Abstract

Development of the Practical Solutions for Pesticide Safety guide used participatory research strategies to identify and evaluate solutions that reduce pesticide exposures for workers and their families and to disseminate these solutions. Project principles were (1) workplace chemicals belong in the workplace, and (2) pesticide handlers and farm managers are experts, with direct knowledge of production practices. The project’s participatory methods were grounded in self-determination theory. Practical solutions were identified and evaluated based on five criteria: practicality, adaptability, health and safety, novelty, and regulatory compliance. Research activities that had more personal contact provided better outcomes. The Expert Working Group, composed of farm managers and pesticide handlers, was key to the identification of solutions, as were farm site visits. Audience participation, hands-on testing, and orchard field trials were particularly effective in the evaluation of potential solutions. Small work groups in a Regional Advisory Committee provided the best direction and guidance for a “user-friendly” translational document that provided evidence-based practical solutions. The “farmer to farmer” format of the guide was endorsed by both the Expert Working Group and the Regional Advisory Committee. Managers and pesticide handlers wanted to share their solutions in order to “help others stay safe,” and they appreciated attribution in the guide. The guide is now being used in educational programs across the region. The fundamental concept that farmers and farmworkers are innovators and experts in agricultural production was affirmed by this study. The success of this process demonstrates the value of participatory industrial hygiene in agriculture.

Keywords: Agriculture, industrial hygiene, participatory research, pesticide safety

Introduction

This article reports on a research program that resulted in the publication of a new safety guide: Practical Solutions for Pesticide Safety.1 We highlight the participatory methods used in this process and the critical role of farm managers and workers in the development of the guide. The guide contains 26 solutions and additional practical information (Table 1).

Table 1.

Summary of Selecteda Practical Solutions: Descriptions, Sources, and Primary Evaluation Method.

| Name | Description | Sourceb | Evaluationc |

|---|---|---|---|

| Mixing and loading | |||

| • Metal mixing table | Table made with expanded metal top and metal legs | Manager built table to withstand weather and not absorb pesticides like wood | Audience participation and field test |

| • Splash shield (Figure 2) | Handlers look through acrylic sheet when measuring pesticides | EWG-designed splash shield as solution for eye splashes | EWG |

| • Premarked measuring containers | Fill marks on measuring containers | Manager taught handlers about US liquid units and reduced errors | Field test |

| Application and drift reduction | |||

| • Thermo-wind meter | Hand-held, battery-operated thermometer and anemometer | Handler recognized that weather conditions vary between nearby locations | Audience participation |

| • Convex side view mirror (Figure 2) | Mirror(s) are mounted on one or both the sides of the tractor | Handler devised to check spray patterns and reduce neck strain | Field test |

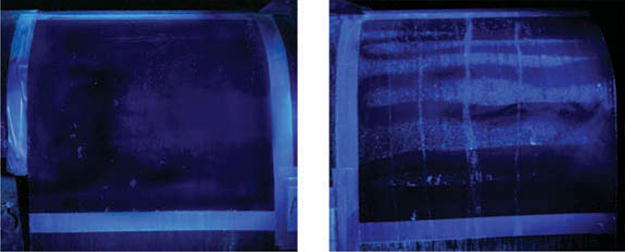

| • Scrub brush for washing (Figure 4) | Pressure washers often used to clean application equipment | EWG wanted to know if scrub brush or pressure washer cleaned best | Research team and EWG |

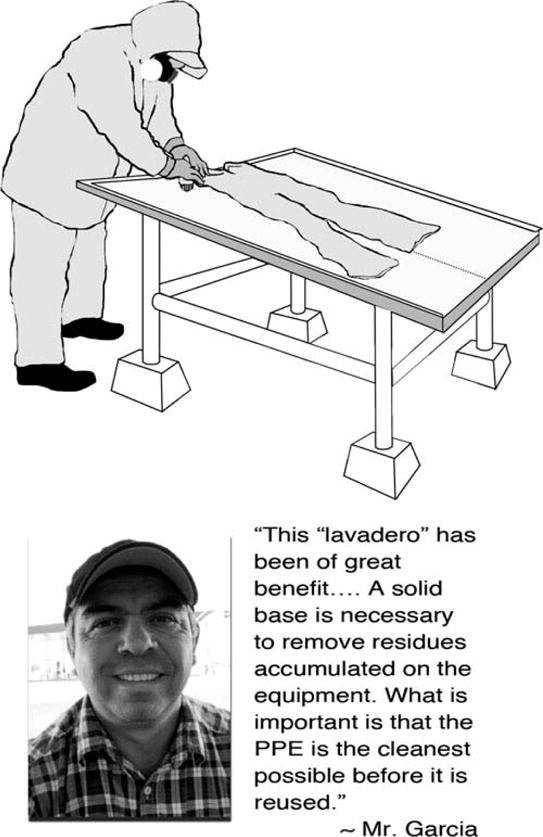

| • Sloping cement pad (Figure 5) | Raised pad provides a hard surface on which to scrub PPE | Manager built it so handlers did not need to bend over | External review |

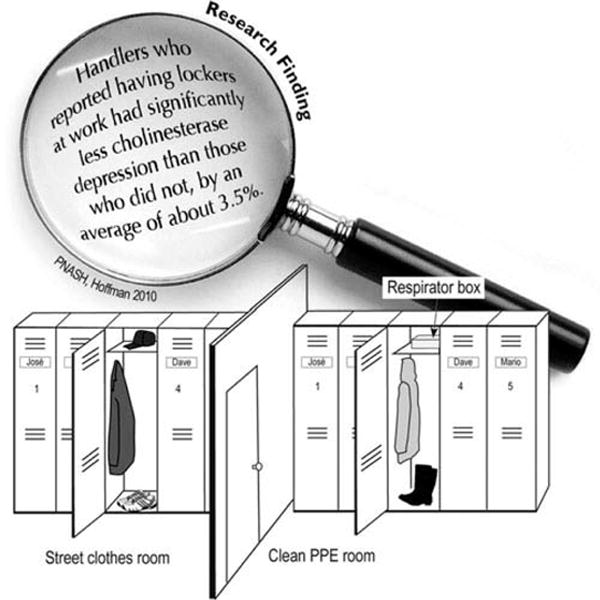

| • Locker system (Figure 1) | Two locker rooms provided; one each for PPE and street clothes | Handlers with lockers had less cholinesterase depressiond | Research team |

| Emergency and sanitation facilities | |||

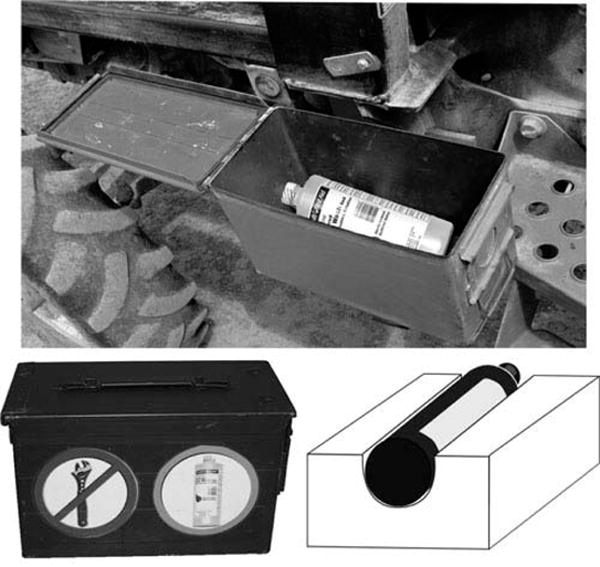

| • Ammunition box for eyewash (Figure 3) | Box attached to tractor; has cradle to secure emergency eyewash bottle | Manager adapted ammunition box used for storing tools on a tractor | Field test |

| • Spill contain with tubs | Plastic wash tubs used to separate and contain spills | The EWG suggested these as an easy alternative | External review |

| Reducing family exposure | |||

| • Dedicated vehicle for handlers | Vehicle used only by handler to drive to and from work. No one else rides in it | Two handlers concerned about work to home exposure | External review |

| • Vacuum station for vehicles | Station located at orchard; workers vacuumed cars before going home | Using a HEPA vacuum for car can decrease pesticide levels in home dustd | Research team |

| PPE suits, respirators, and boots | |||

| • PPE features, procedures, and research results to help pesticide handlers select the best PPE option for them. | EWG | ||

Note. EWG = Expert Working Group; PPE = personal protective equipment.

Complete document is available in Spanish and English at http://depts.washington.edu/pnash/practical_solutions.

Most solutions were identified during farm site visits. Other sources are indicated in the table.

Only the primary evaluation method(s) are listed. All solutions were reviewed with more than one method.

Tree fruit is the top agricultural commodity in Washington State, with a $6.5 billion output impact for the region.2 Pesticides are applied to trees using airblast application technologies over a typical spray season of March through July. The state’s agriculture sector employed 127,000 seasonal and full-time employees in July 2011, many of whom worked in the labor-intensive tree fruit industry.3 As of January 2014, in Washington State there were 5,396 licensed private applicators, the appropriate license for pesticide handlers in the Washington State tree fruit industry.4 However, most handlers in the tree fruit industry are not licensed and handle pesticides under the supervision of a licensed private applicator.5

Pesticide handlers are those agricultural workers who come into direct contact with concentrated or diluted pesticide formulations during the course of mixing, loading, spraying, and equipment decontamination.6 Handlers are considered a high-risk group within all agricultural workers under the US Environmental Protection Agency’s Worker Protection Standard.7 In 2004, Washington State initiated a cholinesterase monitoring program that requires biomonitoring of pesticide handlers exposed to relatively high levels of certain organo-phosphorus and carbamate pesticides.8,9 There is limited published literature on evidence-based safety measures for these workers.10 At this time, protection for pesticide handlers relies heavily on personal protective equipment (PPE), which is at the bottom of the hierarchy of occupational hygiene control methods.11 Some engineering and administrative solutions have resulted from industry movement towards integrated pest management.12

The objectives of this research were to identify and test realistic interventions that reduce pesticide exposures of pesticide handlers and their families and translate these findings into “practical solutions” for agricultural workplaces. Our approach used two guiding principles: (1) workplace chemicals belong in the workplace, and (2) workers and farm managers are the pesticide handling experts, with the direct day-to-day knowledge of production practices. We focused on the tree fruit and other crops such as hops and grapes that use airblast pesticide application technologies.

Different participatory research approaches have been used within agriculture to address farmworker workplace health and safety issues. Many are based in the community rather than the workplace.13,14 Two studies reported success in using participatory research methods with farmers.15,16 Our project was focused on the agricultural workplace, engaging both farmers and farmworkers.

The project’s participatory methods were grounded in self-determination theory, recognizing that human behavior and positive health actions are motivated based on competence (seeking mastery), relatedness (connect and care for others), and autonomy (being the causal agent of one’s own life).17 In this project, pesticide handlers and farm managers were the owners and developers of innovative solutions for their own protection—solutions that were not required, but exceeded or assisted in fulfilling safety standards. The project linked their knowledge to industrial hygiene science while respecting their expertise and motivations. In addition to the guide, the project produced model strategies for participatory research in occupational safety and health and demonstrated the inventiveness and proactive safety motivation of farmers and workers.

Methods

The project spanned 5 years (2007–2012) and had three stages: identification of potential solutions, evaluation of solutions, and translation of findings into the guide, Practical Solutions for Pesticide Safety. Each stage was designed to meet specific goals and used multiple participatory methods (Table 2). Farm managers and pesticide handlers involved in the study were predominately Latino, and many were bilingual, using Spanish as their primary language for communication. Most of the activities described here were conducted in Spanish by bilingual and bicultural research staff. Procedures used in this study were approved by the University of Washington Human Subjects’ Institutional Review Board.

Table 2.

Stages and Activities for Practical Solutions for Pesticide Safety.

| Stage/Activity |

|---|

| Identification of practical solutions |

| Expert interviewsa |

| Expert Working Group inputa⋆ |

| Farm site visitsa⋆ |

| Review of previous research |

| Evaluation of practical solutions |

| Internal review |

| External reviewa |

| Audience participationa⋆ |

| Field testinga⋆ |

| Translation of study findings |

| Audience testinga |

| Regional Advisory Committee workshopsa⋆ |

| Internal graphics design⋆ |

| Research team facilitation and writing |

Participatory research activity.

Exceptional strategies for each stage.

Identification of practical solutions

The identification stage involved expert interviews, formation of an Expert Working Group, farm site visits, and use of findings from recent research projects. Expert interview participants were a convenience sample of 31 handlers, orchard managers, and agricultural health and safety professionals selected from the research team’s network of colleagues, connections, and referrals. The semistructured interviews took 30 to 60 minutes and were conducted by the research team members in the language of each participant’s choice. The interviews included questions about which pesticide safety measures worked well and which did not, barriers to pesticide safety, and pesticide safety solutions they used, knew about, or for which they had ideas.

Expert Working Group (EWG) members were selected from expert interview participants based on the participant’s interest and capacity to engage in a group setting. We aimed for a balance of managers and handlers, English and Spanish speakers, and representatives from small and large operations. The EWG also included the research team’s agricultural industrial hygienists. EWG members were asked for at least a 1-year commitment, with several staying throughout the full 5 years. The EWG met two to four times a year to share knowledge, discuss ideas, and provide social validity (a “reality check”) for the research team. This collaboration provided the practical experience and information needed to identify, select, and field test practical solutions that would be useful and safe. EWG meetings were conducted in Spanish. For meetings with monolingual English speakers, simultaneous translation ensured everyone could express themselves best in their “mother tongue.” The EWG process recognized two critical factors essential for identifying practical solutions and development of the guide: (1) farmers and handlers are problem solvers and construct solutions in their own orchards and shops, and (2) farmers listen to and respect other farmers’ experience.

Farm site visits were initiated in response to EWG members’ advice that many farm owners and managers devised their own solutions as needed, and that they might be willing to share their ideas. We contacted 33 farms and 26 (79%) agreed to participate. At each farm site, the research team conducted a walkthrough of pesticide handling practices and safety measures. Each potential pesticide safety solution was documented through observation notes, photographs, and separate interviews (N = 96) with one manager and one or two handlers. Interviews included a description of the solution, how the idea originated, and benefits from the perspective of the user. Other questions covered practicality, affordability, and adaptability for other farms. Each solution was summarized into a two-page “solution sheet” with photo documentation for use during the evaluation phase.

Research findings from recent projects in our group led us to propose two additional practical solutions to the Expert Working Group: use of lockers (Figure 1) to store PPE at the workplace was associated with lower levels of cholinesterase inhibition; and use of a high-efficiency particulate air (HEPA) filter vacuum to clean commute vehicles at work reduced pesticide levels in homes.19,20

Figure 1.

Locker system. This double locker system separates street clothes from personal protective equipment.

Evaluation of practical solutions

Potential solutions were evaluated through four processes: internal review by the research team; external review by farm managers and pesticide safety educators; direct feedback from pesticide handlers following a public presentation; and field testing in orchards. Internal and external reviews were based on a priori criteria presented in Table 3. The research team review eliminated solutions that were duplicates, did not fit the criteria, or were not amenable to modification. The external review then focused on 26 potential solutions, and involved a survey completed by 11 orchard managers and 18 pesticide safety educators. The survey consisted of 6-point Likert scale items and open-ended questions that addressed the criteria for a practical solution. Each survey participant was provided five randomly selected solutions for review, resulting in a total of 145 completed surveys.

Table 3.

Criteria Established by the Expert Working Group and the Research Team Prior to Evaluation of Potential Practical Solutions.

| Category/Criteria |

|---|

| Practical for handlers and managers |

| Compatible with current pesticide handling activities |

| Convenient for handlers to use |

| Convenient for management to implement and maintain |

| Can be made from familiar materials on-hand or readily available for purchase |

| Adaptable to other operations |

| Initial and recurring costs are affordable for small and/or large operations |

| Solution is transferable to small and/or large operations |

| Addresses health and safety issues |

| Does not increase risk of exposure to occupational safety or health hazards |

| Contributes to minimizing pesticide exposure |

| Novelty of solution |

| Uncommon or unique practice |

| Complies with regulations and standards |

| Worker Protection Standard |

| Washington State Departments of Labor and Industry,a Agriculture, and Transportation |

| US Environmental Protection Agency |

| Global GAP and other food safety management standards |

Washington has a state OSHA program that includes agricultural workers.

Direct feedback was solicited from an audience of pesticide handlers after a 1-hour talk on pesticide safety in Spanish at the 2009 Washington State Horticultural Association meeting. Participants were asked to evaluate eight solutions using the Audience Response System (ARS) (TurningPoint software; Turning Technologies, Youngstown, OH) by answering three questions. Have you used or seen this solution in the last season? If available would you use it? Will it make handling pesticides easier? The responses were simple, either dichotomous or multiple choice with three options.

Field testing in orchards was pursued for seven solutions with questions about practicality in cooperation with the pesticide safety experts from the Washington Department of Agriculture Farmworker Education Program (WSDA).16 This group simulated the use of the solutions and then discussed elimination of the solution or modifications needed to improve it. The EWG recommended orchard field trials for two solutions illustrated in Figure 2 (splash shield and the convex side view mirror). Handlers and managers were surveyed after using these solutions. The EWG also raised the question: “Do pressure washers or scrub brushes do a better job of cleaning or decontaminating application equipment?” On-site tests were conducted with a fluorescent tracer in lieu of pesticide. The research team conducted standardized cleaning procedures based on observation of typical cleaning methods used by handlers.

Figure 2.

New and novel solutions found to be useful and acceptable after orchard field trials. (Left) Splash shield. This splash shield provides added eye protection for handlers when handling liquid pesticides. It also has a clipboard to hold the recipe and a metal tray to catch drips. (Right) Convex side view mirror. This mirror allows the handler to check on the spray pattern without turning his head all the time. It reduced his neck strain as well.

Translation of study findings

Initial audience testing for the guide was conducted at the start of the project during the expert interviews. Six expert interview participants were shown three examples of existing documents communicating safety measures and asked about which they preferred and why.

A Regional Advisory Committee (RAC) was formed near the end of the project after the solutions were selected to review the format and content of the guide for the target audience of farm owners and managers. It was composed of professionals experienced in education and communication in the tree fruit industry and included representatives from government agencies, nongovernmental organizations, commercial suppliers, growers, and agricultural extension, as well as members of the EWG who represented the target audience. The RAC reviewed an early draft to provide substantial redirection to the formative development. Reviewers provided written comments for each solution on the guide’s messages, research evidence, risk communication, best practices, setup tips, images and graphics, and congruence with current regulations and standards. These comments were then discussed during a workshop where the RAC worked in small groups to provide recommendations for individual solutions. The RAC requested that additional industry and regulatory experts participate in a second RAC workshop; similar small work groups made recommendations on the most recent draft and made a final selection of solutions for inclusion in the guide. Discussion focused on overall guide content and timely issues; for example, the current requirements for proper disposable of rinse water from decontaminating equipment relevant to the Rinsate Containment System solution. Participants were asked to respond to two questions. Which solutions would you remove as not a good fit? Which solutions provide the best fit? The final guide contained 26 solutions and one page of PPE recommendations.

Production of the final guide benefited from multiple reviews and edits in each language. A Pacific Northwest Agricultural Safety and Health Center graphic designer with direct knowledge of the project was instrumental in the creation of an effective communication platform (guide, Web site, and promotional materials) for the practical solutions.

Results

Qualitative analysis of expert interviews fell into two major categories: themes related to pesticide safety measures and those relating to workplace safety climate. Participants wanted and were permitted to respond with views not directly related to the questions, but related to pesticide safety in general. Several major safety measure themes were identified: PPE presents many challenges for pesticide handlers (e.g., heat, decontamination, interference with work); respirators are unpleasant to use; and mixing and loading remain an important source of potential pesticide exposure. Five broad themes emerged under workplace safety climate; increase protection of families, coworkers, and neighbors; improve communication and reduce language barriers; develop new approaches to supervision for safety practices; increase awareness and responsibility among handlers; and recognize that positive change is happening.

The EWG initially included 16 participants. Of these, 13 attended at least one meeting, and 6 attended at least four meetings. At the end of the project there were nine active members. Some members discontinued participation for work or personal reasons. Others, although remaining active contributors, were unable to attend meetings due to work demands. New participants were recruited through additional contacts and completed the expert interview prior to being asked to join the group.

Criteria for identifying and evaluating solutions were drafted and validated by the EWG early in the project (Table 3). The EWG provided ideas and innovations for practical solutions, as well as questions about the efficacy of current practices. Open-end efforts to elicit ideas identified legitimate needs, such as “more training,” but were not solutions that could be evaluated or used in a guide. The EWG meetings were most productive in providing ideas and solutions when the research team adjusted the agenda and presented data relevant to the members’ experience or specific ideas for solutions. For example, after presenting results from a Washington State Department of Health report that identified splashes to the eye as a primary cause of injury,17 EWG members wanted to find a solution. While working in an orchard shop, the group came up with a cardboard prototype for the mixing splash shield. Next, during a hands-on meeting, the research team supplied a “sneeze shield” commonly used over restaurant salad bars as an example, and the EWG developed design criteria, including dimensions to accommodate a 5-gallon bucket, a clip for holding the mixing “recipe,” and the requirement that the shield be made of materials familiar and readily available to farmers. A local farmer, with the assistance of an EWG member, volunteered to build the splash shield (Figure 2, left). The farmer used his choice of methods and local materials, and the project paid for construction time and supplies.

Overall, the EWG formed a cohesive group that was open to sharing and discussing different and, at times, conflicting opinions, despite the turnover and last minute work demands that prevented attendance. One key factor was that from the beginning the group agreed that discussions stayed within the EWG and were not shared outside of the group. Another indicator of the group’s success was that it requested meeting times increase from 3 to 4 hours to provide more time for discussion and debate. Members felt comfortable challenging each other’s ideas and discussing differences. Continuing with the splash shield example, several members voiced that they did not think it would work. One member said he could not make up his mind until it was field tested. After the EWG reviewed the positive field test results, the group agreed that the splash shield was a good solution to be in the guide.

The external review process provided an opportunity for additional farm managers and pesticide safety educators to participate in the evaluation process and fostered early buy-in and support for dissemination. Comments on practicality and safety provided valuable insights into the solutions and were used for the guide, but no conclusive results as to which solutions to include or exclude were obtained. Subsequent to these reviews, our research team produced a more streamlined questionnaire that may be used for evaluating solutions in the future.

The ARS audience participation technology was well received, with 257 pesticide handlers participating. Participants had worked in agriculture for 0 to 10 years (36%), 11 to 20 years (36%), or more than 20 years (28%). Of the participants, 95% had pesticide applicator licenses. The majority of participants had not seen or used six of the eight solutions presented. For four of those six, at least 71% said they would use them if available, demonstrating that these four ideas (an expanded metal mixing table, a hand-held wind meter, scrub brush for cleaning PPE, and frame for holding PPE during cleaning) might be good candidates for new solutions.

Field testing facilitated our ability to assess the suitability of several solutions and to make specific modifications to improve others. The research team worked with our experts to resolve differences and improve solutions; for example, the ammunition box for storing personal emergency eye wash (Figure 3) now includes a cradle for protecting the bottle. Orchard field trials provided evidence for the EWG to conclude that two solutions, splash shield and the convex side view mirror, were valuable and they would use them (Figure 2). The pressure washer versus scrub question was also answered. The scrub brush did a superior job (Figure 4).

Figure 3.

Ammunition box for personal emergency eyewash. Easy to open and has a good seal. (Top) The original solution. (Bottom left) Icon labels added to distinguish eyewash box from tool box. (Bottom right) Add a cradle to prevent damage to the bottle from rolling around.

Figure 4.

Question: “Which does a better job of cleaning a sprayer tank?” Answer: A scrub brush. (Left) Scrub brush results. (Right) Pressure washer results.

Early audience testing directed the guide toward (1) Spanish and English versions, (2) realistic images and technical drawings, (3) solutions formatted for a one-page handout, and (4) integration of research evidence or supporting data. Two communication features rose to the top: the first was the “farmers to farmers” (quotes and pictures); the second was giving a name to each solution.

Outcomes from the RAC meetings had a great impact on the guide’s direction. Contributions were made on additional best practices related to the solutions and specific messaging. Content removed included what was considered “extraneous content,” such as information on heat-related illness, pesticide health effects, and regulatory information. These changes ensured that the guide remained relevant as science progresses and regulations change and vary by jurisdiction. Regulations were touched upon in the guide by adding a front-page warning for readers to “STOP” and refer to regulations and local agencies for questions. A critical contribution was a final content review led by WSDA RAC members, including resolution of several key technical issues.

An assessment of the RAC’s process showed that sessions were productive, advisors were engaged, and the small breakout group format worked well. In the future, we would engage the RAC earlier in the project to allow for additional revisions and focus on the more challenging solutions. This participatory working group method would likely be a more effective approach for reviewing solutions than the external review individual survey method used during the evaluation stage.

Discussion

The development of the Practical Solutions for Pesticide Safety guide provided opportunities to utilize different participatory methods for engaging our primary audiences—farm owners, farm managers, and pesticide handlers—as well as educators and other industry stakeholders.

Underlying the project’s success was the EWG, a participatory partnership between experts in agricultural production and the research team. Keys to the success of the EWG process included (1) providing sufficient time for discussion; (2) introducing information, data, and ideas that were directly relevant to the participants’ experience; (3) meeting in orchard shops or on their “home turf” so that they could directly demonstrate their work activities and ideas for the research; (4) providing opportunities for hands-on activities; (5) providing the opportunity for members to give feedback at the end of each meeting; and (6) responding to requests and questions outside the scope of the project. Despite turnover and absences, we were able to maintain group cohesion by having the research team member who facilitated the group interview and meet with potential new team members to help set the stage. He also contributed to the EWG success by staying in touch with members between meetings by telephone or in person.

We also found that research activities that involved more personal contact provided better outcomes for our goals of identifying and evaluating practical solutions. The farm site visits generated most of the practical solutions used in the guide as opposed to the one-on-one expert interviews. The RAC workshops with small working groups provide more useful input to the guide and solutions using less time than the external reviews. The Audience Response System provided a large audience an opportunity to engage actively and see immediate results during the presentation.

The “farmer to farmer” format of the guide came from several sources, including the audience testing, the EWG, the farm site visit participants, and the RAC (Figure 5). Farm managers and pesticide handlers wanted to share their solutions if they could “help others stay safe” and were pleased to have attribution with photos and quotes for their contributions to the guide. More recently an ARS was shown to be effective for data collection using simple multiple choice and dichotomous responses with an immigrant, Hispanic, limited-English-proficiency, and low-literacy population, very similar to our question design and part of our ARS study population.21 The other study participants also found the ARS easy and comfortable to use. These outcomes support the legitimacy of our ARS results.

Figure 5.

Sloping cement pad. “Farmer to farmer” format ideas, photos, and stories in managers’ and handlers’ own words. This practical solution also helped to minimize potential back strain.

Initial dissemination focused on the Pacific Northwest. In 2012, 483 English and 355 Spanish hardcopy guides were disseminated based on direct requests. The guide was highlighted in exhibits at seven industry trade conferences where we also provided educational sessions. Further dissemination is taking place via the Web, professional presentations, and through trade articles. An important outcome is that external organizations are initiating their own use and dissemination. In 2012–2013, a major workers’ compensation company in the Pacific Northwest used the guide as the basis for the annual training they provide for clients, reaching 1,000 growers, managers, and pesticide handlers in English or Spanish. “It’s pure gold!” declared a loss control manager at the company.

As an outgrowth of this dissemination process, we have received requests from pesticide educators for a hands-on training kit. Each includes some supplies for hands-on demonstrations, a resource list for obtaining additional supplies, and a large poster with two key safety messages in Spanish and English.

Conclusion

This project demonstrated that there are farm owners, farm managers, and pesticide handlers with the personal motivation to make positive safety changes on their own. By following the fundamental concept that farmers and farmworkers are innovators and the experts in the day-to day production activities on the farm, and by showing respect by learning from their knowledge and expertise, the production of the Practical Solutions for Pesticide Safety guide demonstrates the value of participatory industrial hygiene to create safer and more sustainable agricultural workplaces.

Acknowledgments

We appreciate the Expert Working Group’s dedication to and belief in this project from inception to completion. We thank the 26 participating farms and the 96 interview participants; Stacey Holland, graphic designer, for providing design elements and the overall look for the guide; Jennifer Crowe for the expert interview qualitative analysis; and many others who provided input and needed insight. We thank especially the staff of the Farm Worker Education Project at the Washington State Department of Agriculture for their time, expertise, and collaboration throughout the project.

Funding

This work was supported by CDC/NIOSH Cooperative Agreement 2U54 OH07544.

References

- 1.Pacific Northwest Agricultural Safety and Health Center. Practical Solutions for Pesticide Safety Pacific Northwest Agricultural Safety and Health Center, School of Public Health. University of Washington; Available at: http://depts.washington.edu/pnash/practical_solutions. Accessed November 1, 2013. [Google Scholar]

- 2.Jenson WS. Washington State Horticultural Association and the Washington State Tree Fruit Research Commission Executive Summary. Vancouver, WA: 2004. The Tree Fruit Industry in Washington State and the Northwest. Available at: http://www.yvgsa.com/pdf/facts/Economic%20Impact%20Study%20-%20Executive%20Summary.pdf. Accessed November 1, 2013. [Google Scholar]

- 3.Washington State Employment Security Department. Agricultural Workforce Report. 2012:11–24. 2011. Available at: https://fortress.wa.gov/esd/employmentdata/docs/industry-reports/ag-annual-2011.pdf. Accessed October 30, 2013.

- 4.Washington State Department of Agriculture. Pesticide and SPI License Lists. Available at: agr.wa.gov/PestFert/LicensingEd/lists. Accessed January 12, 2014.

- 5.Washington State Department of Agriculture. Pesticide/Pest Inspector Licensing. Available at: agr.wa.gov/PestFert/docs/form4375.pdf. Accessed 12 January 2014.

- 6.US Environmental Protection Agency. Agrichemicals. Worker Protection Standard—Pesticide Handler Definition. 2014 Available at: http://www.epa.gov/agriculture/factsheets/epa-305-f-98-029.pdf. Accessed 12 January 2014.

- 7.US Environmental Protection Agency. Pesticides: Health and Safety. Part 170—Worker Protection Standard. 2014 Available at: http://www.epa.gov/oppfead1/safety/workers/PART170.htm Accessed 12 January 2014.

- 8.Washington Administrative Code. Safety Standards for Agriculture. Washington Administrative Code. Chapter 296-307. Available at: http://www.lni.wa.gov/wisha/rules/agriculture/default.htm. Accessed October 30, 2013.

- 9.Washington Administrative Code. Part J-1. Cholinesterase Monitoring. Washington Administrative Code, Chapter 296-307, Safety Standards for Agriculture. Available at: http://www.lni.wa.gov/WISHA/Rules/agriculture/HTML/part-j-1.htm. Accessed November 1, 2013.

- 10.Keifer M. Effectiveness of interventions in reducing pesticide over exposure and poisonings. Am J Prev Med. 2000;18(4S):80–89. doi: 10.1016/s0749-3797(00)00144-6. [DOI] [PubMed] [Google Scholar]

- 11.Keifer M, Gasperini F, Robson M. Pesticides and other chemicals: minimizing worker exposure. J Agromedicine. 2010;15:264–275. doi: 10.1080/1059924X.2010.486686. [DOI] [PubMed] [Google Scholar]

- 12.Washington State University Extension. Tree Fruits IPM. Available at: ipm.wsu.edu/tree/ft.html. Accessed 12 January 2014.

- 13.Crowe JL, Keifer MC, Salazar MK. Striving to provide opportunities for farm worker community participation research. J Agric Saf Health. 2005;14:205–219. doi: 10.13031/2013.24351. [DOI] [PubMed] [Google Scholar]

- 14.Quandt SA, Grzywacz JG, Talton JW, et al. Evaluating the effectiveness of lay health promoter-led, community-based participatory pesticide safety intervention with farmworker families. Health Promot Pract. 2013;14:425–432. doi: 10.1177/1524839912459652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Schiller LF, Donham K, Anderson T, Dingledein DM, Strebel RR. Incorporating occupational health interventions in a community-based participatory prevention health program for farm families: a qualitative study. J Agromedicine. 2010;15:117–126. doi: 10.1080/10599241003622491. [DOI] [PubMed] [Google Scholar]

- 16.Guin SM, Wheat JR, Allinder RS, Fanucchi GJ, Wiggins OS, Johnson GJ. Participatory research and service-learning among farmers, health professional students, and experts: an agromedicine approach to farm safety and health. J Agromedicine. 2012;17:22–29. doi: 10.1080/1059924X.2012.627319. [DOI] [PubMed] [Google Scholar]

- 17.Deci E, Ryan R, editors. Handbook of Self-determination Research. Rochester, NY: University of Rochester Press; 2002. [Google Scholar]

- 18.Washington State Department of Health. (Publication number: DOH 333-172).Contributing Factors to Pesticide Related Illness among Agricultural Workers in Washington State, 2003-2008. 2010 Sep;:16. [Google Scholar]

- 19.Krenz JE, Hofmann JN, Smith TR, et al. Determinants of butyrylcholinesterase inhibition among agricultural pesticide handlers in Washington State: an update. Ann Occup Hyg. 2015;59:25–40. doi: 10.1093/annhyg/meu072. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Ballow C. MS thesis. Seattle, WA: University of Washington, Department of Environmental and Occupational Health Sciences; Jun, 2006. An Intervention Aiding in the Reduction of Organophosphorus Pesticides From Take-Home Pathways. [Google Scholar]

- 21.Keifer MC, Reyes I, Leibman AK, Juarez-Carrillo P. The use of Audience Response System Technology with Limit-English-Proficiency, Low-Literacy, and Vulnerable Populations. J Agromedicine. 2014;19(1):44–52. doi: 10.1080/1059924X.2013.827998. [DOI] [PubMed] [Google Scholar]