Abstract

The characteristics of the vacuum used in a low atmospheric pressure stunning system to stun (render unconscious) poultry prior to slaughter are described. A vacuum chamber is pumped by a wet screw compressor. The vacuum pressure is reduced from ambient atmospheric pressure to an absolute vacuum pressure of ∼250 Torr (∼33 kPa) in ∼67 sec with the vacuum gate valve fully open. At ∼250 Torr, the sliding gate valve is partially closed to reduce effective pumping speed, resulting in a slower rate of decreasing pressure. Ambient temperature affects air density and water vapor pressure and thereby oxygen levels and the time at the minimum total pressure of ∼160 Torr (∼21 kPa) is varied from ∼120 to ∼220 sec to ensure an effective stun within the 280 seconds of each cycle. The reduction in total pressure results in a gradual reduction of oxygen partial pressure that was measured by a solid-state electrochemical oxygen sensor. The reduced oxygen pressure leads to hypoxia, which is recognized as a humane method of stunning poultry. The system maintains an oxygen concentration of <5% for at least 2 minutes, which ensures that birds are irreversibly stunned. Calculated pump down (pressure versus time) data match experimental data very closely because the programmable logic controller and the human machine interface enable precise and accurate control. The vacuum system operates in the turbulent viscous flow regime, and is best characterized by absolute vacuum pressure rather than gauge pressure. Neither the presence of broiler chickens nor different fore-line pipe designs of four parallel commercial systems affected the pressure-time data. Water in wet air always reduces the oxygen concentrations to a value lower than in dry air. The partial pressure of water and oxygen were found to depend on the pump down parameters due to the formation of fog in the chamber and desorption of water from the birds and the walls of the vacuum chamber.

Keywords: animal welfare, vacuum, broiler, hypobaric hypoxia, low atmospheric pressure stunning

INTRODUCTION

With the rapid growth of the human population on Earth, it becomes more critical to apply technology to reduce the time and energy required for production of foods, (Meadows et al., 1992 and FAO, 2011). One example of technology for food production is low atmospheric pressure stunning (LAPS) for humanely rendering chickens unconscious (Purswell et al., 2007, Cheek and Cattaruzzi, 2009, 2010). In this induced unconscious state the bird experiences no pain and discomfort during exsanguination (Vizzier-Thaxton et al., 2010, Martin et al., 2016a,b,c), which is a legal requirement in most countries for the slaughter of animals for food (Council Regulation (EC) No. 1099/2009, OIE, 2013).

The fact that low pressures can be used to stun poultry has been known since the invention of pumps that can be used to produce vacuums. For example, after invention of the Boyle-Hook pump in 1660, Boyle observed that when a “lark was placed in the receiver [it] sprang to a good height on several occasions when the pressure was normal”. But when air was removed, it began to “droop and appear sick, and very soon after was taken with as violent and irregular convulsions as are wont to be observ’d in Poultry, when their heads are wrung off”. (See West, 2005). Boyle found that birds readily recovered from short periods of withdrawal of air but not from longer periods. Gradwell (2006) reviewed the impact of reduced oxygen on man in relation to aviation and space exploration. He concluded that exposure to reduced oxygen concentrations due to vacuum, elevation, and/or altitude leads first to hypoxia (an inadequate oxygen supply to the cells and tissues), which cause loss of cognitive and psychomotor skills and loss of consciousness. Such acute hypoxia is dangerous for aircrew as the onset is insidious and symptoms do not usually cause discomfort or pain (Eurocontrol, 2015). Rapid ascent to high altitudes can cause sudden onset hypoxia, which may result in loss of consciousness before any signs, or symptoms occur (Gradwell, 2006). Further reductions in oxygen concentrations lead to the deterioration of most bodily functions including the loss of voluntary control over the brain, which may be accompanied, by involuntary tonic and clonic spasms prior to death (Dawson et al., 2007; Dawson et al., 2009; EFSA, 2013; Eurocontrol, 2015). Indeed gradual hypoxia is regarded as a humane method of killing of some, but not all, species of animals (Raj, Gregory and Wotton, 1991; Woolley and Gentle, 1998; AVMA, 2013 and Raj et al., 2008).

The LAPS process results in a non-recovery state (Mackie & McKeegan, 2016; Martin et al., 2016a,b,c), a first step in preparing the birds for processing for food. However, it is difficult to quantify the levels of discomfort and pain experienced from the “stunning” procedure. Vizzier-Thaxton et al., 2010 reported corticosterone levels and behavioral parameters. McKeegan et al. (2013a), and Mackie and McKeegan (2016) evaluated behaviors such as posture, wing flapping, convulsions, heartbeat using Electrocardiogram (ECG) data, and brain activity using Electroencephalogram (EEG) data, and found that during induction to unconscious, evidence suggests that LAPS is non-aversive. This has been supported by recent studies on LAPS by Martin et al. (2016b) using an analgesia paradigm to provide evidence that pain and discomfort levels are minimized; Martin et al. (2016a) reported the effects of variation in ambient temperatures on behavioral, EEG, and ECG responses of broilers and also Martin et al. (2016c) showed the effect of LAPS in both dark and light conditions and sham treatment on the behavioral, EEG, and ECG responses of broilers, demonstrating further that that LAPS is non-aversive and allows slaughter which minimizes fear, anxiety, pain, and suffering. AVMA, 2016 concluded that LAPS of poultry produces a quiet transition to unconsciousness without escape behaviors and with minimal physical and wing flapping, which occurs following loss of posture and therefore unconsciousness. This paper is the first report of the vacuum characteristics currently used in commercial LAPS.

The necessary steps to take a chicken from the place where it was reared to that where it is offered as food to the consuming public has been described by Sams (2000). These steps include putting birds into crates on a farm, transporting them by truck to the processing facility, stunning the birds (which means they are rendered unconscious), followed by bleeding and further processing. Joseph et al. (2013) noted that the most common stunning process is electric stunning (ES) in which the chicken are either dumped/tipped out or extracted by hand from the transport crates, and placed upside down in shackles, and passed through a conducting salt water bath with an applied voltage sufficient to cause unconsciousness and/or death. Recognizing that handling and being shackled upside down stresses the birds (Gentle and Tilston, 2000); alternative methods for stunning have been developed, including controlled atmosphere stunning (CAS) and LAPS (Johnson (2014). Some CAS methods rely simply on reduction of oxygen to levels below which the bird cannot survive typically by diluting air with argon or nitrogen so that oxygen is below 2 to 5% for 2 to 5 minutes. Powell (2015) summarized the physiology of hypoxia in poultry and noted that broilers show changes in the depth and rate of respiration at 15% and arrhythmia of the heart rate around 7% oxygen. At ≤5% oxygen, there are profound effects in the brain, respiratory, and cardiovascular systems resulting in cardiovascular collapse (see Raj, Gregory and Wotton, 1991; Woolley and Gentle, 1998; Raj et al., 2008 and Powell, 2015). McKeegan et al. (2013a) conducted detailed behavioral and physiological studies of chickens, ducks, and turkeys to compare the anoxic effects of nitrogen or carbon dioxide in high expansion foams. The target mean residual oxygen was between 1 to 2% but it varied from 0.33 to 4.97%, and showed no difference in the rapid onset of the unconscious state. CAS studies of “anoxic” gas mixtures have aimed for 2% in residual oxygen but such levels of oxygen are difficult to achieve in practice due to mixing of gas and air and also release of air trapped in the feathers. Raj, Gregory and Wotton (1991) used an argon-carbon dioxide gas mixture to show that 5% residual oxygen for 2 minutes was sufficient to irreversibly stun chickens. Raj et al., 2008 concluded that residual oxygen levels up to 5% by volume in inert gas/carbon dioxide mixtures were sufficient to kill poultry rapidly for euthanasia/depopulation for disease control.

During the LAPS process, the birds are inserted into a vacuum chamber in their transport cages making additional handling unnecessary and reducing stress as compared with electrical stunning (Vizzier-Thaxton et al., 2010). Once the birds are inserted into the vacuum chamber, vacuum pumps are used to reduce the concentrations of all gases, including oxygen through reduction in atmospheric pressure. As a result, the oxygen concentration is reduced to below 5% for ≥2 minutes, resulting in irreversible stunning. Once the bird is properly stunned and no longer experiences stress from handling, they are extracted from the transport cages, hung on shackles and bled as required by some food laws such as European Union Food Hygiene legislation (Council Regulation (EC) No. 853/2004).

This paper will discuss the LAPS vacuum technology in some detail. It will quantify critical aspects of the vacuum, such as pump down rates, oxygen concentrations, effects of elevation, rates with and without birds, and the performances of multiple parallel systems with various piping configuration between pumps and chambers. The equipment and the procedure for producing a vacuum, characterizing it to assure compliance with governmental regulations, such as EU Regulation No 1099/2009 will be discussed. A primary focus will be on quantification of the concentration of oxygen that leads to the onset of severe hypoxia and consequently to irreversibly stunned birds.

MATERIALS AND METHODS

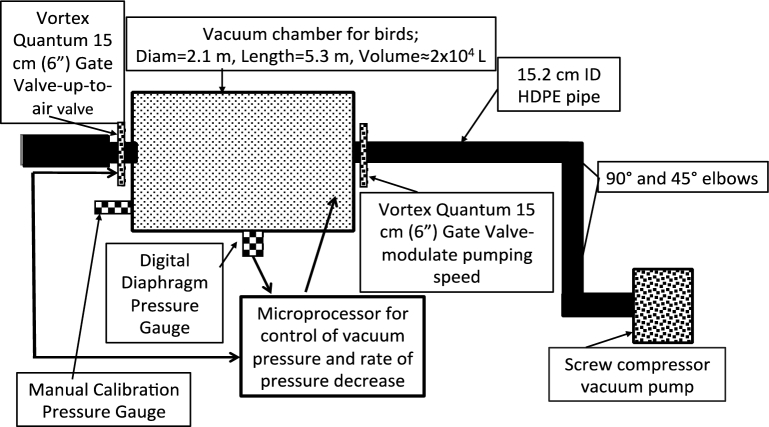

A schematic of the vacuum system used for LAPS is shown in Figure 1. The system is managed by a programmable logic controller, which results in precise and accurate monitoring and control of pump down (pressure versus time). Infrared cameras allow observation of the bird's behavior during the pump down and the status of the transport modules and the vacuum are displayed on the human machine interface. Three LAPS systems of similar design have been evaluated including (1) a commercial installation with four large parallel vacuum systems (e.g., used for studies of the effects of the presence or absence of birds and referred to here as chambers 1, 2, 3, or 4), (2) a single large chamber trailer-mounted portable commercial system (used for study of the effects of elevation, referred to as chamber 5), and (3) a fixed pilot system with a smaller cylindrical chamber, 2.2 m in length and 1.8 m in diameter (used for studies of the effects of ambient temperature on chamber temperature, relative humidity and oxygen levels referred to as chamber 6). All three systems have identical control and monitoring equipment. The vacuum system consists of a number of components, including a large cylindrical vacuum chamber (2.13 m diameter, 5.33 m long for the commercial system) closed on both ends by domed doors (20.3 cm dome on center line). The vacuum chamber has a calculated volume of ∼20,000 L). The vacuum chamber is connected through a vacuum gate valve (Vortex Quantum 15.2 cm (6 inch) orifice slide gate valve) to a high density polyethylene (HDPE) vacuum line that in turn is connected to the single stage, positive displacement, fluid flooded rotary screw compressor vacuum pump (Quincy QSVI-50 Wet Screw Pump) with a pumping speed of 20,700 L/min (730 cubic feet per minute). The screw compressor vacuum pump are sited alongside the chamber. Both Vortex quantum gate valves are situated on top of the vacuum chamber. To create a vacuum, the up-to-air valve (also a Vortex Quantum 15.2 cm (6 inch) orifice slide gate valve) is closed, and the vacuum sliding gate valve is fully opened at time zero. The pressure was measured by a direct reading digital diaphragm gauge (type P62 from Kaeser) under microprocessor control and is situated on the side of the chamber. This Kaeser gauge was calibrated with an Ashcroft precision bellows mechanical total pressure gauge with 0.25% accuracy.

Figure 1.

Schematic of LAPS vacuum system. The microprocessor controls the gate valve attached directly to the vacuum pump (right of vacuum chamber) and also controls the rate of pump down. It is also connected to the gate valve-up-to-air valve (left of the vacuum chamber), which is opened at the end of the cycle to repressurize the chamber with outside air.

The vacuum chamber was initially at ambient atmospheric pressure, which is normally 760 Torr (101.3 kPa) absolute total pressure at mean sea level (MSL). The starting absolute pressure varied because of high and low pressure weather systems, but this barometric pressure variation was typically less than 1% and was automatically compensated by using absolute pressure. The effects of altitude (equivalent to elevation) were examined using either the fixed chambers (1, 2, 3, and 4) at Fort Smith Arkansas at an elevation of 463 ft. (141 m), the portable LAPS small chamber (6) facility in Fayetteville, Arkansas, with an elevation of 1,400 ft. (434 m), or using a portable chamber (5) in Calgary, Canada, at an elevation 3,438 ft. (1,048 m). Ten runs were completed at each site and ambient barometric pressure, temperature, relative humidity, and dew point were recorded along with total pressure, temperature, and oxygen levels within the chamber. The system was operated using either gauge or absolute vacuum pressure. When absolute vacuum pressure (i.e., pressure approaches zero as the air is removed from the chamber) was used to control the system, correction for weather and elevation was automatic (Lide, 2005). When gauge pressure (i.e., pressure defined to be zero at ambient atmospheric conditions) is used to characterize the vacuum, the change in atmospheric pressure from either weather or elevation must be corrected manually.

The oxygen fraction was measured using a PureAire Oxygen Sensor (PureAire Monitoring Systems, Lake Zurich, IL) based upon solid-state electrochemistry. Oxygen from the vacuum chamber diffused through an opening in the sensor cap, and O2− formed when oxygen struck the zirconia (ZrO2) film. The O2− dissolved in the zirconia and was transported to the opposite electrode. The amount of current in the solid-state electrochemical cell is proportional to the amount of oxygen. The sensor was dynamically calibrated and tested by the manufacturer prior to use and had an accuracy of 1% of reading.

Broilers were commercially raised with feed withdrawal of about 8 to 12 hours prior to transport for trials using chambers 1,2,3,4, and 5 and therefore did not require an animal use protocol. Trials using chamber 6 were specifically authorized by the University of Arkansas Institutional Animal Care and Use Committee (Protocol 15031). The care and behavioral observations on the analgesia study were reported by Martin et al., 2016b. Martin et al., 2016a study on effect of various ambient temperatures reported the care and the behavioral EEG and ECG findings. Martin et al., 2016c reported the effects LAPS on broilers in light and dark and sham treatment. This paper reports the vacuum characteristics experienced in those studies. Studies using chamber 6 used Ross breed broiler chickens, average bird weight was 5.5 lbs (2.5 kg), which were and raised and housed according to Ross standards. Commercial protocols were used for provision of feed and water and feed withdrawal was 2 to 6 hours prior to catching and transport in commercial crates.

These observational studies were summarized using mean values and standard error and compared using Student t test and ANOVA using P< 0.05 (XLSTAT-BASE, Addinsoft Limited, Paris, France).

RESULTS AND DISCUSSION

Vacuum Pump Down Cycle for LAPS and Effects of Birds on the Vacuum

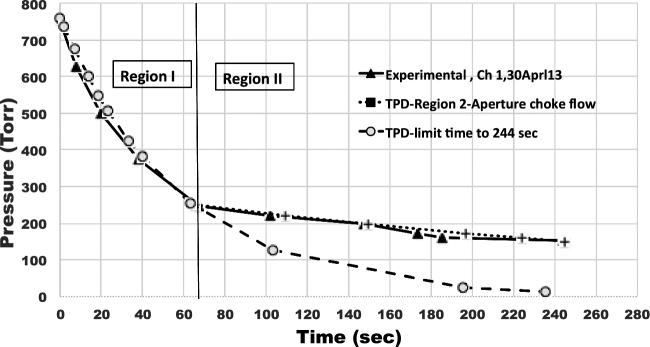

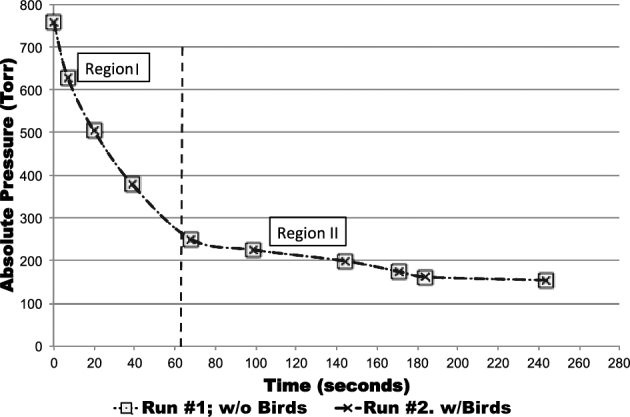

In a typical pump down of the LAPS system, the pressure-time data labeled Region I in Figure 2 show the gradual decrease in pressure in the vacuum chamber from ambient barometric pressure (∼760 Torr, 101.3 kPa, 29.92 in. Hg) to ∼250 Torr (33.3 kPa, 9.8 in. Hg) in about 67 seconds, i.e., at an average rate of −7.5 Torr/sec (−1 kPa/sec). Region I refers to that pumping time period when the vacuum gate valve was fully open. The average chamber pressure and time from without (average of 10 runs) and with (average of 5 runs) birds, respectively, plus the rates of pressure decrease over the increments between data points (data were taken every 5 inches of Hg gauge pressure in Region I) are reported in Table 1. Over the first increment, the pressure decreased from atmospheric to ∼628 Torr in ∼8 sec, giving an average rate of pressure decrease of −16.3 Torr/sec (−2.2 kPa/sec). Between 376 and 250 Torr the pressure decreased at a rate of −4.2 Torr/sec (−0.56 kPa/sec). Between vacuum pressures of ∼250 and ∼160 Torr, (Region II) the microprocessor partially closed the vacuum gate valve to reduce the effective pumping speed at the chamber. Data in Table 1 and Figure 2a show this slower reduction rate in pressure from ∼250 Torr (33.3 kPa, 9.8 in. Hg Mercury) to 160 Torr (20 kPa, 5.9 in. Hg) in 177 seconds (i.e., at an average rate of ∼ −0.51 Torr/sec (−0.068 kPa/sec)). The pressure is then held at ∼160 Torr until pumping time reaches 280 sec when the microprocessor closes the vacuum gate valve and opens the up-to-air gate valve. It takes approximately 15 to 25 seconds to backfill the vacuum chamber to ambient atmospheric pressure, depending on the type of muffler used to suppress the noise from backfilling. The pressures and times cited above for a pump down are typical. However, the cross-over pressure between Regions I and II, and the final pressure of Region II and incremental time over which the rate of decline is slowed may vary by ±10% dependent on parameters which are company proprietary (TechnoCatch LLC, Kosciusko MI).Although the rate at which the pressure falls for the first 67 seconds in Region I is similar for all birds, the “hypoxic” dose varies as oxygen availability varies with air density and levels of water vapor and carbon dioxide. In Region II pressure is lowered faster at lower temperatures to bring forward the hypoxic effects such that all birds are irreversibly stunned when at the end of the 280-second cycle.

Figure 2.

Absolute chamber pressure versus pumping time without and with birds. Note the very high degree of data overlap for the two pump downs. Region I is pump down with gate valve fully open. Region II is pump down with choke flow due to partially closed gate valve.

Table 1.

Average absolute pressure and rate of pressure change versus pumping time in chamber 1 for 10 runs with and 5 runs without birds. The experimental data for chamber 1 is compared to calculated data with no adjustable parameters. The fit between experimental and theoretical pump down data are good because the error in the pressure value was 0.2% and the maximum error in the time was 4%. Region I is that portion of the pump where the vacuum gate valve was wide open. In Region II the gate valve is closed to reduce the pumping speed and the system goes into choke flow. (*T = 60°F, relative humidity = 72, dew point = 51°F, barometric pressure = 29.81 (in. Hg); @ T = 81°F, relative humidity = 34, dew point = 50°F, barometric pressure = 29.86 (in. Hg)).

| Chamber 1 without birds* | Chamber 1 with birds@ | Theoretical pump down+ | ||||||

|---|---|---|---|---|---|---|---|---|

| Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) | Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) | Pressure (Torr)+ | Time (sec) | dP/dt (Torr/sec) |

| 757 | 0 | – | 758 | 0 | – | 758 | 0.0 | – |

| 627 | 8 | − 16.3 | 629 | 7 | − 18.5 | 627 | 12.2 | − 16.1 |

| 501 | 20 | − 10.5 | 503 | 20 | − 9.6 | 502 | 26.4 | − 9.7 |

| 375 | 38 | − 7.0 | 377 | 39 | − 6.7 | 376 | 44.7 | − 6.7 |

| 248 | 67 | − 4.4 | 250 | 68 | − 4.4 | 249 | 70.9 | − 4.4 |

| 222 | 102 | − 0.8 | 224 | 99 | − 0.8 | 125 | 114.7 | − 2.8 |

| 197 | 147 | − 0.5 | 199 | 144 | − 0.6 | 24 | 219.6 | − 1.2 |

| 172 | 173 | − 1.0 | 174 | 171 | − 0.9 | 12 | 263.8 | − 0.3 |

| 159 | 185 | − 1.0 | 161 | 184 | − 0.9 | 0.08 | 624.2 | − 0.03 |

| 153 | 244 | − 0.1 | 154 | 244 | − 0.1 | – | – | – |

The effects of birds on the vacuum pump down may be evaluated using the data in Table 1. The effect of the presence of the birds on the vacuum pump down was minimal and when plotted the data for performance of the system with or without birds overlap completely (Figure 2).

Gas Flow Regime and Calculated Pump Down Curve

It has long been recognized that the transport of gas in a vacuum system can be classified as viscous, molecular, or the transition between viscous and molecular flows (O’Hanlon, 2003). A system is in the viscous flow regime when the Knudsen number, Kn = λ/d < 0.02, where λ is the mean-free-path length between gas molecule scattering, and “d” is a characteristic real dimension of the vacuum chamber (e.g., the chamber diameter of 2.13 m). The viscous flow regime is characterized by molecule-molecule collisions occurring much more frequently than molecule-vacuum chamber wall collisions. Since the vacuum chamber pressure was always between a maximum of atmospheric pressure (760 Torr; λ∼6.5 × 10−6 cm) and a minimum pressure of ∼160 Torr (λ ∼3 × 10−5 cm), the maximum value of Kn was 1.4 × 10−7. Thus, the LAPS vacuum chamber always operates in the viscous flow regime.

To calculate the pressure versus time for a pump down, Roth (1982) used the standard relationship between the effective pumping speed at the chamber (S) and the speed of the pump (SP) and the conductance (C) of the pipe connecting the chamber to the pump:

|

(1) |

The conductance of the pipe can be expressed as shown in (2), D dominates the conductance:

|

(2) |

where D is the inner diameter of the pipe connecting the vacuum pump to the vacuum chamber, η is the viscosity of the gas, L is the length of the connecting pipe, and Pave is the average pressure of gas in the pipe, that can be expressed as:

|

(3) |

where P is the pressure of the gas in the vacuum chamber, and PP is the pressure of the gas at the vacuum pump inlet. The amount of gas removed from the vacuum chamber is expressed as Q (throughput) and is equal to:

|

(4) |

Despite C and PP being functions of pressure, the expression for Q can be integrated to result in:

|

(5) |

where terms are defined above and E = (π/128) [D4/(ηL)]. Therefore P versus t (the pump down curve) is a function of the volume of the vacuum chamber, the speed of the pump, and conductance of the pipe.

Typical pump down curves are shown in Figure 2 and tabulated in Table 1. The calculated (dashed line) pressure versus time data shown in Table 1 and Figure 3 match the experimental data (solid line) very well at pressures greater than 250 Torr and times of less than 67 seconds (Region I in Fig. 2). As discussed above, at a total pressure of 250 Torr, the microprocessor partially closed the vacuum gate valve to reduce the pumping speed. At pressures below 250 Torr, the experimental and calculated curves deviate due to neglecting the closing of the valve in the initial calculated pump down (see figure 3). Neglecting vacuum leaks and outgassing from the chickens and the vacuum chamber walls and fixtures, the area of the valve left open for the maintenance of vacuum pressures between 250 and 150 Torr is very small and represents an aperture. (O’Hanlon, 2003) When the pump inlet pressure PP divided by the inlet pressure of the orifice, P, is less than 0.52, the aperture will be in “choke flow”, i.e., the throughput of gas between the chamber and the pump will be determined by the area of the orifice and will be independent of the conductance of the pipe and of PP. (O’Hanlon, 2003) This condition applies in Region II of the pump down, and the dotted line in figure 3 results from choke-flow.

Figure 3.

Experimental (solid line with triangle symbol) versus calculated (dashed or dotted lines) pump down data. The calculated dashed line (with a circle symbol) assumes the gate valve is fully open the entire time. The dotted line with filled square symbols shows the effects of partial closing of the gate valve to develop “choke flow” at 250 Torr, 67 sec (with a constant aperture area from 67 to 245 sec). Region I is pump down with gate valve fully open. Region II is pump down with choke flow due to partially closed gate valve.

The LAPS system operates completely in the viscous flow regime, and viscous flow may be either turbulent or laminar dependent upon the Reynolds number, Re. The value of Re is equal to ρνd/η, where ρ is the density of the gas, ν is the gas velocity, d is the characteristic dimension of the vacuum system component being evaluated for flow characteristics, and η is the viscosity of the gas. (Roth, 1982) For Re > 2,100, the flow will be turbulent. For Re < 1,100, the flow will be laminar. The LAPS system always operated in the turbulent flow regime, except for the last five seconds of pumping. The characteristics of turbulent flow are eddies and whirlpools between the vacuum chamber surfaces which tends to move dust particles and other debris inside the vacuum system, and reduce by a few percent the effective pumping speed. However none of the pump down data suggest that turbulent versus laminar flow significantly change the performance of the LAPS system.

Performance of Multiple Parallel Systems

To increase the throughput of stunned birds, several parallel vacuum systems may be operated simultaneously. Each parallel system has its own vacuum pump, gate valves, pressure transducer, microprocessor, etc. The effects of pipe length and elbows in the vacuum foreline on total pressure and oxygen concentration were compared using the four parallel systems, which are designated as chambers 1 through 4. Five runs were done in each chamber at similar ambient barometric and weather conditions. The rate at which air was removed from the chamber was controlled by the effective pumping speed at the chamber (see Equation 1 above). This pumping speed is primarily controlled by the speed of the vacuum pump, and the conductance of the 15.2 cm (6 in.) Internal diameter (ID) HDPE pipe that connects the pump to the chamber, taking into account the effects of elbows and the vacuum gate valve. All four chambers had two 90°-elbows and units 1 through 4 had 2, 2, 1, and 0 45°-elbows, respectively, in the vacuum fore line. As discussed by Ryans and Roper (1986), the effects of elbows and valves in a vacuum pumping line can be accurately estimated by increasing the “effective length” of the pipe that connects the pump to the chamber. The equivalent length for a 15.2 cm ID pipe with 90° elbow in viscous turbulent flow is 4.88 m, and that of a 45° elbow is 2.44 m, while that of a valve is 1.07 m. The total equivalent pipe lengths for effective pumping speed calculation were 38.2, 25.9, 21.6, and 16.2 m for chambers 1, 2, 3, and 4, respectively. The vacuum chambers remained in viscous flow (see discussion in previous section) for all conditions of pumping during the LAPS process. The averaged pump down data for each of the four systems are shown in Figure 4 and Table 2, and the curves overlay each other. This overlap of the data show that the diameter of the vacuum pipe connecting the chamber to the pump was sufficiently large to result in the conductance, C, being much greater than the pumping speed SP, therefore Equation (1) reduces to S = SP. In other words, pump down of the vacuum chamber was controlled by the speed of the pump and volume of the chamber, not by the conductance of the pipes and fittings between the chamber and the vacuum pump. As a result, the performances of the four parallel vacuum systems were equal.

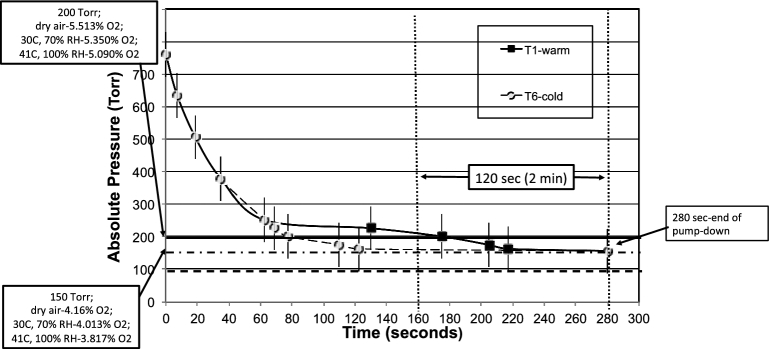

Figure 4.

Pump down data for different ambient temperatures showing that the pump down is the same from 760 to 250 Torr, but a higher pressure is maintained at warmer temperatures (T1) while lower pressures are used for colder temperatures (T6). Note that the final pressure at 280 seconds is 160 Torr for all temperatures. Also reported are the effects of water in the atmosphere on the oxygen levels. At 200 Torr, dry air contains 5.5% oxygen, but the oxygen concentration decreases to 5.35% for a temperature of 30°C, with 70% relative humidity, and further to 5.1% at 41°C, with 100% RH. Similar data are reported for a total pressure of 150 Torr. Region I is pump down with gate valve fully open. Region II is pump down with choke flow due to partially closed gate valve

Table 2.

Mean vacuum pressure and rate of pressure change versus pumping time for chambers 1 through 4. Note that the typical deviation was ±1 Torr and ±1 sec. (T = 81°F (27°C), relative humidity = 34%, dew point = 56°F, barometric pressure = 29.85 (in. Hg; 758 Torr)).

| Chamber 1* | Chamber 2* | Chamber 3* | Chamber 4* | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) | Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) | Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) | Pressure (Torr) | Time (sec) | dP/dt (Torr/sec) |

| 758 | 0 | – | 758 | 0 | – | 758 | 0 | – | 758 | 0 | – |

| 629 | 7 | − 18.5 | 628 | 8 | − 16.3 | 630 | 8 | − 16.1 | 629 | 8 | − 16.3 |

| 503 | 20 | − 9.6 | 501 | 22 | − 9.0 | 503 | 21 | − 9.7 | 503 | 20 | − 9.0 |

| 377 | 39 | − 6.7 | 376 | 40 | − 7.0 | 377 | 40 | − 6.7 | 376 | 38 | − 7.0 |

| 250 | 68 | − 4.4 | 250 | 69 | − 4.4 | 250 | 69 | − 4.4 | 250 | 64 | − 4.4 |

| 224 | 99 | − 0.8 | 224 | 104 | − 0.7 | 224 | 100 | − 0.8 | 224 | 99 | − 0.7 |

| 199 | 144 | − 0.6 | 198 | 150 | − 0.6 | 199 | 145 | − 0.6 | 199 | 144 | − 0.6 |

| 174 | 171 | − 0.9 | 174 | 175 | − 1.0 | 173 | 173 | − 0.9 | 174 | 169 | − 1.0 |

| 161 | 184 | − 0.9 | 161 | 187 | − 1.1 | 161 | 185 | − 1.0 | 161 | 182 | − 1.1 |

| 154 | 244 | − 0.1 | 154 | 244 | − 0.1 | 153 | 244 | − 0.1 | 153 | 244 | − 0.1 |

*Average of 10 cycles.

Effects of Temperature on LAPS

In the discussion above, it was not necessary to consider whether the air was wet or dry. However, in a real operation, the air evacuated from the chamber will be wet air. The behavior of most of the gases in wet air will be ideal during the creation of the vacuum for LAPS. In other words, the behavior of nitrogen, oxygen, argon, etc. will follow the ideal gas law (O’Hanlon, 2003)

|

(6) |

where P is the gas pressure in the chamber, V is volume of the chamber, N is the number of molecules of a gas in the chamber, k is Boltzmann's constant, and T is the gas absolute temperature in degrees Kelvin. The only gas in wet air that does not follow the ideal gas law near room temperature is water vapor. There are at least three important consequences of changes in temperature on the behavior of air in the LAPS system. First, changes in temperature will cause changes in the density and/or pressure of any gas. Second, changes in temperature will change the property of the gas, specifically the viscosity. But the third and most important effect is the change in the saturation vapor pressure of water in air, which will change the fractional concentration of gases in air and specifically will reduce the concentration of oxygen.

With respect to changes in the density and pressure with a change in temperature, the ideal gas law may be rewritten as P = nkT which can be rearranged to: n = P/kT where n = gas density = N/V. For two different temperatures, Thot and Tcold, where the pressure is constant and independent of temperature, then ncold/nhot = Thot/Tcold. Therefore the ideal gas law predicts that the density of cold gas is higher than hot gas when the gas pressures are constant. The presence of water vapor (and metabolic CO2) will reduce available oxygen within the parabronchi, (Powell, 2015) probably more so than in the LAPS container.

For a typical example, if the temperature ranges during the day from a low of 40°F (which is an absolute temperature of 277.59 K) in the morning to a high of 80°F (299.82 K) in the afternoon with a constant barometric pressure, the air is 8% more dense in the morning as compared to the afternoon. This situation is rarely encountered, because the barometric pressure does not remain constant. In general, the density of gas remains constant, meaning that the barometric pressure is typically higher in the afternoon than in the morning (see LeBlancq, 2011, for further information on diurnal pressure variation-tides in the atmosphere). These diurnal variations may require some changes over the course of a day to the operating conditions for LAPS. For example, empirically it has been found (Figure 5) that the modulation of the pump down gate valve must be modified for high versus low ambient temperatures. For cold temperatures, a lower pressure vacuum must be created earlier in the LAPS process. If the birds are warmer, a higher vacuum pressure versus time may be satisfactory.

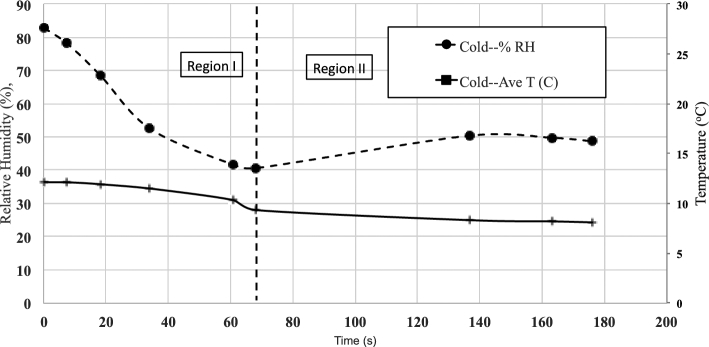

Figure 5.

Mean relative humidity (%) and mean temperature (°C) in chamber 6 as a function of pump down time in seconds for an ambient temperature range 5 to 13°C (28 runs). The RH is initially higher, decreases with pump down time over Region I (t < 67 seconds), and then increases slightly over the remaining pumping time. The temperature decreases over the Region I pump down, and remains constant for the balance of the pump down. Region I is pump down with gate valve fully open. Region II is pump down with choke flow due to partially closed gate valve

The variation during pump down of temperature and relative humidity (RH) averaged over 5 runs are shown in Figure 5. The temperature is higher at the beginning of the run, and decreases approximately 4°C during the run. This decrease in temperature is attributed to adiabatic cooling due to the work done by the change in pressure and gas density of the vacuum (Bailyn, 1994). The lower pressure leads to lower internal molecular energy and heat transfer into the system is slower than the Region I pump down time (67 sec), therefore the temperature of the system decreases are observed.

The adiabatic cooling and wet air in the system leads to the formation of fog in the vacuum system during Region I of the pump down. Formation of fog in a vacuum chamber has been reported previously, and it is a manifestation of the non-ideal gas behavior of water in the vacuum. Fog is a suspension of water droplets or ice crystals, and in the early 1900s nuclear physicists used the formation of fog tracks to identify particles emitted during nuclear reactions. In the present case, water droplets or ice crystals in the vacuum chamber results from heterogeneous nucleation on debris when adiabatic cooling is induced, e.g., by sudden pumping to a lower pressure (Wilson, 1951). Fog formation in vacuum chambers results when air with a high relative humidity experiences adiabatic cooling. Fog is first observed after reducing the pressure to approximately 660 Torr, and is no longer observed when the chamber pressure is below 450 Torr. Fogging is widely used to assist in temperature control of broiler houses and providing very high humidity is avoided it appears be beneficial for the birds. As relative humidity is falling when fog appears during LAPS it appears unlikely to pose any risk to the bird, (Aradas et al., 2005).

However, there are consequences of fog for creation and maintenance of the vacuum. As shown in Figure 5, the relative humidity decreased significantly over Region I of the pump down, but increased slightly in Region II. On the other hand, the average temperature decreased until the end of the vacuum pump down, while the fraction of oxygen decreased near the junction of Regions II and I. These data variations are consistent with the postulates that adiabatic cooling leads to fog formation. When fog forms at ∼660 Torr, the gas flow is turbulent viscous and a large quantity of water is swept out of the vacuum system as condensed water, significantly reducing the relative humidity. At the transition between Regions II and I, fog is no longer observed and the relative humidity increases due to outgassing from the birds and the wall of the chamber (Figure 5).

Oxygen Concentration versus Pump Down Time

As pointed out in the introduction, LAPS is a relatively simple system that is effective for stunning chickens, when the percentage of oxygen, equivalent to atmospheric pressure is less than 5% for periods of few minutes (Raj, Gregory and Wotton, 1991; and Raj et al.; 2008; McKeegan et al., 2013b). The normal fractional concentration of oxygen in dry air is 0.2095, therefore to stun poultry either the percent of oxygen in dry atmospheric pressure air must be reduced by using inert gases (such as nitrogen or argon), or the amount of oxygen remaining in the chamber must be reduced to that equivalent to ≤5% at atmospheric pressure, (equivalent to 38.35 Torr partial pressure of oxygen). This is achieved in LAPS at a total vacuum chamber pressure for ideal dry gases of <180 Torr for a few minutes.

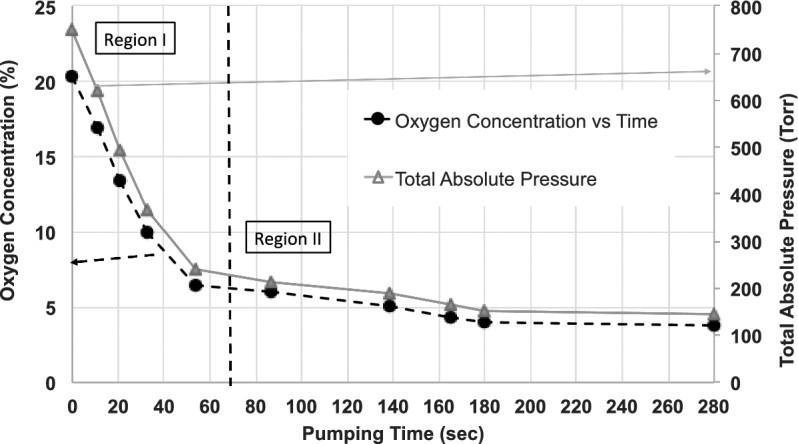

The concentration of oxygen during pump down (see Figure 4) was measured in nine consecutive runs in the small chamber (see discussion above). The vacuum system is designed and operated in the same fashion as the commercial system except for two features: a smaller chamber (cylindrical, 2.2 m in length and 1.8 m in diameter), a smaller poultry transport module (153 cm × 121 cm × 102 cm, three tiers each 23 cm height), and a manually operated door. In Region I, the vacuum chamber pressure is still reduced from ambient atmospheric pressure to an absolute vacuum pressure of 250 Torr (33 kPa) in 67 sec. A sliding gate valve is then partially closed reducing the effective pumping speed to “choke flow” conditions resulting in a slower rate of decreasing pressure. The reduction in total pressure results in a reduced oxygen partial pressure, which was measured by a solid-state electrochemical oxygen sensor. After reaching a vacuum of 160 Torr in 280 sec. the chamber was returned to atmospheric pressure using a baffled air inlet. Compensating for elevation, the starting absolute total pressure was 748 Torr (99.7 kPa). The oxygen fraction was measured using a PureAire Oxygen Sensor based upon solid-state electrochemistry. The fractional concentration of oxygen was measured for each of nine different pump downs and the average oxygen fraction versus pump down time is shown in Table 3. The standard deviation for the oxygen fraction ranged from a minimum of 0.0 to a maximum of 0.1 (at 240 Torr; error of 0.04%), while that of the time ranged from zero (t = 0 and 180 sec.) to 3.689 at 138.1 sec (2.7% error). These error rates are acceptable because they cannot cause either the oxygen levels or the time limits for LAPS to be outside those necessary for stunning of birds. The average fraction of oxygen in the vacuum chamber at ambient atmospheric conditions was 0.2068 (rather than the ideal value of 0.2095 for dry air). The oxygen fraction decreased slightly as the total pressure decreased, reaching 0.2043 at 250 Torr, 60 sec, and 0.1998 at 150 Torr, 280 sec. As discussed above, this reduction in the fraction of oxygen results from increased concentrations of water vapor in the chamber due to outgassing from the birds and from the chamber wall. Table 3 show the percent oxygen (atmospheric equivalent) concentration measured by the electrochemical cell which decreased form 20.35% at atmospheric to 3.77% at a final vacuum pressure of 150 Torr, as shown in Figure 6.

Table 3.

Average fractional and partial pressure and percentage (atmospheric equivalent) oxygen concentrations versus pump down time. The small decline in oxygen fraction (column 2) is attributed to increase water in the vacuum chamber reducing the oxygen concentration.

| Total pressure (Torr) | Average fraction | Standard deviation oxygen fraction. | Time (sec) | Standard deviation time | Oxygen partial pressure (Torr) | Percentage atmospheric equivalent oxygen |

|---|---|---|---|---|---|---|

| 748.06 | 0.207 | 0.067 | 0.000 | 0.000 | 154.68 | 20.35 |

| 621.06 | 0.207 | 0.087 | 10.889 | 0.333 | 128.35 | 16.89 |

| 494.05 | 0.206 | 0.060 | 20.444 | 0.882 | 101.72 | 13.38 |

| 367.05 | 0.206 | 0.067 | 32.778 | 0.667 | 75.53 | 9.94 |

| 240.04 | 0.204 | 0.100 | 53.778 | 1.716 | 49.05 | 6.45 |

| 214.64 | 0.204 | 0.044 | 86.778 | 2.333 | 43.74 | 5.76 |

| 189.24 | 0.203 | 0.100 | 138.111 | 3.689 | 38.35 | 5.05 |

| 163.84 | 0.202 | 0.000 | 164.778 | 1.481 | 32.77 | 4.31 |

| 151.14 | 0.200 | 0.044 | 179.556 | 3.245 | 30.19 | 3.97 |

| 143.52 | 0.200 | 0.044 | 280.000 | 0.000 | 28.67 | 3.77 |

Figure 6.

Percentage oxygen, equivalent atmosphere (left vertical axis; PureAire detector) and total chamber pressure (right vertical axis) versus pump down time (data are averages of nine runs). Region I is pump down with gate valve fully open. Region II is pump down with choke flow due to partially closed gate valve. The equivalent atmosphere oxygen concentrations at pump down times of 180 and 280 sec were 3.9% and 3.7%, respectively.

Additional Effects of Water

The elevation of Ft. Smith (143 ft. above MSL) will reduce the maximum total pressure from 760 to 748 Torr, a 1.7% reduction. For pump down of vacuum chambers, there is no preferential pumping (i.e., pumping one gas faster than another) for ideal gases in the wet screw compressor pump in the viscous flow regime. Non-ideal gases may experience higher pumping speed if a phase change occurs due to adiabatic cooling and/or compression for pumping. Assuming that the condensation to water is minimal, the fraction of oxygen in the residual gas should be constant at 0.2095 if the air in the chamber is dry. However, all real systems deal with wet air and the amount of water varies. In addition to acting non-ideally, water has inconvenient absorption energy on the vacuum chamber walls of ∼15 to 20 kcal/mole, while that of the other constituents of air are < 4kcal. /mole. (Hudson, 1998) Because of this higher absorption energy, water will have a long molecular residence time on the surface of the vacuum system and therefore will desorb later in the pump down cycle. The result will be an increase of the fraction of water and reduction of the fractions of other gases including oxygen. In the present case, the fraction of oxygen decreased from 0.2068 at atmospheric pressure to 0.1998 at 280 sec due to the slow release of water. Increased concentrations of water in the vacuum system from surface desorption is one of two major effects of water in wet air.

The second major effect of water is the reduced fractions of the constituents in wet versus dry air. The composition of air generally given is for dry air (Roth, 1982). The amount of water in the atmosphere is controlled first by the temperature and relative humidity of the air used to back-fill the vacuum system, and second by outgassing of the poultry. The saturation vapor pressure of water in air increases exponentially with temperature. (Lide, 2005). The relative humidity is equal to the partial pressure of water in the air divided by the saturation vapor pressure of water in air at that temperature. In addition, the body temperature of a chicken is ∼41°C and the saturation vapor pressure of water at this temperature is ∼7.8 kPa. If saturation were achieved at this body temperature, the effect on oxygen concentration would be a reduction from 0.2095 to 0.1943. In any case, the effect of water on the fractional concentrations of other constituents of air is to reduce them, and above 20°C, the magnitude of the reduction is significant. In addition, within the bird's respiratory system the partial pressure of both saturated water vapor and exhaled carbon dioxide can reduce partial pressure oxygen available for uptake by the blood of poultry.

The characterization of the vacuum system demonstrated that it was highly accurate and precise in delivering the specified curves, which produced predictable reductions in oxygen levels enabling it to be suitable for reliably producing a humane stun. It has many advantages over other approved killing systems in that it is automatic and does not depend on human skill to cause stunning. The monitoring and control systems using the programmable logic controller and human machine interface effect very reliable control of the vacuum produced during LAPS. As the same pressure is maintained throughout the vessel, all birds receive the same hypoxic dose. In contrast, the use of a specified gas mixture is more complex due to mixing of air and gas and can result in complex types and patterns of flow within the vessel, which makes gaining homogeneity of the mixture a challenge. There is increasing evidence that birds do not experience pain, distress, or suffering during LAPS which includes the physiological and group behavior studies by Vizzier-Thaxton et al., 2010; EEG studies by McKeegan et al., 2013a; and studies on individual bird behavior by Mackie and McKeegan, 2016; also the use of an analgesic paradigm by Martin et al., 2016b and the behavioral, ECG and EEG studies by Martin et al., 2016a, and Martin et al., 2016c. The last two studies also provide evidence of lack of fear and anxiety by demonstration of synchronized EEG pattern during first exposure to LAPS. These studies demonstrate that with relation to bird responses LAPS is at least equivalent to stunning with inert gases. The vacuum characterization and the hypoxic profiles summarized also support the equivalence of LAPS to stunning using inert gases as would be required under EU Regulation 1099/2009 for new systems of stunning in the European Union.

SUMMARY

In summary, the characteristics of a vacuum system used to stun poultry in preparation for processing for the food market have been determined. The rate of pressure change has been determined by both experiment and theory, to be consistent with previous work reporting minimum discomfort and pain during LAPS. The vacuum was shown to operate in the viscous turbulent flow regime and use of absolute vacuum pressures, rather than gauge pressures, allowed for automatic compensation of changes in the ambient pressure due to weather or to changes in elevation of the processing facility. The LAPS process consisted of a pump down from 0 to 67 seconds that was limited by the speed of the screw compressor vacuum pump. For a time period between 67 and 280 seconds, the gate valve was partially closed to slow the rate of pressure decrease to ∼0.5 Torr/sec (0.0038 kPa/sec), resulting in oxygen concentrations <5% for about two minutes. The birds became permanently unconscious due to severe hypoxia. The effects of temperature, water, and outgassing of water on the process was discussed.

Acknowledgments

This vacuum system was designed and constructed by TechnoCatch researchers and engineers. TechnoCatch LLC funded the work. The funders had no role in the study design or analysis, interpretation and publication of the results. We should like to thank Professor Yvonne Vizzier-Thaxton and Dr Karen Christensen, Centre for Food Animal Well-being, University of Arkansas, for their discussions and their support for the field studies; Rodger James and Randolph Cheek of TechnoCatch LLC, Kosciusko, Mississippi for the collection of the data that we analyzed.

REFERENCES

- Aradas N., Naas I., Salgado D.. 2005. Comparing the Thermal Environment in Broiler Houses Using Two Bird Densities Under Tropical Conditions. Agricultural Engineering International: the CIGR Ejournal. Vol. VII. Manuscript BC 03 017. Accessed 11 APRIL 2015. [Google Scholar]

- AVMA 2013. Guidelines for the Euthanasia of Animals: 2013 Edition American Veterinary Medical Association; 2013ISBN 978-1-882691-21-0: https://www.avma.org/KB/Policies/Documents/euthanasia.pdf. Accessed 5 November 2014. [Google Scholar]

- AVMA 2016. Guidelines for Humane Slaughter: 2016 edition ISBN 978-1882691-07-4. Accessed 26 August 2016. [Google Scholar]

- Bailyn M. 1994. A Survey of Thermodynamics, American Institute of Physics Press, New York. [Google Scholar]

- Cheek H., Cattaruzzi B.. 2009. “Method for humanely stunning and slaughtering poultry using controlled low atmosphere stunning”. US Patent No. 2009/0117839.

- Cheek H., Cattaruzzi B.. 2010. “Method for humanely stunning and slaughtering poultry using controlled low atmospheric pressure.” US Patent No. 7662030.

- Council Regulation (EC) No 1099/2009 of 24 September 2009 on the protection of animals at the time of killing 2009Official Journal of the European Union 303:11–30. [Google Scholar]

- Council Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 laying down specific hygiene rules for food of animal origin 2004Official Journal of the European Union; 139:55–205. [Google Scholar]

- Dawson M. D., Johnson K. J., Benson E. R., Alphin R. L., Seta S., Malone G. W.. 2009. Determining cessation of brain activity during depopulation or euthanasia of broilers using accelerometers. J. of Appl. Poult. Res. 18:135–142. [Google Scholar]

- Dawson M. D., Lombardi M. E., Benson E. R., Alphin R. L., Malone G. W.. 2007. Using accelerometers to determine the cessation of activity in broilers. J. of Appl. Poult. Res. 16:583–591. [Google Scholar]

- EFSA 2013. Scientific Opinion on monitoring procedures at slaughterhouses for poultry European Food Standards Agency; Panel on Animal Health and Welfare (AHAW) EFSA Journal :113521- DOI: 10.2903/j.efsa.2013.3521. [Google Scholar]

- Eurocontrol 2015. Hypoxia (OGHFA BN) - SKYbrary. Aviation Safety. Operator's Guide to Human Factors in Aviation. Published 29 March 2015 www.skybrary.aero/index.php/Hypoxi_a_(OGHFA_BN). Accessed 4 June 2015. [Google Scholar]

- FAO 2011. FAO in the 21st Century. Ensuring food security Food and Agriculture Organisation Rome. [Google Scholar]

- Gentle M. J., Tilston V. L.. 2000. Nociceptors in the legs of poultry: implications for potential pain in preslaughter shackling. Anim. Welf. 9:227–236. [Google Scholar]

- Gradwell D. 2006. “Hypoxia and hyperventilation” 41– 56 in Ernsting's Aviation Medicine, 4th Edition, edited byRainford D. J., Gradwell D., 2006 Hodder and Arnold/ CRC Press; Baton Rouge Florida USA. [Google Scholar]

- Hudson J. B. 1998. “Surface Science: An Introduction” (John Wiley and Sons, New York. [Google Scholar]

- Johnson C. I. 2014. A review of bird welfare during controlled atmosphere and electrical water-bath stunning. J. Am. Vet. Med. Assoc., 245:60–68. [DOI] [PubMed] [Google Scholar]

- Joseph P., Schilling M. W., Williams J. B., Radhakrishnan V., Battula V., Christensen K., Vizzier-Thaxton Y., Schmidt T. B.. 2013. Broiler stunning methods and their effects on welfare, rigor mortis and meat quality. World Poultry Science Association 67:99–112. [Google Scholar]

- LeBlancq F. 2011. Diurnal pressure variation: the atmospheric tide. Weather 66:306–7. [Google Scholar]

- Lide D. R. 2005. Handbook of Chemistry and Physics, 85th Edition, Section 14, pp19– 25 CRC Press, Boca Raton, FL. [Google Scholar]

- Mackie N., McKeegan D. E. F.. 2016. Behavioural responses of broiler chickens during low atmospheric pressure stunning. Appl. Anim. Behav. Sci. 174:90–98. [Google Scholar]

- Martin J. E., Christensen K., Vizzier –Thaxton Y., Mitchell A. M., McKeegan D. E. F.. 2016a. Behavioural, brain and cardiac responses to hypobaric hypoxia in chickens. Physiol Behav. 163:25–36. [DOI] [PubMed] [Google Scholar]

- Martin J. E., Christensen K., Vizzier-Thaxton Y., McKeegan D. E. F.. 2016b. Effects of analgesic intervention on behavioural responses to low atmospheric pressure stunning. Appl. Anim Behav. Sci, 180:157–165. [Google Scholar]

- Martin J. E., Christensen K., Vizzier-Thaxton Y., McKeegan D. E. F.. 2016c. Effects of light on responses to Low Atmospheric Pressure Stunning. Brit. Poult. Sci. 57:585–600. [DOI] [PubMed] [Google Scholar]

- Meadows D. H., Meadows D. L., Randers J.. 1992. Beyond the Limits: Global Collapse or A Sustainable Future. Chelsea Green Publishing Company. [Google Scholar]

- McKeegan D. E, Reimert H. G., Hindle V. A., Boulcott P., Sparrey J. M., Wathes C. M., Demmers T. G., Gerritzen M. A.. 2013a. Physiological and behavioral responses of poultry exposed to gas-filled high expansion foam. Poult. Sci. 92:1145–1154. [DOI] [PubMed] [Google Scholar]

- McKeegan D. E. F., Sandercock D. A., Gerritzen M. A.. 2013b. Physiological responses to low atmospheric pressure stunning and the implications for welfare. Poult. Sci. 92:858–868http://dx.doi.org/10.3382/ps.2012-02749. [DOI] [PubMed] [Google Scholar]

- OIE 2013World Organization for Animal Health, Terrestrial Animal Health Code; Section 7; Chapter 7.5 OIE: Paris, France. [Google Scholar]

- O’Hanlon J. F. 2003. “A User's Guide to Vacuum Technology”, (Wiley-Interscience, New York,). [Google Scholar]

- Powell F. L. 2015. Respiration. 301– 336 in Sturkie's Avian Physiology, sixth edition Ed: Scanes C. G., Academic Press Pub Elsevier. [Google Scholar]

- Purswell J. L., Thaxton J. P., Branton S. L.. 2007. Identifying process variables for a low atmospheric pressure stunning-killing system. J. Appl. Poult. Res. 16:509–513. [Google Scholar]

- Raj M., O’Callaghan M., Thompson K., Beckett D., Morris I., Love A., Hickman G., Howson S.. 2008. Large-scale killing of poultry species on farm during outbreaks of disease: evaluation and development of a humane containerised gas killing system. Worlds Poult. Sci. J. 64:227–244. [Google Scholar]

- Raj A. B. M., Gregory N. G., Wotton S.. 1991. Changes in the somatosensory evoked potentials and spontaneous electroencephalogram of hens during stunning in argon-induced anoxia. Br. Vet. J. 147:322–330. [DOI] [PubMed] [Google Scholar]

- Roth A. 1982. “Vacuum Technology”, Second Edition, Chapter 3. Gas flow at low pressures North-Holland, New York, pp. 62–134. [Google Scholar]

- Ryans L., Roper D. L.. 1986. “Process Vacuum System Design and Operation”, McGraw-Hill, New York, Chapter 2. [Google Scholar]

- Sams A. R. 2000. Poultry Meat Processing, First Edition, Edited bySams Alan R, CRC Press, Boca Raton, FL. [Google Scholar]

- Vizzier-Thaxton Y, Christensen K. D., WSchilling M., Buhr R. J., Thaxton J. P.. 2010. A new humane method of stunning broilers using low atmospheric pressure J. Appl. Poult. Res. 19:341–348. [Google Scholar]

- West J. B. 2005. “Robert Boyle's landmark book of 1660 with the first experiments on rarified air”. Journal of Applied Physiology 98:31–39. PMID 15591301. [DOI] [PubMed] [Google Scholar]

- Wilson J. C. 1951. The Principles of Cloud- Chamber Techniques. Cambridge At the University Press; https://archive.org/stream/principlesofclou030937mbp#page/n7/mode/2up. Accessed 15 September 2015. [Google Scholar]

- Woolley S. C., Gentle M. J.. 1998. Physiological and behavioural responses of the domestic hen to hypoxia. Res. Vet. Sci. 45:377–382. [PubMed] [Google Scholar]