Abstract

Aim:

The purpose of this study was to compare the marginal and internal adaptation of cobalt-chromium (Co-Cr) copings fabricated from conventional wax pattern, three-dimensional (3D)-printed resin pattern, and laser sintering technique.

Materials and Methods:

A total of thirty copings were made, out of which ten copings were made from 3D-printed resin pattern (Group A), ten from inlay wax pattern (Group B), and ten copings were obtained from direct metal laser sintering (DMLS) technique (Group C). All the thirty samples were seated on their respective dies and sectioned carefully using a laser jet cutter and were evaluated for marginal and internal gaps at the predetermined areas using a stereomicroscope. The values were then analyzed using one-way ANOVA test and post hoc Bonferroni test.

Results:

One-way ANOVA showed lowest mean marginal discrepancy for DMLS and highest value for copings fabricated from inlay wax. The values for internal discrepancy were highest for DMLS (169.38) and lowest for 3D-printed resin pattern fabricated copings (133.87). Post hoc Bonferroni test for both marginal and internal discrepancies showed nonsignificant difference when Group A was compared to Group B (P > 0.05) and significant when Group A was compared with Group C (P < 0.05). Group B showed significant difference (P < 0.05) when compared with Group C.

Conclusion:

Marginal and internal discrepancies of all the three casting techniques were within clinically acceptable values. Marginal fit of DMLS was superior as compared to other two techniques, whereas when internal fit was evaluated, conventional technique showed the best internal fit.

Keywords: Internal fit, laser sintering, marginal fit, three-dimensional printing

INTRODUCTION

Metal ceramics are still the most widely used material for fabricating complete coverage crowns and fixed partial dentures.[1] The traditional technique for fabricating the metal substructure is the lost wax casting technique introduced by Taggart.[1,2] In the recent years, additive manufacturing has become more attractive in which multiple layers of material are added one by one to fabricate the coping.[3] It includes stereolithography, three-dimensional (3D)-printed resin, and laser sintering technologies.

The marginal accuracy and internal fit of the restoration are the major determining factors for the success of restoration. Any discrepancy at the marginal or internal level may be produced due to cumulative results of many variables, as multiple steps in the production increase the number of variables that can cause misfit. Thus, the fabrication technique plays an important role in providing accuracy. The conventional technique of fabrication is the lost wax technique that includes so many manual steps which always have a greater chance for errors. To deplete all these errors, newer techniques have been introduced such as additive manufacturing techniques.

Many studies have been conducted in the past to compare the discrepancy of the copings fabricated using various casting techniques. In the present study, the copings fabricated from two latest casting techniques, i.e., 3D printing and laser sintering were considered to be the subject of evaluation and were compared with the conventional lost wax technique.

MATERIALS AND METHODS

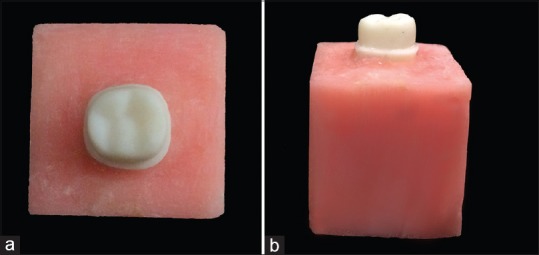

An ivorine tooth (mandibular right first molar, Columbia, Long Island, NY, USA) was selected for the preparation of the master model. It was mounted on a custom-made metallic mold with self-polymerizing acrylic resin DPI RR cold cure, Dental Products of India. The tooth was then prepared with shoulder finish line of 1.5 mm on the buccal aspect, chamfer finish line of 0.5 mm on the lingual aspect, and occlusal reduction of 2 mm [Figure 1].

Figure 1.

Master model (a) occlusal view (b) lateral view

Impression making

A custom tray was fabricated with perforations to make the impression of the prepared ivorine tooth. One-step double-mix elastomeric impression technique was used for the impression which was then poured in a die stone. The procedure was repeated thirty times to obtain thirty stone dies of same dimensions. They were divided into three groups: Group A, Group B, and Group C, with ten dies each for three different coping fabrication techniques, i.e., 3D-printed resin pattern technique, conventional inlay wax pattern technique, and laser sintering technique, respectively. A separate die was poured from this impression to standardize the contour and thickness of the wax patterns of Group B.

Standardization of wax pattern

The contour and thickness of the wax patterns of Group A were standardized using computer-aided software (Exocad DentalCAD, Darmstadt, Germany). For this, first, the stone die was scanned using a dental scanner (Open technology). The designing of the wax pattern of thickness 0.5 mm was then done using the software (ExoCad). This design was used to fabricate the patterns of Group A using a 3D printer (ProJet 1200, 3D SYSTEMS).

For Group B, a master wax pattern was designed using the same Computer aided design (CAD) data as done for Group A on a separate stone die which was poured from the impression of the master model. Then, a putty index of the master wax pattern was made and this was used to standardize all the wax patterns of Group B (inlay wax pattern).

Fabrication of Group A samples (three-dimensional-printed resin patterns)

In Group A, the die was scanned using the dental scanner (open technology). Then, the image was transferred to the computer and the Stereolithographic (STL) file generated was used to design the patterns of uniform dimension (0.5 mm). The design file was transferred to the 3D printer (ProJet 1200, 3D SYSTEMS). The 3D printer has a cartridge filled with pattern resin which is added in incremental layers one after another and the patterns were fabricated and immediately invested for casting. For casting of these patterns, conventional protocol was followed as used for fabrication of Group B samples.

Fabrication of Group B samples (conventional inlay wax pattern)

Ten standardized wax patterns were fabricated using blue inlay wax for this group. All the patterns were checked for standard contour and thickness using the putty index of the master wax up. To avoid any kind of distortion in the wax pattern, they were invested soon after they were fabricated. The copings were casted in cobalt-chromium (Co-Cr) alloy (DFS, Germany).

Fabrication of Group C samples (laser sintering technique)

Ten laser-sintered Co-Cr copings were fabricated using the CAD-designed data (Exocad) as done for the Group A. The laser sintering machine (Pro X, 100DP) works on a movable platform by sintering the incremental layer of the Co-Cr alloy. For each layer, the machine laid down a film of Co-Cr alloy powder. The powder was sintered to a thickness of 20 μm at a speed of 2–20 mm3/s from the occlusal surface to the margin at 1500°C in an inert gas environment (nitrogen atmosphere). The process was continued layer by layer until the complete structure of coping was fabricated. After sintering, the copings were cooled down to room temperature in the furnace.

Sectioning of the samples

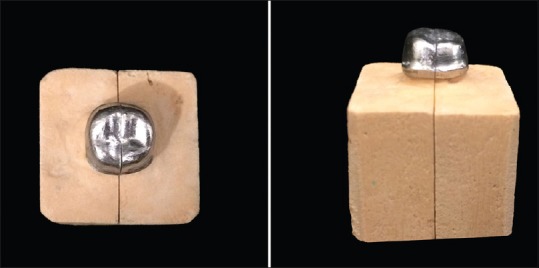

All the copings were sectioned longitudinally in vertical direction using a water jet cutter (Wardjet ZXL 45-5). The metal coping was seated onto the stone die and fixed with screws on the platform of the water jet cutter with blade width of 0.2 mm, and a beam of light was directed buccolingually on the coping placed on the die and sectioning was done [Figure 2].

Figure 2.

Sectioned die

Measurements

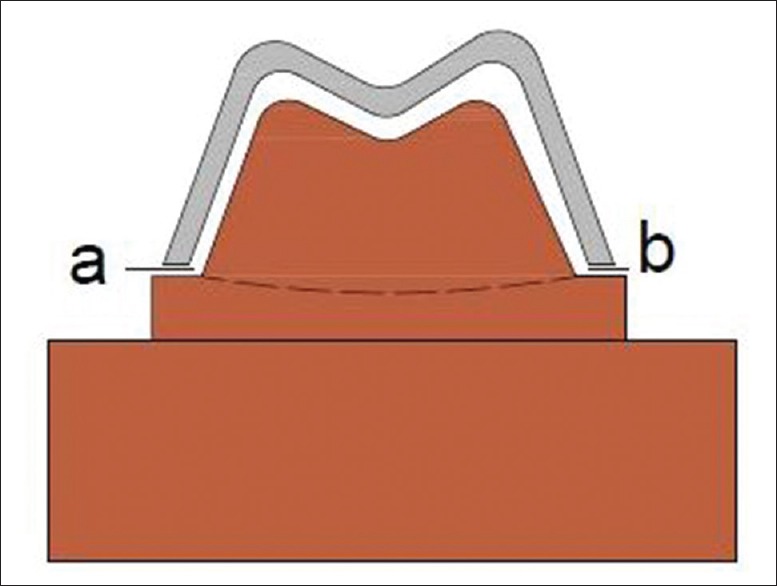

The sectioned samples were scanned under stereomicroscope for marginal and internal gaps. The distance between the most extended point of the coping margin and the external marginal line of the prepared tooth was used to evaluate the marginal gap. For this, two measurement points were determined at the margins, i.e., a (at buccal margin) and b (at lingual margin) [Figure 3].

Figure 3.

Measurement positions for assessing marginal gap (a and b)

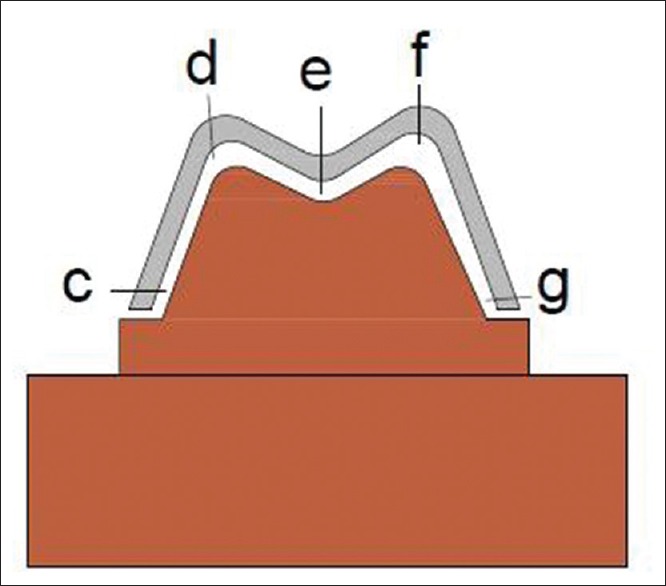

For evaluating internal gap, the perpendicular distances from the internal surface of the coping to the external surface of the preparation were measured. For this, five measurement points were determined, i.e., c and g (1 mm away from the margin), d and f (maximum convexity on the cusp tip), and e (maximum concavity in the central fossa) [Figure 4].

Figure 4.

Measurement positions for internal gap (c) axial, (d) buccal cusp, (e) fossa, (f) lingual cusp, (g) axial

Statistical analysis

The data collected were subjected to one-way ANOVA to compare the mean marginal and internal discrepancies between the three groups. For intergroup comparison, post hoc Bonferroni test was used.

RESULTS

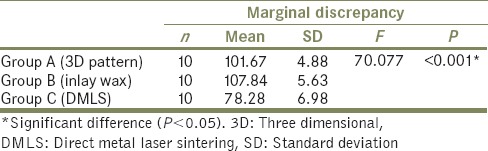

In Table 1, the mean marginal discrepancy was compared between Group A, Group B, and Group C using the one-way ANOVA test. A significant difference (P < 0.05) was found among the three groups. The lowest mean marginal discrepancy was found to be of Group C (direct metal laser sintering [DMLS]) (78.28) followed by Group A (3D pattern) (101.67). Group B (inlay wax) had the highest marginal discrepancy with a value of 107.84.

Table 1.

One-way ANOVA test for marginal discrepancy (μ)

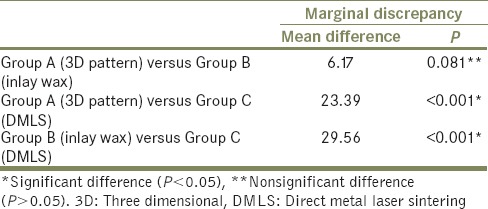

In Table 2, the intergroup comparison of mean marginal discrepancy was done using the post hoc Bonferroni test. The difference was found to be nonsignificant when Group A was compared to Group B (P > 0.05) and significant when Group A was compared with Group C (P < 0.05). Group B showed significant difference (P < 0.05) when compared with Group C.

Table 2.

Post hoc Bonferroni test for marginal discrepancy (μ)

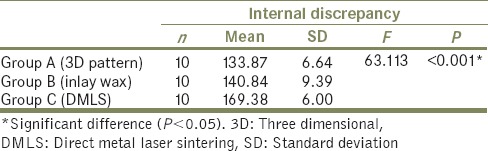

In Table 3, the mean internal discrepancy was compared between the three groups using one-way ANOVA test. A significant difference (P < 0.05) was found among the three groups. The lowest mean internal discrepancy in microns was found to be of Group A (133.87) followed by Group B (140.84). Group C was found to have the highest internal discrepancy with a value of 169.38.

Table 3.

One-way ANOVA test for internal discrepancy (μ)

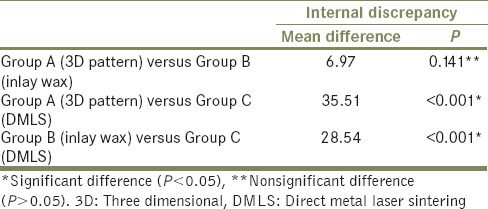

In Table 4, the intergroup comparison of mean internal discrepancy was done using the post hoc Bonferroni test. The difference was found to be nonsignificant when Group A was compared to Group B (P > 0.05) and significant when Group A was compared with Group C (P < 0.05). Group B showed significant difference (P < 0.05) when compared with Group C. Group C showed significant difference (P < 0.05) when compared with both the other groups (Group A and Group B).

Table 4.

Post hoc Bonferroni test for internal discrepancy (μ)

DISCUSSION

Precise marginal and internal fit of cast restorations is an important factor to fulfill biological, physical, and esthetic requirements of restorations. There are different techniques available for fabricating the metal substructure. The present study was conducted to comparatively evaluate the marginal and internal gaps of Co-Cr copings fabricated by conventional casting procedures, 3D-printed pattern resin, and DMLS technique.

An ivorine tooth was selected for the preparation of master model on which tooth preparation was done according to the protocol of the conventional porcelain fused to metal crown as stated by Shillingberg et al.[4] Thirty stone dies were made from the impression on which copings were made from three different techniques. All the thirty copings were seated on their respective dies and sectioned carefully using a water jet cutter. This method of sectioning was chosen as this technique has the ability to cut coping without interfering with its inherent structure as there is no heat-affected zone. Reduction in the effects of heat allowed coping to be sectioned without any change in the intrinsic property. They were evaluated for marginal and internal gaps at the predetermined areas.

Marginal and internal gaps were measured in microns using a stereomicroscope and a digital measurement program. Data obtained were recorded in microns and were subjected to one-way ANOVA test and post hoc Bonferroni test.

Different authors have given different values for clinically accepted range of marginal discrepancy. Fransson et al.[5] and Mclean and von Fraunhofer[6] stated that the clinically acceptable marginal gap after cementation should be <150 and 120 μm, respectively. According to Assif et al.,[7] the mean marginal gap is closer to 140 μm, while Hung et al.[8] suggested a value of 50–75 μm. Quante et al.[9] and Ucar et al.[10] reported 76–93 μm and 62.6 μm, respectively, as the marginal gaps of laser sintering- based fabricated copings. Thus, the clinical acceptance of marginal gaps varies quite across studies. The values of mean marginal discrepancy obtained for all the three casting techniques were within acceptable range in the present study, i.e., 101.67, 107.84, and 78.28 for Group A, Group B, and Group C, respectively.

The mean marginal discrepancy of the copings of Group B was highest among all the groups. The results of our study disagree with the study conducted by Park et al.,[11] who found the lowest discrepancy for the conventional technique. This difference in the result may be attributed to the precision of the scanner used to digitize the working model, precision of the design via computer software, and precision of the machine used to fabricate the 3D design. Our findings agree with the work conducted by Bhaskaran et al.,[12] who compared the marginal gap between the same three casting techniques as done in the present study and found lowest marginal discrepancy for copings fabricated by DMLS and highest for inlay wax technique. A study conducted by Harish et al.[13] and Colaco et al.[14] between conventionally casted crowns and laser-sintered crowns also revealed high marginal discrepancy for the conventional group. The reason for the highest mean marginal discrepancy for Group B could be due to the multiple steps in the production of copings which increase the number of variables that can cause discrepancies in the definitive product. Wax has a tendency to distort or warp when allowed to stand unrestrained. According to Phillips and Biggs,[15] distortion in the wax pattern is evident just 30 min after preparation of the wax pattern. Shrinkage and stress relaxation of the inlay casting wax and high setting expansion of the investment are other factors that can cause discrepancy.

Better marginal fit of Group A than Group B may be due to the software used in Group A which compensated for polymerization shrinkage and increased precision without any chance of manual errors during fabrication process. In addition, the inherent limitations of inlay wax were avoided in this technique.

Group C had the least marginal ga P value than the other two groups as this process eliminated casting and manual errors compared to induction casting procedure which was used to melt the alloy for Groups A and B. According to Schwartz,[16] heating induction coil melts alloy at higher temperature than its melting range. This may cause the alloy to lose its low melting point compositional elements, making it more viscous and affecting its flow.

Group C had lower marginal discrepancy value than Group A because in Group A, although the wax pattern was fabricated using an automated additive technique, casting process was done in the conventional manner as opposed to Group C in which the entire fabrication procedure was automated. Thus, all the casting errors which contributed to marginal discrepancy in Group B also existed for Group A.

Different studies have shown different values for internal discrepancy. However, any clinical acceptance of the internal discrepancy has not been found so far. The internal discrepancy of the single copings fabricated with laser sintering by Quante et al.[9] and Ucar et al.[10] was on an average within the range of 250–350 and 62.6 μm, respectively. Park et al.[11] showed an internal discrepancy of 127.85 and 188.32 μm for copings from conventionally casted and DMLS technique, respectively, at the incisal edge, whereas the values at axial walls were 57.44 and 108.58 μm, respectively. Harish et al.[13] in their study found mean internal discrepancy of 107.60 and 187.09 μm for laser-sintered and conventionally casted crowns, respectively. A study done by Nesse et al.[17] showed an internal discrepancy of 116 μm for cast crowns and 156 μm for selective laser melting technique.

In the present study, Group C had the least marginal discrepancy, but the internal discrepancy of these samples was significantly higher than that of Group A and Group B. The results of our study disagree with that of the study conducted by Harish et al.,[13] who found least internal discrepancy for the laser-sintered group and higher discrepancy values for the conventionally casted crowns, although their result for marginal discrepancy was in accordance to our result. Our results for internal discrepancy are in agreement with the study done by Bhaskaran et al.,[12] Nesse et al.,[17] Ucar et al.,[10] and Ullattuthodi et al.[18]

The reason for the high internal discrepancy in Group C could be because, while scanning the master die and constructing 3D coping shell model image, the margin determination was under manual adjustment, while the external surface scanning of the master die was determined by the nonuniform offsetting and shelling algorithm in the scanning software. The scanning system has the limitation of finite resolution, which can result in edges that are slightly rounded. The point clouds obtained in scanning are transformed through a CAD software algorithm into a smooth and continuous surface which can lead to interfering contact at the occlusal edges, resulting in internal discrepancy. Although the distortion of each layer is minimal, the accumulated error for all the layers can also cause a measurable error. According to Abduo et al.,[19] the accuracy of laser-sintered copings is affected by dimension of laser beam and its intensity. This in combination with other factors as stated above could also be a source of higher internal discrepancy in our result.

Bhaskaran et al.[12] conducted their study using the same three casting techniques as used in the present study, but they did not use a standardized procedure to fabricate the wax patterns for conventional inlay wax technique, whereas in the present study, a putty index was made of the wax pattern fabricated from computerized 3D-printed resin technique, and using this index, all the patterns of inlay wax were fabricated. Sectioning method used in the present study was more standardized as water jet cutter was used, in which all the samples were fixed with screws on the platform, and sectioning was done at the desired location by making a single, continuous, computer-controlled cut with high precision and reduced cutting time. On the other hand, manual sectioning with a diamond saw was carried out in the previous study which had the chance of human error. The heat generated during manual sectioning can disturb the integral structures of the heat-affected zones, which can add to the discrepancy. Use of water jet cutter in the present study avoided this error due to automated constant cooling during sectioning.

There are several limitations in this study. As this is an in vitro study, it cannot simulate oral conditions. The discrepancy was evaluated by sectioning method which could lead to distortion of the copings and abrasion of the stone dies and not by silicon replica technique (nondestructive method) which would have yielded better results. Although precautions were taken to invest all the wax patterns of Group B immediately to minimize distortion, yet some discrepancy might have occurred due to unavoidable delay.

Furthermore, clinical trials with different tooth preparations are needed to verify the present result. The study could have been improved by increasing the number of samples used. This would have given more precise results.

CONCLUSION

Within the limitations of this study, it was concluded that:

Laser sintering technique of coping fabrication showed lowest mean marginal discrepancy followed by 3D-printed resin pattern technique. Conventional inlay wax technique showed the highest mean marginal discrepancy

3D resin pattern technique showed the lowest internal discrepancy followed by conventional inlay wax technique. Laser sintering technique showed the highest mean internal discrepancy.

Still, further long-term studies on the fit and properties of 3D-printed resin and laser sintering technique should be carried out to obtain confirmative and consistent estimate of the marginal and internal discrepancies with this technique for their acceptance in dentistry.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Fathi HM, Al-Masoody AH, El-Ghezawi N, Johnson A. The accuracy of fit of crowns made from wax patterns produced conventionally (Hand formed) and via CAD/CAM technology. Eur J Prosthodont Restor Dent. 2016;24:10–7. [PubMed] [Google Scholar]

- 2.Prabhu R, Prabhu G, Baskaran E, Arumugam EM. Clinical acceptability of metal-ceramic fixed partial dental prosthesis fabricated with direct metal laser sintering technique-5 year follow-up. J Indian Prosthodont Soc. 2016;16:193–7. doi: 10.4103/0972-4052.176526. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Jain R, Supriya, Bindra S, Gupta K. Recent trends of 3-D printing in dentistry – A review. Ann Prosthodont Rest Dent. 2016;2:101–4. [Google Scholar]

- 4.Shillingberg HT, Hobo S, Whitsett L, Jacobi R, Brackett SE. Fundamentals of Fixed Prosthodontics. 3rd ed. Chicago: Quintessenence; 1997. [Google Scholar]

- 5.Fransson B, Oilo G, Gjeitanger R. The fit of metal-ceramic crowns, a clinical study. Dent Mater. 1985;1:197–9. doi: 10.1016/s0109-5641(85)80019-1. [DOI] [PubMed] [Google Scholar]

- 6.McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131:107–11. doi: 10.1038/sj.bdj.4802708. [DOI] [PubMed] [Google Scholar]

- 7.Assif D, Rimer Y, Aviv I. The flow of zinc phosphate cement under a full-coverage restoration and its effect on marginal adaptation according to the location of cement application. Quintessence Int. 1987;18:765–74. [PubMed] [Google Scholar]

- 8.Hung SH, Hung KS, Eick JD, Chappell RP. Marginal fit of porcelain-fused-to-metal and two types of ceramic crown. J Prosthet Dent. 1990;63:26–31. doi: 10.1016/0022-3913(90)90260-j. [DOI] [PubMed] [Google Scholar]

- 9.Quante K, Ludwig K, Kern M. Marginal and internal fit of metal-ceramic crowns fabricated with a new laser melting technology. Dent Mater. 2008;24:1311–5. doi: 10.1016/j.dental.2008.02.011. [DOI] [PubMed] [Google Scholar]

- 10.Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: Laser-sintered Co-Cr crowns. J Prosthet Dent. 2009;102:253–9. doi: 10.1016/S0022-3913(09)60165-7. [DOI] [PubMed] [Google Scholar]

- 11.Park JK, Lee WS, Kim HY, Kim WC, Kim JH. Accuracy evaluation of metal copings fabricated by computer-aided milling and direct metal laser sintering systems. J Adv Prosthodont. 2015;7:122–8. doi: 10.4047/jap.2015.7.2.122. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Bhaskaran E, Azhagarasan NS, Miglani S, Ilango T, Krishna GP, Gajapathi B, et al. Comparative evaluation of marginal and internal Gap of Co-Cr copings fabricated from conventional wax pattern, 3D printed resin pattern and DMLS tech: An in vitro study. J Indian Prosthodont Soc. 2013;13:189–95. doi: 10.1007/s13191-013-0283-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Harish V, Ali SA, NJ, Ifthikar M, Senthil S, Basak D, et al. Evaluation of internal and marginal fit of two metal ceramic system – In vitro study. J Clin Diagn Res. 2014;8:ZC53–6. doi: 10.7860/JCDR/2014/10372.5300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Colaco C, Prasad K, Hegde C. A comparative assessment of marginal fit and marginal microleakage in copings obtained by laser metal sintering and conventional casting technique: An in vitro study. Scholars J Dent Sci. 2016;3:88–94. [Google Scholar]

- 15.Phillips RW, Biggs DH. Distortion of wax patterns as influenced by storage time, storage temperature, and temperature of wax manipulation. J Am Dent Assoc. 1950;41:28–37. doi: 10.14219/jada.archive.1950.0145. [DOI] [PubMed] [Google Scholar]

- 16.Schwartz IS. A review of methods and techniques to improve the fit of cast restorations. J Prosthet Dent. 1986;56:279–83. doi: 10.1016/0022-3913(86)90003-x. [DOI] [PubMed] [Google Scholar]

- 17.Nesse H, Ulstein DM, Vaage MM, Øilo M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J Prosthet Dent. 2015;114:686–92. doi: 10.1016/j.prosdent.2015.05.007. [DOI] [PubMed] [Google Scholar]

- 18.Ullattuthodi S, Cherian KP, Anandkumar R, Nambiar MS. Marginal and internal fit of cobalt-chromium copings fabricated using the conventional and the direct metal laser sintering techniques: A comparative in vitro study. J Indian Prosthodont Soc. 2017;17:373–80. doi: 10.4103/jips.jips_88_17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Abduo J, Lyons K, Bennamoun M. Trends in computer-aided manufacturing in prosthodontics: A review of the available streams. Int J Dent. 2014;2014:783948. doi: 10.1155/2014/783948. [DOI] [PMC free article] [PubMed] [Google Scholar]