Abstract

Employing the antibacterial property of industrial bamboo vinegar (IBV) and the photocatalytic degradation of TiO2, bamboo macromolecules were pretreated and processed into nonvolatile and antibacterial bio board (NVABB). The NVABB was then analyzed by conducting Fourier-transform infrared spectroscopy, thermogravimetric analysis and differential thermal analysis. Results show that NVABB samples had average density of 0.96 g/cm3, which is appropriate for application. In terms of physical and mechanical properties, the best NVABB sample obtained from IBV, TiO2 and bamboo had an IBV pretreatment time of 10 min, 2% TiO2 and 1% bamboo charcoal. Fourier-transform infrared spectroscopy demonstrated that optimum conditions for hot pressing were a temperature of 170 °C, duration of 15 min and the addition of IBV and TiO2. Thermogravimetric analysis/differential thermal analysis curves suggest that the thermal degradation of NVABB was less than that of bamboo and that hot pressing obviously increased the thermal stability of HDBB samples. Analysis of the antimicrobial effect revealed that IBV pretreatment improves the antibacterial property of NVABB.

Keywords: Industrial bamboo vinegar, Nonvolatile and antibacterial bio board, Bamboo macromolecules, Fourier-transform infrared spectroscopy, Thermogravimetric analysis/differential thermal analysis

1. Introduction

Bamboo is a renewable resource that has many advantages, such as its fast growth, easy update and high strength. Bamboo is often used to produce building materials and absorbent materials (Ali et al., 2017). The heating of bamboo at temperatures of 600–900 °C creates bamboo charcoal. The specific surface area and adsorption properties of bamboo charcoal increase obviously when bamboo charcoal is activated by TiO2, which is a white solid or powder that is often used as a catalyst and antiseptic. Bamboo charcoal can consume much bamboo biomass and waste, and its production benefits the environment by reducing the amount of pollutant residue. During the preparation of a charcoal adsorption material, pyrolyzing bamboo will produce large amounts of bamboo vinegar (BV), which is a brown–red transparent liquid that contains many chemical components, such as acetic acid and phenolic compounds (Mu et al., 2013). Nowadays, bamboo charcoal is used to adsorb Pb2+, Cu2+ and other ions from water in the removal of environmental pollutants (Mizuta et al., 2004, Wang et al., 2008). However, there is insufficient use of BV despite its sterilization function in treating bio pesticides. At a time that there is strong demand for green products, the use of vinegar is favored.

With the emergence of bamboo-based panels, there is increasing public demand for a self-binding bio board that is produced without high formaldehyde emissions and that has an antibacterial function (Juan et al., 2008, Sun et al., 2014). A self-binding bio board is a class of bamboo-based panels with bamboo fiber bound together without urea formaldehyde resin under heat and pressure (Jin et al., 2016, Tong, 2016, Qi et al., 2016, Gao et al., 2017). The self-binding bio board was improved by activating bamboo fibers before hot pressing. With strong market demand for bio boards, it is critical to find the self-binding mode of fibers and groups of fibers during hot pressing. There is a need to make full use of BV, bamboo charcoal and TiO2 in producing bio boards that are environmentally friendly and antibacterial. The present studyprepared a nonvolatile and antibacterial bio board(NVABB) by hotpressing, and examined its propertiesby conducting Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), and differential thermal analysis (DTA).

2. Material and methods

2.1. Experimental materials

Bamboo was collected from the Jinggangshan Forest region in China. The bamboo was then dried in air and crushed to the 20–60 mesh level (denoted S0). Bamboo charcoal and industrial bamboo vinegar (IBV), a by-product of charcoal production from bamboo, was obtained from Jinggangshan Charcoal Co., China. The bamboo charcoal was then dried in air and crushed to the 20–60 mesh level. The IBV comprised 80–90% water, 7–11% organic acids, 6–8% phenols, 0.8–1% ketones and 1–3% other materials. Potato dextrose agar medium, acetic acid, TiO2 and water used as reagents in the experiments were all analytical grade.

2.2. Experimental methods

2.2.1. NVABB preparation

A 686-g quantity of bamboo powder was treated with 6860 ml IBV at room temperature for 10–30 min, and dried at 90 °C for 16 h and stored at 15 °C. The content of bamboo charcoal was 1–5% of the charcoal powder by weight while the content of TiO2 was 1–3% of the bamboo charcoal by weight. According to an orthogonal test method of the response surface (described in Table 1), the 686 g of treated bamboo powder, TiO2 and bamboo charcoal were paved in the hand and processed into a high-density complex bamboo bioboard (NVABB) with dimensions of 350 mm × 350 mm × 7 mm by hot pressing at a pressure of 3.5 MPa and a temperature of 170 °C for 15 min. The physical and mechanical properties were obtained according to Chinese standards for particleboard (GB/T 4897–2015).

Table 1.

Hot pressing parameters and results of NVABB samples.

| No. | bamboo charcoal (%) | TiO2 (%) | Pretreatment time (min) | MOR (MPa) | MOE (MPa) | TS (N) | IB (MPa) | ρ (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| S1 | 3 | 3 | 10 | 3.07 | 729.67 | 20.33 | 0.04 | 0.91 |

| S2 | 1 | 1 | 20 | 3.89 | 1054.75 | 24.50 | 0.11 | 0.82 |

| S3 | 3 | 1 | 10 | 7.06 | 1563.50 | 44.50 | 0.25 | 0.88 |

| S4 | 3 | 2 | 20 | 7.06 | 1492.25 | 44.50 | 0.07 | 1.08 |

| S5 | 5 | 2 | 30 | 9.19 | 1428.00 | 57.88 | 0.08 | 1.00 |

| S6 | 3 | 2 | 20 | 4.81 | 1259.25 | 30.88 | 0.42 | 0.92 |

| S7 | 5 | 3 | 20 | 5.77 | 1228.50 | 36.38 | 0.19 | 0.95 |

| S8 | 5 | 2 | 10 | 7.10 | 1312.00 | 44.75 | 0.21 | 0.98 |

| S9 | 3 | 1 | 30 | 3.29 | 954.25 | 20.75 | 0.3 | 0.83 |

| S10 | 1 | 3 | 20 | 7.46 | 1708.00 | 47.00 | 0.1 | 0.96 |

| S11 | 5 | 1 | 20 | 5.71 | 1522.25 | 36.00 | 0.08 | 0.92 |

| S12 | 1 | 2 | 10 | 8.88 | 1285.25 | 56.00 | 0.42 | 1.00 |

| S13 | 3 | 3 | 30 | 12.02 | 1938.50 | 75.75 | 0.14 | 1.06 |

| S14 | 3 | 2 | 20 | 2.56 | 880.00 | 16.13 | 0.09 | 0.80 |

| S15 | 3 | 2 | 20 | 8.19 | 1468.75 | 51.63 | 0.21 | 1.04 |

| S16 | 1 | 2 | 30 | 8.05 | 1326.75 | 50.75 | 0.18 | 1.03 |

| S17 | 3 | 2 | 20 | 5.52 | 1170.50 | 34.75 | 0.24 | 1.08 |

2.2.2. FTIR analysis

FTIR spectra ofsamples were obtained using an FTIR spectrophotometer (IR100) and KBr discs containing 1.00% finely ground sample (Xu et al., 2013).

2.2.3. TGA/DTA

Each sample was analyzed using less than 10 mg of powder. Thermogravimetric spectra were measured from room temperature to 750 °C using a TG20 thermal gravimetric analyzer (209-F1 TG, Netzsch, Germany) and a carrier gas (N2) velocity of 40 mL/min. The heating rate was 20 °C/min.

2.2.4. Antimicrobial effect

The antimicrobial properties of NVABB samples were obtained using the inhibition zone (Jin et al., 2016). The antimicrobial property was measured for the sample at 30 °C after 24 h.

3. Results and discussion

The static bending strength (MOR), elastic modulus (MOE), thickness swelling rate (TS), internal bond strength (IBS) and density (ñ) were measured; values are given in Table 1.

3.1. Physical and mechanical properties of NVABB

High-density bioboard is often desired to have ρ of 0.8–1.0 g/cm3. Table 1 shows that NVABB samples had ρ of 0.82–1.08 g/cm3 and average density of 0.96 g/cm3. The density of NVABB was thus appropriate for practical application. Analysis and statistics show that the physical and mechanical properties of NVABB gradually decreased as the BV pretreatment time prior to hot pressing increased, that they first increased and then decreased as the proportion of TiO2 increased, and that they gradually increased as the proportion of bamboo charcoal increased (Mustafa et al., 2017). The best physical and mechanical properties of NVABB were obtained for 3% bamboo charcoal, 2% TiO2 and a BV pretreatment time of 20 min; in this case, the MOR, MOE, FL, IBS and ρ were respectively 4.81 MPa, 1259.25 MPa, 30.88 N, 0.42 MPa and 0.92 g/cm3. The best physical and mechanical properties of NVABB were obtained for 1% bamboo charcoal, 2% TiO2 and a BV pretreatment time of 10 min; in this case, the MOR, MOE, FL, IBS and ρ were respectively 8.88 MPa, 1285.25 MPa, 56.00 N, 0.42 MPa and 1.00 g/cm3. In summary, an appropriate BV pretreatment time and appropriate amounts of bamboo charcoal and TiO2 are important parameters in the preparation of fine NVABB.

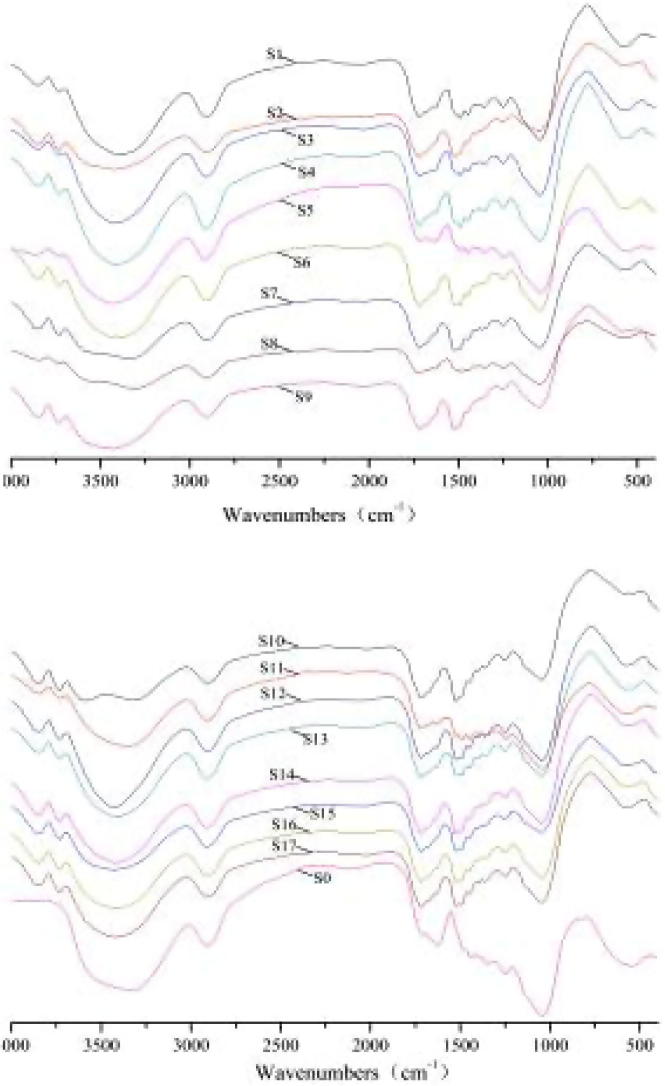

3.2. FT-IR analysis

FTIR spectra were taken to study the structural groups of bamboo and NVABB. For comparison, the spectra of the samples described above are shown in Fig. 1. For bamboo and NVABB, O—H stretching, —C—H stretching, unconjugated C O stretching, C—C (in-ring) stretching, C—C stretching, methylene C—H stretching and C—I stretching are visible at 3411, 2900, 1721, 1512, 1244, 1047 and 555 cm−1, respectively (Xu et al., 2013, Kalpana et al., 2016). All spectra of NVABB had similar spectral patterns except for different intensities of infrared absorptions. The most intense bands at 1721 and 1512 cm−1 represented aromatic regions of BV. The transmitted intensities of all peaks in NVABB were greater than those of bamboo. This suggests that the BV pretreatment time enrichens the groups. As the BV pretreatment time increased from 10 to 30 min, the transmitted intensities of all peaks did not change greatly, showing that the groups were enriched with increasing BV pretreatment time (Samad et al., 2017). As the bamboo charcoal content increased from 1% to 5% for a BV pretreatment time of 10 min, the transmitted intensities of peaks at 3411, 2900, 1721, 1512, 1244, 1047 and 555 cm−1 first decreased and then increased, indicating that 1% or 3% bamboo charcoal is preferred. As the TiO2 content increased from 1% to 3% for 1% bamboo charcoal, the transmitted intensities of peaks at 3411, 2900, 1721, 1512, 1244, 1047 and 555 cm−1 increased gradually, demonstrating that 2% TiO2 is preferred. As the TiO2 content increased from 1% to 3% for 3% bamboo charcoal, the transmitted intensities of peaks at 3411, 2900, 1721, 1512, 1244, 1047 and 555 cm−1 first decreased and then increased, demonstrating that 2% TiO2 is preferred. The transmitted intensities of all peaks were greatest for sample S12. According to the changes of groups, the optimum conditions for hot pressing are a BV pretreatment time of 10 min, 1% bamboo charcoal and 2% TiO2.

Fig. 1.

FT-IR spectra of bamboo and NVABB.

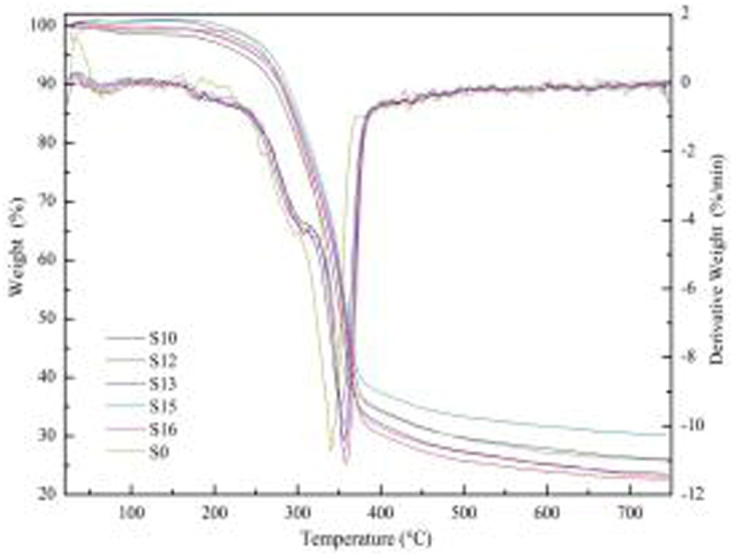

3.3. TGA/DTG analysis

NVABB is used widely in many applications where it is exposed to high temperature, and its thermal stability is thus important. Bamboo and NVABB mass losses due to oxidation, dehydration, hydration, reduction and decomposition were measured in a controlled hot N2 environment (Xuana et al., 2017). Samples S10, S12, S13, S15, S16 and S0 were selected for TGA between room temperature and 750 °C. The TGA and differential thermogravimetry curves are shown in Fig. 2. Thermal degradation of the three samples proceeded over a wide temperature range (100–745 °C). At 3.00% and 62.00% mass loss, the decomposition temperature was respectively 246 and 365 °C for sample S0. At 7.00% and 70.00% mass loss, the decomposition temperature was respectively 303.5 and 374.7 °C for sample S10 and 313.5 and 373.8 °C for S16. At 6.00% and 72.50% mass loss, the decomposition temperature was respectively 313.7 and 375.2 °C for S12. At 5.50% and 69.20% mass loss, the decomposition temperature was respectively 314 and 376 °C for S13. At 3.00% and 65.00% mass loss, the decomposition temperature was respectively 310 and 375 °C for S15. The results indicate that the thermal degradation of S0, S15, S13, S12, S10 and S16 increased gradually at 3.00%, 5.50%, 6.00% and 7.00% mass loss and that the thermal degradation of S0, S15, S13, S10, S16 and S12 increased gradually at 62.00%, 65.00%, 69.20%, 70.00% and 72.50% mass loss. The thermal degradation of NVABB was thus better than that of bamboo. At the maximum temperature of 745 °C, the mass loss was 72.80%, 69.80%, 77.40%, 74.00%, 76.50% and 77.10% for S0, S10, S12, S13, S15 and S16, respectively, meaning that NVABB thermally degraded less than bamboo. At 100 °C, the mass loss was 1.20%, 1.60%, 0.30%, 0.00%, 0.00% and 0.30% for S0, S10, S12, S13, S15 and S16, respectively, meaning that the bamboo and NVABB samples were not very different.

Fig. 2.

TGA/DTG curves of bamboo and NVABB.

The DTA curves present mass loss rates, with DTGmax being the maximum thermal degradation rate, which can be used to estimate the degree of thermal degradation. DTGmax values were 342, 351, 358, 352, 353 and 353 °C for S0, S10, S12, S13, S15 and S16, respectively (Zhenga et al., 2017). A comparative analysis indicated that the thermal stabilities of S0, S10, S13, S15, S16 and S12 increased gradually and that hot pressing obviously increased the thermal stability of NVABB samples.

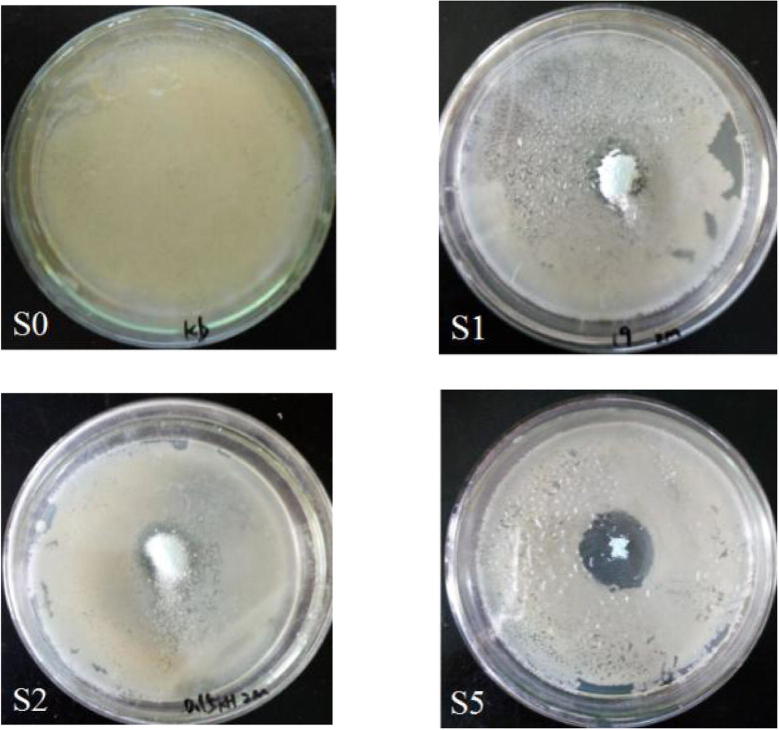

3.4. Antimicrobial effect analysis

In applications, bio board is easily destroyed by insects and bacteria, and greatly reduced. To enhance the antibacterial property of NVABB, bamboo was treated with IBV prior to the production of NVABB by hot pressing. The characteristics of the inhibition zone of NVABB in terms of bacteria growth were observed and are presented in Fig. 3.

Fig. 3.

Antimicrobial effect of bamboo and NVABB.

Fig. 3 shows that the diameters of the inhibition zones for S0, S1, S2 and S5 were respectively 0, 16, 19 and 22 mm, while the diameters for S0, S1, S2 and S5 were all 5 mm. The antibacterial diameters of inhibition zones of S0, S1, S2 and S5 samples were calculated as 0, 11, 14 and 17 mm, respectively. The antibacterial property of NVABB thus improved obviously when the bamboo was treated by IBV. Accordingly, the best antibacterial property of NVABB was achieved by pretreating the bamboo with IBV for 30 min. IBV pretreatment thus improves the antibacterial property of NVABB.

4. Conclusion

Bamboo, IBV, bamboo charcoal and TiO2 were used to make NVABB by hot pressing. The properties of NVABB were obtained and analyzed by FTIR, TGA and DTA. HDBB samples had ρ of 0.82–1.08 g/cm3, and average density of 0.96 g/cm3. The density of NVABB was thus appropriate for application. Furthermore, the best NVABB sample made from IBV, bamboo charcoal and TiO2 was obtained by hot pressing at 170 °C for 15 min with a BV pretreatment time of 10 min using 1% bamboo charcoal and 2% TiO2. According to the changes of groups, optimum conditions for hot pressing were a temperature of 170 °C, duration of 15 min and the addition of IBV, bamboo charcoal and TiO2. TGA/DTG analysis revealed that the thermal degradation of NVABB was less than that of bamboo and that hot pressing obviously increased the thermal stability of NVABB samples. Analysis of the antimicrobial effect showed that IBV pretreatment improves the antibacterial property of NVABB. Comprehensive comparative analysis thus illustrated that bamboo charcoal, TiO2 and IBV from pyrolyzing bamboo are suitable for producing NVABB.

Acknowledgments

This research was supported by the Planned Science and Technology Project of Hunan Province, China (Nos. 2016SK2089; 2016RS2011), Major scientific and technological achievements transformation projects of strategic emerging industries in Hunan Province (2016GK4045), the Postgraduate's Technological and Innovative Project in Hunan Province of China (No. CX2016B321), and the Postgraduate's Technological and Innovative Project of Central South University of Forestry and Technology (No. CX2016B06).

Footnotes

Peer review under responsibility of King Saud University.

Contributor Information

Wanxi Peng, Email: pengwanxi@163.com.

Tay Cai, Email: pengwanxi@163.com.

References

- Ali S., Ali R., Iftikhar A. Physico-chemical and microbiological assessment of some freshwater aquifers and associated diseases in district ghizer, gilgit-baltistan, Pakistan. Acta Sci. Malaysia. 2017;1(1):08–12. [Google Scholar]

- Gao W., Wang Y., Basavanagoud B., Jamil M.K. Characteristics studies of molecular structures in drugs. Saudi Pharm. J. 2017;25(4):580–586. doi: 10.1016/j.jsps.2017.04.027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin J.W., Wu C., Qin D.C., et al. Decay resistance of bamboo oriented strand board pretreated with copper-based preservatives. Bioresources. 2016;11(1):1541–1553. [Google Scholar]

- Juan R.V., Esteban R., David C., Juanita F., Jaime R. Fiberboard manufactured without resin using the fenton reaction. J. Chil. Chem. Soc. 2008;53(4):1722–1725. [Google Scholar]

- Kalpana J., Rao P.S., Rao P.G. Influence of amplitude on the tensile strength of welded joints fabricated under vibratory weld conditioning. J. Mech. Eng. Res. Develop. 2016;39(3):757–762. [Google Scholar]

- Mizuta K., Matsumoto T., Hatate Y., Nishihara K., Nakanishi T. Removal of nitrate-nitrogen from drinking water using bamboo powder charcoal. Bioresour. Technol. 2004;95(3):255–257. doi: 10.1016/j.biortech.2004.02.015. [DOI] [PubMed] [Google Scholar]

- Mu J., Uehara T., Furuno T. Effect of bamboo vinegar on regulation of germination and radicle growth of seed plants. J. Wood. Sci. 2013;49(3):262–270. [Google Scholar]

- Mustafa G., Arif R., Atta A., Sharif S., Jamil A. Bioactive compounds from medicinal plants and their importance in drug discovery in Pakistan. Matrix Sci. Pharma. 2017;1(1):17–26. [Google Scholar]

- Qi L.Q., Cai Y.Y., Wang C.D. An improved ANN model and its application in industrial convergence efficiency evaluation: Taking equipment manufacture industry and producer services as example. J. Mech. Eng. Res. Develop. 2016;39(4):1082–1087. [Google Scholar]

- Samad N.S.A., Amid A., Jimat D.N., Shukor N.A.Ab. Isolation and identification of halophilic bacteria producing halotolerant protease. GaleriWarisanSains. 2017;1(1):07–09. [Google Scholar]

- Sun Y.C., Lin Z., Peng W.X., et al. Chemical changes of raw materials and manufactured binder less boards during hot pressing: lignin isolation and characterization. Bioresources. 2014;9(1):1055–1071. [Google Scholar]

- Tong Z.G. Brief analysis sludge disposal and resource utilization of purification plant. J. Mech. Eng. Res. Develop. 2016;39(4):975–979. [Google Scholar]

- Wang S.Y., Tsai M.H., Lo S.F., Tsai M.J. Effects of manufacturing conditions on the adsorption capacity of heavy metal ions by Makino bamboo charcoal. Bioresour. Technol. 2008;99(15):7027–7033. doi: 10.1016/j.biortech.2008.01.014. [DOI] [PubMed] [Google Scholar]

- Xu G., Wang L., Liu J., Wu J. FT-IR and XPS analysis of the changes in bamboo chemical structure decayed by white-rot and brown-rot fungi. Appl. Surf. Sci. 2013;280(8):799–805. [Google Scholar]

- Xuana G., Zhenga H., Xiaoyua S., Jua L., Sheng W.N. A Two-dimensional lattice Boltzmann method for compressible flows. Acta Mech. Malaysia. 2017;1(1):04–07. [Google Scholar]

- Zhenga H., Xuana G., Xiaoyua S., Jua L., Sheng W.B. An efficient pseudo-potential multiphase lattice Boltzmann simulation model for three-dimensional multiphase flows. Acta Mech. Malaysia. 2017;1(1):08–10. [Google Scholar]