Abstract

Processing and its impacts on proximate composition and fatty acid profile of six sea cucumber species; Bohadschia marmorata, Stichopus chloronotus, Holothuria spinifera, Thelenota anax, Holothuria scabra and Bohadschia sp. 1 collected from the northwest coast of Sri Lanka were analyzed. Sea cucumbers are processed into bêche-de-mer by both domestic and industrial level processors following the similar steps of cleaning, evisceration, first boiling, salting, second boiling and drying. However, domestically processed bêche-de-mer always reported a higher percentage of moisture, crude ash, crude fat and lower percentage of crude protein than industrially processed products. Although processing resulted in a significant reduction of total SFA and MUFA in fresh individuals of most of these species, total PUFA increased significantly in processed individuals excluding Bohadschia species. Palmitic acid was found to be the most dominant fatty acid in all these species followed by eicosapentaenoic acid, which showed a significant increase in processed products, except Bohadschia sp. 1. Total MUFA were higher than total SFA in all sea cucumber species having exceptions in Bohadchia sp.1 and fresh S. chloronotus. These findings will make a significant contribution to fill the gaps in existing information as no any previous information is available for species like H. spinifera and S. chloronotus.

Keywords: Bêche-de-mer, Proximate composition, Fatty acid profile, Processing, Sea cucumbers

Introduction

Sea cucumbers belonging to class Holothuroidea of the phylum Echinodermata are soft-bodied animals comprising a diverse group of flexible, elongated, worm-like organisms. The catching of sea cucumbers is one of the oldest activities of commercial fisheries in Asian and Pacific countries (Conand and Byrne 1993). Currently, more than 70 countries engage in sea cucumber fisheries worldwide targeting 66 sea cucumber species reporting an average annual catch of 100,000 tonnes of live animals (Purcell et al. 2016).

Sea cucumbers are traditionally consumed as raw and dried products and the body wall consists of collagen and mucopolysaccharides is considered as the major edible part. Since sea cucumbers autolyze rapidly after taking out of water, more than 80% of world harvests are usually processed into a dried product known as bêche-de-mer (Duan et al. 2007) which is produced mainly a process of cleaning, boiling, salting and drying. However, slight differences in the major processing steps were evident depending on the species and geographical regions (Conand 1990). An extract of boiled skin, fermented viscera, dry form of ovaries and salted, fermented respiratory trees of sea cucumbers are also considered as delicacies (Conand 1990).

From the nutritional point of view, bêche-de-mer is considered as an ideal tonic food with higher protein and lower fat contents than most other seafood (Conand 1990). However, very few studies have been carried out to analyze the nutritional composition of sea cucumbers. Proximate composition and fatty acid profile of Holothuria tubulosa, H. polii, H. mammata, H. edulis, H. scabra, Apostichopus japonicus, Cucumaria frondosa and Stichopus japonicus have been studied and significant variations with respect to species and their geographical locations were reported (Aydin et al. 2011; Fredalina et al. 1999; Li et al. 2009).

The sea cucumber fishery was introduced to Sri Lanka by the Chinese and bêche-de-mer reported to be one of the major commodities taken to China for centuries. Although around 21 sea cucumber species are commercially exploited in the coastal waters of Sri Lanka (Dissanayake and Stefansson 2012), there is no tradition of consuming sea cucumbers locally and the entire harvest is exported to Singapore, Taiwan and China as bêche-de-mer. Many studies related to sea cucumber fisheries and their culture possibilities have been carried out in Sri Lanka (Dissanayake and Stefansson 2010; Kumara and Dissanayake 2017), but no detailed studies to evaluate any aspects of post-harvest processing or their impacts on the nutritional composition of sea cucumbers. As it was evident that the nutritional composition of sea cucumbers varies with species, geographic location (Neto et al. 2006) and the way of processing (Wen et al. 2010), we aimed to study the processing method/s and the effects of processing on proximate composition and fatty acid profile of 6 commercial sea cucumber species; Bohadschia marmorata, Stichopus chloronotus, Holothuria spinifera, Thelenota anax, Holothuria scabra and Bohadschia sp. 1 (listed in Dissanayake and Stefansson 2010) in the coastal waters of Sri Lanka.

Materials and methods

Processing of sea cucumbers

Major steps involved in the processing of 6 sea cucumber species into bêche-de-mer were studied through direct observations of processing activities carried out by both industrial and domestic level processors in the north-west coast of Sri Lanka from October 2015 to March 2017. Randomly selected thirty two processors (equally representing from both domestic and industrial level) were also interviewed using open-ended and closed-ended questionnaires, semi-structured interviews and group discussions to collect detailed information on major steps involved in sea cucumber processing, average time taken for each processing step and modifications with respect to different species. Their responses were recorded using an audio recorder and confirmed by direct observations.

Proximate composition and fatty acid profile

Sample collection

Fifteen fresh specimens of each sea cucumber species were collected from the commercial divers of the north-west coast of Sri Lanka. Internal organs of the collected individuals were removed by placing a small cut on their ventral body surface and individual weight before and after the evisceration was recorded (Table 1). Each individual was labelled separately, packed in ice and transported to the laboratory of the Department of Zoology, University of Sri Jayewardenepura, Nugegoda, Sri Lanka. Dried specimens of each species were collected from both domestic (n = 15) and industrial (n = 15) level processors, packed in polythene bags and transported to the laboratory. At the laboratory weight of each specimen was measured (Table 1).

Table 1.

Weight range and average weight (± SD) of fresh and processed (both commercial and domestic level) six sea cucumber species collected from the northwest coast of Sri Lanka before and after the evisceration

| Species | Fresh samples | Processed samples | |||||

|---|---|---|---|---|---|---|---|

| Weight range (g) | Average weight (g) | Commercial processors | Domestic processors | ||||

| Before evisceration | After evisceration | Weight range (g) | Average weight (g) | Weight range (g) | Average weight (g) | ||

| H. scabra | 100.11–560.56 | 258.96 ± 167.91 | 141.91 ± 79.05 | 43.56–59.80 | 52.36 ± 7.13 | 14.00–19.66 | 16.63 ± 2.45 |

| H. spinifera | 109.46–220.37 | 171.06 ± 50.03 | 121.63 ± 44.94 | 14.49–21.86 | 16.6 ± 2.99 | 15.45–49.40 | 33.15 ± 13.59 |

| T. anax | 302.23–613.28 | 452.13 ± 129.19 | 369.14 ± 98.05 | 22.19–53.07 | 31.47 ± 11.30 | 48.69–74.38 | 59.58 ± 10.75 |

| B. marmorata | 423.62–1021.27 | 761.58 ± 306.41 | 445.54 ± 140.91 | 34.42–43.84 | 38.72 ± 4.76 | 40.33–60.12 | 51.45 ± 9.33 |

| Bohadschia sp.1 | 335.00–432.39 | 372.98 ± 52.11 | 175.74 ± 5.66 | 27.11–57.89 | 41.0 ± 11.77 | 42.20–65.75 | 52.57 ± 10.11 |

| S. chloronotus | 208.45–328.94 | 251.08 ± 67.53 | 176.48 ± 42.16 | 6.10–33.58 | 19.13 ± 12.28 | 10.49–17.63 | 14.05 ± 3.57 |

Average weights are given in mean weight in grams ± standard deviation in grams

Analysis of proximate composition

Fresh and dried specimens were cleaned and remaining sand particles and visceral organs were carefully removed. Each individual was cut into small pieces and grounded using a grinder to obtain a homogenous sample. The moisture content was determined by drying the samples in a thermostat oven at 100 ± 5 °C until a constant weight was obtained (AOAC 1990). Crude ash content was determined by incinerating the samples in a muffle furnace at 550 °C for 24 h (AOAC 1990). The micro-Kjeldahl method with acid digestion was used to determine the crude protein content and conversion factor 6.25 was used to convert total nitrogen to crude protein (Haider et al. 2015). Bligh and Dyer’s method was used to determine the crude fat content (Bligh and Dyer 1959; Haider et al. 2015). All these analyses were conducted in triplicate.

Analysis of fatty acid profile

Fatty acid composition of fresh and industrially processed specimens of each sea cucumber species was analysed separately. FAME was prepared following the method described by Aydin et al. (2011). Methyl esters were prepared by transmethylation using 2 M potassium hydroxide (KOH) in methanol and n-hexane and 10 mg of extracted oil was dissolved in 2 mL hexane followed by 4 mL of 2 M methanolic KOH. Resulted tubes were vortexed for 2 min at room temperature and centrifuged at 4000 rpm for 10 min. After the centrifugation, hexane layer was separated for GC analysis. Collected samples were kept frozen and analyzed for FAs within a week of arrival.

The fatty acids were determined using a gas chromatography/mass spectrometry (GC/MS) with Agilent Technologies Gas Chromatograph coupled to a Mass Spectrometer (Model Agilent, 7890a and Agilent, 5975c; CinertXLEI/CIMSD with Triple-Axis Detector; 30 m x 250 µm x 0.25 µm fused silica capillary column) and equipped with a split injector (ratio 25:1) available at the Central Instrumentation Facility, University of Sri Jayewardenepura. Helium gas was used as the carrier gas and the temperature of the injector port and the detector was held at 280 and 250 °C, respectively. 2 µL of the sample was injected using an auto-sampler. The initial column temperature was set at 160 °C and kept for 10 min. Then, the temperature was brought up to 190 °C at the rate of 3 °C/min during ramp 1 and kept for 5 min. During ramp 2, the temperature was gradually increased to 232 °C at a rate of 7 °C/min and the temperature was maintained at 232 °C for a period of 14 min. Fatty acids in the sample were identified by comparing the retention times of FAME with Supelco 37 component FAME mixture (Cat. No. CRM47885; Supelco). Each analysis was performed in triplicates and the results were expressed in relative GC area % as the mean ± standard deviation of detected FAMEs.

Statistical analysis

All the proximate components, except moisture were determined on dry weight basis. The means of the proximate composition and fatty acid data were compared using Analysis of Variance (ANOVA) followed by Tukey’s multiple comparison test. Differences were considered to be significant when p < 0.05. All the statistical tests were performed in Minitab 17 for Windows statistical package.

Results

Processing of sea cucumbers

In Sri Lanka, fresh sea cucumbers are processed into bêche-de-mer by both domestic and industrial level processors. Processing mainly involves cleaning, evisceration, first boiling (cooking), salting, second boiling (cooking) and drying. However, deviations in major processing steps such as removal of chalky materials were evident in some species like H. scabra and H. spinifera. As an average, the whole processing process takes ~ 5–10 days.

As soon as sea cucumbers are landed, they are graded into three categories; small, medium and large based on their body size and cleaned using saline water. Evisceration is mainly done by making a small cut (2.5–4.0 cm) at the posterior end of their body, however, in S. chloronotus internal organs are removed by placing a small cut (2.0–2.5 cm) at their ventral body surface. Eviscerated individuals are boiled either using saline (87%) or fresh water (13%) and boiling time varies with species. The highest boiling time was reported for H. scabra and H. spinifera (24 ± 13 min) followed by T. anax (16 ± 6 min). Average boiling time of Bohadschia species ranged from 10 to 15 min and it was ~ 13 min for S. chloronotus. Local processors use several traditional methods to remove chalky materials deposited on the outer body wall of H. scabra and H. spinifera. A widely practised method is brushing or scrubbing the outer body wall after the first boiling or after burying boiled products in the sand for ~ 12–18 h. Some processors mix boiled sea cucumbers with Papaya (Carica papaya) leaves before brushing. All sea cucumbers are salted after first boiling and average salting time varies from 1 to 2 days. Both iodized (86.67%) and non-iodized (13.33%) salts are used for salting and normally 100 individuals are dipped in 5 kg of salts. Salted products are boiled once again around 5 ± 3 min. Sun drying is the widely practised method to dry boiled products and drying time ranges from 3 to 5 days depending on species, size of the individuals and local weather condition. Dried products are packed in gunny bags, polythene bags or cardboard boxes.

It was evident that 5–8% post-harvest losses occur at the end of this processing process. Malpractices such as improper evisceration, intentional adding of sand, over-salting, mixing of low-value species with high-value species and poor hygiene practices were identified as some limitations of the existing processing process.

Proximate composition of fresh and processed sea cucumbers

Proximate compositions of fresh, domestically processed and industrially processed six sea cucumber species are shown in Table 2. The moisture content of fresh sea cucumbers ranged from 80.48 to 92.55% and the highest moisture content was evident in T. anax. There are differences in the percentage moisture content of domestically (21.25–55.61%) and industrially (16.64–32.95%) processed sea cucumbers. Domestically processed individuals, excluding H. spinifera and Bohadschia sp. 1, showed significantly higher moisture content than industrially processed individuals (p < 0.05; ANOVA).

Table 2.

Proximate composition (%) of fresh and processed (both domestic and industrial level) six sea cucumber species collected from the northwest coast of Sri Lanka

| Parameters | Species | |||||

|---|---|---|---|---|---|---|

| H. scabra | H. spinifera | T. anax | B. marmorata | Bohadschia sp. 1 | S. chloronotus | |

| Moisture | ||||||

| Fresh | 81.66 ± 0.67a1 | 80.48 ± 0.44b1 | 92.55 ± 0.31c1 | 84.65 ± 0.41d1 | 86.48 ± 0.92e1 | 92.42 ± 0.48c1 |

| Processed | ||||||

| Domestic | 55.61 ± 7.28a2 | 28.9 ± 9.31b2 | 36.8 ± 1.81ab2 | 30.98 ± 12.3b2 | 21.25 ± 5.04b2 | 26.02 ± 4.78b2 |

| Industrial | 32.95 ± 1.05a3 | 24.52 ± 0.51bc2 | 26.01 ± 2.48b3 | 16.64 ± 3.04d3 | 17.94 ± 3.07d2 | 19.19 ± 0.32 cd3 |

| Ash | ||||||

| Fresh | 34.5 ± 0.87a1 | 48.14 ± 1.43b1 | 35.1 ± 0.89a1 | 18.48 ± 1.88c1 | 17.9 ± 1.76c1 | 27.7 ± 0.24d1 |

| Processed | ||||||

| Domestic | 42.03 ± 2.73a2 | 45.07 ± 0.42a2 | 45.24 ± 2.27a2 | 40.81 ± 4.38a2 | 27.38 ± 5.03b2 | 26.04 ± 0.05b2 |

| Industrial | 43.77 ± 3.54a2 | 31.83 ± 0.13b3 | 31.53 ± 0.34b3 | 33.19 ± 1.52b3 | 34.44 ± 0.48b2 | 16.54 ± 0.28c3 |

| Fat | ||||||

| Fresh | 1.05 ± 0.05a1 | 1.03 ± 0.03a1 | 2.61 ± 0.22b1 | 0.97 ± 0.03a1 | 1.5 ± 0.11c1 | 3.94 ± 0.18d1 |

| Processed | ||||||

| Domestic | 2.07 ± 0.09a2 | 1.04 ± 1.14b1 | 1.13 ± 0.05b2 | 1.12 ± 0.18b1 | 0.89 ± 0.07b2 | 3.38 ± 0.57c1 |

| Industrial | 1.96 ± 0.01ab2 | 1.34 ± 0.21bc1 | 1.17 ± 0.04c2 | 1.25 ± 0.10bc1 | 1.18 ± 0.02c3 | 2.12 ± 0.59a2 |

| Protein | ||||||

| Fresh | 44.63 ± 0.34a1 | 47.16 ± 0.29a1 | 51.63 ± 2.08bc1 | 53.24 ± 2.49b1 | 47.49 ± 0.96ac1 | 57.93 ± 1.47d1 |

| Processed | ||||||

| Domestic | 42.7 ± 21.09a1 | 48.5 ± 0.67b2 | 43.25 ± 2.48a2 | 44.35 ± 3.50ab2 | 46.29 ± 1.40ab1 | 46.62 ± 1.57ab2 |

| Industrial | 49.84 ± 0.78a2 | 58.11 ± 0.46b3 | 56.62 ± 0.23b3 | 48.95 ± 0.86ac12 | 48.21 ± 0.58ac1 | 46.28 ± 2.38c2 |

Note: Values in the same row bearing different letters are significantly different (p < 0.05) and for each component values in same column bearing, different digits are significantly different (p < 0.05), results are expressed in % (m) dry base, for each species 15 samples each with 3 replicates were analysed

The crude ash content of fresh sea cucumbers ranged from 17.90 to 48.14% reporting the highest content in H. spinifera (48.14%). The highest ash content in domestically and industrially processed forms corresponds to T. anax (45.24%) and H. scabra (43.77%), respectively. Significant variations in percentage crude ash among species as well as between fresh and processed forms of each species were evident (p < 0.05; ANOVA). Domestically processed H. scabra, T. anax and Bohadschia species reported significantly higher crude ash content than fresh individuals (p < 0.05, ANOVA). Industrially processed individuals showed significantly lower ash contents than domestically processed individuals, excluding H. scabra and Bohadschia sp.1 whose ash content was not significantly different (p < 0.05, ANOVA).

When compared with other proximate constituents, the percentage crude fat found to be very low in all these sea cucumber species and it ranged from 0.97 to 3.94% in fresh individuals. Crude fat content of the industrially processed individuals was in the range of 0.89–3.38% and it was from 1.17 to 2.12% in domestically processed individuals. S. chloronotus contained the highest fat content, both in fresh and processed forms. There are differences in crude fat content among sea cucumber species and the fresh and processed forms of each species (p < 0.05; ANOVA). Domestically processed T. anax and Bohadschia sp. 1 have a significantly lower fat content than fresh individuals, however industrially processed Bohadschia sp. 1 reported a significantly higher fat content than domestically processed individuals (p < 0.05, ANOVA).

The range of the crude protein content was 47.16–57.93% in fresh, 42.7–48.5% in domestically processed and 46.28–58.11% in industrially processed forms, respectively. Processing has a significant impact on the percentage crude protein content of sea cucumbers. This study revealed a significant increase of relative crude protein content in processed H. scabra, H. spinifera and T. anax than fresh individuals and a significant reduction in B. marmorata and S. chloronotus (p < 0.05; ANOVA). Significantly higher crude protein content was evident in industrially processed individuals than domestically processed ones (p < 0.05; ANOVA).

Fatty acid composition of fresh and processed sea cucumbers

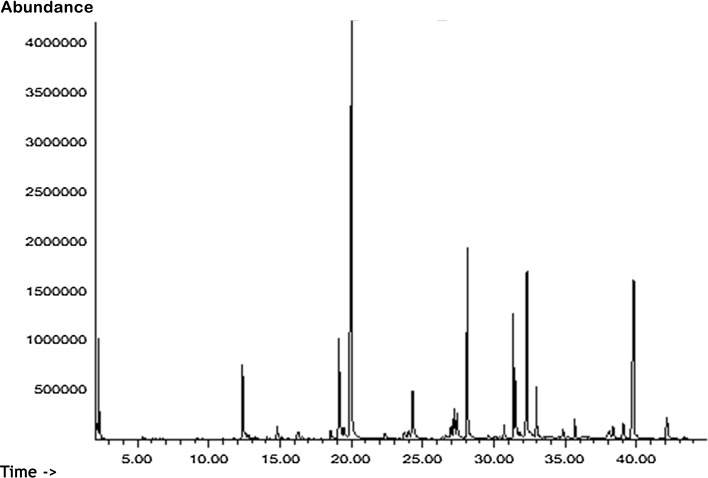

The fatty acid profile of fresh and industrially processed six sea cucumber species was analysed and are summarised in Table 3. A chromatogram corresponds to fresh S. chloronotus is given in Fig. 1. This study revealed the presence of 28 fatty acids in sea cucumbers, among those, 14 are saturated fatty acids (SFA), 6 are monounsaturated fatty acids (MUFA) and 8 are polyunsaturated fatty acids (PUFA).

Table 3.

Fatty acid profile of fresh and processed (both domestic and industrial level) six sea cucumber species collected from the northwest coast of Sri Lanka

| FA type | H. scabra | H. spinifera | T. anax | B. marmorata | Bohadschia sp. 1 | S. chloronotus | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fresh | Processed | Fresh | Processed | Fresh | Processed | Fresh | Processed | Fresh | Processed | Fresh | Processed | |

| C8:0 | 0.53 ± 0.01a | 0.41 ± 0.01b | 0.1 ± 0.00a | 0.23 ± 0.01b | 0.45 ± 0.11a | 0.56 ± 0.03a | 2.07 ± 0.05a | 0.97 ± 0.08b | 1.58 ± 0.22a | 1.51 ± 0.10a | 0.65 ± 0.09a | 0.37 ± 0.04b |

| C10:0 | 0.63 ± 0.01a | 0.49 ± 0.01b | 0.12 ± 0.00a | 0.27 ± 0.01b | 0.54 ± 0.19a | 0.67 ± 0.03a | 2.47 ± 0.06a | 1.14 ± 0.09b | 1.89 ± 0.26a | 1.79 ± 0.12a | 0.77 ± 0.10a | 0.44 ± 0.05b |

| C11:0 | 0.0 ± 0.00a | 0.4 ± 0.01b | 0.09 ± 0.00a | 0.22 ± 0.01b | 0.38 ± 0.15a | 0.55 ± 0.02a | 0.0 ± 0.00a | 0.92 ± 0.06b | 0.0 ± 0.00a | 1.47 ± 0.10b | 0.0 ± 0.00a | 0.36 ± 0.04b |

| C12:0 | 0.69 ± 0.01a | 0.5 ± 0.05b | 0.14 ± 0.01a | 0.37 ± 0.06b | 1.99 ± 0.24a | 0.78 ± 0.14b | 2.44 ± 0.05a | 1.33 ± 0.19b | 1.95 ± 0.28a | 1.83 ± 0.14a | 0.8 ± 0.10a | 0.53 ± 0.05b |

| C13:0 | 0.23 ± 0.01a | 0.16 ± 0.01b | 0.06 ± 0.01a | 0.11 ± 0.01b | 0.19 ± 0.08a | 0.22 ± 0.00a | 0.78 ± 0.02a | 0.36 ± 0.03b | 0.6 ± 0.08a | 0.58 ± 0.05a | 0.24 ± 0.03a | 0.15 ± 0.02b |

| C14:0 | 5.14 ± 0.04a | 3.06 ± 1.21b | 4.88 ± 0.18a | 5.23 ± 0.30a | 3.47 ± 0.52a | 5.38 ± 0.14b | 4.29 ± 0.47a | 4.14 ± 1.77a | 4.24 ± 0.36a | 5.89 ± 0.47b | 6.04 ± 0.10a | 3.7 ± 0.14b |

| C15:0 | 3.52 ± 0.04a | 1.76 ± 0.05b | 1.16 ± 0.04a | 1.81 ± 0.05b | 0.93 ± 0.04a | 0.96 ± 0.11a | 1.96 ± 0.03a | 2.61 ± 1.42a | 1.66 ± 0.28a | 2.16 ± 0.16a | 1.0 ± 0.27a | 0.71 ± 0.09a |

| C16:0 | 15.28 ± 0.15a | 3.44 ± 0.13b | 17.85 ± 1.62a | 17.41 ± 0.37a | 15.63 ± 0.23a | 11.76 ± 1.27b | 9.6 ± 0.75a | 13.56 ± 2.22b | 16.01 ± 2.27a | 15.47 ± 1.74a | 28.3 ± 1.49a | 16.22 ± 0.56b |

| C17:0 | 2.35 ± 0.70a | 2.86 ± 0.10a | 1.88 ± 0.08a | 2.73 ± 0.05b | 2.45 ± 0.42a | 1.74 ± 0.35a | 2.47 ± 0.05a | 1.53 ± 0.54b | 2.07 ± 0.26a | 3.5 ± 1.07a | 1.33 ± 0.13a | 1.75 ± 0.45a |

| C18:0 | 7.56 ± 0.04a | 7.93 ± 2.72a | 8.46 ± 0.23a | 8.28 ± 0.09a | 6.23 ± 1.33a | 6.73 ± 0.21a | 7.71 ± 1.17a | 6.73 ± 3.62a | 7.47 ± 1.29a | 9.32 ± 0.18a | 8.07 ± 0.37a | 6.03 ± 0.09b |

| C20:0 | 2.4 ± 0.05a | 3.07 ± 0.21b | 2.58 ± 0.14a | 1.91 ± 0.01b | 5.17 ± 0.40a | 2.99 ± 0.17b | 4.07 ± 0.53a | 1.31 ± 0.20b | 1.75 ± 0.14a | 4.15 ± 0.00b | 1.89 ± 0.02a | 2.26 ± 0.08b |

| C21:0 | 1.41 ± 0.04a | 1.43 ± 0.05a | 1.44 ± 0.04a | 1.01 ± 0.02b | 3.94 ± 1.26a | 1.72 ± 0.11b | 3.17 ± 0.24a | 2.18 ± 1.26a | 1.54 ± 0.25a | 2.93 ± 0.13b | 1.0 ± 0.03a | 1.38 ± 0.04b |

| C22:0 | 1.41 ± 0.02a | 1.67 ± 0.41a | 1.37 ± 0.41a | 1.22 ± 0.29a | 2.55 ± 0.71a | 2.03 ± 0.30a | 4.77 ± 0.41a | 3.25 ± 0.52b | 2.96 ± 0.34a | 3.07 ± 0.64a | 1.66 ± 0.41a | 1.29 ± 0.31a |

| C23:0 | 0.46 ± 0.11a | 0.66 ± 0.07a | 0.0 ± 0.00a | 0.34 ± 0.12b | 1.1 ± 0.09a | 0.62 ± 0.18b | 1.37 ± 0.06a | 0.68 ± 0.12b | 1.02 ± 0.14a | 0.96 ± 0.07a | 0.47 ± 0.06a | 0.45 ± 0.04a |

| ∑SFA | 41.61 ± 0.78a | 27.82 ± 2.08b | 40.12 ± 0.69a | 41.14 ± 0.92a | 45.02 ± 1.22a | 36.71 ± 1.63b | 47.16 ± 2.44a | 40.71 ± 2.70b | 44.76 ± 3.95a | 54.63 ± 0.62b | 52.21 ± 1.61a | 35.65 ± 0.61b |

| C14:1 | 7.02 ± 0.11a | 4.93 ± 0.45b | 8.33 ± 0.21a | 6.68 ± 0.94b | 5.04 ± 1.21a | 7.77 ± 0.13b | 1.91 ± 0.68a | 5.61 ± 2.65a | 2.49 ± 1.66a | 3.92 ± 0.02a | 7.44 ± 0.49a | 4.73 ± 0.08b |

| C16:1 | 7.05 ± 0.23a | 3.92 ± 0.27b | 10.35 ± 0.30a | 10.41 ± 0.13a | 7.17 ± 0.80a | 5.19 ± 0.08b | 5.07 ± 0.79a | 4.52 ± 1.45a | 7.26 ± 1.16a | 3.2 ± 0.84b | 6.33 ± 0.15a | 5.05 ± 0.08b |

| C17:1 | 1.04 ± 0.32a | 0.53 ± 0.00a | 0.26 ± 0.09a | 0.37 ± 0.08a | 0.68 ± 0.04a | 0.73 ± 0.03a | 2.67 ± 0.05a | 1.24 ± 0.12b | 2.04 ± 0.28a | 1.93 ± 0.13a | 0.83 ± 0.11a | 0.47 ± 0.06b |

| C18:1n9c | 1.56 ± 0.50a | 1.5 ± 0.02a | 1.91 ± 0.06a | 0.75 ± 0.09b | 3.09 ± 0.99a | 1.21 ± 0.10b | 2.5 ± 0.10a | 1.97 ± 1.10a | 3.89 ± 0.49a | 1.86 ± 0.15b | 1.47 ± 0.09a | 1.7 ± 0.88a |

| C18:1n9t | 1.79 ± 0.06a | 3.39 ± 0.18b | 4.22 ± 0.52a | 3.67 ± 0.11a | 2.92 ± 1.00a | 1.44 ± 0.48a | 0.67 ± 0.19a | 3.27 ± 1.65a | 1.62 ± 1.80a | 1.31 ± 0.29a | 0.91 ± 0.37a | 1.57 ± 0.13b |

| C20:1n9 | 3.69 ± 0.08a | 5.13 ± 0.24b | 5.66 ± 0.27a | 3.9 ± 0.07b | 10.56 ± 1.48a | 4.38 ± 0.13b | 6.54 ± 1.18a | 12.04 ± 3.11b | 5.4 ± 0.34a | 7.22 ± 0.43b | 3.59 ± 0.10a | 4.97 ± 0.24b |

| ∑MUFA | 22.14 ± 0.72a | 19.4 ± 0.22b | 30.72 ± 0.37a | 25.78 ± 0.99b | 29.47 ± 0.06a | 20.71 ± 0.34b | 19.37 ± 2.24a | 28.64 ± 6.32a | 22.71 ± 0.51a | 19.44 ± 1.01b | 20.56 ± 0.19a | 18.49 ± 0.40b |

| C18:3n6 | 0.64 ± 0.01a | 0.5 ± 0.02b | 0.2 ± 0.03a | 0.31 ± 0.04b | 0.46 ± 0.18a | 0.76 ± 0.09a | 2.45 ± 0.04a | 1.13 ± 0.08b | 1.88 ± 0.24a | 1.76 ± 0.12a | 0.86 ± 0.12a | 0.53 ± 0.01b |

| C18:2n6c | 0.81 ± 0.07a | 0.63 ± 0.24a | 0.4 ± 0.09a | 0.51 ± 0.15a | 0.97 ± 0.74a | 0.89 ± 0.24a | 1.62 ± 0.09a | 1.18 ± 0.55a | 1.68 ± 0.04a | 1.14 ± 0.09a | 0.94 ± 0.22a | 0.99 ± 0.43a |

| C20:4n6 | 7.32 ± 0.15a | 11.11 ± 0.64b | 8.47 ± 0.23a | 10.78 ± 0.42b | 6.25 ± 3.42a | 13.49 ± 0.60b | 9.15 ± 0.26a | 7.08 ± 2.15a | 8.14 ± 0.97a | 4.37 ± 0.23b | 5.47 ± 0.14a | 10.88 ± 0.38b |

| C20:5n3 | 18.55 ± 0.57a | 27.06 ± 0.67b | 10.95 ± 0.26a | 14.84 ± 0.92b | 5.51 ± 0.78a | 18.71 ± 0.88b | 3.71 ± 0.26a | 6.33 ± 3.36a | 9.3 ± 4.03a | 5.54 ± 0.41a | 13.0 ± 1.47a | 24.19 ± 0.73b |

| C20:3n6 | 5.6 ± 0.16a | 7.95 ± 0.23b | 3.09 ± 0.07a | 4.35 ± 0.26b | 1.9 ± 0.46a | 5.71 ± 0.25b | 3.53 ± 0.75a | 2.31 ± 1.17a | 4.02 ± 0.95a | 2.43 ± 0.43a | 4.2 ± 0.32a | 7.11 ± 0.20b |

| C20:2 | 1.58 ± 1.63a | 3.84 ± 1.43a | 5.1 ± 0.21a | 0.77 ± 0.10b | 8.9 ± 0.51a | 0.88 ± 0.08b | 6.6 ± 0.22a | 9.63 ± 2.25a | 2.66 ± 1.50a | 6.08 ± 0.12b | 0.74 ± 0.17a | 0.77 ± 0.02a |

| C22:6n3 | 1.27 ± 0.14a | 1.27 ± 0.48a | 0.61 ± 0.15a | 1.3 ± 0.28b | 0.99 ± 0.41a | 1.61 ± 0.25a | 4.54 ± 0.09a | 2.07 ± 0.15b | 3.47 ± 0.47a | 3.28 ± 0.23a | 1.43 ± 0.19a | 1.05 ± 0.11b |

| C22:2 | 0.48 ± 0.02a | 0.42 ± 0.07a | 0.33 ± 0.11a | 0.23 ± 0.01a | 0.55 ± 0.08a | 0.53 ± 0.04a | 1.87 ± 0.01a | 0.93 ± 0.02b | 1.39 ± 0.18a | 1.31 ± 0.09a | 0.6 ± 0.10a | 0.35 ± 0.02b |

| ∑PUFA | 36.25 ± 0.63a | 52.78 ± 2.30b | 29.16 ± 0.35a | 33.09 ± 1.75b | 25.51 ± 1.28a | 42.57 ± 1.79b | 33.48 ± 0.43a | 30.65 ± 3.89a | 32.53 ± 4.19a | 25.92 ± 0.40a | 27.23 ± 1.50a | 45.86 ± 0.89b |

| ω-3/ω-6 | 1.21 | 1.16 | 0.66 | 0.95 | 0.34 | 0.91 | 0.33 | 0.38 | 0.65 | 0.52 | 1.13 | 1.22 |

Note: For each species values in the same row bearing different letters are significantly different (p < 0.05); ∑ω-3 = C20:5n3 + C22:6n3; ∑ω-6 = C18:3n6 + C18:2n6c + C20:4n6 + C20:3n6 + C20:2 + C22:2; SFA, saturated fatty acid; MUFA, monounsaturated fatty acid; PUFA, polyunsaturated fatty acid, for each species 15 samples each with 3 replicates were analysed

Fig. 1.

The chromatogram of fresh S. chloronotus. Abundance of fatty acid components is given by y axis and corresponding time is given in x axis

Processing has resulted a significant reduction of total saturated fatty acids (∑SFA) in fresh form of sea cucumber species with an exception of Bohadschia sp. 1 in which a significant increase in ∑SFA was evident in processed form (p < 0.05, ANOVA). The highest percentage of total SFA corresponded to the processed Bohadschia sp. 1 (54.63%). Palmitic acid (C16:0) is the most dominant saturated fatty acid in all these sea cucumber species followed by stearic acid (C18:0) and myristic acid (C14:0). The level of palmitic acid ranged from 9.60 to 28. 30% in fresh and 3.44–17.41% in processed form, respectively. Processing caused to reduce the palmitic acid content in fresh H. scabra, T. anax and S. chloronotus significantly. However, a significant increase of palmitic acid content was evident in B. marmorata after the processing (p < 0.05, ANOVA). Although undecanoic acid (C11:0) was not recorded in fresh individuals of H. scabra, Bohadschia species and S. chloronotus, it was detected in processed individuals in very low percentages.

Total MUFA in fresh sea cucumbers ranged between 19.37 and 30.70% and processing has resulted in significant reduction of ∑MUFA in all sea cucumber species except in B. marmorata. Myristoleic acid (C14:1), palmitoleic acid (C16:1) and gondoic acid (C20:1n9) are the most dominant monounsaturated fatty acids present in sea cucumbers and significant variations in these fatty acids in fresh and processed individuals were evident (p < 0.05; ANOVA). Total unsaturated fatty acids in both fresh and processed forms were found to be higher than total saturated fatty acid in all sea cucumber species excluding processed Bohadchia sp.1 and fresh S. chloronotus.

Arachidonic acid (C20:4n6), eicosapentaenoic acid (EPA, C20:5n3) and homo-γ-linolenic acid (C20:3n6) are the most predominant polyunsaturated fatty acids (PUFAs) reported in these sea cucumber species. Arachidonic acid was found in all these species and a significant increase in the relative percentage of this fatty acid was evident in H. scabra, H. spinifera, T. anax and S. chloronotus after the processing. Processed T. anax (13.49%) reported the highest percentage of arachidonic acid. Processed sea cucumbers, except for Bohadschia sp. 1 have significantly higher EPA than the fresh individuals. Results revealed that linoleic acid (C18:2n6c) is present in all these species and the highest percentage of linoleic acid and docosahexaenoic acid (DHA, C22:6n3) are in Bohadschia species. Processed sea cucumbers excluding Bohadschia species showed a significant increase of total PUFA than the fresh individuals and the highest percentage of total PUFA was evident in H. scabra. Further, H. scabra has the highest ω-3/ω-6 ratio followed by S. chloronotus.

Discussion

The market demand of bêche-de-mer mainly fluctuates with species and product quality. Shape, appearance, colour, odour, and moisture content are the key determinants of bêche-de-mer product quality and these parameters are mainly influenced by the processing method. Therefore, there is a great interest to find out the proper methods of sea cucumber processing among sea cucumber producing nations. According to Conand (1990), bêche-de-mer is produced mainly by a process of cleaning, boiling, salting, and drying. This study also revealed similar steps in processing though slight differences in major processing steps were seen with species. Previous studies also proved that slight differences in major processing steps can occur with respect to species, geographical areas and method of processing (Conand 1990; Choo 2004).

Although processors carried out cooking in an ad hoc manner, it is the most important step in the processing chain as it damages to the product in an irreversible way acquiring rotting and undesirable smell (Li 2004). Proper cooking will enhance the palatability, shelf life, stiffness and colour of sea cucumbers. This study revealed that boiling time varied with species and similar findings were reported in Madagascar. However, due to lack of a proper scientific base to judge the appropriate level of boiling and boiling time, many processors face difficulties as over or under cooking reduces the product quality. Although some processors in Madagascar and Malaysia employed one time boiling; many processors practised second boiling after the salting as reported in this study (Choo 2004).

To gain the best market price, removal of the chalky material presence in the integument of some sea cucumber species is essential during the processing. According to Choo (2004), similar methods reported in this study are practised in Pacific Island countries, Malaysia and Madagascar to remove chalky materials of H. scabra and H. spinifera. Burying of boiled sea cucumbers in the sand around 12–18 h enhance bacterial actions which soft the external part of the integument enabling removal of decomposed integument containing chalky materials while rubbing or scraping. When Papaya leaves are used chemicals like papain may react with calcium carbonate deposits. Salting after first boiling limits desiccation and minimises weight and length losses during processing. Sun drying is the widely practiced method to dry sea cucumbers in many parts of the world, although some disadvantages like non-uniformity in drying and product damage by rodents are recorded (Choo 2004).

This study revealed the quality of domestically processed bêche-de-mer is lower than the industrially processed bêche-de-mer as the former contains a high level of moisture, crude ash, crude fat and low level of proteins. Similar observations have been reported in previous studies carried out in Pacific Island countries (Ram et al. 2014) and New Calidonia (Purcell et al. 2009). According to Ram et al. (2014), fishers who are doing small-scale domestic level sea cucumber processing often face problems of producing good quality bêche-de-mer as they rush some processing steps to save time and lack of proper understanding of gutting position, salting time, the importance of repeated cooking and proper drying.

Although, information on nutritional composition of sea cucumbers are available for a few species (Maziar Yahyav et al. 2012; Salarzadeh et al. 2012; Haider et al. 2015; Ibrahim et al. 2015), still there are many gaps. According to Chang-Lee et al. (1989), the moisture content of fresh sea cucumbers varied from 82 to 92.6% and the results of the present study were in agreement with their findings. Improper drying and packing could be the possible reasons for observed significant variations of moisture content in domestically and industrially processed sea cucumbers (Özer et al. 2004). However, when compared with other studies, Bêche-de-mer from Sri Lanka contains a higher level of moisture than the products from other regional countries (Wen et al. 2010; Bechtel et al. 2012; Ibrahim et al. 2015). Over salting and improper removal of gut contents may be some possible reasons for the observed high level of ash contents in processed sea cucumbers.

Previous studies have revealed that sea cucumbers contain a high protein and low-fat levels (Prim et al. 1976; Wen et al. 2010) and this study also supports these findings. Out of six species studied, previous information on protein content are available only for dried H. scabra, T. anax and fresh B. marmorata (Wen et al. 2010; Nahla 2013; Ibrahim et al. 2015) and the present findings are in conformity with their findings. Observed significant changes in protein content of processed sea cucumbers could be a result of alterations in protein content due to different processing tactics, removal of some body parts and relative losses or addition of other constituents during processing.

Wen et al. (2010) reported significantly higher fat content in T. anax (9.9 ± 0.27) than the values reported in the current study, however, fat content reported for H. scabra by Ibrahim et al. (2015) was similar to our results. As stated by Neto et al. (2006), differences in food availability in marine environments and selective feeding behaviour of sea cucumbers could be some possible reasons for the observed differences in fat and fatty acid profile of sea cucumber species.

This study revealed that processing has resulted a significant reduction of total SFA and MUFA and an increased in total PUFA in many sea cucumber species studied and similar results have been reported previously by Aydin et al. (2011) for H. tubulosa, H. polli and H. marmorata collected from Turkey. Removal of body parts during the processing could be a possible reason for relative percentage changes of these fatty acids.

Although Nahla (2013) reported that both H. scabra and B. marmorata contain higher total saturated fatty acids than total unsaturated fatty acids, the results of this study do not support for their findings. Haider et al. (2015) reported the presence of lower chain SFAs such butyric acid (C4:0) and caproic acid (C6:0) in sea cucumbers, however, these FAs were not detected in the current study probably due to the presence of these compounds below detection levels. Further, Fredalina et al. (1999) have reported that extraction procedures can affect the content of FAs in sea cucumbers and probably our procedure is not strong enough to extract some FAs.

Among the essential FAs, only linoleic acid was reported in these species. Although, the presence of α-linolenic acid in sea cucumbers was reported previously (Wen et al. 2010; Nahla 2013; Haider et al. 2015), it was not recorded in these species similar to the findings of Maziar Yahyav et al. (2012) and Ridzwan et al. (2014). As stated previously, the absence of these FAs may be due to their dietary differences or presence in undetectable levels.

This study revealed the presence of high EPA and low DHA levels in sea cucumbers similar to the findings of Li et al. (2009) and Xiang et al. (2006). However, the absence of DHA in many sea cucumber species including T. anax was recorded in some other studies (Wen et al. 2010; Haider et al. 2015). Aydin et al. (2011) found low EPA and high DHA levels in H. tubulosa and H. mammata. This study also proved that sea cucumbers are rich with arachidonic acid (Wen et al. 2010; Aydin et al. 2011; Haider et al. 2015). Further, it reveals that some FAs remained without any change even after the processing and this may be due to processing does not cause oxidation of these FAs.

Although sea cucumbers contain very low level of crude fat content, fatty acid compositions of sea cucumbers have been analyzed previously to prove that sea cucumbers are rich with healthy composition of fatty acid. This study also confirmed that H. scbara and S. chloronotus are having the recommended ω-3/ω-6 ratio for good health status of human (Simopoulos 2002).

In conclusion, proximate composition and fatty acid profile of sea cucumbers can be significantly affected by processing. Processing has resulted a significant reduction in relative percentages of total SFAs and MUFAs and increased in PUFAs in most of these sea cucumber species. All these species are rich with arachidonic acid (C20:4n6), eicosapentaenoic acid (C20:5n3) and homo-γ-linolenic acid (C20:3n6). As there are differences in the nutritional composition of sea cucumbers in relation to species, geographic locations and methods of processing, the findings of this study will make a significant contribution to fill the gaps in existing information as no previous information are available for some species like H. spinifera and S. chloronotus. However, it is recommended to analyze effects of processing on the proximate and fatty acid compositions of these sea cucumber species further by considering more samples belonging to wider size and depth ranges as dietary sources and dietary preferences could be varied with such factors.

Acknowledgements

The authors gratefully acknowledge the financial support received from the National Research Council (NRC) Grant No 15-50. Technical support given by Prof. Savim Kose, Dr. Asitha Cooray and staff members of the Central Instrumentation Facility of the University of Sri Jayewardenepura and Suganth International (Pvt.) Ltd. are highly appreciated.

References

- AOAC (1990) Official methods of analysis of AOAC international, 17th edn

- Aydin M, Sevgili H, Tufan B, et al. Proximate composition and fatty acid profile of three different fresh and dried commercial sea cucumbers from Turkey. Int J Food Sci Technol. 2011;46:500–508. doi: 10.1111/j.1365-2621.2010.02512.x. [DOI] [Google Scholar]

- Bechtel PJ, Oliveira ACM, Demir N, Smiley S. Chemical composition of the giant red sea cucumber, Parastichopus californicus, commercially harvested in Alaska. Food Sci Nutr. 2012;1:63–73. doi: 10.1002/fsn3.12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bligh EG, Dyer WJ. A rapid method of total lipid extraction and purification. Can J Biochem Physiol. 1959;37:911–917. doi: 10.1139/y59-099. [DOI] [PubMed] [Google Scholar]

- Chang-Lee MV, Price RJ, Lampila LE. Effect of processing on proximate composition and mineral content of sea cucumbers (Parastichopus spp.) J Food Sci. 1989;54:567–568. doi: 10.1111/j.1365-2621.1989.tb04653.x. [DOI] [Google Scholar]

- Choo P-S. Fisheries, trade and utilization of sea cucumbers in Malaysia. Adv Sea Cucumber Aquac Manag FAO Fish Tech Pap. 2004;463:57–68. [Google Scholar]

- Conand C (1990) The fishery resources of Pacific island countries. Part 2: Holothurians. In: FAO Fish. Tech. Paper. p 143

- Conand C, Byrne M. A review of recent developments in the world sea cucumber fisheries. Mar Fish Rev. 1993;55:1–13. [Google Scholar]

- Dissanayake DCT, Stefansson G. Abundance and distribution of commercial sea cucumber species in the coastal waters of Sri Lanka. Aquat Living Resour. 2010;23:303–313. doi: 10.1051/alr/2010031. [DOI] [Google Scholar]

- Dissanayake DCT, Stefansson G. Present status of the commercial sea cucumber fishery off the north-west and east coasts of Sri Lanka. J Mar Biol Assoc UK. 2012;92:831–841. doi: 10.1017/S0025315411001019. [DOI] [Google Scholar]

- Duan X, Zhang M, Mujumdar AS. Studies on the microwave freeze drying technique and sterilization characteristics of cabbage. Dry Technol Int J. 2007;25:1725–1731. doi: 10.1080/07373930701591044. [DOI] [Google Scholar]

- Fredalina BD, Ridzwan BH, Abidin AAZ, et al. Fatty acid compositions in local sea cucumber, Stichopus chloronotus, for wound healing. Gen Pharmacol. 1999;33:337–340. doi: 10.1016/S0306-3623(98)00253-5. [DOI] [PubMed] [Google Scholar]

- Haider MS, Sultana R, Jamil K, et al. A study on proximate composition, amino acid profile, fatty acid profile and some mineral contents in two species of sea cucumber. J Anim Plant Sci. 2015;25:168–175. [Google Scholar]

- Ibrahim MY, Elamin SM, Gideiri YBA, Ali SM. The proximate composition and the nutritional value of some sea cucumber species inhabiting the Sudanese Red Sea. Food Sci Qual Manag. 2015;41:11–17. [Google Scholar]

- Kumara PADA, Dissanayake DCT. Priliminary study on broodstock rearing, induced breeding and grow-out culture of the sea cucumber Holothuria scabra in Sri Lanka. Aquac Res. 2017;48:1058–1069. doi: 10.1111/are.12948. [DOI] [Google Scholar]

- Li X (2004) Fishery and resource management of tropical sea cucumbers in the islands of the South China Sea. In: Advances in sea cucumber aquaculture and management. Fishers Technical paper 463, FAO, pp 261– 265

- Li DT, Chang YQ, Wu ZH, et al. Analysis of nutritive composition of body wall in wild sea cucumber Apostichopus japonicus Selenka at Zhangzi Island in spring and autumn. Fish Sci. 2009;28:365–369. [Google Scholar]

- Nahla ESESO. Nutritional value of some Egyptian sea cucumbers. Afr J Biotechnol. 2013;12:5466–5472. doi: 10.5897/AJB2013.13020. [DOI] [Google Scholar]

- Neto RR, Wolff GA, Billett DSM, et al. The influence of changing food supply on the lipid biochemistry of deep-sea holothurians. Deep Res I Oceanogr Res Pap. 2006;53:516–527. doi: 10.1016/j.dsr.2005.12.001. [DOI] [Google Scholar]

- Özer NP, Mol S, Varlık C. Effect of the handling procedures on the chemical composition of sea cucumber. Turkish J Fish Aquat Sci. 2004;4:71–74. [Google Scholar]

- Prim P, Lawrence JM, Turner RL. Protein, carbohydrate, and lipid levels of the adult body wall of Actinopyga agassizi, Synaptula hydriformis and Pentacta pygmaea (Echinodermata: Holothuroidea) Comp Biochem Physiol B Biochem. 1976;55:307–309. doi: 10.1016/0305-0491(76)90246-7. [DOI] [Google Scholar]

- Purcell SW, Gossuin S, Agudo NS (2009) Status and management of the sea cucumber fishery of La Grande Terre, New Caledonia. In: WorldFish center studies and review N0 1901. The WorldFish Center, Penang, Malaysia, p 136

- Purcell SW, Ngaluafe P, Aram KT, Lalavanua W. Trends in small-scale artisanal fishing of sea cucumbers in Oceania. Fish Res. 2016;183:99–110. doi: 10.1016/j.fishres.2016.05.010. [DOI] [Google Scholar]

- Ram R, Chand RV, Southgate PC (2014) Effects of processing methods on the value of bêche-de-mer from the Fiji islands. 10.4172/2155-9910.1000152

- Ridzwan BH, Hanita MH, Nurzafirah M, et al. Free fatty acids composition in lipid extracts of several sea cucumbers species from Malaysia. Int J Biosci Biochem Bioinf. 2014;4:204–207. [Google Scholar]

- Salarzadeh AR, Afkhami M, Bastami KD, et al. Proximate composition of two sea cucumber species Holothuria pavra and Holothuria arenicola in Persian Gulf. Ann Biol Res. 2012;3:1305–1311. [Google Scholar]

- Simopoulos AP. The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomed Pharmacother. 2002;56:365–379. doi: 10.1016/S0753-3322(02)00253-6. [DOI] [PubMed] [Google Scholar]

- Wen J, Hu C, Fan S. Chemical composition and nutritional quality of sea cucumbers. J Sci Food Agric. 2010;90:2469–2474. doi: 10.1002/jsfa.4108. [DOI] [PubMed] [Google Scholar]

- Xiang Y-H, Su X-R, Dong M-M. The composition of amino acids and fatty acids in body walls and alimentary canals of sea cucumber Apostichopus japonicus. Fish Sci. 2006;25:280–282. [Google Scholar]

- Yahyav Maziar, Afkhami M, Javadi A, et al. Fatty acid composition in two sea cucumber species, Holothuria scabra and Holothuria leucospilata from Qeshm island (Persian Gulf) Afr J Biotechnol. 2012;11:2862–2868. [Google Scholar]