present study; however, they used the Alloy Primer as a conventional MDP-containing primer, in contract to Alloy Primer that contains 6-(4-vinyl benzyl-n-propyl amino)-1, 3, 5-trazoine-2, 4-dithione (VBATDT) and acetone solvent. This monomer contains sulfur and, it was selected to promote the adhesion to noble and base metal alloys greatly. [15,32] In the current study, the Z-Prim Plus containing ethanol and two adhesive monomers (carboxylate and MDP) were used as a conventional MPD-containing primer. It was in contrast with the present study.

The dual-resin cement (Variolink N) that has no MDP monomer was used in this study as a control to differentiate the effects of conventional and universal MDP in surface conditioning primers. In addition, nanofilled composite resin was used since surface characteristics of core material are imperative factors for the high bond strength between composite resin core and resin cements.[2] In addition, nanoparticles in this composite resin decreased the polymerization shrinkage and increased the mechanical properties such as Vickers microhardness, static and dynamic of modulus of elasticity.[23] In shearbond strength tests, the large mismatch between the elastic modulus of composite cylinder and elastic modulus of zirconia, as a substrate, resulted in concentration of the high stresses at the interface and decreased the bond strength values. [34] With the use of the nanofilled composite resin in this study, it seems that the mismatch of modulus of elasticity between the two substrates (composite resin and zirconia) decreased and more real bond strength values were achieved.

In the present study, the failure modes of the experimental groups were evaluated under a stereomicroscope. In the control group (I), with the lowest bond strength values, only adhesive failures were found, whereas in groups II and III, with higher bond strength values due to primer treatments, mixed failure modes were also observed. These results were typically explained in the literature.[4,17-18] Cohesive failures within the zirconia specimens did not occur, which is one of the most important advantages for zirconia restorations because the intraoral repair of zirconia restorations is difficult and adequate bond cannot be achieved to repair zirconia with composite resin.[17]

In addition, SEM observations in the groups that MDP-containing primers were used showed mixed fractures (predominantly in the composite resin), a corrugated fracture appearance, and thick layers of primer. This may be explained by the strong adhesion phenomenon with zirconia surfaces and confirm the results of shear bond strength tests. While in the representative SEM images of the control group, only adhesive failures were observed. They were more from interfacial type due to the weak bond obtained; moreover, air-abraded surfaces of zirconia ceramic could be seen. These results were similar to those of previous. [3,11,32]

Despite the limitations in this study, it seems that both MDP-containing primers (All-Band Universal and Z-Prime Plus) might be appropriate to bond with zirconia ceramic, mainly after air-abrasion process; however, for evaluating their long-term effects further studies are necessary. In addition, due to the presence of different environments in the oral cavity such as saliva, temperature and pH level changes that might considerably affect the bond strength between the zirconia ceramic, resin cement and composite resin, further studies are required to evaluate these parameters.

Conclusion

Under the limitations of this study, it can be concluded that the bond strength between zirconia ceramic, composite resin and resin cement was affected by the chemical surface treatment. Treatment with both primers (Z-Prime Plus, All-Bond Universal) resulted in higher bond strength than the control group (without any primer). Treatment by Z-Prime Plus can be used effectively to promote adhesion to zirconia ceramic because it resulted in a higher bond strength than the universal MDP-containing adhesive (All-Bond Universal) after air-abrasion process.

All the failures at the zirconia surface in the control group were adhesive failures while use of MDP-containing primers resulted in mixed failure modes.

Acknowledgement

The authors would like to thank the Vice Chancellery of Research, Shiraz University of Medical Sciences, for financial support of this research with project code: 94-01-03-10931. The authors also thank Dr. Vosooghi for the statistical analysis and the Biomaterial Research Center and Mrs. Bagheri for testing the specimens.

Conflict of Interest:The authors of this manuscript certify that they have no conflict of interest regarding this research.

References

- 1.Guarda GB, Correr AB, Gonçalves LS, Costa AR, Borges GA, Sinhoreti MA, et al. Effects of surface treatments, thermocycling, and cyclic loading on the bond strength of a resin cement bonded to a lithium disilicate glassceramic. Oper Dent. 2013; 38: 208–217. doi: 10.2341/11-076-L. [DOI] [PubMed] [Google Scholar]

- 2.Polat S, Cebe F, Tunçdemir A, Öztürk C, Üşümez A. Evaluation of the bond strength between aged composite cores and luting agent. J Adv Prosthodont. 2015; 7: 108–114. doi: 10.4047/jap.2015.7.2.108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Tashkandi E. Effect of surface treatment on the micro-shear bond strength to zirconia. Saudi Dent J. 2009; 21: 113–116. doi: 10.1016/j.sdentj.2009.10.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Pereira Lde L, Campos F, Dal Piva AM, Gondim LD, Souza RO, Özcan M. Can application of universal primers alone be a substitute for airborne-particle abrasion to improve adhesion of resin cement to zirconia? J Adhes Dent. 2015; 17: 169–174. doi: 10.3290/j.jad.a33974. [DOI] [PubMed] [Google Scholar]

- 5.Tzanakakis EG, Tzoutzas IG, Koidis PT. there a potential for durable adhesion to zirconia restorations? A systematic review. J Prosthet Dent 2016; 115: 9–19. doi: 10.1016/j.prosdent.2015.09.008. [DOI] [PubMed] [Google Scholar]

- 6.Xie ZG, Meng XF, Xu LN, Yoshida K, Luo XP, Gu N. Effect of air abrasion and dye on the surface element ratio and resin bond of zirconia ceramic. Biomed Mater. 2011; 6: 065004. doi: 10.1088/1748-6041/6/6/065004. [DOI] [PubMed] [Google Scholar]

- 7.Su N, Yue L, Liao Y, Liu W, Zhang H, Li X, et al. The effect of various sandblasting conditions on surface changes of dental zirconia and shear bond strength between zirconia core and indirect composite resin. J Adv Prosthodont. 2015; 7: 214–223. doi: 10.4047/jap.2015.7.3.214. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009; 88: 817–822. doi: 10.1177/0022034509340881. [DOI] [PubMed] [Google Scholar]

- 9.Tanış MÇ, Akay C, Karakış D. Resin cementation of zirconia ceramics with different bondingagents. Biotechnol Biotechnol Equip. 2015; 29: 363–367. doi: 10.1080/13102818.2014.996606. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Ahn JS, Yi YA, Lee Y, Seo DG. Shear Bond Strength of MDP-Containing Self-Adhesive Resin Cement and Y-TZP Ceramics: Effect of Phosphate Monomer-Containing Primers. Biomed Res Int. 2015; 2015: 389234. doi: 10.1155/2015/389234. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Komine F, Fushiki R, Koizuka M, Taguchi K, Kamio S, Matsumura H. Effect of surface treatment on bond strength between an indirectcomposite material and a zirconia framework. J Oral Sci. 2012; 54: 39–46. doi: 10.2334/josnusd.54.39. [DOI] [PubMed] [Google Scholar]

- 12.Zandparsa R, Talua NA, Finkelman MD, Schaus SE. An in vitro comparison of shear bond strength of zirconia to enamel using different surface treatments. J Prosthodont. 2014; 23: 117–123. doi: 10.1111/jopr.12075. [DOI] [PubMed] [Google Scholar]

- 13.Shin YJ, Shin Y, Yi YA, Kim J, Lee IB, Cho BH, et al. Evaluation of the shear bond strength of resin cement to Y-TZP ceramic after different surface treatments. Scanning. 2014; 36: 479–486. doi: 10.1002/sca.21142. [DOI] [PubMed] [Google Scholar]

- 14.Wang C, Niu LN, Wang YJ, Jiao K, Liu Y, Zhou W, et al. Bonding of resin cement to zirconia with high presure primer coating. PLoS One. 2014; 9: e101174. doi: 10.1371/journal.pone.0101174. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Kim JH, Chae SY, Lee Y, Han GJ, Cho BH. Effects of multipurpose, universal adhesives on resin bonding to zirconiaceramic. Oper Dent. 2015; 40: 55–62. doi: 10.2341/13-303-L. [DOI] [PubMed] [Google Scholar]

- 16.Yoshida F, Tsujimoto A, Ishii R, Nojiri K, Takamizawa T, Miyazaki M, et al. Influence of surface treatment of contaminated lithium disilicate and leucite glass ceramics on surface free energy and bond strength of universal adhesives. Dent Mater J. 2015; 34: 855–862. doi: 10.4012/dmj.2015-123. [DOI] [PubMed] [Google Scholar]

- 17.Seabra B, Arantes-Oliveira S, Portugal J. Influence of multimode universal adhesives and zirconia primerapplication techniques on zirconia repair. J Prosthet Dent. 2014; 112: 182–187. doi: 10.1016/j.prosdent.2013.10.008. [DOI] [PubMed] [Google Scholar]

- 18.Xie H, Li Q, Zhang F, Lu Y, Tay FR, Qian M, et al. Comparison of resin bonding improvements to zirconia between one-bottle universal adhesives and tribochemical silica coating, which is better? . Dent Mater. 2016;32:403–411. doi: 10.1016/j.dental.2015.12.014. [DOI] [PubMed] [Google Scholar]

- 19.Ikemura K, Tanaka H, Fujii T, Deguchi M, Endo T, Kadoma Y. Development of a new single-bottle multi-purpose primer for bonding to dental porcelain, alumina, zirconia, and dental gold alloy. Dent Mater J. 2011; 30: 478–484. doi: 10.4012/dmj.2010-182. [DOI] [PubMed] [Google Scholar]

- 20.Inokoshi M, Poitevin A, De Munck J, Minakuchi S, Van Meerbeek B. Bonding effectiveness to different chemically pre-treated dental zirconia. Clin Oral Investig. 2014; 18: 1803–1812. doi: 10.1007/s00784-013-1152-7. [DOI] [PubMed] [Google Scholar]

- 21.Kim BK, Bae HE, Shim JS, Lee KW. The influence of ceramic surface treatments on the tensile bond strength of composite resin to all-ceramic coping materials. J Prosthet Dent. 2005; 94: 357–362. doi: 10.1016/j.prosdent.2005.08.012. [DOI] [PubMed] [Google Scholar]

- 22.Sharafeddin F, Salehi R, Feizi N. Effect of Dimethyl Sulfoxide on Bond Strength of a Self-Etch Primer and an Etch and Rinse Adhesive to Surface and Deep Dentin. J Dent (Shiraz) 2016; 17(3 Suppl): 242–249. [PMC free article] [PubMed] [Google Scholar]

- 23.Beun S, Glorieux T, Devaux J, Vreven J, Leloup G. Characterization of nanofilled compared to universal and m-crofilled composites. Dent Mater. 2007; 23: 51–59. doi: 10.1016/j.dental.2005.12.003. [DOI] [PubMed] [Google Scholar]

- 24.De Moraes RR, Gonçalves Lde S, Lancellotti AC, Consani S, Correr-Sobrinho L, Sinhoreti MA. Nanohy-brid resin composites: nanofiller loaded materials or traditionalmicrohybrid resins? Oper Dent. 2009; 34: 551–557. doi: 10.2341/08-043-L. [DOI] [PubMed] [Google Scholar]

- 25.Fazi G, Vichi A, Ferrari M. Influence of surface pretreatment on the short-term bond strength of resin composite to a zirconia-based material. Am J Dent. 2012; 25: 73–78. [PubMed] [Google Scholar]

- 26.Attia A, Kern M. Long-term resin bonding to zirconia ceramic with a new universal primer. J Prosthet Dent. 2011; 106: 319–327. doi: 10.1016/S0022-3913(11)60137-6. [DOI] [PubMed] [Google Scholar]

- 27.Tsuo Y, Yoshida K, Atsuta M. Effects of alumina-blasting and adhesive primers on bonding between resin luting agent and zirconia ceramics. Dent Mater J. 2006; 25: 669–674. doi: 10.4012/dmj.25.669. [DOI] [PubMed] [Google Scholar]

- 28.Ozcan M, Nijhuis H, Valandro LF. Effect of various surface conditioning methods on the adhesion of dual-cure resin cement with MDP function-al monomer to zirconia after thermalaging. Dent Mater J. 2008; 27: 99–104. [PubMed] [Google Scholar]

- 29.Panah FG, Rezai SM, Ahmadian L. The influence of ceramic surface treatments on the micro-shear bondstrength of composite resin to IPS Empress 2. J Pros-thodont. 2008; 17: 409–414. doi: 10.1111/j.1532-849X.2007.00296.x. [DOI] [PubMed] [Google Scholar]

- 30.Kim RJ, Woo JS, Lee IB, Yi YA, Hwang JY, Seo DG. Performance of universal adhesives on bonding to leucite- reinforced ceramic. Biomater Res. 2015; 19: 11. doi: 10.1186/s40824-015-0035-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Magne P, Paranhos MP, Burnett LH Jr. New zirconia primer improves bond strength of resin-based cements. Dent Mater. 2010; 26: 345–352. doi: 10.1016/j.dental.2009.12.005. [DOI] [PubMed] [Google Scholar]

- 32.Yi YA, Ahn JS, Park YJ, Jun SH, Lee IB, Cho BH, et al. The effect of sandblasting and different primers on shear bond strength between yttria-tetragonal zirconia polycrystal ceramic and a self-adhesiveresin cement. Oper Dent. 2015; 40: 63–71. doi: 10.2341/13-149-L. [DOI] [PubMed] [Google Scholar]

- 33.Román-Rodríguez JL, Fons-Font A, Amigó-Borrás V, Granell-Ruiz M, Busquets-Mataix D, Panadero RA, et al. Bond strength of selected composite resin-cements to zirconium-oxide ceramic. Med Oral Patol Oral Cir Bucal. 2013; 18: e115–e123. doi: 10.4317/medoral.18243. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Zhang X, Chai ZG, Wang H, Wang YJ, Chen JH. Influence of different adherend materials and combinations on in vitroshear bond strength. Dent Mater J. 2013; 32: 622–627. doi: 10.4012/dmj.2013-032. [DOI] [PubMed] [Google Scholar]