Abstract

Conventional systematically-administered drugs distribute evenly throughout the body, get degraded and excreted rapidly while crossing many biological barriers, leaving minimum amounts of the drugs at pathological sites. Controlled drug delivery aims to deliver drugs to the target sites at desired rates and time, thus enhancing the drug efficacy, pharmacokinetics, and bioavailability while maintaining minimal side effects. Due to a number of unique advantages of the recent microfluidic lab-on-a-chip technology, microfluidic lab-on-a-chip has provided unprecedented opportunities for controlled drug delivery. Drugs can be efficiently delivered to the target sites at desired rates in a well-controlled manner by microfluidic platforms via integration, implantation, localization, automation, and precise control of various microdevice parameters. These features accordingly make reproducible, on-demand, and tunable drug delivery become feasible. On-demand self-tuning dynamic drug delivery systems have shown great potential for personalized drug delivery. This review presents an overview of recent advances in controlled drug delivery using microfluidic platforms. The review first briefly introduces microfabrication techniques of microfluidic platforms, followed by detailed descriptions of numerous microfluidic drug delivery systems that have significantly advanced the field of controlled drug delivery. Those microfluidic systems can be separated into four major categories, namely drug carrier-free micro-reservoir-based drug delivery systems, highly integrated carrier-free microfluidic lab-on-a-chip systems, drug carrier-integrated microfluidic systems, and microneedles. Microneedles can be further categorized into five different types, i.e. solid, porous, hollow, coated, and biodegradable microneedles, for controlled transdermal drug delivery. At the end, we discuss current limitations and future prospects of microfluidic platforms for controlled drug delivery.

Keywords: Controlled drug delivery, Microfluidic lab-on-a-chip platforms, Microfluidic devices, Micro-reservoir, Drug Carriers, Microneedles, Nanomaterials for drug delivery

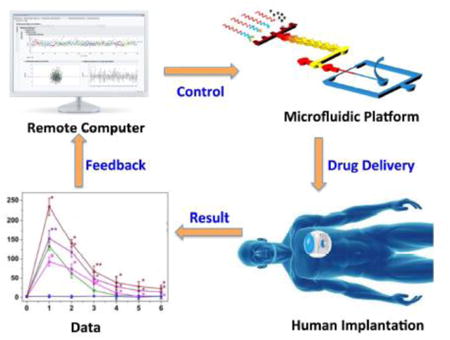

Graphical abstract

This article reviews recent advances of controlled drug delivery using microfluidic platforms which can be implanted in human bodies to control drug release in real time through an on-demand feedback mechanism.

1. Introduction

Drug delivery systems to administer a therapeutic substance to a biological system have been crucial to ensuring that the administered substances/drugs lead to desired therapeutic efficacy with minimal side effects. Drugs can be delivered through various routes including hypodermic injections, oral administration, inhalation, and transdermal administration [1]. Drug delivery systems ensure maximum efficacy of the therapeutic drugs by delivering drugs to the target sites, immediately releasing the drugs, lengthening the release of drugs or making a pulsatile release based upon disease conditions and working mechanisms of the drugs.

Conventional methods of drug delivery possess several drawbacks although they are the most common delivery methods. One of the major drawbacks of conventional drug delivery is the difficulty associated with achieving targeted delivery to specific cells and tissues as they are evenly distributed throughout the body before reaching pathological sites of action and may get inactivated or degraded while crossing different biological barriers [2]. Further, drugs may become less effective as the final effective concentrations at the site of action are lowered. Almost 80 % of the drugs are administered orally [1]. Oral administrations have limitations in terms of absorption and metabolism. Enzymatic degradation, degradation due to change in pH within the body, side effects, varying transit times, and first-pass metabolism represent some other limitations associated with oral administration [3]. Hypodermic injections lead to pain because of long needles that pierce through the nerve endings. In addition, conventional drug delivery systems usually have a burst release of drugs instead of sustained release, which decreases the efficacy of therapeutic drugs. Drugs may have to be used at higher concentrations, ultimately increasing cytotoxicity and side effects of the drugs. Finally, conventional methods are also limited by drug's poor solubility, non-specificity, and undesired release profiles [4]. Sustained release of drugs where the drugs' concentrations remain within the therapeutic range for a long time is often required for the desired therapeutic efficacy. For some specific therapeutic effects, it is desired to deliver drugs according to the circadian behavior of the disease. These chrono-therapeutic drugs for diseases such as arthritis, epilepsy, asthma, ulcer, and diabetes, where pharmacokinetics is not constant within 24 h due to rhythmic circadian of the body, may require the pulsatile release of the drugs [5, 6].

Controlled drug delivery systems started in the early 1950s with the development of oral and transdermal sustained release systems, followed by the development of zero-order release systems, microtechnology- and nanotechnology-based delivery, and self-regulated drug delivery systems [7]. The growth in the field has led to the development of numerous novel systems for controlled drug delivery, including micro-reservoir implants, transdermal patches, nanoparticles (NPs), antibody-drug conjugates, and microneedles (MNs) [8]. Controlled drug delivery systems help to improve the administration, efficiency, and pharmacokinetics of therapeutic drugs such as peptides, vaccines, enzymes, and other drugs. They improve the bioavailability of therapeutic drugs by increasing the uptake, preventing the premature degradation, maintaining drugs at the therapeutic window, and reducing the side effects by targeting drugs to particular cells or tissues. A drug delivery system that can be controlled to release the drugs in the desired amount would enable patients to achieve reproducible, on-demand, and tunable dosing at the required time. Such a system allows accurate regulation of dosage for desired effects, minimizes the related side effects, and averts repeated drug administration or implantation of devices, ultimately increasing the patient compliance [9].

1.1. Microtechnology for controlled drug delivery

Microfluidic lab-on-a-chip (LOC) is a rapidly growing field where a tiny amount of fluids is manipulated within a device with micro-scale structures inside. Microfluidic devices produced by microfabrication techniques integrate multiple components and functionalities ranging from sampling and synthesis to testing within a small device and can be automated to analyze complex biological fluids or deliver therapeutic compounds [10]. In addition, it has several other remarkable features including low-cost, portable, well-controlled microenvironments, and high throughput. Processes within a miniaturized microfluidic device can be controlled precisely and efficiently. LOC finds applications in varieties of fields including drug and gene delivery, particles and drug-carriers synthesis, detection of infectious diseases and cancers, cellular analysis, tissue engineering and so on [9, 11-14]. The microtechnology for controlled drug delivery involves the fabrication and assembly of various components for drug delivery devices, implantation of the devices within human or animal bodies, synthesis of therapeutic vessels/carriers, and delivery of the drugs to the targeted cells or tissues. Both the synthesis of therapeutic drugs and delivery to specific sites can also be integrated into a single device [15].

To address various drawbacks of conventional delivery systems, microfluidic devices are being widely used in controlled drug delivery as they have certain unique features such as the precise control of flow and integrated processing [16-18]. LOC-based devices can deliver drugs at a sustained rate, increasing the therapeutic efficiency and overcoming the burst release in conventional methods and its associated side effects [19]. Peptides, proteins or DNA-based drugs may be ineffective due to enzymatic degradation while traveling through the long pathway in conventional drug delivery system [20]. Recent developments in microfluidic technologies can help controlled and targeted drug delivery (e.g. through implanted microdevices) and minimize the delivery pathway. As LOC technology can precisely manipulate nano-liter volumes of liquid, it can synthesize drug carriers with precise sizes, shapes, and compositions, leading to a more predictable drug release profile [21, 22]. To obtain a reproducible release profile, mono-dispersed drug carriers are required, which is very challenging without the use of LOC technologies as conventional methods of emulsification generally produce multi-dispersed carriers. In addition, miniaturized microfluidic devices help to reduce pain and improve portability and safety, and in some cases, do not require trained personnel.

This article reviews recent advances in controlled drug delivery using microfluidic platforms. After a brief description of drug delivery systems and microfabrication techniques, this article reviews different microfluidic controlled drug delivery platforms based upon three broad categories, i.e. drug carrier-free microfluidic systems, drug carrier-integrated microfluidic LOC systems, and MNs-based drug delivery systems. Because MNs have attracted a lot of attention, we separate MNs into a stand-alone section. Drug carrier-free microfluidic systems further include micro-reservoir systems and microfluidic LOC devices, because of different degree of integrations. Certain drug carriers can improve the delivery and effectiveness of drugs. Hence, different kinds of drug carriers including microcapsules, nanoemulsions, and NPs, are discussed within drug carriers-integrated microfluidic systems. Similarly, MNs-based drug delivery systems include different varieties of MNs including solid, porous, hollow, coated, and dissolvable MNs, based upon their structures and modes of delivery of therapeutics drugs. Lastly, we briefly discuss current limitations and future trends in the field of controlled drug delivery using microfluidic platforms.

1.2 Microfabrication techniques

Currently, there are a variety of techniques to fabricate these microsystems, including micromilling, micromachining, photolithography, etching, deposition, mold replication, laser ablation, and assembly [10, 23-26]. In general, there are basically four processes to fabricate these microsystems, involving patterning, deposition, etching, and bonding [23]. Particularly, in microfabrication techniques, patterning is the fundamental process, which is applied to transfer the designed sketches of each component, like microchannels, onto a chip substrate such as silicon, glass, metals, and polymers [24, 27]. Photolithography and soft lithography have been widely used for patterning by transferring a pattern from a photomask onto a photoresist layer under the exposure to ultraviolet illumination [21, 24, 28, 29]. In addition, deposition of thin films is another crucial procedure, in which thin films with the thickness of micrometers are deposited usually via the physical deposition or chemical deposition or grown on a substrate. Evaporation, sputtering and electroplating are commonly used as deposition techniques for metal substrates [23]. Besides, etching methods such as isotropic and anisotropic etching are applied to remove materials selectively to create different types of features for defined patterns, with a complementary set of materials and etchants [16]. Most structures can be displayed after the sequential etching processes. Moreover, in many situations, there is a need to form a closed system. Therefore, two or even more substrates are required to be bonded together reversibly or irreversibly via various bonding processes, such as thermal bonding, anodic bonding, and photopolymer adhesives [30-34]. Since microfabrication is not the focus of this review article, more detailed information regarding microfabrication techniques can be found from these review articles and books [10, 35, 36].

2. Drug carrier-free microfluidic systems for controlled drug delivery

Microfluidic platforms have been increasingly applied for controlled drug delivery, either through the direct drug carrier-free delivery, or the integration of drug carriers on a chip [21]. Drug carrier-free microfluidic systems can be separated into two categories, namely simple micro-reservoir-based devices and highly integrated microfluidic LOC devices, with tremendous interest in implantable devices [16, 23, 25, 37].

2.1. Micro-reservoir systems

Micro-reservoir systems consisting of one or more drug reservoirs are utilized for temporary storage of drugs and have been applied to provide well-controlled platforms for carrier-free drugs loading and delivery at the microscale [38, 39]. Micro-reservoir systems which are fabricated via the microfabrication technology provide more precise control over drug delivery rates and allow physicians to actively start, modify, and stop drug release at desired locations in an interactive format [40]. Micro-reservoir systems also have the capacity to accommodate various delivery schemes, such as zero order, pulsatile, and on-demand dosing, compared with conventional burst release delivery systems [41-44]. Moreover, the use of micro-reservoirs in drug delivery, whether external to the body or implanted, has shown increased drug stability and prolonged delivery time [41]. Recently, the development of micro-reservoir-based systems for controlled drug delivery shows potential for difficult-to-treat medical applications (e.g., ocular diseases) [40, 45, 46].

Current drug delivery strategies in drug carrier-free micro-reservoir systems can be categorized into two main modes based on different actuation mechanisms: the passive mode and the active mode. Stable and prolong drug release profiles can be achieved in the passive mode, while the release time and rates can be precisely and promptly controlled in the active mode [47-49].

In the passive mode, drugs are released slowly via the osmotic potential, diffusive transport, concentration gradients, or in response to other external environmental stimuli [40, 50]. The passive mode is applied for drug delivery when the release rate is decided in advance, and usually used in self-regulated drug delivery systems [51].

For instance, Adrus and Ulbricht fabricated a micro-reservoir system within a confined support membrane as “sieving networks” to delivery dextrans by using a temperature-responsive poly(N-isopropylacrylamide) (PNIPAAm) hydrogel, with the diameter between 200 to 5000 nm. The hydrogel was synthesized via photoinitiated in situ copolymerization through grafting of linear PNIPAAm chains as pre-modification steps (Fig. 1 (A)). Specifically, the linear polymer chains were grafted to the surface of the support membrane via pre-adsorption of a photoinitiator during UV exposure. Desired transport properties of dextrans were achieved via identifying suitable filling conditions, resulting in a tunable size-selectivity delivery mechanism. Stable drug delivery can also be obtained with higher selectivity under diffusive than under convective flow conditions. When temperature increased up to 32 °C, the flux increased and rejection decreased significantly, resulting in a reversible microfiltration behavior. This temperature-responsive strategy showed broader implications on the passively controlled microfluidic systems for drug delivery [52]. Barash et al. developed another passively controlled drug delivery system for therapeutic proteins, which was based on an in situ cross-linking hybrid hydrogel combining polysaccharide hydrogels and gelatin [53]. The hybrid hydrogel was formed by injecting two compositions into a rubber mold sandwiched between two glass slides, with the whole diameter of 1.2 cm and the thickness of 3.5 mm. The addition of gelatin made the hydrogels less porous, thus contributing to a prolonged release process of proteins for more than 3 weeks. Moreover, bioactivity studies of proteins during the releasing process were conducted and the results showed high activity (>70%) maintained throughout the releasing process. This system consisted of the microporous structure as depots or micro-reservoirs for the local or systemic release of proteins, in which the protein release was tuned by varying the initial polysaccharide composition. The system was easy to fabricate and handle, where therapeutic proteins could be delivered via minimally invasive methods.

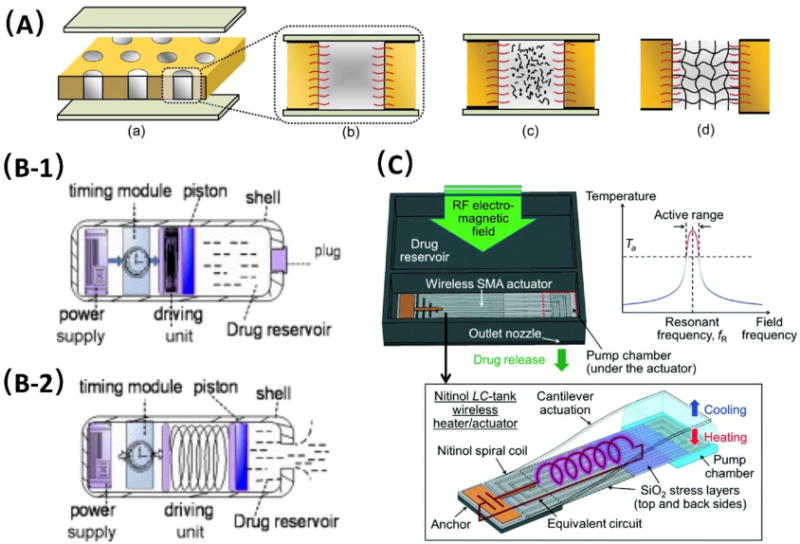

Fig 1.

Drug carrier-free micro-reservoir systems for controlled drug delivery in passive mode (A) and active mode (B and C). (A) Schematic illustration of pore-filling functionalization via in situ photopolymerization during different stages including (a) filling and equilibration of the membrane, (b) during equilibration with reaction mixtures, (c) during UV initiated in situ crosslinking polymerization, and (d) after complete reaction toward hydrogel pore-filled composite membrane. Adapt from Adrus et al. [52]. Copyright RSC 2012. (B) Schematic illustration of two stages of actively controlled drug delivery using a piston: drug inside the electronic capsule (B-1) and drug being released (B-2). Adapted from Zhuang et al. [60]. Copyright Elsevier 2011. (C) Conceptual diagram and frequency-sensitive working principle of the Radio-frequency (RF) powered and implantable chip for local drug delivery operated using tuned RF electromagnetic fields. Adapted from Fong et al. [63]. Copyright RSC 2014.

Similarly, Spieth et al. proposed another micro-reservoir-based implantable micropump for passive drug delivery [54]. Each micro-reservoir was preloaded with 0.25 μL of drug solutions before implantation, and the drug was displaced from the reservoirs due to local and irreversible thermal expansion by short heating pulses applied to a polydimethylsiloxane (PDMS) layer containing Expancel microspheres. While implanted, the system released drugs to neural tissues by diffusion, in which 0.06 μL of a drug solution could be released within the first three days after implantation. Such a system was proved to be advantageous for behavioral experiments of small animals in neuroscience, yet further improvement could be made, such as increasing the long-term stability and replacing the micropump with wireless control. In general, passive controlled micro-reservoir devices are usually less complex and much easier to fabricate, in which no external power is needed. However, drug release in passive micro-reservoir systems demonstrates limited control during delivery processes and is susceptible to environmental stimuli, such as temperature, pH, biological agents, ionic strength, and drug degradation rates [55].

In the active mode, drugs can be released at desired time and release rates from a pre-pressurized reservoir, either via mechanical, electrochemical and laser means, thermal, or magnetic actuation [38]. Generally, microelectromechanical technology has been commonly used in the fabrication of the active micro-reservoir systems, which provides great potential to develop drug delivery devices with precise electronic control of drug release, especially for implantable devices [56-58]. Particularly, actuators [59] and active valves [60] that are controlled using electrochemical and electrothermal methods are commonly employed for the precise dose release of stored drugs inside each reservoir [58, 61]. For instance, Song et al. reported an implantable microelectromechanical system (MEMS)-based device, which was actively controlled for the in vitro programmed delivery of doxorubicin [59]. This device, containing a micro-reservoir, a cannula layer, and a flexible membrane, was fabricated and sealed by PDMS and silicon with high biocompatibility. The drug release was electrochemically actuated through a diaphragm membrane. Individualized disease treatment schedules were programmed and studied by delivering doxorubicin to two pancreatic cancer cell line cultures. Colony growths turned out to be inhibited for both cell lines via the MEMS drug delivery strategy. In comparison with other MEMS devices used for in vitro/in vivo cancer treatment, the presented device enabled a relatively higher dosage of drugs (one dose of 100 μL) with good flexibility. A long-term treatment (up to seven days) was achieved by using this device, confirming the reliability of the system without the aid of replantation.

Alternatively, another MEMS-based controlled drug delivery device was proposed by Zhuang et al. which was actuated by a piston and applied for drug release in the alimentary canal [60]. The device was fabricated with a length of 30.0 mm and an external diameter of 10.6 mm, involving four components: a time module, a driving unit, a microfluidic chamber for drug reservoir, and a power supply, as shown in Fig. 1 (B-1). All components were integrated to form a swallowable capsule, which had an interface to set the timing parameter and an indicator signal to monitor the working state. Once the system was powered on, the desired dose of the fluid drug (up to 0.5 mL) was thus released from the reservoir through a one-way valve activated by a piston (Fig. 1 (B-2)). The proposed micro-reservoir system was further tested both in vitro and in vivo. As a proof-of-concept, this device was claimed to be superior in the accuracy of drug release time and turned out to be unaffected by digestive tract liquid, though the presented device could be further miniaturized.

Recently, some important improvement of actively controlled micro-reservoir drug delivery systems has emerged to apply wireless actuation strategy. However, the usage of the external power, especially the wired connection of electrical circuitry, causes complexities and inconvenience for drug release [40, 62, 63]. Farra et al. developed an implantable MicroCHIPS® device which can be triggered wirelessly. This device was fabricated using a biodegradable polymer containing lyophilized proteins and small molecular compounds and could be used to activate individually addressable reservoirs which held 300 nL of the drug, human parathyroid hormone fragment (1-34) [PTH(1-34)], through a thermal mechanism. The drug dosing can be terminated without the aid of device extraction. This MicroCHIPS® device has been further used for successful human clinical trials of subcutaneous delivery of an anabolic agent for the treatment of osteoporosis [64]. Similarly, Rahimi and Takahata developed another implantable micro-reservoir drug delivery device which was wirelessly controlled by radiofrequency magnetic fields [65]. This device was fabricated with thermos-responsive hydrogel microvalves which could be activated by a specific resonant frequency. Therefore, the model drug (fluorescein) was released from reservoirs at the desired rate by tuning the frequency of the magnetic field and showed no detectable leak for 12 hours.

In addition, Huang et al. proposed another wirelessly controlled drug delivery system using electrolysis [66]. The reservoirs were fabricated and sealed using PDMS through soft lithography, and each reservoir was 210 μm in length and 110 μm in width. Wireless components including a receiver, microcontrol unit, regulator, clock divider, and power-on reset were integrated for remote drug activation with the total size of 2.48 mm2. The printed circuit board (PCB) was also integrated on the chip. Electrolysis was applied to generate microbubbles with the power of 7.57 mW to provide the force to open the reservoirs, thus releasing drugs. In vivo studies were conducted by delivering a model drug, a fluorescent dye (Rhodamine B). Fast response was achieved after the drug was released, and only 1.5 s was needed to open the reservoir after the opening command was given to the device. This approach provided a novel method to introduce the wireless control by using electrolysis and further broadened its biomedical applications. Another wireless implantable chip was presented by Fong et al., in which a nitinol-based pump was integrated for radio-controlled local drug delivery [63]. This device was fabricated with a polyimide casing (10 × 10 × 2 mm3), and consisted of a drug reservoir with the volume of 76 μL, a positive displacement pump, and check valves created by micromachining Parylene C. Pumping in the device was achieved by a wireless shape-memory alloy (SMA) actuator, which was based on a biocompatible nitinol, serving as a frequency-sensitive heater. The chip was designed to have a rectangular spiral-coil shape with an integrated capacitor to form an inductor-capacitor (LC) tank, and the working principle is illustrated in Fig. 1(C). The stress layers of the compressive SiO2 film were patterned on the nitinol spiral coil to fix the capacitor side on the substrate. The resonant radio-frequency (RF) nitinol actuator was applied for wireless control by tuning the radiation of the RF electromagnetic field, through which enough force was produced to pump the drug-filled Parylene chamber, thus releasing the drug with a single release volume of 219 nL. This device was further used for anabolic osteoporosis treatment, and demonstrated good drug- loading and delivery performance for up to 5 months without refilling, with an output power of 1.1 W. The frequency-sensitive wireless control principle provided promising potential to integrate multiple actuators directly for the delivery of multiple drugs from a single chip, whereas the device design could be optimized to improve the performance of the wireless actuator in force as well as the speed.

Along with the integration of wireless actuation, there has been some other improvement on actively controlled devices recently, in order to meet the requirements of different kinds of drugs, such as developing multi-reservoir microdevices, and the use of refillable drug reservoirs [37, 67-70]. By developing multi-reservoir devices, the consequences of a reservoir loading failure can be minimized, and the dosing from each reservoir can be controlled simply and individually at its desired release rate without metering by actuators or valves [68, 69]. The development of refillable micro-reservoirs can reduce the dependency on a large reservoir size, thus increasing the drug loading volume as well as reducing the sizes of whole devices. However, there are some issues while using refillable micro-reservoirs drug delivery systems, involving running risks to the patients when the devices were implanted to a fragile and sensitive part of the body like eye tissues, and difficulties to avoid the overfilling of the reservoir due to the lack of filling indicators [71-76]. Overall, actively controlled micro-reservoir drug delivery systems demonstrated to be advantageous over the passively controlled counterparts at the release time, rates, and real-time adjustment, especially after implantation. However, the complexities of the design and fabrication and inconveniences for the connection between actuation powers and drug release sections on actively controlled devices restricted their broad applications [77, 78].

2.2. Highly integrated drug carrier-free microfluidic lab-on-a-chip devices

Other than micro-reservoir devices, highly integrated drug carrier-free microfluidic lab-on-a-chip (LOC) devices, which integrates more components than micro-reservoirs have also been applied in controlled drug delivery systems. In comparison with micro-reservoir devices, these devices usually consist of substrates, micro-reservoirs, microchannels or microcapillaries, and micro-valves or actuators [16, 22, 23, 25]. The fabrication procedures for these devices are more complicated and require intensive integrations as compared to the fabrication of micro-reservoir systems.

Similar to micro-reservoir systems, highly integrated microfluidic LOC devices can also be categorized into the passive mode and the active mode [23]. In the passive mode, osmotic potentials, diffusive transports, and concentration gradients have been widely applied in microfluidic LOC devices, where the release profiles involving the dosage and rates can be simply modulated by changing the geometries of micro-channels [16, 25]. For example, Lee et al. proposed an implantable microfluidic LOC drug delivery device for releasing bupivacaine hydrochloride (BHCl) at a constant rate [79]. The device was constructed by using 85/15 poly (L-lactide-co-glycolide) and contained a drug reservoir (80 μm in depth) and two microchannels (20 μm in width × 20 μm in depth), which were finally bonded via a thermal bonding process. Furthermore, a co-delivery profile of acidic additives was applied to minimize the issue of BHCl precipitation. Cumulative release profiles of the devices with BHCl and other acidic additives were investigated in vitro by varying different geometric parameters. The amount of drug release was measured by the specific absorption of UV light at 262 nm. The release rate via diffusion was demonstrated to follow the Fick's law, thus forming a zero-order drug delivery profile for a week without the initial burst. Lee et al. developed another implantable drug-delivery microchip for controlled delivery of diclofenac sodium (DS). The microchip was made of poly(methyl methacrylate) (PMMA), consisting of a pair of microchannels and micro-wells [80]. A water-soluble polymer, polyethylene glycol (PEG), was used to fill the microchannels and worked as a drug diffusion barrier. The release rates varied according to the channel dimensions. The cross-sectional areas and lengths of micro-channels were optimized to modulate the drug release profile. As a result, this microchip with micro-channels exhibited almost zero-order drug release for 31 days (R2 > 0.996) after the immediate release onset on day 0.5. DS could be released in a sustained manner with a minimized initial burst. After implantation in living rats, the microchip showed good biocompatibility and the released drug in the blood maintained at 148 ng/mL-225 ng/mL for the first 23 days.

Alternatively, another passive implantable ocular drug delivery device was fabricated using PDMS by Marsh et al., which consisted of microchannels embedded between cover layers with a drug reservoir [81]. Six different microchannel configurations were designed (within a range of 1.5 ∼ 8.0 mm in length, 5 ∼ 100 μm in depth, and 50 ∼ 500 μm in width), and analyzed for their diffusion characteristics. The obtained result showed that the delivery of the Fluocinolone Acetonide drug was driven only by the concentration gradient. Two devices were finally selected to meet the diffusion rate specifications (less than 0.07 nL/min) for the ocular drug delivery, which produced a constant delivery rate, and was favorable for the eye disease treatment. Additionally, Ferrati et al. developed another passively controlled drug delivery on another implantable LOC device with nanochannels as small as 2.5 nm. These nanochannels controlled the release of drugs by physical-electrostatic confinement, resulting in constant drug diffusion, as shown in Fig. 2(A) [82]. By varying the size of nanochannels, sustained and constant plasma levels of various drugs such as leuprolide, letrozole, octreotide, and human growth hormone were delivered at clinically relevant doses. This device was demonstrated to maintain sustaining target doses for up to 70 days after its implantation. Further validation was achieved by introducing a PhoA pathway inhibitor on the drug delivery system to prevent chronic rejection of cardiac allografts in rats. This platform has the potential for long-term treatment, especially in chronic conditions.

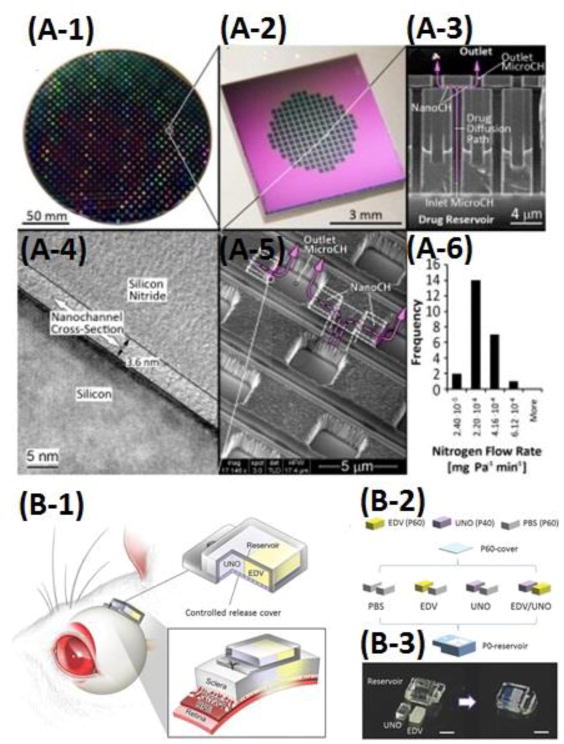

Fig 2.

Drug carrier-free microfluidic LOC systems for controlled drug delivery. (A1-A6) A nanochannel-controlled drug delivery system. (A-1) Image of a wafer containing ∼700 nanochannel membranes; (A-2) A nanochannel membrane; (A-3) A cross section showing the vertically oriented inlet and outlet microchannels connected by the horizontally oriented nanochannels; (A-4) A transmission electron micrograph (TEM) of a nanochannel; (A-5) A scanning electron micrograph (SEM) of the outlet microchannels; (A-6) A histogram showing the results of quality-control gas testing performed on 24 membranes. The pink arrows depict the drug delivery path. Adapted from Ferrati et al. [82]. Copyright 2013 Elsevier. (B-1) Schematic of an implantable device on the rat sclera. (B-2) Device conditions for in vivo study of synergistic protective effects of EDV and UNO. (B-3) Photographs of the device before assembling and after assembling. Adapted from Nagai et al. [84]. Copyright 1999-2017 John Wiley & Sons, Inc.

In the active mode, various controllers or actuators have been integrated on microfluidic LOC devices for drug delivery, in which drug release was actuated and controlled either manually by applying an external power, or wirelessly by using a magnetic field. Lee et al. presented a microfluidic-based device to generate on-demand combinatorial dilutions of all input samples in the range of a 3D simplexcentroid [83]. The combinatorial device was designed based on a microfluidic network which allowed adjusting the mixing ratios and desirable concentrations of samples. This combinatorial dilution module could generate a full set of seven combinations of the three drugs (Mitomycin C, Doxorubicin, and 5-FU) while the diluted samples flowed through the device. The device was also integrated with an initial PDMS concentration control module involving a single common channel to dilute samples independently in response to variable input flows. Computational simulations were performed to investigate the performance of the initial concentration controller. As a proof-of-concept, this integrated device was applied to perform a simple combinatorial cytotoxicity test using three drugs on MCF-7 cancer cells. Another microfluidic LOC platform was proposed by Nagai et al. for controlled transscleral co-delivery of two drugs, edaravone (EDV) and unoprostone (UNO), to the retina in rats in the active mode [84]. This LOC device, as shown in Fig. 2(B), was integrated with a controlled-release cover and drug formulations. The drug formulations and the cover were fabricated based on the photopolymerized tri(ethyleneglycol)dimethacrylate (TEGDM) and poly(ethyleneglycol)dimethacrylate (PEGDM). The drug release of both EDV and UNO could be controlled at independent release rates via the transscleral route. The active release of both drugs was achieved by changing the ratio of PEGDM/TEGDM in the formulations and its cover. This system provided better synergistic retinal neuroprotection against light injury in rats, compared with single-drug-loaded devices, and thus a safer and more bioavailable therapeutic method than intravitreal injections for retinal disease treatment.

Similarly, Pirmoradi et al. developed a magnetically controlled MEMS device for on-demand release of an antiproliferative drug, docetaxel (DTX) [67]. The LOC device consisted of a drug-loaded micro-reservoir (6 mm × 550 μm) which was sealed by an elastic magnetic PDMS membrane (6 mm × 40 μm), and a laser-drilled aperture (∼100 × 100 μm). By applying a magnetic field, the drug solution was released due to the deformation of the magnetic PDMS membrane. Controlled DTX release at a rate of 171 ± 16.7 ng per actuation interval was achieved for 35 days under the 255- mT magnetic fields, in which the background leakage of drug solutions through the aperture could be negligible. Moreover, the biological activity of the released drug was investigated by studying cell apoptosis of two cell lines, Human umbilical vein endothelial cells and PC3 (prostate cancer) cells. Reproducible release rates were achieved and the full pharmacological efficacy of drugs were maintained within the device for more than two months. Although this device was at the proof-of-concept stage, it provided a promising platform for drug delivery in nanomolar concentrations, especially for hydrophobic drugs. More recently, another pressure-driven drug release study was performed on an implantable microfluidic LOC device based on induction heating by Jo et al. [85]. The delivery device consisted of a drug reservoir, a microchannel, and an actuator chamber, all of which were integrated on a semicircular copper disc (5 mm × 6 mm × 100 μm) with a thermally conductive tape in between. Nitrogen gas was generated by induction heating of azobisisobutyronitrile to act as the driving force, and thus the entire drug solution (28 μL) was driven out of reservoirs and released through micro-channels at the rate of 6 μL/s under the magnetic intensity of 160 μT. After implantation in the subcutaneous skin layer of a mouse, a highly concentrated calcein solution as a model drug was completely released from the device under the wireless actuation in 5 s, implying that more biological and medical applications could be achieved with this wireless actuating device.

In addition to these aforementioned microfluidic LOC devices for active drug delivery, there are also some other LOC devices focusing on the integration of microelectrodes to facilitate controlled drug delivery to research animals, humans, and brain-machine interfaces [86]. Those integrated microelectrodes serve different functions such as microheaters [54], catalysts [37], or microprobes [87]. For example, Spieth and his colleagues developed a NeuroMedicator device for behavioral studies in rodents and they further improved this device by integrating the wireless control to create a miniaturized electrodes-based drug delivery system using PMMA [54]. This compact device (20 × 17.5 ×5 mm3) integrated with a microheater was composed of a microelectrodes-based PCB, individual liquid reservoirs with a thermally expandable layer for actuation, two silicon microprobes, and fluidic microchannels. All components were implemented into a cyclic olefin polymer plate and sealed by an elastic thermoplastic elastomer membrane. After drug loading, the expandable material under the reservoirs was locally heated and became inflated by the microheater, which was controlled and pre-programmed via the wireless microcontroller, allowing the delivery of drug solutions with the volume of 0.3 μL per reservoir. The Neuromedicator as a single wireless headstage was loaded with the NMDA receptor antagonist 3-((R)-2-Carboxypiperazin-4-yl)- propyl-1-phosphonic acid, and finally implanted into the medial prefrontal cortex of a rat to perform a behavioral test of visual attention and impulsivity (the 5-choice serial reaction time task, 5-CSRTT). As a result, both electrophysiological recording and controlled drug delivery were successfully accomplished on this highly integrated device [48]. Similarly, a refillable and implantable micropump system integrated with a microelectrode-based actuator was developed by Gensler et al., and for the first time applied for controlled drug delivery in small animals (e.g. mice) [37]. This device fabricated on the biocompatible silicone rubber included a drug reservoir, a refill port, a catheter, a highly integrated electrolysis actuator, and a check valve to ensure safe dosing. The bellows electrolysis actuator was constructed with a pair of interdigitated platinum electrodes and a bellows filled with electrolytes, possessing both ON and OFF states. When the electrolysis actuator was set to ON, hydrogen and oxygen gasses were generated by the electrolysis reaction, serving as the driving force to allow the fluid surrounding the bellows to flow out of the reservoir to the desired site. Inversely, the platinum microelectrodes acted as a catalyst to recombine water when at the OFF state. Therefore, the release rate of the drug could be adjusted to achieve the desired delivery regimen. The device was further implanted in mice for anti-cancer drug delivery, showing potential for not only drug delivery, but also highly flexible pharmaceutical studies in research animals.

Alternatively, Altuna et al. designed another microelectrode-based microfluidic device with multiple fluidic channels for simultaneous depth recording and drug delivery using the polymer SU-8 as the structural material [87]. The electrodes were employed to obtain the simultaneous recordings of neuronal activities at the microscale resolution via cyclic voltammetry. In addition, the tetrode-and linear-like electrode pattern was combined with both single and double fluidic microchannels, which enabled the independent drug delivery. The device acting as an encapsulated microprobe was capable of recording detailed spatiotemporal features of local field potentials and single-cell activities at the high resolution. Moreover, drug delivery in the brain was achieved with high spatial and temporal precision through in vivo studies of an anesthetized rat using a fluorescent vital dextran, Texas Red, as a model drug. The designed device was demonstrated to allow simultaneous monitoring of brain activities and drug delivery precisely in a range from tens of nanoliters to a few microliters.

3. Integration of Drug Carriers in Microfluidic Platforms

Drug carriers are defined as the substances which are incorporated to improve the delivery and the effectiveness of drugs [88-90]. A wide variety of drug carriers have been studied and employed in controlled drug delivery with some significant features such as the precise targeting ability, the accurate release of drugs, and the improved pharmacokinetic and biodistribution characteristics of drugs, and so on. Microfluidic platforms offer great opportunities especially for production and screening of drug carriers for controlled drug delivery [91]. The properties of the synthesized drug carriers using microfluidic platforms can be effectively and reproducibly modified at high throughput and low cost since the geometries and flow rates of the microfluidic devices can be easily adjusted. In this section, most widely used drug carries integrated into microfluidic platforms are categorized into three major types: microcapsules, nanoemulsions, and nanoparticles, and the synthetic process and applications of each type in controlled drug delivery are elaborated, as follows. The main materials, the size, synthetic methods, drugs, and drug targets/applications of different drug carriers integrated into microfluidic platforms are summarized in Table 1.

Table 1. Summary of different drug carriers integrated into microfluidic platforms.

| Drug Carrier Type | Main Material | Size | Synthetic Method | Drug | Target/Application | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| Microcapsules | P(NIPAM-co-AAPBA-co-AAc) | ID ∼240 μm; OD ∼360 μm | Microfluidic double emulsion | Rhodamine B; insulin | Glucose-responsive controlled release | [99] | ||

| PAA-b-PMMA | OD ∼120-150 μm | Microfluidic double emulsion | -- | pH-responsive controlled release | [100] | |||

| PDM | ID ∼294 μm; OD ∼402 μm | Microfluidic double emulsion | -- | pH-responsive controlled release | [101] | |||

| Alginate; chitosan | OD 472-740 μm | Electrostatic microfluidic droplets | Ampicillin; diclofenac | pH-responsive controlled release; Dual-drug carriers | [102] | |||

| Ca-alginate | OD 60-105 μm | gradient-microfluidic droplets | BSA | Pharmaceutical area; Therapeutic proteins | [103] | |||

| Ca-alginate | ID ∼383 μm; OD ∼467 μm | Microfluidic double emulsion | BSA | Pharmaceutical area; Therapeutic proteins | [104] | |||

| PVA, PCL, PEG | OD 23-47 μm | Microfluidic double emulsion | BSA | Pharmaceutical area; Therapeutic proteins | [105] | |||

| PAH, PSS, FITC | OD 50-80 μm | Microfluidic droplet merging and droplet storage functions | MnCO3 | Drug effects on specific cells | [106] | |||

| Nanoemulsions | Six dietary lipids (corn oil, canola oil, olive oil, palm oil, coconut oil, MCTs) | ∼160-180 nm | Micro-fluidization | BC | Caco-2 cells | [133] | ||

| Labrafil M, Tween 80, ethanol | ∼30-50 nm | Spontaneous emulsification | AB | Heart | [134] | |||

| Soybean oil, PEGylated lipids, oleic acid-coated FeO, Cy7 | 50 nm | Immediate evaporation | PAV | Kidney, liver | [138] | |||

| PFPE | 180 nm | Self-assembly and high energy emulsification | Celecoxib | FSDCs | [139] | |||

| PAM | 20-32 nm | Rapid microfluidic mixing | Ketoprofen | Gastro intestinal tract | [140] | |||

| NPs | Lipid NPs | POPC, cholesterol, triglyceride triolein | 20-50 nm | Rapid microfluidic mixing | Doxorubicin | Pharmaceutical area | [132] | |

| DLinKC2-DMA, phospholipid, cholesterol, PEG | ∼80 nm | Rapid microfluidic mixing | siRNA | Therapeutic siRNA | [152] | |||

| Polymer NPs | Chitosan | 75-122 nm | Rapid microfluidic mixing | Paclitaxel | Anticancer drug | [155] | ||

| Chitosan | ∼73-216 nm | Rapid microfluidic mixing | Paclitaxel | Anticancer drug | [156] | |||

| Chitosan | 200-300 nm | Rapid microfluidic mixing | Clindamycin phosphate; tretinoin | Transdermal multidrug delivery | [157] | |||

| PLGA-PEG | 25-200 nm | Rapid microfluidic mixing | Docetaxel | Drug discovery and clinical translation | [175] | |||

| Ag@CD NPs | 20-60 nm | Conventional method | Dihydro-artemisinin | Monitoring of drug effect on cancer cells | [177] | |||

| Carboxymethyl chitosan, PAMAM dendrimer | ∼50 nm | Conventional method | -- | Monitoring of drug effect on cancer cells | [178] | |||

| Nano-sized polymeric conjugates | FA, RA | 130 nm | Rapid microfluidic mixing | Heparin | KB and A549 cells | [169] | ||

| PEG, PCL, PEI | 179 ± 11 nm | Rapid microfluidic mixing | siRNA | SKOV3 cells | [171] | |||

| Hybrid NPs | PLGA, cholesterol | ∼103-106 nm | Rapid microfluidic mixing | Doxorubicin; combretastatin A4 | Anticancer drug | [174] | ||

Note, chemical structures and formulas of small molecular drugs are shown in supplementary Table S2.

3.1. Microcapsules

With a pore size of a few micrometers, excellent properties of biocompatibility and biodegradability, and capability of targeted or programmed drug release, microcapsules are very attractive drug carriers for controlled drug delivery [92]. The conventional approaches (e.g. the bulk layer-by-layer technique) for manufacturing microcapsules have the problem of low encapsulation efficiency because of the post-fabrication loading [93]. In addition, the functions and applications of the microcapsules are often restricted by lack of monodispersity, material stability, and diversity. The droplet-based microfluidic double emulsions, or in other words “emulsions of emulsions” or “droplets-in-droplets” (oil-water-oil or water-oil-water), are complex systems that the dispersed droplets contain one or more types of smaller dispersed droplets themselves. It provides a powerful tool with flexibility and reliability for manufacturing complex and uniform microcapsules with desired properties by precise control over the size distribution and scale-up possibility [94] and demonstrates enormous potential for drug carrier synthesis and controlled release of encapsulated actives [95, 96].

Glucose and temperature-responsive microcapsules have demonstrated promising applications for various biomedical applications including controlled drug (e.g. insulin) release and biomolecular sensing [97, 98]. However, the monodispersity of microcapsules as a critical factor for the precise loading control and the release kinetics of encapsulated substances is still a challenge [99], which affects the potential applications of glucose and temperature-responsive microcapsules. A microfluidic double-emulsion approach was developed to synthesize monodisperse microcapsules for glucose response at the physiological temperature, demonstrating a promising self-regulated drug delivery model for diabetes and cancer therapy [99]. In the polymer hydrogel shell of the synthesized microcapsules, the temperature-responsive poly(N-isopropylacrylamide) network, the glucose-responsive 3-aminophenylboronic acid moiety, and the acrylic acid moiety were used for actuation, glucose response, and adjusting the volume phase transition temperature of the shell, respectively. The prepared microcapsules demonstrated reversible and repeated swelling and shrinking response to glucose concertation changes within the physiological blood glucose level (0.4-4.5 g/L) at the physiological temperature of 37 °C. The potential application of the glucose-responsive microcapsules for controlled drug release was successfully demonstrated by using model drugs, rhodamine B and fluorescein-isothiocyanate-labeled insulin.

Controlled drug release of pH-responsive microcapsules has been achieved by using microfluidic double emulsions. The biocompatible pH-responsive polymer shells of the produced microcapsules could dissolve and degrade at a desired trigger pH, and release the active drug molecules or chemicals encapsulated in microcapsules at a prescribed rate. This goal was achieved by fabricating hybrid solid shells composed of a precisely controlled mixture of a pH-responsive polymer and another pH-unresponsive polymer with varying proportions on a glass capillary microfluidic device, and by carefully controlling the thickness of the shells [100]. The poly(N, N-dimethylaminoethyl methacrylate) (PDM) with both biocompatibility and cationic pH-responsive properties was innovatively used for the preparation of pH-responsive microcapsules [101]. Because of the protonation of -N(CH3)2 groups in the cross-linked PDM networks, the prepared microcapsule swelled at low pH. High pH-sensitivity of the microcapsules was achieved at high pH and low cross-linking density during the synthesis process. The pH-responsive microcapsules can be used as carriers for controlled drug delivery for tumor therapy. Recently, dual pH-responsive microcapsules were presented as a remarkable candidate for dual-drug carriers [102]. Generated by combining both electrostatic droplets and microfluidic droplets, the microcapsules were composed of a monodisperse core (alginate) and shell (chitosan) structure with dual pH-responsive drug release functions in both acidic and alkaline environments. Two model drugs, ampicillin and diclofenac, respectively loaded in the chitosan shell and the monodisperse were used for the drug delivery study. Compare to the respective core or shell particles, the core-shell structure microcapsules exhibited better drug release efficiency than individual core or shell particles and demonstrated positive cell viability of about 80% in a biocompatibility test.

Calcium-alginate microcapsules with large cavities have been efficiently synthesized using microfluidic approaches to encapsulate drugs or nutrients such as therapeutic proteins for drug delivery and pharmaceutical applications. For example, by using gradient-droplet-based microfluidics, different sizes of monodisperse calcium-alginate microcapsules (diameters: 60-105 μm) with different concentrations of a model protein (bovine serum albumin, BSA) were simultaneously generated for drug release [103]. The preparation of calcium-alginate microcapsules was also reported via internal gelation in microfluidic double emulsions. The internal gelation was induced by crosslinking alginate polymers with Ca2+ ions initiated by UV exposure of the photoacid generator on CaCO3 particles for double emulsions. Proteins such as BSA can be encapsulated after the preparation of microcapsules, providing an alternative route for loading active drugs or nutrients into microcapsule carriers without inactivation during the microcapsule preparation [104]. This microfluidic double emulsion approach was demonstrated as a powerful technique to develop microcapsule formulations of therapeutic proteins. With an 84% high encapsulation efficiency of proteins (i.e. BSA), the microcapsules were stable up to 4 weeks and released 30% of their content within 168 h [105].

Recently, a novel droplet-based microfluidic device with functions of both droplet merging and droplet storage for controlled drug release from microcapsules was reported for studying drug effects on specific cells [106]. The microcapsules were produced by using a simple layer-by-layer nanoassembly process with a drug model MnCO3 encapsulated inside. The merging function unit and the storage function chambers were used for dynamically adding the control solution into the droplets and for collecting droplets that contained drugs within the microcapsules, respectively. The controlled release of drugs from specific microcapsules in the storage chambers could be monitored for an extended period of time. As a controlled drug release microfluidic platform, this system is especially useful for single cell analysis by studying the drug effects on specific cells in a controlled manner.

3.2. Nanoemulsions

Nanoemulsions refer to multiphase colloidal dispersion, which contains small particles or droplets with the average diameters ranging from 20 to 200 nm (transparent), or up to 500 nm (milky appearance) [107-110]. Since the preparation of first nanoemulsions in the 1940s, they have been widely used for drug delivery. Based on their compositions, there are three types of nanoemulsions: oil-in-water, water-in-oil, and bicontinuous. In all three types of nanoemulsions, the interface is stabilized by various surfactants and/or co-surfactants [111]. There are abundant merits for nanoemulsion-based delivery systems over other dosage forms, such as high surface area, unique transparent appearance, tunable rheology, good stability and bioavailability, and rapid and efficient penetration of the drug moiety [111-118]. Nanoemulsion is currently employed as an important drug carrier in the development of drug formulations for providing pharmaceutically accepted ingredients [112, 119-121].

There are currently several kinds of techniques for the preparation of nanoemulsions, namely, ultrasonication, the high-pressure valve homogenization, and the microfluidization technology [111, 122-124]. The microfluidization technology relies on microfluidic platforms, and the general principle of microfluidization involves the high-pressure streams (aqueous phase and oil phase) moving towards to the interaction chamber or an impingement area, thus causing a high shearing action and fine emulsions within the submicron range [124]. Microfluidization technology was reported to achieve the smallest particle sizes with less heat produced, thus resulting in a more efficient nanoemulsification process under the same homogenization conditions, compared to other nanoemulsion methods [125, 126]. In this section, we focus on recent advances of nanoemulsions as drug carriers for controlled drug delivery using microfluidic devices (Table 1) [118, 127].

Nanoemulsions have been applied to enhance numerous properties of drug molecules, including the stability, solubility, bioaccessibility, and bioavailability [109, 112, 119, 127-131]. The stable triglyceride nanoemulsions with the size ranging from 20 to 50 nm were developed for the first time by Zhigaltsev et al. for loading doxorubicin stably and efficiently [132]. The nanoemulsions were produced on a microfluidic mixing device, as illustrated in Fig. 3 (A), which was composed of a 200 μm wide and 79 μm high mixing channels fabricated by soft lithography. Lipids in ethanol and an aqueous buffer were pumped into two inlets respectively using a syringe pump, leading to the rapid mixing of the injected streams using a staggered herringbone micromixer (SHM). Doxorubicin hydrochloride was dissolved in saline and added to the ammonium sulfate-containing lipid nanoparticles (LNP), and the fluorescence intensities were measured to determine the loading efficiencies by varying the drug-to-lipid molar ratios. Approximately 100% of loading efficiencies were observed under the optimized drug-to-lipid ratios up to 0.2 (mol/mol). This method allowed the robust “bottom-up” synthesis of nanoemulsions with well-defined size.

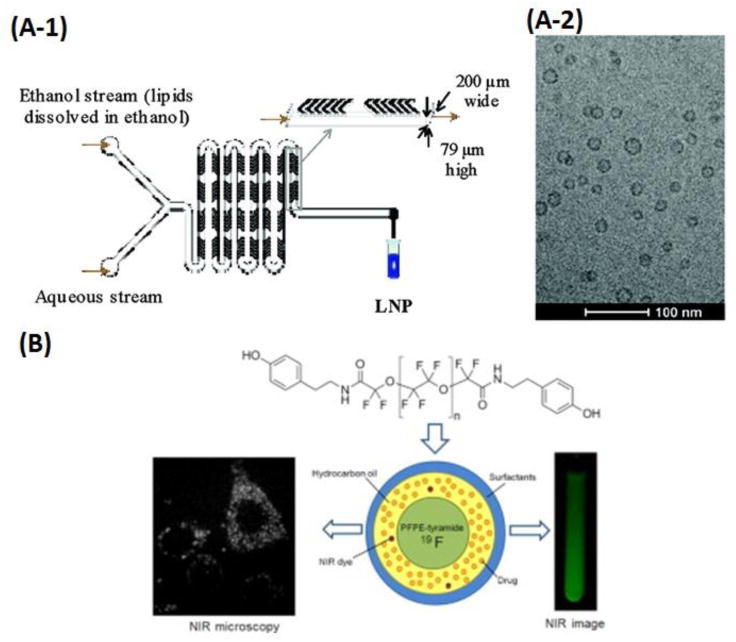

Fig 3.

Syntheses of nanoemulsions-based drug carriers in microfluidic platforms. (A-1) Schematic of LNP formulation process employing a staggered herringbone micromixer. (A-2) Cryo-TEM micrographs of limit size LNP with the total lipid concentration in the ethanol phase of 10 mg/mL. Adapted from Zhigaltsev et al. [132]. Copyright 2012 American Chemical Society. (B) Schematic of the PFPE-tyramide nanoemulsions for imaging-guided drug delivery. FSDCs cellular uptake of nanoemulsions visualized by NIR microscopy (left) and NIR fluorescence imaging (at 800 nm, right). Adapted from Hanlon et al. [139]. Copyright 2012 Elsevier.

Similarly, another nanoemulsions-based system was proposed by Zhong et al., to study the effect of oils on β-Carotene (BC) bioaccessibility [133]. In this approach, six dietary lipids (corn oil, canola oil, olive oil, palm oil, coconut oil, and MCTs) were selected to produce BC carriers, and all six BC nanoemulsions were prepared by microfluidization. The positive and linear correlation was observed between BC release and bile salts concentrations. In addition, the usage of pancreatin facilitated BC's release in simulated digestion. The relative bioaccessibility of BC in the nanoemulsion delivery systems was significantly improved to 70.9% as compared to 4.6% in the control (bulk oil). This nanoemulsions-based delivery system turned out to be beneficial to encapsulate and deliver BC as well as other bioactive lipophilic carotenoids in a wide range of commercial products. Chhabra et al. demonstrated another nanoemulsion-based system for amlodipine besylate (AB), in which both solubility and oral bioavailability of AB were enhanced [134]. The partition coefficient and the percent dissolution efficiency were correlated to predict the drug release from nanoemulsions to achieve localized delivery of drugs at the target site. It was demonstrated that the in vitro release of AB from nanoemulsions was significantly higher (p < 0.01) than the marketed tablet formulation. Furthermore, in almost all the tested organs, the uptake of AB from nanoemulsions was significantly higher (p < 0.05) than AB suspension, especially in the heart with a drug-targeting index of 44.1%, which also confirmed the high efficacy of nano-sized formulation at therapeutic sites. A relative bioavailability of 475% against AB suspensions was obtained in the pharmacokinetics and biodistribution studies with the optimized radiolabeled formulation in mice; a three-fold increase in the overall residence time further displayed the advantage of nanoemulsions as drug carriers for enhancing both solubility and bioavailability of AB.

Recently, many new nanoemulsion-based drug delivery systems have been explored for imaging guided therapy [135-137] [138] [139]. For example, Gianella et al. reported a 50 nm nanoemulsion-based platform for loading hydrophobic materials, which could be applied as a theranostic tool for simultaneous imaging-guided drug delivery in cancer [138]. The oil-in-water nanoemulsions were produced from soybean oil, PEGylated lipids, and oleic acid-coated iron oxide (FeO) nanocrystals for magnetic resonance imaging (MRI). The fluorescent dye Cy7 was introduced for near-infrared fluorescence (NIRF) imaging, while the hydrophobic glucocorticoid prednisolone acetate valerate (PAV) was applied for therapeutic purposes. When subcutaneous tumors were palpable, the nanoemulsions were controlled at a dose of 30 mg of FeO/kg and 10 mg of PAV/kg. MRI and NIRF imaging showed significant nanoparticle accumulation in the tumors, and tumor growth profiles revealed a potent inhibitory effect in all of the PAV nanoemulsion-treated animals, in comparison with the control samples treated with nanoemulsions, the free drug, and saline, respectively. This complex nanoemulsion-based system loaded with PAV, iron oxide nanocrystals, and Cy7 represented a flexible, versatile, and unique multifunctional theranostic platform for imaging guided therapy of cancer. Similarly, Hanlon et al. reported another theranostic platform for imaging-guided drug delivery and therapy.[139] The nanoemulsions with the average size of 180 nm and low polydispersity index (PDI) less than 0.2 were synthesized from perfluoropolyether (PFPE) by microfluidization, with PFPE-tyramide as a 19F MRI tracer. Hydrocarbon oil, surfactants, and a near-infrared (NIR) dye, and a water-insoluble model nonsteroidal anti-inflammatory drug, celecoxib (0.2 mg/mL), were contained in this system. Therefore, with the aid of nanoemulsions, the whole formulation enabled the non-invasive monitoring of drug biodistributions using two imaging modalities, 19F MRI and NIR optical imaging, as shown in Fig. 3 (B). The nanoemulsions loaded into fetal skin dendritic cells (FSDCs) could remain stable for 30 days at 4 °C, resulting in a promising theranostic system for cancer imagings as well as treatments.

Alternatively, some nanoemulsions can be utilized as new templates for the synthesis of other particles for drug delivery using microfluidics. By using nanoemulsions as templates, Khan et al. developed a two-step semi-continuous process for the synthesis of poly(acrylamide) (PAM) Trojan microparticles for the delivery of ketoprofen via two different microfluidic devices [140]. An elongational-flow micromixer was first used to synthesize polymerizable nanoemulsions with the size varying from 98 to 132 nm, which were then emulsified into microdroplets in a co-axial capillary-based microfluidic droplet generator. The nanoemulsion droplets and microdroplets were both polymerized under UV irradiation. The polymerization using poly(ethyl acrylate) shrank the size of nanoemulsions down to 20 to 32 nm. While those microdroplets were lastly hardened into Trojan particles consisting of a crosslinked network of PAM chains. About 35 % of encapsulated ketoprofen was released over 24 h from the Trojan microparticles. These microparticles prepared using nanoemulsions as templates in microfluidic devices can potentially improve delivery of drug-loaded nanoparticles at the desired locations, such as in the gastrointestinal tract.

3.3. Nanoparticles (NPs)

With fine sizes usually between 1 and 100 nm, nanoparticles can be taken up by cells. Moreover, nanoparticles can be simply immobilized with small molecules, nucleic acids, peptides, and proteins to target particular tissues without being excluded by the immune system [141-143]. Therefore, nanoparticles have tremendous potential as drug carriers by loading drug molecules for controlled drug delivery. The recent advances of nanoparticles as drug carriers integrated on microfluidic platforms have been listed in Table 1. Lipid and/or polymer nanoparticles are common nanoparticle-based drug carriers due to their advantages such as biocompatible and biodegradable properties, low toxicity, and high efficacy [144, 145].

3.3.1. On-chip synthesis of nano-sized drug carriers

The unique properties (e.g. optical, thermal, magnetic and electrical properties) of nanoparticles are highly related to their sizes and morphology. However, conventional batch processes by bulk mixing and nanoprecipitation are technically challenging in fabricating monodisperse nanoparticles with a desired size and morphology, which compromises the properties of the produced nanoparticles [146]. Microfluidic systems have opened a new horizon for the development of novel nanoparticles as drug carriers [147, 148]. The rapid and tunable mixing in microfluidics makes it capable for precious control over the synthesis processes of nanoparticles by systematically varying parameters such as flow rates, reagent concentrations and compositions, temperature, and mixture time. Thus, nanoparticles with desirable sizes and morphology can be homogeneously and reproducibly synthesized in a high-throughput and reproducible manner [147]. In this section, we focus on the synthesis of four types of nanoparticle drug carriers using microfluidic platforms, including lipid nanoparticles, polymer nanoparticles, nano-sized polymeric conjugates, and lipid-polymer hybrid nanoparticles.

A) On-chip synthesis of lipid nanoparticles

Nanoparticles in the size range of 10-50 nm can progressively access and accumulate in target tissues in the body such as lymphatics and poorly vascularized tumors. Thus, the synthesis of such nanoparticles is attractive and important for drug delivery [149, 150]. However, producing lipid nanoparticles smaller than 80 nm is challenging due to the lack of effective methods with good scalability and reproducibility [132]. To solve this problem, Zhigaltsev et al. [132] reported a millisecond microfluidic mixing approach for the synthesis of two types of limit size (20-50 nm) lipid nanoparticle drug carriers with either polar (aqueous) or nonpolar (triglyceride) cores. In this approach, limit size lipid nanoparticles were synthesized by millisecond mixing of ethanol streams containing dissolved lipids and aqueous streams at high flow rates (> 2 mL/min) to drive a bottom-up synthesis process by the spontaneous assembly. The synthesized limit size lipid nanoparticles could be loaded with doxorubicin and other weak base drugs, indicating potential as ultrasmall lipid nanoparticle drug carriers.

Lipid nanoparticles are regarded as promising carriers of delivering siRNA for therapeutic applications [151]. To figure out the structure of lipid nanoparticles containing siRNA, Leung et al. [152] successfully synthesized lipid-siRNA nanoparticles (∼15 nm) by employing a similar rapid microfluidic mixing approach to mix cationic lipids in an ethanol solution with siRNA in an aqueous medium, and applied various techniques (i.e. cryo-transmission electron microscopy and molecular modeling, etc.) to characterize the structure. It was discovered that a nanostructured electron-dense core was observed in the lipid-siRNA nanoparticles, which helped better understand and construct more sophisticated lipid-siRNA nanoparticles.

B) On-chip synthesis of polymer nanoparticles

Among different polymers, chitosan with three types of reactive functional groups and hydrophilic property is regarded as one of the most promising biopolymers for preparing nanoparticles for pharmaceutical applications thanks to its outstanding biologic properties such as bioactivity, biocompatibility, biodegradability, and the capacity to open tight junctions [153, 154]. However, chitosan is not appropriate for carrying hydrophobic drugs, and it is challenging to achieve monodisperse nanoparticles by using the conventional bulk mixing methods. To address these issues, Majedi et al. [155] presented a microfluidic hydrodynamic focusing and self-assembly approach to synthesize monodisperse chitosan-based nanoparticles as hydrophobic drug delivery agents. In this work, the self-assembly synthesis of monodisperse hydrophobically-modified chitosan-based nanoparticles occurred as a consequence of the changes in the physiological pH in a PDMS microfluidic device to provide hydrophobic drug packing. As a result, the synthesized monodisperse chitosan-based nanoparticles were capable of encapsulating hydrophobic anticancer drugs, which provided a sustainable release profile for controlled drug delivery [156]. The synthesized polymer nanoparticles were employed to encapsulate a common anticancer drug, paclitaxel, and compared them with the corresponding bulk synthesized nanoparticles for the in vitro investigation of the effectiveness of the microfluidic method-synthesized nanoparticles. It was found that compared to the bulk mixing method-generated nanoparticles, the microfluidic generated nanoparticles exhibited considerably smaller sizes, lower values of the diffusion coefficient, and extended t50 (the time of 50% drug release). The results are consistent with the results reported by using microfluidic generated chitosan-based nanoparticles for a transdermal multidrug (clindamycin phosphate and tretinoin) delivery application, which exhibited a higher thermal stability, minimum inhibitory, and bactericidal concentrations, compared to the bulk mixing method generated nanoparticles as well [157].

Some other polymer nanoparticles have also been synthesized by rapid nanoprecipitation in microfluidic devices [145]. For instance, Liu et al. [158] reported a superfast sequential microfluidic nanoprecipitation approach for the synthesis of core/shell structured polymer nanoparticle drugs. The enteric coating polymer, hypromellose acetate succinate, was used to encapsulate two water-soluble anticancer drugs, sorafenib and paclitaxel. Through the superfast (i.e. milliseconds) sequential nanoprecipitation processes, the polymer nanoparticle drugs were stably synthesized in a homogeneous size distribution without using any stabilizers. A high-throughput production rate of ∼700 g/day on a single microfluidic device was achieved. Othman et al. [159] reported another rapid nanoprecipitation approach for the synthesis of poly(d,l-lactide) polymer nanoparticles that encapsulated paracetamol drugs in a co-flow microfluidic device. The synthesized polymer nanoparticles exhibited a drug encapsulation efficiency of 38.5% and extended the drug release rate in simulated intestinal fluids at pH 7.4.

C) On-chip synthesis of nano-sized polymeric conjugates

Except for polymer nanoparticles, there is another category of polymer-based drug carriers, nano-sized polymeric conjugates, which have been integrated into microfluidic platforms for controlled drug delivery. Nano-sized polymeric conjugate, as a general name for a group of multifunctional systems, usually in the size range of 1 to 200 nm, has been applied to deliver bioactive agents to the desired sites. Unlike polymer nanoparticles, nano-sized polymeric conjugates are generally designed and synthesized by conjugating polymeric carriers and bioactive molecules directly, such as drugs, proteins, and oligonucleotides [160-163]. Nano-sized polymeric conjugates are advantageous over traditional polymeric drug carriers in controlled drug delivery systems, due to low nanotoxicity, adequate drug loading capacity, good aqueous solubility, excellent circulation and bioavailability, and enhanced permeation and retention effects [16, 27, 164-166].

In conventional synthetic methods, the polymeric conjugates, or polymer-drug conjugates are obtained via coupling reactions by the conjugation of drug molecules with hydrophilic polymers. However, multi-step conjugation reactions are often required, which take long reaction time and large consumption of drugs in order to get high drug coupling ratios. To solve these issues, microfluidics has emerged recently as a novel technology to generate polymeric conjugates, especially in nano-size, because of the rapid and accurate operations to deal with conjugation reactions within small volumes [167, 168].

Microfluidic devices have provided an excellent platform to synthesize polymeric drug conjugates for controlled drug delivery, generally via rapid mixing of polymers and drug molecules. An efficient synthetic method to obtain the nano-sized Heparin-folic acid-retinoic acid (HFR) bioconjugates was developed on a microfluidic device by Tran et al. [169]. This device was fabricated using perfluoropolyether, consisting of two inlets, one outlet, and a solvent resistant fluoropolymer microfluidic channel (500 μm × 50 μm × 40 cm). The mixing and a single-step conjugation of unfractionated heparin, folic acid (FA), and aminated retinoic acid (RA) occurred in the microchannel to obtain HFR and the reaction time and rate were precisely controlled by a dual rack syringe pump. The approach demonstrated that well-defined HFR nanoparticles were produced with uniform size distribution in aqueous media, and HFR bioconjugates with high drug coupling ratios could be achieved within several minutes, providing a powerful tool to synthesize advanced polymeric conjugates. Microfluidic mixing techniques have also been explored by Shi et al. and Endres et al. to develop nano-sized particulate carriers for drug and gene delivery [170, 171]. Nano-suspensions were first prepared from acetone and amphiphilic cationic block copolymers, poly(ethylene glycol) (PEG), poly(ε-caprolactone) (PCL), and poly(ethylene imine) (PEI), via magnetically stirring. The Fluence Microfluidic Tool Kit (Epigem Ltd., Redcar, UK) consisting of a three-way mixing chip was then applied, where cationic NS and nucleic acid (siRNA) were driven and mixed with the aid of syringe-pump drives. The size of siRNA-loaded PEG-PCL-PEI nano-carriers through microfluidic mixing was characterized to be 179 ± 11 nm (PDI = 0.205 ± 0.028), which was smaller than that via classical pipetting (230 ± 97 nm, PDI = 0.353 ± 0.161). Additionally, the size distribution of the complexes on the microfluidic devices was unimodal, whereas two different size distributions were observed in classical pipetting. With uniform surface coating on the nano-sized carrier, less aggregation of RNA was observed through the microfluidic mixing process, thus enhancing RNA protection and transfection performance. The microfluidic complexation strategy provides an easy-to-use, uniform and stable formulation for drug and gene delivery [171].

D) On-chip synthesis of lipid-polymer hybrid nanoparticles

Lipid-polymer hybrid nanoparticles are emerging drug carriers for various medical therapy for cancer, cardiovascular diseases, and tuberculosis in a controlled manner [172]. Recently, three-dimensional monodisperse lipid-polymer hybrid nanoparticles were synthesized by using three-channel pathway and mixing microchannels in a microfluidic device, which accelerated the research and development process of lipid- polymer hybrid nanoparticles as drug carriers for controlled delivery [173]. The structure of the functionalized lipid shells was significant in the biocompatibility and in vivo stability of the lipid-polymer hybrid nanoparticles. To examine the structure and the effect on the cell-particle interaction of the lipid shells in nanoparticles, the structurally well-defined lipid-polymer hybrid nanoparticles covered with either a lipid-monolayer-shell as monolayer nanoparticles or lipid-bilayer-shell as bilayer nanoparticles were synthesized on a PDMS microfluidic device [174]. Compared to the bilayer nanoparticles, the monolayer nanoparticles exhibited lower flexibility, resulting in more efficient cellular uptake and thus enhanced anticancer effects. This flexibility-regulated cell-nanoparticle interaction study provides important implications for the design of lipid-polymer hybrid nanoparticle drug carriers.

3.3.2. Integrated nanoparticle drug carrier synthesis and drug delivery testing on a chip

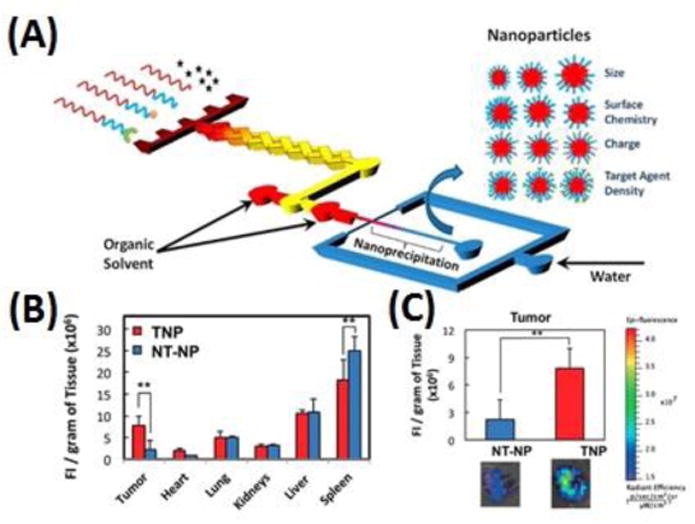

Microfluidic platforms can integrate both synthesis and optimization of nanoparticle drugs, which could potentially accelerate both the discovery and clinical translation of nanoparticle drugs. For instance, Valencia et al. [175] developed such a PDMS microfluidic system for integrated synthesis and screening of targeted nanoparticle drugs for cancer therapy (see Fig. 4). In this system, numbers of polymeric nanoparticle precursors with varying sizes and surface compositions could be rapidly and reproducibly synthesized, followed by the rapid in vitro screening. By using this in vitro microfluidic screen approach, the nanoparticle drugs against prostate cancer cells with the low macrophage uptake level were selected. The in vivo pharmacokinetic studies demonstrated a 3.5-fold increase in the selected nanoparticle drugs in tumor accumulation in mice than non-targeted nanoparticle drugs.

Fig 4.

A microfluidic system for integrated synthesis and screening of nanoparticle drug carriers for cancer therapy. (A) Schematic of rapid synthesis of nanoparticles on a PDMS microfluidic device upon self-assembly through nanoprecipitation. (B) Biodistribution and (C) tumor accumulation of the targeted nanoparticle drugs and non-targeted nanoparticle drugs. Adapted from Valencia et al.[175]. Copyright 2012 ACS.

Current technologies are limited to monitor the nanoparticles entering the treated cells, which is an important factor in developing nanoparticle drugs for anticancer treatment [176]. Microfluidic platforms have exhibited the potential in monitoring and assessing uptake of nanoparticles into target cells. For instance, Zhai et al. [177] have recently demonstrated a microfluidic approach of monitoring uptake of nanoparticles into living cells via surface-enhanced Raman spectroscopy. The fabricated beta-cyclodextrin-coated silver nanoparticles (Ag@CD NPs) were surface modified with para-aminothiophenol (p-ATP) and folic acid (FA). The p-ATP acted as the Raman reporter and the FA had a high affinity for folate receptors (FR) that are over-expressed on cancer cells surface. The FR-targeted dihydroartemisinin (DHA) was used as a model drug. The Ag@CD@p-ATP@FA NPs were successfully employed in a well-controlled way to quantitatively assess the number of nanoparticles entering FR-positive living cells and examine the FR-targeted DHA drug effect on cancer cells as well as the interaction between the nanoparticles and cells. Carvalho et al. [178] proposed a microfluidic platform for real-time monitoring of the cellular uptake of nanoparticles and tracking the fate of cancer cells. In this study, carboxymethylchitosan/poly(amidoamine) dendrimer nanoparticles were synthesized and labeled with fluorescein-5(6)-isothiocyanate. HeLa, HCT-116 and U87MG cancer cells were 3D dynamically cultured in a microfluidic device in the presence of those nanoparticles, and the subsequent investigation of cell viability and internalization efficiency was performed and compared with the standard 2D static culture. It was found that the dynamically cultured cancer cells with nanoparticles were viable and exhibited higher internalization levels as compared with statically cultured cells. Those studies demonstrated the potential application of the microfluidic-based platform for real-time monitoring and assessment of effects of nanoparticle drug release on cancer cells.