Introduction

Wastewater systems contribute to significant negative impacts not only on a regional water body, but also to global energy, climate, and sustainability. In thinking holistically of water and wastewater management, energy recovery from wastewater becomes an appealing option to achieve greater resource recovery1, 2. The most common form of energy recovery is Anaerobic Digestion, which is the biological degradation of organic matter in the absence of oxygen with subsequent conversion of chemical energy in organic carbon into biogas3. Typically, Anaerobic Digestion has been used with wastewater sludge treatment and reduction, agricultural manure management and food waste management 3. To accomplish more sustainable resource recovery and reduce the overall energy footprint, wastewater can be regarded as a renewable resource for converting embedded chemical energy into biogas 4.

In the United States, currently there are 16,000 publicly owned wastewater systems. Only 544 of these use Anaerobic Digestion 3. That means there are at least 15,000 facilities that send their sludge to landfills or incinerators which contributes to global warming and air pollution. The importance of Anaerobic Digestion arises with the ability to convert the organic compounds in waste into biogas. Biogas is comprised of 60%–70% methane, 30%–40% CO2 and a small percentage of trace gases. A combined heat and power (CHP) engine can use this biogas to create electricity and heat, or the compressed biogas can be used as fuel to power fleet vehicles. Compressed methane or natural gas is often viewed as a cleaner alternative to diesel fuels 5. With this ability to create electricity and fuel, wastewater treatment plants (WWTPs) have the potential to not only power their entire facility, but also receive revenue by sending excess electricity to the grid.

Currently, a few WWTPs are sending electricity back to the grid. Whereas, most WWTPs that use Anaerobic Digestion as one of the treatment process, either use produced biogas to heat their buildings, heating influents and flare the excess biogas or profit from “tipping fees” paid by other local companies. A tipping fee is a fee charged for the amount of waste disposed to a landfill 7, 8. Not only can Anaerobic Digestion create energy from waste, but through the Anaerobic Digestion process, digestate that is the material remaining after the Methanogenesis stage is called “biosolids”. The biosolids can be further treated to produce higher quality biosolids either grade A or B which can be sent to local farms or nursery stores as a fertilizing compound or as soil conditioner.

The Co-digestion Economic Analysis (Co-EAT) model developed by US EPA allows the user to input current operating parameters which tailors the model to plant specific operations9. This model is designed to quantify the impacts associated with adding co-digestion onto an existing Anaerobic Digestion system. The Co-EAT model can predict the quantity of biogas production based on volume of volatile solids (VS) destroyed daily or annually9. Furthermore, the model can also estimate economic parameters such as tipping fees, market value of the biogas and associated disposal costs. It can also compare these economic and physical characteristics under a variety of differing scenarios. For this contribution, this model has been applied to the following two case studies.

Case Study: Quasar Wooster, OH

The first case study is for a facility located in Wooster, OH. This facility, operated by Quasar, applies an Anaerobic Digestion technology for a municipal WWTP, producing biogas from sludge, food waste and agriculture waste 10. The resulting biogas is used for electricity and thermal heat, and natural gas or compressed natural gas as fuel for fleet vehicles 10. The facility’s mission is to reduce greenhouse gas emissions, divert waste from landfills and contribute to a cleaner environment while receiving economic benefits.10

At the Quasar operation adjacent to the Wooster WWTP, the digestion feed is derived from sludge, wastes from poultry operations, grain, food, and other manufacturing companies such as Smuckers. The multiple feed inputs lend to the name “co-digestion”, because of the mixture of different types of organic wastes. Primarily, this Quasar’s facility was operating at around 1 million gallons per day (MGD) and receiving around 60,000 gallons per day of combined food waste, fats, oils, and greases. Typically, food waste is around 5% Total Solids. 11With the biogas generated, the CHPs were able to heat the inflows, power the entire plant and send excess electricity back to the grid. The biosolids that were generated as by-products of Anaerobic Digestion were sent to local farms for use as fertilizer. However, most of the profits received were the result of tipping fees from those local food/agricultural companies which sent their waste to Quasar instead of for landfilling or incineration. Table 1 shows the results of biogas generation, the energy recovered, and the revenues from different biogas applications for the Wooster, OH facility. Biogas production values are labeled in blue and cost values are labeled in green.

Table 1.

Biogas Production and Values Using Co-Eat Model: Quasar Operation

| Quasar Biogas Production Using Co-Eat | ||

| • Combined Heat and Power Efficiency (CHP) = 28% | ||

| • Biogas to Natural Gas Conversion Factor = 60% | ||

| • Total Solids % for Food Waste = 5% | ||

| • Total Solids % for Fats, Oil, Grease = 5% | ||

| • Total Solids % for 1 MGD = 1% | ||

| • Natural Gas ($/unit) = $2.44 | ||

| • Electricity ($/unit) = $0.05 | ||

| • Tipping Fees ( $/unit) = $0.07 | ||

| Quasar | ||

| 4/20/16 | ||

| Biogas Production (ft3/day) | 227,091 | |

| Annual Biogas Production (ft3/yr) | 101,138,396 | |

| Electrical Energy Generated via CHP (KWh/yr) | 4,780,458 | |

| Biogas Value (Boiler + Flare) ($/yr) | $ 531,242.46 | |

| Value of Electrical Energy via CHP ($/yr) | $ 239,023.00 | |

| Value of Compressed Natural Gas (Bioler + Vehicle Fuel) ($/yr) | $1,126,515.00 | |

Case Study: Dayton Wastewater Treatment Plant; Dayton, OH

The next case study is for a Water Reclamation Plant located in Dayton OH. The Dayton Water Reclamation plant is much larger when compared to the Quasar facility in Wooster, OH. Anaerobic Digestion at Dayton uses primary sludge and secondary activated sludge generated from municipal wastewater, with operations of approximately 38 MGD. With that magnitude of input, there is a potential to create biogas averaging between 600,000 – 700,000 ft3 per day. Below in Table 2 are the results from applying the Co-EAT model illustrating the potential of biogas generation for the Dayton Water Reclamation Plant9.

Table 2.

Biogas Production and Values Using Co-Eat Model: Dayton WWTP

| Dayton WWT Biogas Production Using Co-Eat | ||

| • Combined Heat and Power Efficiency (CHP) = 2894 | ||

| • Biogas to Natural Gas Conversion Factor = 60% | ||

| • Total Solids % for 38 MGD = 1% | ||

| • Natural Gas ($/unit) = $2.44 | ||

| • Electricity ($/unit) = $0.05 | ||

| • Tipping Fees ($/unit) = $0.07 | ||

| Dayton Water Reclamation Plant | ||

| 4/26/16 | ||

| Biogas Production (ft3/day) | 684,295 | |

| Annual Biogas Production (ft3/yr) | 249,767,753 | |

| Electrical Energy Generated via CHP (KWh/yr) | 11,805,649 | |

| Biogas Value (Boiler + Flare) ($/yr) | $ 1,311,937.31 | |

| Value of Electrical Energy via CHP ($/yr) | $ 590,283.00 | |

| Value of Compressed Natural Gas (Bioler + Vehicle Fuel) ($/yr) | $ 2,782,002.00 | |

In this evaluation, some operating parameters were set to be identical between the two facilities to allow for a direct comparison. These parameters were Combined Heat and Power Efficiency, Biogas to Natural Gas Conversion Factor, Total Solids Percentage for municipal wastewater, Natural Gas ($/unit), Electricity ($/unit), and Tipping Fees ($/unit). However, for Quasar case study the operating parameters Total Solids Percentage of food waste, fats, oils and greases were assumed.

It is apparent using biogas for electrical energy via CHP and Compressed Natural Gas (CNG) could be very profitable for a facility. If sending the sludge to a landfill or an incinerator, a plant that is in comparable in size to the Dayton’s facility, can lose a potential revenue stream of anywhere between $2–3 million dollars.

From the comparison of the Quasar operation with that of the Dayton Water Reclamation Plant, there are many potential benefits for co-digestion of different waste sources within the vicinity of the plant. Dayton primarily uses primary sludge and waste activated sludge compared to Quasar’s operation of food and agricultural waste, which has higher organic content. Dayton Water Reclamation Plant is much larger than Quasar’s operation with a daily influent rate 38x that of Quasar’s. In terms of biogas production, Dayton’s facility generates a daily biogas production around 700,000 ft3/day compared to Quasar’s daily biogas production of 200,000 ft3/day. This is significant because Quasar is a much smaller operation than Dayton Water Reclamation Plant. This shows the benefits of co-digestion with higher organic waste content for biogas production.

Conclusion

Traditionally, Anaerobic Digestion has been seen as a waste management option in agricultural waste management. Many facilities and plants have not implemented Anaerobic Digestion due to high capital costs associated with building new digesters or upgrading existing digesters to meet the needs associated with the addition of other organic streams, such as food waste.

Time and funding constrains are other obstacles many facilities and plants face when trying to adopt Anaerobic Digestion. Many facility process engineers do not have the time or resources to further investigate new technologies due to their existing workloads and the complexity of retrofitting the existing plants. Furthermore, many plants and facilities either keep status quo or hire outside consultants if budget allows to try to optimize plant operations. Another obstacle facing the transition to Anaerobic Digestion application is the stigma that biosolids, such as composting waste, produces a foul odor.

Aside from all the obstacles, Anaerobic Digestion is a technology that offers the potential for energy recovery and revenue generation. Sludge from wastewater treatment plants is either being sent to landfills or burnt in incinerators, leading to greenhouse gas generation that affects the environment and is an untapped resource and revenue stream. If the biogas is harnessed from the sludge and wastes, from local food and agricultural industries, it can achieve overall system efficiency with economic and environmental benefits. Implementing this technology would allow reductions in greenhouse emissions, utility operational expenditure and dependence on other energy resources.

Future work can include the evaluation of the Return on Investment (ROI) when implementing a new Anaerobic Digestion system for a facility. The system analysis such as Life Cycle Assessment (LCA) should be performed not just for Anaerobic Digestion unit process, but also the system of wastewater treatment train as a whole to evaluate trade-offs of this new technology.

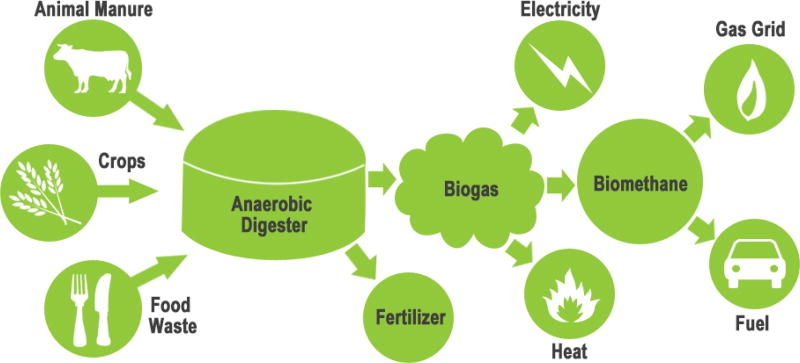

Figure 1.

Anaerobic Digestion Process6

Acknowledgments

This project was supported by the US Environmental Protection Agency and the University of Cincinnati Research Training Program. The authors would like to acknowledge Phil Bennington from Dayton Reclamation Plant for providing the data required for this project along with the continued support and encouragement, the staff from Quasar for providing a tour of their facility as well as the necessary information regarding their operation, and the US EPA researchers Dr. Steve Rock and Jonathan Ricketts for the discussions of the Co-EAT model.

Footnotes

Disclaimer

The views expressed in this article are those of the authors and do not necessarily reflect the view or policies of the U.S. Environmental Protection Agency. Any mention of specific products or vendors does not represent endorsement by the U.S environmental Protection Agency.

Contributor Information

Vincent Vutai, Department of Biomedical, Chemical and Environmental Engineering, University of Cincinnati, Cincinnati, OH.

Xin (Cissy) Ma, US EPA ORD, National Risk Management Research Laboratory, Sustainable Technology Division, Cincinnati, OH.

Mingming Lu, Department of Biomedical, Chemical and Environmental Engineering, University of Cincinnati, Cincinnati, OH.

References

- 1.McCarty PL, Bae J, Kim J. Domestic Wastewater Treatment as a Net Energy Producer–Can This be Achieved? Environmental Science & Technology. 2011;45(17):7100–7106. doi: 10.1021/es2014264. [DOI] [PubMed] [Google Scholar]

- 2.Guest J, Skerlos S, Barnard J, Beck M, Daigger G, Hilger H, Jackson S, Karvazy K, Kelly L, Macpherson L, Mihelcic J, Pramanik A, Raskin L, Van Loosdrecht M, Yeh D, Love N. A New Planning and Design Paradigm to Achieve Sustainable Resource Recovery from Wastewater. Environmental Science Technology. 2009;43:6126–6130. doi: 10.1021/es9010515. [DOI] [PubMed] [Google Scholar]

- 3.Ma X, Xue X, González-Mejía A, Garland J, Cashdollar J. Sustainable Water Systems for the City of Tomorrow—A Conceptual Framework. Sustainability. 2015;7(9):12071. [Google Scholar]

- 4.Grant SB, Saphores J-D, Feldman DL, Hamilton AJ, Fletcher TD, Cook PLM, Stewardson M, Sanders BF, Levin LA, Ambrose RF, Deletic A, Brown R, Jiang SC, Rosso D, Cooper WJ, Marusic I. Taking the “Waste” Out of “Wastewater” for Human Water Security and Ecosystem Sustainability. Science. 2012;337(6095):681–686. doi: 10.1126/science.1216852. [DOI] [PubMed] [Google Scholar]

- 5.U. S. Department of Energy. [accessed Sep 22, 2016];Natural Gas Vehicle Emissions. http://www.afdc.energy.gov/vehicles/natural_gas_emissions.html.

- 6.JFS & Associates. [accessed Sep 22, 2016];How does it work? http://www.jfsassociates.co.uk/how-does-it-work/

- 7.California Energy Commission. [accessed Sep 22, 2016];Anaerobic Digestion. http://www.energy.ca.gov/biomass/anaerobic.html.

- 8.Waste Management. [accessed Sep 22, 2016];Glossary. http://www.wm.com/glossary.jsp.

- 9.U. S. Environmental Protection Agency. [accessed Sep 22, 2016];Organics: Co-Digestion Economic Analysis Tool (CoEAT) https://archive.epa.gov/region9/organics/web/html/index-2.html.

- 10. [accessed Sep 22, 2016];Quasar Energy Group. http://www.quasarenergygroup.com/pages/quasar.html.

- 11.Moriarty K. Feasibility Study of Anaerobic Digestion of Food Waste in St. Bernard, Louisiana: A Study Prepared in Partnership with the Environmental Protection Agency for the RE-Powering America's Land Initiative, Siting Renewable Energy on Potentially Contaminated Land and Mine Sites. National Renewable Energy Laboratory; 2013. [Google Scholar]