Abstract

The goal of this study was to develop a fish-based product suitable for people with celiac disease. Water and gluten-free flours (rice, corn, amaranth or quinoa) were added to improve cooking yield, texture parameters and as an aid in improving quality attributes such as taste and juiciness. Cooking yields of patties containing gluten-free flours were higher than control and maximum values ranged between 91 and 93%. Hardness was higher in patties made with amaranth or quinoa flour, whereas cohesiveness and springiness were higher in patties made with corn and rice flour, respectively. Response surface methodology was used to optimize patties formulations. Optimized formulations were prepared and evaluated showing a good agreement between predicted and experimental responses. Also, nutritional value and consumer acceptance of optimized formulations were analysed. Flours addition affected proximate composition increasing carbohydrates, total fat and mineral content compared to control. Sensory evaluation showed that no differences were found in the aroma of products. Addition of rice flour increased juiciness and tenderness whereas taste, overall acceptance and buying intention were higher in control patty, followed by patties made with corn flour. The present investigation shows good possibilities for further product development, including the scale up at an industrial level.

Keywords: Fish patty, Gluten-free flour, Response surface methodology, Consumer acceptability, Sensorial analysis

Introduction

Spotted sorubim (Pseudoplatystoma corruscans), a large catfish found in the main South American hydrographic basins, has a high commercial value because of their high protein content, healthy fatty acid profile and tasty meat (Lobo et al. 2015). This fish, usually marketed unprocessed, is becoming an interesting alternative as a raw material in fish-based food production. Commonly, meat product manufacture requires the inclusion of non-meat ingredients, which is considered a significant strategy for reducing overall production costs while preserving nutritional and sensory qualities of end products. In this regard, ingredients from vegetables sources, especially those rich in carbohydrates, are widely used in meat industry to improve water and fat retention.

Quantity and type of additives are important factors in the elaboration process of these products, since they influence colour and technological properties, such as yield and texture. Wheat flour is one of the most used ingredients, because of its high ability to retain water and fat (Muthia et al. 2010; Ranathunga et al. 2015). This flour has been used in a wide variety of products such as sausages, chicken burgers or fish croquettes (Hernandez Barros Fuchs et al. 2013; Ranathunga et al. 2015). However, the use of this flour makes meat products not suitable for celiac population due to its gluten content. Therefore, alternative grains could be used as potential raw material for developing gluten-free products in meat industry. For example, rice flour was used to improve water and fat retention in pork patties (Gao et al. 2014) or to improve functional properties, including moisture retention, in emulsified sausages (Pereira et al. 2016); chickpea and lentil flours were used as binders in low-fat beef burgers (Shariati-Ievari et al. 2016); oat flour was incorporated into chicken nuggets to increase cooking yield (Santhi and Kalaikannan 2014); and influence of corn flour content on cooking properties was evaluated in fish patties (Makri and Douvi 2014). In this regard, others non-traditional ingredients, like amaranth and quinoa flours depict a great technological interest in meat product manufacture because of their high carbohydrate and protein content, healthy fatty acids profile, antioxidant compounds and high iron content (Ramos Diaz et al. 2015).

The motivation of this research was to introduce non-conventional flours in the formulation of freshwater fish products suitable for celiac population. To achieve this, finding an optimal combination of ingredients that allows obtaining a product with acceptable characteristics is a priority process, being response surface methodology one of the most common tool used. Therefore, the objectives of this work were to develop pre-cooked fish patties by adding gluten-free flours and water, and to evaluate the nutritional value, textural properties and consumer acceptance of the optimized developed products.

Materials and methods

Raw material

Gutted and headless specimens of spotted sorubim (Pseudoplatystoma corruscans) were purchased fresh from a local retailer and transported on ice to the university laboratory where they were sliced, packed in polystyrene bags and frozen at -18 °C. Wheat (Triticum aestivum L.), rice (Oryza sativa L.), corn (Zea mays L.), amaranth (Amaranthus cruentus L.) and quinoa (Chenopodium quinoa Willd.) flours were obtained from a local market and used without modifications. Table 1 shows proximate composition and mineral content of raw material.

Table 1.

Proximate composition and mineral content of raw material

| Composition | Fish meat | Wheat flour | Rice flour | Corn flour | Amaranth flour | Quinoa flour |

|---|---|---|---|---|---|---|

| Moisture* | 64.81 ± 0.59 | 12.41 ± 0.11 | 12.71 ± 0.13 | 11.80 ± 0.06 | 11.11 ± 0.09 | 16.11 ± 0.13 |

| Fat | 17.79 ± 0.79 | 1.84 ± 0.25 | 0.04 ± 0.05 | 1.23 ± 0.25 | 19.80 ± 0.94 | 4.95 ± 0.21 |

| Protein | 16.75 ± 0.65 | 12.01 ± 0.13 | 7.28 ± 0.09 | 5.66 ± 0.18 | 14.99 ± 0.18 | 13.64 ± 0.35 |

| Carbohydrates | 0.44 ± 0.11 | 72.29 ± 0.51 | 79.50 ± 0.71 | 73.75 ± 0.35 | 54.50 ± 0.71 | 65.50 ± 0.70 |

| Ash | 2.09 ± 0.01 | 1.42 ± 0.04 | 0.36 ± 0.00 | 0.68 ± 0.02 | 3.34 ± 0.03 | 2.26 ± 0.02 |

| Na** | 257.56 ± 2.26 | 100.82 ± 4.91 | 38.80 ± 2.32 | 36.02 ± 4.00 | 56.65 ± 2.81 | 49.93 ± 2.34 |

| K | 191.30 ± 0.57 | 202.27 ± 1.13 | 40.65 ± 0.35 | 108.06 ± 0.66 | 395.73 ± 2.94 | 293.75 ± 3.30 |

| Ca | 11.49 ± 0.03 | 18.25 ± 0.63 | 4.86 ± 0.44 | 7.13 ± 0.53 | 69.09 ± 1.85 | 19.48 ± 0.73 |

| Fe | 1.13 ± 0.44 | 0.73 ± 0.11 | 0.69 ± 0.15 | 0.52 ± 0.09 | 4.51 ± 0.37 | 6.16 ± 0.11 |

*Raw material composition (Moisture, Fat, Protein, Carbohydrates, and Ash) is expressed in g/100 g of sample

**Mineral content (Na, K, Ca, and Fe) is expressed in mg/100 g of sample

Values represent the mean ± standard deviation of three determinations

Experimental design and statistical analysis

Response surface methodology was used to investigate the effect of two independent factors (water and gluten-free flour content) at three levels (0, 15 and 30% for water; 0, 5 and 10% for flours) on cooking yield, textural properties (hardness, cohesiveness, springiness and chewiness) and colour parameters (lightness, redness and yellowness) of pre-cooked fish patties. Maximum quantities of water and flour were chosen according to levels established by Argentinian Food Code. A 32 Multilevel Factorial Design was constructed using the software Statgraphics Centurion XV version 15.2.06 (Statpoint Technologies, Inc. Warrenton, Virginia, USA). The experimental design involved nine experiments for each gluten-free flour (Table 2). Fish patty without added water or flour was assumed as control patty. In addition, a reference patty was elaborated with water (15%) and wheat flour (10%). Experiments were done in duplicate and runs were randomized to avoid block effects. The analysis of variance was carried out to determine the significance of the effects. Fisher’s LSD method was performed for simultaneous pairwise comparisons.

Table 2.

Experimental design and responses for fish patties

| Run | Variables | Yield | Textural properties | Colour properties | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 | |

| RP* | 15 | 10 | 95.90 | 15.01 | 0.62 | 4.80 | 44.84 | 68.28 | 1.34 | 14.38 |

| 1** | 0 | 0 | 79.28 | 15.81 | 0.62 | 4.15 | 41.09 | 65.43 | 6.23 | 15.20 |

| 2A*** | 30 | 5 | 90.24 | 8.95 | 0.55 | 5.49 | 26.94 | 72.46 | 0.50 | 17.78 |

| 2B | 30 | 5 | 81.63 | 4.30 | 0.56 | 3.31 | 7.94 | 73.81 | 5.98 | 17.25 |

| 2C | 30 | 5 | 86.15 | 7.08 | 0.45 | 3.71 | 11.91 | 69.94 | 5.38 | 14.03 |

| 2D | 30 | 5 | 88.84 | 5.39 | 0.41 | 3.21 | 7.04 | 67.26 | 5.25 | 15.00 |

| 3A | 0 | 10 | 91.56 | 16.00 | 0.49 | 7.20 | 57.20 | 69.63 | 0.73 | 16.34 |

| 3B | 0 | 10 | 92.45 | 19.82 | 0.61 | 4.29 | 51.89 | 67.31 | 7.04 | 20.87 |

| 3C | 0 | 10 | 89.31 | 20.07 | 0.57 | 3.65 | 41.17 | 64.69 | 7.48 | 17.46 |

| 3D | 0 | 10 | 93.42 | 20.57 | 0.48 | 4.10 | 40.34 | 62.51 | 6.86 | 16.16 |

| 4A | 15 | 10 | 93.78 | 15.44 | 0.54 | 6.29 | 53.08 | 71.63 | 0.50 | 15.91 |

| 4B | 15 | 10 | 93.29 | 16.13 | 0.61 | 4.39 | 43.57 | 71.47 | 7.38 | 20.73 |

| 4C | 15 | 10 | 91.37 | 18.14 | 0.50 | 3.89 | 35.01 | 68.11 | 6.66 | 16.46 |

| 4D | 15 | 10 | 93.26 | 9.22 | 0.38 | 3.65 | 12.92 | 64.36 | 6.13 | 15.81 |

| 5 | 30 | 0 | 72.85 | 3.54 | 0.45 | 3.65 | 5.74 | 74.33 | 4.80 | 15.85 |

| 6A | 15 | 5 | 90.89 | 11.13 | 0.50 | 5.13 | 28.30 | 73.98 | 0.64 | 14.50 |

| 6B | 15 | 5 | 86.45 | 9.15 | 0.62 | 4.26 | 22.92 | 68.09 | 7.15 | 17.83 |

| 6C | 15 | 5 | 87.09 | 14.69 | 0.61 | 4.21 | 37.19 | 67.24 | 5.75 | 15.55 |

| 6D | 15 | 5 | 91.97 | 7.60 | 0.43 | 3.34 | 10.96 | 67.51 | 5.29 | 14.20 |

| 7A | 0 | 5 | 89.97 | 12.01 | 0.46 | 5.37 | 27.00 | 72.64 | 0.48 | 16.14 |

| 7B | 0 | 5 | 85.01 | 13.03 | 0.56 | 4.42 | 33.10 | 67.98 | 7.60 | 17.66 |

| 7C | 0 | 5 | 85.17 | 17.95 | 0.55 | 4.21 | 42.04 | 62.51 | 7.66 | 16.75 |

| 7D | 0 | 5 | 90.11 | 12.99 | 0.43 | 4.34 | 23.98 | 65.73 | 6.61 | 16.31 |

| 8A | 30 | 10 | 91.98 | 10.48 | 0.49 | 6.36 | 32.63 | 75.80 | 0.41 | 15.06 |

| 8B | 30 | 10 | 91.71 | 5.12 | 0.54 | 4.08 | 11.34 | 72.29 | 6.18 | 18.83 |

| 8C | 30 | 10 | 88.39 | 7.64 | 0.47 | 3.66 | 12.16 | 70.11 | 5.64 | 13.85 |

| 8D | 30 | 10 | 90.46 | 4.84 | 0.39 | 3.27 | 5.13 | 65.25 | 6.71 | 16.00 |

| 9 | 15 | 0 | 83.14 | 9.47 | 0.52 | 3.90 | 18.76 | 68.43 | 6.54 | 17.04 |

Variables: X1 = Water content (g/100 g of sample); X2 = Flour Content (g/100 g of sample)

Responses: Y1 = Cooking yield (%); Y2 = Hardness (N); Y3 = Cohesiveness (−); Y4 = Springiness (mm); Y5 = Chewiness (N.mm); Y6 = Lightness (L*); Y7 = Redness (a*); Y8 = Yellowness (b*)

*RP: Reference Patty was formulated with wheat flour

**Run 1, fish patty without added water or flour was assumed as control

***Flours used in experiments were (A) Rice, (B) Corn, (C) Amaranth, (D) Quinoa, and (E) Wheat

A second order polynomial regression Eq. (1) was fitted to the experimental data of all responses

| 1 |

Where Y is the observed response, X1 and X2 are the independent variables, and β0 is a constant, β1 and β2 are linear coefficients, β11 and β22 are quadratic coefficients, and β12 is the interaction coefficient.

Lack-of-fit was used to assess the fits of the mathematical models. Model fit was assessed by the coefficient of determination R2. Perturbation plots were obtained using the software Design Expert Version 7.0.0 Trial version (State Ease, Minneapolis, USA).

Fish patties formulation and processing

Before processing, fish slices were thawed at room temperature and subsequently unpacked, skinned and deboned to obtain fish meat, which was minced using a hand-held food processor and mixed with appropriate quantities of water and gluten-free flours (see Table 2). Then, sodium chloride (1.2 wt%) and butylhydroxyanisole (0.01 wt %) were added. Fish patties (100 ± 0.5 g) were shaped (diameter = 100 mm; thickness = 20 mm) and cooked in an electric oven (180 °C) until thermal centre reached 78 °C. After cooking, patties were cooled at room temperature, packed in polyethylene bags (oxygen permeability = 2000 cm3/m2 day) and stored at − 18 °C until analysis. All analyses were done within 3 days after elaboration.

Physicochemical analyses

Cooking yield measurements

Cooking yield of fish patties was determinate according to Gao et al. (2014):

Texture profile analysis (TPA)

TPA was performed in cooked fish patties as described by Yi et al. (2012) with some modifications. A Texture Analyser Pro CT V1.4 Build 17 (Brookfield Engineering Labs, Inc.) equipped with a load cell of 45 N and the software Texture ProC3 (USA) was used. TPA parameters, namely hardness (N), cohesiveness (–), springiness (mm), and chewiness (N × mm), were computed using the available computer software. Five patties from each formulation were analysed. Fish patties (20 mm in height and 20 mm in diameter) were placed on the centre of the TPA plate and compressed to 40% of their original height at a constant test speed of 0.5 mm/min (pre-test speed and post-test speed were 2 mm/min and 0.5 mm/min respectively; sampling frequency was 100 point/s; recovering time was 1 s).

Colour measurements

Colour measurements were performed using a Thermo Scientific Evolution 600 UV–Vis Spectrophotometer equipped with an integrated sphere. CIE L*, a*, and b* values were obtained by using VISIONlite colorCalc software (Germany). L* value indicates lightness; a* value indicates redness; and b* value indicates yellowness. Ten determinations were carried out per sample.

Optimization of pre-cooked fish patties formulation

Optimum formulation for each treatment was found using a desirability function, according to Mudgil et al. (2016). The desired goal for each dependent variable was selected. For numerical optimization, all independent variables were kept within range while the dependent variables; cooking yield and L* value were maximized, whereas chewiness was minimized. Hardness, cohesiveness and springiness were not employed in optimization analysis due to they are already included in chewiness calculation. Desirability function combine the goals into an overall composite function, which is defined as:

where, d1, d2,…,dn are the responses and ‘n’ is the total number of responses in the measure.

Response surface graphs were generated using the software Statgraphics Centurion XV version 15.2.06 (Statpoint Technologies, Inc. Warrenton, Virginia, USA). The point that enhances desirability function to maximum numerical optimization was determinate. The experiment was replicated twice.

Characterization of nutritional value of optimized pre-cooked fish patties

Proximate composition

Moisture, fat, protein and ash contents were analysed according to AOAC methods 950.46, 960.52, 991.36, and 920.153 respectively (AOAC 1998). Total carbohydrates were quantified by anthrone method (Clegg 1956) in a UV–Vis spectrophotometer (Thermo Scientific UV–Vis, Evolution 600). All analyses were carried out in duplicate and the mean calculated as g/100 g of sample.

Mineral content

Sodium, potassium and calcium content was determined by flame photometry after hydrochloric acid digestion. Iron content was determined by ferrozine method, according to Carpenter and Ward (2010). All analyses were carried out in duplicate and the mean calculated as mg mineral/100 g of sample.

Lipid profile

Extraction and purification of fat was performed according to Bligh and Dyer Method (1959), using BHA as antioxidant. The fatty acid methyl esters were prepared according to AOAC Method 969.33 (AOAC 1998), and quantified with an Agilent Technologies gas chromatograph equipped with a 60 m capillary column Supelco 2340 and FID detector. The oven temperature program was 5 min at 140 °C, then 4 °C/min to 240 °C and finally 240 °C for 15 min. Identification of fatty acid methyl esters was based on retention time of standard methyl esters (Supelco® 37 Components FAME Mixture, Bellefonte, PA), plus Conjugated Linoleic Acids (Sigma-Aldrich) eluting from the capillary column. Peak areas were integrated using chromatography data software, and concentrations of each ester were calculated as a percentage of the total area of the chromatogram.

Sensory evaluation of optimized pre-cooked fish patties

Fish patties were assessed by 30 untrained evaluators under controlled conditions of light, temperature and humidity. Panellists were selected according to their preference for fish and patties consumption. They were students and professors from the National University of Chaco Austral; age 19–58, mean 35.43; 19 females and 11 males. All members were given verbal instructions before testing the products. Written informed consent was obtained from each subject after the description of the experiment. Each evaluator received the evaluation form, also an unsalted cracker and a glass of water at room temperature to cleanse the palate before testing each sample. Samples were preheated in oven (90 °C) for 2 min, codified with three-digit numbers and served to evaluators in white plastic dishes, in individual cabins. A five-point scale was used according to Yi et al. (2012), with minor modifications. The panellists were asked to evaluate colour, aroma, juiciness, tenderness, taste, and overall acceptability. Colour, aroma, taste and overall acceptability ranging between 1 = definitely did not like it and 5 = definitely like it; the juiciness and tenderness range between 1 = extremely dry/though and 5 = extremely juicy/tender. At the end of the evaluation form each panellist was asked to declare his buying intention of the product with a five-point scale ranging between 1 = I will surely not buy it and 5 = I will surely buy it.

Results and discussion

Cooking yield

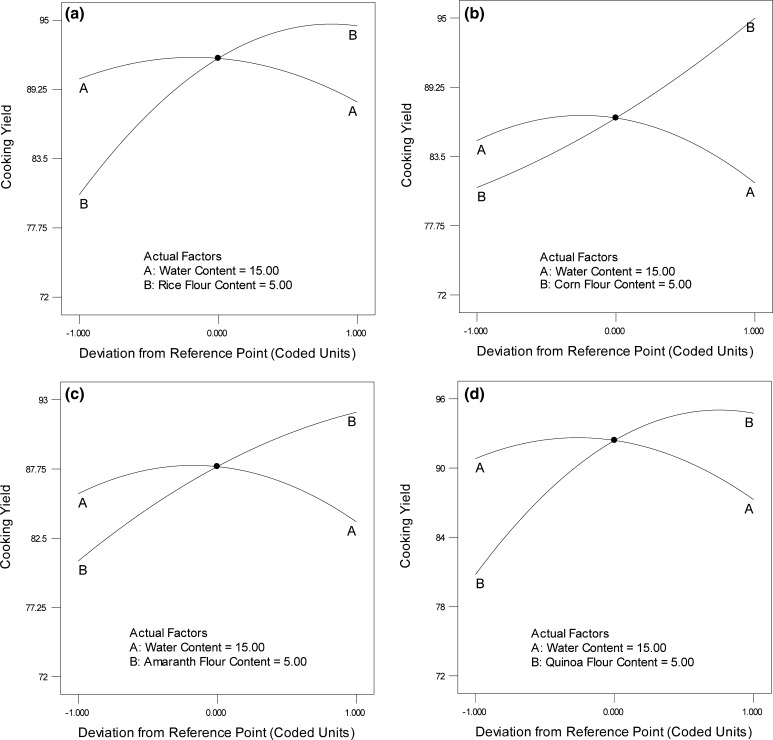

Cooking yield was increased (P < 0.05) by both wheat flour and gluten-free flours addition in all treatments (Table 2). The type of flour had no influence (P > 0.05) on the maximum values. For gluten-free patties, maximum values of cooking yield were achieved in patties with 10 wt% of flour and 15 wt% of added water. These values ranged between 91 and 93%, probably due to a stronger emulsion formed because of the higher protein and carbohydrates content in flours. These results are comparable to those found by Riernersman et al. (2016) and Tahmasebi et al. (2016) in meat products elaborated with different additives. The individual effect of independent variables on cooking yield was found by perturbation plots. Results revealed that cooking yield was highly sensitive to gluten-free flours content and almost insensitive to water content (Fig. 1).

Fig. 1.

Perturbation plot showing the effect of tested factors on cooking yield of pre-cooked fish patties added with different gluten-free flours: a rice, b Corn, c amaranth and d quinoa

Cooking yields of patties containing gluten-free flours were lower (P < 0.05) than value for reference patty (91–93 vs 96%). This difference could be attributed to the higher protein content of wheat flour compared to rice and corn flours, and to the higher carbohydrate content of wheat flour compared to amaranth and quinoa flours.

Texture

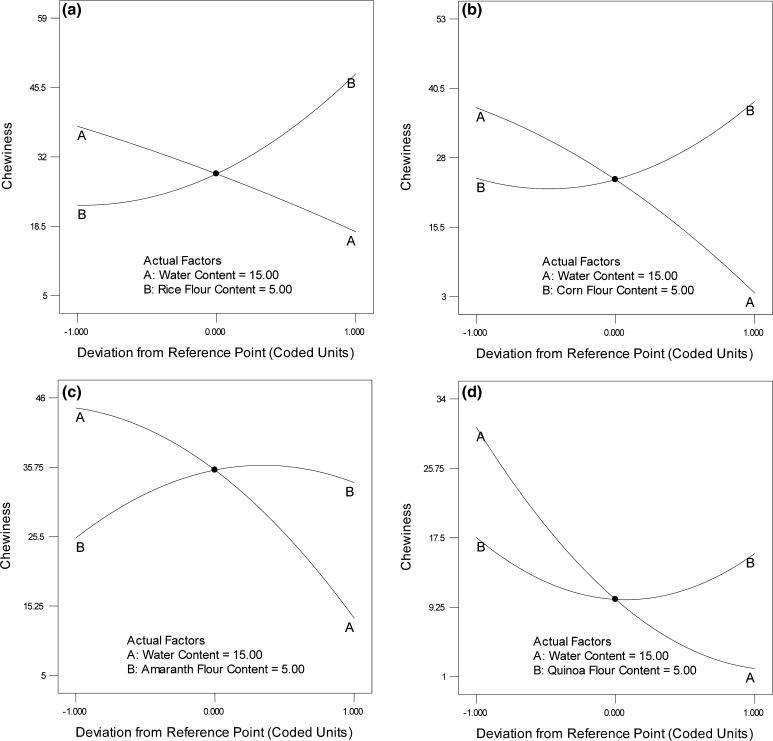

Table 2 shows the effects of adding different amounts of gluten-free flours and water in fish patties formulation. Significant changes in texture parameters were recorded among treatments both in comparison between samples and when comparing with the control patty (P < 0.05). The addition of flours increased hardness (P < 0.05), reaching a maximum value (20.00 ± 0.50 N) for patties manufactured with 10% of amaranth or quinoa flour; and decreased to a minimum (3.54 ± 0.08 N) in patty with 30% of water and no added flours. The cohesiveness and springiness values increased with increasing levels of gluten-free flours and water (P < 0.05). Cohesiveness value was higher in treatment with 10% corn flour (P < 0.05), while springiness was higher in patties added with 10% of rice flour and 30% of water. Chewiness represents the effort required to break a food until it is ready to be swallowed, thus a bigger effort indicates a harder food. Regarding this parameter, it decreased with the increasing water content, reaching a minimum value of 5.74 ± 1.02 N for the formulation with 30% of water. These effects are evidenced in perturbation plots (Fig. 2), where water content has a negative effect and flour content has, to a lesser extent, a positive effect on chewiness of all gluten-free patties. Changes in texture parameters might be due to moisture retention properties of the different flours which leads to a stronger or weaker three-dimensional network of protein matrix attributed to incorporation of flours (Verma et al. 2015).

Fig. 2.

Perturbation plot showing the effect of tested factors on chewiness of pre-cooked fish patties added with different gluten-free flours: a rice, b Corn, c amaranth and d quinoa

When comparing results obtained for reference patty (at the same water and flour content) with those of gluten-free patties it is observed that patty made with wheat flour showed higher hardness than patty made with quinoa flour (P < 0.05), lower hardness than patty made with amaranth flour (P < 0.05) and similar hardness to patties made with rice or corn flours (P > 0.05). Cohesiveness of reference patty was higher than cohesiveness of gluten-free patties (P < 0.05), except the one made with corn flour. Finally, elasticity and chewiness of reference patty were comparable to patty made with corn flour (P > 0.05), lower than that of patty made with rice flour (P < 0.05) and higher than that of patties made with amaranth or quinoa flours (P < 0.05). Similar results were found in duck sausage elaborated with tapioca, wheat, sago and potato flours (Muthia et al. 2010).

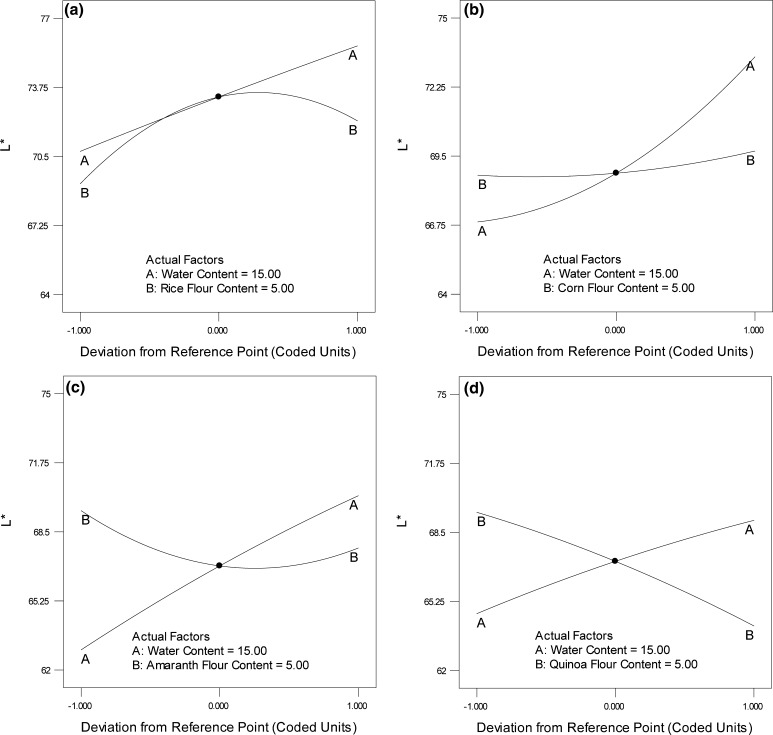

Colour

L*, a* and b* parameters were measured to evaluate eventual colour modifications in fish patties, as shown in Table 2. Both levels of additives modified colour parameters of patties as compared to control (P < 0.05). Lightness (L*) was mostly affected by water addition, reaching higher values in patties with 30% of added water (L* ranged between 70 and 75) except for patties made with quinoa flour (L* = 67). Perturbation plots (Fig. 3) show a positive effect of water content on lightness of patties, whereas flour effect was dependent of the type of flour. Rice and quinoa flours presented positive and negative effect, respectively, while lightness of patties was insensitive to corn and amaranth flour contents. Redness (a*) increased in products with both levels of corn and amaranth flour, reaching values of 7.60 ± 0.56 and 7.66 ± 0.19 for 5% of flours. These changes might be due to the non-enzymatic browning reaction between carbohydrates present in flours and fish protein during cooking (Verma et al. 2015). Compared to control, yellowness (b*) differed in treatments (P < 0.05). Similar results were reported by Lee and Ahn (2005) and Verma et al. (2012) in turkey breast rolls formulated with different plum extract concentration; and in chickpea hull flour chicken nuggets, respectively.

Fig. 3.

Perturbation plot showing the effect of tested factors on lightness (L*) of pre-cooked fish patties added with different gluten-free flours: a rice, b Corn, c amaranth and d quinoa

Statistical analysis of model fitting

Response surface analysis was done to analyse the effects of water and gluten-free flour levels on physicochemical properties of fish patties. The coefficients of determination (R2) of mathematical models were higher than 0.7, indicating that models can satisfactory explain the variation of dependent variables, with exception of springiness and yellowness. Among physicochemical properties, the models that showed a stronger relationship between experimental data and predicted values were cooking yield, hardness and chewiness for textural properties, and lightness for colour properties. The lack of fit was not significant (P > 0.05) in all fitted models, with the exception of yellowness. The result of the regression analysis for all models is reported in Table 3.

Table 3.

Regression coefficients of physical properties of gluten-free fish patties

| Factor | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 |

|---|---|---|---|---|---|---|---|---|

| β0 | ||||||||

| A* | 79.99 | 14.47 | 0.58 | 4.10 | 34.02 | 66.35 | 6.31 | 15.46 |

| B* | 80.33 | 14.51 | 0.59 | 4.20 | 36.34 | 65.41 | 6.42 | 15.35 |

| C* | 79.64 | 14.80 | 0.60 | 4.14 | 37.66 | 64.87 | 6.64 | 15.64 |

| D* | 79.85 | 15.26 | 0.60 | 4.28 | 38.60 | 65.65 | 6.70 | 15.99 |

| β1 | ||||||||

| A | 0.26 | − 0.23 | − 2.47E − 03 | − 0.04 | − 0.63 | 0.16 | 0.01 | 0.01 |

| B | 0.30 | − 0.18 | − 8.61E − 04 | 2.11E − 03 | − 0.61 | 0.17 | 0.04 | 0.15 |

| C | 0.33 | − 0.11 | − 1.97E − 03 | 2.36E − 03 | − 0.54 | 0.31 | − 0.04 | 0.12 |

| D | 0.31 | − 0.57 | − 0.01 | − 0.04 | − 1.82 | 0.25 | − 0.07 | 0.00 |

| β2 | ||||||||

| A | 3.03 | − 0.34 | − 0.02 | 0.32 | − 0.90 | 1.29 | − 1.65 | 0.17 |

| B | 0.69 | − 0.60 | 0.01 | − 0.01 | − 1.33 | 0.33 | 0.29 | 0.34 |

| C | 1.68 | 0.89 | 1.92E − 03 | 0.05 | 2.33 | − 0.78 | 0.11 | − 0.01 |

| D | 3.19 | − 0.40 | − 0.03 | − 0.07 | − 2.92 | − 0.18 | − 0.19 | − 0.30 |

| β11 | ||||||||

| A | − 1.46E − 02 | − 3.94E − 03 | − 4.07E − 05 | 1.16E − 03 | − 7.17E − 03 | 1.65E − 03 | − 1.63E − 03 | 1.09E − 03 |

| B | − 1.69E − 02 | − 5.85E − 03 | − 1.19E − 04 | − 8.96E − 04 | − 1.44E − 02 | 3.83E − 03 | − 3.20E − 03 | − 4.09E − 03 |

| C | − 1.63E − 02 | − 9.28E − 03 | − 1.11E − 04 | − 7.26E − 04 | − 2.06E − 02 | − 4.07E − 04 | − 5.37E − 04 | − 3.68E − 03 |

| D | − 1.61E − 02 | 7.82E − 03 | 9.26E − 05 | 6.85E − 04 | 2.82E − 02 | − 7.78E − 05 | 4.15E − 04 | 3.11E − 04 |

| β12 | ||||||||

| A | 2.29E − 02 | 2.25E − 02 | 5.50E − 04 | − 1.15E − 03 | 3.60E − 02 | − 9.08E − 03 | 3.73E − 03 | − 6.43E − 03 |

| B | 1.90E − 02 | − 8.12E − 03 | 3.50E − 04 | 9.33E − 04 | − 1.73E − 02 | − 1.31E − 02 | 1.93E − 03 | − 8.93E − 03 |

| C | 1.84E − 02 | − 5.50E − 04 | 2.17E − 04 | 1.68E − 03 | 2.12E − 02 | − 1.16E − 02 | − 1.35E − 03 | − 1.42E − 02 |

| D | 1.16E − 02 | − 1.16E − 02 | 2.67E − 04 | − 1.13E − 03 | 4.83E − 04 | − 2.06E − 02 | 4.28E − 03 | − 2.70E − 03 |

| β22 | ||||||||

| A | − 0.20 | 0.04 | 8.33E − 04 | − 2.83E − 03 | 0.29 | − 0.09 | 0.11 | − 0.01 |

| B | 0.04 | 0.11 | − 8.67E − 04 | 3.23E − 03 | 0.30 | − 3.40E − 03 | − 0.02 | 0.02 |

| C | − 0.08 | − 0.03 | − 7.00E − 04 | − 0.01 | − 0.19 | 0.08 | − 1.53E − 03 | 0.02 |

| D | − 0.20 | 0.08 | 1.93E − 03 | 0.01 | 0.27 | − 4.70E − 03 | 0.02 | 0.03 |

| R2 | ||||||||

| A | 0.94 | 0.89 | 0.43 | 0.91 | 0.82 | 0.69 | 0.98 | 0.16 |

| B | 0.96 | 0.94 | 0.74 | 0.33 | 0.92 | 0.85 | 0.91 | 0.95 |

| C | 0.92 | 0.96 | 0.77 | 0.38 | 0.95 | 0.95 | 0.74 | 0.87 |

| D | 0.95 | 0.92 | 0.83 | 0.39 | 0.92 | 0.88 | 0.67 | 0.30 |

| Lack of Fit | ||||||||

| A | 0.48 | 0.12 | 0.47 | 0.44 | 0.09 | 0.06 | 0.27 | 0.00 |

| B | 0.45 | 0.68 | 0.05 | 0.71 | 0.15 | 0.08 | 0.18 | 0.32 |

| C | 0.31 | 0.36 | 0.37 | 0.88 | 0.64 | 0.09 | 0.05 | 0.02 |

| D | 0.24 | 0.26 | 0.27 | 0.84 | 0.28 | 0.41 | 0.39 | 0.07 |

Y1 = Cooking yield (%); Y2 = Hardness (N); Y3 = Cohesiveness (–); Y4 = Springiness (mm); Y5 = Chewiness (N.mm); Y6 = Lightness (L*); Y7 = Redness (a*); Y8 = Yellowness (b*)

*Flours used in experiments were (A) Rice, (B) Corn, (C) Amaranth and (D) Quinoa

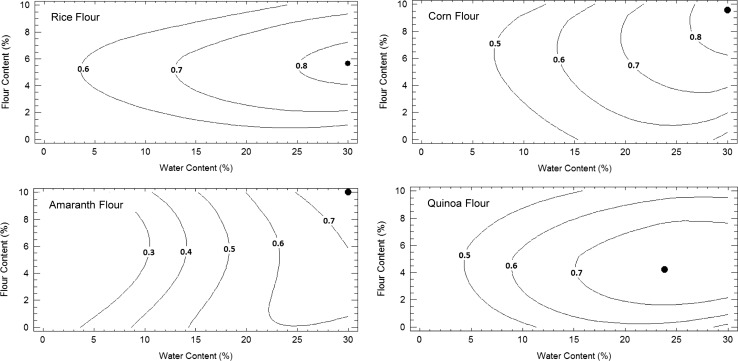

Formula optimization of pre-cooked fish patties

The optimization of fish patty formulations was done using multiple response optimization. Optimum values of independent variables were obtained after assigning certain constraints (maximize or minimize) on response variables (cooking yield, chewiness and lightness).

Once the optimum formulations were determined (Fig. 4), they were used to elaborate optimized fish patties and all the responses variables were analysed and compared with predicted values given by the mathematical models (Table 4). There were no differences between the experimental and predicted values (P > 0.05).

Fig. 4.

Contour plots for results of overall desirability function for pre-cooked fish patties added with different gluten-free flours; bullet operator indicates the point where the desirability function reaches its optimal value

Table 4.

Predicted and experimental responses for optimized gluten-free fish patties

| Optimum formulations | Response Variables | Predicted value | Experimental value |

|---|---|---|---|

| Water = 30 g/100 g | Cooking Yield (%) | 89.38 | 89.92 ± 0.61 |

| Rice Flour = 5.66 g/100 g | Chewiness (N.mm) | 19.65 | 19.18 ± 0.71 |

| D(x)* = 0.823 | Lightness (−) | 75.70 | 73.89 ± 0.30 |

| Water = 30 g/100 g | Cooking Yield (%) | 89.93 | 92.80 ± 0.63 |

| Corn Flour = 9.55 g/100 g | Chewiness (N.mm) | 14.60 | 12.80 ± 3.09 |

| D(x) = 0.849 | Lightness (−) | 73.01 | 75.51 ± 0.64 |

| Water = 30 g/100 g | Cooking Yield (%) | 88.78 | 90.11 ± 0.59 |

| Amaranth Flour = 10 g/100 g | Chewiness (N.mm) | 13.74 | 12.26 ± 0.57 |

| D(x) = 0.778 | Lightness (−) | 70.37 | 66.36 ± 0.25 |

| Water = 23.82 g/100 g | Cooking Yield (%) | 89.11 | 91.98 ± 1.00 |

| Quinoa Flour = 4.20 g/100 g | Chewiness (N.mm) | 3.74 | 3.37 ± 0.58 |

| D(x) = 0.769 | Lightness (−) | 68.70 | 67.63 ± 0.52 |

*D(x): desirability function

Experimental Values represent the mean ± standard deviation of two determinations

Characterization of optimized pre-cooked fish patties

Proximate composition

Proximate composition of patties added with different flours are given in Table 5. Flours addition affected proximate composition compared to control (P < 0.05). Total fat and carbohydrates content was increased with flours addition (P < 0.05), while (as expected) control patty had the higher protein and ash content (27.31 and 2.55% respectively). The increase of carbohydrates and decrease of protein content of optimized patties respect to control could be explained by the replacement of fish meat by flours and water. The increase of total fat content could be due to oil retention induced by added flours. Similar effects were reported in meatballs made with different types of flour (Ikhlas et al. 2011); and in low-fat chicken nuggets with the inclusion of oat flour (Santhi and Kalaikannan 2014).

Table 5.

Proximate composition, mineral content, and fatty acid profile of optimized cooked gluten-free fish patties

| Composition | Fish Patty (FP)* | FP added with Rice Flour | FP added with Corn Flour | FP added with Amaranth Flour | FP added with Quinoa Flour |

|---|---|---|---|---|---|

| Moisture** | 64.43 ± 0.28a | 67.95 ± 0.33d | 66.72 ± 0.05c | 64.80 ± 0.04a | 65.74 ± 0.25b |

| Fat | 10.45 ± 0.04a | 12.49 ± 0.08b | 20.28 ± 0.01e | 13.66 ± 0.26d | 13.08 ± 0.05c |

| Protein | 27.31 ± 0.52d | 12.67 ± 0.70a | 12.73 ± 0.31a | 15.05 ± 0.39b | 17.14 ± 0.18c |

| Carbohydrates | 0.44 ± 0.11a | 5.90 ± 0.09c | 7.36 ± 0.26e | 6.50 ± 0.06d | 4.92 ± 0.15b |

| Ash | 2.55 ± 0.00d | 1.45 ± 0.01a | 1.44 ± 0.00a | 1.82 ± 0.02c | 1.70 ± 0.02b |

| Na*** | 345.06 ± 5.71c | 228.11 ± 2.14a | 233.54 ± 2.72ab | 229.63 ± 2.26a | 237.06 ± 2.31b |

| K | 198.92 ± 0.62d | 138.89 ± 0.33c | 124.19 ± 0.57a | 197.28 ± 0.91d | 134.66 ± 0.96b |

| Ca | 12.89 ± 1.49c | 8.93 ± 1.79a | 6.98 ± 0.42a | 25.17 ± 0.66e | 18.88 ± 2.33d |

| Fe | 0.75 ± 0.03b | 0.11 ± 0.12a | 0.79 ± 0.01b | 4.39 ± 0.08d | 1.17 ± 0.08c |

| Miristic (C14:0)**** | 2.53 ± 0.01a | 2.63 ± 0.04a | 2.56 ± 0.02a | 2.55 ± 0.05a | 2.60 ± 0.08a |

| Palmitic (C16:0) | 23.50 ± 0.01a | 23.65 ± 0.06a | 23.43 ± 0.29a | 23.49 ± 0.23a | 23.40 ± 0.40a |

| Stearic (C18:0) | 7.45 ± 0.06b | 7.27 ± 0.03ab | 7.12 ± 0.12a | 7.10 ± 0.10a | 7.14 ± 0.13a |

| ∑SFA | 37.04 ± 0.01a | 37.23 ± 0.09a | 36.69 ± 0.46a | 36.80 ± 0.47a | 36.63 ± 0.23a |

| Palmitoleic (C16:1) | 13.05 ± 0.01a | 13.86 ± 0.06c | 13.39 ± 0.12ab | 13.35 ± 0.22ab | 13.62 ± 0.24bc |

| Vaccenic (18:1n7) | 7.45 ± 0.06a | 7.27 ± 0.03a | 7.12 ± 0.12a | 7.10 ± 0.10a | 7.14 ± 0.13a |

| Oleic (C18:1n9) | 19.43 ± 0.03a | 20.42 ± 0.10b | 20.19 ± 0.36b | 20.02 ± 0.05b | 20.05 ± 0.18b |

| Eicosenoic (C20:1n9c) | 2.16 ± 0.01b | 0a | 2.17 ± 0.02b | 2.17 ± 0.02b | 2.24 ± 0.04c |

| ∑MUFA | 35.01 ± 0.08a | 35.35 ± 0.01ab | 36.30 ± 0.21c | 36.60 ± 0.14c | 35.96 ± 0.99b |

| Linoleic (C18:2n6) | 2.98 ± 0.01a | 3.36 ± 0.02c | 4.12 ± 0.07e | 3.78 ± 0.01d | 3.23 ± 0.01b |

| Linolenic (C18:3n3) | 4.24 ± 0.02a | 4.74 ± 0.02d | 4.59 ± 0.02bc | 4.52 ± 0.06b | 4.63 ± 0.04c |

| Arachidonic (C20:4) | 2.92 ± 0.01d | 2.71 ± 0.01c | 2.59 ± 0.05ab | 2.57 ± 0.04a | 2.70 ± 0.01bc |

| EPA (C20:5n3) | 4.12 ± 0.01b | 4.12 ± 0.05b | 3.87 ± 0.06a | 3.86 ± 0.11a | 4.00 ± 0.01ab |

| DPA (C22:5n3) | 5.34 ± 0.02c | 5.25 ± 0.01bc | 5.00 ± 0.05a | 4.86 ± 0.18a | 5.05 ± 0.02ab |

| DHA (C22:6n3) | 4.13 ± 0.02b | 3.55 ± 0.21a | 3.55 ± 0.07a | 3.46 ± 0.15a | 3.59 ± 0.04a |

| ∑PUFA | 25.86 ± 0.09a | 25.87 ± 0.17a | 25.79 ± 0.25a | 25.18 ± 0.59a | 25.25 ± 0.19a |

*Fish patty without added water or flour was assumed as control

**Patty composition (Moisture, Fat, Protein, Carbohydrates, and Ash) is expressed in g/100 g of sample

***Mineral content is expressed in mg/100 g of sample

****Fatty acid content is expressed in g/100 g of fat

abcDifferent letter in the same row indicate significant differences at P < 0.05

ΣSFA, ΣMUFA and ΣPUFA are total saturated, monounsaturated and polyunsaturated fatty acids, respectively

Values represent the mean ± standard deviation of two determinations

Mineral content

Mineral content of patties added with different flours is presented in Table 5. Sodium content in all samples was lower (P < 0.05) than control. Among formulations, potassium value of patty made with amaranth flour was comparable to control (P > 0.05). This patty formulation had the highest calcium and iron contents; besides, calcium and iron contents in patty made with quinoa flour were higher than control and patties made with rice or corn flours (P < 0.05). In the present study, the higher value of minerals and high variability could be due to the mineral content of the flours used. Similar results were informed by Mishra et al. (2015) in chicken meat rings using spent hen meat and different extenders.

Lipid profile

As expected, fatty acid composition was affected by different flours (P < 0.05); main fatty acids are reported in Table 5. Addition of different flour increased oleic, linoleic and linolenic fatty acids and decreased eicosapentaenoic, docosapentaenoic and docosahexaenoic fatty acids respect to control. Fatty acid composition present in each product was consistent with the different lipid material sources. Rodríguez-Carpena et al. (2012) and Pintado et al. (2016) also informed changes in fatty acid composition of products according to the ingredients used in the formulation.

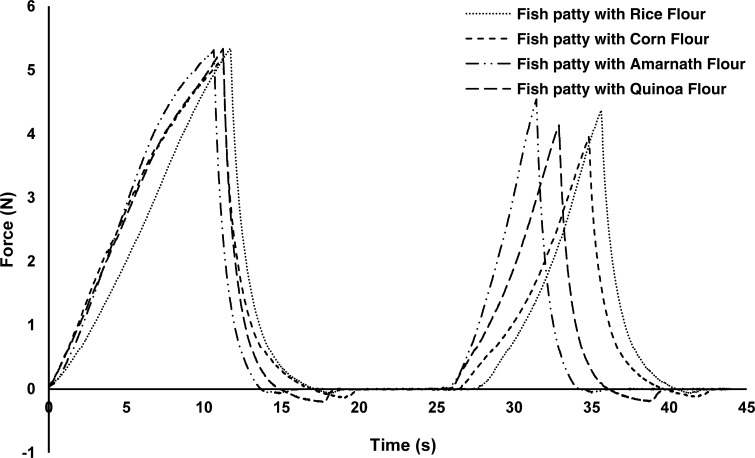

Texture profile analysis

TPA of optimized patties elaborated with gluten-free flours is shown in Fig. 5. Gluten-free flours affected texture parameters of patties (P < 0.05). Hardness ranged between 5.25 ± 0.15 and 6.62 ± 0.32 N, being the lowest value found the fish patties made with amaranth or quinoa flour and the highest value found in patties made with corn flour; cohesiveness ranged between 0.19 ± 0.07 and 0.43 ± 0.10 having the lowest value the patties elaborated with quinoa flour and the highest value found in samples with rice flour; elasticity ranged between 3.42 ± 0.61 mm and 6.80 ± 0.25 mm, having the lowest value the patties elaborated with quinoa flour and the highest value found in samples with rice flour. Results found in this research are consistent with others reports (Ergezer et al. 2014; Pereira et al. 2016), where it was also observed that meat and nonmeat additives interactions may affect the gelling properties and protein binding in emulsified meat products through modifying the product texture.

Fig. 5.

Texture profile analysis of cooked fish patties added with different gluten-free flours

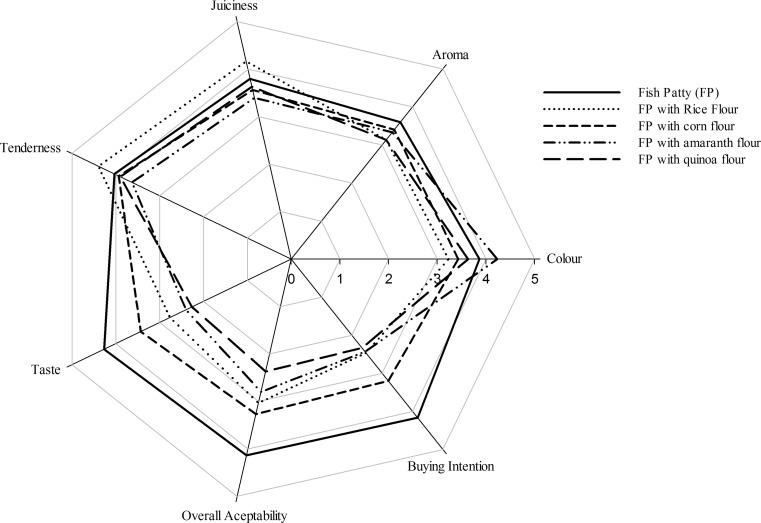

Sensory properties

Results of sensory evaluation of gluten-free patties are shown in Fig. 6. Colour was affected by the incorporation of flour, having patties made with rice flour the lowest score (P < 0.05) and patties made with amaranth flour the higher score (P < 0.05), probably because of the original brown colour of amaranth flour. These results are consistent with the obtained for the instrumental colour values (Table 2), in which samples added with amaranth flour presents the higher score for a* and b* colour components. Colour evaluation indicate that consumers choose samples with a higher brown colour, related with the Maillard process carried out in cooked products, reaction often used in industry for giving foods different taste, color, and aroma (Tamanna and Mahmood 2015). These are in agreement with that informed by Hwang et al. (2013) in deep fried chicken nuggets added with ganghwayaksussuk and Netto et al. (2014) in snack made with minced Nile tilapia and starch, indicating that additives characteristics and percentage added to the product influence on color, among others characteristics. No differences were found in the aroma of products (P > 0.05). Addition of rice flour increased juiciness and tenderness (P < 0.05), which could be attributed to the increased moisture and fat retention observed in cooked patties; however amaranth flour decreased both parameters (P < 0.05). Yi et al. (2012) and Gao et al. (2014) report the same effect for juiciness and tenderness in ground pork patties added with glutinous rice flour and seasoned beef patties with added glutinous rice flour respectively. As expected, taste, overall acceptability and buying intention were highest in control samples (P < 0.05), since fish was perfectly detected. The taste of patties added with flours was decisive for buying intention. Regarding samples added with different flours, the highest buying intention was for those made with corn flour (P < 0.05); but there were no significant differences among other formulations (P > 0.05), which indicates that the panelists did not dislike these products.

Fig. 6.

Sensory evaluation, overall acceptability and buy intention of cooked fish patties added with different gluten-free flours

Conclusion

Gluten-free fish patties were elaborated and tested to assess the influence of different gluten-free flours and water levels on physicochemical and technological characteristics. Regarding to patties with no added flours, cooking yield and proximate composition (especially fat content) of developed patties were improved by the addition of all gluten-free flours. Generally, sodium and potassium content decreased with the addition of gluten-free flours, while calcium and iron content increased in patties with amaranth or quinoa flour. Addition of gluten-free flours also modified lipid profile of patties, increasing oleic, linoleic, and linolenic and decreasing EPA, DPA and DHA fatty acids content. In relation to consumer acceptance, results indicate that, although panelists liked all gluten-free flours added patties, they preferred patties added with corn flour. Although further studies about the microbiological, lipid oxidation and sensory evaluation throughout storage of these patties should be carried out, results of this investigation could be useful for further products development and scaling up at an industrial level.

Acknowledgements

This research was supported by the Universidad Nacional del Chaco Austral (UNCAus, Argentine) through Grant No. 42/2014. Additional support was given by Consejo Nacional de Investigaciones Científicas y Tecnológicas (CONICET, Argentine).

Footnotes

Mara C. Romero and Ricardo A. Fogar have contributed equally to this research and should be considered co-first authors.

References

- AOAC . Official methods of analysis of AOAC International. 16. Gaithersburg, MD: AOAC International; 1998. [Google Scholar]

- Bligh EG, Dyer WJ. A rapid method of total lipid extraction and purification. Can J Biochem Physiol. 1959;37:911–917. doi: 10.1139/y59-099. [DOI] [PubMed] [Google Scholar]

- Carpenter C, Ward R. Iron determination in meat using ferrozine assay. In: Nielsen SS, editor. Food analysis laboratory manual. Boston, MA: Springer; 2010. pp. 69–73. [Google Scholar]

- Clegg KM. The application of the anthrone reagent to the estimation of starch in cereals. J Sci Food Agric. 1956;7:40–44. doi: 10.1002/jsfa.2740070108. [DOI] [Google Scholar]

- Ergezer H, Akcan T, Lu MS. The effects of potato puree and bread crumbs on some quality characteristics of low fat meatballs. Korean J Food Sci Anim Resour. 2014;34:561–569. doi: 10.5851/kosfa.2014.34.5.561. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gao X, Zhang W, Zhou G. Effects of glutinous rice flour on the physiochemical and sensory qualities of ground pork patties. LWT Food Sci Technol. 2014;58:135–141. doi: 10.1016/j.lwt.2014.02.044. [DOI] [Google Scholar]

- Hernandez Barros Fuchs R, Pereira Ribeiro R, Matsushita M, et al. Enhancement of the nutritional status of Nile tilapia (Oreochromis niloticus) croquettes by adding flaxseed flour. LWT Food Sci Technol. 2013;54:440–446. doi: 10.1016/j.lwt.2013.07.004. [DOI] [Google Scholar]

- Hwang KE, Choi YS, Choi SM, et al. Antioxidant action of ganghwayakssuk (Artemisia princeps Pamp.) in combination with ascorbic acid to increase the shelf life in raw and deep fried chicken nuggets. Meat Sci. 2013;95:593–602. doi: 10.1016/j.meatsci.2013.05.035. [DOI] [PubMed] [Google Scholar]

- Ikhlas B, Huda N, Noryati I. Chemical composition and physicochemical properties of meatballs prepared from mechanically deboned quail meat using various types of flour. Int J Poult Sci. 2011;10:30–37. doi: 10.3923/ijps.2011.30.37. [DOI] [Google Scholar]

- Lee EJ, Ahn DU. Quality characteristics of irradiated turkey breast rolls formulated with plum extract. Meat Sci. 2005;71:300–305. doi: 10.1016/j.meatsci.2005.03.017. [DOI] [PubMed] [Google Scholar]

- Lobo CMDO, Torrezan R, de Furtado ÂAL, et al. Development and nutritional and sensory evaluation of cachapinta (Pseudoplatystoma sp.) pâté. Food Sci Nutr. 2015;3:10–16. doi: 10.1002/fsn3.183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Makri M, Douvi X. Quality Evaluation of gilthead sea bream (Sparus aurata) patties formulated with corn flour. Br J Appl Sci Technol. 2014;4:2684–2698. doi: 10.9734/BJAST/2014/10612. [DOI] [Google Scholar]

- Mishra BP, Chauhan G, Mendiratta SK, et al. Development and quality evaluation of dehydrated chicken meat rings using spent hen meat and different extenders. J Food Sci Technol. 2015;52:2121–2129. doi: 10.1007/s13197-013-1197-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mudgil D, Barak S, Khatkar BS. Optimization of textural properties of noodles with soluble fiber, dough mixing time and different water levels. J Cereal Sci. 2016;69:104–110. doi: 10.1016/j.jcs.2016.02.015. [DOI] [Google Scholar]

- Muthia D, Nurul H, Noryati I. The effects of tapioca, wheat, sago and potato flours on the physicochemical and sensory properties of duck sausage. Int Food Res J. 2010;17:877–884. [Google Scholar]

- Netto JDPC, de Oliveira Filho PRC, Lapa-Guimarães J J, Viegas EMM. Physicochemical and sensory characteristics of snack made with minced Nile tilapia. Food Sci Technol. 2014;34:591–596. doi: 10.1590/1678-457x.6395. [DOI] [Google Scholar]

- Pereira J, Zhou G, Zhang W. Effects of rice flour on emulsion stability, organoleptic characteristics and thermal rheology of emulsified sausage. J Food Nutr Res. 2016;4:216–222. [Google Scholar]

- Pintado T, Herrero AM, Jiménez-Colmenero F, Ruiz-Capillas C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016;114:75–84. doi: 10.1016/j.meatsci.2015.12.009. [DOI] [PubMed] [Google Scholar]

- Ramos Diaz JM, Suuronen JP, Deegan KC, et al. Physical and sensory characteristics of corn-based extruded snacks containing amaranth, quinoa and kañiwa flour. LWT - Food Sci Technol. 2015;64:1047–1056. doi: 10.1016/j.lwt.2015.07.011. [DOI] [Google Scholar]

- Ranathunga RAA, Jayawardena BC, Gunasekara GTN. Effect of different extenders on physical, chemical and sensory characteristics of sausage production. Int J Inf Res Rev. 2015;2:1311–1314. [Google Scholar]

- Riernersman CN, Romero AM, Doval MM, Judis MA. Whole Chia flour as yield enhancer, potential antioxidant and input of n-3 fatty acid in a meat product. Food Nutr Sci. 2016;7:855–865. doi: 10.4236/fns.2016.710085. [DOI] [Google Scholar]

- Rodríguez-Carpena JG, Morcuende D, Estévez M. Avocado, sunflower and olive oils as replacers of pork back-fat in burger patties: effect on lipid composition, oxidative stability and quality traits. Meat Sci. 2012;90:106–115. doi: 10.1016/j.meatsci.2011.06.007. [DOI] [PubMed] [Google Scholar]

- Santhi D, Kalaikannan A. The effect of the addition of oat flour in low-fat chicken nuggets. J Nutr Food Sci. 2014;4:1–4. [Google Scholar]

- Shariati-Ievari S, Ryland D, Edel A, et al. Sensory and physicochemical studies of thermally micronized chickpea (Cicer arietinum) and green lentil (Lens culinaris) flours as binders in low-fat beef burgers. J Food Sci. 2016;81:S1230–S1242. doi: 10.1111/1750-3841.13273. [DOI] [PubMed] [Google Scholar]

- Tahmasebi M, Labbafi M, Emam-Djomeh Z, Yarmand MS. Manufacturing the novel sausages with reduced quantity of meat and fat: the product development, formulation optimization, emulsion stability and textural characterization. LWT Food Sci Technol. 2016;68:76–84. doi: 10.1016/j.lwt.2015.12.011. [DOI] [Google Scholar]

- Tamanna N, Mahmood N. Food processing and Maillard reaction products: effect on human health and nutrition. Int J Food Sci. 2015;2015:1–6. doi: 10.1155/2015/526762. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Verma AK, Banerjee R, Sharma BD. Quality of low fat chicken nuggets: effect of sodium chloride replacement and added chickpea (Cicer arietinum L.) hull flour. Asian-Australas J Anim Sci. 2012;25:291–298. doi: 10.5713/ajas.2011.11263. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Verma AK, Chatli MK, Kumar D, et al. Efficacy of sweet potato powder and added water as fat replacer on the quality attributes of low-fat pork patties. Asian-Australas J Anim Sci. 2015;28:252–259. doi: 10.5713/ajas.14.0291. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yi HC, Cho H, Hong JJ, et al. Physicochemical and organoleptic characteristics of seasoned beef patties with added glutinous rice flour. Meat Sci. 2012;92:464–468. doi: 10.1016/j.meatsci.2012.05.012. [DOI] [PubMed] [Google Scholar]