Abstract

Probiotic soy-cheese spread was prepared by fermenting soymilk with specific probiotic starter culture, and there after processing the coagulated mass. Soy cheese spread samples had more than 109 cfu/g of viable probiotic count at the time of preparation; and had around 17.6% protein, 25.3% fat and 19.8% total soluble sugar. Compared to commercially available dairy cheese spread, probiotic soy cheese spread had significantly higher protein and anti-oxidant activity. Soy cheese spreads, prepared from pure soymilk as well as by mixing with dairy milk, were studied with respect to the differences in their rheological behavior during storage at refrigerated conditions. A dynamic oscillatory test was used to measure the viscoelastic properties of spreads at 0, 7, 14, 21 and 28 days of storage. It was observed that the storage modulus (G′) was higher than the loss modulus (G″) throughout the storage period indicating that the soy cheese spreads exhibit predominantly elastic behavior. The cheese spread sample prepared by adding okara in soymilk had the highest values of G′ and complex viscosity (1120 Pa and 11.5 Pa s, respectively at an angular frequency of 100 s−1). G′, G″ and viscosity of cheese spread did not change significantly up to 14 days, with values of 650, 225 Pa and 7.43 Pa s, respectively for the sample prepared from soymilk alone. However, these values increased thereafter which might be an indication of structural changes in the cheese spread samples.

Keywords: Probiotic, Rheology, Soy-cheese, Viscosity, Colour

Introduction

Soybeans are rich in proteins (40%), lipids (20%), carbohydrates (35%), minerals and vitamins. Among plant based protein sources, soy proteins are highly digestible after proper heat treatment and their amino acid profile is well balanced to meet the requirements for human nutrition (Agrahar-Murugkar 2015; Giri and Mangaraj 2012). Food and Drug Administration (FDA) has approved the soy protein health claim in 1999. According to that claim consumption of foods derived from soybean has been associated with many health benefits, and 25 g of soy protein per day may reduce the risk of heart disease (FDA 1999). Asian populations, with their intake of soy derived isoflavones, are known to have the lowest incidence of osteoporosis, menopausal symptoms, mortality from cardiovascular disease, and cancer (Chun et al. 2008). Though soymilk has several health benefits, its consumption is limited due to presence of a strong beany flavor that is unacceptable to many consumers.

Conversion of soymilk to different fermented products has been attempted to overcome the problem of beany flavour (Blagden and Gilliland 2005). Wang et al. (2003) reported that fermentation with probiotic lactic acid bacteria (LAB) provided an improved volatile profile to soymilk. Soymilk is a suitable nutrient source for growth of LAB (Liu et al. 2006). Soy cheese and yogurt are such fermented foods, which have wider acceptability in several countries. Soy cheese, also known as sufu, furu or fermented soybean curd, is a traditionally important and popular fermented food product in China. Such fermented soy foods with properly selected probiotics strain may become a unique functional food because it would not only improve the organoleptic characteristics but could also give the consumer beneficial properties such as enhanced shelf life and stimulating their natural defense system. Consumption of probiotic bacteria via food products is an ideal way to reestablish the intestinal microflora balance. Probiotic lactic acid bacteria are widely used in dairy and meat products (Iravani et al. 2015), but little information is available about the use of probiotics in soy food production.

Soy cheese is quite similar to dairy cheese in terms of physical appearance, texture, and the basic processing technology (Metwalli et al. 1982). However literature on texural and rheological properties of probiotic soy cheese spread is scarce. Rheological properties are necessary to understand the structural and functional properties of the food products. They are also used for design and development of processing equipment and quality control. Changes in viscoelastic properties such as storage modulus (G′) and loss modulus (G″) can affect the energy requirement in processing operations. Hence the objective of the study was to develop and characterize probiotic based soy cheese spread, and to study the rheological behavior of the same during storage.

Materials and methods

Particularly JS 335 (JAWAHAR SOYBEAN 335) variety was used to prepare soymilk i.e. aqueous extract of dehulled split soybeans. Probiotic culture (Lactobacillus casei ssp. Casei NCDC-0017) was obtained from National Dairy Research Institute, Karnal, India. Tofu whey and MRS media were used for production of probiotic culture for this study.

Preparation of probiotic soy cheese spread

Soymilk was prepared in the laboratory by airless hot grinding method (Giri and Mangaraj 2014). Soybeans were soaked in water for 4 h, and then were washed with fresh water and hulls were removed. The soaked soybeans were ground under a steam environment at around 110 °C in the soymilk pilot plant. The soybeans and water ratio used was 1:7 (w/v). The resultant slurry was then filtrated manually with a muslin cloth to obtain soymilk, while the residue (okara) was dried to obtain okara powder. The sterilized soymilk was mixed with soybean oil, sucrose and okara powder to form an emulsion. Thereafter, the emulsion was inoculated with 1% (v/v) culture (over night grown Lactobacillus casei ssp.casei NCDC-0017) and maintained at a temperature of 37 °C for 5 h and at 55° C until curd was formed. After coagulation, the whey was drained and the coagulated mass was transferred and made into fine slurry by churning in a mechanical mixer to obtain the cheese spread like product. The product was further mixed with salt and matured.

Cheese spread samples were also prepared by the mixing dairy milk to soymilk (50:50 v/v) with or without addition of okara in order to study the effect of composition on rheological and colour parameters of the spread.

Characterization of probiotic soy cheese spread

Viable cell count in the soy-cheese spread was determined by standard plate count method and presented as colony-forming units (CFU) per gram. Samples were serially diluted in 0.85% NaCl solution and plate count was performed using MRS agar by pour plate method (Miller 1972). Fat content, crude protein, ash content and moisture content were determined according to AOAC Methods (1999). Titratable acidity was determined by titration with sodium hydroxide and phenolphthalein to the establishment of the equivalent point of neutralization, and has been expressed as percent lactic acid (Subramanian and Rodriguez-Saona 2010). Anti-oxidant activity was determined using DPPH assay (Chinma et al. 2014; Tuberoso et al. 2007). The pH of samples was measured using a hand held pH meter (Model Ph 323, Ser.Nr.63260002, WTW 82362 Weilheim Germany).

Textural parameters of soy-cheese spread samples were measured via measurement of the force time curve using a Texture analyser (model TA-XT2, Texture Technologies Corp., Scarsdale, NY) attached with a cylindrical back extrusion cell (50 mm diameter and 60 mm deep). A 50 kgf load cell was used and the cross-head speed was set to 5.0 mm/s. Measurements were performed in triplicate and data were collected using the Exponent software (Stable Microsystems, Surrey, England). The force in Newton (N) required to extrude the sample was recorded as a function of time. Parameters like Firmness (measure of resistance to deformation of the product), Consistency (related to thickness and viscosity of the product) and Cohesiveness (measure of stickiness of the product) which characterized the textural parameters of the products were obtained from the software. Colour parameters (L, a, b, yellowness index and whiteness index) of different soy cheese spread samples were measured in triplicate in a Lab Scan XE Spectro colorimeter (HAL, USA, Model 45/0-L, version V.4000) using 10 mm aperture window.

Rheological analyses of soy cheese spread

The dynamic oscillatory test was used to measure the viscoelastic properties of soy cheese spread samples by using a controlled-strain rheometer (Anton Paar, Germany Physica MCR 51) equipped with a built-in Peltier temperature control (Accuracy ± 0.1 °C). The measurements were done at 0, 7, 14, 21 and 28 days of storage. A scoop of each sample was tested using 25-mm ∅ parallel plate geometry with a gap of 1800 µm. The storage modulus (G′), loss modulus (G″) and complex viscosity values were determined during a frequency sweep which increased linearly from 1 to 100 Hz at a constant 0.5% strain over a period of 10 min. All tests were conducted in triplicate at 70 °C temperature.

Results and discussions

Properties of the developed probiotic soy cheese spread

The soy cheese spread had a viable count of more than 109 cfu of the probiotic species per gram at the time of preparation, indicating its probiotic nature (Boylston et al. 2004; Tripathi and Giri 2014). Viability of the probiotic species in cheese spread samples was also examined during storage by counting the species at 14, 21 and 30 days of storage. The viable count of probiotic culture was found to be more than 108cfu/g in the vacuum packaged sample after 30 days of storage in refrigerated conditions.

Different properties like proximate composition, biochemical, physical (colour and texture), and rheological parameters of the developed cheese spread samples were measured and in some cases compared with those of commercially available dairy cheese spread (Table 1). The probiotic soy cheese spread (PSCS) was found to have less fat, less sugar and more protein in comparison to the commercially available dairy cream cheese spread (DCCS) sample. This may be attributed to less fat and carbohydrate content in soymilk compared to cow milk (Hajirostamloo 2009). Soybean has been known as the best source of plant protein containing about 40% of protein (dry basis), the highest protein content among legumes and cereals (Giri and Mangaraj 2012). The addition of probiotics might also have decreased the total soluble sugar content of soy cheese spread. pH and titratable acidity of both the products were found comparable. The antioxidant activity in soy cheese spread was around 60% higher than DCCS, owing to its probiotic nature. In vitro and in vivo study provides that probiotics exhibit antioxidant potential (Mishra et al. 2015).

Table 1.

Composition and biochemical parameters of Probiotic soy cheese spread (PSCS) and dairy cream cheese spread (DCCS) samples

| Parameters | PSCS | DCCS |

|---|---|---|

| Fat (g/100 g) | 25.32 ± 1.3a | 28.74 ± 1.1a |

| Total protein content (g/100 g) | 17.60 ± 0.84a | 6.40 ± 0.36b |

| Moisture content (g/100 g) | 49.62 ± 1.35a | 54.48 ± 1.47a |

| Total soluble sugar (mg/g) | 19.8 ± 0.64a | 27.6 ± 1.21b |

| Ash content (g/100 g) | 1.72 ± 0.14a | 1.93 ± 0.21a |

| pH | 6.25 ± 0.42a | 6.30 ± 0.34a |

| Titratable acidity (% lactic acid) | 0.39 ± 0.082a | 0.30 ± 0.078a |

| Antioxidant activity (% inhibition) | 53 ± 3.6a | 33 ± 2.7b |

| Textural parameters | ||

| Firmness (g) | 982 ± 11.3a | 692 ± 14.7b |

| Consistency (g s) | 24,422 ± 1673a | 11,869 ± 874b |

| Cohesiveness (g) | 793 ± 62.4a | 751 ± 58.6a |

Values given are mean of three replications ± standard deviation

Different letters in each row indicate parameters are significantly different at p ≤ 0.01, as found by one way ANOVA

Texture analysis of the soy cheese spread samples was carried out by back extrusion cell in a Texture Analyzer and compared to those of dairy cheese spread (Table 1). Soy cheese spread samples were found to be more firm and viscous compared to dairy cheese. Pair-wise comparison of the results showed that there was a significant difference (p < 0.01) between the samples for the parameters ‘firmness’ and ‘consistency’. The consistency value of probiotic soy cheese spread sample was higher than that of dairy cream cheeses spread. In agreement with the texture results observed in this study, Matias et al. (2014) found that the instrumental texture parameters (hardness, adhesiveness, cohesiveness, and gumminess) of soy-based cheese products were higher than those of milk-based petit-suisse cheese. Park et al. (2005) also observed that a skimmed milk yogurt had a lower hardness value than soy yogurt. Additionally, they evaluated the syneresis of both products and observed that it was higher in skimmed milk yogurt than in the soy yogurt. Thus, the occurrence of syneresis might have resulted in lower hardness of milk cheese compared to soy based cheese samples during storage. Matias et al. (2014) related the higher hardness and gumminess values of soy based cheese products to the presence of gums and fat, which may have contributed for the formation of a firm soy proteins gel network. Soy protein is generally regarded as the storage protein held in discrete particles called protein bodies, and with big molecular size. Therefore the products made from soybean sources usually had a grainy texture in comparison to the smooth, uniform texture normally associated with spreads made from dairy cheeses (Endres 2001). Solubility, hydrodynamic properties, hydrophobicity and microstructure of proteins have been reported to play an important role in the rheological properties of proteins (Krause et al. 2001; Krase et al. 2002). Hard grainy texture of soy proteins might be another reason for higher firmness and consistency of the soy cheese spread.

The colour parameters of soy cheese spread samples were measured using a Hunter lab colorimeter. The parameters L (Lightness/brightness), Yellowness index (YI) and whiteness index (WI) of soy cheese spread samples prepared with different composition are depicted in Fig. 1. Cheese samples exhibited high luminosity, as indicated by L-values in the range of 80-85 close to the positive limit of the scale. The high L-values are explained by the glowing effect caused by the superficial fatty layer of cheese (Fernandes et al. 2018). It was observed that addition of okara or dairy milk in soymilk further increased the lightness and whiteness index of the cheese spread samples. Puligundla et al. (2015) also observed that the brightness (L* value) and redness (a* value) of mayonnaise samples increased with increasing level of starch substitution. The Hunters b-value was found to be positive and below a value of 15 in the colour scale for all samples, indicating slight yellowness of soy cheese spreads.

Fig. 1.

Effect of composition on different colour parameters of probiotic soy cheese spread

The L-value decreased and yellowness increased during storage of the soy cheese spread samples for a period of 4 weeks. Fernandes et al. (2018) also observed that the b-value of goat milk cheese increased during ripening, which was most likely due to a slight browning effect typical in cheese maturation.

Rheological study of Soy cheese spread samples

The rheological parameters (G′, G″ and complex viscosity) of soy cheese spread made with different compositions were measured at regular intervals of 7 days during storage up to 4 weeks. G′ represents the elastic (solid) behaviour and is a measure of deformation energy stored in the sample during shear process. On the other hand, G″ represents the viscous (liquid) behaviour of the sample and is a measure of deformation energy used up and lost during shearing (Singh et al. 2016). Combination of both the parameters provides important information on viscoelastic behavior and on the sol–gel transition of the material. The variations in these parameters for different cheese spread samples and changes with storage time have been explained in the following paragraphs.

Storage modulus and loss modulus

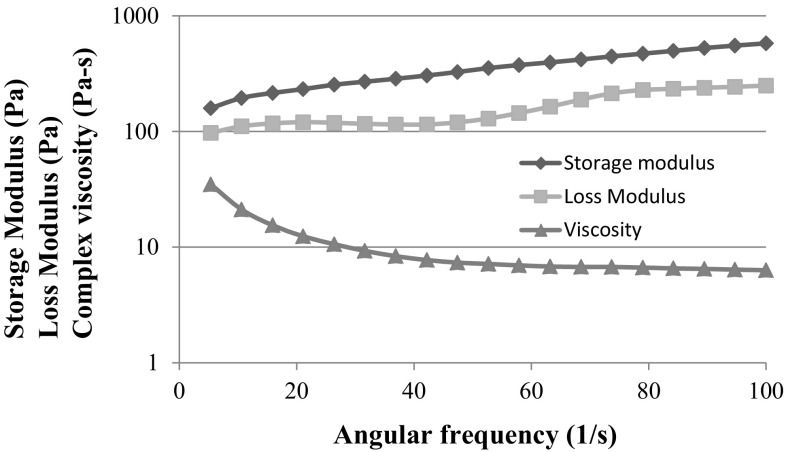

Variations in the values of G′, G″ and viscosity with angular frequency as obtained in the dynamic frequency sweep test for the probiotic soy cheese spread sample (prepared from soymilk alone) is shown in Fig. 2. It was observed that the storage modulus (G′) was higher than the loss modulus (G″) at day 1 as well as at day 21. Similar trends were also observed in other soy cheese spread samples prepared by mixing okara and dairy milk with soymilk. This suggests that the soy cheese spread samples exhibited a solid-like behavior within the range of frequencies studied, and also during storage period. Oscillatory sweeps are used to infer the microstructure in viscoelastic materials to find out how strong it is. A microstructure means that there are forces between the molecules or particles in the material. To break the microstructure, there is a need to apply a force larger than the ones holding it. When the applied force is smaller than the molecular or inter particle forces, then G′ is larger than G″; the material has some capacity to store energy and should be able to return, to some extent, to its initial configuration before a mechanical force was applied. The material behaves as an elastic solid, although not an ideal one because some of the mechanical energy is dissipated. But when applied force is higher, the microstructure collapses and the mechanical energy given to the material is dissipated, meaning that the material flows. In such cases, G″ becomes larger than G′. Kealy (2006) has reported similar solid like behavior in various commercial cream cheeses.

Fig. 2.

Rheological parameters of fresh soy cheese spread made from soymilk alone

Increasing the angular frequency i.e. shearing the samples more quickly resulted in higher G′ values, indicating the cheese spread samples become more elastic. Florencia (2013) reported a rise in G′ value of spreadable goat milk cheese with increasing the angular frequency. It was hypothesized that this increase in the value of storage modulus is due to fusion of casein particles as a consequence of rearrangement of inter- and intra-molecular forces, which in turn results in an increased contacting surface between the casein aggregate (Hernandez-Tinoco et al. 2004). There was also a sharp increase in loss modulus (G″) values between the angular frequency values of 60–100 rad/s.

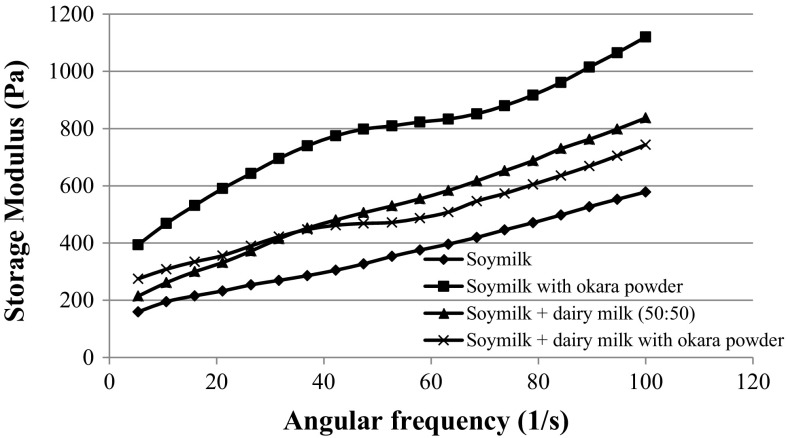

Effect of composition on rheological parameters of soy cheese spread

When the values of storage modulus (G′) of different samples were compared (Fig. 3), it was observed that cheese spread prepared from soymilk added with okara in it had the highest values of G′. This indicated more elastic behavior of the sample which could be due to higher solid (fiber) content in it. Okara contains around 50% fibers (Li et al. 2012). Addition of fibers has been reported to impart a reinforcement which allows stress transfer from the matrix to the fiber. The stress transfer increases with increase in fiber content i.e. the storage modulus of the product increases with fiber content (Mohanty et al. 2006). Singh et al. (2016) observed higher values of G′ and G″ in rice flour batters when dietary fibers and xanthan gums were added in it. Fibres reduced the amount of free water available to facilitate the movement of particles. Addition of dairy milk with soymilk also increased the elasticity of cheese spread.

Fig. 3.

Storage modulus of different soy cheese spread samples

The loss modulus (G″) of fresh cheese spread sample prepared from a combination of soymilk and dairy milk (50:50) with okara had the highest value, indicating that addition of dairy milk and okara resulted in more viscous cheese. Different additives in cheese affects the values of G′ and G″. Berta et al. (2016) studied the effect of composition on the viscoelastic properties of two types of cheese viz. mozzarella cheese and its cheaper substitute ‘imitation cheese’ used for pizza. Imitation cheese contained higher amount of starch than mozzarella cheese. Shear results differed significantly for the two cheese types. The loss modulus was found to be constantly higher than the storage modulus for the mozzarella cheese at a temperature of 60°C, indicating a liquid-like behaviour for these measuring conditions, whereas, imitation cheese displayed a viscoelastic behaviour typical of soft semi-solid materials, with G′ > G″. The authors related this kind of behavior to the respective microstructural features. The lubrication effect of many serum pockets and oil droplets contained by the mozzarella cheese determined a liquid like behaviour at low oscillatory strain while the soft-solid like behaviour of the imitation cheese reflects the presence of starch in its composition. Wen et al. (2012) showed that the treatment of skimmed milk with horseradish peroxidase (HRP) and ferulic acid (FA) modified the viscoelastic properties of the prepared set yoghurt. The yoghurt sample prepared from the skimmed milk treated with HRP and FA had the higher G′ and G″ values than the control milk based sample. Anema et al. (2005) investigated the effect of TGase-induced cross-linking of milk proteins on the viscoelastic properties of the acid gels, and found a marked increase in G′ and G″. The above results indicated that modification of the rheological properties of treated skimmed milk might be related to the modification of the milk proteins. Matheis and Whitaker (1984) had confirmed that dityrosine and tertyrosine were formed during cross-linking of casein or soybean proteins by peroxidase treatment. Thus, addition of dairy milk in soymilk might have resulted in a changed protein structure that increased G″ values.

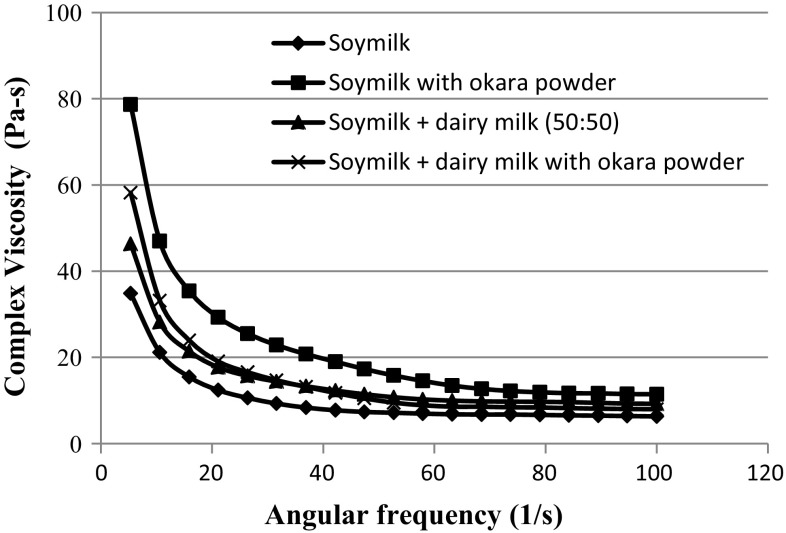

The complex viscosity measures the resistance to flow and is determined by dividing the complex modulus by angular frequency. Complex viscosity, when plotted as a function of angular frequency, can be correlated to shear viscosity as a function of shear rate for some materials. The complex viscosity of cheese spread samples depended very much on the applied frequency. There was a steady decrease in complex viscosity of all samples with increased shear rate (frequency), which means that the probiotic cheese spread samples exhibited shear thinning behavior (pseudo plasticity). This kind of behavior suggested the formation of solid-like structure i.e. through droplet interactions at low frequency and as a fragmented structure at a higher frequency (Long et al. 2016). A higher number of smaller particles results in more particle–particle interactions and an increased resistance to flow. The effect is more common at low shear rates, as a particle–particle interaction is a weak force (Ogah et al. 2014). Complex viscosity was also found to be higher in cheese samples to which okara was added during manufacturing process (Fig. 4). Thus okara had a thickening effect in the cheese spread and increased the internal cohesive force. Ogah et al. (2014) reported similar increase in complex viscosity of high-density polyethylene bio-composites when different agro-fibers were added to it. It was explained that the fiber particles may disturb the flow and provide obstruction to the flow, thus causing a rise in viscosity.

Fig. 4.

Complex viscosity of different soy cheese spread samples

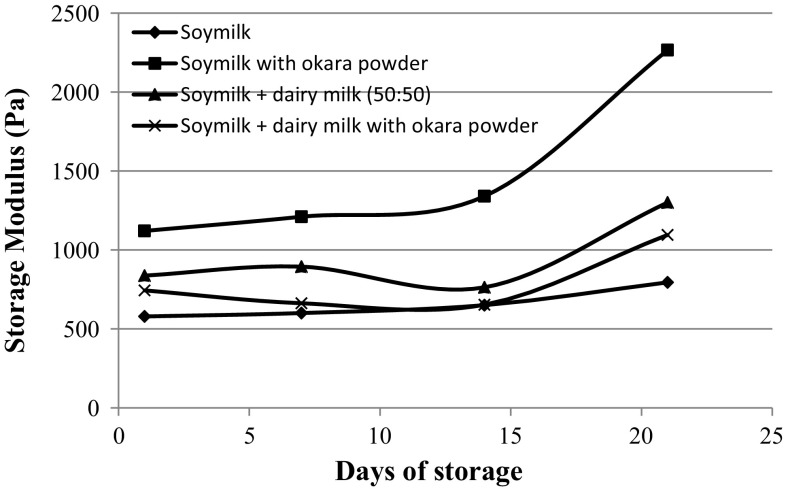

Effect of storage on rheological parameters of soy cheese spread

Changes in G′ values of different soy cheese spread samples during storage for a period of 3 weeks are depicted in Fig. 5. Similar trends were observed for loss modulus and complex viscosity (data not shown). These parameters did not change much up to a period of 14 days, and thereafter increased significantly.

Fig. 5.

Changes in storage modulus of cheese spread samples (at angular frequency of 100 Hz) with storage time

Gabriele et al. (2001) and Piska and Stetina (2004) related the increase in values of storage and loss modulus to the rising gel strength of semi-solid materials including foodstuffs. Ray et al. (2016) observed that as the age of chedder cheese increased its viscosity increased, and a higher temperature is required to reach the elastic to viscous crossover i.e. to initiate melting of the cheese. This might be due to an increased level of total solids through ripening driven dehydration. Farbod et al. (2013) found the hardness of cheese samples increased significantly during the first month and then decreased in the second month of storage period. The authors were of the view that the cheese hardness increases initially because of breaking sub-micelles into small casein aggregates and significant pH decrease. In the second month of storage, further breakdown of casein (proteolysis) happens and big molecules including large oligopeptides and peptides convert into small peptides and amino acids (proteinase and peptidase activities of lactic acid bacteria), and cheese texture become softer in this period. Thus the results found in the present study i.e. increase in G′, G″ and viscosity of probiotic soy cheese spread samples up to a duration of 4 weeks are in agreement with the findings of previous researchers. Slight strengthening of the protein matrix, changes in the structure of protein and fat, and thickening of samples might have taken place during storage of the probiotic soy-cheese spread.

Conclusion

The use of probiotic culture ‘Lactobacillus casei ssp. Casei NCDC-0017’ for fermentation of soymilk with other ingredients resulted in a coagulated mass that can further be processed into a cheese spread like product with sufficient viable counts (109 cfu/g) of the probiotic microorganism. The viability of the microorganism was maintained during storage period meeting the requirements to be considered as a probiotic food product. Considering the evaluated parameters, several significant differences were found between soy cheese spread and commercially available dairy cheese spread. The former contained higher protein and a higher antioxidant activity being probiotic in nature. Textural and rheological studies showed that the developed probiotic soy cheese spread samples were harder than dairy cheese spread and had a solid like behavior. Addition of okara and dairy milk with soymilk resulted in a spread with higher values of storage (elastic) modulus and complex viscosity. All the rheological parameters were found to increase significantly after 2 weeks of storage period, indicating structural changes in the components of the spread. There is scope for upscaling the process for commercial production of probiotic soy cheese spread, and the product has the potential of a nutraceutical food especially for vegetarians and for those who consume soybean.

References

- Agrahar-Murugkar D. Effect of different process parameters on the quality of soymilk and tofu from sprouted soybean. J Food Sci Technol. 2015;52(5):2886–2893. doi: 10.1007/s13197-014-1320-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Anema SG, Lauber S, Lee SK, Henle T, Klostermeyer H. Rheological properties of acid gels prepared from pressure and transglutaminase-treated skim milk. Food Hydrocoll. 2005;19:879–887. doi: 10.1016/j.foodhyd.2004.12.001. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 1999. [Google Scholar]

- Berta M, Muskens E, Schuster E, Stading M. Rheology of natural and imitation mozzarella cheese at conditions relevant to pizza baking. Int Dairy J. 2016;57:34–38. doi: 10.1016/j.idairyj.2016.02.038. [DOI] [Google Scholar]

- Blagden TD, Gilliland SE. Reduction of levels of volatile components associated with the “beany” flavor in soymilk by lactobacilli and streptococci. J Food Sci. 2005;70(3):M186–M189. doi: 10.1111/j.1365-2621.2005.tb07148.x. [DOI] [Google Scholar]

- Boylston TD, Vinderola CG, Ghoddusi HB, Reinheimer JA. Incorporation of bifidobacteria into cheeses: challenges and rewards. Int Dairy J. 2004;14:375–387. doi: 10.1016/j.idairyj.2003.08.008. [DOI] [Google Scholar]

- Chinma CE, Ilowefah M, Shammugasamy B, Ramakrishnan Y, Muhammad K. Chemical, antioxidant, functional and thermal properties of rice bran proteins after yeast and natural fermentations. Int J Food Sci Technol. 2014;49:2204–2213. doi: 10.1111/ijfs.12533. [DOI] [Google Scholar]

- Chun J, Kim JS, Kim JH. Enrichment of isoflavone aglycones in soymilk by fermentation with single and mixed cultures of Streptococcus infantarius 12 and Weissella sp. 4. Food Chem. 2008;109(2):278–284. doi: 10.1016/j.foodchem.2007.12.024. [DOI] [PubMed] [Google Scholar]

- Endres JG. Soy Protein Products: Characteristics, Nutritional Aspects, and Utilization. Champaign: AOCS Press; 2001. [Google Scholar]

- Farbod F, Kalbasi A, Moini S, Emam-Djomeh Z, Razavi H, Mortazavi A, Beheshti H-R. The effects of storage time on physiochemical, rheological, micro-structural and sensory properties of feta cheese fortified with fish and olive oils. J Nutr Food Sci. 2013;3(5):230. doi: 10.1007/s13197-013-1163-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- FDA (1999) Food labeling health claims, soy protein and coronary heart disease. Food and Drug Administration, 21 Code of Federal Regulations, part 101 [PubMed]

- Fernandes A, Barreira JCM, Barros L, Mendonça A, Ferreira Isabel CFR, de Sousa FR. Chemical and physicochemical changes in Serrana goat cheese submitted to extra-long ripening periods. LWT Food Sci Technol. 2018;87:33–39. doi: 10.1016/j.lwt.2017.08.071. [DOI] [Google Scholar]

- Florencia FS. Rheology of spreadable goat cheese made with autochthonous lactic cultures differing in their ability to produce exopolysaccharides. Food Sci Technol (Campinas) 2013;33(2):233–238. doi: 10.1590/S0101-20612013005000034. [DOI] [Google Scholar]

- Gabriele D, de Cindio B, D’Antona P. A weak gel model for foods. Rheol Acta. 2001;40:120–127. doi: 10.1007/s003970000139. [DOI] [Google Scholar]

- Giri SK, Mangaraj S. Processing influences on composition and quality attributes of soymilk and its powder—a review. Food Eng Rev. 2012;4(3):149–164. doi: 10.1007/s12393-012-9053-0. [DOI] [Google Scholar]

- Giri SK, Mangaraj S. Soymilk concentration by ultrafiltration: effects of pore size and transmembrane pressure on filtration performance. Int J Food Sci Technol. 2014;49(3):666–672. doi: 10.1111/ijfs.12348. [DOI] [Google Scholar]

- Hajirostamloo B. Comparison of nutritional and chemical parameters of soymilk and cow milk. Int J Biol Biomol Agric Food Biotechnol Eng. 2009;3(9):455–457. [Google Scholar]

- Hernandez-Tinoco A, Ramos-Ramirez EG, Falcony-Guajardo CY, Salazar-Montoya JA. Rheometry and scanning electron microscopy study of casein curds added with mequite seed gum and soy proteins. Latin Am Appl Res. 2004;42:195–202. [Google Scholar]

- Iravani S, Korbekandi H, Mirmohammadi SV. Technology and potential applications of probiotic encapsulation in fermented milk products. J Food Sci Technol. 2015;52(8):4679–4696. doi: 10.1007/s13197-014-1516-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kealy T. Application of liquid and solid rheological technologies to the textural characterisation of semi-solid foods. Food Res Int. 2006;39:265–276. doi: 10.1016/j.foodres.2005.07.016. [DOI] [Google Scholar]

- Krase JP, Schultz M, Dudek S. Effect of extraction conditions on composition, surface activity and rheological properties of protein isolates from flaxseed (Linum usitativissimum L.) J Sci Food Agric. 2002;82(9):970–976. doi: 10.1002/jsfa.1140. [DOI] [Google Scholar]

- Krause JP, Bagger Ch, Schwenke KD. Rheological properties of modified lupin proteins. Food/Nahrung. 2001;45(6):412–415. doi: 10.1002/1521-3803(20011001)45:6<412::AID-FOOD412>3.0.CO;2-J. [DOI] [PubMed] [Google Scholar]

- Li B, Qiao M, Lu F. Composition, nutrition, and utilization of okara (soybean residue) Food Rev Int. 2012;28:231–252. doi: 10.1080/87559129.2011.595023. [DOI] [Google Scholar]

- Liu D-M, Li L, Yang X-Q, Liang S-Z, Wang J-S. Survivability of Lactobacillus rhamnosus during the preparation of soy cheese. Food Technol Biotechnol. 2006;44(3):417–422. [Google Scholar]

- Long Z, Zhao M, Sun-Waterhouse D, Lin Q, Zhao Q. Effects of sterilization conditions and milk protein composition on the rheological and whipping properties of whipping cream. Food Hydrocolloids. 2016;52:11–18. doi: 10.1016/j.foodhyd.2015.06.015. [DOI] [Google Scholar]

- Matheis G, Whitaker JR. Peroxidase-catalyzed cross linking of proteins. J Protein Chem. 1984;3:35–48. doi: 10.1007/BF01024835. [DOI] [Google Scholar]

- Matias NS, Bedani R, Castro IA, Saad SMI. A probiotic soy-based innovative product as an alternative to petit-suisse cheese. LWT Food Sci Technol. 2014;59:411–417. doi: 10.1016/j.lwt.2014.05.054. [DOI] [Google Scholar]

- Metwalli NH, Shalabi SI, Zahran AS, El-Demerdash O. The use of soybean milk in soft cheese making II. Organoleptic and chemical properties of Domiati cheese made from a mixture of soybean milk and whole milk. Int J Food Sci Technol. 1982;17(3):297–305. doi: 10.1111/j.1365-2621.1982.tb00186.x. [DOI] [Google Scholar]

- Miller JH. Determination of viable cell counts: bacterial growth curves. In: Miller JH, editor. Experiments in Molecular Genetics. 3. New York: Cold Spring Harbor Laboratory; 1972. pp. 31–36. [Google Scholar]

- Mishra V, Shah C, Mokashe N, Chavan R, Yadav H, Prajapati J. Probiotics as potential antioxidants: a systematic review. J Agric Food Chem. 2015;63(14):3615–3626. doi: 10.1021/jf506326t. [DOI] [PubMed] [Google Scholar]

- Mohanty S, Verma SK, Nayak SK. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos Sci Technol. 2006;66:538. doi: 10.1016/j.compscitech.2005.06.014. [DOI] [Google Scholar]

- Ogah AO, Afiukwa JN, Nduji AA. Characterization and comparison of rheological properties of agro fiber filled high-density polyethylene bio-composites. Open J Polym Chem. 2014;4:12–19. doi: 10.4236/ojpchem.2014.41002. [DOI] [Google Scholar]

- Park DJ, Oh S, Ku KH, Mok C, Kim SH, Imm JY. Characteristics of yogurt-like products prepared from the combination of skim milk and soymilk containing saccharified-rice solution. Int J Food Sci Nutr. 2005;56:23–34. doi: 10.1080/09637480500082181. [DOI] [PubMed] [Google Scholar]

- Piska I, Stetina J. Influence of cheese ripening and rate of cooling of the processed cheese mixture on rheological properties of processed cheese. J Food Eng. 2004;61:551–555. doi: 10.1016/S0260-8774(03)00217-6. [DOI] [Google Scholar]

- Puligundla P, Yong-Hwa C, Young-Tack L. Physicochemical and sensory properties of reduced-fat mayonnaise formulations prepared with rice starch and starch-gum mixtures. Emirates J Food Agric. 2015;27(6):463–468. doi: 10.9755/ejfa.2015.04.081. [DOI] [Google Scholar]

- Ray CA, Gholamhosseinpour A, Ipsen R, Hougaard AB. The effect of age on Cheddar cheese melting, rheology and structure, and on the stability of feed for cheese powder manufacture. Int Dairy J. 2016;55:38–43. doi: 10.1016/j.idairyj.2015.11.009. [DOI] [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53(2):1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Subramanian A, Rodriguez-Saona L. Chemical and instrumental approaches to cheese analysis. Adv Food Nutr Res. 2010;59:167–213. doi: 10.1016/S1043-4526(10)59005-3. [DOI] [PubMed] [Google Scholar]

- Tripathi MK, Giri SK. Probiotic functional foods: survival of probiotics during processing and storage. J Funct Foods. 2014;9:225–241. doi: 10.1016/j.jff.2014.04.030. [DOI] [Google Scholar]

- Tuberoso CIG, Kowalczyk A, Sarritzu E, Cabras P. Determination of antioxidant compounds and antioxidant activity in commercial oilseeds for food use. Food Chem. 2007;103(4):1494–1501. doi: 10.1016/j.foodchem.2006.08.014. [DOI] [Google Scholar]

- Wang Y-C, Yu R-C, Yang H-Y, Chou C-C. Sugar and acid contents in soymilk fermented with lactic acid bacteria alone or simultaneously with bifidobacteria. Food Microbiol. 2003;20(3):333–338. doi: 10.1016/S0740-0020(02)00125-9. [DOI] [Google Scholar]

- Wen Y, Liu N, Zhao X-H. Chemical composition and rheological properties of set yoghurt prepared from skimmed milk treated with horseradish peroxidase. Food Technol Biotechnol. 2012;50(4):473–478. [Google Scholar]