Abstract

This article assesses sugarcane yield gaps (YG) in Brazil to determine the degree to which production can be increased without land expansion. In our scenario assessments, we evaluated how much of the projected sugarcane demand to 2024 (for both sugar and bioethanol) can be satisfied through YG closure. The current national average yield is 62% of yield potential estimated for rainfed conditions (i.e., a YG of 38%). Continuing the historical rate of yield gain is not sufficient to meet the projected demand without an area expansion by 5% and 45% for low- and high-demand scenarios, respectively. Closing the exploitable YG to 80% of potential yield would meet future sugarcane demand, with an 18% reduction in sugarcane area for the low-demand scenario or a 13% expansion for the high-demand scenario. A focus on accelerating yield gains to close current exploitable YG is a high priority for meeting future demand while minimizing pressure on additional land requirements.

Keywords: sugarcane, ethanol, yield gap, intensification, land-use change

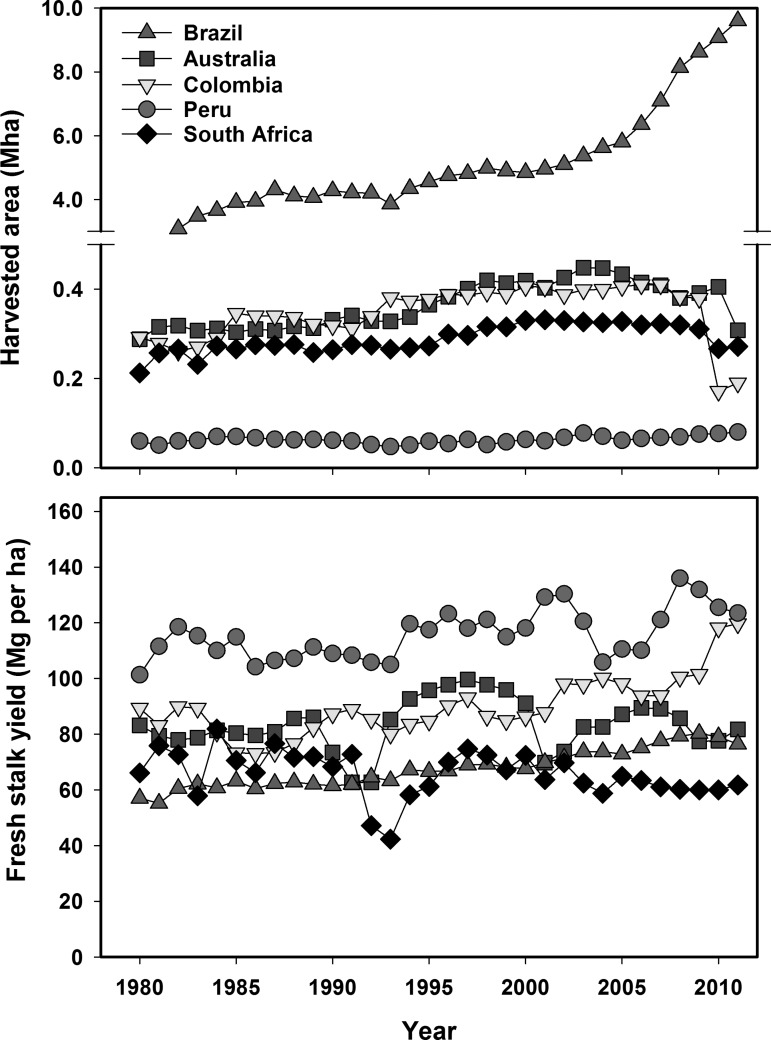

Concerns about food security, greenhouse gas missions, and loss of habitat for biodiversity from direct and indirect land-use change are recognized as important issues for evaluating future options to achieve increased crop production (Lepers et al. 2005, Oliveira et al. 2005, Burney et al. 2010, Vermeulen et al. 2012, Laurance et al. 2014). These issues are of central importance for Brazil because, although sugarcane production has more than doubled from 2000 to 2013, 88% of this increase came from the expansion of sugarcane production area and only 12% from yield increase (figure 1).

Figure 1.

Trends in sugarcane harvested area (top panel) and fresh stalk yield (bottom panel) in five major sugarcane-producing countries from 1980 to 2011. Abbreviations: ha, hectares; Mg, megagrams; Mha, megahectares. Source: FAOSTAT (http://faostat.fao.org)

Brazil is the world's largest producer of both sugarcane and sugarcane-ethanol: during the 2013–2014 crop year, approximately 9 million hectares of sugarcane produced 659 megatonnes (Mt) of harvested cane, 38 Mt of sugar, and nearly 28 billion liters of ethanol (CONAB 2014). Indeed, Brazil is the second largest bioethanol producer behind the United States, which mostly produces maize-ethanol, and the two countries account for nearly 90% of global bioethanol production. Sugarcane ethanol is an alcohol-based fuel produced by the fermentation of sugarcane juice, molasses, and, more recently, cellulose through “second-generation” approaches (Goldemberg et al. 2014). Biofuel production is expected to increase because of renewable-fuel mandates that seek to leverage the potential of sugarcane ethanol for mitigating greenhouse gas (GHG) emissions (Goldemberg 2007, Naylor et al. 2007). Brazil has a comparative advantage to help meet demand for GHG-mitigating biofuels because of plentiful land and water resources, but the rate of sugarcane yield gain in Brazil has been relatively low, and average yields remain well below yield levels achieved by several other sugarcane producing countries (figure 1).

The challenge is to increase sugarcane yields on existing farmland given concerns about the conversion of grassland and rainforest to crop production and the rapidly increasing global demand for sugarcane ethanol. A key issue, therefore, is the extent to which the rate of yield gain can be accelerated above the yield trajectory of the past two decades to achieve greater sugarcane production through higher yields without further expansion of sugarcane production area. Yield-gap analysis provides a robust quantitative framework to answer this question (Lobell et al. 2009, van Ittersum et al. 2013). Although there have been a few studies addressing this question for specific areas of Brazil (Marin et al. 2008, Marin and Carvalho 2012), a thorough assessment of potential sugarcane production across all major sugarcane producing regions in Brazil is lacking. Following Evans (1993), yield potential (Yp) is defined as the yield of an adapted crop cultivar when grown with water and nutrients nonlimiting and biotic stress effectively controlled. Therefore, Yp is determined only by solar radiation, temperature, atmospheric carbon dioxide (CO2) concentration, and genetic traits that govern the length of the growing period and light interception by the crop canopy. In the case of rainfed crops, water-limited yield potential (Yw) represents the yield ceiling and, in addition to factors governing Yp, the rainfall amount and distribution during the crop growing season; soil and terrain properties that determine the water supply available for crop transpiration are also sensitive factors governing Yw. Actual yield (Ya) is the average yield obtained by crop producers within a defined geographic region. For rainfed cropping systems, the yield gap (Yg) is defined as the difference between Yw and Ya. The size of Yg ultimately determines the additional production capacity that is possible on existing production area for a given crop and region.

In this article, we performed Yg analysis of sugarcane in Brazil using a well-validated sugarcane crop model; the best available data for crop harvested area, long-term weather, soil properties, and Ya; and a bottom-up approach to upscale results from specific locations to regional and national levels. The specific objectives were to (a) determine the magnitude of the current sugarcane Yg in major sugarcane producing regions of Brazil, (b) estimate the additional production that could be achieved by closing the exploitable Yg on existing sugarcane area, and (c) assess the degree to which this extra production can satisfy the expected future sugarcane demand while avoiding or minimizing sugarcane area expansion.

Data sources used for the determination of yield potential, actual yield, and yield gaps

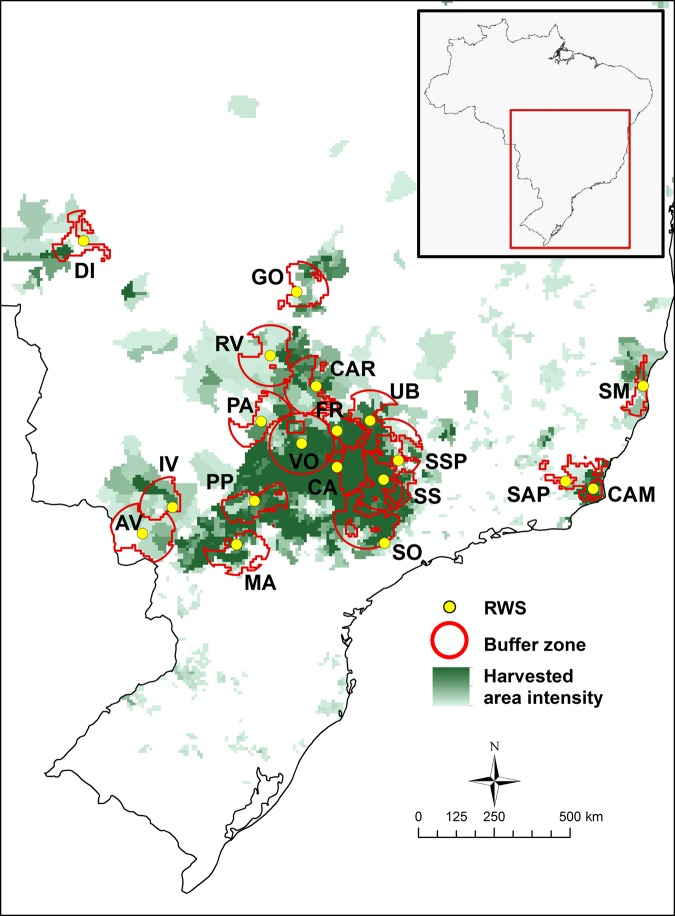

Our analysis focuses on estimating the Yw and Yg of rainfed sugarcane in ratoon-crop systems because more than 90% of all sugarcane in Brazil relies on rainfall (i.e., without irrigation) and about 80% is produced in ratoon-crop systems. Estimating Yg followed the generic protocols developed by the Global Yield Gap Atlas (Grassini et al. 2015, van Bussel et al. 2015, www.yieldgap.org). Briefly, sugarcane area was estimated within a 100-kilometer-radius circular area around existing weather stations (hereafter called buffers) on the basis of recent 5-year (2006–2010) statistics on sugarcane harvested area reported at the municipality level (IBGE 2014). Municipalities correspond to the smallest administrative unit in Brazil, with an average area of 36,000 square kilometers. Each buffer was “clipped” by the boundaries of the climate zone in which the weather station was located using the climate zonation scheme of Van Wart and colleagues (2013a). Buffers were ranked by the sugarcane area they contained (from highest to lowest) and selected until achieving approximately 50% coverage of the total harvested sugarcane area in Brazil. Previous work by Van Wart and colleagues (2013b) showed that achieving 50% coverage of the production area was sufficient to obtain a robust estimate of Yg at a national scale. Following this approach, 19 weather stations were selected, hereafter called reference weather stations (RWS; figure 2, table 1). Selected RWS buffers contained 47% of the total Brazilian sugarcane area, whereas the climate zones in which the RWS were located accounted for 88% of the national sugarcane area (table 1). Therefore, the 19 RWS selected for this national assessment of sugarcane yield gaps were representative of sugarcane-producing areas throughout Brazil and provided adequate coverage to achieve a robust estimate of Yg within climate zones and at a national scale.

Figure 2.

The spatial distribution of reference weather stations (RWS) and associated buffers selected for the simulation of sugarcane water-limited yield potential in Brazil. Location codes for station names are provided in tables 1 and 2. The data on crop management, soil properties, and actual yield data were collected to represent sugarcane production within each RWS buffer. Sugarcane harvested area (in hectares) is shown in green and is based on recent (2006–2010) municipality-level statistics. The inset shows the location of the study area within Brazil. Abbreviation: km, kilometers.

Table 1.

Selected reference weather stations (RWS), their locations and associated codes (see figure 2), soil and climate characteristics, the harvested area within each RWS buffer, and withing the climate zone (CZ) in which the RWS is located.

| Weather station (and its code) | Latitude (in degrees) | Longitude (in degrees) | Elevation (in meters) | Soil classification | Soil depth (in meters) | Climatea | RWS area (in 1000 hectares) | CZ area (in 1000 hectares) |

|---|---|---|---|---|---|---|---|---|

| Sorocoba (SO) | –23.36 | –47.52 | 645 | Oxisol-Ultisol | 2 | 21.6°C, 1310 mm | 540 (7%) | 1892 (28%) |

| Catanduva (CAT) | –21.11 | –48.93 | 570 | Ultisol | 1.5 | 23.8°C, 1324 mm | 508 (7%) | |

| Sao Simão (SS) | –21.48 | –47.55 | 617 | Oxisol | 2.5 | 22.9°C, 1460 mm | 590 (8%) | 1375 (20%) |

| Uberaba (UB) | –19.73 | –47.95 | 737 | Oxisol | 2.5 | 23.5°C, 1565 mm | 252 (3%) | |

| Maringá (MA) | –23.4 | –51.91 | 542 | Oxisol | 2.5 | 22.7°C, 1631 mm | 111 (2%) | |

| Avaré (AV) | –23.08 | –54.7 | 813 | Ultisol-Oxisol | 2 | 21.1°C, 1474 mm | 40 (1%) | |

| Votuporanga (VO) | –20.41 | –49.98 | 502 | Oxisol | 2.5 | 24.5°C, 1379 mm | 496 (7%) | 1322 (17%) |

| Campos (CAM) | –21.75 | –41.33 | 11.2 | Ultisol | 1.5 | 24.9°C, 1011 mm | 43 (1%) | |

| Presidente Prudente (PP) | –22.11 | –51.38 | 435 | Ultisol | 1.5 | 23.5°C, 1346 mm | 192 (3%) | 802 (11%) |

| St Antonio de Padua (SAP) | –21.53 | –42.15 | 95 | Oxisol-Ultisol | 2 | 21.6°C, 1310 mm | 46 (1%) | |

| Frutal (FR) | –20.03 | –48.93 | 543 | Oxisol | 2.5 | 25.0°C, 1226 mm | 231 (3%) | 643 (8%) |

| Capinópolis (CAR) | –18.71 | –49.55 | 620 | Ultisol | 2.5 | 24.5°C, 1470 mm | 85 (1%) | |

| Paranaíba (PA) | –19.75 | –51.18 | 331 | Oxisol-Ultisol | 2 | 24.8°C, 1434 mm | 45 (1%) | |

| São Mateus (SM) | –18.7 | –39.85 | 25 | Oxisol-Ultisol | 2 | 24.9°C, 1346 mm | 20 (1%) | |

| Rio Verde (RV) | –17.8 | –50.91 | 774 | Oxisol | 2.5 | 23.6°C, 1628 mm | 70 (1%) | 401 (5%) |

| Ivinhema (IV) | –22.3 | –53.81 | 369 | Oxisol | 2.5 | 23.6°C, 1460 mm | 54 (1%) | |

| Sao Seb.Paraiso (SSP) | –20.91 | –47.11 | 1026 | Oxisol | 2.5 | 21.2°C, 1799 mm | 182 (2%) | 218 (3%) |

| Goiás (GO) | –15.91 | –50.13 | 512 | Oxisol | 2.5 | 26.2°C, 1777 mm | 38 (1%) | 38 (1%) |

| Diamantino (DI) | –14.4 | –56.45 | 286 | Oxisol-Ultisol | 2 | 26.4°C, 1807 mm | 42 (1%) | 75 (1%) |

| Total | 3617 (47%) | 6734 (88%) |

Note: The values in parentheses represent the relative contribution of each RWS or CZ to the total sugarcane production area in Brazil (in %). aLong-term annual average temperature and total annual precipitation.

Long-term (1981–2010) daily rainfall and temperature data were available for each selected RWS from the Brazilian Institute of Meteorology (INMET; table 1, figure 2). Incident solar radiation was estimated from measured air temperature using the Bristow and Campbell method (1984), with local calibration for Brazilian sugarcane-producing areas (Fonseca and Marin 2007). This approach gave a reasonable agreement between measured and estimated radiation (root mean square error: 3.5 megajoules, MJ, per square meter per day) based on a subset of daily-measured radiation data (n = 2261) and gives confidence in estimated incident solar radiation across the sugarcane-producing areas in Brazil.

For each RWS, Yw was simulated over a 30-year period (1981–2010) using the DSSAT/CANEGRO (DC) model (Singels et al. 2008; see the following section for more details). Simulations were initiated one year before sugarcane planting, with a soil-water content near field capacity. The dominant management practices (start of crop growing season, plant density, and cultivar) and soil types were obtained from local experts and official statistics for each RWS buffer. The harvest season typically starts in April and finishes in November; therefore, we assumed three harvest times for ratoon crops: early (March 15), middle (August 15), and late harvest (November 15), which account for a respective 28%, 44%, and 28% of the harvested area (PMGCA 2012). Those dates were chosen to represent the main sprouting period for ratoon crops. The dominant soil types and associated soil and terrain properties (e.g., texture, water-holding capacity, rootable soil depth, and slope) were retrieved for each RWS buffer from the soil database created by the Radambrasil Project (1973–1986) database (Cooper et al. 2005). The soil-water parameters were estimated using the pedo-transfer functions developed by Tomasella and colleagues (2000) for soils in Brazil. Further details about the method followed to obtain soil properties for crop yield simulation can be found in Marin and colleagues (2015).

The average Yw for each RWS buffer was calculated on the basis of the simulated Yw for each crop starting date, weighted according to their relative contribution to the total sugarcane harvested area. Following van Bussel and colleagues (2015), upscaling of the Yw estimated for a RWS was based on relative contribution of the harvested sugarcane area within each RWS buffer zone to the total harvest area at the climate zone and national spatial scales (Table 1).

The average 5-year (2006–2010) Ya was estimated from official statistics reported for the municipalities that overlapped with each of the selected RWS buffers. This recent 5-year time period was selected because longer time periods would underestimate actual yields because of the inclusion of a small but significant technological trend (figure 1). Ya values were upscaled from RWS buffer to climate zone and country following the same procedure as for Yw, and Yg was calculated as the difference between average 30-year (1981–2010) simulated Yw and average 5-year (2006–2010) Ya at each spatial level (RWS buffer, climate zone, and country). Yw, Ya and Yg were expressed in stalk fresh mass (SFM), which is typically 25 to 33% dry matter.

Calibration of sugarcane crop model for simulating yield potential

The DC model was used to simulate sugarcane Yw. The DC model is based on a physiological description of sugarcane growth and development processes, including phenology, canopy development, tillering, root growth, biomass accumulation and partitioning among organs, water stress, and lodging (Singels et al. 2008). In the present study, the DC model was calibrated by minimizing the root mean square error (RMSE) for SFM and leaf area index (LAI) using field data for the cultivar RB867515, which is grown on nearly one-third of the sugarcane area in Brazil (PMGCA 2012). Marin and colleagues (2015) described the experimental data used for model calibration, which were collected from seven experiments located throughout Brazil and conducted over several years across a wide range of climate and soil types representative of the major sugarcane production regions. At all seven experimental sites, the sugarcane crop was grown with good management that avoided growth limitations from nutrient deficiencies and biotic stresses from pests and diseases. It is therefore expected that yields obtained in these experiments were very close to Yw for each site and representative of the Yw across years and major sugarcane-producing regions in Brazil. Detailed descriptions of the procedures followed for model calibration can be found in Marin and colleagues (2011, 2015).

After calibration, the DC model reproduced well the observed temporal growth dynamics in SFM and LAI across the seven experiments, and SFM yields measured at harvest (range: 77 to 152 megagrams, Mg, per hectare, ha) were in reasonable agreement with simulated values (root mean square error = 16.5 Mg per ha). This level of error is comparable to the error reported in previous studies that evaluated sugarcane crop models (Keating et al. 1999, Cheeroo-Nayamuth et al. 2000, O'Leary 2000, Singels and Bezuidenhout 2002, Marin et al. 2012). Therefore, the DC model calibrated in the present study provides a competent tool for estimating sugarcane Yw across the range of climate and soils where sugarcane is grown in Brazil.

An assessment of future scenarios for sugarcane area and yield in Brazil

The sugarcane production in Brazil required for satisfying demand for sugar and ethanol by 2024 is projected to reach (a) 851 million Mg SFM, as was reported by FIESP (2014), or (b) 1179 Mg SFM, as was reported by FAPRI (2011). The FIESP (2014) projection is based on an input–output model evaluating the global balance of food production and consumption, in which the demand of each country is established from food income elasticities and expected population- and economic-growth rates. Similarly, the FAPRI (2011) projection is based on an econometric model evaluating future demographics and economic growth. Second-generation biofuels are not taken into account in these projections. These two contrasting 2024 sugarcane projections are hereafter called low-production (LP) and high-production (HP) projections, respectively. Sugarcane area requirements required to meet the LP and HP projections were assessed for two sugarcane yield scenarios (S1 and S2): (1) S1: projected production met, assuming that future yields follow the historical rate of yield gain achieved from 1990 to 2012; (2) S2: projected production met by closing the Yg such that Ya reaches 80% of Yw on current production area by 2024.

For both scenario assessments, sugarcane area and Ya in 2014 were the baseline, and the proportion of the production area under irrigation was assumed to remain constant (currently less than 10% of total area). The historical rate of yield used for S1 was estimated for the 1990–2012 time period on the basis of publicly available statistics (IBGE, FAOSTAT). The 80% of Yw threshold used in the S2 scenario is based on the assumption that this yield level represents the upper ceiling on attainable yields at a regional or national scale, because it is not feasible or economically viable for commercial-scale farming to achieve the degree of perfection in crop and soil management required to eliminate all abiotic and biotic stresses, which is a prerequisite for attaining Yw (Cassman et al. 2003). Likewise, there is a growing body of evidence indicating that national crop yields plateau at yield levels that are 75%–85% of potential yields (Van Wart et al. 2013b).

Yield potential and yield gaps

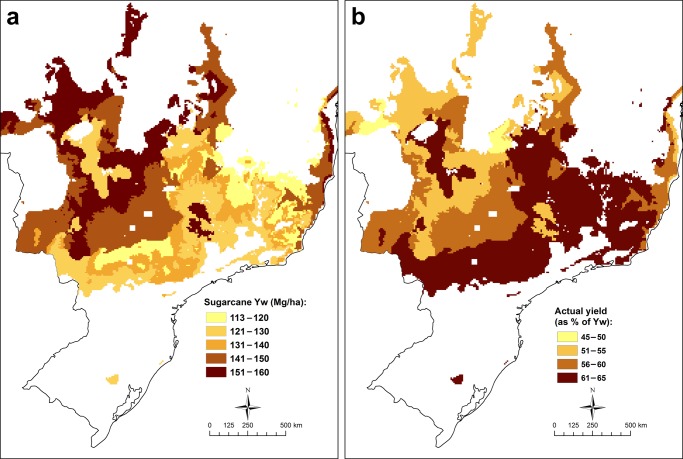

The upscaled national average Yw estimated for sugarcane in Brazil was 134 Mg per ha. Given the current national average Ya of 82 Mg per ha, the average Yg is 52 Mg per ha, which represents 38% of Yw (table 2). The magnitude of Yg, as a percentage of Yw, falls within the range of Yg for large- (23%) and small-scale sugarcane farmers (53%) in South Africa, as was estimated by van den Berg and Singels (2013). Figure 3 shows variation in Yw and Ya (expressed as percentage of Yw) across the major climate zones in which sugarcane production takes place in Brazil. Both highest Yw (figure 3a) and lowest Ya as a percentage of Yw (i.e., largest Yg; figure 3b) were found in the north–central and western sugarcane-producing regions, where sugarcane is a relatively new crop with most of the production initiated within the past 10 years. The large Yg in these regions may be explained in large part by the lack of farmer experience in sugarcane management, relatively low fertility soils, and difficulties in acquiring healthy seedlings, fertilizers, and agrochemicals in these “frontier” production areas (Manzatto et al. 2009). In coming years, however, and assuming a supportive economic environment for sugarcane production, Yg will likely decrease as farmers begin to gain access to the required inputs and become more proficient at adapting management practices to climate and soils in these frontier sugarcane-production areas. In contrast, Ya as a percentage of Yw was much larger (i.e., the Yg was considerably smaller) in regions with a longer history of sugarcane production, such as in the southern fringe of sugarcane-production area, which corresponds to the states of Sao Paulo and Minas Gerais (figure 3b).

Table 2.

The average water-limited yield potential (Yw), actual yield (Ya), and yield gap (Yg) for the 19 reference weather stations (RWS) in and for the associated climate zones (CZ) selected for sugarcane yield-gap analysis in Brazil.

| RWS (in megagrams per hectare) | CZ (in megagrams per hectare) | |||||

|---|---|---|---|---|---|---|

| Weather station (code) | Yw | Ya | Yg | Yw | Ya | Yg |

| Sorocoba (SO) | 121 (15%) | 80 | 41 | 118 (9%) | 83 | 34 |

| Catanduva (CAT) | 113 (12%) | 86 | 27 | |||

| Sao Simão (SS) | 152 (6%) | 83 | 68 | 146 (5%) | 84 | 61 |

| Uberaba (UB) | 136 (13%) | 88 | 48 | |||

| Maringá (MA) | 141 (9%) | 85 | 56 | |||

| Avaré (AV) | 126 (14%) | 71 | 55 | |||

| Votuporanga (VO) | 144 (6%) | 86 | 57 | 141 (6%) | 83 | 58 |

| Campos (CAM) | 110 (17%) | 48 | 62 | |||

| Presidente Prudente (PP) | 110 (7%) | 79 | 31 | 114 (6%) | 73 | 41 |

| St Antonio de Padua (SAP) | 128 (11%) | 49 | 80 | |||

| Frutal (FR) | 154 (4%) | 87 | 66 | 141 (4%) | 84 | 57 |

| Capinópolis (CAR) | 128 (14%) | 81 | 47 | |||

| Paranaíba (PA) | 109 (28%) | 76 | 32 | |||

| São Mateus (SM) | 120 (16%) | 65 | 54 | |||

| Rio Verde (RV) | 157 (9%) | 83 | 74 | 157 (6%) | 84 | 74 |

| Ivinhema (IV) | 157 (4%) | 84 | 72 | |||

| Sao Sebastião do Paraiso (SSP) | 157 (14%) | 83 | 74 | 157 (14%) | 84 | 74 |

| Goiás (GO) | 154 (6%) | 75 | 79 | 154 (6%) | 75 | 79 |

| Diamantino (DI) | 140 (10%) | 66 | 74 | 140 (10%) | 66 | 77 |

| National weighted average | 134 (4%) | 82 | 52 | |||

Note: The parenthetic values for Yw are the temporal coefficients of variation.

Figure 3.

Maps of (a) water-limited yield potential (Yw; in megagrams [Mg] per hectare [ha]) and (b) rainfed actual farm yield (expressed as percentage of Yw) for sugarcane across the major climate zones where sugarcane is produced in Brazil.

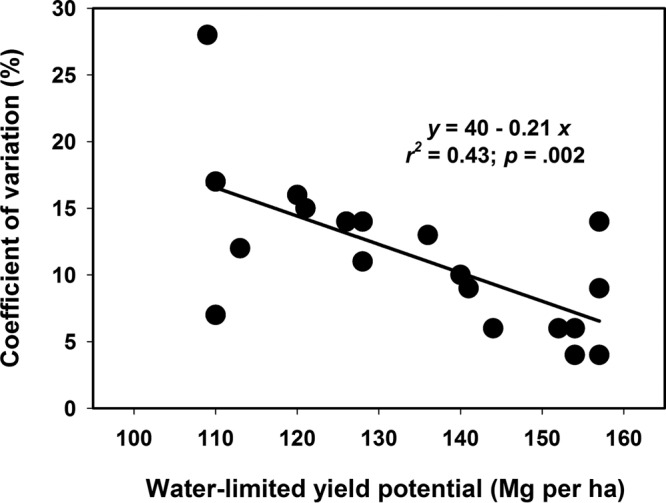

There was substantial variation in average Yw across the 19 selected RWS, ranging from 109 to 157 Mg per ha (table 2). This range compares well with the range in Ya reported for well-managed, high yield sugarcane crops grown in South Africa and Australia (Keating et al. 1999), and with the range of SFM yields measured under near-optimal production conditions by Marin and colleagues (2011, 2015). In addition, Yw was remarkably stable across years for a rainfed crop production system, as was indicated by the small interannual coefficients of variation (CV; table 2). Of the 19 locations at which Yw was simulated, nine had a CV of less than 10%, and only three locations had a CV of more than 15%, indicating the preference of producers to grow sugarcane in favorable environments with reliable rainfall. Indeed, there was an inverse relationship between average Yw and the associated CV (figure 4), which highlights the importance of the high-yield regions for both their large contribution to national production and production stability. Likewise, year-to-year variation in Yw decreases with larger spatial aggregation, moving from RWS (CV range: 6%–28%) to CZ (CV range: 4%–14%) and country (CV: 4%) spatial scales (table 2). This scaling trend suggests that countries with large crop-production area spread across a number of different climate zones (as in Argentina, Brazil, China, and the United States) are somewhat buffered against low national yields in a given year because of unfavorable climatic events, such as drought, because these events rarely occur across a majority of the production area within a country.

Figure 4.

The relationship between long-term (1981–2010) average sugarcane water-limited yield potential and its interannual coefficient of variation. Each data point represents one of 19 reference weather stations selected for the evaluation of sugarcane yield gaps in Brazil. Abbreviations: ha, hectares; Mg, megagrams.

How much additional sugarcane can Brazil produce without area expansion?

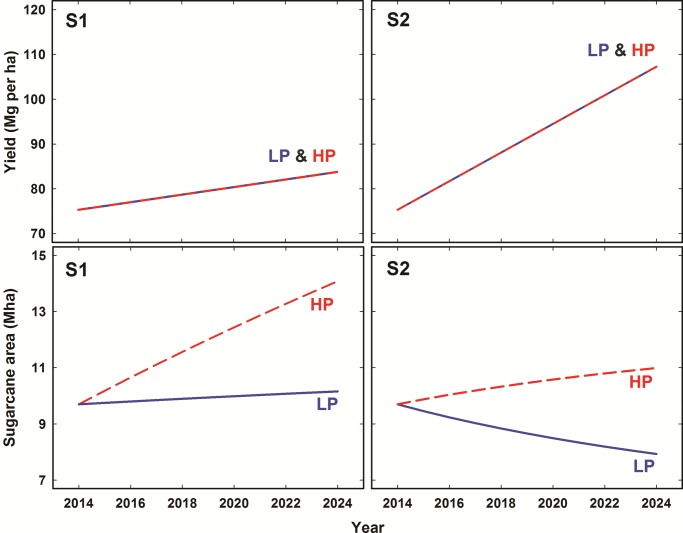

Maintaining the historical rate of yield gain of 0.85 Mg per ha per year (S1) will require a respective 5% and 45% expansion in sugarcane production area to meet the LP and HP projections by 2024, which represents a respective 0.4% per-year and 4% per-year annual increase in production area (figure 5, table 3). The S1 scenario assumes that the expansion in sugarcane area will occur in areas with Yw similar to the average Yw of 134 Mg per ha estimated for Brazil in this study. If sugarcane expansion were to take place in harsher rainfed environments or on poorer soils, the additional land requirement would be greater. Nevertheless, the estimated land requirement to satisfy sugarcane demand by the year 2024 seems modest under the LP scenario, and although much greater under the HP scenario, the area expansion is still much smaller than the rate of increase in sugarcane area that occurred from 2004–2013 (7.5% per year).

Figure 5.

The pathways to meet future sugarcane demand in Brazil showing the sugarcane yield (upper panels) and sugarcane area (lower panels) required to meet 2024 “low” (LP, blue solid line) and “high” (HP, red dashed line) production projections for two scenarios: demand met with historical rate of yield gain (S1, left panels) and demand met by closing the exploitable yield gap to 80% of water-limited yield potential (S2, right panels). Abbreviations: ha, hectares; Mg, megagrams; Mha, megahectares.

Table 3.

The required sugarcane area to meet the 2024 projected “low” (LP) and “high” (HP) production projections for two scenarios: demand met by the historical rate of yield gain (S1) or demand met by closing the exploitable yield gap to 80% of water-limited yield potential (Yw) (S2).

| 2024 scenarios | ||||

|---|---|---|---|---|

| Parameter | Projected productiona | 2014 baseline | S1 | S2 |

| Sugarcane area (Mha) | LP | 9.7b | 10.2 (+5%) | 7.9 (–18%) |

| HP | 14.1 (+45%) | 11.0 (+13%) | ||

| Production (million Mg) | LP | 732b | 851 (+17%) | |

| HP | 1179 (+62%) | |||

| Actual yield (Mg per ha) | LP, HP | 75b | 84 (+11%) | 107 (+42%) |

| 2014–2024 yield gain rate (Mg per ha per year) | LP, HP | 0.85c | 0.85 (0%) | 3.20 (+278%) |

Note: The parenthetic values are the percentage change relative to 2014 baseline values. Abbreviations: ha, hectares; Mha, megahectares; Mg, megagrams. a“Low” (LP, 851 million Mg) and “high” (HP, 1179 million Mg) projected 2024 production as reported by FIESP (2014) and FAPRI (2011), respectively. bAverage of 2011–2013 data (IBGE, FAOSTAT). cHistorical yield gain rate was estimated for the 1990-2012 time period (IBGE, FAOSTAT).

If research and extension focused on closing the current Yg using improved management and best available cultivars to close the exploitable yield gap such that average farm yields reach 80% of Yw by 2024 (S2), equivalent to an average national yield of 107 Mg per ha, it will be possible to meet the LP sugarcane demand while reducing land requirements by 18% compared with current sugarcane area (figure 5, table 3). In contrast, closing the exploitable yield gap on existing sugarcane area will not be sufficient to meet the HP demand scenario, and a 13% increase in sugarcane area will be required, which represents a rate of area expansion of approximately 1.2% per year. However, the area increase under the HP–S2 scenario is 71% less than that required by the “business-as-usual” HP–S1 scenario. At issue, however, is whether it would be possible to increase the historical annual yield gain more than threefold (from 0.85 to 3.2 Mg per ha per year) and sustain such high rates of gain during the next 10 years to close the exploitable yield gap by 2024.

Finally, it is notable that potential production can be further increased (and land requirements reduced) if expansion of irrigated area takes place in current sugarcane-production areas. Indeed, there are prospects for expanding irrigation in many parts of central Brazil (IICA and PROCISUR 2010). Likewise, the demand for additional sugarcane area can be easily met through modest productivity gains in pastoral livestock systems, given the sizeable land-saving effects that would arise from such improvements (Martha et al. 2012).

The findings of this study are subject to uncertainty related to (a) the quality of long-term weather, soil, crop management, and production statistics data required for yield-gap estimation (Grassini et al. 2015); (b) upscaling methods (van Bussel et al. 2015); and (c) assumptions underpinning scenarios of future sugarcane demand (FIESP 2014, FAPRI 2011). Despite these uncertainties, this article represents the first quantification of sugarcane-production potential on existing sugarcane area in Brazil using the best available data and published projections of future sugarcane demand, a “state-of-the-art” biophysical sugarcane simulation model, and a bottom-up spatial framework that covers 88% of the national sugarcane production area with only 19 locations strategically selected for their location within climate zones with the greatest sugarcane-production area.

Conclusions

This article estimates sugarcane yield gaps at different spatial scales using a novel bottom-up scaling approach to assess future scenarios of sugarcane production and land use by 2024. The results suggest that Brazil has the potential to meet the projected demand under a high-demand scenario with a modest expansion of crop area (+13%)—or even with an 18% reduction in area for the low-demand scenario. However, this would require a large acceleration in the rate of yield gain compared with the historical trend, which would be difficult to achieve without a concentrated and well-funded research and extension effort. In contrast, if yields continue to increase following the historical trajectory of the past two decades, a respective expansion of 5% and 45% of sugarcane area would be needed to satisfy the low- and high-demand scenarios by 2024. We conclude that a focus on accelerating the rate of gain in sugarcane yields is the key to minimizing land requirements for sugarcane, and the results from this study can help inform policies and the prioritization of investments in research and development to meet sugarcane demand while also addressing associated environmental concerns.

Acknowledgments

Funding sources include the Robert B. Daugherty Water for Food Institute (University of Nebraska–Lincoln), the Brazilian Research Council (CNPq grant nos. 301424/2015–2 403946/2013-1, 302872/2012-4, and 480702/2012-8), and the Research Foundation of the State of São Paulo (FAPESP grant nos. 2014/12406-4 and 2014/50023-0).

References cited

- Bristow KL, Campbell GS. On the relationship between incoming solar radiation and daily maximum and minimum temperature. Agricultural and Forest Meteorology. 1984;31:159–166. [Google Scholar]

- Burney J, Davis SJ, Lobell DB. Greenhouse gas mitigation by agricultural intensification. Proceedings of the National Academy of Science. 2010;107:12052–12057. doi: 10.1073/pnas.0914216107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cassman KG, Dobermann A, Walters DT, Yang H. Meeting cereal demand while protecting natural resources and improving environmental quality. Annual Review Environmental Resources. 2003;28:315–358. [Google Scholar]

- Cheeroo-Nayamuth FC, Robertson MJ, Wegener MK, Nayamuth ARH. Using a simulation model to assess potential and attainable sugar cane yield in Mauritius. Field Crops Research. 2000;66:225–243. [Google Scholar]

- [CONAB] Companhia Nacional de Abastecimento . Sugarcane: Third survey for 2014/2015 season. CONAB; 2014. (26 March 2015; www.conab.gov.br/conteudos.php?a = 1253&ordem = produto) [Google Scholar]

- Cooper M., Mendes LMS, Silva WLC, Sparovek G. A national soil profile database for Brazil available to international scientists. Soil Science Society of American Journal. 2005;69:649–652. [Google Scholar]

- Evans L. Crop Evolution, Adaptation, and Yield. Cambridge University Press; 1993. [Google Scholar]

- [FAOSTAT] Food and Agriculture Organization . Statistical database. FAOSTAT; 2014. (12 January 2016; http://faostat.fao.org/) [Google Scholar]

- [FAPRI-ISU] Food and Agricultural Policy Research Institute, Iowa State University . World Agricultural Outlook Database. 2011. (26 March 2015; www.fapri.iastate.edu/tools/outlook.aspx) [Google Scholar]

- [FIESP] Federação das Indústrias do Estado de São Paulo . Outlook Federação das Indústrias do Estado de São Paulo 2024: Projeções para o Agronegócio Brasileiro. FIESP; 2014. (26 March 2015; http://apps2.fiesp.com.br/outlookDeagro/pt-BR). [Google Scholar]

- Fonseca MA, Marin FR. Avaliação de modelos de estimativa de valores diários da radiação solar global com base na temperatura do ar. Revista Brasileira de Agrometeorologia. 2007;15:103–108. [Google Scholar]

- Goldemberg J. Ethanol for a sustainable energy future. Science. 2007;315:808–810. doi: 10.1126/science.1137013. [DOI] [PubMed] [Google Scholar]

- Goldemberg J, Mello FFC, Cerri CEP, Davies CA, Cerri CC. Meeting the global demand for biofuels in 2021 through sustainable land use change policy. Energy Policy. 2014;69:14–18. [Google Scholar]

- Grassini P, van Bussel L, van Wart J, Wolf J, Claessens L, Yang H, Boogaard H, Groot H, Cassman KG, van Ittersum MK. How good is good enough? Data requirements for reliable crop yield simulations and yield-gap analysis. Field Crops Research. 2015;177:49–63. [Google Scholar]

- [IBGE] Instituto Brasileiro de Geografia e Estatística . Agricultural Production at County Level: Producau Agricola Municipal. IBGE; 2014. (12 January 2016; www.sidra.ibge.gov.br/bda/pesquisas/pam/default.asp) [Google Scholar]

- [IICA] Inter-American Institute for Cooperation on Agriculture, [PROCISUR] Proyectos Y Construcciones Inmobiliarios del Sur . El Riego en los Países del Cono Sur. IICA; 2010. (26 March 2015; http://repiica.iica.int/docs/B2113e/B2113e.pdf). [Google Scholar]

- Keating BA, Robertson MJ, Muchow RC, Huth NI. Modelling sugarcane production systems I: Development and performance of the sugarcane module. Field Crops Research. 1999;61:253–271. [Google Scholar]

- Koning N, van Ittersum MK. Will the world have enough to eat? Current Opinion in Environmental Sustainability. 2009;1:77–82. [Google Scholar]

- Laurance WF, Sayer J, Cassman KG. Agricultural expansion and its impact on tropical nature. Trends in Ecology and Evolution. 2014;29:107–116. doi: 10.1016/j.tree.2013.12.001. [DOI] [PubMed] [Google Scholar]

- Lepers E, Lambin EF, Janetos AC, DeFries R, Achard F, Ramankutty N, Scholes RJ. A synthesis of information on rapid land-cover change for the period 1981–2000. BioScience. 2005;55:115–24. [Google Scholar]

- Lobell DB, Cassman KG, Field CB. Crop Yield Gaps: Their importance, magnitudes, and causes. Annual Review of Environment and Resources. 2009;34:179–204. [Google Scholar]

- Manzatto C, Assad ED, Bacca JFM, Zaroni MJ, Pereira SEM. Sugarcane agroecological Zoning for Brazil. Expandir a Producao, Preservar a Vida, Garantir o Fu-turo. Embrapa Soils; 2009. [Google Scholar]

- Marin FR, Carvalho GL. Spatio-temporal variability of sugarcane yield efficiency in the state of São Paulo, Brazil. Pesquisa Agropecuária Brasileira. 2012;47:149–156. [Google Scholar]

- Marin FR, Lopes-Assad ML, Assad ED, Vian CE, Santos MC. Sugarcane crop efficiency in two growing seasons in São Paulo State, Brazil. Pesquisa Agropecuária Brasileira. 2008;43:1449–1455. [Google Scholar]

- Marin FR, Jones JW, Royce F, Suguitani C, Donzelli JL, Pallone W, Nassif D. Parameterization and evaluation of predictions of DSSAT/CANEGRO for Brazilian sugarcane. Agronomy Journal. 2011;103:304–311. [Google Scholar]

- Marin FR, Jones JW, Singels A, Royce F, Assad ED, Pellegrino GQ, Justino FB. Climate change impacts on sugarcane attainable yield in Southern Brazil. Climatic Change. 2012;117:1–13. [Google Scholar]

- Marin FR, Thorburn PJ, Nassif DSP, Costa LG. Sugarcane model intercomparison: Structural differences and uncertainties under current and potential future climates. Environmental Modelling and Software. 2015;72:372–386. [Google Scholar]

- Martha GB, Jr, Alves E, Contini E. Land-saving approaches and beef production growth in Brazil. Agricultural Systems. 2012;110:173–177. [Google Scholar]

- Naylor RL, Liska AJ, Burke MB, Falcon WP, Gaskell JC, Rozelle SD, Cassman KG. The ripple effect: Biofuels, food security, and the environment. Environment. 2007;49:30–43. [Google Scholar]

- O'Leary GJ. A review of three sugarcane simulation models with respect to their prediction of sucrose yield. Field Crops Research. 2000;68:97–111. [Google Scholar]

- Oliveira MED, Vaughan BE, Rykiel EJ., Jr Ethanol as fuel: Energy, carbon dioxide balances, and ecological footprint. BioScience. 2005;55:93–602. [Google Scholar]

- [PMGCA] Programa de Melhoramento Genético da Cana-de-Açúcar . Cultivar Census for 2011/2012 Sugarcane Growing Season. 2012. (13 March 2015; http://pmgca.dbv.cca.ufscar.br/htm/catal/censovar.php) Radambrasil Project. 1973–1986. Brazilian Survey of Natural Resources, vols. 31–32. Instituto Brasileiro Geografia e Estatıtica. [Google Scholar]

- Singels A, Bezuidenhout CN. A new method of simulating dry matter partitioning in the Canegro sugarcane model. Field Crops Research. 2002;78:151–164. [Google Scholar]

- Singels A, Jones M, van den Berg M. DSSAT v4. 5-Canegro Sugarcane Plant Module. South African Sugarcane Research Institute; 2008. [Google Scholar]

- Tomasella J, Hodnett MG, Rossato L. Pedotransfer functions for the estimation of soil water retention in Brazilian soils. Soil Science Society of America Journal. 2000;64:327–338. [Google Scholar]

- Van Bussel L, et al. From field to atlas: Upscaling of location-specific yield gap estimates. Field Crops Research. 2015;177:98–108. [Google Scholar]

- Van den Berg M, Singels A. Modelling and monitoring for strategic yield gap diagnosis in the South African sugar belt. Field Crops Research. 2013;143:143–150. [Google Scholar]

- Van Ittersum MK, Cassman KG, Grassini P, Wolf J, Tittonel P, Hochman Z.2013Yield gap analysis with local to global relevance: A review Field Crops Research 1434–17. [Google Scholar]

- Van Wart J, et al. Use of agro-climatic zones to upscale simulated crop yield potential. Field Crops Research. 2013a;143:44–55. [Google Scholar]

- Van Wart J, Kersebaum C, Peng S, Milner M, Cassman KG. Estimating crop yield potential at regional to national scales. Field Crops Research. 2013b;143:34–43. [Google Scholar]

- Vermeulen SJ, Campbell BM, Ingram JSI. Climate change and food systems. Annual Review Environmental Resource. 2012;37:195–222. [Google Scholar]