Abstract

The influence of accelerated weathering, xenon-arc light and freeze-thaw cycling on wood plastic composites extruded from a recycled plastic was studied. The results showed that, in general, weathering had a stronger impact on samples made from plastic waste compared to a sample made from virgin material. After weathering, the mechanical properties, tensile and flexural, were reduced by 2–30%, depending on the plastic source. Wettability of the samples was shown to play a significant role in their stability. Chemical analysis with infrared spectroscopy and surface observation with a scan electron microscope confirmed the mechanical test results. Incorporation of carbon black retained the properties during weathering, reducing the wettability of the sample, diminishing the change of mechanical properties, and improving color stability.

Keywords: Environmental science, Mechanical engineering, Materials science

1. Introduction

One of the priorities in the EU community development strategy is a transition to a more circular economy through resource efficiency, which allows reducing the pressure on the environment, increasing the competitiveness and innovativeness of economy as well as its growth along with creating new jobs [1]. Using waste as a resource is one of the goals for sustainable consumption and production, and essential for the realization of the close-loop economic option. Plastic is included in the five priorities of the action plan for circular economy. The rate of plastic recycling is planned to increase up to 55%, and landfilling is planned to be reduced to no more than 10% by 2030 [2]. Today, multiple small-scale local companies focusing on better collecting and sorting are already working in this area. The global plastic recycling market was valued at US% 31.5 bn in 2015 and is expected to be growing at a 6.9% annual growth rate during the period 2016–2024 [3]. The leaders in recycling are high density polyethylene (HDPE) and polyethylene terephthalate (PET), followed by low density polyethylene (LDPE), polypropylene (PP), polyvinyl chloride (PVC), and other grades. PET is largely recycled into PET fibers and yarns for textile application, whereas most plastics end up as construction products, including plastic lumber, landscaping furniture, and roof and floor tiles [3].

The growing demand for new construction materials with improved mechanical properties and other working characteristics, which are capable to substitute traditional materials, metal and wood, is the key for the expansion of the wood plastic composite (WPC) market. In Europe, WPC production increased from 150 000 tons in 2010 to 250 000 tons in 2015 with an 11% annual growth rate [4]. WPC has also potential for recycled plastic applications, due to the large portion of plastic in the composition of WPC, up to 50 per cent of weight/volume. Several studies have been published where mainly the mechanical properties of WPC manufactured from plastic waste have been examined [5, 6, 7]. Due to the fact that WPC is generally applied in outdoor applications, durability is important issue for the manufacturers and customers. The lifespan of WPC is limited due to the negative impact of ambient climate conditions on its characteristics [8, 9, 10, 11, 12, 13, 14, 15, 16, 17]. Thus, the realistic WPC design values should include correction factors due to its performance loss under different environmental factors [18]. Both virgin and recycled plastics principally suffer from the same degradation mechanisms [19]. However, the presence of prodegradants in post-consumer plastics, e.g. carbonyl groups which absorb harmful light, facilitates photo-degradation process. Possible immiscibility between different polymer grades in the recycled polymer blend along with matrix/filler weak interaction can also have a negative influence on the wettability of the material. Wettability, as it known, is critical factor that affects composite durability.

As it was mentioned above, the retention of operational characteristics of composites during long-term service is a critical issue, especially in outdoor applications. Material degradation occurs usually due to cumulative actions of several factors, including thermo- and photo-oxidation and biodegradation during exposal to environmental conditions, as well as thermo-mechanical oxidation, which can occur during material processing [20]. In addition to the above, changes of temperature from negative to positive, and ambient conditions from wet to dry, are also actual in northern regions. Commercial equipment and standard tests are readily available for the study of these processes. Accelerated weathering tests, xenon-arc light and water immersion-freeze-thaw, are most commonly applied for WPC abiotic degradation studies and are well documented in research publications [21]. Tables 1 and 2 show the selected results of water immersion-freeze-thaw and xenon-arc accelerated weathering of natural fibre composites based on different matrices and fillers. As can be seen, the overall tendency is a significant decline of properties after the aging period. In both types of test, freeze-thaw [22, 24] and xenon-arc [13], moisture has been shown to have a critical effect on the stability of the composite. Due to high hydrophilicity, lignocellulosic fibres absorb moisture, and swell, destroying interfacial interaction and inducing cracks in composites. Thus, increasing the wood component ratio in the composite leads to a decrease of its stability [11, 12, 30]. Improved interfacial interaction, e.g. the loading of a compatibilizer, results in more stable material [24, 25, 29]. Using a less hydrophilic filler compared to wood or cellulose, e.g. peat, can improve the stability of the composite significantly [27]. The bleaching of wood fibres, removal of lignin and reducing the amount of hemicelluloses, decreases the stability of the composite slightly [29]. However, both bleached and unbleached cellulose fibre -loaded PP composites are more stable compared to pure PP. Stark (2006) reports that the durability of composites depends on the method of manufacturing [13]. Injection molded samples with higher density and improved interfacial quality compared to extruded ones are more stable under weathering conditions. Concerning the stability of WPC made from recycled plastic, Homkhiew et al. (2014) report that recycled plastic had a negative effect on the stability [30], whereas Adhikary et al. (2010) found that composites from secondary material were more stable than virgin ones [17].

Table 1.

Selected test results of water immersion-freeze-thaw cycling accelerated weathering.

| Matrix/NF | NF, ratio | Number of cycles | Flexural properties loss, % |

Reference | |

|---|---|---|---|---|---|

| Strength | Modulus | ||||

| PVC/maple | 100 phr | 5 | 15 | 34 | [22] |

| PVC/maple | 100 phr | 5 (f–t) | NS | NS | |

| PVC/pine | 100 phr | 5 | 13 | 30 | |

| PVC/pine | 100 phr | 5 (f–t) | ˜+3 | ˜+7 | |

| HDPE/maple | 50% | 15 | 21 | 50 | [23] |

| HDPE/pine | 50% | 5 | 38 | ||

| HDPE/rice husk | 65% | 12 | 38 | 67 | [24] |

| 65% + CA | 5 | 23 | |||

| HDPE/pine | 40% | 5 | NS | 18; 261 | [25] |

| 40% + CA | NS | 5 | |||

| PE/rice husk | 6 | 39 | 55 | [26] | |

| HDPEv/pine | 40% | 12 | 5 | 0 | [17] |

| HDPEv/pine | 50% | 30 | 16 | ||

| HDPEr/pine | 50% | 9 | 43 | ||

| HDPEr/pine | 50% + CA | 9 | 67 | ||

| PPv/pine | 50% | 31 | 19 | ||

| PPr/pine | 50% | 24 | 39 | ||

| PPr/pine | 50% + CA | 18 | 61 | ||

| PP/cellulose | 30% | 3 | 48 | 85 | [27] |

| PP/peat | 50% | 9–242 | 26–57 | ||

NF - natural fibres; f–t - only freeze-thaw actions; NS - non-significant; v - virgin; r - recycled; CA - coupling agent.

Depending on HDPE type.

Depending on the peat composition.

Table 2.

Selected test results of xenon-arc light accelerated weathering.

| Matrix/NF | NF, ratio | Test period | Mechanical properties loss, % |

Reference | |

|---|---|---|---|---|---|

| Strength | Modulus | ||||

| PVC/maple | 15 phr | 2600 h | +7 | 3 | [11] |

| 30 phr | 5 | 9 | |||

| 45 phr | 12 | 14 | |||

| PP/conifer wood | WF 25% | 8 weeks | 18 | n.d. | [12, 21] |

| WF 50% | 25 | n.d. | |||

| WF 25% + CA | 17 | 15 | |||

| WF 50% + CA | 22 | 24 | |||

| HDPE/pine | WF 49% + lub (Ex) | 3000 h | 34 (UV + ws) | 52 (UV + ws) | [13] |

| +1 (UV) | 12 (UV) | ||||

| WF 49% + lub (M) | 32 (UV + ws) | 41 (UV + ws) | |||

| 10 (UV) | +22 (UV) | ||||

| PP/pine | WF 40% (uBl) + CA | 1000 h | 13 | 11 | [21, 28] |

| WF 40% (Bl) + CA | 17 | 11 | |||

| PPr/pine | 50% | 2000 h | 19 | 10 | [29] |

| 50% + CA | 9 | 8 | |||

NF - natural fibres; CA - coupling agent; lub - lubricant; Ex - extrusion; M - molding: Bl - bleached; uBl - unbleached; r - recycled; ws - water spray.

This study is a part of ongoing research concerning the recyclability of plastic waste and using it in WPC manufacturing. The mechanical properties of WPCs prepared by using construction and household mixed plastic waste have been examined previously [31]. The aim of this work was to study the durability of those composites. Three tests were performed: water absorption, accelerated xenon-arc light weathering and freeze-thaw cycling. The influence of xenon-arc aging was examined on the basis of tensile properties and color changes. The influence of freeze-thaw cycling was studied on the basis of changes in flexural properties. Fourier transform infrared (FTIR) spectroscopy and scan electron microscope (SEM) analysis were used for the estimation of the surface changes during aging.

2. Materials and methods

2.1. Materials

Low density polyethylene (LDPE), Lupolen 2420K, density 0.924 g/cm3, melting point 111 °C, and melt mass-flow rate 4 g/10 min (190 °C/2.16 kg), was supplied by LyondellBasell, Europe. Maleated anhydride polyethylene (MAPE), Fusabond, was used as the coupling agent. Struktol TPW 113 was used as lubricant. The recycled plastic sources were household and construction solid waste. Samples PB_C1 – PB_C9 were manufactured by using the ‘light fraction’ (PP and PE) extracted from a construction plastic blend; and PB_C10 was manufactured from mixed household plastic waste. The ratio of PE in PE/PP blend was estimated by FTIR analysis [32] and shown in Table 3. Spruce wood flour (WF) particles, on average 2.1 mm long, were produced in the laboratory. LDPE-based WPC was used as a reference. The components were loaded in the following proportions: LDPE (or plastic blend (PB))/WF/MAPE/lubricant = 40/54/3/3. The PB_C4_CB composite was loaded with carbon black powder (PB_C4 + 3%CB).

Table 3.

Matrix contents and water absorption (WA) and thickness swelling (TS). Standard deviations are given in parenthesis.

| Sample | PE1, wt% | WA, % | TS, % |

|---|---|---|---|

| Reference | 100 | 6.6 (0.3) | 0.8 (0.6) |

| PB_C1 | 53 (3) | 12.3 (0.5) | 2.0 (0.6) |

| PB_C2 | 69 (3) | 10.6 (0.2) | 1.2 (0.8) |

| PB_C3 | 72 (3) | 11.3 (0.2) | 1.4 (0.8) |

| PB_C4 | 69 (4) | 14.8 (0.8) | 2.6 (0.5) |

| PB_C5 | 64 (6) | 10.4 (1.2) | 1.9 (0.6) |

| PB_C6 | 62 (2) | 11.1 (0.2) | 2.5 (1.2) |

| PB_C7 | 32 (2) | 20.5 (1.1) | 4.2 (0.5) |

| PB_C8 | 52 (2) | 18.0 (0.9) | 2.9 (1.1) |

| PB_C9 | 84 (4) | 12.2 (0.2) | 2.2 (0.5) |

| PB_C10 | – | 29.2 (1.3) | 7.9 (0.9) |

| PB_C4_CB | 69 (4) | 12.4 (1.7) | 2.5 (0.6) |

2.2. Manufacture of composites

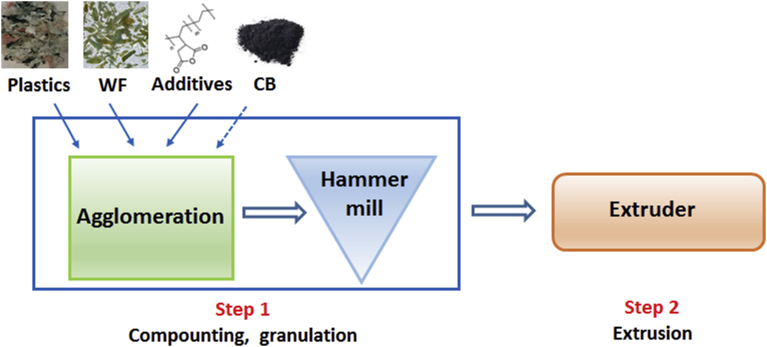

Composites were manufactured using two-step procedure (Fig. 1). PLASMEC TRL 100/FV/W turbomixer was used for the components agglomeration where all components, polymer, wood particles, coupling agent and other additives were mixed at 150–180 °C (depending on the sample content) and ambient pressure during about 40 min. After cooling the size of granules were homogenized using hammer Akro FH100, mesh size 4 mm. Composites hollow profile, 126 × 20 × 3000 mm, were extruded using Weber CE 7.2 conical counter-rotating twin-screw extruder. WPC granules were fed into extruder through gravimetric feeding system. The barrel temperatures were 160–180 °C. The melt temperature was approximately 173 °C. The pressure at the die varied between 22 and 48 bar, and the material output was 25 kg/h.

Fig. 1.

Two steps in composites processing.

2.3. Testing and analysis

2.3.1. Freeze-thaw cycling test

The resistance of the composites to moisture and freeze-thaw actions was tested under cyclic conditions specified by the standard EN 321. The test samples were exposed to three cycles, each comprising immersion in water at 23 °C for 70 ± 1 h, freezing at the temperature of –20 °C for 24 h, and drying at the temperature of 70 °C for 70 ± 1 h. The flexural properties of the samples before and after the freeze-thaw experiments were determined by three point loading test according to the EN 310 standard on a Zwick/Roell Z020 machine. Crosshead speed was 25 mm min-1. Samples for bending test, 50 × 20 × 450 mm, were cut from whole profile. Experiments were carried out with eight sample replicates.

2.3.2. Xenon-arc lamp accelerated weathering

Accelerated weathering tests were conducted in a Q-Lab Xenon Test Chamber, Model Xe-3-HS. The weathering procedure consisted of 102 min of UV irradiation (with average irradiance of 0.51 W/m2 at 340 nm) at chamber temperature of 38 °C and (50 ± 10%) relative humidity, followed by 18 min of water spraying, according to the ISO 4892-2:2013 standard. The specimens were measured for color characteristics after 0–500 h of exposure. The tensile properties of the samples before and after aging were determined according to the ISO 527-1:2012 standard on a Zwick/Roell Z020 machine. Specimens 1A type, 20 × 5 × 150 mm, were cut from top of the composite profile. The crosshead test speed was 2 mm min-1 for modulus testing and 50 mm min-1 for the other measurements. The gauge length was 75 mm. Experiments were carried out with eight sample replicates.

2.3.3. Water absorption (WA) and thickness swelling (TS)

WA and TS were determined by weighting and thickness dimension measuring of the samples according to EN 317. Test specimens, 50 × 20 × 50 mm, were cut from whole profile of composite. Water immersion period was 28 days. The parameters were calculated using following equations:

| (1) |

| (2) |

where m0 and mt are the mass of the sample before and after immersion, g: T0 and Tt are the thickness of the sample before and after immersion, m. Before measurements, excess of water was removed with wipe paper. Weight of specimen was defined by using balance with 0.01 resolution. Thickness of specimen was measured by using digital micrometer (Mitutoyo, Japan) with 0.001 resolution. Experiments were carried out with twenty sample replicates.

2.3.4. FTIR analysis

A Spectrum 100 FTIR spectrometer (Perkin-Elmer, UK) equipped with an attenuated total reflection (ATR) accessory (Perkin Elmer) was used for the surface analysis of the composite. The spectra were collected by co-adding 14 scans at a resolution of 4 cm−1 in the range from 4000 to 400 cm−1. All spectra were normalized by 2917 cm−1 (C–H band), the specific peak intensity of PE. This peak was selected as the reference peak because it changed the least during weathering. For the estimation of degree of aging of the samples the area of carbonyl groups region 1800-1600 cm−1 was calculated. Eight replicates for each type of composite were measured.

2.3.5. Color analysis

The specimens were measured for color characteristics after 0–500 h of exposure. The color of the composite surface was measured with a Minolta CM-2500d spectrophotometer (Konica Minolta Sensing Inc., Japan). The CIELAB color system was used to measure the surface color in L, a, b coordinates. L represents the lightness coordinate and varies from 100 (white) to 0 (gray); a represents the red (+a) to green (–a) coordinate; and b represents the yellow (+b) to blue (–b) coordinate. The lightness change (ΔL) was determined as the difference between the final and initial lightness values. A positive ΔL means lightening, a negative ΔL means darkening of the sample surface. The surface color for eight replicates was measured at three locations on each composite sample.

2.3.6. Microstructure analysis

The microstructures of the composite surface were studied by using a Hitachi SU3500 scanning electron microscope (SEM) at an accelerated voltage of 10 or 15 kV.

2.3.7. Statistical analysis

Standard deviation of each measurement was calculated by using a standard program in Excel. Error bars in Fig. 2 represent the standard deviation of the mean of the data set. Standard deviations for data in Table 3 are given in parenthesis.

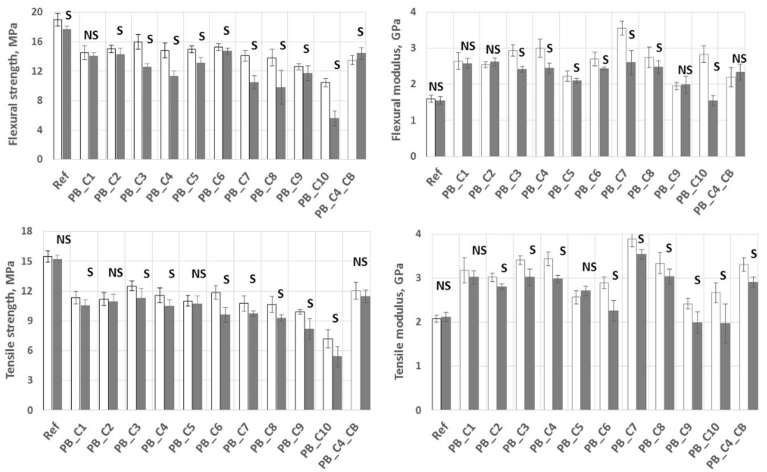

Fig. 2.

Change of flexural properties after the freeze-thaw cycling test (top) and tensile properties after xenon-arc light accelerated weathering (bottom); N and NS denote statistically significant and insignificant changes, respectively.

Statistical significance between the weathered and non-weathered samples data was tested by using Daniel's XL Toolbox Excel software. The data was analyzed by using the one-way ANOVA Bonferroni-Holm post hoc testing algorithm.

3. Results and discussion

3.1. Mechanical properties

3.1.1. Freeze-thaw cycling

The effect of water immersion-freeze-thaw actions on the flexural properties of the composites is presented in Fig. 2. It was detected that the flexural properties declined by 2–26% and 2–30% for strength and modulus, respectively. However, the flexural modulus (FM) for some samples, PB_C2, PB_C9 and PB_C4_CB, and the flexural strength (FS) of PB_C4_CB improved slightly. The significance of the changes is denoted as S or NS, meaning statistical significance or insignificance, respectively, and can be seen in Fig. 2.

Moisture sorption, was shown, has a primary impact on the properties of weathered composites [22, 24]. Pilarski et al. (2005), who studied freeze-thaw cycling on maple or pine PVC based composites, showed that properties loss after full cycling was similar to the properties loss after solely water immersion, whereas properties loss after freeze-thaw cycling without water immersion periods was negligible [22]. Absorbed moisture degrades interfacial interaction in the composite, reducing stress transfer and, hence, lowering the mechanical properties. Also, presence of water causes wood particles swelling that leads to stress in matrix and microcracking formation. Microcracks then contribute to further water ingress into the composite at the later expose. The effect of water is often irreversible, and the properties of the materials are not recovered after drying. In the present study the most significant changes found in the sample where matrix produced from the household mixed plastic blend. This result is consistent with the water absorption experiment (Table 3), where this sample had the highest wettability. The most insignificant changes were detected in the reference sample, which also had the lowest WA and TS parameters. Wood particles encapsulated into the matrix are less accessible to water, making the material properties less dependent on the ambient humid conditions. Adhikary et al. (2010) studied the influence of freeze-thaw cycling on composites from virgin and recycled HDPE or PP; they report that properties declined in all formulations independently on the matrix source [17]. However, the loss in the strength was lesser in the composites based on the recycled plastic. The main reason for that was attributed to the impurities and the original processing of the recycled plastics. We compared our results also with others published previously, Table 1. According to our data, freeze-thaw cycling resulted in the weakened flexural strength and modulus, 2–26 and 2–30% respectively. Represented in Table 1 experimental results for water immersion freeze-thaw cycling experiments for pine-based WPC showed that decline in the properties were in the range 0–30 and 5–67% for strength and modulus, respectively. Despite on the more complicated plastic source used in the present study, our results are comparable with a results found from literature or even better. However, such behavior can be explain by shorter experimental period applied for our experiments compared to experiments presented in Table 1.

3.1.2. Xenon arc light test

Fig. 2 shows the changes in composite properties after xenon-arc light accelerated weathering. According to the test result, the tensile strength (TS) and modulus (TM) decreased, by 2–25% and 5–25%. However, the TM of two samples, the reference and PB_C5, increased slightly, by 2 and 5%, respectively. According to statistical analysis, the changes in the reference during the test were insignificant for both TS and TM. For most of the other samples, the failure of properties was statistically significant.

As it was described in the previous section, absorbed water weakened interfacial interaction in the composite that was the main reason for the degradation of the mechanical properties. Similarly to the freeze-thaw cycling test results, the greatest loss of mechanical properties after the xenon-arc aging was in the case for household plastic waste, with the highest rating of WA and TS parameters. The insignificance of the changes in the reference can be associated with strong interfacial interaction in the composite. Homkhiew et al. (2014) studied natural weathering of PP-based, virgin and recycled, wood plastic composites, and found that a virgin PP -containing composite had smaller percentage changes of lightness and smaller loss of hardness, strength and modulus than those based on recycled PP [30]. The better resistance to weathering was due to better encapsulation of wood flour in the virgin polypropylene.

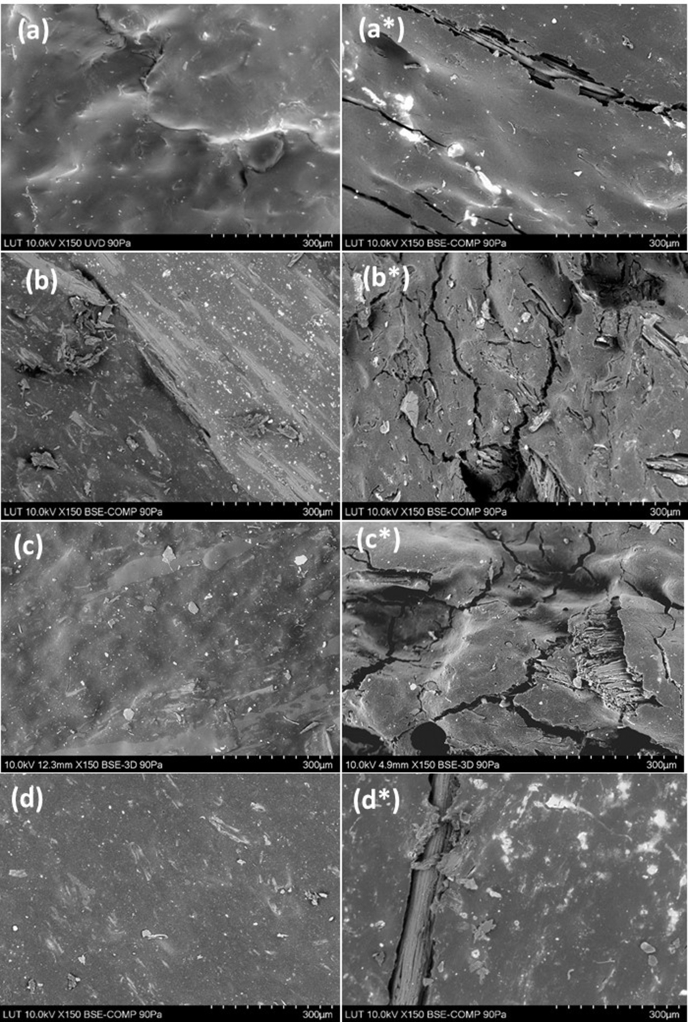

Inspection of the surface with the SEM technique revealed significant changes on the composite surfaces. Prior to weathering (Fig. 3(a)–(d)), the surfaces were smooth; the wood particles were covered with the matrix. However, some difference was observed in the composite produced from household mixed plastic waste PB_C10 (Fig. 3(b)). Slight roughness on the surface was observed, confirming that compatibility in the composite was weak, which was detected and described previously [31]. After weathering, cracks could be found on all surfaces of the studied composites (Fig. 3(a)*–(d)*). Surface crazing can be induced by photo-oxidative processes in the matrix, as well as expansion/contraction of wood particles due to water absorption/desorption. WPCs made from secondary plastic source without carbon black additive had the largest disorder on the surface after 500 h weathering, Fig. 3(b)* and (c)*.

Fig. 3.

SEM micrographs of selected composites before and after weathering; (a) reference, (b) PB_C10, (c) PB_C4; (d) PB_C4_CB; asterisk denotes the composite surface after weathering.

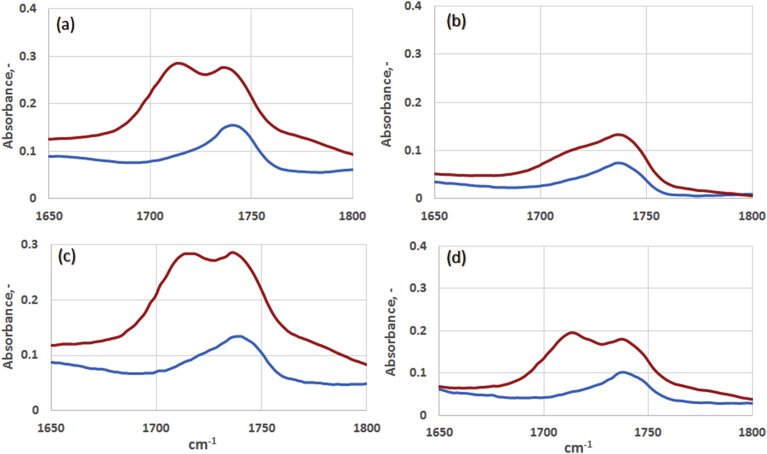

Additional information about the weathering effect can be received through chemical analysis of composite surfaces before and after aging, e.g. FTIR spectral analysis. The rate of surface degradation can be estimated by the degree of the changes in the carbonyl groups region, 1800-1600 cm−1, during experimental time, see Fig. 4 and Table 4. This region is assigned to carbonyl groups which are mainly formed during polymer photo-degradation [33]. As can be seen in Fig. 4, the intensity of two peaks at 1714 cm−1 and 1737 cm−1, which corresponds to ketone and ester carbonyl groups, respectively, increased significantly after the weathering. A small peak at 1737 cm−1 was also observed before weathering. The presence of carbonyl group peaks in unweathered samples is usually attributed to thermal degradation of the polymer during composite processing, the presence of additives, or some other reasons [34, 35], as well as aging signs of a secondary plastic source. As can be seen, the area under the peak in the carbonyl region increased for all samples, but changes in the peaks in samples manufactured from plastic waste, PB_C4 and PB_C10, were visibly higher than those in the reference and CB-loaded sample. Besides, the intensity of ketone groups increased more in the composites produced from secondary materials. The same tendency was described by Maxwell (2008) [33], who studied virgin and secondary HDPE. Ketone group peaks increased more rapidly, confirming the presence of degraded material in the recycled grade. Such degraded material along with impurities can play role of prodegradants which initiate and facilitate photo-oxidation. In addition, PB_C4 and PB_C10 showed the high wettability, which also could promote photo-degradation. Water, as it known, assists to deeper light penetration providing thereby more sites for further degradation [15]. Reference, on the other hand, in the absence of prodegradants and having low wettability showed smaller carbonyl peak changes. The relative stability of CB-containing samples can be attributed to CB action. CB is known as a light stabilizing additive for polymers working as a UV absorber, a radical trap and a terminator of the free radical chains through which the photo-oxidative reactions propagate [36, 37].

Fig. 4.

Carbonyl region in FTIR spectrum of WPC surface before (blue) and after (dark red) 500 h xenon arc light weathering: PB_C4 (a), PB_C4_CB (b), PB_C10 (c) and reference (d).

Table 4.

Carbonyl region area (ACR) of selected WPC samples before and after xenon arc light weathering.

| Sample/ACR | ACR before | ACR after |

|---|---|---|

| Reference | 1.64 | 5.9 |

| PB_C4 | 2.14 | 8.3 |

| PB_C10 | 2.34 | 8.7 |

| PB_C4_CB | 1.92 | 4.1 |

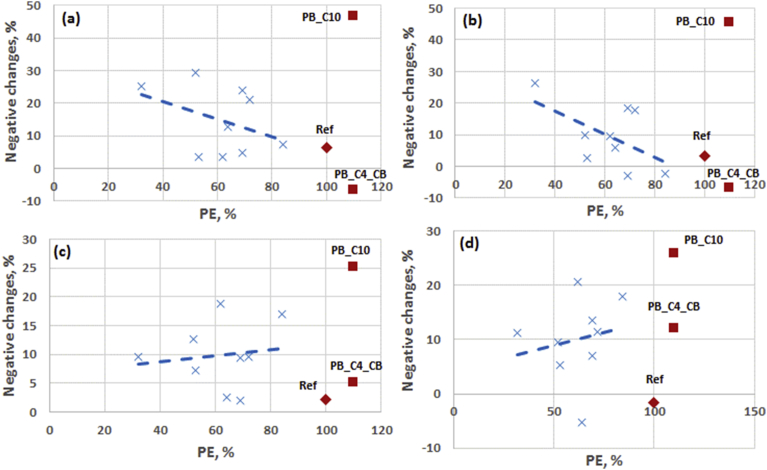

As reported previously, the matrix content can influence the composite properties to some extent [31]. In order to find out how samples content influences on the composites aging, the degree of changes were represented as function of PE content, Fig. 5. As it seen, composites properties loss after freeze-thaw cycling decreased when the amount of PE in the matrix increased, Fig. 5(a) and (b). This was possibly because MAPE worked better for the PE-rich matrix samples due to MAPE and PE consist of the same monomer units. A positive influence of the compatibilizer on the composite durability has been reported by Adhikary et al. (2009; 2010) [17, 29]. In the case of xenon-arc light weathering, the tendency of the property change dependence on PE/PP ratio was less obvious, Fig. 5(c) and (d). Although the trend indicated by the regression lines was upward, the data was too scattered around this line and could not be used for prediction of the results. Secondary materials could contain different additives, e.g. UV protectors, as well as degraded materials which absorb UV radiation, making the properties of this material less predictable, at least without more detailed analysis. Previous elemental analysis of the matrix used in these composites showed presence of chemical elements which could be attributed to fire retardants or other additives [32].

Fig. 5.

Change in the mechanical properties after accelerated weathering and polyethylene (PE) content correlation; changes in flexural strength (a) and modulus (b) after freeze-thaw cycling test, and tensile strength (c) and modulus (d) after 500 h xenon-arc light weathering.

3.2. Influence of carbon black (CB) on composite properties

In the frame of this work, the effect of carbon black on the composite properties was studied. Sample PB_C4 was modified by the incorporation of 3% of carbon black; the sample is denoted as PB_C4_CB. The experimental results are shown in Fig. 2. Despite on the potential reinforcing properties of CB, the tensile properties of the composite were influenced insignificantly by the CB loading, i.e. the changes were within experimental error. The flexural strength declined from 14.8 MPa (PB_C4) to 13.5 MPa (PB_C4_CB) and modulus from 3 GPa (PB_C4) to 2.2 GPa (PB_C4_CB), which was statistically significant. The most probable reason for that was poor dispersion of CB-particles in the matrix. Sumita et al. (1991) reported that CB distributes unevenly in each component of the polymer blend [38]. There are two types of distribution: (a) particles predominantly distributed in one phase of the blend matrix; (b) the filler distribution concentrates at interface of two polymers. As long as the viscosities of two polymers are comparable, interfacial energy is the main factor determining uneven distribution of fillers in the polymer blend matrices [38]. Studying CB distribution in HDPE/PP blend the same authors showed that CB distribution could be controlled by changing thermodynamic parameters of component, e.g. CB [39]. Untreated CB particles had higher affinity to HDPE, whereas modified CB distributed at the HDPE/PP interface. Thermodynamic parameters of recycled polymers could differ from pure ones and difficult to predict due to possible presence of different additives. Incorporation of CB into PB_C4 sample negatively influenced on the mechanical parameters that can be explained by the accumulation of CB particles on the PE/PP interface. However, due to the fact that CB is often used as pigment in polymer product manufacturing, some amount of CB might be present in the recycled material. Thus, the cumulative amount of CB might be high, resulting in poor dispersion and property loss.

Concerning aging, the mechanical properties of CB-containing sample were retained or even improved after accelerated weathering, showing protective properties of CB. As can be seen in Table 3, PB_C4_CB sample absorbed less moisture (12.4%) compared to PB_C4 (14.8%). This decreased wettability could have a positive effect on the durability of the composite in general. Thus, the flexural strength and modulus of PB_C4_CB improved after the freeze-thaw cycles, up to 7% for both (denoted as S for strength and NS for modulus), whereas PB_C4 sample showed significant decline in the strength and modulus, by 24% and 19%, respectively. After the xenon light weathering, the tensile properties changes were comparable for both samples: the tensile strength decreased by 9 and 5% for PB_C4 (denoted as S) and PB_C4_CB (denoted as NS) while the tensile modulus decreased by 13 and 12% (denoted as S for both), respectively.

According to the SEM micrographs, after weathering, cracks on the CB-containing sample surface (Fig. 3d*) were smaller compared to PB_C4 (Fig. 3c*). Thus, weathering caused more serious defects on the CB-free surface, where the polymer top layer was almost completely destroyed. The PB_C4_CB surface, however, in addition to the cracks shown in the micrograph, had small-scale micro cracking on the surface, which was visible at larger magnification (not shown here). More comments about CB action are presented in Xenon arc light test (above) and Color analysis (below) sections.

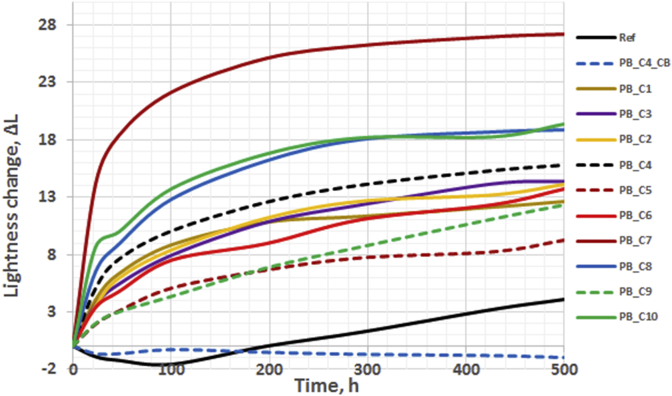

3.3. Color analysis

The influence of accelerated weathering on the lightness change ΔL of the composites is shown in Fig. 6. As all the samples for the secondary material had different initial color (Table 5) and due to unknown exact chemical composition of composites matrix, i.e. the presence of possible additives (e.g. pigments) in the waste polymers, we can only state color changes, which were much higher than in the reference. The initial color of recycled material was mostly gray and green and was discolored fast, as seen in Fig. 6. The carbon black -containing sample, PB_C4_CB, had a significantly decreased color change compared to its ‘precursor’ PB_C4. CB is widely used as black pigment, and its UV protection capability is known very well. It could be noted that the reference sample had small color changes, similarly to the CB containing one. It is known that wood, mainly lignin, is sensitive to UV light and responsible for wood-based composite discoloration. Thus, the very slow whitening of the reference sample can be explained by complete encapsulation of wood particles in the matrix and strong interfacial interaction. This result is in line with the mechanical properties data, as well as the water absorption parameters. However, after a longer period, due to UV aging of the polymer layer, as well as water action and increased temperature, which are responsible for weakening of interfacial interaction, the rate of the discoloration of the reference sample increased.

Fig. 6.

Lightness change after 500 h of xenon-arc light weathering.

Table 5.

Color characteristics of the composite samples before xenon-arc light weathering.

| Sample | L* | a* | b* |

|---|---|---|---|

| Reference | 58 | 7 | 29 |

| PB_C1 | 36 | −0.6 | 1.2 |

| PB_C2 | 40 | 1 | 3 |

| PB_C3 | 40 | −1.5 | 1.3 |

| PB_C4 | 38 | −1.6 | 1.3 |

| PB_C5 | 29 | −0.1 | 1.3 |

| PB_C6 | 35 | 0.2 | 4 |

| PB_C7 | 43 | −6 | 8 |

| PB_C8 | 46 | −2 | 8 |

| PB_C9 | 37 | −0.4 | 0.7 |

| PB_C10 | 46 | −0.5 | 10 |

| PB_C4_CB | 26 | −0.1 | −1 |

4. Conclusions

The purpose of the present study was to estimate the durability of the composites manufactured from plastic waste of different sources. Composite samples were weathered under accelerated freeze-thaw cycling and xenon-arc light standard conditions. Results showed that the composites had significant changes in their tensile and flexural properties, decreasing by 2–30%. In the same weathering conditions, the property changes in the reference, processed from virgin polymer, were insignificant according to the ANOVA test. Chemical analysis by using infrared spectroscopy confirmed surface degradation, e.g. carbonyl groups formation during UV radiation period. The degree of the surface degradation was also estimated with a scan electron microscope. In the frame of this study, the influence of carbon black on the properties of recycled composites was also examined. Incorporation of CB negatively influenced on the mechanical properties of composite most likely due to CB poor dispersity in the matrix. However, incorporated CB was capable to retain the properties during weathering.

Declarations

Author contribution statement

I. Turku: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

T. Kärki: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

A. Puurtinen: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This work was supported by ERDF, grant/award number: A71163.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.European commission . 2015. Closing the Loop-An EU Action Plan for the Circular Economy COM; p. 614. final. [Google Scholar]

- 2.http://ec.europa.eu/environment/waste/plastic_waste.htm.

- 3.www.transparencymarketresearch.com/plastic-recycling-market.html.

- 4.Eder A., Carus M. Global trends in wood-plastic composites (WPC) Bioplastic Mag. 2013;8:16–17. [Google Scholar]

- 5.Tzankova Dintcheva N., La Mantia F.P. Recycling of the ‘‘light fraction” from municipal post-consumer plastics: effect of adding wood fibers. Polym. Adv. Technol. 1999;10:607–614. [Google Scholar]

- 6.Tzankova Dintcheva N., La Mantia F.P., Trotta F., Luda M.P., Camino G., Paci M., Di Maio L., Acierno D. Effect of filler type and processing apparatus on the properties of the recycled ‘light fraction’ from municipal post-consumer plastics. Polym. Adv. Technol. 2001;12:552–560. [Google Scholar]

- 7.Selke S.E., Wichman I. Wood fiber/polyolefin composites. Compos Part A Appl. Sci. Manuf. 2004;35(3):321–326. [Google Scholar]

- 8.Li R. Environmental degradation of wood-HDPE composite. Polym. Degrad. Stab. 2000;70(2):135–145. [Google Scholar]

- 9.Joseph P.V., Rabello M.S., Mattoso L.H.C., Joseph K., Thomas S. Environmental effects on the degradation behavior of sisal fibre reinforced polypropylene composites. Comp. Sci. Technol. 2002;62(10-11):1357–1372. [Google Scholar]

- 10.Lundin T., Cramer S.M., Falk R.H., Felton C. Accelerated weathering of natural fiber-filled polyethylene composites. J. Mater. Civ. Eng. 2004;16(6):547–555. [Google Scholar]

- 11.Matuana L.M., Kamdem D.P. Accelerated ultraviolet weathering of PVC/wood-flour composites. Polym. Eng. Sci. 2002;42(8):1657–1666. [Google Scholar]

- 12.Seldén R., Nyström B., Långström R. UV aging of poly(propylene)/wood-fiber composites. Polym. Compos. 2004;25(5):543–553. [Google Scholar]

- 13.Stark N.M. Effect of weathering cycle and manufacturing method on performance of wood flour and high-density polyethylene composite. J. Appl. Polym. Sci. 2006;100(4):3131–3140. [Google Scholar]

- 14.Stark N.M., Matuana L.M. Surface chemistry and mechanical property changes of wood-flour/high-density-polypropylene composites after accelerated weathering. J. Appl. Polym. Sci. 2004;94(6):2263–2273. [Google Scholar]

- 15.Stark N.M., Matuana L.M. Influence of photostabilizers on wood flour–HDPE composites exposed to xenon-arc radiation with and without water spray. Polym. Degrad. Stab. 2006;91(12):3048–3056. [Google Scholar]

- 16.Kiguchi M., Kataoka Y., Matsunaga H., Yamamoto K., Evans P.D. Surface deterioration of wood-flour polypropylene composites by weathering trials. J. Wood Sci. 2007;53(39):234–238. [Google Scholar]

- 17.Adhikary K.B., Pang S., Staiger M.P. Effects of accelerated freeze-thaw cycling on physical and mechanical properties of wood flour-recycled thermoplastic composites. Polym. Compos. 2010;31(2):185–194. [Google Scholar]

- 18.Friedrich D., Luible A. Standard-compliant development of a design value for wood-plastic composite cladding: an application-oriented perspective. Case Stud. Struct. Eng. 2016;5:13–17. [Google Scholar]

- 19.La Mantia F. Rapra Technology Limited; 2002. Handbook of Plastic Recycling. [Google Scholar]

- 20.Vilaplana F., Strömberg E., Karlsson S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010;95:2147–2161. [Google Scholar]

- 21.Friedrich D., Luible A. Investigation on ageing of wood-plastic composites for outdoor applications: a meta-analysis using empiric data derived from diverse weathering trials. Constr. Build. Mater. 2016;124:1142–1152. [Google Scholar]

- 22.Pilarski J.M., Matuana L.M. Durability of wood flour-plastic composites exposed to accelerated freeze-thaw cycling. Part I. Rigid PVC matrix. J. Vinyl Addit. Techn. 2005;11(1):1–8. [Google Scholar]

- 23.Pilarski J.M., Matuana L.M. Durability of wood-flour-plastic composites exposed to accelerated freeze-thaw cycling. II. High density polyethylene matrix. J. Appl. Polym. Sci. 2006;100(1):33–39. [Google Scholar]

- 24.Panthapulakkal S., Law S., Sain M. Effect of water absorption, freeze and thawing, and photo-aging on flexural properties of extruded HDPE/rice husk composites. J. Appl. Polym. Sci. 2006;100(95):3619–3625. [Google Scholar]

- 25.Bengtsson M., Stark N.M., Oksman K. Durability and mechanical properties of silane cross-linked wood thermoplastic composites. Comp. Sci. Technol. 2007;67(13):2728–2738. [Google Scholar]

- 26.Wang W.H., Wang Q.H., Xiao H., Morrell J.J. Effect of moisture and freeze-thaw cycling on the quality of rice-hull- PE composite. Pigm. Resin Technol. 2007;36:344–349. [Google Scholar]

- 27.Koivuranta E., Hietala M., Ämmälä A., Oksman K., Illikinen M. Improved durability of lignocellulose-polypropylene composites manufactured using twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2017;101:265–272. [Google Scholar]

- 28.Beg M.D.H., Pickering K.L. Accelerated weathering of unbleached and bleached Kraft wood fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2008;93:1939–1946. [Google Scholar]

- 29.Adhikary K.B., Pang S., Staiger M.P. Accelerated ultraviolet weathering of recycled polyethylene–sawdust composites. J. Thermopl. Comp. Mater. 2009;22(6):661–679. [Google Scholar]

- 30.Homkhiew C., Ratanawilai T., Thongruang W. Effects of natural weathering on the properties of recycled polypropylene composites reinforced with rubberwood flour. Ind. Crops Prod. 2014;56:52–59. [Google Scholar]

- 31.Turku I., Keskisaari A., Kärki T., Puurtinen A., Mattila P. Characterization of wood plastic composites manufactured from recycled plastic blends. Compos. Struct. 2017;161:469–476. [Google Scholar]

- 32.Turku I., Kärki T., Rinne K., Puurtinen A. Characterization of plastic blends made from mixed plastic waste of different sources. Waste Manage. Res. 2017;35(2):200–206. doi: 10.1177/0734242X16678066. [DOI] [PubMed] [Google Scholar]

- 33.Maxwell A.S. Weathering of recycled photo-degraded polyethylene. Polym. Eng. Sci. 2008;48(2):381–385. [Google Scholar]

- 34.Gardette J.L., Sinturel C., Lemaire J. Photooxidation of fire retarded polypropylene. Polym. Degrad. Stab. 1999;64(3):411–417. [Google Scholar]

- 35.Kazayawoko M., Balatinecz J.J., Woodhams R.T. Diffuse reflectance Fourier transform infrared spectra of wood fibres treated with maleated polypropylenes. J. Appl. Polym. Sci. 1997;66(6):1163–1173. [Google Scholar]

- 36.Du H., Wang W., Wang Q., Zhang Z., Sui S., Zhang Y. Effect of pigments on the UV degradation of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2010;118(2):1068–1076. [Google Scholar]

- 37.Liu M., Horrocks A.R. Effect of carbon black on UV stability of LLDPE films under artificial weathering conditions. Polym. Degrad. Stab. 2002;75(3):458–499. [Google Scholar]

- 38.Sumita M., Sakata K., Asai S., Miyasaka K., Nakagawa H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 1991;25(2):265–271. [Google Scholar]

- 39.Asai S., Sakata K., Sumita M., Miyasaka K. Effect of interfacial free energy on the heterogeneous distribution of oxidized carbon black in polymer blends. Polym. J. 1992;24(5):415–420. [Google Scholar]