Abstract

During the past few decades, supercritical fluid (SCF) has emerged as an effective alternative for many traditional pharmaceutical manufacturing processes. Operating active pharmaceutical ingredients (APIs) alone or in combination with various biodegradable polymeric carriers in high-pressure conditions provides enhanced features with respect to their physical properties such as bioavailability enhancement, is of relevance to the application of SCF in the pharmaceutical industry. Herein, recent advances in drug delivery systems manufactured using the SCF technology are reviewed. We provide a brief description of the history, principle, and various preparation methods involved in the SCF technology. Next, we aim to give a brief overview, which provides an emphasis and discussion of recent reports using supercritical carbon dioxide (SC-CO2) for fabrication of polymeric carriers, for applications in areas related to drug delivery, tissue engineering, bio-imaging, and other biomedical applications. We finally summarize with perspectives.

Keywords: bioavailability enhancement, biomedical applications, drug delivery, polymeric carriers, supercritical fluids, tissue engineering

1. Introduction

The supercritical fluid (SCF) technology is perhaps one of the most renowned high-pressure techniques so far to obtain products with better performances. This technology has been commercially used for many years in the pharmaceutical, textile, and food industries.[1] The reasons behind the wide adoption of this technology are not only due to its environmentally benign nature in various processes but also because of its economically promising character.[2] While many conventional pharmaceutical products rely on the use of organic solvents,[3] the SCF technology, by contrast, takes advantage of benign solvents such as CO2 and water to replace the organic solvents, therefore serving as an alternative in synthesizing delivery systems.

Drug delivery relies on various formulations and strategies for transporting pharmaceutically active compounds to achieve desired therapeutic effects.[4] However, it has been associated with challenges related to solubility and diffusion.[5] Regarding this, the biopharmaceutical classification system (BCS) has clearly categorized all drugs, and specific formulations based on their physical and chemical properties as well as their pharmacokinetics and pharmacodynamics.[5a,6] New chemical entities also suffer from poor solubility and stability and require frequent administration.[7] To overcome these issues, excipients such as biodegradable polymers are utilized in many pharmaceutical formulations to encapsulate the core materials such as active pharmaceutical ingredients (APIs) or drugs, which coalesce to form matrices/frameworks.[7b,8] Particles synthesized via micronization can be administered through various routes such as intravenous, intramuscular, pulmonary, and others, in addition to oral delivery.[8a] Furthermore, the use of particles helps to protect the sensitive agents from the harsh environments in the body.[7b,9]

According to a formulator anticipation, the ideal drug delivery system should carry a high payload to the desired site and release in a controlled manner, which reduce the frequency of dosage.[6,9c] In few instances, chemical modification of drug or attachment to macromolecules such as polymers or polysaccharides to increase the drug encapsulation efficiency may be chosen to accomplish the design.[4a,7b,10] More often, sustained delivery of drugs from encapsulating polymeric particles such as those micro- or nanoscale in size also improves the efficacy and reduces the undesired side effects.[11] These advancements have integrated materials science with drug delivery to deal with controlling parameters (such as morphology) and manufacturing process of particle formation.[5b] However, conventional particle fabrication technologies have a few limitations, such as thermal and chemical degradation of drugs, the use of large amounts of organic solvents, broad particle size distribution, and solvent residues in the end products.[8b,12] To overcome these limitations, an efficient production platform applying particle engineering at industrial scale is necessary.[7b,13] To this end, the compressed/pressurized fluid bottom-up technique utilizing supercritical solvents has largely addressed the challenges. This technology precipitates micro-[14] as well as nano-sized particles[15] with large surface areas, controlled uniform particle sizes, and smooth surfaces,[5b,14,16] which eventually augment drug bioavailability.

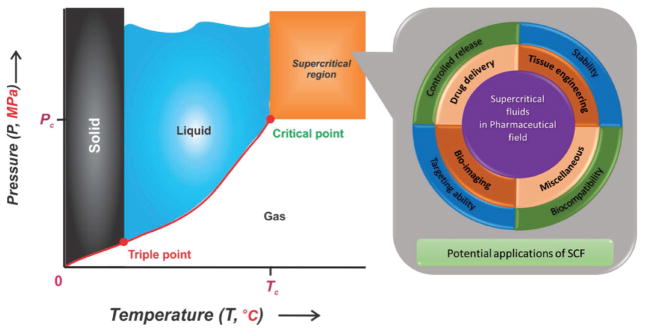

Recently, the application of the SCF technology has attracted interest of many researchers as it is non-toxic, non-flammable, non-reactive, economical, and non-polluting.[17] This green technology has a potentially high impact in the pharmaceutical field to overcome the curbs of various conventional methods such as spray-drying and others.[12,18] Indeed, SCF exists as a single phase beyond critical conditions (i.e., temperature and pressure). Furthermore, the physical properties (density, diffusivity, and viscosity) of the SCF are intermediate between liquid and gas and can be easily manipulated by adjusting the temperature and pressure during operations.[3,6,16c,17] In general, CO2 is the most used supercritical solvent and is recognized as safe by the United States Food and Drug Administration (US-FDA) in the pharmaceutical processing,[19] i.e., drug delivery applications, because of its low toxicity, low cohesive energy, as well as low density. Supercritical CO2 (SC-CO2) is a cost-effective solvent operated at mild conditions (critical temperature (Tc = 31.1 °C) and low critical pressure (Pc = 7.38 MPa)) at gaseous standard state under ambient circumstances (Figure 1). It has been extensively used as a solvent, anti-solvent, and plasticizer for synthesis, modification, and purification of both natural and synthetic polymers.[17] Moreover, other SCFs include water[20] and solvents such as acetone, CO2/ethanol (EtOH) mixture, chlorodifluoromethane, diethyl ether, nitrous oxide, propane, and trifluoromethane operated at their respective supercritical conditions.[20e,21] Recent literature have already reported the properties including solubility and critical parameters of several commonly used supercritical solvents.[22]

Figure 1.

Schematic representation of CO2 phase diagram elucidating CO2 existence as various phases along with the supercritical phase beyond the critical point (Tc = 31.1 °C, Pc = 7.38 MPa) (Left). Graphic illustration elucidating the potential applications of SCF (Right).

SCF is dense, but can be highly compressible, where the solvation power and pressure changes merely result in density alteration at the critical point.[3] The high diffusivity of SCF results in the ease of penetration of CO2 into the polymers, and the fluctuation in diffusivity determines the supercritical status of the fluid with the non-homogenous distribution of molecules in the space.[13b,17] In the SCF-assisted process, the mechanism lying behind the particle formation or crystallization is the attainment of a high degree of supersaturation state of the material in non-equilibrium conditions of temperature and pressure, which leads to nucleation, crystal growth, and eventually agglomeration.[13b] The control over the critical conditions during operation is highly advantageous over conventional process. Since it is operated at extreme conditions using pressurized gasses and solvents, this process usually requires safety rules and stringent regulations such as Current-Good Manufacturing Practices (cGMP) to control the mechanical and chemical hazards.[3]

Despite many reviews[1,2,3,5b,8b,9a,12,13,17,18b,20d,e,23] published on the potential of the SCF technology, very few focused on the use of it for fabrication of particulate delivery systems.[1,3,5b,23b,e] Few reports focused only on carriers intended for one of the drug delivery routes or the SCF process of particle formation, and critical analysis on a theoretical basis.[23d,h,p] Herewith, we present a perspective on an extensive survey of the past two decades on the use of the SCF technology in drug delivery and related biomedical applications.

2. Supercritical Processes for Particle Formation

Conventional methods (i.e., mechanical or chemical) for synthesizing polymeric particles have several limitations, such as heterogeneous particle size distribution, particle damage by shear forces, and others.[24] Indeed, utilizing the SCF technology in pharmaceutical manufacturing and processing, the internal obstacles caused by conventional approaches can be minimized. Further, this technology has probably become the most sustainable process for addressing environmental concerns.[21a,23c,d] The first report of the SCF technology was from Hannay et al. in 1879,[25] following which variants in the technology have been developed to fabricate drug delivery vehicles. Different processes (Figure 2) of particle formation are categorized based on the behavior of SCF as solute (particle formation from gas-saturated solutions (PGSS)); solvent (rapid expansion of supercritical solutions (RESS));[26] anti-solvent (supercritical anti-solvent (SAS),[27] gaseous anti-solvent (GAS),[28] aerosol solvent extraction system (ASES),[21a] precipitation with compressed anti-solvent (PCA),[29] supercritical anti-solvent with enhanced mass transfer (SAS-EM),[30] solution enhanced dispersion by supercritical fluids (SEDS),[31] suspension-enhanced dispersion by supercritical fluids (SpEDS)[32]); and others such as depressurization of an expanded liquid organic solution (DELOS)[1a,33] and the supercritical-assisted atomization (SAA) process, etc.[34] SCF acts as a re-precipitation aid for rapid and uniform nucleation of solute in all the above-mentioned methods of fine particle formation. The performance efficiency of this technology is based on proper solvent selection and by adjusting critical parameters (temperature and pressure) during operations.[12] Herewith, we discuss these various supercritical processes involving particle formation in brief.

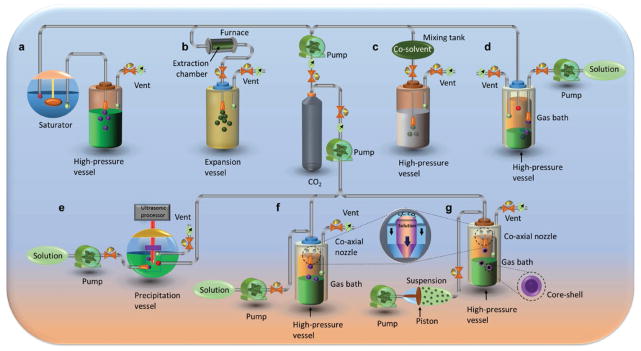

Figure 2.

Conceptual representation of various processes of particle formation using SC-CO2. a) Particle formation from gas saturated solutions (PGSS). b) Rapid expansion of supercritical solutions (RESS). c) Rapid expansion of a supercritical solution into a liquid solvent (RESOLV). d) Precipitation with compressed anti-solvent (PCA)/Aerosol solvent extraction system (ASES). e) Supercritical antisolvent with enhanced mass transfer (SAS-EM). f) Solution enhanced dispersion by supercritical fluids (SEDS). g) Suspension enhanced dispersion by supercritical fluids (SpEDS).

2.1. PGSS Process

SCF acts as a solute in the PGSS method (Figure 2a).[35] The SC-CO2 is compressed and dissolved in a molten polymer after autoclave treatment, where the solution expands and becomes cooled by the Joule-Thomson effect.[21a] Microparticles are formed when operated at a relatively low pressure.[21a] This approach is advantageous over other SCF techniques since it uses low volumes of SCF.[21a,35] However, the application of this process is limited due to particle agglomeration and nozzle blockage.[23f]

2.2. RESS Process

In a RESS process, SCF acts as a solute carrier, and this solution is expanded adiabatically leading to a rapid drop in temperature and pressure and further generation of small-sized particles after spraying through a nozzle (Figure 2b).[21a,26,36] In designing this process, the solubility of the material plays a crucial role in particle formation and processing since most of the pharmaceutical substances such as polymers, drugs, and high-molecular weight proteins are polar in nature. In few instances, small amounts of organic solvents are added to improve the affinity of polar drug molecules.[23b] RESS is the simplest and an efficient method in the SCF technology, but it is limited in its application because of its relatively high cost and poor solubility of polymers in non-polar SC-CO2. High amounts of SC-CO2 are preferred at industrial scale to address this issue.[24] Further, the advancements in the RESS process have been made to overcome certain limitations. One of them is the RESS process in an aqueous solution containing a surfactant or other reducing agents known as the rapid expansion of a supercritical solution into a liquid solvent (RESOLV) process (Figure 2c),[21b] where the SCF is expanded into a liquid medium. This modified process inhibits the particle agglomeration in the expansion jet.[37] The other modified process is the rapid expansion of a supercritical solution with solid co-solvent (RESS-SC), which results in smaller-sized particles. During synthesis, the added co-solvent improves the solubility of the APIs to a greater extent by avoiding superficial contact between particles, which increases the surface area of exposure to SCF and eventually, lyophilization can remove the co-solvent.[38] Despite its advancements, RESS still has certain limitations that are surpassed by the altered SCF behavior as anti-solvent in the reaction vessel.

2.3. SAS Process

The SAS process is proposed to process the molecules with poor solubility in SCF. This process predominantly utilizes an organic solvent such as acetone, dichloromethane (DCM), and dimethyl sulfoxide (DMSO), to dissolve the materials, where SCF behaves as a non-solvent to solute/API.[6] During the process, the mixture expands to supersaturation and results in fast nucleation, demonstrating the high mass transfer ratio due to the low viscosity and high diffusivity of SCF.[6] The outcome of this process utterly depends on the order of addition of solvent, SCF, and other substrates. Additionally, factors such as temperature, pressure, chemical composition of solute (drug, polymer), as well as organic solvent are required to be optimized. SAS has gained better drug loading than the RESS process, enabling the formation of fine particles.[23b] Other SAS processes comprise of GAS, which is based on the recrystallization of SCF insoluble solute and has a flexibility of choosing organic solvent to improve the solubility. This process has less operational problems compared to the conventional SAS method and is easy to scale-up in the manufacturing.[28] Recent advancements in SAS micronization techniques include, i.e., expanded liquid anti-solvent (ELS)[39] and the supercritical-assisted injection in a liquid anti-solvent (SAILA) methods;[40] however, deep analyses on these processes yet remain to be reported. ELS is operated using SCF and an organic solvent at expanding liquidity conditions.[39] The other modified SAS techniques include ASES,[21a] SCF-assisted extraction of emulsions (SFEE),[41] SAS-EM,[30] SEDS,[14,42] and SpEDS.[32]

2.4. ASES Process

Particle generation in ASES happens to be favorable at high anti-solvent-to-solvent ratio after spraying the drug/polymer solution into SCF via an atomization device. Further, the mass transfer of SCF depends on atomization efficiency, while solvent mass transfer relies on dispersing and mixing of SCF and organic solvent. This process is not suitable to load high amounts of drugs due to their usually high affinity towards organic solvent, which eventually reduces the loading amount in polymer after organic solvent extraction.[23b] Furthermore, a slight modification of ASES, known as the PCA manufacturing process (Figure 2d) effectively produces particles with a narrow size distribution.[23p] This process has been reported as a single-step technique operated to precipitate proteins.[23p]

2.5. SFEE Process

SFEE has emerged as a modified SAS process to encapsulate poorly water-soluble drugs. SCF interacts with the emulsion droplets and extracts the organic solvents/oily phase and leads to rapid precipitation of microparticles.[43] The advancement is to minimize the separation of the solid phase and agglomeration of particles during the SAS process.

2.6. SAS-EM Process

SAS-EM is an advanced SAS process to overcome the existing limitations of the SAS process.[30] The modification of the technique is that it utilizes a vibrating ultrasonic processor to atomize the solution jet into micro-droplets (Figure 2e). This processing method yields high turbulence, which enhances the mixing operation and subsequently the mass transfer and generates smaller-sized particles.[44]

2.7. SEDS Process

SEDS is another important process of SAS technique operated at a lesser drying time and increased mass transfer rates, which minimize the ASES process limitations. In a typical SEDS process (Figure 2f), the dispersed components are sprayed through a specially designed co-axial nozzle to control the particle morphology.[23b] Mass transfer of SCF into the sprayed droplet determines the particle formation by the rate of solvent transfer into SCF phase. A high mass transfer allows a faster nucleation and results in smaller particle sizes with less agglomeration.[23p] In fact, the polymer processing using organic solvents is highly accessible with this process because of solubility problems. Moreover, the continuous SEDS operation has extended the shelf life of polymeric materials. Water-soluble compounds can also be dealt with by introducing organic solvent through a co-axial three-compartment nozzle.[45]

2.8. SpEDS Process

SpEDS is an advancement of the SEDS process to overcome its processing damage issues.[32a] The apparatus and operation of both processes are almost similar, but SpEDS has an auxiliary injector setup to effectively pump the loaded suspension (Figure 2g).[32a] This process is designed to obtain core-shell structured microparticles with higher drug encapsulation efficiency and longer sustained drug release property compared to other SCF-assisted co-precipitation processes.[46]

2.9. Others

DELOS is another process of operation utilizing traces of organic solvent for the precipitation of particles.[23h] In this process, SCF acts as a co-solvent and is suitable for thermo-sensitive substances over various SAS methods. Other advantages of this process include minimum CO2 consumption and easier scalability of micronization of drugs.[33b]

Other important processes include the SAA process[34] and the CO2-assisted nebulization with a bubble dryer (CAN-BD) process[47] for aerosolization of particles, where SCF assists the nebulization for processing. Despite the similarity, CAN-BD requires no sophisticated setup for processing and is more suitable for thermolabile substances. An SAA approach resembles the DELOS process except that SAA uses water during operation. Moreover, by introducing a hydrodynamic cavitation mixer, the hybridized supercritical-assisted atomization-hydrodynamic cavitation mixer (SAA-HCM) was developed to improve the mixing operation during synthesis.[48] Several other methods such as microemulsion method, drying medium in the sol-gel process, and metal particles in SCF as the reaction medium, among others, are under practice as well.[49]

Drugs are also successfully encapsulated using the supercritical solvent impregnation (SSI) process involving a series of steps.[50] Initially, the drug is dissolved/saturated in SCF and then mixed with the polymer, and further optimization of operation parameters at the time of impregnation results in higher drug loading efficiency. Co-solvency is also used to support better drug impregnation; however, a better understanding is necessary.[9a]

SCF-assisted spray-drying (SASD) process is another method developed as a valid alternative technique to the conventional spray-drying (SD) process and SAS process for the preparation of nanoparticles. Herewith, SCF plays multiple roles such as co-solvent and partially miscible solvent, and and in addition, as a pneumatic agent to generate fine particles through atomization.[51] In another case, the SCF process is hybridized with a conventional method of particle formation results in SCF processing (SCP), which acts as an alternative to solvent evaporation method for manufacturing very tiny particles.[52] SCF-expansion depressurization (SFED) process is another innovative technique, which has shown great potential in micronization of water-soluble drugs, where SCF acts neither as solvent nor anti-solvent; however, when SCF is in contact with ternary phase mixture, it starts dissolving in the solution.[53]

The supercritical hydrothermal process is another process of the SCF technology, which is treated as an extension of the conventional hydrothermal technology operating just near or above the supercritical temperature of water.[20e,54] One of the advantages of this process during particle formation is the higher reaction rates, which lead to fast nucleation and result in small-sized particles.[54] Adschiri et al. pioneered this technique for the preparation of metal oxide nanomaterials for bio-imaging applications.[20e]

All these methods and their properties have been utilized for the production of the pure drug and composite (polymer-drug) particles for different deliveries, with the added advantages of impurity separation, selective precipitation, and control of crystalline forms. Basic safety hazards and precautionary measures should be strictly followed while operating SCF equipment.

3. Drug Delivery

Solid dosage forms are of primary choice for drug formulations and are mostly administered through the oral route.[3,7b] However, they face manufacturing hurdles such as physical instability during particle formation.[4a] Moreover, traditional methods undergo a multi-step process to manufacture dosage forms. Increased demand of pharmaceutical industries in developing new approaches for drug delivery, has evidenced the SCF technology as an alternative[55] for the syntheses of micro-[35,56] as well as nano-size particles[20d,e,57] with homogenous size distribution and high-performance.[21a] Indeed, this technology has been used to manufacture various formulations of different drug categories such as those treating anesthesia,[58] antibiotics,[53,59] asthma,[60] cancer,[61] central nervous system,[62] cardiovascular system,[31a] diabetes,[28] diuretics,[63] inflammation (steroidal[64] and non-steroidal anti-inflammatory agents[65]), lipid-lowering,[66] among others, administered through oral,[67] intravenous,[41] ophthalmic,[68] pulmonary,[47] transdermal,[61c] and polymeric implants for sustained delivery.[69] Revercheon et al. have highlighted the production of various nanoconstructs such as nanoparticles,[70] nanofibers,[71] nanowires,[72] nanotubes,[73] and other nanostructured materials using supercritical-based techniques.[20d] In addition, Adschiri et al. explored the adaptive properties of SCF for the synthesis of advanced nanomaterials include carbon nanotubes (CNTs), fullerenes, magnetic particles, quantum dots, phosphors, nanocomposites (e.g., peptide/hydroxyapatite (HAp)), and gold nanoshells for drug delivery and other biomedical applications such as imaging, sensing, and cancer theranostics.[20e]

The SCF processing of drugs improves bioavailability with also a significant increase in the surface area of the particles after micronization. However, the solubility of the drug in SCF and size of the particles depend on the density of the fluid and the pre-expansion concentration of the solute, respectively.[71] Eventually, to improve the drug dissolution characteristics, the amorphous form of poorly water-soluble drugs and their uniformly sized particles are feasible, because of their higher surface area exposure to solvent. The high surface area increases dissolution rate and subsequently, results in higher efficacy and lower dosage requirement for administration.[74]

3.1. Polymeric Carriers for Controlled Drug Release

To improve the fate and performance of a drug,[75] a protein,[76] or a vaccine,[77] a suitable carrier is required to change its delivery pattern.[72,78] Recently, controlled delivery using various polymers has garnered increasing interest, which prolongs the drug effect by maintaining the levels in the therapeutic window. In addition, targeted delivery such as magnetically directed[30,79] or using targeting ligands[61b,80] is anticipated to make APIs available at the desired sites with minimum adverse effects.[7b,61b,c] Several efforts are being made to address various challenging issues in preparing delivery systems by tailoring the morphology of polymeric carriers. Impurities-free biodegradable polymers are the best choice due to their versatility for encapsulation and efficiency in delivering various pharmaceutical agents in the body to a specific site in a controlled fashion. Spray-drying, emulsions, ionic gelation, phase separation, polyelectrolyte complexation, and SCF-assisted precipitation are the most preferred processes for polymeric micro-/nano-encapsulation.[23l] The adaptive properties of SCF are quite promising, and this green technology has emerged for particle design with low residual solvent in the product. Polymer selection is crucial based on its solubility in SCF and other solvents to overcome its separation during the manufacturing process. Further, the physical properties of polymer and operation conditions should be optimized to generate particles with different desired morphologies.[1]

As depicted in Table 1, many APIs have been encapsulated in biodegradable polymers to synthesize different sizes of particles for controlled delivery.[26,65a,b,81] Generally, the drug encapsulation in the polymeric shell involves sequential steps as follows. In the case of non-polar or low-molecular weight drugs, the API is initially soluble in SCF. Subsequently, the polymer is added for impregnation. Eventually, the SCF is separated to remove the free drug, followed by the extraction of organic solvent, if used. In few cases, multiple drugs were also impregnated through this technology.[62b] In fact, large molecules such as proteins are difficult to be absorbed when administered through non-invasive routes and are usually compromised by using absorption enhancers. The SCF technology has created a new path in fabricating sustain delivery carriers for the transport of large molecules with structural stability.[18a,24,82] Eventually, this strategy has surpassed the drawbacks of conventional processes such as solubility and recrystallization issues.

Table 1.

Polymeric drug delivery systems synthesized using various methods of preparation with the SCF technology.

| Pharmaceutical compound | SCF Process | Polymer | Solvent | Purpose | Reference |

|---|---|---|---|---|---|

| 2,6-Dimethyl-8-(2-ethyl-6-methylbenzylamino)-3-hydroxymethylimidazo-[1,2-a] pyridine mesylate | SEDS | Eudragit® E100, Mannitol | Acetone, DMSO, MeOH | Bioavailability enhancement | [42a] |

| 5-Aminosalicylic Acid | SEDS | Eudragit® S100 | Acetone, DMSO | Bioavailability enhancement | [190] |

| 5-Fluorouracil | SEDS | PLA | DCM | Controlled release | [61a] |

| PLA, Silica | DCM | [191] | |||

| PEG, PLA–PEG | Acetone, DCM, Water | [192] | |||

| SAS + SSI | PLA | EtOH | [18a] | ||

| SCP | PLGA | - | [85b] | ||

| PLA | EtOH | [193] | |||

| 17α-Methyltestosterone | SAS | PCL, PLA | DCM | Controlled release | [27] |

| α-Tocopheryl acetate | SSI | MCM-41-type silica | EtOH, Toluene | Controlled release | [194] |

| β-Carotene | SFEE | PCL | DCM | Controlled release | [195] |

| SEDS | PHBV | - | [196] | ||

| β-Estradiol | SCP | PLGA | - | Controlled release | [85b] |

| PVP | EtOH | [197] | |||

| β-Sitosterol | RESS | - | Trifluoromethane | Bioavailability enhancement | [81d] |

| Acetaminophen | RESS-N | EC, PEG, PEG-PPG-PEG, PLA, PMMA | EtOH | Controlled release | [81b] |

| SAS | Eudragit® RL100 | Acetone | [75] | ||

| Adefovir dipivoxil | RESS | - | - | Bioavailability enhancement | [13c] |

| Ampicillin | SAA | - | Acetone, MeOH | Bioavailability enhancement | [34a] |

| SAS | - | DMSO, EtOH, NMP | [198] | ||

| SAS | EC | DCM, DMSO | Controlled release | [199] | |

| SAA | HPMC | Phosphate buffers | [200] | ||

| Amoxicillin | SAS | - | NMP | Injectable | [83a] |

| - | DMSO, EtOH | [201] | |||

| SCF-PI | PMMA | Acetone, DMSO | Controlled release | [202] | |

| PVDF–HFP | Acetone | [203] | |||

| SEDS | Chitosan | - | Bioavailability enhancement | [204] | |

| Arbutine | SAS | - | EtOH | Topical administration | [205] |

| Artemisinin | RESS | PVP-K25 | DCM | Oral delivery | [81a] |

| - | - | Bioavailability enhancement | [206] | ||

| SCP | Silica, Sodium alginate, and Starch aerogels | EtOH, Isopropanol | [207] | ||

| Aspirin | RESS-N | PEG | EtOH | Controlled release | [81b] |

| SCF-MIP | P(DEGDMA) | [101] | |||

| Avidin | SCP | PLA | – | Controlled release | [149] |

| Azacytidine | SAS | PLA | DCM, DMSO | Controlled release | [208] |

| Baicalein | SEDS | – | Acetone, DMSO, EtOH | Bioavailability enhancement | [209] |

| Bevacizumab | SCF-PQT | PLA, PLGA | DCM | Controlled release | [50] |

| BSA | SEE-C | PCL, PLA, PVA | Acetone, Glycerol, Water | Controlled size | [210] |

| SSI | Chitosan, PNIPAAm | Acetic acid | Stimuli-responsive release | [76] | |

| PGSS | Chitosan, PEG, PLGA | – | Controlled release gastroretentive system | [67] | |

| SAA | PLA | Chloroform | Stability improvement | [211] | |

| Bupivacaine HCl | SAS | PLA, PLGA | DCM, EtOH | Controlled release | [91] |

| Calcitonin (Salmon) | SASD | Chitosan glutamate | EtOH, Water | Bioavailability enhancement | [51] |

| Camptothecin | SAS | Dextran | DMSO | Targeted delivery | [80] |

| Carbamazepine | SSI | PVP | – | Controlled release | [98a] |

| GAS | PEG | Acetone | Bioavailability enhancement | [212] | |

| SCP | Gelucire, PVP-K30, TPGS | MeOH | [52] | ||

| Celicoxib | SEDS | PLGA | n-Butyl acetate | Injectable | [31a] |

| Cefuroxime axetil | SEDS | HPMC, PVP-K30 | DCM, EtOH | Bioavailability enhancement | [213] |

| Chelerythrine | SEDS-PA | – | MeOH | Bioavailability enhancement | [214] |

| Chlorohexidine diacetate | SSI | PEMA, THFMA | – | Polymeric foam | [215] |

| Cilostazol | SAS | – | DCM | Bioavailability enhancement | [216] |

| Cholesterol | SSI | PCL, PMMA | – | Controlled release | [217] |

| Cu2(indomethacin)4DMF2 | ASES, GAS | – | DMF | Bioavailability enhancement | [21c] |

| Curcumin | SEDS | – | Acetone | Bioavailability enhancement | [218] |

| SF | HFIP | [219] | |||

| Dexamethasone | SAA | – | Acetone, MeOH | Bioavailability enhancement | [34a] |

| Diclofenac sodium | SFEE | PLGA, PVA | EA, Water | Injectable | [41] |

| Dihydroquercetin | SCP | Starch aerogels | EtOH | Oral delivery | [207] |

| Dithranol | SCP | Silica aerogels | ACN, MeOH | Oral delivery | [220] |

| Docetaxol | SCP | PVP-K17 | Myristyl alcohol | Bioavailability enhancement | [221] |

| Erlotinib HCl | SAS | – | MeOH | Bioavailability enhancement | [74] |

| HPMC-phthalate | DMSO | [222] | |||

| Felodipine | PGSS | PEG-4000 | – | Bioavailability enhancement | [35] |

| SAS | HPMC | DCM, EtOH | [223] | ||

| Fenofibrate | PGSS | PEG-4000 | – | Bioavailability enhancement | [35] |

| RESOLV | Alginate, HPMC, PLGA | – | [37] | ||

| SCP | Silica matrix | – | [224] | ||

| Fumed silica | – | [225] | |||

| Silica SBA-15 | – | [226] | |||

| Fenprofen | RESS | – | – | Bioavailability enhancement | [227] |

| Fluconazole | SAS | – | Acetone, DCM, EtOH | Bioavailability enhancement | [228] |

| Flufenamic acid | SCF-MIP | Methacrylic acid, NIPAAm cross-linked EGDMA | – | Controlled release | [102] |

| Fulvestrant | SAS | – | EA | Bioavailability enhancement | [74] |

| Furosemide | SAS | PVP | Acetone, EtOH, MeOH | Bioavailability enhancement | [63] |

| Gentamycin | PCA | PLA | DCM | Controlled release | [29] |

| PVM-MA | Acetone | [85a] | |||

| PLGA | Acetone | Intracellular targeting | [229] | ||

| Griseofulvin | RESS | – | Trifluoromethane | Bioavailability enhancement | [81d] |

| RESS-SC | – | DCM, Menthol | [38] | ||

| SFEE | PVA, PVP | DCM, EA | [230] | ||

| SCP | Silica aerogels | ACN, MeOH | Oral delivery | [220] | |

| Human growth hormone | SEDS | – | Isopropanol | Bioavailability enhancement | [231] |

| Hydrocortisone | SEDS | PCL, PLA, PLGA | Acetone, DCM, EA, Hexane, Isopropanol | Controlled release | [95] |

| SFEE | PLGA | DMSO, EA, EtOH | [232] | ||

| Ibuprofen | SSI | PVP | EtOH | Controlled release | [65a] |

| PMMA, PVP | EtOH, Toluene | [233] | |||

| Chitosan, PNIPAAm | Acetic acid | Stimuli-responsive release | [76] | ||

| Gelatin, Silica | Acetone | Controlled release | [234] | ||

| SCFS | PCL, Starch | Menthol | [235] | ||

| RESOLV | PEG, PVA, PVP | – | [70a] | ||

| SCP | PLA | Chloroform | [145a] | ||

| PGSS | Gelucire, Glyceryl Monostearate, Pluronic F127 | Water | [236] | ||

| SCF-PI | CA | Acetone | [134b] | ||

| SCP | PCL | – | [237] | ||

| PEG, PVP | EtOH | [98b] | |||

| MCM-41-type silica | – | [238] | |||

| Silica, Sodium alginate, and Starch aerogels | EtOH | Oral delivery | [207] | ||

| Immunoglobulin G (IgG) | SAS | – | EtOH | Biopharmaceutical powders | [239] |

| Indinavir | SAS | – | Acetone | Bioavailability enhancement | [240] |

| Indomethacin | SAS, SAS-EM | Eudragit® RS 100, Magnetite, PLGA, PMMA | DCM | Magnetically responsive drug release | [30] |

| SFEE | Eudragit RS®, PLGA | EA | Controlled release | [96b] | |

| SEDS | PLA, PLGA | DCM | [14] | ||

| Iron oxide, PLA | DCM | Magnetically responsive drug release | [241] | ||

| SSI | Chitosan | – | Controlled release | [81c] | |

| HPMC | – | [242] | |||

| PLA, PLA-PEG, PLGA | Acetone, Water | [243] | |||

| Insulin | SAS | PLA | DCM, DMSO | Subcutaneous delivery | [130] |

| GAS | PEG, PLA | DMSO | Controlled release | [131] | |

| PEG, PLA | DCM, DMSO | [244] | |||

| SFEE | PLGA | – | [245] | ||

| SCP | Chitosan, PAA, PEO | – | Bioavailability enhancement | [246] | |

| Itraconazole | SCP | HPMC, PVP | Cetyl alcohol | Bioavailability enhancement | [247] |

| Ketoprofen | SSI | PVP-K10 | – | Bioavailability enhancement | [248] |

| Gelatin, Silica | Acetone | Controlled release | [234] | ||

| PGSS | Gelucire, PEG | – | [65c] | ||

| SCF-IP, SSI | PVP | – | Oral delivery | [115a] | |

| SFEE | PLGA | EA | Bioavailability enhancement | [249] | |

| Eudragit RS®, PLGA | Controlled release | [96b] | |||

| SCFD | Alginate | EtOH | Oral delivery | [250] | |

| SCP | PLGA | – | Controlled release | [251] | |

| Silica aerogels | ACN, MeOH | Oral delivery | [220] | ||

| Levothyroxine sodium | GAS, ARISE | – | EtOH | Bioavailability enhancement | [252] |

| Lipase | RESS-N | PEG, PEG-PPG-PEG, PLA, PLGA, PMMA | Acetone, EtOH, MeOH, Propanol, Toluene | Bioavailability enhancement | [87] |

| Loratidine | SCP | Silica, and Starch aerogels | EtOH, Isopropanol | Oral delivery | [207] |

| Lovastatin | RESS | PLA | - | Bioavailability enhancement | [55] |

| Lutein | SEDS | Zein | Acetone, DMSO | Controlled release | [253] |

| Lysozyme | SFEE | PLGA | DMSO, EA | Bioavailability enhancement | [254] |

| RESS-N | PEG, PEG-PPG-PEG, PLA, PLGA, PMMA | EtOH, Toluene | [87] | ||

| ASES | PLA | DMSO | [255] | ||

| PCA | PLA, PLGA | DCM | [92] | ||

| SEDS | PEG, PLA | DMSO | [256] | ||

| Mangiferin | SAS | – | Acetone, DMSO, EtOH, NMP | Bioavailability enhancement | [257] |

| Megestrol acetate | SAS | HPMC, PVP, PEG | DCM, EtOH | Bioavailability enhancement | [258] |

| Methotrexate | SpEDS | Iron oxide, SF | DCM, HFIP | Transdermal delivery | [61c] |

| PEG, PLA | Acetone, DMSO | Controlled release | [32a] | ||

| Iron oxide, PEG, PLA | DCM | Targeted Controlled release | [46] | ||

| SEDS | – | DMSO | Bioavailability enhancement | [259] | |

| Miconazole | SCP | Silica aerogels | ACN, MeOH | Bioavailability enhancement | [220] |

| Minocycline | SAS | – | EtOH | Bioavailability enhancement | [260] |

| Morphine | SEDS | PLA-PEG-PLA | DCM, MeOH | Controlled release | [261] |

| PLA | DCM, EtOH, Water | [262] | |||

| Naloxone | PCA | PLA | DCM | Controlled release | [29] |

| Naphthalene | SSI | PMMA | – | Controlled release | [263] |

| Naproxen | SAS | EC, Methyl cellulose | DCM, DMSO | Oral delivery | [264] |

| RESS | PLA | – | Bioavailability enhancement | [65b] | |

| SCP | Ethylene-vinyl-acetate, Eudragit® E100 | DCM | Transdermal controlled delivery | [99] | |

| Naltrexone | PCA | PLA | DCM | Controlled release | [29] |

| Niclosamid | SCP | Silica aerogels | ACN, MeOH | Oral delivery | [220] |

| Nifedipine | PGSS | PEG-4000 | – | Bioavailability enhancement | [35] |

| Nilotinib | SAS | HPMC-phthalate, | Acetone, Chloroform, DMSO | Bioavailability enhancement | [222] |

| Nimesulide | SAS | – | Acetone, Chloroform, DCM | Bioavailability enhancement | [265] |

| SSI | PDMS | – | Controlled release | [266] | |

| Olanzapine | RESS, RESSAS | HPMC, PEG | – | Oral delivery | [267] |

| Oxaliplatin | SCP | – | Myristyl alcohol | Oral delivery | [268] |

| Oxeglitazar | SAS | PEG, Poloxamer 188 and 407, PVP-K17 | Chloroform, DCM, DMSO, EtOH, NMP, THF | Oral delivery | [25] |

| pDNA | SCF foaming | Chitosan, PLGA | – | Controlled release | [156] |

| Paclitaxel | SSI | PLA | EtOH | Controlled release | [269] |

| SEDS | PEG-PLA | DCM | Targeted delivery | [61b] | |

| PLA, PLGA | DCM | Controlled release | [270] | ||

| GAS, SCF-PI | Basil seeds mucilage | DMSO, EtOH | Bioavailability enhancement | [271] | |

| RESOLV | PVP | – | [272] | ||

| Phenytoin | RESS-SC | – | Menthol | Bioavailability enhancement | [62a] |

| Piroxicam | SAILA | PLA, PLGA | – | Controlled release | [40b] |

| SSI | PDMS | – | [266] | ||

| SFEE | PLGA, PVA | EA, Water | Injectable | [41] | |

| PCA | PVP | – | Bioavailability enhancement | [273] | |

| Progesterone | SCP | PEG, Gelucire 44/14 TPGS | – | Transdermal delivery | [274] |

| PGSS | – | Bioavailability enhancement | [275] | ||

| Puerarin | SEDS | PLA | DCM | Bioavailability enhancement | [15,276] |

| Quercetin | SFEE | Pluronic L64, Soybean lecithin | EA | Bioavailability enhancement | [43] |

| Retinyl acetate | SFEE | PLGA | Acetone | Sustained release | [277] |

| Retinyl palmitate | RESOLV | PLA | – | Bioavailability enhancement | [278] |

| Rhodamine | SFEE | PLA | EA | Controlled release | [279] |

| Rifabutin | SCP | Silica, Sodium alginate, and Starch aerogels | EtOH, Isopropanol | Oral delivery | [207] |

| RNA | SEDS | PEG, PLA | DCM | Transdermal controlled delivery | [280] |

| Salbutamol | SCFD | Chitosan | EtOH | Controlled release | [281] |

| Salicylic acid | SCF-MIP | P(DEGDMA) | EtOH | Controlled release | [101] |

| SSI | Alumina, Amberlite, Silica gel | - | [62b] | ||

| Silymarin | SEDS | Phospholipids | DCM, EtOH | Bioavailability enhancement | [282] |

| Simvastatin | RESS | - | Trifluoromethane | Bioavailability enhancement | [66] |

| Sulfamethizole | SAS | - | Acetone, DMF | Ultrasound application | [283] |

| Sulfathiazole | SAS | - | Acetone, MeOH | Bioavailability enhancement | [284] |

| Terfenadine | SCP | Silica aerogels | ACN, MeOH | Oral delivery | [220] |

| Tetanus toxoid | SCP | PLA | - | Sustained release | [77] |

| Theophylline | SAS | HPMC | - | Controlled release | [285] |

| RESS-N | EC, PEG | EtOH | [81b] | ||

| Timolol maleate | SSI | Chitosan derivatives | EtOH | Ophthalmic delivery | [142c] |

| PCL, PCL/POE, PCL/PEVA | THF | Controlled release | [141] | ||

| Tolfenamic acid | SAS | - | Acetone, EA | Bioavailability enhancement | [286] |

| Triclabenzadol | SAA | - | Acetone, MeOH | Bioavailability enhancement | [34a] |

| Triflusal | SCP | PMMA | Acetone | Controlled release | [287] |

| PMMA, Silica | - | Bioavailability enhancement | [70b] | ||

| SSI | Gelatin, Silica | Acetone | Controlled release | [234] | |

| Trypsin | SAA-HCM | Chitosan | Water | Controlled release | [82] |

| Vitamins (2-methyl-1, 4-naphthquinone (vitamin K3) cholecalciferol (vitamin D3)) | SSI | Sodium alginate aerogels | EtOH | Controlled release | [288] |

| Zidovudine | SAS | PLA | DCM, EtOH | Bioavailability enhancement | [289] |

Abbreviations: 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP), Acetonitrile (ACN), Aerosol solvent extraction system (ASES), Atomized rapid injection solvent extraction process (ARISE), Bovine serum albumin (BSA), Cellulose acetate (CA), Continuous-Supercritical emulsions extraction (SEE-C), D-alpha tocopheryl polyethylene glycol-1000 succinate (TPGS), Dichloromethane (DCM), Dimethylformamide (DMF), Dimethylsulfoxide (DMSO), Ethanol (EtOH), Ethyl acetate (EA), Ethyl cellulose (EC), Ethylene glycol dimethacrylate (EGDMA), Gas anti-solvent (GAS), Hydroxypropyl methylcellulose (HPMC), Methanol (MeOH), Mobil composition of matter (MCM), N-methylpyrrolidone (NMP), Particle formation from gas saturated solutions (PGSS), Poly(3-hydroxybutyrate-co-3-hydroxy valerate) (PHBV), Polycaprolactone (PCL), Polydimethylsiloxanes (PDMS), Poly(lactide-co-glycolide) (PLGA), Polyethylene glycol (PEG), Poly(ethyl methacrylate)/tetrahydrofurfuryl methacrylate (PEMA/THFMA), Poly(ethylene-vinyl acetate) (PEVA), Polyethylene oxide (PEO), Polylactic acid (PLA), Poly(methyl methacrylate) (PMMA), Poly(diethylene glycol dimethacrylate) P(DEGDMA), Poly(methyl vinyl ether-co-maleic anhydride) (PVM-MA), Poly(N-isopropylacrylamide) (PNIPAAm) Poly(oxyethylene) (POE), Polypropylene glycol (PPG), Poly-vinyl alcohol (PVA), Poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF–HFP), Polyvinylpyrrolidone (PVP), Precipitation with Compressed anti-solvent (PCA), Rapid expansion of a supercritical solution into a liquid solvent (RESOLV), Rapid expansion of supercritical solutions (RESS), Rapid expansion of supercritical solutions into aqueous solution (RESSAS), Rapid expansion from supercritical solution with a non-solvent (RESS-N), Rapid expansion of supercritical solution with solid co-solvent (RESS-SC), Santa Barbara Amorphous (SBA), Silk fibroin (SF), Solution-enhanced dispersion by supercritical fluids (SEDS), Solution-enhanced dispersion by supercritical fluids-prefilming atomization (SEDS-PA), Supercritical-assisted injection in a liquid anti-solvent (SAILA), Supercritical anti-solvent (SAS), Supercritical anti-solvent with enhanced mass transfer (SAS-EM), Supercritical-assisted atomization (SAA), Supercritical-assisted atomization-hydrodynamic cavitation mixer (SAA-HCM), SCF-assisted molecular imprinting (SCF-MIP), SCF-assisted spray drying (SASD), SCF-drying (SCFD), SCF-assisted extraction of emulsions (SFEE), SCF-inkjet printing (SCF-IP), SCF-phase inversion process (SCF-PI), SCF-pressure-quench technology (SCF-PQT), SCF-assisted processing (SCP), SCF-assisted sintering (SCFS), Supercritical solvent impregnation (SSI), Suspension-enhanced dispersion by supercritical fluids (SpEDS), Tetrahydrofuran (THF).

In general, drugs with poor oral bioavailability, i.e., either with low solubility or low intestinal permeability, are opted to improve by optimizing the conditions of the manufacturing process.[4a,5b] Numerous studies with respective to delivery systems using the SCF technology are compiled and tabulated focusing on the relevant parameters related to the purpose of delivery and method of preparation (Table 1). Few of the studies have reported the micronization of APIs alone[81d,83] and few were impregnated in various water-soluble polymeric matrices such as polyvinylpyrrolidone (PVP), starch derivatives, modified cellulose, and some other synthetic polymers.[1,3,5b,23b,e,61b,84]

Polymers are highly advantageous as carriers because of easy drug impregnation, ability to carry a high payload of drugs, biocompatibility, biodegradability, and sustainability of drug release from the matrix.[7b,85] Polymers are chosen based on polarity and thermosensitivity. The key feature is the polymer solubility in SCF, which favors the reduction of polymer melting temperature and subsequently decreased viscosity[86] guided by the molecular structure, i.e., functional group, and its morphology. Polymers usually have low solubility in SCF. However, the increase in pressure or temperature results in enhancement of their solubility.[23b] Notably, few polymers are soluble only in the organic solvents, whose industrial applicability is limited.[87] To this end, phase mixing in a combination of solvents can be pursued to overcome this issue.[88]

During the supercritical process, polymeric particle formation undergoes sequential steps: initially, nucleation phase, which results in the formation of the polymeric nucleus and then followed by growth phase yielding desired particles.[13b] In fact, altered operating conditions (i.e., temperature, pressure, and solution flow rate) result in different shapes of polymeric composites such as microspheres and microfibers. The various shapes with altered critical conditions result in changes in the polymeric physical properties such as reduction in melting point and solubility improvement in relatively high-pressure systems.[89]

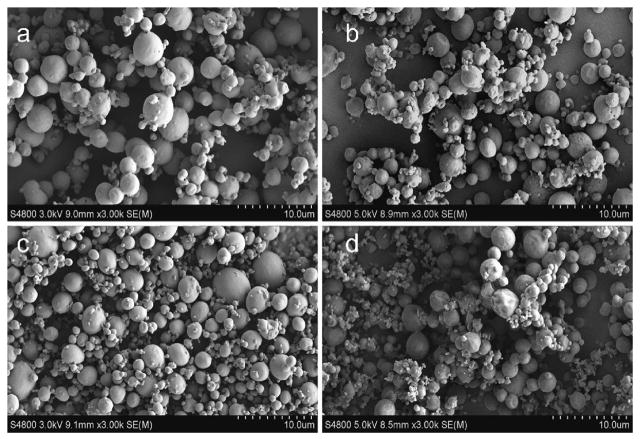

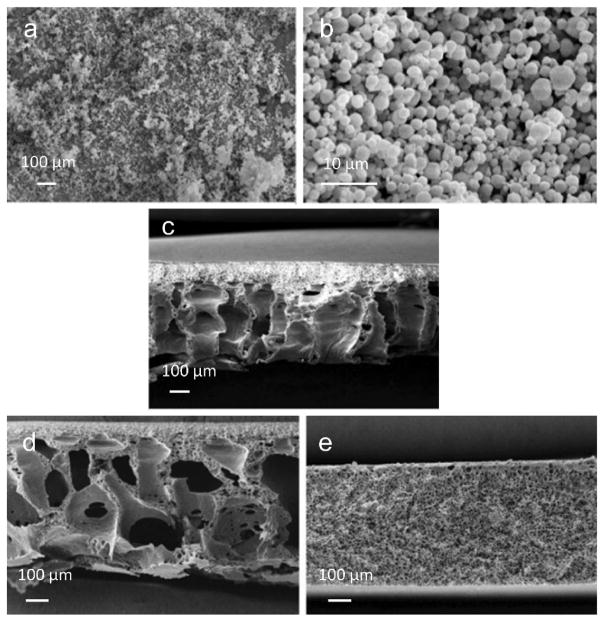

Most of the microencapsulated systems are prepared using biodegradable polylactic acid (PLA),[84b,90] since it is suitable for controlling delivery of short half-life drugs or highly potent drugs due to its long in vivo degradation time. For example, paclitaxel (PTX) was loaded in a synthetic biodegradable diblock copolymer poly(ethylene glycol)-PLA (PEG-PLA), and subsequently conjugated with folic acid (FA) in the PEG terminal ends to form FA-PEG-PLA complex (Figure 3). The hydrophobic drug-loaded microparticles for use as the tumor-targeted delivery system (PTX-FA-PEG-PLA) were produced via the SEDS process, which resulted in a spherical shape and presented significantly higher cellular uptake than FA-free carriers (PTX-PEG-PLA) in the tumor tissue. This study and others demonstrate that the semi-crystalline and amorphous forms of PLA, and amorphous poly(lactide-co-glycolide) (PLGA) are all suitable in the SCF technology for particle formation.[61b,84a]

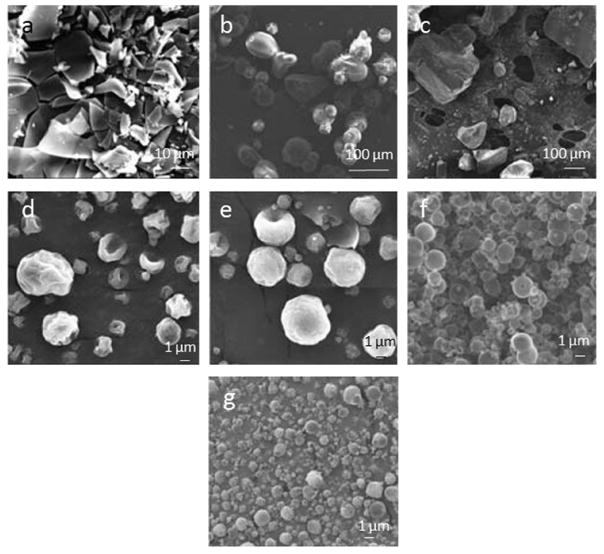

Figure 3.

SEM images showing microparticles prepared by the SEDS process. a) FA-PEG-PLA, b) PTX-loaded FA-PEG-PLA, c) PEG-PLA, and d) PTX-loaded PEG-PLA particles. Reproduced with permission.[61b] Copyright 2015, Springer.

Among all the SCF methods for particle formation, the SAS process is one of the most efficient to produce microparticles with desired morphologies, where SCF acts as the anti-solvent, and the alternative organic solvent is used to dissolve the polymer. Further, the SCF miscibility with organic solvent leads to its expansion and subsequent reduction in density and the solvation capacity. These consequences enable supersaturation, solute nucleation, and particle formation.[8b] Different linear polyesters of lactic acid (e.g., PLA) and their co-polymers with polyvinyl alcohol (PVA) such as PVA-PLA and PVA-PLGA are processed through the SAS method.[8b,91] Solvent selection plays a crucial role in polymer dissolution and mutual miscibility with SCF.

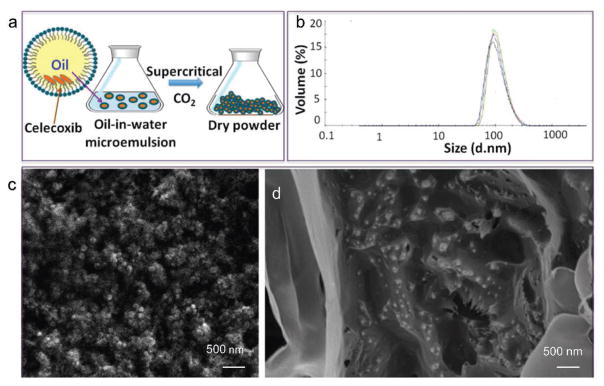

In addition to micro-size particles, SCF can generate nanometric domains with improved therapeutic efficacy. In a case, Zare et al. prepared nanometric domains of celecoxib by SC-CO2 extraction from a volatile oil-in-water microemulsion (Figure 4a). Celecoxib and PLGA (lactide:glycolide = 75:25) were dissolved in the dispersed phase (n-butyl acetate); concomitant extraction yielded solid powder composed of spherical nanoparticles with an average size of 110 nm (Figure 4b and c). In addition, these polymeric nanocarriers were dispersed in an injectable crosslinked hydrogel (Figure 4d) composed of biocompatible and biodegradable polymers, PVA (Mw = 89–98 KDa, 10 wt.%) and PVP (Mw ≈ 40 KDa, 3 wt.%). Celecoxib was capable of inducing angiogenesis in normally perfused and ischemic organs, and the intravenously administered nanoparticle formulation profoundly worked for improving therapeutic angiogenesis.[31a]

Figure 4.

Celecoxib nanoparticles formation and characterization. a) Schematic representation of nanoparticle formation process. b) Particle size measurements in water by dynamic light scattering (DLS). c) SEM image of nanoparticles in powder. d) SEM image of nanoparticles embedded in hydrogel (dried). Reproduced with permission.[31a] Copyright 2015, American Chemical Society.

The SCF technology is rather the alternative to treat/encapsulate large molecules such as proteins due to its promising operating conditions. Polymeric carriers such as biodegradable PLGA microspheres are usually chosen to encapsulate and deliver because of their sensitivity and relatively fast degradation behavior.[17,23b,31a] This impregnation of proteins surpasses limitations such as agglomeration and limited solubility of proteins in organic solvents.[92] Most of the proteins processed as inhalation powders for therapeutic delivery are prepared using SAS[93] and its associated processes.[94]

In addition, polymeric particle formation in PGSS is easier after solubilizing SCF in polymers (i.e., PEG and polyethylene (PE)) through rapid depressurization and their phase-separation by pressure alteration. Polymer plasticization upon SCF treatment results in substantial reduction in its viscosity and results in smaller particles and allows effective immobilization of drugs.[8b] This reduction in particle size demonstrates the effective dissolution of particles and exhibits controlled release of drugs from the hydrophilic polymer matrix. Out of all processing techniques operated to synthesize drug delivery vehicles using the SCF technology, PGSS holds several advantages over others, such as no organic solvent requirement for solubilizing polymers, and eventually no extraction process for solvent removal.[17]

In general, the SCF technology is operated using any one of the supercritical solvents available. Few instances, combination of SCFs are preferred to minimize severe flocculation of polymeric microparticles due to plasticizing effect of residual SCF and this approach also results in fine-sized particles.[95] Eventually, these green solvents are also utilized to extract the residual organic solvent at <100-psi pressures from the conventional preparations, which enables increasing the particle porosity.[96]

During particle fabrication, the SCF technology offers many advantages over other processes such as colloid chemistry, microfluidics, spray-drying, and electrospray. Unlike these conventional processes, the SCF technology does not rely on the use of organic solvents. This green technology precipitates micro- and nano-sized particles with narrow size distribution by altering critical conditions (i.e., temperature and pressure) and flow rate of SCF and others.[5b,20d,21a,23r] The SCF possesses unique properties such as its solvating power, anti-solvent effect, and large compressibility.[3] The SCF technology provides many ways of particle fabrication (See Section 2) such as rapidly exceeding the saturation point of a substrate and rapid depressurization, among others.[1,21a,23e] These SCF processes yield smaller-sized particles usually faster than other techniques such as those based on microfluidics. The polymeric particles fabricated by the SCF processes can be completely dispersed in most cases, unlike various colloidal particles that rely on certain interaction forces such as electrostatic, steric, and van der Waals forces to disperse.[97] Another advantage of the SCF technology is that it allows single-step fabrication of particles that are difficult to obtain by traditional techniques.

Despite the efficiency of SCF in producing particulate delivery systems, poor solubility of polar substrates (i.e., drugs and polymers) in SCF has remained as a challenge.[98] Several alternatives can overcome this issue, such as pre-mixing of substrates and usage of organic solvent. Pre-mixing involves the mixing of all the substrates, i.e., drug and polymer, as well as other excipients, before the SCF treatment.[98] In addition, the drug is dissolved in an organic solvent before pressurizing CO2. Further, the resultant solution is supplied to a polymer, which facilitates the impregnation of drug in the swollen polymer.[99] Eventually, the organic solvent traces can be removed post-fabrication, which results in unaltered surface properties of the particles.[17]

In addition to carrier design, the SCF technology is also used to synthesize certain biodegradable polymers by rapid depressurization at the end of polymerization.[100] Indeed, the SAS process is preferred to co-precipitate desired molecules of interest and is beneficial over other conventional methods. The plasticization phenomena of polymers in compressed SCF has a great impact on their physical and mechanical properties, which alters glass transition temperature of the polymer and allows to design advanced materials.[23g] Molecular imprinting (MIP) is one such method to synthesize polymers using various polymerization mechanisms. It has enormous applicability in different fields, which has also inspired the pharmaceutical field to design controlled release systems with high encapsulation efficiency.[101] This technique is very precise and easy to tailor the polymer because monomer is chosen based on the requirement to obtain the desired polymer.[68] Copolymer MIP process is also applied in the manufacturing process to attain control over the therapeutic release and the nature of interaction confinement during self-assembly to direct the drug release, which depends on molecular recognition of functional monomers.[102]

In addition to polymers, cyclodextrins (CD) are the most used pharmaceutical delivery vehicles to produce solid-state inclusion complexes.[3,103] Inclusion approach alters the physicochemical properties such as solubility and dissolution rate to enhance the bioavailability of poorly soluble drugs.[103f] The specific interactions present between the host and guest molecules direct the release rate of the drug.[104] Several conventional methods in the past were used to prepare the CD complexes, which were time-consuming multi-stage processes and resulted in traces of organic solvents after preparation.[103f] The SCF technology is probably the most suitable method for the preparation of inclusion complexes using various CDs (Table 2). Following the solubilization of the drug in SCF, inclusion of the drug is possible by partitioning the dissolved drug with the SCF phase and hydrophobic CD cavity and establishes the molecular interactions such as hydrogen bonding.[103e] The SCF technology has remained as the most advantageous method of preparation over traditional methods to load large molecules in CD complexes.[103g,h]

Table 2.

Inclusion complexes of various cyclodextrins synthesized using various methods of preparation with the SCF technology.

| Pharmaceutical compound | SCF Process | CD | Solvent | Purpose | Reference |

|---|---|---|---|---|---|

| Benzocaine | SCI | β-CD | EtOH | Bioavailability enhancement | [58] |

| Budesonide | SEDS | γ-CD | EtOH | Bioavailability enhancement | [103g,h] |

| SCI | HP-β-CD | - | [103e] | ||

| Bupivacaine HCl | SCP | β-CD | EtOH | Bioavailability enhancement | [58] |

| Curcumin | ARISE | HP-β-CD | Acetone, EtOH | Inhalation powders | [290] |

| Econazole | SCI | β-CD | - | Bioavailability enhancement | [291] |

| Eflucimibe | SAS | γ-CD | DMSO | Bioavailability enhancement | [292] |

| Fluconazole | SCI | β-CD | - | Bioavailability enhancement | [291] |

| Flurbiprofen | SCP | Trimethyl-β-CD | EtOH | Bioavailability enhancement | [293] |

| Ibuprofen | SCI | Methyl-β-CD | - | Bioavailability enhancement | [103d] |

| β-CD | - | [103f,294] | |||

| Imazalil | SCI | β-CD | - | Bioavailability enhancement | [295] |

| Indomethacin | SCI | HP-β-CD | - | Bioavailability enhancement | [103e] |

| Methyl-β-CD | - | [296] | |||

| Itraconazole | ASES | HP-β-CD | DCM, EtOH | Bioavailability enhancement | [297] |

| SCI | β-CD | - | [291,298] | ||

| Ketoprofen | SCI | Methyl-β-CD | - | Bioavailability enhancement | [103b] |

| Mepivacaine | SCI | β-CD | EtOH | Bioavailability enhancement | [58] |

| Miconazole | SCI | β-CD | - | Bioavailability enhancement | [299] |

| HP-γ-CD | - | [300] | |||

| Naproxen | ASES | HP-β-CD, Methyl-β-CD | Acetone, DMSO, EtOH | Pulmonary delivery | [103c] |

| SCP | Trimethyl-β-CD | EtOH | Bioavailability enhancement | [293] | |

| SCI | β-CD | - | [301] | ||

| Olanzapine | SCI | Methyl-β-CD | - | Bioavailability enhancement | [104] |

| Piroxicam | SCI | β-CD | - | Bioavailability enhancement | [299,302] |

| Acetone, EtOH | [303] | ||||

| Quercetin | PGSS | HP-β-CD | - | Bioavailability enhancement | [304] |

| Simvastatin | SAS | HP-β-CD | DCM, EtOH | Bioavailability enhancement | [305] |

| Tocopherol | PGSS | HP-β-CD | - | Bioavailability enhancement | [304] |

Abbreviations: Aerosol solvent extraction system (ASES), Atomized rapid injection solvent extraction process (ARISE), Cyclodextrin (CD), Dichloromethane (DCM), Dimethylsulfoxide (DMSO), Ethanol (EtOH), Hydroxypropyl-β-cyclodextrin (HP-β-CD), Particle formation from gas saturated solutions (PGSS), Polyvinylpyrrolidone (PVP), Solution-enhanced dispersion by supercritical fluids (SEDS), Anti-solvent (SAS), SCF-assisted processing (SCP), Supercritical inclusion (SCI) method.

Liposomes are the versatile delivery systems formed by the colloidal association of amphiphilic lipid substances,[23i,106] which are suitable for delivering both hydrophilic and hydrophobic drugs[107] as well as proteins.[108] Most of the genes are delivered using adenoviral or liposomal vectors, in addition to non-viral vectors known as polymers.[109] SCF has received considerable attention as a green alternative in liposome scale-up because conventional processes require large amounts of organic solvents.[3,105,106b,110] The SCF-treated liposomes resulted in higher encapsulation efficiency[3,106b,108] than the conventional liposome preparation methods.[111] Two ways have been used to prepare liposomes, one of them is performed by mixing all components, i.e., phospholipids, SCF, and organic solvent together followed by decompression, and the other is by mixing phospholipids, SCF, and organic solvent and pumping the mixture into an aqueous phase.[23]

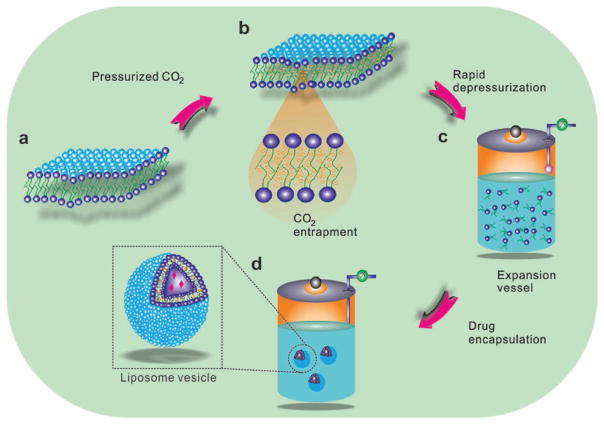

Zhao et al. prepared liposomes utilizing modified supercritical process involving the equilibration of phospholipid suspension in water with the high-pressure CO2 and the CO2-expanded liquid phase at a constant depressurization rate. The mechanism behind the liposome yield is simultaneous pressurization and depressurization phenomena, which leads to a dispersing effect of CO2 in phospholipids and released upon depressurization.[105] Eventually, due to hydrophobic interactions, phospholipids aggregate to yield spherical bilayers (Figure 5). This is similar to conventional homogenization process; however, the heat is removed from the phospholipid suspension, resulting in a temperature drop and cooling effect in the liposome suspension.[105] These lead to nano-sized particles at elevated pressure while higher depressurization rates contribute to enhanced uniformity.

Figure 5.

Schematic mechanism of liposome formation by the modified supercritical method. a) Phospholipid curvatures present at ambient condition, b) formation of expanded phospholipid bilayers after pressurization and equilibration with CO2, c) formation of an instantaneous dispersion of discrete phospholipid molecules during depressurization and release of CO2, and d) formation of liposome vesicle due to hydrophobic interactions after depressurization. Reproduced with permission.[105] Copyright 2015, Elsevier.

Lipid delivery vehicles manufactured through the SCF technology (Table 3) possess different physicochemical properties with high stability and narrow particle size distribution.[106b] The single-step continuous mode is under operation to improve the process,[112] which has no interference in encapsulation efficiency and no loss of entrapped drug. High drug entrapment efficiency in liposomes is yielded when they are prepared from unsaturated phospholipids.[113] This approach was later utilized to develop various drug formulations using SCF after optimization of formulation variables.[114] Although much research has been done in preparing liposomes through the SCF technology, the scalability and industrial implementation of these processes are expensive.[105,106b]

Table 3.

Liposomes as drug delivery carriers synthesized using various methods of preparation with the SCF technology.

| Pharmaceutical compound | SCF Process | Lipid | Solvent | Purpose | Reference |

|---|---|---|---|---|---|

| BSA | SuperLip | Phospholipids | EtOH | Controlled size | [108,306] |

| DELOS | PEG, Phospholipids | - | Targeted delivery | [33b] | |

| Cyclosporin A | SAS | Cholesterol, Phospholipids | EtOH | Stability improvement | [111] |

| SCP | Phospholipids | - | Ocular delivery | [307] | |

| Docetaxol | SAS | Cholesterol, PEG, Phospholipids | Chloroform, MeOH | Controlled release | [114] |

| Human growth hormone | SAA | PEG, Phospholipids, Tristearin | DMSO | Oral delivery | [308] |

| Insulin | SAA | PEG, Phospholipids | DMSO | Oral delivery | [308,309] |

| Ketoprofen | PGSS | Glycerolipids | - | Controlled release | [310] |

| Miconazole | ASES | Phospholipids | DCM, MeOH | Pulmonary delivery | [311] |

| Ribonuclease A | PGSS | PEG, Phospholipids | DCM, DMSO | Controlled release | [312] |

| Silymarin | SEDS | Phospholipids | DCM, EtOH | Bioavailability enhancement | [282] |

| Theophylline | PGSS | Hydrogenated palm oil | - | Controlled release | [313] |

Abbreviations: Aerosol solvent extraction system (ASES), Bovine serum albumin (BSA), Depressurization of an expanded liquid organic solution (DELOS), Dichloromethane (DCM), Dimethylsulfoxide (DMSO), Ethanol (EtOH), Methanol (MeOH), Particle formation from gas saturated solutions (PGSS), Polyethylene glycol (PEG), Solution-enhanced dispersion by supercritical fluids (SEDS), Supercritical anti-solvent (SAS), Supercritical-assisted atomization (SAA), Supercritical-assisted liposome formation (SuperLip), SCF-assisted processing (SCP).

3.2. Mechanisms of Drug Release

Drug delivery systems generally consist of a drug encapsulated within a biocompatible polymeric matrix, which is intended to release the drug through various mechanisms in the body. The release mechanism depends on a few factors such as the type of polymer used and the method of preparation of any formulation.[4a,6] These factors influence successful encapsulation of drug in the polymeric matrix or a micro-reservoir either in a laboratory or during scale-up, while other factors such as pH of the target environment also play a crucial role in its release.[4a] The incorporated drug can be released through two major ways of diffusion and burst-out phenomena.[6] In a diffusion process, the high affinity or specific interactions between the encapsulated drug and the polymeric matrix are weakened and the polymeric matrix becomes porous and subsequently releases the drug in a controlled fashion. The other way is the burst release, where the drug in the polymeric matrix is weakly bound and after exchange of the surrounding fluid it results in burst-out release of almost the entire drug cargo. The burst-out phenomena can be achieved through pH-/temperature-sensitive polymers used for encapsulation.[76] In addition, surface-adsorbed drug molecules during co-precipitation process may result in their immediate release. Currently, drug delivery vehicles have been designed to contain different payload of single/multiple drugs in a formulation possessing various release characteristics such as initial burst release from the outer layer and sustained release pattern from the inner layer within the same vehicle.[23c] Others include micro-reservoir-like vehicles, where the mode of release is modulated through a microchannel array.[115]

3.3. Pulmonary Delivery

Pulmonary delivery of drugs has become an attractive target in healthcare as the lung is suitable for absorption of many drugs due to its high surface area,[116] receipt of the entire cardiac output, low enzyme activity,[23a] and lack of the first-pass metabolism.[117] This non-invasive route is now used for the administration of various drugs and proteins for systemic as well as localized therapy through pressurized metered-dose inhalers (MDIs), nebulizers, and dry powder inhalers (DPIs) containing very tiny particles (<7 μm) for efficient deposition in lungs.[51,118] These formulations should provide excellent aerodynamic performance with suitable electrostatic charge and morphology, as well as long shelf-life stability and high deposition rate.[23j] In addition to aerodynamic performance, inter-particulate interactions are also considered, which significantly depends on the particle dispersibility to define the overall particle size distribution and deposition after inhalation.[23j] These aerosol formulations are produced widely by traditional ways, such as milling or spray drying;[51] however, the end product of these methods has few limitations such as remnants of solvents and sensitive molecules (proteins, and genes) encapsulated are susceptible to degradation.[51] In addition, selection of suitable excipients also remains a challenge for formulating sustained-release pulmonary delivery systems.[119]

Researchers have applied the SCF technology using CO2 and other solvents to synthesize fine particles of drugs,[51,59a,60,64,83,103c,120] proteins,[28,93b,c,121] and genes[122] for inhalation delivery (Table 4). Many inhalation formulations are produced at a high yield using a single-step SCF process, which can fine-tune the particle morphology, size, and charge after optimizing of all parameters.[23a] The ease of modulations has resulted in product with excellent aerodynamic performance as well as pulmonary deposition after nebulization.[23f] Particle size plays a crucial role in sustained pulmonary delivery, where larger-sized particles face difficulty in attaining bronchial penetration,[123] and small-sized particles are prone to alveolar macrophages uptake.[124] The SAS-EM technique is optimum to improve the particle size distribution in sub-micron range using the ultrasonic frequency vibrations.[93a]

Table 4.

Drug delivery systems intended for pulmonary route of administration synthesized using various methods of preparation with the SCF technology.

| Pharmaceutical compound | SCF Process | Polymer | Solvent | Purpose | Reference |

|---|---|---|---|---|---|

| 5-Fluorouracil | SAS | α-Lactose monohydrate | Acetone, DCM, EtOH, MeOH | Inhalation powders | [314] |

| Amphotericin B | CAN-BD | – | EtOH | Pulmonary delivery | [47] |

| Albuterol sulfate | SEDS | α-Lactose monohydrate | DCM, MeOH | Inhalation powders | [315] |

| Amoxicillin | SAS | – | NMP | Inhalation powders | [83a] |

| – | DMSO, EtOH | [201] | |||

| – | DMSO, NMP | Pulmonary delivery | [120a] | ||

| Beclomethasone-17, 21-dipropionate | GAS | – | Acetone, EtOH, MeOH | Pulmonary delivery | [316] |

| ASES | – | DCM, MeOH | Pulmonary delivery | [64] | |

| Betamethasone-17-valerate | ASES | – | DCM, MeOH | Pulmonary delivery | [64] |

| BSA | ASES | PLA-PLGA | DCM, MeOH, TFE | Pulmonary delivery | [317] |

| SAA-HCM | – | Water | [48] | ||

| Budesonide | ASES | – | DCM | Inhalation powders | [83b] |

| – | DCM, MeOH | Pulmonary delivery | [64] | ||

| SEDS | – | Acetone, MeOH | Inhalation powders | [318] | |

| α-Lactose monohydrate | Acetone | [315] | |||

| Calcitonin (Salmon) | SASD | Chitosan glutamate | EtOH, Water | Nasal powders | [51] |

| Celicoxib | SCF-PQT | PLGA | – | Sustained release | [124] |

| Cyclosporin A | RESS, PGSS | – | – | Inhalation powders | [319] |

| Curcumin | ARISE | HP-β-CD, PVP | Acetone, EtOH | Inhalation powders | [290] |

| Dexamethasone | ASES | – | DCM, MeOH | Pulmonary delivery | [64] |

| Flunisolide | ASES | – | DCM, MeOH | Pulmonary delivery | [64] |

| SEDS | – | Acetone, MeOH | Inhalation powders | [318b] | |

| Fluticasone-17-propionate | ASES | Heptafluoropropane-227 | DCM | MDI | [120c] |

| – | DCM, MeOH | Pulmonary delivery | [64] | ||

| Hydrocortisone | SEDS | – | Acetone, MeOH | Inhalation powders | [320] |

| Insulin | SAS | Mannitol | DMSO | Pulmonary delivery | [93b] |

| SCFD | Trimethyl chitosan, Dextran | [321] | |||

| SAS | – | HFIP | Inhalation powders | [121a] | |

| GAS | – | DMF, DMSO | [28] | ||

| Ipratropium bromide | ASES | – | DMF, EtOH | Pulmonary delivery | [129,322] |

| Ketoprofen | SFEE | Starch | EtOH | Aerogels | [128] |

| Levofloxacin hydrochloride | SAA-HCM | – | MeOH | Pulmonary delivery | [323] |

| Lysozyme | SAS | – | DMSO | Aerosol delivery | [93c] |

| PCA | PLA | DCM | Pulmonary delivery | [324] | |

| SEDS | – | DMSO | [94] | ||

| SAA-HCM | – | EtOH, Water | [325] | ||

| SAS-EM | – | DMSO | Controlled release | [93a] | |

| Miconazole | ASES | Cholesterol, Phospolipids, Poloxamer 407 | DCM, MeOH | Pulmonary delivery | [311] |

| Nalmefene | SAS | – | EtOH | Pulmonary delivery | [21a,326] |

| Naproxen | ASES | HP-β-CD, Methyl-β-CD | Acetone, DMSO, EtOH | Pulmonary delivery | [103c] |

| CAN-BD | – | EtOH | [47] | ||

| Nicotinic acid | SEDS | – | MeOH | Pulmonary delivery | [327] |

| pDNA | SEDS | Mannitol | Isopropanol, Water | Inhalation powders | [122] |

| SCP | Chitosan, Mannitol | EtOH, Water | [109,132] | ||

| SFEE | PLGA | EA, Water | Pulmonary delivery | [328] | |

| Prednisolone | ASES | – | DCM, MeOH | Pulmonary delivery | [64] |

| Rifampicin | SAS | PLA | DCM | Inhalation powders | [59a] |

| – | DMSO | [120g] | |||

| SAA | – | MeOH | [329] | ||

| RNA | SCP | Chitosan, Mannitol | EtOH | Inhalation powders | [119] |

| Salbutamol | SAS | – | DMSO, MeOH, EtOH | Pulmonary delivery | [60] |

| SCP | – | Menthol | Inhalation powders | [125,330] | |

| Salmeterol xinafoate | SEDS | – | Acetone, MeOH, THF | Inhalation powders | [331] |

| Terbutaline | SAA | – | Water | Aerosol delivery | [120d] |

| ASES | – | DMF, EtOH | Pulmonary delivery | [129] | |

| SEDS | α-Lactose monohydrate | EtOH, MeOH, Water | Inhalation powders | [120e] | |

| Tetracycline | SAS | – | NMP | Pulmonary delivery | [120f] |

| SFED | – | EtOH, Water | Inhalation powders | [53] | |

| SAA | – | Water | [329] | ||

| Triamcinolone acetonide | ASES | – | DCM, MeOH | Inhalation powders | [64] |

Abbreviations: 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP), 2,2,2-Trifluoroethanol (TFE), Aerosol solvent extraction system (ASES), Atomized rapid injection solvent extraction process (ARISE), Bovine serum albumin (BSA), Carbon dioxide-assisted nebulization with a bubble dryer (CAN-BD), Cyclodextrin (CD), Dichloromethane (DCM), Dimeth-ylformamide (DMF), Dimethylsulfoxide (DMSO), Ethanol (EtOH), Ethyl acetate (EA), Gas anti-solvent crystallization technique (GAS), Hydroxypropyl-β-cyclodextrin (HP-β-CD), Metered dose inhaler (MDI), Methanol (MeOH), N-methylpyrrolidone (NMP), Particle formation from gas saturated solutions (PGSS), Poly(lactide-co-glycolide) (PLGA), Polylactic acid (PLA), Polyvinylpyrrolidone (PVP), Precipitation with Compressed anti-solvent (PCA), Rapid expansion of supercritical solutions (RESS), Solution-enhanced dispersion by supercritical fluids (SEDS), Supercritical anti-solvent (SAS), Supercritical anti-solvent with enhanced mass transfer (SAS-EM), Supercritical-assisted atomization (SAA), Supercritical-assisted atomization-hydrodynamic cavitation mixer (SAA-HCM), SCF-assisted spray drying (SASD), SCF-assisted drying (SCFD), SCF-expansion depressurization (SFED), SCF-assisted extraction of emulsions (SFEE), SCF-pressure-quench technology (SCF-PQT), SCF-assisted processing (SCP), Tetrahydrofuran (THF).

DPIs are one of the most used inhalation formulations, and their clinical performance completely depends on the inspiratory flow of a patient.[17,23a,f,p] DPIs prepared using SCF are less susceptible to flow patterns than others. Further, the formulation is tolerant to physical stress, but the particles can break down upon inhalation.[125] During the processing of proteins for inhalation formulation, conditions should be optimized in the SCF technology to yield the end product with no significant change in protein conformation.[23a,126] In addition, poorly soluble proteins are also facilitated to increase their solubility in the supercritical atmosphere, suggesting the new path for bioavailability improvement in formulating protein powders. Most of the protein inhalation formulations are prepared by the SAS process, where SCF acts as an anti-solvent and an organic solvent is chosen for protein precipitation.[28,93b,c,121a] DMSO is one the most commonly used organic solvents to disperse proteins, because of its ability of expansion with pressure.[93b,127] DMSO usually disrupts the protein conformation; however, proteins such as lysosome and trypsin refold on rehydration of inhaled powders.[23a] The resultant protein product is very fine, uniform, and discrete particles (<4 μm in size) with relatively insensitive morphology and no loss of bioactivity at the varied conditions of temperature and pressure. Similar to SAS, the SFEE process also results in the formation of uniform crystalline drug particles for inhalation formulation and helpful in coating of microparticles to prevent agglomeration, which is a serious consequence in conventional coating techniques.[128]

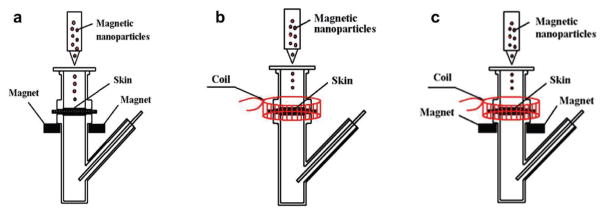

In a comparative study involving powder formulation of salmon calcitonin (sCT) from both the conventional SD and the innovative SASD methods to investigate the role of CO2 in the particle formation process,[51] Various formulations were designed with both the methods utilizing stabilizer (inulin, trehalose) and absorption enhancers (chitosan, sodium taurocholate, β-CD) (Figure 6). Particle size distribution of the SASD process was in a nanometric range, whereas SD resulted in >2 μm in size on average in all the formulations, and failed to detect the size of pure sCT particles accurately by zetasizer due to its poor dispersibility. The particle formation in SASD involves the origination of secondary droplets from the first droplets, which are generated by atomization through a nozzle. These secondary particles are the resultant droplets due to the rapid expansion of CO2 within the primary droplets (decompressive atomization). In vivo absorption capacity of SASD-processed sCT in rats showed much higher nasal absorption than unprocessed and SD-processed sCT, demonstrating that the preparation of fine nasal powder with a proper absorption enhancer using the SCF process could be a promising approach.[51]

Figure 6.

SEM images of (a) raw salmon calcitonin, (b) raw inulin, (c) raw trehalose, formulations prepared by (d,e) SD method, and (f, g) SASD method. Reproduced with permission.[51] Copyright 2015, Elsevier.

Optimization of the physical parameters for better performance of inhalation powders is still under development.[129] Few alternatives were discussed to improve the performance, for example, different constituents (polymer and drug) in a formulation have different solubility rate, which can be addressed by optimizing the amounts and solvent admixture preparation.[130] Furthermore, the addition of lower-molecular weight PEG can enhance the drug release because of its dissolution and concomitant pore formation.[131] Moreover, albumin addition can affect the particle morphology, which results in aerosolization improvement and consistency in lung deposition.[129]

Genes have also been formulated using the SCF technology (Table 4) for better stability during preparation, storage, and delivery[109,122,132] via the pulmonary route to avoid degradation in blood, and reduce the dosage.[23a,109] Eventually, the SCF technology is anticipated to be successful in fabricating various drug, protein, and gene formulations for pulmonary delivery.

3.4. Transdermal Delivery

The transdermal delivery has been a major route of drug administration in pharmaceutics, due to advantages such as pain-free self-administration, minimal frequency of dosing, and avoidance of hepatic first-pass metabolism by escaping from various metabolic enzymes.[3,133] Nevertheless, it is yet to be an alternative to oral or parenteral delivery since it is limited to delivery of drugs with narrow therapeutic ranges.[133] Many synthetic polymers such as PE, PLA, PLGA, poly(urethanes) (PU), polycaprolactone (PCL), poly(acrylonitrile) (PAN), silicone rubbers, and natural polymers (such as cellulose, chitosan, alginate, collagen, and gelatin) are utilized to prepare these topical delivery systems.[133,134] Although polymeric carriers have shown potential in delivering drugs, the penetrating ability of the therapeutic molecules is still limited. Further, this delivery system has progressed with very few active strategies to deliver therapeutic moieties and cosmetic application[135] for enhanced percutaneous permeation studies including electroporation,[136] iontophoresis,[137] microneedle,[138] and ultrasound pretreatment[139] and others.[133] However, these methods have their own limitations such as inflammation in the microneedles technique and skin rupture due to electric field associated devices such as electroporation.[61c]