Abstract

Growth of transition metal dichalcogenide (TMD) monolayers is of interest due to their unique electrical and optical properties. Films in the 2H and 1T phases have been widely studied but monolayers of some 1T′-TMDs are predicted to be large-gap quantum spin Hall insulators, suitable for innovative transistor structures that can be switched via a topological phase transition rather than conventional carrier depletion [Qian et al. Science 2014, 346, 1344–1347]. Here we detail a reproducible method for chemical vapor deposition of monolayer, single-crystal flakes of 1T′-MoTe2. Atomic force microscopy, Raman spectroscopy, X-ray photoelectron spectroscopy, and transmission electron microscopy confirm the composition and structure of MoTe2 flakes. Variable temperature magnetotransport shows weak antilocalization at low temperatures, an effect seen in topological insulators and evidence of strong spin–orbit coupling. Our approach provides a pathway to systematic investigation of monolayer, single-crystal 1T′-MoTe2 and implementation in next-generation nanoelectronic devices.

Keywords: Transition metal dichalcogenide, monolayer growth, CVD, 1T′-MoTe2, weak antilocalization

Graphical abstract

Two-dimensional transition-metal dichalcogenides (MX2) have attracted great attention due to the broad set of material characteristics that can be accessed by varying the identity of the transition metal and chalcogenide atoms.1–6 The promise of MX2 monolayer films for energy7 and other applications have been made apparent through investigations of their optical,8,9 electrical,9 and mechanical10/tribological11 properties. Development of reproducible growth methods for high-quality monolayer MX2 films is a key step in advancing basic and applied research into these materials. MX2 materials can crystallize in different forms12 with the 2H phase of MoS2 being most widely studied to date. Other structural phases, such as 1T and 1T′, are of great interest and are being explored at a rapid pace. The monolayer 1T′-MX2 compounds with molybdenum or tungsten as the transition metal are predicted to be large-gap quantum spin Hall (QSH) insulators,13 making them promising for applications in novel switching devices,13 spintronics, and quantum computation.14–16 One method to obtain 1T and 1T′-MX2 is by phase transformation.17 Examples include transformation of MoS2 from 2H to 1T by treatment with n-butyl lithium,18 and conversion of MoTe2 from 2H to 1T′ by laser patterning.19 Computational studies suggest that it is possible to induce a transition from 2H to 1T′ phase in MX2 materials by application of stress,20 but this approach is complicated by the need to control the homogeneity of the strain across the sample. The metastable nature of 1T′-MoTe2 makes direct growth by chemical vapor deposition (CVD) a challenge,21 but CVD growth of few-layer MoTe2 in the 2H and 1T′ phases was recently reported.21,22 There are as yet no reports of a reliable CVD growth method for monolayer, single-crystal, MoTe2 in the 1T′ phase, which would represent a critical step to enable systematic investigations of topological effects in this system.

Here we report direct CVD growth of single-crystal monolayer flakes of MoTe2 in the 1T′ phase along with associated measurements of key chemical, electrical, and physical properties. X-ray photoelectron spectroscopy (XPS) was used to confirm that the chemical composition of the monolayer flakes corresponds to MoTe2. Atomic force microscopy (AFM) revealed that the flakes are monolayer thickness with minimal (<5%) bilayer and multilayer content. Raman spectroscopy, transmission electron microscopy (TEM), and aberration-corrected scanning TEM (ACSTEM) confirmed that the monolayer MoTe2 flakes were single crystal and grown directly in the 1T′ phase. TEM imaging and electron diffraction were used to identify a preferential crystal growth direction along the axis. Finally, temperature-dependent magneto-conductance measurements showed a weak antilocalization effect, which is observed in many topological insulators due to their strong spin–orbit coupling.23 These investigations set the stage for further explorations of monolayer MoTe2 and its eventual application in next-generation electronic, sensor, and optoelectronic devices.

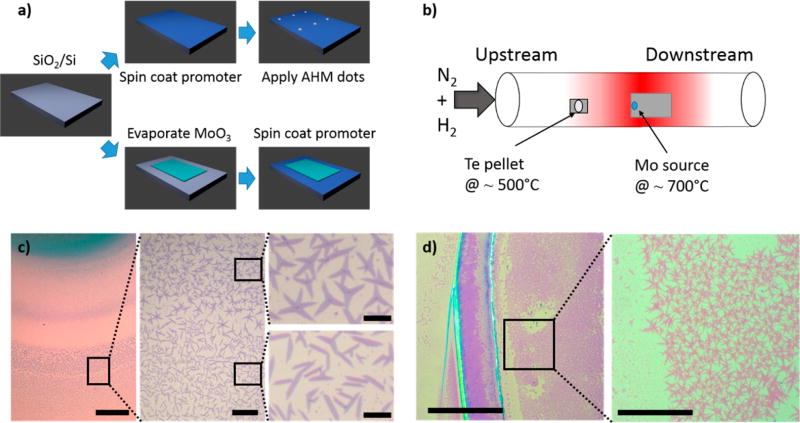

Monolayer MoTe2 flakes were grown directly on a 300 nm SiO2/Si substrate by CVD. First, a 1% sodium cholate solution, known to act as a growth promoter for MoS2,24 is spin coated at 4000 rpm for 60 s onto the SiO2 substrate. A droplet of a saturated solution of ammonium heptamolybdate in deionized (DI) water is deposited onto the substrate, providing the molybdenum feedstock (Figure 1a). The substrate is placed in the center of a 1 in. CVD tube furnace, and 15 mg of solid tellurium is placed 5 cm upstream from the substrate (Figure 1b). Growth occurs at atmospheric pressure in a flow of 400 sccm of nitrogen gas and 25 sccm of hydrogen (both 99.999% purity). The furnace temperature is ramped to 700 °C at a rate of 70 °C min−1. While the Mo source and SiO2 growth substrate reach 700 °C, the maximum temperature of the tellurium pellet is ~500 °C. After a 5 min growth period, the furnace is opened, and the sample is rapidly cooled to room temperature in 1000 sccm flowing nitrogen.

Figure 1.

MoTe2 growth. (a) Process steps for droplet (above) and evaporation (below) methods. (b) Schematic of the CVD growth setup. (c) Optical micrograph displaying MoTe2 flakes grown by the droplet method revealing coffee ring growth region. The inner region has polycrystalline flakes while the outer region has single crystal flakes. Scale bars are 200, 40, and 10 µm, respectively. (d) Optical micrograph displaying MoTe2 flakes grown by the evaporation method. Scale bars are 200 and 40 µm, respectively.

After growth, the substrate is typically sparsely covered with monolayer MoTe2 flakes that grow in a millimeter-scale “coffee ring” pattern around the location of the AHM droplet. In contrast to very regular triangular domains observed for MoS2 grown by CVD,25 MoTe2 flakes are frequently rectangular in shape, as expected for oriented, single crystalline material with typical dimensions of 3 × 10 µm (Figure 1c). Two distinct growth regions are observed in the coffee ring, each with different crystal growth shapes. In the inner part of the ring, the flakes are more dendritic in shape (polycrystalline), while in the outer part of the ring, the flakes are rectangular (single crystal). The crystal orientation can be determined from the shape of the flakes, as discussed below. These two different growth regions in the coffee ring suggest characteristics of the growth mechanism. The inner region of the coffee ring is closer to the Mo feedstock material (AHM). This region is expected to receive a larger Mo flux compared to the outer part of the ring. In the outer part of the coffee ring, the nucleation density and relative flux ratio of Mo to Te atoms are apparently better optimized for growth of single-crystal 1T′-MoTe2 flakes with less perturbation from neighboring growth. In the inner region of the coffee ring, the flux of Mo atoms is higher, resulting in denser growth and polycrystalline 1T′-MoTe2 flakes. This growth mechanism is in agreement with other reports of CVD growth of MX2 materials.24,26

A second growth method provided larger areal density of monolayer MoTe2 flakes. A 20 nm thick rectangle of MoO3 is deposited by thermal evaporation onto the growth substrate using a shadow mask. A 1% sodium cholate solution is spin coated onto the substrate at 4000 rpm for 60 s. The sample growth then proceeds as described above. Samples show a higher density of flakes (Figure 1d), mostly with a star shape, in contrast to the rectangular single crystal flakes described previously. The growth region in this case is the entire area covered by Mo source material, which is on the order of 1–5 cm2 in this experiment. This large-area growth method thus offers a path for future optimization of flake shape and surface coverage. Flakes from both growth methods were characterized as described below, and no significant differences were found. We found that growth of single-crystal monolayer flakes requires both the presence of the growth promoter and careful control of the quantity of molybdenum source material. If either of these parameters is outside of the ideal window, there will either be no growth or multilayer crystallites will be formed.

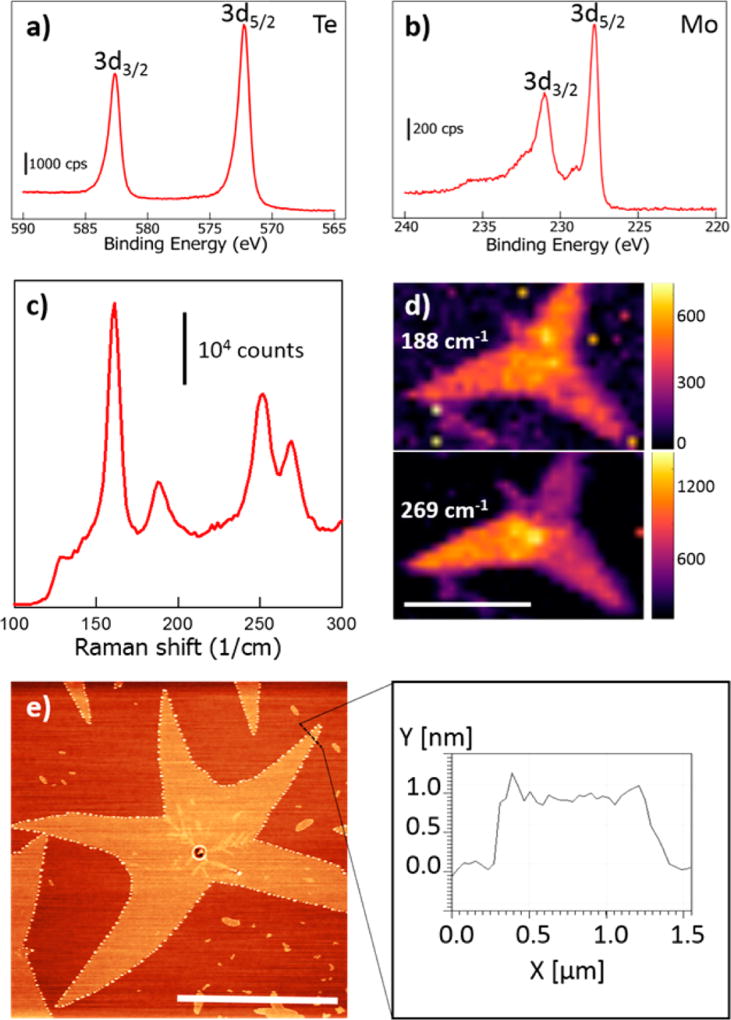

XPS was used to determine the elemental and bond composition of the flakes. Peaks were observed at 572.1, 582.5, 227.7, and 231.0 eV, corresponding to the Te 3d5/2, Te 3d3/2, Mo 3d5/2, and Mo 3d3/2, respectively (Figure 2a,b).21 In group-6 TMDs, the 1T′ signal is typically downshifted by ~0.8 eV relative to the 2H phase,17 and the peaks we observe show the expected downshift compared to the XPS spectrum for 2H-MoTe2 reported by others.21 XPS is not sensitive to the difference between the 1T and 1T′ structures.17 On the basis of these data, the Te/Mo atomic ratio is measured to be 2.1, very close to the ideal value for MoTe2. The full XPS spectrum and details as to how the stoichiometry was determined can be found in the Supporting Information and Figure S1.

Figure 2.

Characterization of MoTe2 flakes by XPS and Raman spectroscopy. (a) XPS spectrum showing 3d3/2 and 3d5/2 Te peaks. (b) XPS spectrum showing 3d3/2 and 3d5/2 Mo peaks. (c) Raman spectrum of MoTe2 flake is consistent with monolayer 1T′-MoTe2. (d) Raman mapping of the amplitude of the 188 and 269 cm−1 peaks. The scale bar is 10 µm. (e) AFM topographic image reveals a clean surface with minimal bilayer content. The scale bar is 10 µm. The line scan indicates a thickness of 0.8 nm, as expected for monolayer material.

Raman spectroscopy with an excitation wavelength of 532 nm was performed to examine the vibrational modes of the MoTe2 flakes. Raman peaks were observed at 112, 127, 161, 252, and 269 cm−1 (Figure 2c), corresponding to five Raman-active Ag modes of monolayer MoTe2 in the 1T′ phase predicted at 111.27, 125.69, 161.10, 254.58, and 269.22 cm−1.27 The spectrum agrees well with previous reports of few layer MoTe2 in the 1T′ phase21,22,28 and it differs significantly from the experimental spectrum for the 2H and theoretical 1T phase.21,27,29 An additional predicted Raman-active mode27 at 80.41 cm−1 is removed by the edge filter of the apparatus and is not expected to be observed. To our knowledge, this is the first experimental report of the peak at 269 cm−1, which is expected to blueshift from 258 to 269 cm−1 as the material is reduced from bulk to monolayer.28 Here, the peak is very distinct at 269 cm−1, indicating the presence of monolayer 1T′-MoTe2. Additionally, an unidentified peak at 188 cm−1 was observed, which is in agreement with an earlier report.21 During Raman mapping measurements conducted in air, the flakes deteriorated over the course of a few hours, likely due to oxidation. To passivate the material, a sheet of monolayer CVD graphene was transferred over the sample immediately after growth and prior to taking Raman spectra, enabling the Raman mapping to be performed over many hours with no degradation of the material. The addition of the graphene layer did not affect the Raman modes (Figure S2). A Raman map of the amplitude of the 269 cm−1 peak for a star-shaped MoTe2 flake is shown in Figure 2d. The map shows a slight intensity variation among the three segments of the flake (we confirmed that the peak position was fixed at 269 cm−1 over the entire flake). This suggests that the different arms of the star are each monolayer 1T′-MoTe2 but with different crystal orientations. The 188 cm−1 intensity map (Figure 2d) reveals that this peak is active across the entire flake, which argues against a contamination effect and raises the question of which yet unidentified vibrational mode is associated with the peak at 188 cm−1. AFM reveals a sample height of ~0.8 nm, as expected for monolayer MoTe2 (Figure 2e).22,29 The AFM image also shows the growth of a partial second layer of MoTe2 near the center of the flake.

To transfer CVD-grown monolayer MoTe2 flakes onto a new substrate, a procedure was developed where the SiO2 interface layer was etched using hydrofluoric acid (HF). In this process, the sample is first spin coated with C4 PMMA (Microchem) at 3000 rpm for 60 s, and then the sample is carefully floated on top of a dilute HF solution (1:50 in DI water). The sample is gently pressed down so the solution covers the edges of the SiO2 without covering the PMMA. The HF solution etches the SiO2 beneath the MoTe2 flakes until the PMMA/MoTe2 stack is released and floats on the solution. The sample is lifted using a polyethylene terephthalate (PET) sheet and transferred to multiple DI water baths to clean the sample. Finally the sample is picked up onto the desired substrate. The substrate is then put into an acetone bath for 3 min to dissolve the PMMA, rinsed in isopropanol for 1 min, and dried using a N2 gun.

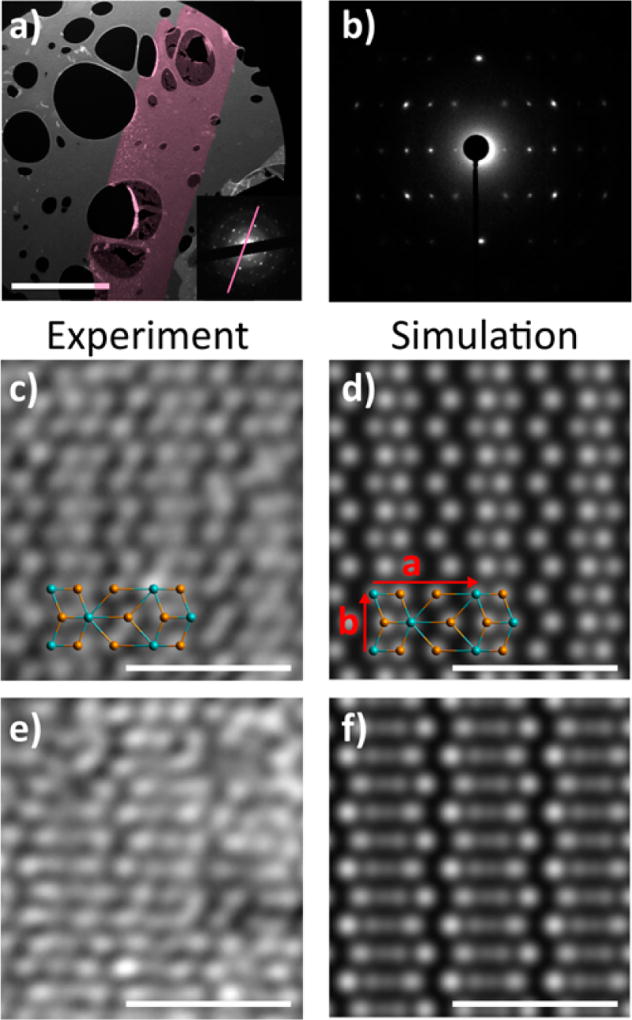

The crystal structure of as-grown MoTe2 flakes was determined using selected area electron diffraction (SAED) after the sample was transferred onto a holey-carbon TEM grid (Figure 3a,b). A dark-field TEM (DF-TEM) image of rectangular MoTe2 flake is shown in Figure 3a (200 kV accelerating voltage); the inset shows the associated diffraction pattern. Both bulk and monolayer 1T′-MoTe2 belong to space group P21/m (No. 11). The rectangular reciprocal lattice is characteristic of the 1T′ phase, which is in contrast to the at least 3-fold symmetry expected for the 2H and 1T phases. The 21 screw axis is parallel to (Te zigzag chain direction) in 1T′-MoTe2, so the odd (0k0) diffraction spots are forbidden, consistent with the observed SAED pattern. The SAED pattern shows excellent agreement with the simulated monolayer SAED pattern (Figure S3). A selected-area aperture of effective size ~1 µm was used, so the SAED pattern confirms that the MoTe2 flakes are in the 1T′ phase and shows the long-range order of the 1T′ lattice. The (0k0) axis in the SAED pattern (purple line in inset) corresponds to the direction in the real-space DF-TEM image. Therefore, the lattice is oriented such that the direction points along the long-axis of the rectangular flake. This was confirmed by lattice resolution images at higher magnifications and was consistent for each observed flake. To our knowledge, this is the first demonstration of oriented crystallite growth in this system.

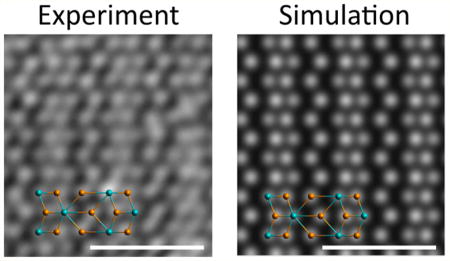

Figure 3.

MoTe2 TEM characterization. (a) DF-TEM image (200 keV) of a single-crystal, rectangular MoTe2 flake on a holey-carbon TEM grid. The scale bar is 2 µm. Inset: SAED pattern of the MoTe2 flake at 200 kV, revealing a single crystal in the 1T′ phase. The pink line indicates the direction of the (0k0) diffraction spots, corresponding to the direction (Te zigzag chain direction) in the real-space, dark-field image. (b) SAED pattern of a MoTe2 flake at 80 kV, along the [001] zone axis (perpendicular to the monolayer flake), revealing a single crystal in the 1T′ phase. (c) HAADF image taken with ACSTEM revealing Mo and Te atoms in the monolayer 1T′ configuration. The schematic overlay shows the rectangular unit cell and the location of the Mo (blue) and Te (orange) atoms. The scale bar is 1 nm. (d) Multislice HAADF simulation of monolayer 1T′-MoTe2, using lattice parameters a = 6.33 Å and b = 3.47 Å.31 (e) HAADF image of a bilayer region. The scale bar is 1 nm. (f) Multislice HAADF simulation of bilayer 1T′-MoTe2.

In addition to single-crystal, rectangular monolayer MoTe2 flakes, the growth procedure also produced polycrystalline flakes. The structure of one flake was analyzed by DF-TEM, where an aperture is used to select certain diffracted beams for image formation,25,30 and a tilt boundary with a crystal lattice rotation of 121.7° ± 0.5° was identified, as shown in Figure S4. The measured boundary rotation, the SAED pattern at the boundary between the legs of the flake (Figure S4 center inset), and the DF-TEM image of the boundary indicate that the boundary lies along the (110) plane of one crystallite and the (11̄0) plane of the other, although grain boundaries were not imaged with atomic resolution. This particular rotation pattern was consistently observed in many polycrystalline flakes, implying that the legs of the polycrystalline flakes were grown at the same time and are not collisions of randomly oriented grains.

To image the atomic structure of 1T′-MoTe2, aberration-corrected, high-angle annular dark field (HAADF) images were taken in a JEOL 200CF (Figure 3c,e) with a CEOS corrector for the STEM probe. The ACSTEM was operated at 80 kV to reduce beam-induced displacements (“knock-on” damage), although damage occurred, as expected given the weak bonding in MoTe2. The images were postprocessed with a low-pass filter to remove high-frequency noise. The HAADF image in Figure 3c clearly reveals the atomic structure expected for monolayer 1T′-MoTe2, where atoms in one of the unit cells are labeled for comparison. The HAADF image shows excellent agreement with the monolayer ball–stick model and a multislice HAADF simulation32 of monolayer 1T′-MoTe2 (Figure 3d). The lattice constants are found to be a = 6.34 Å and b = 3.42 Å, which is in excellent agreement with previous reports.13,31 In the images, the Te atoms are slightly brighter than the Mo atoms, as expected because the HAADF intensity is proportional to the square of the atomic number for monolayer samples. The majority of each flake was monolayer, but small (~10 × 10 nm) double-layer regions were also found, as shown in Figure 3e. The bilayer HAADF image is in excellent agreement with the simulated image (Figure 3f). The brightness in the double-layer regions is roughly twice that of the monolayer regions, which is in agreement with simulated images of mono- and bilayer regions (Figure S5). To our knowledge, this is the first report of atomic resolution images of monolayer 1T′-MoTe2.

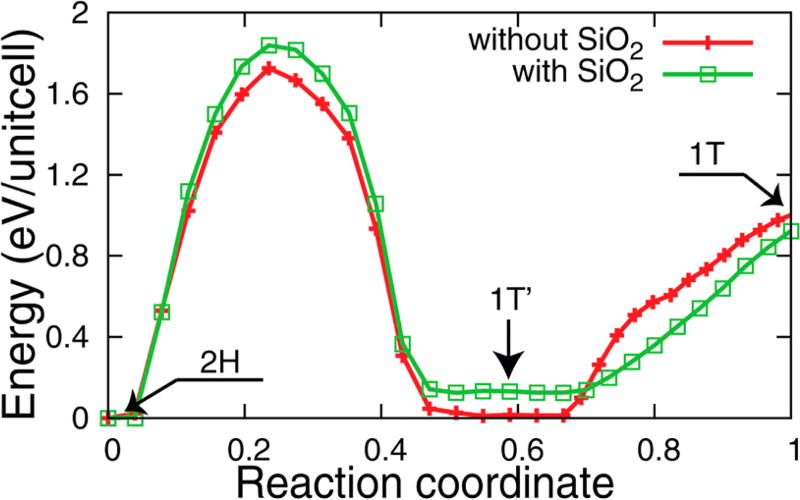

To further study the structural stability of monolayer 1T′-MoTe2 on a SiO2 substrate, we performed theoretical work using first-principles calculations. We first find that the 1T′-MoTe2 layer adheres to the SiO2 substrate with binding energy of 65 meV per unit cell of MoTe2, which is a typical van der Waals-type interaction. We also find that the energy barrier between 1T′ and 2H increases from 1.73 to 1.85 eV/unit cell on the SiO2 substrate (Figure 4). The 2H phase is slightly more stable on SiO2, but the energy barrier between 1T′ and 2H is similar to and without a substrate. So while a phase transformation from 1T′ to 2H is possible if the right amount of energy is brought to the system, observing a phase transformation to 1T is unlikely as it would quickly revert back to the 1T′ phase. Thus, the SiO2 substrate is a good platform to study the 1T′ phase of monolayer MoTe2 and these computations support our hypothesis that monolayer MoTe2 was grown directly in the 1T′ phase.

Figure 4.

Stability computation using first-principals. Structural stability of monolayer transition metal MoTe2 with and without a SiO2 substrate.

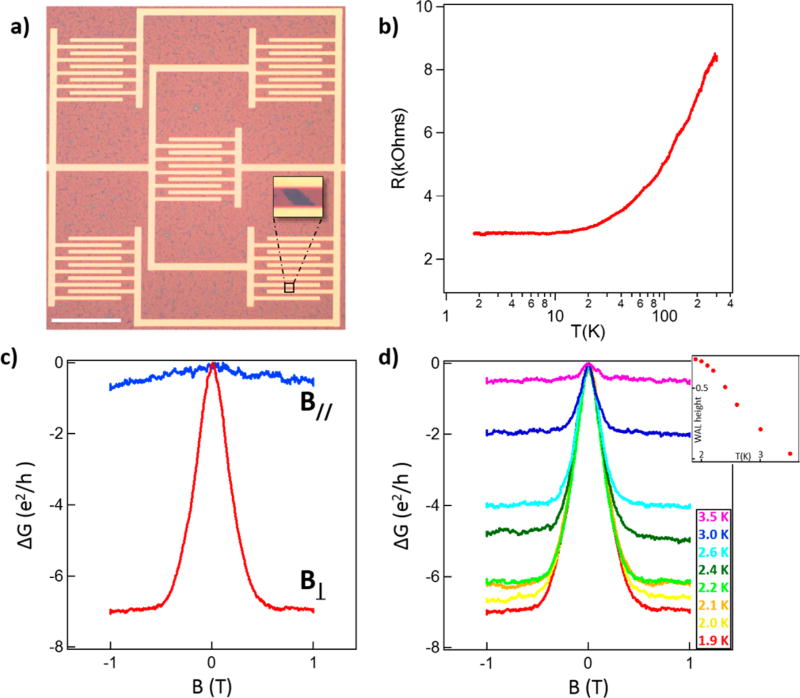

For electrical measurements of monolayer MoTe2, samples were transferred onto a 275 nm SiO2/Si substrate with prepatterned set of Au electrodes made by electron beam lithography. In order to preferentially probe the properties of the material rather than grain boundaries, care was taken to create the sample from a region dominated by rectangular single-crystal flakes rather than polycrystalline material. To minimize sample exposure to air, the transfer process was begun within minutes after growth and completed within 15–20 min. Each device contained five areas of interdigitated source and drain fingers (Figure 5a). To ensure that multiple MoTe2 flakes bridge the electrode pairs, the electrode areas are separated laterally to sample a large growth area (~0.5 mm × 0.5 mm), and the source-drain separation is 5 µm, smaller than the typical size of MoTe2 flakes (10–20 µm). Two devices were measured to determine the effect of temperature and applied magnetic fields on the electrical properties.

Figure 5.

Electrical measurements of monolayer MoTe2-1T′. (a) Optical image of a device with MoTe2 flakes contacted by electrodes. The scale bar is 100 µm. (Inset) Magnified view of a flake spanning the electrodes (image contrast has been enhanced). (b) Resistance versus temperature for monolayer 1T′-MoTe2. (c) Magnetoconductance for applied fields parallel (blue) and perpendicular (red) to the sample at T = 1.9 K. (d) Magnetoconductance for temperatures from 1.9 to 3.5 K showing that the weak antilocalization feature disappears at higher temperatures. (Inset) WAL amplitude as a function of temperature.

The electrical resistance was monitored as the samples were cooled from 300 to 1.9 K. One sample had decreasing resistance with decreasing temperature, clearly demonstrating metallic behavior (Figure 5b). The resistance of the second sample generally increased with decreasing temperature, but nevertheless exhibited metallic behavior at low temperature as indicated by a positive slope of the reduced activation energy −d(ln R)/d(ln T) on a log–log plot versus temperature (Figure 6b). Measurements of the anisotropic magnetoconductance at various temperatures were quantitatively similar in both shape and absolute size for both samples (Figure 6d), strongly suggesting that the difference in temperature-dependent resistance arises from a series contact resistance. At low temperature, both samples exhibited a weak antilocalization (WAL) cusp-like feature at zero magnetic field (Figure 5c), which diminished with increasing temperature and could not be resolved for T > ~4 K (Figure 5d). The WAL effect is a signature of a metallic state in the presence of strong spin–orbit coupling23,33,34 and can be associated with either bulk or topological surface states. A similar effect was recently reported for few-layer samples of WTe2 produced by mechanical exfoliation.36 We varied the applied field angle in order to examine the residual isotropic magnetoconductance. The WAL cusp disappears when the field is applied parallel to the plane of the material (Figure 5c), confirming the 2D nature of the WAL effect. Similar temperature and magnetic field dependence of the WAL cusp has been observed in topological insulator materials,23,33,35–38 and the data demonstrate that these materials possess strong electronic spin–orbit effects that are essential for the emergence of nontrivial topological electronic states.

In summary, we report the growth of monolayer, single-crystal 1T′-MoTe2 over large areas by chemical vapor deposition. XPS measurements confirm the expected stoichiometry for MoTe2. AFM, Raman, TEM, and ACSTEM measurements convincingly establish that the MoTe2 material is of monolayer thickness in the 1T′ phase and single crystal. We were able to orient the crystalline axes based on the shape of rectangular crystallites, and we identified a clear preferential crystal growth direction for the MoTe2 flakes along the axis. Low-temperature magnetoconductance measurements confirm the presence of a WAL cusp in monolayer MoTe2. Thus, the structural and electronic ingredients necessary to realize topological surface states exist within this material. This advance in CVD growth and microscopic analysis paves the way for more detailed exploration of monolayer 1T′-MoTe2, including its potential topological insulator properties and implementation in novel switching and sensor devices.

Methods

XPS

The chemistry of the near-surface region was investigated by XPS using a customized XPS spectrometer (VG Scienta AB, Uppsala, Sweden).39 XPS analyses were performed using a monochromatic Al Kα source (photon energy 1486.6 eV). The residual pressure in the analysis chamber was less than 1 × 10−8 Torr. The spectrometer was calibrated according to ISO 15472:2001 with an accuracy of ±0.05 eV. Survey and high-resolution spectra were acquired in constant-analyzer-energy mode with the pass energies of 200 and 100 eV, respectively. The spectra were processed using CasaXPS software (v.2.3.16, Casa Software Ltd., Wilmslow, Cheshire, U.K.). Background subtraction was performed using the Shirley–Sherwood method. The quantitative evaluation of the XPS data was based on integrating the intensity of the Mo 3d5/2 and Te 3d5/2 peaks by taking the atomic sensitivity factors for those signals into account. The atomic sensitivity factors used were 1.66 for the Mo 3d5/2 peak and 5.4 for the Te 3d5/2 peak.40 The reference energies for Mo 3d5/2 and the Te 3d5/2 peaks are 227.7 and 572.1 eV, respectively.

Raman

Raman was conducted on samples directly after growth. For single Raman spectra, spectroscopy was performed under ambient conditions with and excitation wavelength of 532 nm. An ND-MDT spectrometer was used. For Raman maps, graphene was transferred onto the MoTe2 immediately following growth. This passivated the MoTe2 from the environment and allowed Raman mapping to proceed for many hours without sample deterioration.

ACSTEM

For ACTEM imaging, MoTe2 flakes were transferred onto a holey-carbon TEM grid using a PMMA-assisted transfer. ACSTEM of suspended MoTe2 flakes was performed with a JEOL ARM 200CF equipped with a CEOS corrector. The TEM was operated at 80 kV to reduce knock-on damage. Images were acquired with a high-angle annular dark field detector. A low-pass filter was applied to the images to reduce noise. Selected-area electron diffraction patterns were acquired in TEM mode using a selected-area aperture with an effective size at the sample of ~1 µm.

HAADF Simulations

QSTEM32 was used to perform multislice HAADF-STEM simulations. Microscope parameters for the 80 kV JEOL ARM 200CF were used for the simulation. These include Cs = 635 nm and C5 = −55 µm. Other parameters used were Cc = 1 mm, dE = 0.5 eV, convergence angle = 20 mrad, HAADF detector inner angle = 70 mrad, HAADF detector outer angle = 200 mrad, defocus = −2 nm, brightness = 5 × 108 A/cm2sr, and a dwell time of 1 µs. For each simulation, the simulation window size used was one unit cell, 6.33 Å × 3.469 Å with sampling 20 pix × 20 pix.

Structural Stability Simulations

To access the influence of SiO2 on the stability of MoTe2 single layer in 1T′ phase, we performed first-principles calculations based on density functional theory (DFT). We use the Perdew–Burke–Ernzerhoftype generalized gradient approximation41 as implemented in the Quantum Espresso package.42 Norm-conserving, optimized, designed nonlocal pseudopotentials are generated using the Opium package.43,44 The energy barriers of MoTe2 were calculated employing the nudged elastic band (NEB) approach as found in the Quantum Espresso package. The SiO2 substrate was modeled using a slab geometry with four unit cells along (100) and a 3 × 1 supercell along (010) and (001) directions, respectively. The outer oxide atoms were passivated with hydrogen atoms. A 2 × 2 unitcell of MoTe2 of 1T′ phase was placed on a SiO2 substrate, which induces a negligible strain on MoTe2 and 15 and 7% artificial compressive strain on the SiO2 substrate. The structure of substrate is fully optimized without MoTe2 under strain then used throughout the energy barrier calculations of MoTe2/SiO2 system. The van der Waals interaction is described based on the semiempirical dispersion-correction DFT (DFT-D) method.45

Electrical Measurements

Samples were loaded onto a rotating insert in a Quantum Design Physical Property Measurement System (PPMS). Temperature and magnetic field-dependent electrical measurements were taken using a 1.0 mV source-drain bias using a Keithley 237 Source-Measure Unit. Current–voltage curves were collected at temperatures from 1.9 to 300 K in order to determine the regime of linear operation, and the source-drain bias chosen accordingly. The angle of the magnetic field was calibrated first visually and then trimmed by nulling the WAL effect to determine the angle for B‖.

Supplementary Material

Acknowledgments

Funding

This work was supported by NSF MRSEC DMR-1120901.

The authors acknowledge use of the Raman mapping system supported by NSF Major Research Instrumentation Grant DMR-0923245. W.M.P. and M.D. acknowledge funding from NIH grant R21HG007856. R.W.C. and F.S. acknowledge support from NSF Grant CMMI-1334241. Y.R.Z. acknowledges the support of the Penn’s VIPER program. The authors gratefully acknowledge use of the HR-TEM in the Krishna Singh Center for Nanotechnology at the University of Pennsylvania and the use of the AC-TEM facility at Lehigh University.

ABBREVIATIONS

- CVD

chemical vapor deposition

- WAL

weak antilocalization

- TEM

transmission electron microscopy

- ACSTEM

aberration-corrected scanning TEM

- TMD

transition metal dichalcogenide

- AFM

atomic force microscopy

- XPS

X-ray photoelectron spectroscopy

Footnotes

ASSOCIATED CONTENT

- Supplementary XPS, Raman, TEM, electrical data, and discussion about the metastability of the sample.(PDF)

Author Contributions

A.T.C.J. directed the research. C.H.N. proposed and designed the experiment and carried out 1T′-MoTe2 growth. Electrical measurements were performed by J.M.K. Devices for electrical measurements were prepared by C.H.N. and Y.R.Z. C.H.N., W.M.P., and Z.G. performed AFM and Raman characterization; W.M.P., C.H.N., and J.P. performed the TEM experiments (under the supervision of M.D.) and W.M.P. performed the SAED and HAADF simulations. Y.K. performed the stability computation (under the supervision of A.M.R.). F.S. performed the XPS measurement (under the supervision of R.W.C.). C.H.N., W.M.P. and A.T.C.J. wrote the manuscript with input and approval from all the authors.

The authors declare no competing financial interest.

References

- 1.Mak KF, Lee C, Hone J, Shan J, Heinz TF. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 2010;105:136805. doi: 10.1103/PhysRevLett.105.136805. [DOI] [PubMed] [Google Scholar]

- 2.Huang X, Zeng Z, Zhang H. Metal dichalcogenide nanosheets: preparation, properties and applications. Chem. Soc. Rev. 2013;42:1934–46. doi: 10.1039/c2cs35387c. [DOI] [PubMed] [Google Scholar]

- 3.Chhowalla M, Shin HS, Eda G, Li L-J, Loh KP, Zhang H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013;5:263–275. doi: 10.1038/nchem.1589. [DOI] [PubMed] [Google Scholar]

- 4.Tan C, Zhang H. Two-dimensional transition metal dichalcogenide nanosheet-based composites. Chem. Soc. Rev. 2015;44:2713–2731. doi: 10.1039/c4cs00182f. [DOI] [PubMed] [Google Scholar]

- 5.Zhang H. Ultrathin Two-Dimensional Nanomaterials. ACS Nano. 2015;9:9451–9469. doi: 10.1021/acsnano.5b05040. [DOI] [PubMed] [Google Scholar]

- 6.Han SA, Bhatia R, Kim S-W. Synthesis, properties and potential applications of two-dimensional transition metal dichalcogenides. Nano Converg. 2015;2:17. [Google Scholar]

- 7.Li H, Shi Y, Chiu M-H, Li L-J. Emerging Energy Applications of Two-Dimensional Layered Transition Metal Dichalcogenides. Nano Energy. 2015;18:293–305. [Google Scholar]

- 8.Lee B, Park J, Han GH, Ee HS, Naylor CH, Liu W, Johnson ATC, Agarwal R. Fano Resonance and Spectrally Modified Photoluminescence Enhancement in Monolayer MoS2 Integrated with Plasmonic Nanoantenna Array. Nano Lett. 2015;15:3646–3653. doi: 10.1021/acs.nanolett.5b01563. [DOI] [PubMed] [Google Scholar]

- 9.Wang QH, Kalantar-Zadeh K, Kis A, Coleman JN, Strano MS. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012;7:699–712. doi: 10.1038/nnano.2012.193. [DOI] [PubMed] [Google Scholar]

- 10.Feng J, Qian X, Huang C-W, Li J. Strain-engineered artificial atom as a broad-spectrum solar energy funnel. Nat. Photonics. 2012;6:866–872. [Google Scholar]

- 11.Lee C, Li QY, Kalb W, Liu XZ, Berger H, Carpick RW, Hone J. Frictional Characteristics of Atomically-Thin Sheets. Science. 2010;328:76–80. doi: 10.1126/science.1184167. [DOI] [PubMed] [Google Scholar]

- 12.Wilson JA, Yoffe AD. The transition metal dichalcogenides discussion and interpretation of the observed optical, electrical and structural properties. Adv. Phys. 1969;18:193–335. [Google Scholar]

- 13.Qian X, Liu J, Fu L. Quantum spin Hall effect in two-dimensional transition metal dichalcogenides. Science. 2014;346:1344–1347. doi: 10.1126/science.1256815. [DOI] [PubMed] [Google Scholar]

- 14.Hasan MZ, Kane C. L Colloquium: Topological insulators. Rev. Mod. Phys. 2010;82:3045–3067. [Google Scholar]

- 15.Kane CL, Mele EJ. Quantum Spin Hall Effect in Graphene. Phys. Rev. Lett. 2005;95:226801. doi: 10.1103/PhysRevLett.95.226801. [DOI] [PubMed] [Google Scholar]

- 16.Kane CL, Mele EJ. Z2 Topological Order and the Quantum Spin Hall Effect. Phys. Rev. Lett. 2005;95:146802. doi: 10.1103/PhysRevLett.95.146802. [DOI] [PubMed] [Google Scholar]

- 17.Voiry D, Mohite A, Chhowalla M. Phase engineering of transition metal dichalcogenides. Chem. Soc. Rev. 2015;44:2702–2712. doi: 10.1039/c5cs00151j. [DOI] [PubMed] [Google Scholar]

- 18.Kappera R, Voiry D, Ebru S, Branch B, Gupta G, Mohite AD, Chhowalla M. Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 2014;13:1128–1134. doi: 10.1038/nmat4080. [DOI] [PubMed] [Google Scholar]

- 19.Cho S, Kim S, Kim JH, Zhao J, Seok J, Keum DH, Baik J, Choe D-H, Chang KJ, Suenaga K, Kim SW, Lee YH, Yang H. Phase patterning for ohmic homojunction contact in MoTe2. Science. 2015;349:625–628. doi: 10.1126/science.aab3175. [DOI] [PubMed] [Google Scholar]

- 20.Duerloo K-AN, Li Y, Reed EJ. Structural phase transitions in two-dimensional Mo- and W-dichalcogenide monolayers. Nat. Commun. 2014;5:1–9. doi: 10.1038/ncomms5214. [DOI] [PubMed] [Google Scholar]

- 21.Zhou L, Xu K, Zubair A, Liao AD, Fang W, Ouyang F, Lee Y-H, Ueno K, Saito R, Palacios T, Kong J, Dresselhaus MS. Large-Area Synthesis of High-Quality Uniform Few-Layer MoTe2. J. Am. Chem. Soc. 2015;137:11892–11895. doi: 10.1021/jacs.5b07452. [DOI] [PubMed] [Google Scholar]

- 22.Park JC, Yun SJ, Kim H, Park J-H, Chae SH, An S-J, Kim J-G, Kim SM, Kim KK, Lee YH. Phase-Engineered Synthesis of Centimeter-Scale 1T- and 2H-Molybdenum Ditelluride Thin Films. ACS Nano. 2015;9:6548–6554. doi: 10.1021/acsnano.5b02511. [DOI] [PubMed] [Google Scholar]

- 23.Bao L, He L, Meyer N, Kou X, Zhang P, Chen ZG, Fedorov AV, Zou J, Riedemann TM, Lograsso TA, Wang KL, Tuttle G, Xiu F. Weak Anti-localization and Quantum Oscillations of Surface States in Topological Insulator Bi2Se2Te. Sci. Rep. 2012;2:1–7. doi: 10.1038/srep00726. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Han GH, Kybert NJ, Naylor CH, Lee BS, Ping JL, Park JH, Kang J, Lee SY, Lee YH, Agarwal R, Johnson ATC. Seeded growth of highly crystalline molybdenum disulfide monolayers at controlled locations. Nat. Commun. 2015;6:6128. doi: 10.1038/ncomms7128. [DOI] [PubMed] [Google Scholar]

- 25.van der Zande AM, Huang PY, Chenet DA, Berkelbach TC, You Y, Lee G-H, Heinz TF, Reichman DR, Muller DA, Hone JC. Grains and grain boundaries in highly crystalline monolayer molybdenum disulphide. Nat. Mater. 2013;12:554–61. doi: 10.1038/nmat3633. [DOI] [PubMed] [Google Scholar]

- 26.Ling X, Lee YH, Lin YX, Fang WJ, Yu LL, Dresselhaus M, Kong J. Role of the Seeding Promoter in MoS2 Growth by Chemical Vapor Deposition. Nano Lett. 2014;14:464–472. doi: 10.1021/nl4033704. [DOI] [PubMed] [Google Scholar]

- 27.Kan M, Nam H, Lee YH, Sun Q. Phase Stability and Raman Vibration of Molybdenum Ditelluride (MoTe2) Monolayer. Phys. Chem. Chem. Phys. 2015;17:14866–14871. doi: 10.1039/c5cp01649e. [DOI] [PubMed] [Google Scholar]

- 28.Keum DH, Cho S, Kim JH, Choe DH, Sung HJ, Kan M, Kang H, Hwang JY, Kim SW, Yang H, et al. Bandgap opening in few-layered monoclinic MoTe2. Nat. Phys. 2015;11:482–486. [Google Scholar]

- 29.Yang J, Lü T, Myint YW, Pei J, Macdonald D, Zheng J-C, Lu Y. Robust Excitons and Trions. ACS Nano. 2015;9:6603–6609. doi: 10.1021/acsnano.5b02665. [DOI] [PubMed] [Google Scholar]

- 30.Huang PY, Ruiz-Vargas CS, van der Zande AM, Whitney WS, Garg S, Alden JS, Hustedt CJ, Zhu Y, Park J, McEuen PL, Muller DA. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature. 2011;469:389–392. doi: 10.1038/nature09718. [DOI] [PubMed] [Google Scholar]

- 31.Brown BE. The crystal structures of WTe2 and high-temperature MoTe2. Acta Crystallogr. 1966;20:268–274. [Google Scholar]

- 32.Koch C. Dissertation. Arizona State University; Tempe, Arizona: 2002. Determination of core structure periodicity and point defect density along disclocations. [Google Scholar]

- 33.Chen J, Qin HJ, Yang F, Liu J, Guan T, Qu FM, Zhang GH, Shi JR, Xie XC, Yang CL, Wu KH, Li YQ, Lu L. Gate-Voltage Control of Chemical Potential and Weak Antilocalization in Bi2Se3. Phys. Rev. Lett. 2010;105:176602. doi: 10.1103/PhysRevLett.105.176602. [DOI] [PubMed] [Google Scholar]

- 34.Fu L, Kane CL, Mele EJ. Topological insulators in three dimensions. Phys. Rev. Lett. 2007;98:1–4. doi: 10.1103/PhysRevLett.98.106803. [DOI] [PubMed] [Google Scholar]

- 35.Cha JJ, Kong D, Hong SS, Analytis JG, Lai K, Cui Y. Weak Antilocalization in Bi2 (Se_xTe_1-x) Nanoribbons and Nanoplates. Nano Lett. 2012;12:1107–1111. doi: 10.1021/nl300018j. [DOI] [PubMed] [Google Scholar]

- 36.Wang L, Gutierrez-Lezama I, Barreteau C, Giannini E, Morpurgo AF. Tuning magnetotransport in a compensated semimetal at the atomic scale. Nat. Commun. 2015;6:8892. doi: 10.1038/ncomms9892. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.He H-T, Wang G, Zhang T, Sou I-K, Wong GKL, Wang J-N, Lu H-Z, Shen S-Q, Zhang F-C. Impurity Effect on Weak Antilocalization in the Topological Insulator Bi2Te3. Phys. Rev. Lett. 2011;106:166805. doi: 10.1103/PhysRevLett.106.166805. [DOI] [PubMed] [Google Scholar]

- 38.Liu MH, Zhang JS, Chang CZ, Zhang ZC, Feng X, Li K, He K, Wang LL, Chen X, Dai X, et al. Crossover between weak antilocalization and weak localization in a magnetically doped topological insulator. Phys. Rev. Lett. 2012;108:1–5. doi: 10.1103/PhysRevLett.108.036805. [DOI] [PubMed] [Google Scholar]

- 39.Mangolini F, Ahlund J, Wabiszewski GE, Adiga VP, Egberts P, Streller F, Backlund K, Karlsson PG, Wannberg B, Carpick RW. Angle-resolved environmental X-ray photoelectron spectroscopy: A new laboratory setup for photoemission studies at pressures up to 0.4 Torr. Rev. Sci. Instrum. 2012;83:093112. doi: 10.1063/1.4754127. [DOI] [PubMed] [Google Scholar]

- 40.Wagner CD, Davis LE, Zeller MV, Taylor JA, Raymond RM, Gale LH. Empirical atomic sensitivity factors for quantitative analysis by electron spectroscopy for chemical analysis. Surf. Interface Anal. 1981;3:211–225. [Google Scholar]

- 41.Perdew JP, Burke K, Ernzerhof M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996;77:3865–3868. doi: 10.1103/PhysRevLett.77.3865. [DOI] [PubMed] [Google Scholar]

- 42.Giannozzi P, Baroni SBN, Calandra M, Car R, Cavazzoni C, Ceresoli D, Chiarotti GL, Cococcioni M, Dabo I, Dal Corso A, et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys.: Condens. Matter. 2009;21:395502. doi: 10.1088/0953-8984/21/39/395502. [DOI] [PubMed] [Google Scholar]

- 43.Ramer NJ, Rappe AM. Designed nonlocal pseudopotentials for enhanced transferability. Phys. Rev. B: Condens. Matter Mater. Phys. 1999;59:12471. [Google Scholar]

- 44.Rappe AM, Rabe KM, Kaxiras E, Joannopoulos JD. Optimized pseudopotentials. Phys. Rev. B: Condens. Matter Mater. Phys. 1990;41:1227–1230. doi: 10.1103/physrevb.41.1227. [DOI] [PubMed] [Google Scholar]

- 45.Steffen C, Thomas K, Huniar U, Hellweg A, Rubner O, Schroer A. TmoleX–a graphical user interface for TURBOMOLE. J. Comput. Chem. 2010;31:2967–2970. doi: 10.1002/jcc.21576. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.