Abstract

Objective:

The aim of this in vitro study is to evaluate the effect of expiration date on some mechanical properties of resin composites after controlled storage of syringes and compules in a refrigerator at 4°C.

Materials and Methods:

Specimens were tested at 7 days after storage in distilled water at room temperature. The investigated properties are the static modulus of elasticity, the flexural strength, and the Vickers microhardness. Same batches of restorative materials were examined at baseline (at least 1 year before their expiration date) and 1 year after they expired.

Results:

Paired t-test is used to compare the results between the two groups using StatView software (version 5.0) SAS Campus Drive Cary, North Carolina, USA. Except for the flexural strength, no statistical differences were found between the mechanical properties of the expired and the unexpired group.

Conclusion:

The 1-year expiry date did not seem to affect the investigated mechanical properties.

Keywords: Expiration date, mechanical properties, resin composites, water storage

INTRODUCTION

Restorative composites are essentially polymeric materials, and their in vitro and in vivo performance is associated to the chemical structural configuration and its rate of degradation and time.[1] The degradation process of resin composites is complex and includes many aspects. Two majors forms can be observed: intraoral degradation (mechanical, physical, or chemical) and extraoral degradation due to the storage of the material and its shelf life. Many materials used in dentistry are perishable and have specific storage requirements to maintain optimum properties and maximize their shelf life.

The degradation may be mainly chemical where a combination of effects arises from oxidative chain scission, oxidation hydrolysis, changes in crystallinity, and other factors that may be dependent on the environmental storage.[2]

When a dentist purchases a syringe of composite, three important informations are printed on the box: the batch number, the expiration date, and the storage conditions. Most of direct composite restoratives have a limited shelf life. According to the ANSI,[3] the shelf life of a material is the length of time (from the date of manufacture) where a material retains the physical and mechanical properties necessary to accomplish its prescribed purpose.

Dental materials are kept for long periods between different usage on a shelf or in the refrigerator. Consequently, during this out-of-use period, the material's constituents must not separate or evaporate, nor react together, neither degrade.[4]

Resin-based materials must be stored properly to maintain maximum effectiveness.[5] Usually, a temperature between 4°C and 20°C is recommended. However, as storage conditions of resin composite may vary according to the geographical and climatic conditions (sun exposure and humidity) of the country, most of the dental manufacturers recommend a refrigerated storage of resin composites.

Ideally, chemically- and dual-cured composites are stored under refrigeration when not in use and allowed to come to room temperature for at least 1 h before use. Autocured component of dual composites has a shelf life of about 18–24 months when kept in cool place. However, when kept at room temperature, these composites have a shorter life. In contrast, light-cured composite is stable at room temperature if kept sealed to avoid monomer evaporation, and consequently, their expected shelf life is about 5 years.[5]

The effect of uncontrolled outdoor storage under variable conditions was investigated. Compared to light-cured composites, chemically-cured composites seem to be more affected by the storage conditions.[6,7] Several studies concerning the storage stability of restorative dental biomaterials have been reported.[8,9,10,11,12,13]

The expiration date of a resin composite is an important factor to be considered. Theoretically, if used after the specified expiration date, material properties may be affected. From a clinical point of view, this may lead to failures such as fracture, excessive wear, and discoloration. In their daily practice, dentists can have some resin composites after the expiration date announced by the manufacturer. Should they discard those materials or they can keep using them over a short period?

The aim of this study is to assess the mechanical properties of some resin composites after 1 year of their expiration date following controlled refrigerated storage.

MATERIALS AND METHODS

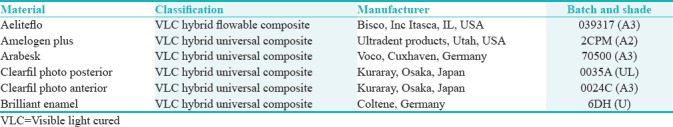

Six resin composites were selected to study the effect of expiration date. The study was conducted between 2010 and 2012. The materials and their specifications are listed in Table 1. The mechanical properties investigated are the modulus of elasticity, the flexural strength, and the Vickers microhardness.

Table 1.

List of the tested materials

The sample size (n = 5) was determined according to power analysis.

This following in vitro study did not need any approval of the review board since it does not include any biological samples.

Ten barshaped specimens (25 mm × 2 mm × 2 mm) were prepared in metallic molds. After filling the mold to excess, the material surface was covered with a mylar strip and a glass slide, then pressure was applied to extrude excess material. Specimens were light cured during 60 s by overlapping, as recommended in ISO 4049. Two Light Emitting Diode curing units (Demetron, Kerr-USA) with a tip diameter of 8 mm were simultaneously used to enlarge the irradiated surface. The intensity of the light curing units was regularly checked using a radiometer to ensure a minimum intensity of 800 mW/cm2.

The static modulus of elasticity and the flexural strength were measured by the three-point bending test as described earlier, according to the ISO 4049.[14] Samples were loaded in an Instron machine at a speed rate of 0.75 mm/min until fracture and modulus value was determined as:

Es = Fl3/ 4bh3 d where F = load, l = distance between the support, b = width of the bar, h = thickness of the bar, d = deflexion corresponding to load F.

The flexural strength was calculated as follows:

σ = 3Fl/2 bh2 where F is the maximum load at the point of fracture, l = distance between the supports, b = width of the specimen, h = height of the specimen.

Hardness measures were carried out on the fractured samples issued from the previous test of flexural strength (n = 5). The Vickers hardness was measured with a Durimet microhardness tester (Leitz, Wetzlar, Germany). A load of 200 g was applied during 30 s on the surface. Then, the length of the diagonal of each indentation was measured in μm directly using a graduated eyelens. The mean length of the diagonals is converted to Vickers hardness number (VHN) from catalogued data (through a conversion table). Four indentations were made for each sample that means a total of 20 measures for each material. The Vickers Hardness Number (VHN) is obtained from the following formula:

H = (1854.4 × P)/d2

where H = Vickers hardness in kg/mm2, P = load in g, and d = length of the diagonals in μm.

Baseline measurements were accomplished at least 1 year before the expiration date, and the materials were also tested 1 year after they expired. Same batches of composites were used. They were stored in a refrigerator under controlled temperature (4°C).

Five specimens were tested at 7 days (baseline) and five others at 1 year after storage in distilled water at room temperature.

The mean values and standard deviations of the investigated properties were calculated for each group of materials, and results were compared using a paired t-test (P > 0.05).

RESULTS

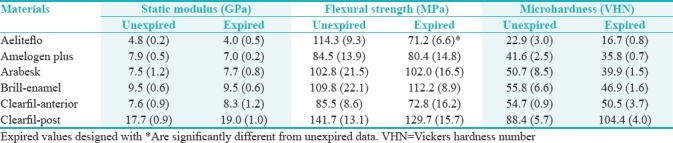

Results, expressed as means and standard deviations, of the mechanical properties of unexpired and expired resin composites are shown in Table 2. For the static moduli of elasticity, values ranged from 4.8 to 17.7 GPa for the unexpired specimens and from 4 to 19 GPa for the expired ones. For the flexural strength, values ranged from 84.5 to 141.7 MPa for the unexpired specimens and from 71.2 to 129.7 MPa for the expired ones. For Vickers microhardness, values ranged from 22.9 to 88.4VHN for the unexpired specimens and from 16.7 to 104.4 VHN for the expired ones.

Table 2.

Mean values and standard deviations of mechanical properties of unexpired and expired resin composites at 7 days

T-test (P ≥ 0.05) showed that except flexural strength, the 1-year expiration date neither affect the modulus of elasticity nor the microhardness of resin composites.

DISCUSSION

The key finding of this study is the effect of expiration date on the mechanical properties of the investigated composites.

Except for flexural strength, the modulus of elasticity and the Vickers microhardness were stable after storage in a refrigerator 1 year after their expiration date.

Concerning Vickers microhardness, although the values of the expired composites were lower than the unexpired specimens, no statistical differences were found. Consequently, it can be assumed that the composite behavior may be more affected by the organic fraction of the material. In fact, the fillers are relatively inert inorganic materials; however, the coupling agents are themselves prone to hydrolysis through ester linkage within the molecules or siloxane links that are formed with the filler particle.[15] As the filler surface degrades, stress transfer will tear away the coupling agent from the filler surface, causing complete debonding.[16] Theoretically, highly filled composites are supposed to have a better mechanical behavior than microfine and flowable composites, due to their lower percentage of monomers. In the present study, the microfine composite Clearfil-Anterior and the flowable composite Aeliteflo showed lower microhardness and flexural strength after expiration date testing. However, except the flexural strength of Aeliteflo, the differences were not statistically significant.

Other important factors that affect the longevity and the stability of a resin composite are the photoinitiator, the stabilizers, and the polymerization inhibitors incorporated in the resin matrix. Any alteration of those components will affect negatively the polymerization of the material and thus its properties. Resin composites differ in the amount of photoinitiator they contain. All photoinitiators deteriorate over time.[6] The key of longevity is the catalyst peroxide contained in the paste. Some are stabilized better than others.[5]

In general, light-cured resin composites are more stable than chemically-cured composites that are more sensitive to storage conditions and thus have lower shelf life. This is due to the unstable benzoyl peroxide initiator that is a component of their curing system.[6] Consequently, the storage of resin composites in dark and under refrigeration prolongs significantly their shelf life by slowing the decomposition of the initiator.[17]

When stored in the refrigerator, composites should be allowed to return to room temperature before use. This will ensure that the material does not experience water condensation, which will both weaken and discolor the restoration, and that, it has the proper viscosity and setting rate.[17] Since the matrix resin is the weak component of composites, materials with high filler loadings would be preferred.

Hondrum and Fernandez[6] studied the storage stability of resin composite over a 7-year period. They compared physical properties (diametral tensile strength, flexural strength, flexural modulus, and microhardness) as well as color changes of a chemically-cured and a light-cured resin composite at intervals of 1 year under controlled storage conditions. No statistically significant difference was observed between control and experimental group. The study showed that if refrigerated (6°C ± 2°C), chemically-cured resin composites may retain efficacy for several years past recommended shelf life.

Fallo et al.[5] studied the effects of uncontrolled outdoor storage on the polymerization, manipulation, and appearance of visible light-cured composite resin and resin-modified glass ionomer materials. Results showed that polymerization of all materials tested was apparently unaffected to any significant clinical degree by outdoor storage at temperatures ranging from 20°F to 112°F over 12 months.

Garcia Lda et al.[18] evaluated the conversion degree, the microhardness, and the surface roughness of four composite resins used 180 days before and after their expiration dates. The data showed a reduction in microhardness for the composites used after their expiration dates.

Another study evaluated the mechanical and morphological characteristics of different classifications of dental composites as a function of the material condition (new, accelerated aging, and expired). The flexural strength and modulus of elasticity showed a decrease after their expiration date.

Although the dental manufacturers may not be able to control variables as storage temperature and transportation conditions, these effects on the composite clinical performance can be minimized if properly considered.[13]

One of the limitations of this study is that it includes one flowable resin composite among the six investigated resin-based materials.

Other properties having clinical implication such as working time, consistency, and effect of ambient light should be investigated for a better understanding of the expiration date effect on resin-based materials.

CONCLUSION

Under the limitation of the present study, all of the investigated properties except one were maintained 1 year after their expiration date. Nevertheless, few materials showed a decrease of their flexural strength and microhardness. Storing resin composites in a refrigerator helps to preserve their degradation. The expiration date of resin composites is assigned by the manufacturers but other important factors that are beyond their control, such as the delay and the way of shipping and storage conditions, must be taken into consideration.

Currently, no specification offers a measure for the shelf life of a resin composite. Thus, storage stability must be more emphasized and standardized.

FINANCIAL SUPPORT AND SPONSORSHIP

Nil.

CONFLICTS OF INTEREST

There are no conflicts of interest.

ACKNOWLEDGMENTS

The authors would like to thank the manufacturers for supplying materials.

REFERENCES

- 1.Drummond JL. Degradation, fatigue, and failure of resin dental composite materials. J Dent Res. 2008;87:710–9. doi: 10.1177/154405910808700802. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Ferracane JL. Hygroscopic and hydrolytic effects in dental polymer networks. Dent Mater. 2006;22:211–22. doi: 10.1016/j.dental.2005.05.005. [DOI] [PubMed] [Google Scholar]

- 3.Chicago: Council on Scientific Affairs, American Dental Association; 1984. American National Standards Institute/American Dental Association Specification 33, Dental Terminology. [Google Scholar]

- 4.Albers H. Resins. 8th ed. Pmph USA Ltd Series Santa Rosa; 2002. Tooth-Colored Restoratives; pp. 111–25. [Google Scholar]

- 5.Fallo GJ, Wakefield CW, Czerw RJ. Effects of uncontrolled outdoor storage on the polymerization, manipulation, and appearance of visible light-cured composite resin and resin-modified glass ionomer materials. Mil Med. 1996;161:290–3. [PubMed] [Google Scholar]

- 6.Hondrum SO, Fernandez R., Jr The storage stability of dental composite resins: Seven-year results. Gen Dent. 1997;45:382–9. [PubMed] [Google Scholar]

- 7.D'Alpino PH, Svizero Nda R, Arrais CA, de Oliveira M, Alonso RC, Graeff CF, et al. Polymerization kinetics and polymerization stress in resin composites after accelerated aging as a function of the expiration date. J Mech Behav Biomed Mater. 2015;49:300–9. doi: 10.1016/j.jmbbm.2015.05.016. [DOI] [PubMed] [Google Scholar]

- 8.Chaves FO, Farias NC, Medeiros LM, Alonso RC, Di Hipólito V, D'Alpino PH, et al. Mechanical properties of composites as functions of the syringe storage temperature and energy dose. J Appl Oral Sci. 2015;23:120–8. doi: 10.1590/1678-775720130643. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Rohr N, Fischer J. Effect of aging and curing mode on the compressive and indirect tensile strength of resin composite cements. Head Face Med. 2017;13:22. doi: 10.1186/s13005-017-0155-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Blumer L, Schmidli F, Weiger R, Fischer J. A systematic approach to standardize artificial aging of resin composite cements. Dent Mater. 2015;31:855–63. doi: 10.1016/j.dental.2015.04.015. [DOI] [PubMed] [Google Scholar]

- 11.Liebermann A, Roos M, Stawarczyk B. The effect of different storage media on color stability of self-adhesive composite resin cements for up to one year. Materials (Basel) 2017;10 doi: 10.3390/ma10030300. pii: E300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.de Lange C, Bausch JR, Davidson CL. The influence of shelf life and storage conditions on some properties of composite resins. J Prosthet Dent. 1983;49:349–55. doi: 10.1016/0022-3913(83)90276-7. [DOI] [PubMed] [Google Scholar]

- 13.D'Alpino PH, Vismara MV, Mello LM, Di Hipólito V, González AH, Graeff CF, et al. Resin composite characterizations following a simplified protocol of accelerated aging as a function of the expiration date. J Mech Behav Biomed Mater. 2014;35:59–69. doi: 10.1016/j.jmbbm.2014.03.015. [DOI] [PubMed] [Google Scholar]

- 14.International Standard Organisation. Specification 4049. Resin-Based Filling Materials. 2002 [Google Scholar]

- 15.Santerre JP, Shajii L, Leung BW. Relation of dental composite formulations to their degradation and the release of hydrolyzed polymeric-resin-derived products. Crit Rev Oral Biol Med. 2001;12:136–51. doi: 10.1177/10454411010120020401. [DOI] [PubMed] [Google Scholar]

- 16.D'Alpino PH, Svizero Nda R, Bim Júnior O, Valduga CJ, Graeff CF, Sauro S, et al. Effects of age condition on the distribution and integrity of inorganic fillers in dental resin composites. Clin Oral Investig. 2016;20:1011–9. doi: 10.1007/s00784-015-1599-9. [DOI] [PubMed] [Google Scholar]

- 17.Hondrum SO. Storage stability of dental luting agents. J Prosthet Dent. 1999;81:464–8. doi: 10.1016/s0022-3913(99)80015-8. [DOI] [PubMed] [Google Scholar]

- 18.Garcia Lda F, Roselino Lde M, Pires-de-Souza Fde C, Consani S. Evaluation of the conversion degree, microhardness, and surface roughness of composite resins used after their expiration date. Gen Dent. 2010;58:e262–7. [PubMed] [Google Scholar]