Abstract

Bamboo macromolecules were pretreated with bamboo vinegar, which has an antibacterial property, and processed into antibacterial bioboard (ABB) by hot pressing. The ABB was then analyzed by conducting Fourier-transform infrared spectroscopy, thermogravimetric analysis and differential thermal analysis. Results showed that ABB samples had average density of 1.0 g/cm3, which is appropriate for application. The physical and mechanical properties were best for the ABB sample pretreated with bamboo vinegar and hot pressed at 165 °C for 10 min. Fourier-transform infrared spectroscopy revealed that the optimum conditions for hot pressing were a temperature of 165 °C, duration of 10 min, and the addition of bamboo vinegar. Thermogravimetric analysis/differential thermal analysis curves indicated that the thermal degradation of the ABB was less than that of bamboo, revealing that hot pressing increased the thermal stability of ABB samples. Analysis revealed that pretreatment with bamboo vinegar improved the antibacterial property of the ABB.

Keywords: Bamboo vinegar, Bamboo macromolecule, Antibacterial bioboard, Fourier-transform infrared spectroscopy, Thermogravimetric analysis/differential thermal analysis

1. Introduction

Bamboo is a renewable bio resource if the cycle of its plantation and use is not deliberately destroyed. Pyrolyzing bamboo under oxygen-limited conditions produces bamboo charcoal (Zhao et al., 2008, Xia and Li, 2016). Bamboo vinegar (BV) is a brown-red transparent liquid produced during the pyrolysis of bamboo charcoal and contains more than 200 chemical components, such as acetic acid, phenolic compounds, alkane compounds, alcohol compounds and aldehyde compounds, among which acetic acid is the main component. Nowadays, bamboo charcoal is used to adsorb Pb2+, Cu2+, Zn2+and other ions from water in the removal of environmental pollutants (Mizuta et al., 2004). Meanwhile, BV has also attracted great attention and the commercial production of BV in China is increasing. Because of the acetic acid and phenolic compound contents, BV has various effective uses; e.g., it is used as a natural insecticide, natural fungicide, soil disinfectant, compost fermenting agent, plant growth regulator and microorganism activator (Kartal et al., 2004, Liu and Liu, 2010, Gao et al., 2017). Currently, not enough is known enough about the structural transformations that occur during hot pressing and it is therefore not possible to improve important technologies for industrial production.

With the emergence of wood-based panels, there is increasing public demand for self-binding bio boards that can be produced without the large emission of formaldehyde and that can be made antibacterial (Liu et al., 2014). Self-binding bio boards are a class of bamboo-based panels with bamboo fiber bound together without urea formaldehyde resin under heat and pressure (Shao et al., 2008). Self-binding bio boards have been improved by activating the bamboo fibers before hot pressing (Lin et al., 2015, Mi et al., 2014). With the strong market demand for bio boards, a critical task is to find the self-binding mode of fibers and groups of fibers during hot pressing. Furthermore, it is important to make full use of BV such that bio boards have an antibacterial function. An antibacterial bio board (ABB) was thus prepared by hot pressing, and its properties were examined by conducting Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA) and differential thermal analysis (DTA).

2. Materials and methods

2.1. Experimental materials

Bamboo was collected from the Jinggangshan Forest region in China. The bamboo was then dried in air and crushed to the 20–60 mesh range (denoted B0). Industrial BV, a by-product of charcoal production from bamboo, was obtained from Jinggangshan Charcoal Co., China. The BV comprised 80–90% water, 7–11% organic acids, 6–8% phenols, 0.8–1% ketones, and 1–3% other substances. Potato dextrose agar medium, acetic acid and water used as reagents in the experiments were all analytical grade (Liu, 2012).

2.2. Experimental methods

2.2.1. ABB preparation

A 686-g quantity of bamboo powder was treated with 6860 ml BV at room temperature for 10–30 min, and dried at 90 °C for 16 h and stored at 15 °C. According to an orthogonal test method of the response surface (described in Table 1), the 686 g of treated bamboo powder was paved in the hand and processed into a 350 mm × 350 mm × 7 mm ABB by hot pressing with pressure of 3.5 MPa. The physical and mechanical properties were obtained according to Chinese standards for particleboard (GB/T 4897–2015).

Table 1.

Hot pressing parameters and results of ABB samples.

| No. | Hot press temperature (°C) | Time (min) | Pretreatment time (min) | MOR (MPa) | MOE (MPa) | TS (N) | IB (MPa) | ρ (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| B1 | 165 | 15 | 20 | 4.47 | 1036.67 | 23.17 | 0.04 | 0.63 |

| B2 | 165 | 15 | 20 | 3.47 | 727.25 | 21.33 | 0.05 | 0.99 |

| B3 | 150 | 20 | 20 | 1.91 | 340.00 | 12.00 | 0.05 | 0.33 |

| B4 | 165 | 20 | 30 | 10.16 | 1919.50 | 64.00 | 0.06 | 0.84 |

| B5 | 180 | 20 | 20 | 5.26 | 1429.00 | 33.13 | 0.04 | 0.83 |

| B6 | 165 | 20 | 10 | 5.79 | 1249.25 | 36.50 | 0.05 | 0.95 |

| B7 | 150 | 15 | 10 | 7.18 | 1364.50 | 45.25 | 0.3 | 0.99 |

| B8 | 150 | 15 | 30 | 5.34 | 1100.25 | 33.63 | 0.14 | 1.03 |

| B9 | 180 | 15 | 10 | 10.66 | 2105.00 | 67.13 | 0.51 | 1.03 |

| B10 | 165 | 15 | 20 | 4.66 | 1105.00 | 29.38 | 0.43 | 0.89 |

| B11 | 165 | 15 | 20 | 3.33 | 855.25 | 21.00 | 0.06 | 0.87 |

| B12 | 165 | 10 | 30 | 7.38 | 1196.00 | 46.50 | 0.15 | 1.00 |

| B13 | 165 | 10 | 10 | 11.88 | 1846.25 | 74.88 | 0.83 | 1.28 |

| B14 | 180 | 10 | 20 | 9.62 | 2157.00 | 60.63 | 0.03 | 0.95 |

| B15 | 150 | 10 | 20 | 3.06 | 683.15 | 19.25 | 0.03 | 0.87 |

| B16 | 165 | 15 | 20 | 12.10 | 1966.25 | 76.25 | 0.06 | 1.12 |

| B17 | 180 | 15 | 30 | 12.58 | 2058.75 | 79.25 | 0.24 | 0.99 |

2.2.2. FT-IR analysis

FTIR spectra of the samples were obtained using an FTIR spectrophotometer (IR100) and KBr discs containing 1.00% finely ground sample.

2.2.3. TGA/DTG analysis

Each sample was analyzed using less than 10 mg of powder (Atta et al., 2017). Thermogravimetric spectra were measured from room temperature to 750 °C using a TG20 thermal gravimetric analyzer (209-F1 TG, Netzsch, Germany) and a carrier gas (N2) velocity of 40 mL/min. The heating rate was 20 °C/min.

2.2.4. Antimicrobial effect

The antimicrobial effect of ABB samples was measured according to the inhibition zone (Wen et al., 2013, Jin et al., 2016).

3. Results and discussion

The static bending strength (MOR), elastic modulus (MOE), thickness swelling rate (TS), internal bond strength (IB) and density (ρ) were measured; values are given in Table 1.

3.1. Physical and mechanical properties of ABB

It is often desirable for bioboard to have ρ of 0.6–0.3 g/cm3. Table 1 shows that ABB samples had ρ of 0.63–1.23 g/cm3 and average density of 1.0 g/cm3. The density of the ABB was thus appropriate. According to analysis and data statistics, effects of various factors on physical and mechanical properties of the ABB are shown in Fig. 1. For RBVPT = 5.43 > RTemperature = 5.19 > RTime = 2.30, the BV pretreatment time significantly affected the MOR of the ABB. The MOR of the ABB decreased and then increased with increasing BV pretreatment time, increased with the rise in temperature and decreased with the extension of time (Viju et al., 2013). For RTemperature = 1101.59 > RRBVPT = 695.36 > RTime = 246.42, the temperature significantly affected the MOE of the ABB. The MOE of the ABB followed the same trend as the MOR. For RRBVPT = 0.37 > RTime = 0.23 > RTemperature = 0.09, the BV pretreatment time significantly affected the IB of the ABB. The trend of the IB of the ABB was the same as that of the MOR. For RBVPT = 34.22 > RTemperature = 32.74 > RTime=14.52, the BV pretreatment time significantly affected the TS of the ABB. The TS of the ABB followed the same trend as the MOR. The best ABB sample was produced from BV and bamboo by hot pressing at a temperature of 165 °C for 10 min.

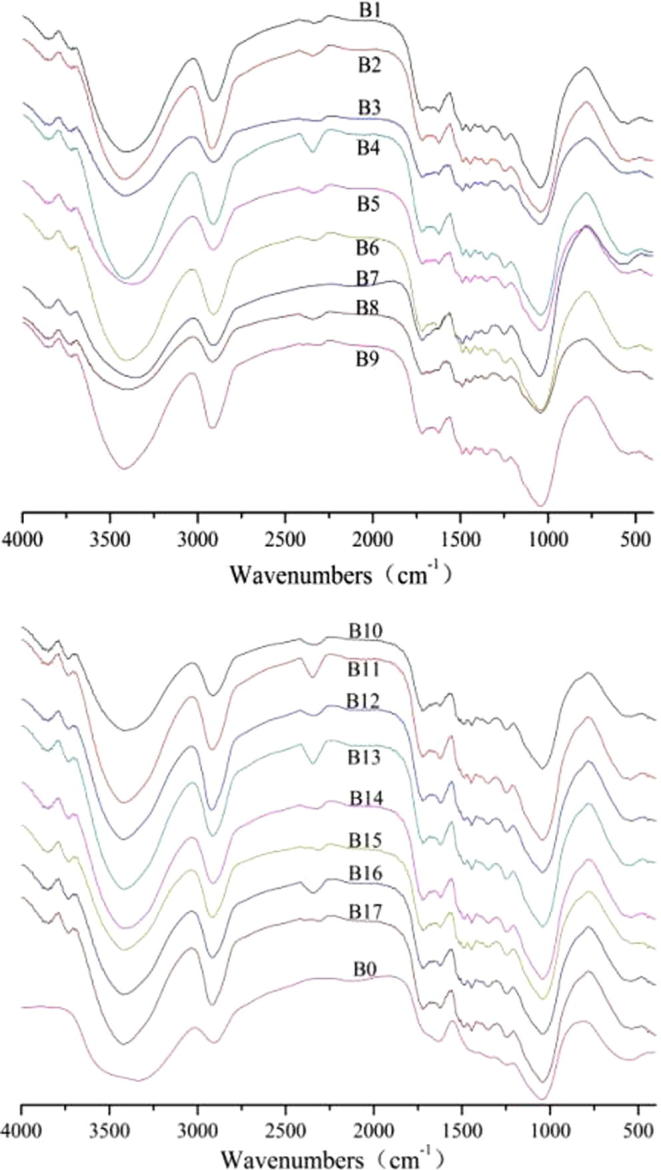

Fig. 1.

FT-IR spectra of bamboo and ABB.

3.2. FT-IR analysis

FTIR spectra were taken to study the structural groups of bamboo and MDBLB. For comparison, the spectra of the samples described above are shown in Fig. 1. For the bamboo, O—H stretching, —C—H stretching, unconjugated C O stretching, C C stretching, C—C (in-ring) stretching, aromatic ring C—H stretching, C—H bending stretching, C—C stretching, methylene C—H stretching and C—I stretching are visible at 3430, 2920, 1716, 1605, 1500, 1431, 1360, 1241, 1043 and 569 cm−1, respectively. All spectra had similar patterns except for the different intensities of infrared absorptions. The most intense bands (1716, 1500, 1431 and 1360 cm−1) represent aromatic regions of BV. The transmitted intensities of all peaks in ABB were greater than those of the bamboo sample. This suggests that hot pressing enrichens the groups at 150, 165 and 180 °C. As the hot-press temperature increased from 150 to 165 °C, the transmitted intensities of all peaks increased gradually. As the hot-press temperature increased from 165 to 180 °C, the transmitted intensities of all peaks did not change greatly. The groups were thus enriched as the temperature increased. As the hot-press time increased from 10 to 20 min at a hot-press temperature of 165 °C, the transmitted intensities of peaks at 3430, 2920, 1716, 1605, 1500, 1431, 1360, 1241, 1043 and 569 cm−1 first decreased and then increased; i.e., a hot-press time of 10 or 20 min provided better results. As the hot-press temperature increased from 150 to 180 °C for a hot-press time of 10 min, the transmitted intensities of peaks at 3430, 2920, 1716, 1605, 1500, 1431, 1360, 1241, 1043 and 569 cm−1 increased gradually, demonstrating that the hot-press temperature of 165 °C gave the best results. As the hot press temperature increased from 150 to 180 °C for a hot-press time of 20 min, the transmitted intensities of peaks at 3430, 2920, 1716, 1605, 1500, 1431, 1360, 1241, 1043 and 569 cm−1 first increased and then decreased, again demonstrating that the hot-press temperature of 165 °C is preferred. In particular, the transmitted intensities of all peaks of the B13 sample are the greatest. According to the changes of groups, the optimum conditions for hot pressing are a temperature of 165 °C, duration of 10 min and the addition of BV.

3.3. TGA/DTG analysis

ABB is used widely in many applications in which it is exposed to high temperature, and its thermal stability is thus important. A controlled hot N2 environment was used to measure the loss of mass of bamboo and ABB by oxidation, dehydration, hydration, reduction and decomposition (Ishaq and Jafri, 2017). Samples B1, B4, B9, B13, B16 and B0 were used for TGA between room temperature and 750 °C. The TGA and differential thermogravimetry curves are shown in Fig. 2. Thermal degradation of the three samples proceeded over a wide temperature range (100–745 °C). At 5.00% and 60.00% mass loss, the decomposition temperature was respectively 250 and 362 °C for the B0 sample. At 8.00% and 70.00% mass loss, the decomposition temperature was respectively 300 and 371 °C for the B9 sample and 308 and 372 °C for the B16 sample. At 15.00% and 70.00% mass loss, the decomposition temperature was respectively 256 and 370 °C for the B1 sample. At 8.00% and 75.00% mass loss, the decomposition temperature was respectively 306 and 373 °C for the B13 sample. At 8.00% and 60.00% mass loss, the decomposition temperature was respectively 255 and 365 °C for the B4 sample. These results suggest that the thermal degradation of B0, B4, B1, B9, B13 and B16 increased gradually at 5.00%, 8.00% and 15.00% mass loss and that the thermal degradation of B0, B4, B1, B9, B16 and B13 increased gradually at the 60.00%, 70.00% and 75.00% mass loss. The thermal degradation of ABB was thus worse than that of bamboo. However, at the maximum temperature of 745 °C, the mass loss was 72.80%, 75.20%, 90.30%, 83.20%, 89.30% and 78.30% for B0, B1, B4, B9, B13 and B16, respectively, showing that the thermal degradation of ABB was less than that of bamboo. At 100 °C, the mass loss was 2.20%, 4.40%, 0.30%, 2.20%, 2.20% and 2.20% for B0, B1, B4, B9, B13 and B16 samples, respectively, showing that bamboo and ABB samples were not very different (Muhammad et al., 2017).

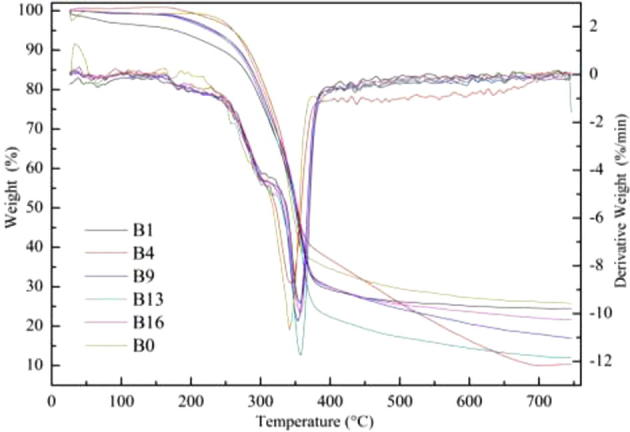

Fig. 2.

TGA/DTG curves of bamboo and ABB.

The DTA curves present mass loss rates, with DTGmax being the maximum thermal degradation rate, which can be used to estimate the degree of thermal degradation. The DTGmax values were 342, 344, 358, 355, 358 and 358 °C for B0, B1, B4, B9, B13 and B16, respectively (Sarfraz et al., 2017). A comparative analysis reveals that the thermal stabilities of B0, B4, B1, B9, B13 and B16 increased gradually and that hot pressing obviously increased the thermal stability of ABB samples.

3.4. Antimicrobial effect analysis

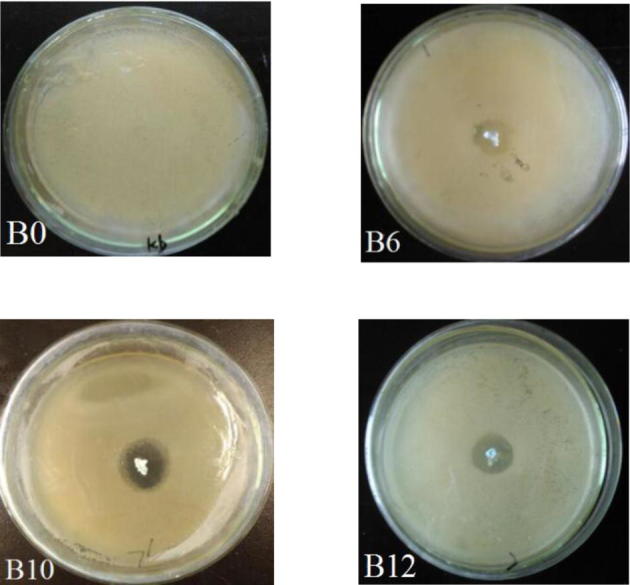

In applications, bioboard is easily destroyed by insects and bacteria, and greatly reduced. To enhance the antibacterial effect of ABB, bamboo was treated with BV and then hot pressed to make ABB. The characteristics of the inhibition zone of ABB for bacteria growth were observed and are listed in Fig. 3.

Fig. 3.

Antimicrobial effect of bamboo and ABB.

Fig. 3 shows that the diameters of the inhibition zone for B0, B6, B10 and B12 samples were 0, 11, 12 and 12.5 mm, respectively, while the diameters for B0, B6, B10 and B12 were all 5 mm. The antibacterial diameters of the inhibition zones of B0, B6, B10 and B12 samples were calculate as 0, 6, 7 and 7.5 mm, respectively (Xu, 2017). The antibacterial property of ABB therefore improved obviously when the bamboo was treated with BV. The antibacterial property of ABB was best for the bamboo pretreated with BV for 30 min. BV pretreatment therefore improves the antibacterial effect of ABB.

4. Conclusion

Bamboo macromolecules were pretreated with BV and ABB was made by hot pressing. The properties of ABB were obtained and analyzed by FTIR, TGA and DTA. ABB samples had ρ of 0.63–1.28 g/cm3, with average density of 1.0 g/cm3. This density of ABB was appropriate for application. Furthermore, the best ABB sample made from BV and bamboo macromolecules was obtained by hot pressing at a temperature of 165 °C for 10 min. According to the changes of groups, the optimum conditions for hot pressing were a temperature of 165 °C, duration of 10 min and the addition of BV. TGA/DTA revealed that the thermal degradation of ABB was less than that of bamboo. Hot pressing therefore obviously increased the thermal stability of ABB samples. Analysis showed that ABB had a good antibacterial property.

Acknowledgments

This research was supported by the Planned Science and Technology Project of Hunan Province, China (Nos. 2016SK2089; 2016RS2011), Major Scientific and Technological Achievements Transformation Projects of Strategic Emerging Industries in Hunan Province (2016GK4045), the Postgraduate's Technological and Innovative Project in Hunan Province of China (No. CX2016B321), and the Postgraduate's Technological and Innovative Project of Central South University of Forestry and Technology (No. CX2016B06).

Footnotes

Peer review under responsibility of King Saud University.

References

- Atta A., Mustafac G., Sheikh M.A., Shahid M., Xiao H. The biochemical significances of the proximate, mineral and phytochemical composition of selected vegetables from Pakistan. Matrix Sci. Pharma. 2017;1(1):06–09. [Google Scholar]

- Gao W., Wang Y., Basavanagoud B., Jamil M.K. Characteristics studies of molecular structures in drugs. Saudi Pharma. J. 2017;25(4):580–586. doi: 10.1016/j.jsps.2017.04.027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ishaq S., Jafri L. Biomedical importance of cocoa (Theobroma cacao): significance and potential for the maintenance of human health. Matrix Sci. Pharma. 2017;1(1):01–05. [Google Scholar]

- Jin J.W., Wu C., Qin D.C., et al. Decay resistance of bamboo oriented strand board pretreated with copper-based preservatives. Bioresources. 2016;11(1):1541–1553. [Google Scholar]

- Kartal S.N., Imamura Y., Tsuchiya F., Ohsato K. Evaluation of fungicidal and termiticidal activities of hydrolysates from biomass slurry fuel production from wood. Biores. Technol. 2004;95:41–47. doi: 10.1016/j.biortech.2004.02.005. [DOI] [PubMed] [Google Scholar]

- Lin Z., Ge S.B., Li D.L., Peng W.X. Structure characteristics of acidic pretreated fiber and self-bind bio-boards for public health. J. Pure. Appl. Microbiol. 2015;9:221–226. [Google Scholar]

- Liu C., Zhang Y., Wang S.Q., Meng Y.J., Hosseinaei O. Micromechanical properties of the interphase in cellulose nanofiber-reinforced phenol formaldehyde bondlines. Bioresources. 2014;9(3):5529–5541. [Google Scholar]

- Liu H.B., Liu Z.L. Recycling Utilization Patterns of Coal Mining Waste in China. Resour. Reserv. Recycl. 2010;12:1331–1340. [Google Scholar]

- Liu Z.L. The dynamic analysis of China's energy-economy-environment system: VAR and VEC modeling. Adv. Inf. Sci. Serv. Sci. 2012;4(14):210–218. [Google Scholar]

- Mi C., et al. A novel experimental teaching approach for electrical engineering based on semi-physical simulation. World Trans. Eng. Technol. Educ. 2014;12(4):779–783. [Google Scholar]

- Mizuta K., Matsumoto T., Hatate Y., Nishihara K., Nakanishi T. Removal of nitrate-nitrogen from drinking water using bamboo powder charcoal. Biores. Technol. 2004;95:255–257. doi: 10.1016/j.biortech.2004.02.015. [DOI] [PubMed] [Google Scholar]

- Muhammad G., Rashid I., Firyal S., Saqib M. Successful treatment of idiopathic generalized subcutaneous emphysema in kajli a ram by large bore injection needle. Matrix Sci. Medica. 2017;1(1):01–02. [Google Scholar]

- Sarfraz M., Ashraf Y., Ashraf S. A Review: Prevalence and antimicrobial susceptibility profile of listeria species in milk products. Matrix Sci. Medica. 2017;1(1):03–09. [Google Scholar]

- Shao S.L., Wen G.F., Jin Z.F. Changes in chemical characteristics of bamboo (Phyllostachys pubescens) components during steam explosion. Wood. Sci. Technol. 2008;42(6):439–451. [Google Scholar]

- Viju N., Satheesh S., Vincent S. Antibiofilm activity of coconut (Cocos nucifera Linn.) husk fibre extract. Saudi J. Biol. Sci. 2013;20(1):85–91. doi: 10.1016/j.sjbs.2012.11.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wen J.L., Sun S.L., Xue B.L., Sun R.C. Quantitative structures and thermal properties of the birch lignins after ionic liquid-based biorefinery. J. Agric. Food Chem. 2013;61:635–645. doi: 10.1021/jf3051939. [DOI] [PubMed] [Google Scholar]

- Xia J., Li G. Cross layer transmission of advanced orbiting systems. J. Mech. Eng. Res. Dev. 2016;39(4):889–896. [Google Scholar]

- Xu L. Study on PC continuous girder mechanical properties based on tendon tensioning pattern. Acta Mech. Malaysia. 2017;1(1):16–20. [Google Scholar]

- Zhao R.S., Yuan J.P., Jiang T., Shi J.B., Cheng C.G. Application of bamboo charcoal as solid-phase extraction adsorbent for the determination of atrazine and simazine in environmental water samples by high-performance liquid chromatography–ultraviolet detector. Talanta. 2008;76:956–959. doi: 10.1016/j.talanta.2008.04.029. [DOI] [PubMed] [Google Scholar]