Abstract

Bone is the second most commonly transplanted tissue worldwide, with over four million operations using bone grafts or bone substitute materials annually to treat bone defects. However, significant limitations affect current treatment options and clinical demand for bone grafts continues to rise due to conditions such as trauma, cancer, infection and arthritis. Developing bioactive three-dimensional (3D) scaffolds to support bone regeneration has therefore become a key area of focus within bone tissue engineering (BTE). A variety of materials and manufacturing methods including 3D printing have been used to create novel alternatives to traditional bone grafts. However, individual groups of materials including polymers, ceramics and hydrogels have been unable to fully replicate the properties of bone when used alone. Favourable material properties can be combined and bioactivity improved when groups of materials are used together in composite 3D scaffolds. This review will therefore consider the ideal properties of bioactive composite 3D scaffolds and examine recent use of polymers, hydrogels, metals, ceramics and bio-glasses in BTE. Scaffold fabrication methodology, mechanical performance, biocompatibility, bioactivity, and potential clinical translations will be discussed.

Keywords: Bioactive composites, 3D scaffold, 3D printing, Bioprinting, Bone, Tissue engineering

Graphical abstract

Highlights

-

•

This review will examine recent use of polymers, hydrogels, metals, ceramics and bio-glasses in bone tissue engineering..

-

•

3D scaffold biofabrication, biocompatibility, bioactivity, mechanical properties and clinical translation will be discussed.

-

•

3D printing and 3D bioprinting offer hope for patient-specific, cost-effective and reproducible treatment in the future.

1. Introduction

1.1. Clinical demand for bone grafts, bone substitutes & implants

The capacity for bone to self-regenerate has prompted study and intrigue since the times of Hippocrates and Galen [1]. Despite this, congenital and acquired pathologies including trauma, infection, neoplasm and failed arthroplasty remain capable of leaving patients with bone defects beyond a critical-size which the body cannot heal. Such patients often require invasive surgical intervention to aid healing. This can involve clinical use of bone grafts, bone substitute materials, growth factors, free fibula vascularized grafts and insertion of metalwork to aid stability and bone regeneration [2], [3]. As a result, bone is the second most commonly transplanted tissue worldwide, with at least four million operations making use of bone grafts and bone substitute materials annually [4], [5], [6].

However, significant limitations affect current treatment options. Bone grafts taken from one part of a patient for use in their own body (autografts) are considered the gold standard but are restricted by the size of graft that can be harvested and carry a further risk of donor site morbidity including infection and ongoing pain following surgery [7], [8]. Allograft tissue harvested from cadaveric and living sources (such as femoral heads removed during hip replacements) is in relatively greater supply compared to autograft tissue. However, allografts carry potential risk of disease transmission and immune response, whilst lacking a cellular component to aid tissue regeneration. Metalwork and bone substitutes can also be inserted to aid bone regeneration; limitations associated with their use include bone thinning due to stress shielding, wear and failure over time and risk of revision surgery [6]. Non-invasive therapies including ultrasound treatment have also show promise in aiding bone healing, although use is often restricted to stable, well aligned and well reduced fracture non-unions in adult patients [9].

To overcome the limitations of current treatment options, significant research in the field of bone tissue engineering (BTE) has been directed towards creating novel alternatives to traditional bone grafts. Porous 3D scaffolds fabricated through a variety of methods and including a range of biomaterials have been utilised to aid and direct bone regeneration [10], [11], [12]. However, the perfect scaffold material has yet to be encountered and clinical translation of 3D scaffolds has been limited as a result [13].

Bone is a heterogenous composite material with constituents including hydroxyapatite mineral (Ca10(PO4)6(OH)2) [14], a mixed organic component (type I collagen, lipids and non-collagenous proteins) and water [15], [16]. During scaffold manufacture it would therefore seem logical to include a combination of materials to create a composite scaffold, potentially allowing greater scaffold bioactivity and structural biomimicry to be achieved.

Scaffold bioactivity is also increased by incorporating materials that possess the ability to interact with or bind to living tissues. Increased scaffold bioactivity can in turn lead to improved bone cell ingrowth (osteoconduction), stable anchoring of scaffolds to host bone tissue (osseointegration), stimulation of immature host cells to develop into osteogenic cells (osteoinduction) and increased vascularisation [17], [18], [19], [20].

This review will therefore examine some of the significant bioactive composites that have been utilised recently in BTE after reference to the properties of an ideal scaffold and available scaffold manufacturing methods. 3D scaffolds that have successfully bridged bone defects whilst actively inducing bone regeneration will be highlighted.

2. Properties of an ideal scaffold

In general terms, the ideal 3D scaffold is composed of a biocompatible, biodegradable material with similar mechanical properties to the tissue which it is to be implanted in. Scaffolds by design are not intended to be permanent implants and will ideally facilitate host cells to deposit extracellular matrix (ECM) and replace the scaffold structure over time. The 3D architecture of the scaffold should be highly porous with an interconnected structure to allow cell and nutrient migration. The scaffold surface should also be optimised to facilitate cell attachment, proliferation and differentiation (see Table 1). Form a surgical point of view, it is also desirable for the scaffold material to be easily manipulated into different shapes and sizes to allow in-situ treatment of individual patient bone defects [13], [21], [22], [23].

Table 1.

Summary of desirable scaffold properties.

| Scaffold Characteristics | Desirable Features |

|---|---|

| Biocompatibility |

|

| Biodegradability |

|

| Bioactivity |

|

| Scaffold Architecture |

|

| Mechanical Properties |

|

Scaffolds and their breakdown products must above all be biocompatible. This requires scaffold materials to be nontoxic to cells, easily eliminated from the body and to elicit negligible immune response through their presence [11], [24], [25]. Controlled biodegradability is also an essential characteristic for a scaffold to achieve; if a scaffold degrades too quickly, mechanical failure could occur. This is particularly relevant in BTE, as an implanted scaffold is likely to undergo load-bearing and could fracture if unable to provide mechanical support whilst new bone is forming. Similarly, if a scaffold does not degrade sufficiently quickly an inflammatory response could be triggered towards the foreign material of the scaffold, impairing tissue regeneration [26].

Growth factors also have a significant role to play in successful bone tissue engineering scaffolds. The processes of new bone formation and extracellular matrix deposition are regulated by a range of growth factors and biomolecules. Bone morphogenic proteins (BMP) play a critical role in bone and cartilage development, and have the ability to trigger proliferation and differentiation of osteoprogenitor cells [27]. There are several examples of scaffolds that have successfully incorporated BMPs resulting in improved bone formation. However, risk of bone formation within soft tissues, or heterotopic ossification, is also associated with use of BMPs [28], [29], [30], [31], [32]. Vascular endothelial growth factor (VEGF) has also frequently been included in scaffolds, with desirable properties including the ability to enhance blood vessel formation and bone formation in vivo [33], [34], [35]. Transforming growth factor β (TGF β), platelet-derived growth factor (PDGF), insulin-like growth-factor 1 (IGF-1), and fibroblast growth factors (FGFs) provide further examples of growth factors that have been utilised in bone and cartilage tissue engineering [36], [37].

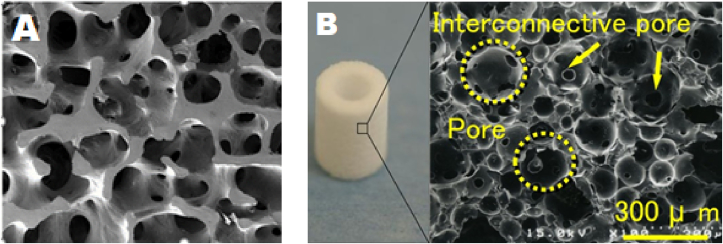

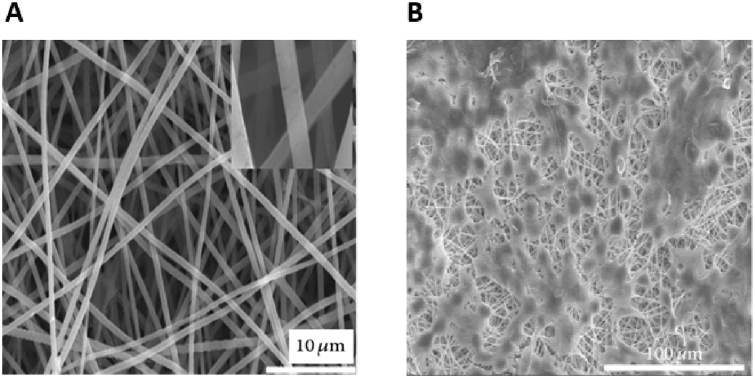

The microarchitecture of scaffolds is also centrally important in encouraging cell viability and fostering tissue ingrowth. An interconnected pore structure, in the absence of an engineered blood supply, allows inwards diffusion of oxygen and nutrients and outwards diffusion of waste products from the scaffold. Porosity also supports cell migration into the scaffold and improves available surface area for cell-scaffold binding and interaction with surrounding tissues [38], [39], [40] (Fig. 1A and B). Individual pore size within the scaffold is also an important consideration. It has previously been shown that scaffold pore density and size significantly impact upon cellular growth and attachment [41], [42]. As pore size decreases, the surface area of the scaffold increases. This increases the availability of scaffold ligands for cells to bind to and interact with. However, if pore sizes become too small, cells may struggle to migrate into the scaffold structure. Scaffolds must therefore be precisely engineered with parameters favourable to the cells and tissue that they will be exposed to. For example, it has been shown that scaffolds implanted in vivo with pore sizes close to 300 μm promote osteogenesis due to higher permeability and potential for vascularisation, whereas smaller pore sizes closer to 100 μm are more favourable for chondrogenesis [43], [44], [45]. Increased scaffold macroporosity has also been shown to improve angiogenesis in vivo [46], whilst a degree of microporosity (pores with diameters lower than 10 μm) can improve cell-scaffold interactions, resulting in osteogenic effects [47], [48], [49]. Scaffolds for BTE therefore need to contain a mixture of macropores allowing cell and osteon ingrowth in vivo, and micropores to encourage cell-scaffold ligand interactions [50].

Fig. 1.

(A) SEM image showing interconnected porous structure of human trabecular bone (B) Pores and interconnecting pores demonstrated in hydroxyapatite scaffold. Pores are circled; arrows indicate interconnecting pores which allow communication between pores. Adapted from Doi et al. [51].

In addition to pore size and overall porosity, mechanoregulatory effects are thought to be key in influencing bone tissue growth and cellular differentiation in vivo. If a scaffold is unable to replicate the mechanical forces transferred to cells in physiological conditions, cells may be stimulated to differentiate away from an osteogenic lineage towards an undesirable morphology [52], [53], [54]. Selecting scaffold materials with similar stiffness to native bone would therefore seem advantageous [55], [56]. However, scaffold mechanical stiffness and porosity are directly conflicting physical properties, with mechanical strength inversely related to increasing scaffold porosity. In terms of load bearing, important scaffold mechanical properties include Young's modulus (also known as elastic modulus, a measure of the stiffness of a solid material), compressive strength (capacity of a scaffold to withstand loads tending to reduce size) and fatigue strength (the highest stress that a material can withstand for a given number of cycles without breaking) [11], [57], [58]. The ideal scaffold would have a compressive strength comparable to cortical bone, which along the long axis is approximately 100–230 MPa, with a Young's modulus close to 7–30 GPa and a tensile strength of 50–151 MPa [59], [60], [61], [62]. Ideally this compressive strength would be complemented by a porosity between 60% and 90% and an average pore size of >150 μm [63], [64].

Achieving a successful balance in vivo between the properties of a scaffold favourable to cellular function, cellular viability and mechanical integrity under load bearing therefore remains challenging [65], [66].

3. Scaffold fabrication methods

A large variety of techniques have been used in the fabrication of 3D scaffolds, sometimes in combination. In general, it is difficult to create complex scaffold microarchitectures with precise control using conventional techniques. However, the integration into BTE of 3D printing using computer-aided design (CAD) modelling has greatly increased scaffold manufacture precision and repeatability, with control over scaffold macro- and microporosity possible. The advantages and disadvantages of conventional scaffold manufacturing methods and more recent 3D printing techniques will therefore be discussed and summarized in this section (see Table 2).

Table 2.

Comparison of scaffold fabrication methods.

| Manufacturing Method | Benefits | Potential Limitations |

|---|---|---|

| Solvent casting/particulate leaching |

|

|

| Gas Foaming |

|

|

| Emulsification Freeze-Drying |

|

|

| Phase Separation |

|

|

| Electrospinning |

|

|

3D Printing

|

|

|

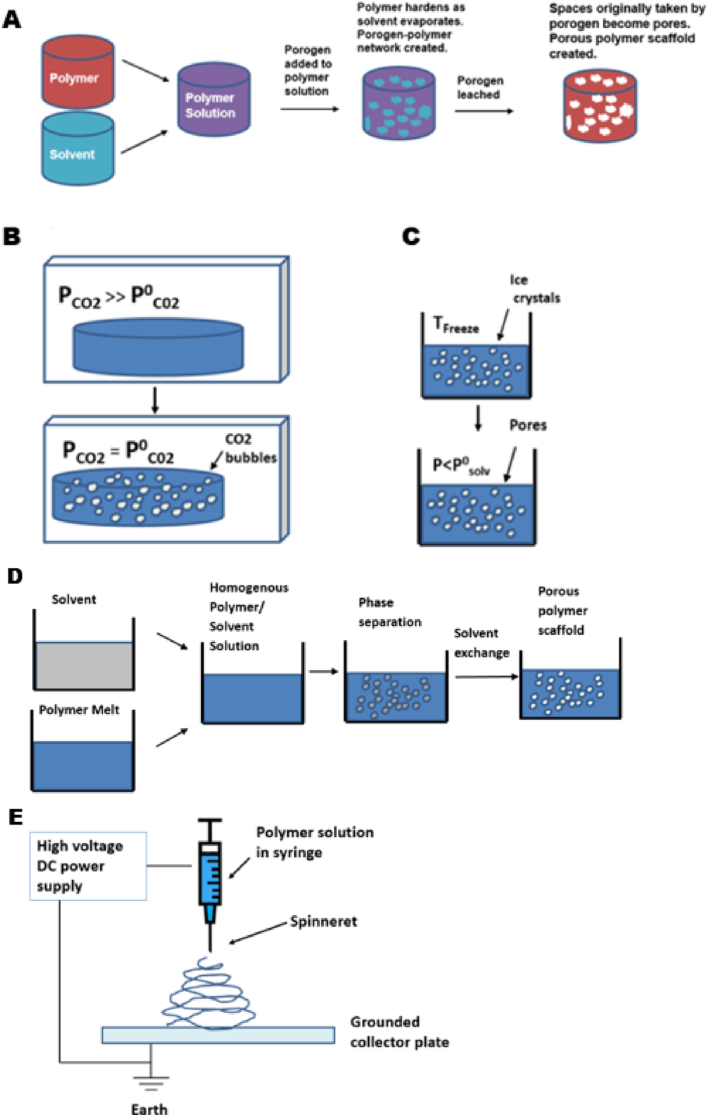

3.1. Conventional scaffold fabrication

Solvent casting/particulate leaching is a traditional method of scaffold manufacture that begins with dissolution of a polymer in an organic solvent (Fig. 2A). The technique uses porogens, substances that can be dispersed into a moulded structure and subsequently dissolved once the structure has set, resulting in the creation of pores. Porogens are added to the polymer solution to create a polymer-porogen network. The polymer is subsequently hardened as the solvent evaporates, with water then used to dissolve the porogen which is often a salt such as sodium chloride. A hardened polymer scaffold with a porous network is left behind, although it is difficult to control pore shape and pore interconnectivity of scaffolds produced by this method [67], [68].

Fig. 2.

Common scaffold fabrication techniques. (A) Solvent casting-particle leaching process (B) Gas foaming (C) Freeze-drying (D) Phase separation (E) Electrospinning. Adapted from Puppi et al. [71].

Gas foaming eliminates the use of solvents deployed in solvent casting/particulate leaching methods (Fig. 2B). This technique creates a porous structure through the nucleation and growth of gas bubbles dispersed throughout a polymer. Compression moulding is first used to create solid discs of a scaffold material, such as poly(lactic-co-glycolic acid), within a heated mould. Following this, the discs are saturated with carbon dioxide by exposure to high pressure CO2 gas (5.5 MPa) for 72 h at room temperature, before solubility of the gas in the polymer is rapidly decreased by reducing CO2 pressure to atmospheric levels (P0CO2). This causes the CO2 gas to clump together, creating pores. Porosities of up to 93% and pore sizes of up to 100 mm can be obtained using this technique. However, it is difficult to control pore connectivity and pore sizes by gas foaming [7], [68], [69], [70].

Freeze-drying begins with freezing of a polymer solution, resulting in the formation of solvent ice crystals surrounded by polymer aggregates (Fig. 2C). The surrounding pressure is then reduced via a vacuum, to a level lower than the equilibrium vapor pressure of the frozen solvent (P0). The solvent is thus triggered to undergo sublimation directly into gas from the solid phase. When the solvent is completely sublimated, a dry polymer scaffold with an interconnected porous structure remains. Emulsification freeze drying can also be used as a primary scaffold fabrication method. The process begins by dissolving polymers/ceramics in a solvent and then mixing with water, to obtain an emulsion. The mixture is poured into a mould and frozen before the two phases can separate. The frozen emulsion is then freeze-dried to remove the solvent and dispersed water, creating pores in a solidified scaffold [72].

Phase separation relies on changes in thermal energy to induce the de-mixing of a homogenous polymer/solvent solution. When a polymer such as PLLA is dissolved in a solvent, it can become thermodynamically unstable at a low temperature and spontaneously separate into a polymer-rich phase and a solvent-rich phase. Phase separation scaffold manufacture takes advantage of this phenomenon and begins with dissolution of a polymer in a high-boiling, low molecular weight solvent at an elevated temperature, typically around the melting point of the polymer, allowing formation of a homogenous melt-blend. The solution is then cast into a desired scaffold shape, and cooled in a controlled manner to induce phase separation and precipitation of the solution into a polymer-rich phase and a solvent-rich phase, creating a nanofibrous matrix (Fig. 2D). The solvent which is in the solvent-rich phase will then be removed through extraction, evaporation, or sublimation. This creates a porous scaffold, as removal of the solvent leaves pores behind in the polymer matrix.

Electrospinning is another popular scaffold fabrication technique with the ability to create nanofibrous interconnected porous scaffolds (Fig. 2E). This method uses an externally applied electric field to draw charged threads of polymer solutions or polymer melts as thin jets from a capillary tube towards a collector plate. Fibres in the micro- and nanometre range can be created and deposited sequentially to create a scaffold, with potential to include composite materials and biomolecules [73], [74], [75], [76].

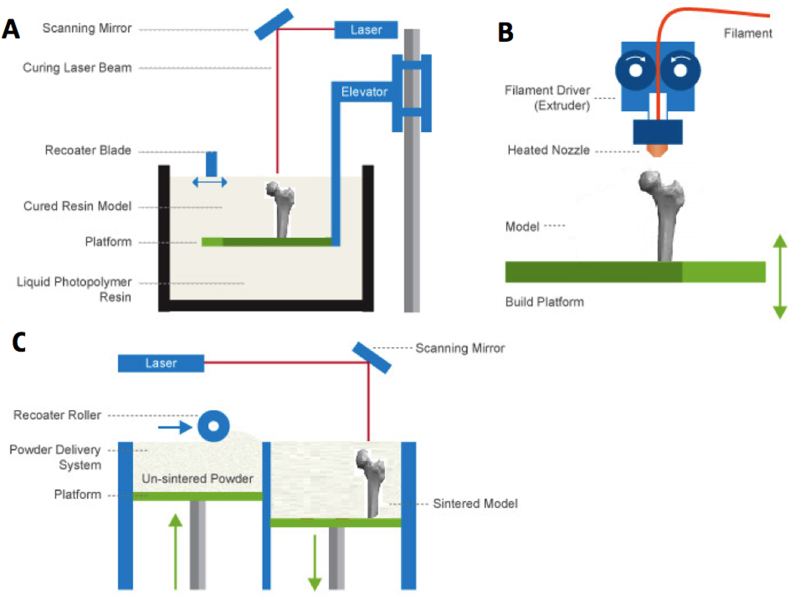

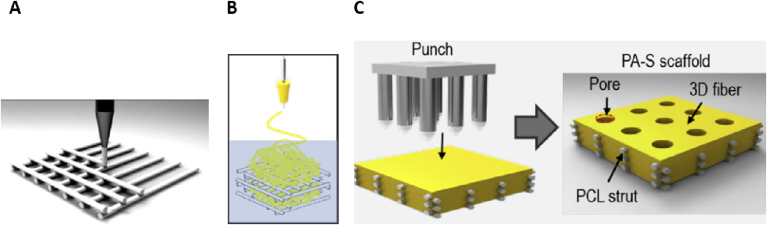

3.2. 3D printing techniques

The traditional methods of scaffold fabrication that have been discussed in brief so far generally offer limited control over pore size, geometry and interconnectivity. Overtime there has been an improvement in the ability to spatially control scaffold microarchitecture and spatial content as technologies such as 3D printing have emerged. In general, 3D printing fabricates objects via layer-by-layer processing of powder, liquid or solid material substrates. Starting from the bottom and building up, each newly formed layer is triggered to adhere to the previous layer, resulting in the creation of construct of gradually increasing size. The structure of a 3D printed object is dictated by a computer-aided design (CAD) model loaded onto a 3D printer. CAD models describe 3D objects in a series of cross-sectional layers, allowing 3D printers to physically reproduce models through an additive process.

Patient specific CAD models can be created by converting computed tomography (CT) or magnetic resonance imaging (MRI) of clinical defects into (CAD) models. Further software is then used to slice CAD models into G-code, which encodes 3D CAD models in a format that can control 3D printers. Parameters such as print speed, layer height, print head temperature and pressure can all be modified and optimised through G-code.

Several 3D printing methods have been adapted into BTE, with stereolithography (SLA) representing one of the earliest 3D printing techniques to have been developed (Fig. 3A).

Fig. 3.

Common 3D Printing Techniques. (A) Stereolithography (B) Fused deposition modelling (C) Selective laser sintering. Adapted from Jaster L [77].

It relies on the directed use of a laser to polymerize liquid UV-curable photopolymer resin layer-by-layer, resulting in a solidified 3D model. The UV laser can solidify the model's cross-section, leaving remaining areas in liquid form. After each cross-section, the print platform moves down, covering the solid polymer with another layer of resin for curing. Excess resin that has not been cured is then removed from the 3D structure, allowing rapid fabrication of a structure that can be cured further in an oven. Whilst SLA can quickly produce scaffolds with controlled architecture and micrometre-level resolution, there is a limited number of materials applicable to this costly technique [78].

Fused deposition modelling (FDM) uses a temperature controlled printhead to deposit thermoplastic material onto a platform in a layer by layer manner to build up a 3D construct (Fig. 3B). A thermoplastic filament is driven into a heated printhead, causing the filament to melt, allowing thin layers of a semi-molten polymer such as polycaprolactone to be precisely deposited sequentially. The molten filament cools in the air of the print environment, allowing filaments to fuse together rapidly to create a scaffold. FDM has been successfully adapted into BTE as method of producing synthetic scaffolds, although the elevated temperatures involved limit the inclusion of biomolecules and hydrogels [79], [80].

Selective laser sintering (SLS) involves the use of a computer controlled laser beam to fuse layer-upon-layer of a powder, sintering the powder material together to build a solid 3D structure (Fig. 3C). Some success with this technique has been demonstrated, through the production of bioactive, composite scaffolds with similar mechanical properties to trabecular bone [81], [82]. However, the elevated temperatures involved in the process limit the inclusion of cells and biomaterials directly into SLS scaffolds.

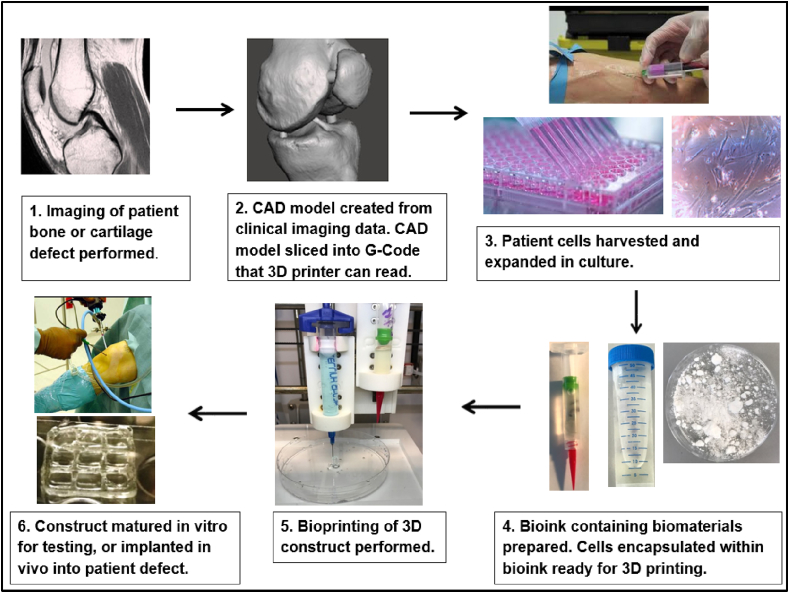

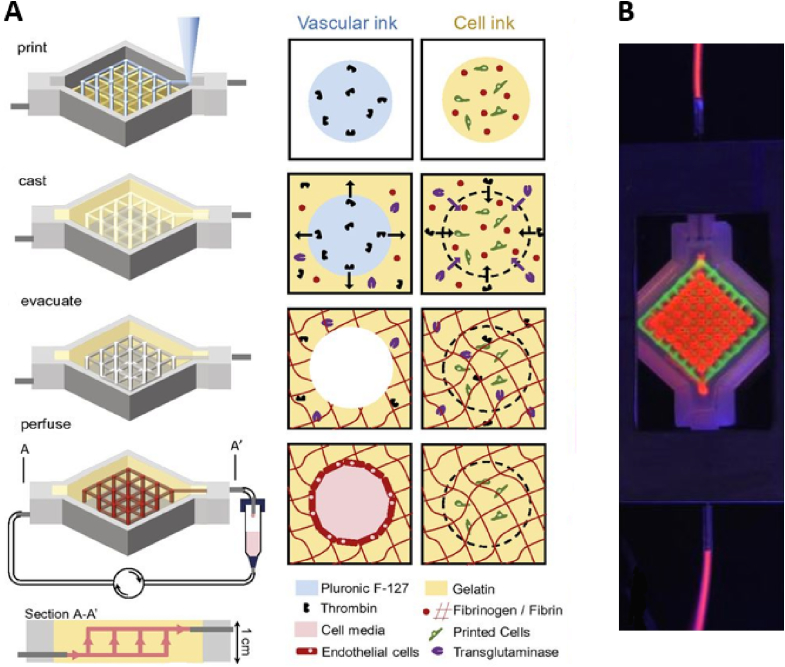

3.3. 3D bioprinting

As an emerging technology, 3D bioprinting offers a potential solution to help ease the burden of arthritis and other cause of bone defects within orthopaedics. Bioprinting can be used to deposit living cells, extracellular matrices and other biomaterials in user-defined patterns to build complex tissue constructs “from the bottom up.” The potential to create inherent vascular structures is also improved by bioprinting, as internal channels containing vascular cells can be printed into constructs, fostering the ingrowth of blood vessels in vivo. By contrast, the conventional tissue engineering method of seeding cells onto a pre-fabricated scaffold does not allow for precise 3D placement of cells or biological content, limiting capacity to create complex hierarchical tissue constructs [83], [84].

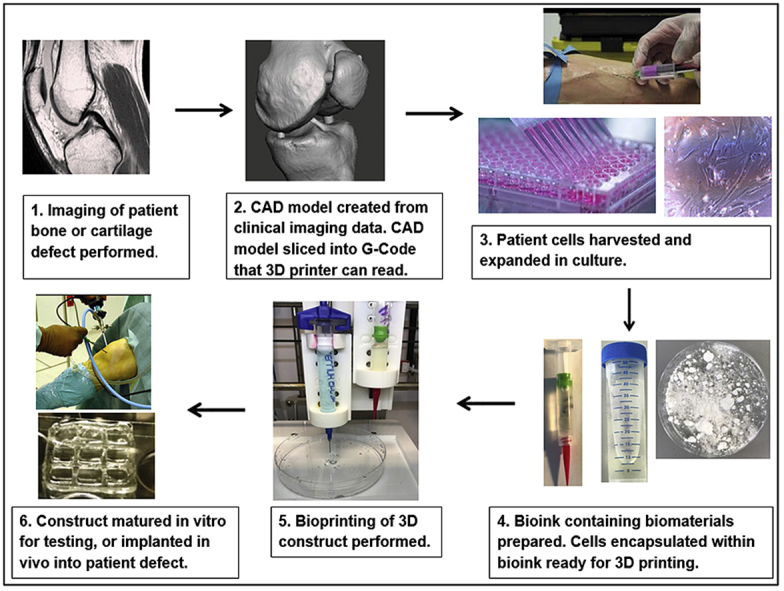

The process of bioprinting typically begins with the selection of cells and biomaterials for inclusion in bioprinted constructs (Fig. 4). Cells for printing can be sourced from tissue biopsies, blood samples and from other sources, and expanded in number through culture to maximise cell density on bioprinting. The additional step of 3D cell culture may also be performed to creating aggregates of cells for printing. Cell aggregates or spheroids have superior intercellular communication and extracellular matrix development when compared to cells grown in 2D culture, potentially accelerating the growth of printed constructs towards functional tissue after bioprinting [85]. Mesenchymal stem cell spheroids also exhibit enhanced in vitro and in vivo osteoregenerative potential compared to MSCs cultured in monolayer [86], [87].

Fig. 4.

Summary of bioprinting process.

Following culture, cells and selected biomaterials such as hydroxyapatite are encapsulated in a delivery medium, or bioink. Print cartridges containing bioink are then loaded into a 3D bioprinter, which dispenses the bioink in a pre-determined 3D geometry according to a CAD model. Bioprinters often have multiple print nozzles, allowing combinations of cells and biomaterials to be included within a printed construct. A high degree of spatial control can therefore be achieved over construct architecture and content [88], [89]. Following printing the construct can be directly implanted into a patient, or alternatively matured first in vitro. Biologically active culture environments known as bioreactors are available to help direct and support cell growth towards specific tissue types.

3.4. 3D bioprinting techniques

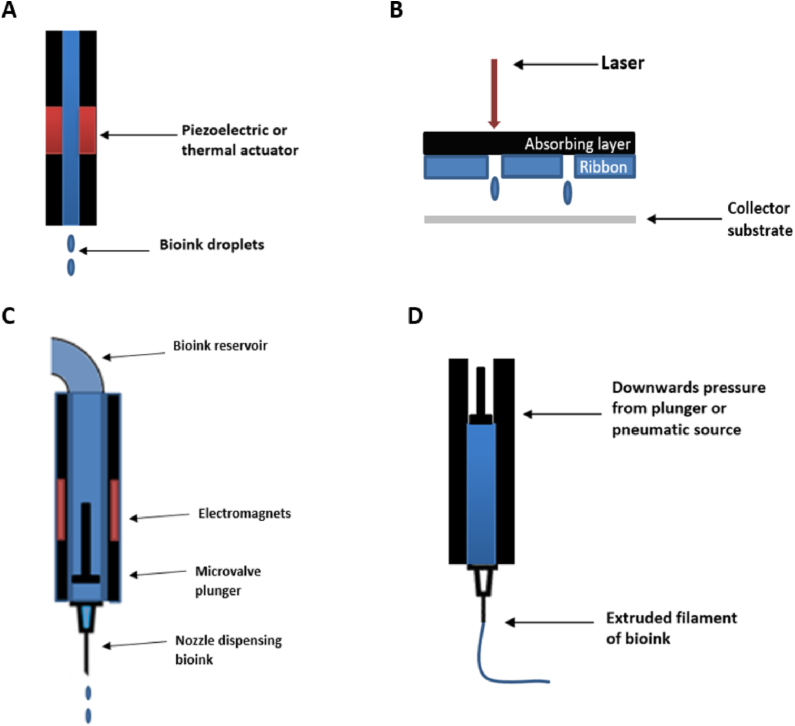

Commonly used bioprinting techniques include inkjet, laser-assisted, microvalve and extrusion bioprinting.

Inkjet bioprinting (or drop-on-demand bioprinting) uses thermal or acoustic forces to eject droplets from a pint head nozzle (Fig. 5A). Thermal inkjet printers use heat to generate a pressure pulse within a print head for a brief period, causing ejection of a droplet of bioink. Other systems rely on piezoelectric crystals, which become mechanically stressed by the application of a voltage and as a result change shape. This generates an acoustic wave which in turn creates sufficient pressure to eject droplets from a nozzle. As a technology adapted form desktop inkjet printers, benefits include low cost, wide availability and high print speed. However, limitations include frequent nozzle clogging, risk of exposing cells and materials to thermal and mechanical stress and nonuniform droplet size. The liquid droplet deposited is also of low viscosity, relying on further gelation or crosslinking to create a solid structure [90], [91], [92].

Fig. 5.

Common bioprinting techniques: (A) Inkjet, (B) Laser-assisted, (C) Microvalve, and (D) Extrusion bioprinting.

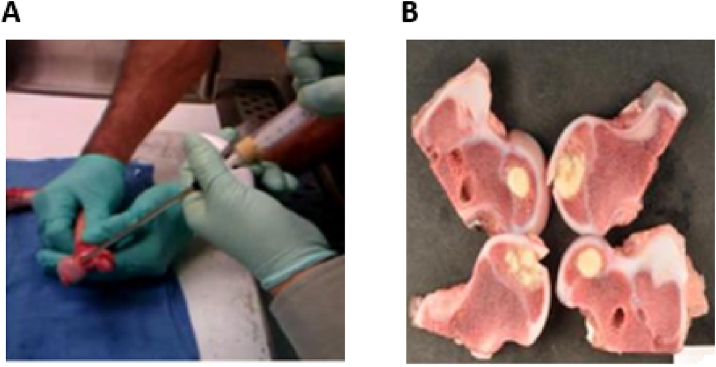

Laser-assisted bioprinting (LAB) systems avoid the use of a nozzle; instead they rely on a pulsed laser beam to generate a high-pressure bubble, which in turn propels cell-containing materials toward a collector substrate from an initial print material “ribbon” (Fig. 5B). Recently Keriquel et al. used LAB to print mesenchymal stromal cells, associated with collagen and nano-hydroxyapatite, directly in situ onto a mouse cranial defect to aid bone regeneration [93]. Some limitations of LAB include potential heat-induced damage to cells, difficulty of creating 3D structures, high system costs and the time-consuming nature of creating ribbons with high cell and biomaterial concentrations [94].

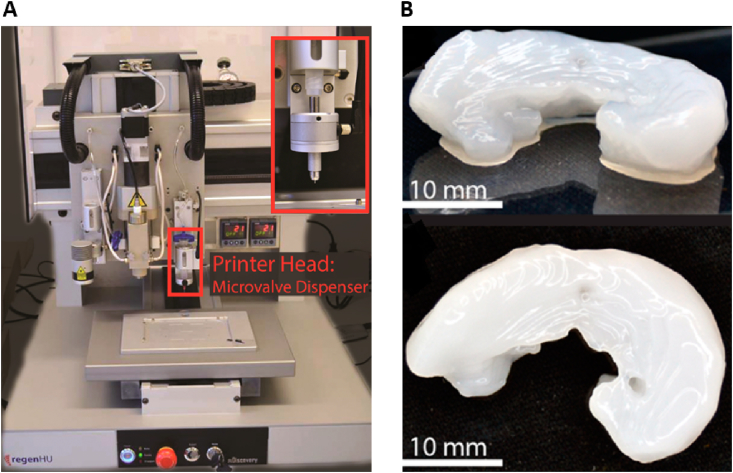

Microvalve bioprinting is a droplet-based system where fluids under a constant pneumatic pressure are dispensed from cartridge tips by opening and closing a small valve (Fig. 5C). The valve in question can be controlled mechanically, electrically or magnetically. Microvalve systems can print cells including MSCs with high viability and functionality, with deposition of other biomaterials also possible such as collagen and bone morphogenic protein [95], [96], [97].

Extrusion bioprinters deposit continuous filaments of materials rather than individual droplets (Fig. 5D). Pneumatic or mechanical pressure is applied to a syringe to cause bioink extrusion through a nozzle. A significant advantage of this approach is the ability to deposit very high cell densities, with some studies manging to purely print cells, for example as filaments of cartilage [98]. A broad range of bioinks have been successfully extrusion bioprintined, including tissue spheroids, tissue strands, cell pellets, decellularized matrix components and cell-laden hydrogels. Potential limitations and challenges include achieving high print resolution, shear stress effect on cells within print nozzles and development of printable bioinks [99].

4. Materials used within bone tissue engineering

Materials that have been utilised within bone repair and regeneration include metals, ceramics, polymers, hydrogels and related composites. Groups of materials will be reviewed in the following corresponding sections and summarized (see Table 3).

Table 3.

Comparison of scaffold materials.

| Manufacturing Material | Benefits | Potential Limitations |

|---|---|---|

| Hydrogels |

|

|

| Polymers |

|

|

| Ceramics |

|

|

| Bioactive glasses |

|

|

| Metals |

|

|

4.1. Metals

Metal alloys such as cobalt-chromium, zirconium, titanium and stainless steel have excellent biocompatibility and strength [21], [100]. As such, they are commonly used in joint replacement and fracture fixation implants to offer support for healing bone [101]. However, a lack of biodegradability makes them less suited to BTE where the aim is for native tissue to resorb and replace implanted constructs. Additional surgery is often required to remove metallic implants, particularly when they are used in paediatric patients who have not reached skeletal maturity [102]. The superior elastic modulus of metals relative to bone can also predispose to stress shielding occurring. In this phenomena, mechanical bypass of loads occurs in the bone surrounding implants, leading to bone resorption and increased fracture risk [103]. Despite these limitations, some success has been achieved through creation of composite metal scaffolds. Strontium (Sr) was combined via freeze-drying with hydroxyapatite (HA) and chitosan (CS) by Lei et al. to create composite nanohybrid scaffolds. The presence of SrHA nanocrystals in the scaffolds was found to significantly enhance cell proliferation and osteogenic differentiation of human bone marrow mesenchymal stem cells (hBMSCs) [104]. Hierarchical structure was developed by Wu et al. on a microporous nickel-titanium composite (NiTi) scaffold by treating the surface with sodium hydroxide in a hydrothermal reaction. This led to the creation of a nanostructured, microporous exposed surface on an already microporous NiTi scaffold. Improved surface hydrophilicity, deposition of hydroxyapatite, accelerated cell attachment and proliferation was seen in vitro as a result [105]. Titanium based scaffolds were also fabricated by Chen et al., who sintered microporous Ti spheres and Ti powder. Maximum porosity of 50% was achieved, with scaffold compressive strength reported to be up to 109 MPa. In vitro, the microporosity of the scaffolds helped promote attachment and growth of mesenchymal stem cells (MSCs) [106].

Chou et al. utilised 3D inkjet printing to create iron-magnesium (FeMg) composite scaffolds (Fig. 6). Following 3D printing, the FeMg constructs were found to have an open, porous structure with similar tensile mechanical properties to cancellous bone. In vitro analysis found good cell viability on exposure to the scaffolds, with cell infiltration into pores also seen [107].

Fig. 6.

SEM images of MC3T3 cells on the surface of 3D-printed Fe–Mg scaffold. White arrow denotes a cell–cell junction after one day; black arrows denote cellular extensions to pore walls after 3 days [107].

Selective laser sintering (SLS) is another 3D printing method that has used to successfully produce composite metallic scaffolds. Layer-upon-layer of a titanium powder and silica sol slurry were sintered by Liu et al. to produce composite titanium-silica scaffolds with complex geometry [108]. Scaffold compressive strength was increased by heat treatment post-fabrication, with significant human sarcoma cell (MG63) proliferation seen over 7 days. However, the significant heat involved in manufacturing metallic scaffolds using SLS and other methods limits the potential to directly include biomolecules. Attempts have therefore been made to coat the surface of metallic scaffolds with bioactive ceramics such as HA and calcium silicate [75].

Stainless steel, titanium and cobalt chromium alloys have all been combined using SLS and secondarily modified using phosphonic acid. This process results in the creation of a composite scaffold with a biocompatible phosphonic layer on the scaffold surface. Biomolecules and drugs including paracetamol and antibiotics have then been successfully deposited on scaffold phosphonic acid surfaces, improving bioactivity [109], [110].

4.2. Bioceramics

Bioceramics, including ceramic composites, amorphous glasses and crystalline ceramics, show great promise within BTE as mechanically strong materials, with favourable bioactivity [111]. Further material properties can include corrosion resistance, resistance to compression, and a weakness to shearing and tensile forces, resulting in brittleness [112].

Perhaps the most frequently utilised crystalline bioceramics in BTE are calcium phosphates (CaPs), partly due to their prevalence in native bone tissue [113]. Hydroxyapatite (HA), tricalcium phosphate (TCP) and a composite of both substances known as biphasic calcium phosphate (BCP) have all been adapted in BTE scaffolds. Cell mediated degradation of these ceramics in vivo produces calcium and phosphate ions, which promote new bone formation through osteoinduction [114], [115]. CaPs also share a large degree of similarity in structure and chemical composition to the mineral content of native bone. This allows CaP constructs to provide a biocompatible, osteoconductive interface capable of facilitating integration with host tissue without formation of scar tissue [116], [117].

HA has excellent properties for BTE, including biocompatibility, controlled degradation and lack of cytotoxicity. HA also has a strong compositional similarity to bone, with proven osteoinductive and osteoconductive properties allowing HA constructs to form a strong bond with surrounding bone [118], [119]. HA can also stimulate endogenous expression of osteogenic growth factors such as bone morphogenetic protein (BMP) and enhance alkaline phosphatase (ALP) activity in mesenchymal stem cells (MSCs). This is particularly important as ALP activity is pivotal in the early mineralization process associated with bone formation [120], [121], [122]. However, in common with other ceramics, HA has properties of being hard and brittle, which limits HA construct load-bearing and manipulation into shapes specific to individual bone defects. HA also has a slow degradation rate in vivo which can predispose to mechanical failure at implant sites [114], [119]. To overcome these mechanical limitations, HA has been combined with several naturally occurring and synthetic polymers to create composite scaffolds, as will be discussed later [17], [30], [123], [124], [125], [126], [127], [128], [129].

Dicalcium phosphate (DCP) has been used much less frequently than HA within BTE, due to weak, brittle mechanical properties and a high in vivo resorption rate [115]. Although DCP/synthetic polymer composites have been produced resulting in improved mechanical properties, success has been limited in comparison to HA and tricalcium phosphate based scaffolds with degradation rates difficult to control [130], [131], [132].

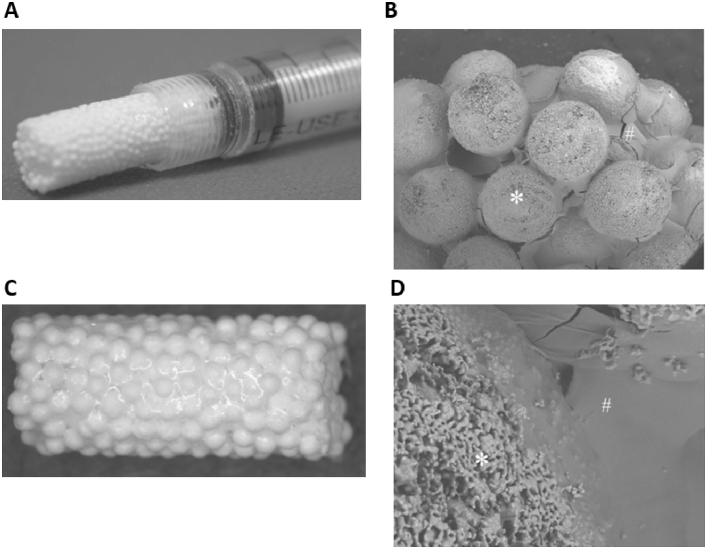

Tricalcium phosphate (TCP) is another popular bioceramic that has been adapted into BTE, with commercial products already available. Beta-TCP (β-TCP) beads have been combined with alginate gels to create injectable 3D scaffolds, capable of supporting in vivo osteogenic differentiation of MSCs [133] (Fig. 7). The β-TCP allotrope has also been combined with type I collagen to produce porous scaffolds with equivalent clinical performance to autografts in a spinal fusion model [134]. Nanocomposite TCP/collagen scaffold performance has also been compared favourably to HA scaffolds in vivo. Histologically advanced bone formation was found after 45 days in TCP/collagen scaffolds that had been implanted in a rabbit segmental femur bone defect, with superior results found compared to implanted HA scaffolds [135].

Fig. 7.

Photograph of injectable 3D-formed composite of β-TCP beads and alginate capable of triggering MSC osteogenic differentiation in vivo. (A) and light microscope photograph of the composite (B). SEM photographs of the composite (C) and surface of the composite (D). The composite was composed of β-TCP beads (∗) and alginate (#). Adapted from Matsuno et al. [133].

Tarafder and Bose 3D printed a TCP scaffold, with polycaprolactone (PCL) and alendronic acid coating (AL) of the scaffold performed post-fabrication [136]. It was found that in vivo local AL delivery from PCL-coated TCP scaffolds led to increased early bone formation compared to bare TCP and PCL coated TCP scaffolds.

A further study 3D printed a composite 3D TCP scaffold, with magnesium oxide and silicon dioxide doping incorporated into the scaffold design [137]. Significantly higher bone and blood vessel formation was seen in Mg and Si containing scaffolds compared to bare TCP controls in vivo. However, the hard material based scaffold lacked a soft niche to support neo-angiogenesis in vivo. This ultimately impaired integration of the construct into host rat tissue. Overall the results suggest that magnesium and silicon incorporated into 3DP TCP scaffolds could have potential for future bone tissue repair and regeneration.

Rakovsky et al. employed salt leaching to create a composite β-TCP and polylactic acid (PLA) scaffold. Composite scaffolds were produced with 50% porosity and a large pore size (300–420 μm), potentially favourable to BTE. Further analysis found a compressive strength of ∼5 MPa, comparable to trabecular bone, although in vivo cellular response was not assessed [138].

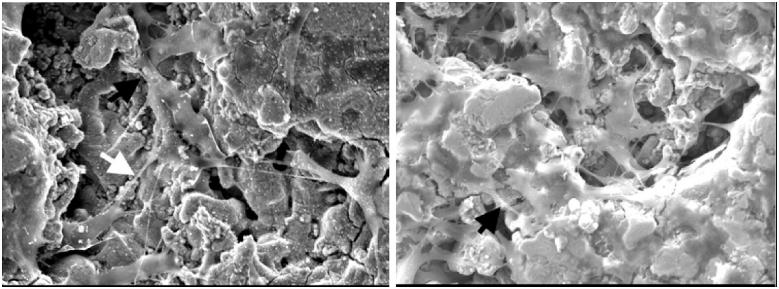

Silica-based bioceramic composites have also received significant attention within BTE. The ionic breakdown products of Si-containing scaffolds have the attractive property of being osteoconductive [75], [139], [140], [141], [142]. Feng et al. created a calcium silicate matrix via SLS as a starting point and incorporated HA whiskers to improve scaffold strength. It was found that compressive strength of scaffolds with ∼45% porosity increased from 15 MPa to 27 MPa with the addition of 20 wt% HA whiskers. Furthermore, scaffold degradation rate decreased as HA whisker content increased. Mineralization of apatite occurred on the scaffold surfaces in vitro, with osteoblast-like MG-63 cells seen to infiltrate the scaffolds and proliferate with increasing culture time [143] (Fig. 8).

Fig. 8.

SEM images of (A) 10% and (B) 30% HA whiskers present in calcium silicate matrix. Adapted from Feng et al. [143].

Dai et al. sintered CaCO3 and SiO2 to create a novel, porous β-dicalcium silicate (β-Ca2SiO4) scaffold. Mechanical analysis found maximum scaffold compressive strength of 28.1 MPa and porosity of up to 71%. Good biocompatibility was also evident, with MG-63 cells and MSCs proliferating on the scaffolds in vitro, with surface apatite formation also seen. In vivo analysis in mice found bone tissue generation in the scaffolds after 9 weeks, suggesting osteoinductive scaffold properties [144].

Feng et al. utilised 3D printing in the form of SLS to fabricate composite akermanite (Ca2MgSi2O7) scaffolds reinforced with nano-titania particles. They reported a maximum compressive strength of 23 MPa for scaffolds with ∼58% porosity after addition of 5 wt% nano-titania. Fracture toughness, hardness, compressive strength and stiffness were significantly increased with increasing nano-TiO2 content from 0 to 5 wt%. Bone-like apatite was formed on the scaffolds in vitro, with MG-63 cells adhering to the scaffolds and proliferating well [145].

Properties such as corrosion resistance, biocompatibility and stiffness have led to widespread use of bioceramics within clinical orthopaedics. Thousands of patients already benefit from ceramic joint replacement components, and ceramic powders and granules used for filling bone defects [146], [147]. However, within the context of BTE, ceramic scaffolds can be prone to brittleness. In common with metallic based scaffolds, they also have degradation rates that can be difficult to finely control. Increasing attention has therefore been applied to developing ceramic/polymer composite scaffolds, which will also subsequently be reviewed.

4.3. Bioactive glasses

Bioactive glasses (BGs) represent a subgroup of ceramic materials that have been extensively researched within the field of BTE. BGs can be considered as surface reactive glass-ceramic biomaterials with amorphous structures. This group of materials was first pioneered by Professor Larry Hench at the University of Florida in the late 1960s, as he sought to find a bone substitute materials to treat Vietnam War veterans [148]. The field of BGs began with development of Na2O–CaO–SiO2–P2O5 glasses, the most bioactive of which is known as 45S5 Bioglass®. Once implanted, BG dissolution helps create a biologically active layer of HA on the surface of the glass, which in turn interacts with the collagen fibrils in host bone to create a strong bond. In fact, the bond formed with bone is so strong that BG often cannot be removed with breaking the surrounding bone [149]. Dissolution products such as calcium and silica ions are also thought to stimulate host cells to produce bone matrix [18], [150]. Within bone, BGs can act as osteoconductive materials, although evidence for osteoinductive properties is more limited [151], [152]. The interconnected porous structure of BGs is similar to trabecular bone, providing cells with a temporary template to regenerate into [153].

The two main manufacturing processes used to make glass are melt-quenching and the sol-gel route. Melt-quenching involves melting oxides together at elevated temperature, before quenching them together in water or a graphite mould; 45S5 BG and other commercial bioactive glasses are made by this method. Components of different size and shape can be produced through this method, including prosthetic middle ear ossicles [154].

Clinical applications of BGs have so far included prostheses used in the fields of orthopaedic and maxillofacial surgery; granules and particulates have also been used in place of conventional bone grafting to aid treatment of chronic osteomyelitis, soft tissue defects and wounds [18], [155], [156]. More than a million patients within orthopaedics and maxillofacial surgery have now had bone defects repaired with 45S5 Bioglass® [148]. Within the field of spinal surgery, a study comparing 45S5 Bioglass® versus iliac crest autograft for spinal fusion in adolescent idiopathic scoliosis (AIS) demonstrated positive results in a series of 88 patients. 45S5 BG® was found to be as effective as iliac crest graft, the current gold standard for spinal fusion, in terms of ability to achieve deformity correction and spinal fusion in AIS patients. Additionally, the morbidity of harvesting an iliac crest graft was avoided in BG patients, who also experienced fewer complications [157].

Whilst properties such as bioactivity and osteoconductivity are attractive, the inherent brittle nature of bioactive glasses represents a major potential limitation in their clinical application [155], [158]. Through incorporation of biodegradable polymers to create BG composites, properties such as porosity, degradation rate and elastic modulus can be improved [159], [160].

Vergnol et al. investigated the potential of a polylactic acid (PLLA)-bioactive glass composite for bone fixation devices. PLLA has previously been reported to require up to 4 years to fully degrade in humans and lacks osteointegration ability [161]. The in vivo behaviour of PLLA-HA composites has already been investigated, with osteointegration found to be significantly improved in PLLA-HA composites compared to pure PLLA structures [162], [163], [164], [165]. Vergnol et al. therefore attempted to characterise the performance of 45S5 BG® -PLLA composites in vitro and in vivo. Composites containing increasing 45S5 BG® content with PLLA were manufactured by injection moulding and tested for up to 56 days in simulated body fluid (SBF). Whilst formation of a mineralised or HA layer was not seen on the surface of PLLA polymer, crystallisation of HA and calcite was evident on composite 45S5 BG® -PLLA scaffolds on X-ray diffraction analysis. Larger 45S5 BG® content, especially 30–50%, led to rapid HA crystallisation on the surface of composite scaffolds. However, degradation of composites containing 50% 45S5 BG® occurred rapidly within 7 days in vitro. Therefore, it was concluded that composites with 30% 45S5 BG® seemed to exhibit the best balance between bioactivity and stability at least during the first weeks of immersion in contact with SBF. In vivo analysis of the 30% 45S5 BG® -PLLA composite within rabbits also found strong osseointegration a month after implantation.

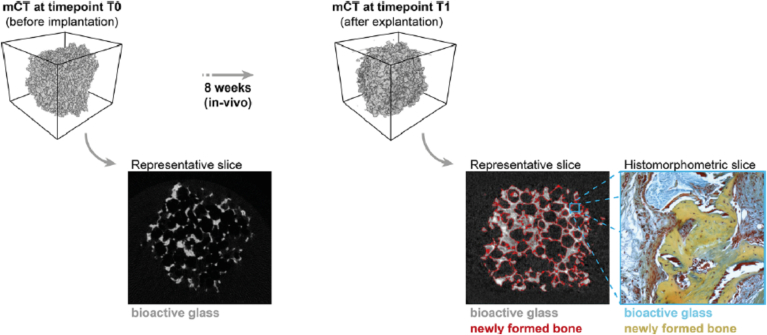

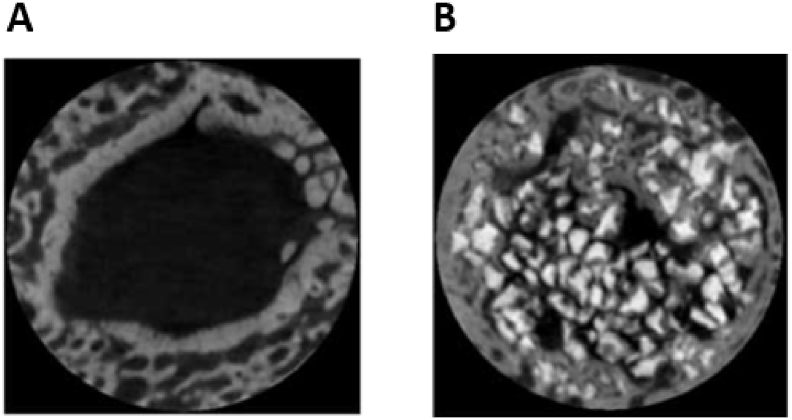

Westhauser et al. investigated the osteoinductive properties of different polymer coated 3D-45S5 BG® scaffolds seeded with human MSCs (hMSCs) in vivo [166]. 45S5 BG® scaffolds were dip-coated with either gelatin, cross-linked gelatin, or poly(3-hydroxybutyrate-co-3-hydroxyvalerate). After seeding with hMSCs, the scaffolds were implanted into immunodeficient mice. Histomorphometry and micro-computed tomography (micro-CT) was then performed after 8 weeks (Fig. 9). Although bone formation was detected in all scaffolds, gelatin-coated 45S5 BG® scaffolds performed the best overall with further studies required to fully evaluate their potential for BTE on a larger scale.

Fig. 9.

Micro-CT and histomorphic analysis showing new bone formation in polymer-coated BG scaffolds implanted in mice for 8 weeks [166].

Murphy et al. utilised 3D extrusion bioprinting to create a composite polycaprolactone (PCL)/BG scaffold containing human adipose-derived stem cells (ASCs). Borate glass and PCL were initially dissolved in organic solvent to create a paste with printable viscosity. ASCs suspended in Matrigel were then co-printed via a second syringe as droplets into the PCL-BG scaffold. Degradation of the scaffolds in SBF was analysed, with 23.2 ± 4% weight loss due to controlled BG dissolution found at 14 days. Cell viability after 24 h was 70 ± 10% and after 7 days was 58 ± 11%. Scaffold pore sizes ranged from 100 to 300 μm, making it ideally suited for BTE. Bioactivity of the BG component was also seen, with formation of HA crystals witnessed on the scaffold surface. This study therefore demonstrated the potential for solvent-based 3D bioprinting to fabricate a scaffold containing cells and BG-polymer composites for BTE applications [167].

Baino et al. utilised a sponge template method involving sintering to fabricate a silicate-based glass-ceramic scaffold. Their intention was to create a scaffold capable of repairing large defects in load-bearing bones. Total scaffold porosity was 56%, with pore sizes ranging from 100 to 500 μm on micro-CT analysis. When tested under compression, the scaffolds had an elastic modulus of 380 MPa and a compressive strength of 18 MPa [168].

Eqtesadi et al. utilised the 3D printing technique of robocasting to fabricate 13–93 BG scaffolds with a pore size of ∼230 μm and 51% overall porosity. The scaffolds unfortunately showed brittle characteristics with a compressive strength of 86 MPa and a modulus of rupture of 15 MPa. PCL was therefore added to the BG to create composite scaffolds, as an attempt to address the brittleness and flexural strength of scaffolds. Whilst compressive strength of the scaffolds was maintained, brittleness was significantly reduced as 13–93/PCL composite scaffolds were able to survive large stains [169].

BGs have also been used to improve the surface bioactivity of 3D printed β-TCP scaffolds, with promising results found. Zhang et al. spin-coated mesoporous (pores with diameters between 2 and 50 nm) bioactive glass (MBG) nanoparticles onto porous β-TCP scaffolds to create a 100 nm layer of MBG on scaffold surfaces [170]. This resulted in a hierarchical pore structure with both MBG mesopores and BG macropores present in the scaffold. The compressive strength and mineralization of MBG-β-TCP scaffolds were also significantly enhanced as compared to β-TCP scaffolds without the MBG nanolayer. Culture of human umbilical vein endothelial cells (HUVECs) found increased cell attachment, viability and angiogenic gene expression compared with conventional BG-modified β-TCP (BG-β-TCP) and pure β-TCP scaffolds. Furthermore, MBG-β-TCP scaffolds significantly enhanced the formation of new bone in vivo as compared to BG-β-TCP and β-TCP scaffolds.

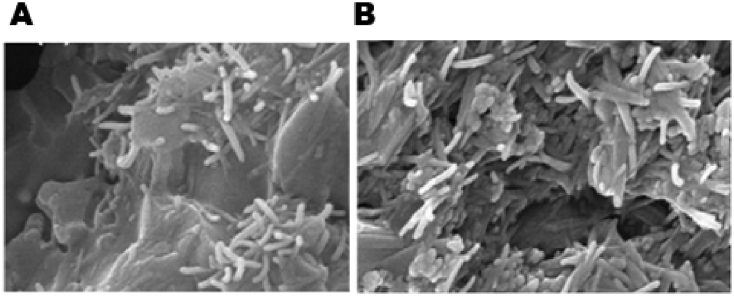

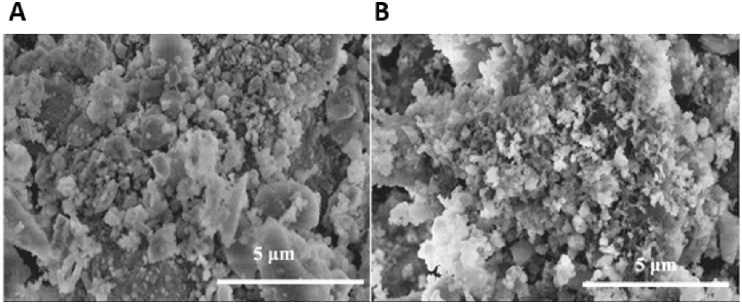

The majority of drugs used in clinical practice are measured on the nanometre scale and can therefore be introduced into mesoporous bioglass structures, potentially improving bioactivity and drug delivery [171]. Jiang et al. coated mesoporous BG scaffolds with amides, with subsequent gentamicin loading onto the scaffold mesoporous surface achieved. As a result, higher gentamicin loading and longer drug release were achieved in vitro compared to BG scaffolds that had not undergone amination. In vitro bioactivity was also improved, with increased formation of surface hydroxyapatite found after soaking in simulated body fluid for 3 days (Fig. 10) [172]. MBGs have been utilised by several other studies to create composite scaffolds with increased bioactivity [170], [173], [174], [175].

Fig. 10.

SEM images of the amine-coated MBG before (A) and after (B) soaking in SBF. Formation of a crystalline HA layer was confirmed on Fourier transform infrared spectroscopy [172].

BG composites have also been used as injectable cements in some studies, with antibiotic [176], natural polymer [177] and synthetic polymer [178] composites found to be cell friendly and capable of treating in vivo bone and cartilage defects. Zhang et al. prepared a strontium-doped, borate bioactive glass (BBG)-chitosan composite cement and evaluated in vitro and in vivo performance [179]. The Sr-BBG cement showed the valuable ability to set in situ (initial setting time = 11.6 ± 1.2 min) and a compressive strength of 19 ± 1 MPa. The Sr-BBG cement was also found to enhance the proliferation and osteogenic differentiation of hBMSCs in vitro when compared to a similar cement composed of chitosan-bonded BBG particles without Sr. The cement was then injected into rabbit femoral condyle defects, with new bone formation supported by the Sr-BBG cement. It would therefore appear to be a promising treatment for treating irregularly shaped bone defects through minimally invasive surgery.

4.4. Polymers

Use of natural polymers in scaffolds has attracted great interest within BTE due to favourable properties including ductility, biocompatibility and biodegradability. As a further benefit, natural polymers often contain biofunctional molecules on their surface that can aid cell attachment, integration and differentiation on scaffolds. Naturally occurring polymers that have been investigated in BTE include collagen, silk, alginate, chitosan and hyaluronic acid. However, use of naturally occurring polymers can also be subject to limitations including presence of pathogenic impurities such as endotoxin [180], lack of tuneability of degradation rates and degradation related inhibition of local cells. Mechanical properties of natural polymers are also suboptimal for BTE, although crosslinking of polymers can enhance structural properties [181], [182], [183].

Synthetic polymers that have been deployed in BTE include poly(lactic acid) (PLA), poly(glycolic acid) (PGA), poly(caprolactone) (PCL) and poly(ethylene glycol) (PEG). Co-polymers including poly(lactic-co-glycolic acid) (PLGA) have also been used. Synthetic polymers can be created with tailored pore size, porosity, degradation rate and mechanical strength as required [184], [185], [186], [187]. However, they are often hydrophobic and lack cell recognition sites, limiting application without secondary modification to improve bioactivity [188], [189]. Synthetic and natural polymers in general have relatively poor load bearing capacity when used alone, with low elastic moduli compared to metallic and ceramic compounds [190], [191]. However, the mechanical requirements of BTE scaffolds are complex, with compressive, tensile and fatigue properties all required for load bearing [192].

One approach that has proved popular in addressing these limitations is the combination of polymers with bioceramics or bioglasses to produce composite scaffolds. Most often, bioceramics or bioglasses are added as a coating or filler to a polymer matrix to improve bioactivity in addition to ramifying mechanical properties [180], [193], [194]. Porosity can also be added to composite polymer-ceramic scaffolds with varying levels of precision using techniques including 3D printing [80] and electrospinning [127], [195]. These techniques are capable of depositing material with gaps between fibres to allow interconnectivity. Alternatively, porogens can be incorporated into the structure before being dissolved out, or chemically triggered to release gas, to create pores [196], [197], [198]. Combining use of porogens with techniques such as 3D printing during manufacturing can increase micro and macroporosity. Polymer-based scaffold surfaces have also been secondarily chemically treated to increase microporosity, through use of organic solvents [199], [200]. Scaffold performance can also be increased by surface modification with bioactive substances including growth factors and surface ligands to aid cell adhesion and proliferation [121], [193], [201], [202], [203].

4.4.1. Collagen –based composite scaffolds

Amongst the natural polymers used in bone tissue engineering, collagen is perhaps the most frequently adapted into scaffolds. Collagen composes 90% of the total weight of bone extracellular matrix proteins and is therefore a logical choice for inclusion in a composite BTE scaffold. Although there are approximately twenty-nine known types of collagen, type I collagen has been used most frequently within BTE due to the lack of immune reactivity associated its use [204]. As part of the normal ECM it is inherently biocompatible, biodegradable and can stimulate cell proliferation and differentiation [205], [206]. Furthermore, the mechanical and degradation properties of collagen can be tailored through the process of crosslinking [207]. However, in common with other natural polymers, collagen has mechanical properties that are insufficient for creating a load-bearing scaffold [208]. It is therefore often combined with more robust materials within BTE to create composite scaffolds. As the major inorganic component of bone, hydroxyapatite (HA) has frequently been combined with collagen in composite scaffolds.

Villa et al. developed a collagen-HA (Col-HA) scaffold through a co-precipitation and freeze casting process [209]. The scaffold created had a high degree of permeability suitable for cell infiltration, attachment and osteogenesis with 99% interconnectivity of pores. Mouse bone marrow derived mesenchymal stem cells (BMSCs) were seeded onto the scaffold and seen to be well attached after 12 h in vitro culture. Subsequently the scaffolds were implanted into a mouse calvarial defect. After three weeks in vivo, near complete filling of the calvarial defects with bone on radiographic and mineralization analysis was found. After several weeks, host matrix metalloproteinase breakdown of collagen had to led to scaffold degradation occurring. By contrast, Marcacci et al. previously found that a pure HA scaffolds failed to degrade 6 years after insertion into 4 patients with long bone defects [210]. However, compliant mechanical properties of the Col-HA scaffold were observed making it perhaps best suited for non-load bearing applications such as craniofacial repair [209]. Alternatively, it could be used to aid treatment of a complex fracture in the same way that bone substitutes or bone grafts are commonly used, in combination with mechanical fixation [211].

Calabrese et al. also demonstrated the osteoinductive potential of a type 1 collagen (30%) -HA (70%) scaffold. The scaffold in this instance was prepared by a freeze casting process, with the addition of a magnesium to create bioactive Mg-doped HA (MHA) nano-crystals. Human MSCs isolated from adipose tissue were seeded onto the scaffold and cultured in vitro in the absence of specific osteogenic inducing factors. Analysis through quantitative PCR and immunohistochemistry at up to 8 weeks demonstrated osteogenic differentiation of MSCs. This study therefore showed that the scaffold materials alone could trigger osteogenic differentiation of MSCs, with extracellular matrix production, gene expression and mineralization analysis all demonstrating the osteoinductive potential of the scaffold. Nevertheless, osteogenic differentiation was found to be significantly accelerated with the addition of osteogenic factors to the culture medium [123]. In vivo analysis was then performed of the scaffold in mice, with ectopic osteoinductive and angiogenic performance of the Col-MHA composite scaffold compared to a pure collagen scaffold. Bone augmentation and angiogenesis were found to spontaneously occur into the composite Col-MHA scaffold, with recruitment of host cells into the structure. The Col-MHA scaffold performed significantly better than the collagen alone scaffold, with less fibrotic tissue and more osteogenic tissue deposited at up to 16 weeks [212].

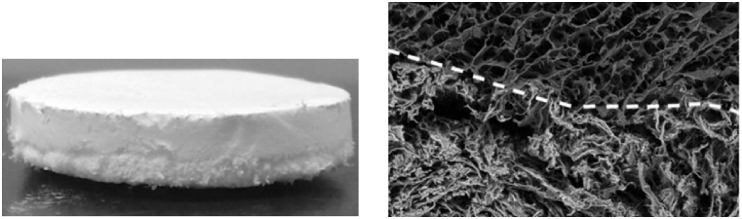

Grigolo et al. also utilised a scaffold composed of type 1 collagen and Mg doped-HA. The scaffold was designed to be biomimetic, with three distinct layers included to replicate the cartilaginous, tidemark and subchondral layered structure of articulating bone [213], [214]. The cartilaginous layer was composed of purely type 1 collagen; the intermediate layer type I collagen (60%) and Mg-HA (40%); and the sub-chondral layer type I collagen (30%) and Mg-HA (70%). The scaffold was manufactured by combining a sintering and a freeze-drying technique, to obtain an integrated monolithic composite. Human MSCs (hMSCs) were seeded onto the single layers of the composite scaffold individually, and onto the integrated composite scaffold. Cells were then grown in either chondrogenic or osteogenic media for comparison. Immunostaining confirmed chondrogenic differentiation of hMSCs in the collagen-only cartilaginous layer when using chondrogenic media. Chondrogenic differentiation did not occur in the Mg-HA bone layer despite use of chondrogenic media. Immunostaining also confirmed osteogenic differentiation of hMSCs in both layers containing Mg-HA, and infiltration into the cartilaginous layer when osteogenic media was used, but this did not occur in the presence of chondrogenic media. Therefore, the processes of osteogenic and chondrogenic differentiation tended to depend mainly on the media used for culture, rather than the biomaterial composition in this study [215] (Fig. 11). Human bone marrow concentrate was then used in place of hMSCs on the three-layered scaffold in a further study. Having found a lack of osteogenesis in the cartilaginous layer, and a similar lack of chondrogenesis in the bone layer, they decided to induce chondrogenic differentiation only in the cartilaginous layer and osteogenesis in the composite layer (type I collagen (60%) and Mg-HA (40%)) and bone layer (type I collagen (30%) and Mg-HA (70%)). After 52 days in vitro, cell viability remained high and differentiation of cells down both the chondrogenic and osteogenic pathways was demonstrated on histological and immunohistochemical analysis. This biomimetic, nano-composite material would therefore appear to offer a potential option for treating osteochondral lesions. In combination with patient-derived bone marrow concentrate, chondrogenic and osteogenic areas could be combined into the same scaffold to offer a “one step” transplantation procedure for osteochondral defects [216].

Fig. 11.

Photograph of the biomimetic scaffold showing the external appearance and layered structure; SEM images showing the interface between scaffold layers [215].

Kane et al. looked to improve upon the mechanical properties of collagen-HA scaffolds previously described by modifying the freeze-drying process most commonly used in their manufacture [217], [218], [219]. Attempting to improve scaffold porosity and mechanical strength, they used compression moulding to combine HA, paraffin micro-spheres and concentrated collagen fibrils. The paraffin micro-spheres were then leached out, acting as porogens, and the collagen was chemically cross-linked [126]. Interconnected pores of 300–400 μm in size with walls 3–100 μm thick were found on micro-CT analysis, with overall 85–90% porosity. This is significant, as scaffold pores greater than 300 μm have been shown to be favourable for osteointegration [160]. Mechanical testing found scaffolds with 60% HA to exhibit fully elastic deformation upon loading to 50% compressive strain, maintained over greater than 100 000 cycles. Compared to Col-HA scaffolds created through freeze-drying, the compressive modulus of the scaffold created in this study was a magnitude greater at approximately 1 MPa. These properties make the scaffold well suited to clinical application, as elastic deformation would potentially facilitate surgical handling and manipulation, whilst the compressive modulus demonstrated would potentially facilitate a degree of load bearing. In vitro bioactivity was investigated by seeding murine adipose derived stromal cells (mASCs) onto the scaffolds and culturing in osteogenic media. After 14 days, significant increases in ALP activity were seen, with complete infiltration of the scaffold by mASCs. HA containing scaffolds showed vastly superior bioactivity compared to collagen-only scaffolds, in keeping with other studies [180], [220], [221], with increased osteogenic differentiation and ALP levels found. However, increasing HA content beyond 40% had no significant benefit. In vivo angiogenesis and osteogenesis in 40% HA scaffolds was then evaluated by implanting acellular scaffolds subcutaneously in mice for 8 weeks. In vivo the scaffold was shown to be conducive to the infiltration and differentiation of endogenous cells, with osteogenesis and angiogenesis observed on histological analysis, suggesting the scaffold is osteoinductive. Therefore, the collagen-HA scaffolds in this study would appear to have potential for clinical use as a synthetic bone graft replacement, given their superior mechanical properties to scaffolds prepared by freeze-drying and favourable osteoinductive and angiogenic properties.

Meagher et al. investigated the impact of HA volume fraction on the in vivo performance of Col-HA scaffolds produced by compression moulding. Acellular collagen scaffolds containing 0, 20, and 40 wt% HA were implanted subcutaneously for up to 12 weeks in mice. Endogenous cell infiltration after 6 weeks was increased in scaffolds containing HA versus collagen alone. Angiogenesis, remodelling of the original scaffold matrix, mineralization and osteogenic gene expression was evident in scaffolds containing HA, but not observed in pure collagen scaffolds. Increasing scaffold HA content was found to be directly correlated with improved vascularity, cell density, matrix deposition and mineralization on histological and micro-CT analysis. It would therefore seem that HA promotes the recruitment and differentiation of endogenous cell populations, leading to angiogenic and osteogenic activity in collagen scaffolds. Contrastingly, collagen scaffolds exhibited no matrix deposition, mineralization, osteogenic gene expression and a significantly lower cell infiltration density [222].

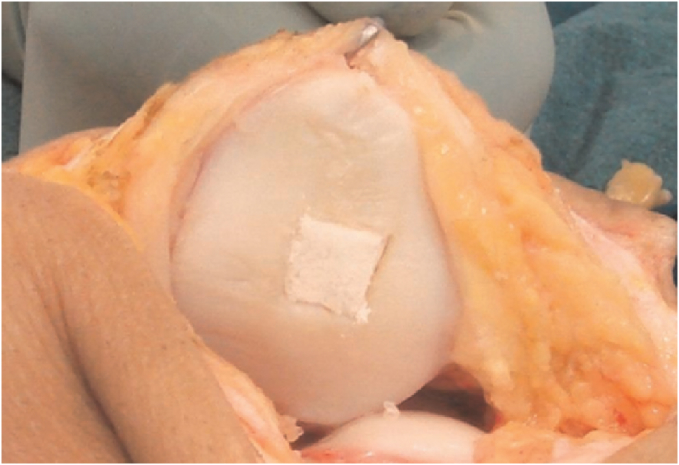

Perdisa et al. demonstrated the osteoinductive potential of Col-HA scaffolds further in a prospective clinical study involving patients with patellar osteochondral defects [223] (Fig. 12). Cell-free Col-HA scaffolds were implanted into knee or patellar osteochondral lesions, with MRI imaging performed 24 months following surgery. The composite scaffold in this study utilised the same three-layered approach as used by Grigolo et al. [215]; the cartilaginous layer was made of type I collagen with a smooth surface; the intermediate layer had a combination of type I collagen (60%) and HA (40%); and the lower layer was a mineralised blend of type I collagen (30%) and HA (70%), mimicking subchondral bone composition. Patient functional outcome scores improved significantly at 12 and 24 months follow up, with MRI showing complete filling of the cartilage in 87.0% of the lesions, complete integration of the graft in 95.7% of lesions, and intact repair tissue surface in 69.6% of patients. However, osteophytes or more extensive bony overgrowth was also documented in.8% of the patients, though no correlation was found between MRI findings and clinical outcome [223].

Fig. 12.

Osteochondral scaffold, sized and press-fit into a patella defect. Adapted from Perdisa et al. [223].

4.4.2. Chitosan – based composite scaffolds

Chitosan (CS) is a polysaccharide normally found in the shell of crustaceans including crabs, lobsters and shrimp. As a versatile, semi-synthetic polymer it has favourable biocompatibility and biodegradability in addition to antibacterial and bioadhesive characteristics [197], [224], [225]. Within BTE chitosan has been combined with a number of materials in scaffolds including calcium phosphate [226], calcium sulfate [227], hydroxyapatite [228] and other natural polymers including silk [229], [230], [231].

Microparticle-based chitosan scaffolds have been produced by several groups [106], [232], [233], [234]. Jiang et al. produced a composite CS/poly(lactic acid-co-glycolic acid) (CS/PLAGA) sintered microsphere scaffold, functionalizing the scaffold surface further with heparin molecules [235]. Scaffolds had a mean pore size of 172 μm, with a compressive strength in the region of trabecular bone. Mechanical testing showed that heparinization of chitosan/PLAGA scaffolds did not significantly alter scaffold mechanical properties or porosity. Osteoblast-like cells were observed to proliferate faster on CS/PLAGA scaffolds as compared to pure PLAGA scaffolds. Furthermore, it was shown that the presence of CS on microsphere surfaces increased the ALP activity of the cells cultured on the composite scaffolds and up-regulated gene expression of osteopontin and bone sialoprotein. This study therefore demonstrated the potential of functionalized chitosan/PLAGA scaffolds.

Nano-fibre based composite chitosan scaffolds have also been investigated within BTE, fabricated using methods such as wet spinning [236], [237] and electrospinning [238] and including materials such as silicon [239] and nano-hydroxyapatite (nHA) [240]. However, electrospinning of CS can be difficult and scaffold stability inside aqueous solutions is unreliable. Secondary crosslinking with agents such as poly(ethylene oxide) (PEG) and blending with other polymers such as silk, collagen and PCL to create composites can however significantly reduce the degradation rate of CS in electrospun scaffolds and improve bioactivity [241].

CS has also been combined with collagen and bone morphogenic protein (BMP) in composite scaffolds, with in vivo performance in dog and rabbit models analysed [31], [242].

Shi et al. encapsulated BMP in poly-L-lactide-co-glycolide (PLGA) biodegradable microspheres, before dispersing them in a chitosan/collagen composite scaffold. The scaffolds were implanted in dog mandibles for 4 weeks, with histologically enhanced bone formation found in BMP/PLGA microsphere loaded scaffolds compared to control chitosan/collagen scaffolds also containing BMP. It was therefore concluded that sustained release of BMP from microspheres was more effective in inducing implant osseointegration compared to BMP bound to scaffolds.

Hou et al. prepared chitosan microspheres (CMs) and combined them with an absorbable collagen sponge with freeze-drying performed, to achieve controlled-release of BMP. The BMP-loaded composite scaffolds were implanted into 15 mm radius defects of rabbits and the bone-repair ability was evaluated. Defects were found to be bridged by new bone as early as 4 weeks, with complete healing and recanalization of the bone-marrow cavity at 12 weeks evident on X-ray and histological analysis. These results demonstrated that the composite CS-Col scaffold is a promising carrier of BMP-2 for the treatment of segmental bone defects [242].

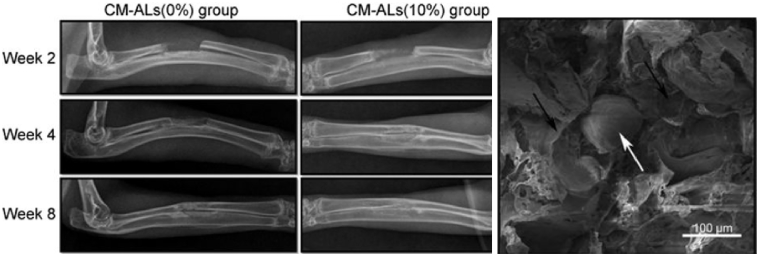

Wu et al. developed a novel, composite scaffold of poly(L-lactic acid)/nHA/Alendronate-loaded chitosan microspheres (CS-ALs) with promising application for drug delivery and BTE demonstrated in vitro and in vivo [243] (Fig. 13). Alendronic (AL) acid has been used in an increasing number of BTE studies, with known properties including potent osteoinduction and inhibition of bone resorption [244], [245]. Using a room temperature moulding/particle leaching method [246], followed by compression moulding, porous scaffolds of PLLA/nHA/CS-AL were prepared with the concentrations of CS/nHA-AL ranging from 0 to 20%. Porous PLLA/nHA scaffolds with only PLLA and nHA were also produced for use as controls. SEM found the scaffolds to exhibit a homogeneously interconnected porous structure, with the pore diameters of 150–250 μm. Scaffolds with 10% of CS/nHA-AL were then analysed in vitro, having been found to possess the most favourable drug release, degradation and mechanical properties. Culture of rabbit adipose stem cells (ASCs) found rapid cell proliferation and ECM production after 5 days, with no apparent cytotoxicity seen. Growth in osteogenic media led to significantly increased ALP activity and calcium deposition, with CS-AL scaffolds containing CS/nHA-AL having significantly better results than control scaffolds. Scaffolds containing 10% and 0% CS-ALs were then implanted into a rabbit bone defect model to further evaluate in vivo bone regeneration. Bone defects were healed with new bone formation seen during 4–8 weeks of implantation. New bone formation was significantly higher in CS-ALs (10%) group when compared with CS-ALs (0%), an effect that increased with time on histological analysis. Sustained release of AL was also found for up to 30 days. This study therefore showed promising application of CS-AL microsphere loaded (10%) scaffolds for both drug delivery and bone tissue engineering.

Fig. 13.

Comparison of CS-ALs (10%)-implanted group to CS-ALs (0%) found significantly higher new bone formation, a finding which increased with time. SEM images of the CS-AL scaffold, with black arrows indicating the PLLA/nHA matrix and the white arrow indicating a CS/nHA-AL microspheres [243].

4.4.3. Hyaluronic acid – based composite scaffolds

Hyaluronic acid (HLA) is a natural glycosaminoglycan found widely throughout connective, epithelial and neural tissues. As one of the chief components of the extracellular matrix, HLA contributes significantly to cell proliferation and migration. It typically has a very large molecular weight and has been adapted into attempts at both hard and soft tissue engineering, particularly as a hydrogel (as discussed in the later hydrogel section) [247], [248]. The mechanical properties of HA can be readily improved through processes such as crosslinking [79], [249], whilst it is naturally viscoelastic, biodegradable and biocompatible, making it an ideal material for BTE [250].

HLA has been implemented in composite scaffolds by several groups. Kim et al. recently looked to combine favourable properties of multiple materials in fabricating a graphene oxide (GO)–Chitosan (CS)–Hyaluronic acid (HLA) based bioactive composite scaffold also containing an osteogenesis-inducing drug simvastatin (SV) [251]. Interestingly, SV is capable of initiating osteoblast differentiation of human adipose derived stem cells (hADSCs) and is well known for its property to enhance bone morphogenic proteins (BMPs). In fact, there are several examples in the literature of SV being used in composite scaffolds and injectable gels for bone regeneration, with improved osteogenesis seen [252], [253], [254], [255], [256], [257], [258]. The SV loaded GO–CS–HLA scaffold in this study was prepared in brief by mixing dissolved CS and HLA, with GO added through continuous stirring to create a composite blend, before a freezing and lyophilisation step to add SV was performed. Finally, the obtained composite scaffolds were cross-linked with N,N-(3-dimethylaminopropyl)-N-ethylcarbodiimide (EDC). Electron microscopy found the scaffolds to have an interconnected porous morphology. The addition of GO also resulted in less swelling and ultimately contributed to enhanced structural integrity of the scaffold. However, introduction of GO also caused a 35% reduction in porosity of the GO–CS–HLA scaffold. MC3T3 (Osteoblasts) cells were seen to adhere and proliferate better on SV loaded GO–CS–HLA scaffolds throughout 48 h of in vitro analysis. This was reflected by significantly higher scaffold mineralization being found in SV loaded scaffolds after 14 days of analysis. Overall, the SV loaded GO–CS–HLA scaffold appeared to offer a successful option for BTE, with the addition of SV significantly accelerating bioactivity and osteogenesis.

Jing et al. also combined HLA and CS in a porous scaffold for bone tissue engineering [259]. Mixing CS and HLA together as liquids, they used a freeze-drying approach to form porous, 3D scaffolds. By performing a further cross-linking step, the elastic modulus and structural integrity of the scaffold was increased. Stem cell colonisation and proliferation within the scaffold was demonstrated by DNA assays and confocal imaging. Correia et al. also used a freeze-drying processed to prepare composite scaffolds of chitosan and HLA, though directed their scaffolds at cartilage tissue engineering. Within this study incorporation of HLA enhanced cartilage ECM production, chondrocyte proliferation and cell adhesion to scaffold surfaces [260].

Kim et al. combined HLA and collagen in a scaffold directed at regenerating cartilage [261]. The hybrid scaffolds were prepared by adding 0.1, 0.3 or 0.5 wt% collagen to HLA. The HLA was then crosslinked with ethylene glycol diglycidyl ether, followed by a freeze-drying process. The resulting composite scaffolds had a three-dimensional structure with interconnected pores and showed an increase in tensile strength with increasing collagen concentration. The degradation time of the hybrid scaffolds in vitro increased with increasing collagen concentration. In vitro chondrocyte growth on the scaffolds was also improved by increasing collagen concentration over 2 weeks in culture. Furthermore, glycosaminoglycan (GAGA) concentration in the hybrid scaffolds was higher than in pure HLA scaffolds. These composite scaffolds would therefore seem to have potential for in vivo cartilage regeneration.

HLA has also been used as a delivery agent to improve bioactivity in bone substitute materials. Chang et al. investigated whether the use of HLA as an aqueous binder of hydroxyapatite/beta-tricalcium phosphate (HA-βTCP) particles could reduce the amount of bone graft needed and increase ease of graft handling in clinical situations [262] (Fig. 14). HA/βTCP was loaded into crosslinked HLA to form a novel HLA/HA-βTCP composite, which was then injected into rabbit skull defects in vivo. Histological and micro-CT analysis found that HLA allowed bone regeneration to be maintained even when HA-βTCP particle numbers were reduced. In fact, compared to the control scaffold, HLA/HA-βTCP samples had 1.7 times larger bone formation after 2 weeks. Overall, the addition of HLA to bone grafts not only promoted osteoconduction but also improved handling characteristics in clinical situations.

Fig. 14.

Micro-CT images of the artificial skull defects after 4 weeks, showing significant bone regeneration in HLA/HA-β-TCP composites (B) compared to control (A).

4.4.4. Silk - based composite scaffolds

Silk fibroin (SF) is a natural protein-based polymer mainly produced by silkworms and spiders. SF possesses several characteristics desirable for use in bone tissue engineering, including biocompatibility, low immunogenicity, limited bacterial adhesion, tuneable biodegradability, mechanical integrity and the ability to support the differentiation of mesenchymal stem cells along the osteogenic lineage [263], [264], [265].

McNamara et al. developed a new technique in fabrication of porous HA-silk scaffolds. Firstly, they mixed silk together with HA powder before addition of silk macroporogens. The mixtures were then sintered, with silk acting as a sacrificial polymer creating porosity. The resulting silk-HA scaffolds could be moulded into large, complex shapes, and further machined post-sinter to generate specific three-dimensional geometries. Scaffolds also supported bone marrow-derived MSC attachment and proliferation, with no signs of cytotoxicity [266].

Kweon et al. compared the performance of HA-coated silk scaffolds and HA-coated collagen scaffolds. They implanted both scaffold variants into rat tibias, with histological analysis of bone formation around the scaffolds performed after 6 weeks in vivo. They found that coating silk based scaffolds with HA promoted bone regeneration and bone to scaffold contact, with superior results demonstrated compared to HA-coated collagen scaffolds [267].

Silk has also been used to coat BTE scaffolds, with encouraging results found. In one study, PCL nanofibers were coated with silk and combined with biphasic calcium phosphate (BCP) in a composite scaffold [268]. Addition of silk-coated PCL nanofibers improved scaffold compressive strength (from 0.07 MPa for BCP to 0.42 MPa), elastic modulus (from 5 MPa for BCP to 25 MPa), and bioactivity whilst also preserving porosity (85%) and interconnectivity (99%). Furthermore, osteoblast proliferation and differentiation rates were increased in the BCP/PCL-silk scaffolds compared to that in the BCP/PCL and BCP scaffolds. Jaio et al. also modified BCP scaffolds with silk, applying multiple coatings to the scaffold surface. In doing so they managed to significantly enhance scaffold mechanical performance, with properties comparable to native bone tissue found. Once again osteogenesis by hMSCs was found to be positively influence by silk over an extended period in culture [269].

Cao et al. used a HA-mineralised silk to mechanically reinforce an injectable bone cement [270]. In this study, a hydroxyapatite (HA)–silk fibroin (SF) complex was synthesised through a co-precipitation method and added to an injectable CPC/SF composite. The compressive strength of the three-component composite, CPC/HA–SF/SF, kept increasing as HA–SF content was increased to 3 wt%. The setting time of CPC/HA–SF/SF composites also decreased as a function of HA–SF content, with no apparent effect on injectability. Furthermore, the CPC/HA–SF/SF composites showed good biocompatibility both in vitro and in vivo. It was therefore suggested that the composite could hold promise for orthopaedic applications, including serving as filler materials for minimally invasive surgeries to treat vertebral fractures.

In a further study, attempts were made to enhance the mechanical properties of electrospun SF scaffolds by uniformly dispersing hydroxyapatite (HA) nanoparticles within SF nanofibers [271]. Addition of HA content up to 20 wt% increased the mechanical properties of the composite scaffolds, while further increases above 20 wt% disrupted the polymer chain networks within SF nanofibers and weakened overall mechanical strengths.

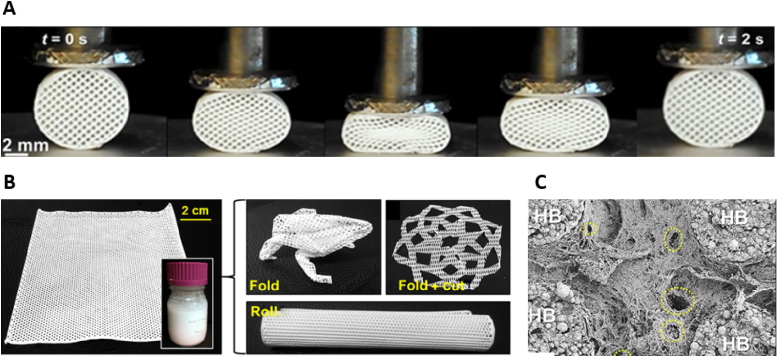

4.4.5. Synthetic polymer composites