Significance

Carbon dioxide removal through the permanent sequestration of biogenic CO2 is a critical technique for climate change mitigation, but most bioenergy with carbon capture and sequestration (CCS) technologies are technically immature or commercially unavailable. In contrast, examples of CCS of biogenic CO2 resulting from fermentation emissions already exist at scale. Here, we evaluate low-cost, commercially ready sequestration opportunities for existing biorefineries in the United States. We find that existing and proposed financial incentives suggest a substantial near-term opportunity to catalyze the growth of CCS infrastructure, improve the impacts of conventional biofuels, support development of carbon-negative biofuels, and satisfy low-carbon fuel policies.

Keywords: carbon dioxide removal, bioenergy, climate policy, carbon capture, energy systems

Abstract

Capture and permanent geologic sequestration of biogenic CO2 emissions may provide critical flexibility in ambitious climate change mitigation. However, most bioenergy with carbon capture and sequestration (BECCS) technologies are technically immature or commercially unavailable. Here, we evaluate low-cost, commercially ready CO2 capture opportunities for existing ethanol biorefineries in the United States. The analysis combines process engineering, spatial optimization, and lifecycle assessment to consider the technical, economic, and institutional feasibility of near-term carbon capture and sequestration (CCS). Our modeling framework evaluates least cost source–sink relationships and aggregation opportunities for pipeline transport, which can cost-effectively transport small CO2 volumes to suitable sequestration sites; 216 existing US biorefineries emit 45 Mt CO2 annually from fermentation, of which 60% could be captured and compressed for pipeline transport for under $25/tCO2. A sequestration credit, analogous to existing CCS tax credits, of $60/tCO2 could incent 30 Mt of sequestration and 6,900 km of pipeline infrastructure across the United States. Similarly, a carbon abatement credit, analogous to existing tradeable CO2 credits, of $90/tCO2 can incent 38 Mt of abatement. Aggregation of CO2 sources enables cost-effective long-distance pipeline transport to distant sequestration sites. Financial incentives under the low-carbon fuel standard in California and recent revisions to existing federal tax credits suggest a substantial near-term opportunity to permanently sequester biogenic CO2. This financial opportunity could catalyze the growth of carbon capture, transport, and sequestration; improve the lifecycle impacts of conventional biofuels; support development of carbon-negative fuels; and help fulfill the mandates of low-carbon fuel policies across the United States.

Atmospheric carbon dioxide removal will likely play a critical role in climate change mitigation and in deep decarbonization of energy and land sectors worldwide (1, 2). A promising class of technologies for carbon removal is known as bioenergy with carbon capture and sequestration (BECCS), which involves the capture and permanent sequestration of biogenic CO2 produced during energy conversion. However, many BECCS technologies, including thermochemical conversion and postcombustion CO2 capture, are commercially and technologically immature (3, 4). For instance, large-scale biomass gasification faces technical hurdles, while cellulosic ethanol production and carbon capture and sequestration (CCS) have not yet reached widespread commercial adoption, despite policy support. In light of the perceived near-term unavailability of BECCS, CCS, and advanced bioenergy conversion processes, many have criticized the large-scale inclusion of these techniques in century-scale climate change mitigation pathways (5). For instance, gigatonne-scale BECCS deployment will likely require construction of a large-scale CO2 transport network to suitable geologic sequestration sites, commercialization of advanced biomass conversion technologies, and cultivation of novel bioenergy feedstocks at an unprecedented scale (3, 6, 7). Underpinning these challenges is the fact that many existing bioenergy facilities are distant from geologic formations that allow for safe, reliable, and permanent CO2 sequestration.

Near-term opportunities to develop, demonstrate, and deploy BECCS technologies can reduce costs, improve performance, and clarify their sustainable scale (8). In particular, analysis that identifies opportunities to leverage existing infrastructure, technologies, and policies can enhance both near-term and long-term mitigation efforts by deploying existing technologies and developing experience in CCS. These opportunities, however, are currently limited: robust carbon pricing regimes to support BECCS have not yet been implemented, and the United States seems poised to reduce its commitment to energy innovation in the near term (9). Existing deployment of BECCS and CCS lags several orders of magnitude behind stringent climate change mitigation scenarios, while advanced bioenergy and CCS technologies have faced numerous setbacks in recent years (3). At present, 3.7 MtCO2/y is sequestered in dedicated geologic storage worldwide via four CCS projects, while 28 MtCO2/y of industrial CO2 is utilized for enhanced oil recovery (EOR) (10). In contrast, recent 2 °C-consistent scenarios by the International Energy Agency envisage 4.2 GtCO2/y of emissions reductions via CCS by 2050, while median BECCS deployments in 2100 reach 12 GtCO2/y in 2 °C-consistent scenarios analyzed by the Intergovernmental Panel on Climate Change (5).

Capture of biogenic CO2 from fermentation is unique because, unlike many other BECCS technologies, it does not require a costly separation of CO2 and can be applied at existing biorefineries. Practiced commercially for several decades, fermentation of sugars and starch currently produces over 26 billion gallons/y of ethanol worldwide. Moreover, fermentation produces a high-purity (99%) gaseous CO2 stream consisting only of CO2, H2O, and small amounts of organic and sulfur compounds (11). Thus, purification, dehydration, and compression of fermentation CO2 streams can be accomplished at relatively low cost via existing technologies, including reciprocating or centrifugal compressors, pumps, and glycol dehydration (12). Cost estimates for CO2 capture and compression from fermentation are typically $30/tCO2, among the lowest of all CO2 point sources (12–14). In comparison, the ranges of estimates of capture and compression costs from coal-fired power plants and other large-scale industrial processes that emit dilute combustion gases are 60–90 and 100–120 $/tCO2, respectively (13, 15). A typical dry mill ethanol plant in the midwestern United States can reduce the lifecycle carbon intensity of its ethanol by over 30 gCO2-eq/MJ through deployment of CCS, reducing overall carbon intensity by 40% (16). CCS technologies can also be applied to ethanol production via fermentation of lignocellulosic and sugarcane feedstocks, enabling carbon-negative fuels production (17).

Indeed, carbon capture, utilization, and sequestration from corn ethanol have found a number of applications in recent years. Fermentation from corn ethanol is the largest source for merchant CO2 markets, such as food, beverage, and dry ice, in the United States (18). CO2 from ethanol fermentation has also been used for EOR and sequestered in deep saline aquifers (19). For instance, the Illinois Industrial CCS project in Decatur, Illinois, captures 1 MtCO2/y from a corn ethanol facility with 300 million gallon/y capacity for sequestration in the Mt. Simon sandstone, a saline aquifer. This project has developed technical capacity in geologic storage site characterization, reservoir monitoring, and project development (20). Similarly, Red Trail Energy in Richardton, North Dakota, plans to sequester 180,000 tCO2/y from ethanol fermentation in the Broom Creek Formation by 2020 (21). Both projects take advantage of their proximity to saline aquifers suitable for geologic sequestration, which is one option for long-term CO2 storage. These geologic formations have sufficient volume, permeability, and overlying cap rocks to ensure permanent retention of the injected CO2.

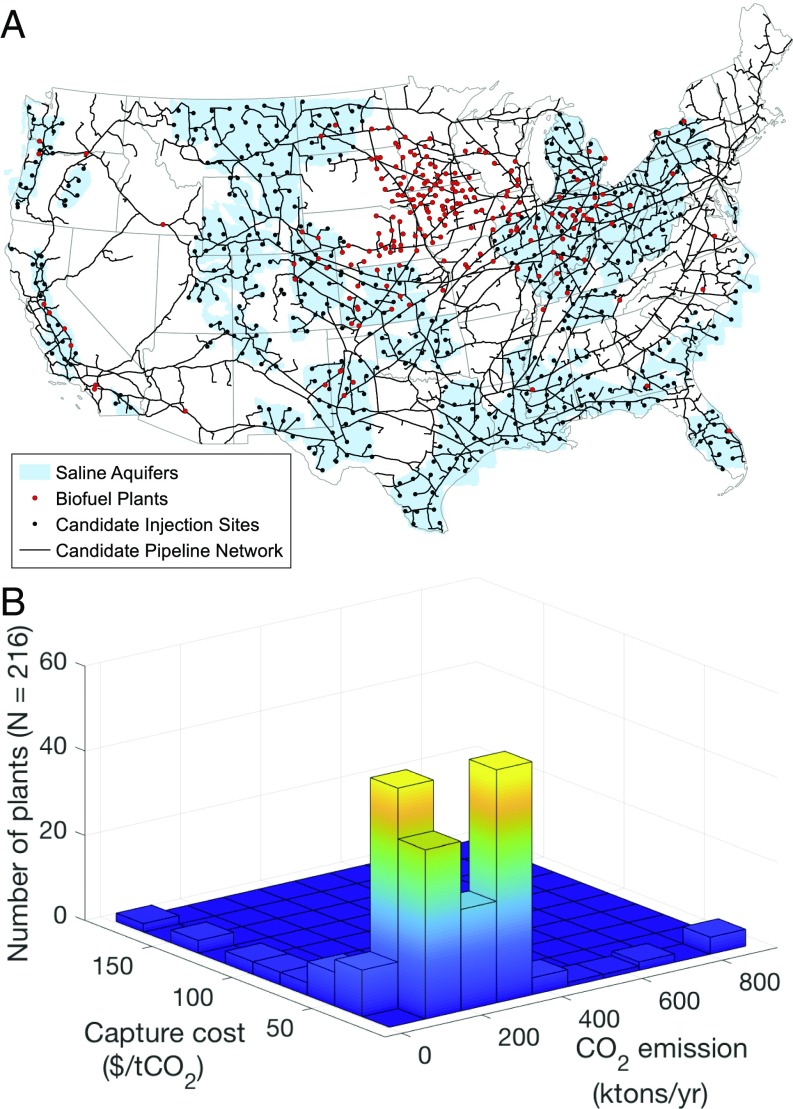

As of late 2016, the United States had capacity to produce 15.8 billion gallons/y of ethanol from 216 biorefineries, equivalent to 6% of the US on-road transportation energy demand (22). These facilities primarily use corn as a feedstock, although some use sorghum, wheat starch, cellulosic biomass, tobacco, and food-processing waste (e.g., cheese whey). Biorefineries producing ethanol are located in 28 US states but are concentrated in the Midwest, where most corn is grown (Fig. 1A). However, large portions of the Midwest do not overlie geology suitable for geologic sequestration. As a result, permanent sequestration of fermentation-derived CO2 from existing biorefineries will necessitate construction of pipelines to transport CO2 to more prospective areas of the United States. Pipeline transport exhibits economies of scale (23, 24), which motivates aggregation of multiple small-volume sources for higher-volume transportation. The cost of long-distance transport of relatively small volumes of CO2 emitted from biorefineries may be prohibitive, especially should aggregation not occur.

Fig. 1.

(A) Existing and planned ethanol biorefineries, saline aquifers, candidate CO2 pipeline rights of way, and candidate injection sites in the United States. Lack of adequate sequestration capacity in proximity of existing biorefineries necessitates the construction of a CO2 transportation network to achieve high levels of abatement. (B) Contour plot of modeled abatement costs and scales for CO2 capture and compression for biorefineries (n = 216); 60% of fermentation CO2 emissions are available for pipeline transport for under $25/tCO2.

Since 2005, the United States and other countries have developed energy and climate policies that could incentivize CO2 capture and sequestration from existing biorefineries. For example, CCS applied to ethanol production can be valued under low-carbon fuels policy, biofuels mandates, supportive CCS policy, and other climate policy instruments as long as emissions benefits are quantified and credited appropriately (25). These policies exist at the subnational, national, and international level.

Here, we evaluate the technical, economic, and institutional feasibility of near-term CO2 capture opportunities for existing biorefineries in the United States using process engineering, spatial optimization, and lifecycle assessment. We provide detailed spatial characterization of (i) fermentation CO2 emissions, (ii) capture and compression costs, (iii) sequestration and abatement costs, and (iv) CO2 transportation costs to sequestration sites. Our modeling framework explicitly considers the economies of scale that can be achieved through aggregation of CO2 sources into integrated pipeline networks, which can reduce overall transportation costs. We also examine recent and proposed policies for low-carbon fuels and CCS to better understand how they might incentivize CCS deployment.

Results

Large-scale deployment of CCS at existing US biorefineries requires detailed characterization of costs and candidate CO2 transport networks. Below, we study (i) fermentation CO2 emissions, (ii) capture and compression costs, (iii) sequestration and abatement costs, (iv) transport costs, and (v) profits under different incentive scenarios. Aggregating quantities and costs results in supply curves for CO2 sequestration and abatement (Methods).

The majority of midwestern biorefineries are not colocated with suitable sites for geologic sequestration (Fig. 1A). Based on source–sink matching, 60% of current nationwide capacity requires pipeline transport to basins in, for instance, Illinois, the Dakotas, Wyoming, or Kansas. Cumulatively, US ethanol biorefineries emit 45 MtCO2/y from fermentation processes. Of this 45 MtCO2/y, 60% (27 MtCO2/y) can be captured, compressed, and dehydrated for pipeline transport for under $25/tCO2 ($0.05 per 1 gallon of ethanol), including both capital and operating expenses (Fig. 1B). Furthermore, 90% (40.5 MtCO2/y) can be made available for pipeline transport for less than $32/tCO2 (Methods). These costs do not include transport or injection into an aquifer. We observe economies of scale in capture costs, with larger facilities generally having lower capture costs. Industrial electricity costs drive the remainder of variation in capture costs among biorefineries.

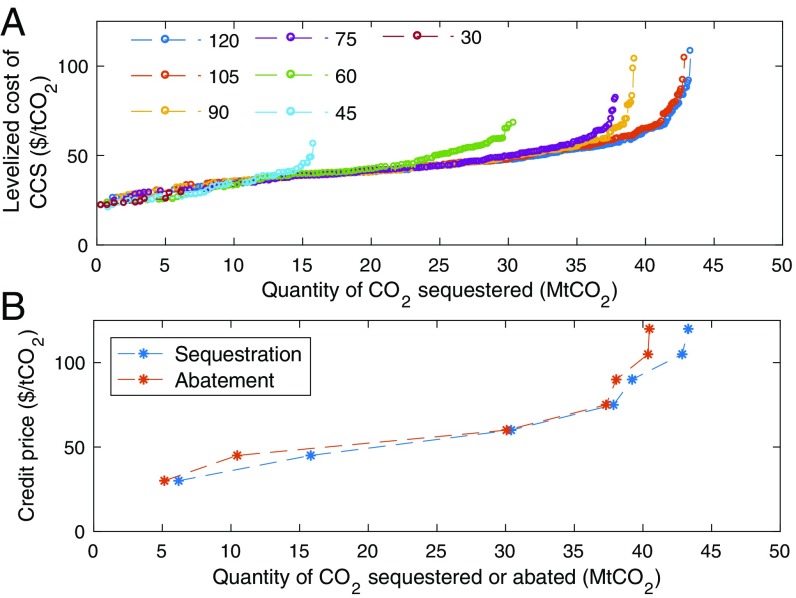

Emissions abatement via CCS is cost-effective over the range of credit prices studied. We determine optimal CCS networks from biorefineries for a range of sequestration credits ($/tCO2 sequestered), which award credit based on the amount of CO2 sequestered, and abatement credits ($/tCO2 abated), which award credit based on the lifecycle amount of CO2 abated. The CO2 emissions abated are always less than the amount of CO2 sequestered due to energy consumption and emissions from capture and compression (Methods and SI Text). Sequestration credits mirror existing CCS tax credits, while abatement credits resemble existing tradeable CO2 credits under energy and climate policies. Sequestration credits of 30, 60, 90, and 120 $/tCO2 are sufficient to sequester 6, 30, 39, and 43 Mt of CO2, respectively (Fig. 2A). Larger facilities generally have lower CCS costs: for instance, a sequestration credit of $60/tCO2 incentivizes capture and sequestration of 68% of available emissions but only from 49% of biorefineries. The quantities of CO2 abated are 7–17% lower than quantities of CO2 sequestered across equivalent price scenarios (Fig. 2B). Across facilities, the ratio of abated to sequestered emissions is 0.93, which indicates that CO2 abatement is nearly as effective as sequestration. The ratio of abated to sequestered CO2 emissions is much higher than for other applications of CCS, as capturing fermentation CO2 emissions does not require energy for dilute CO2 separation (26).

Fig. 2.

Optimal supply curves for (A) CO2 sequestration credits reported at the facility level and (B) system-level CO2 sequestration and CO2 abatement potential under a range of sequestration and abatement credits, respectively. Range: $30–$120/tCO2 in $15 increments.

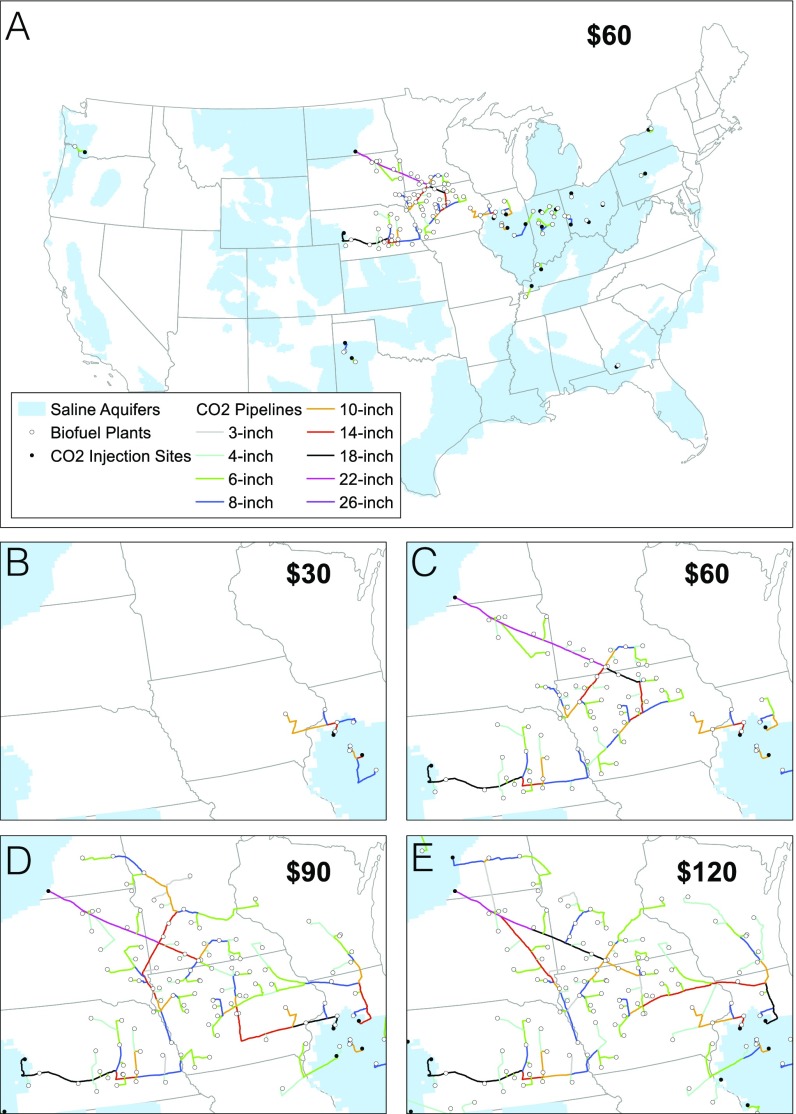

The analyzed sequestration credits drive construction of large-scale CO2 infrastructure throughout the United States, enabling low-cost CCS (Fig. 3). Sequestration credits of $60/tCO2 are sufficient to build large-scale CO2 transportation networks throughout the Midwest as well as point-to-point CO2 transport in the East, the Southeast, the South, and the Northwest (Fig. 3A). This credit incentivizes 6,900 km (4,300 mi) of CO2 pipeline, similar to the existing distance of CO2 pipelines in the United States. We observe larger pipeline networks with larger sequestration credits. For instance, sequestration credits of 30, 90, and 120 $/tCO2 incentivize 690, 11,000, and 15,000 km of pipeline, respectively. High sequestration credits enable transport of increasingly isolated sources of CO2 for geologic sequestration. At $30/tCO2, a low credit price, 64% of abatement with optimized transport networks occurs from biorefineries within 50 miles of an injection point. However, at $90/tCO2, only 35% of abatement occurs within 50 miles. Quantity-weighted average network size increases from 343 km at $30/tCO2 to 3,813 km at $90/tCO2 as CO2 is increasingly transported through large pipeline networks. Similarly, the share of transportation costs in total costs increases from 35 to 43% between these two scenarios (Fig. 4A). These results largely agree with other studies, which indicate that integrated regional networks are valuable for linking CO2 storage capacity to low-cost CO2 resources (6, 27).

Fig. 3.

Optimal capture, transportation, and sequestration networks for (A) sequestration credit of $60/tCO2 at the scale of the United States and sequestration credits of (B) $30/tCO2, (C) $60/tCO2, (D) $90/tCO2, and (E) $120/tCO2 focusing on the midwestern United States.

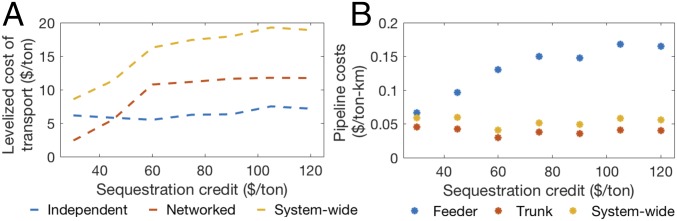

Fig. 4.

(A) Levelized transport costs (dollars per ton) and (B) pipeline costs (dollars per ton-kilometer) across sequestration credit scenarios. Levelized transport costs associated with individual plants are disaggregated between feeder and trunk pipelines. Levelized pipeline costs are allocated between trunk pipelines, which handle CO2 from multiple biorefineries, and feeder pipelines, which transport the CO2 of a single biorefinery. The levelized cost of networked transport increases at higher credit prices as CCS at biorefineries farther from injection points becomes cost-effective and necessitates larger pipeline networks. Trunk pipelines exhibit economies of scale, but feeder pipelines do not. Nevertheless, the levelized cost of transport does not exceed $19/tCO2 in any scenario.

Aggregation of CO2 sources into integrated pipeline networks enables cost-effective long-distance pipeline transport (Fig. 4 and SI Text). Trunk pipelines (i.e., those that carry captured CO2 from multiple biorefineries) can benefit from economies of scale, whereas feeder pipelines that serve only one plant do not. In fact, the levelized cost of feeder pipelines increases with a larger subsidy as smaller biorefineries utilizing smaller feeder pipelines are added to the system. Between sequestration credits of $30 and $120/tCO2, the levelized cost of pipeline transport declines from 4.5¢ to 4.0¢/ton-km for trunk pipelines but increases from 6.6¢ to 16.5¢/ton-km for feeder pipelines (Fig. 4B). For instance, the largest CO2 pipeline is 18 inches for a sequestration credit of $30/tCO2, carrying 3.7 MtCO2/y. In contrast, this amount increases to 22 inches, carrying at least 9.8 MtCO2/y, for sequestration credits between $60 and $120/tCO2. Larger pipeline networks would become increasingly cost-effective if CCS from nonethanol sources of CO2, such as power plants and other industrial sources, becomes economically feasible.

Constraints on geologic storage capacity were not a strong factor in CCS network construction for existing biorefineries. Nevertheless, we find that some saline aquifers bordering the Midwest approach, but do not exceed, their storage capacity over a 20-y injection period. For instance, some injection sites in eastern North Dakota reach up to 69% of their capacity across analyzed sequestration credits, while others in Illinois reach 45%. However, we do not consider competition for storage between biorefineries and fossil fuel plants or other industrial sources of CO2, both of which are situated throughout much of the Midwest. Should other facilities perform CCS in capacity-limited regions, biorefinery operators could be forced to transport their CO2 longer distances.

Profits increase with sequestration and abatement credits, making CCS increasingly lucrative for ethanol producers. Average profits, defined as the difference between cost and credit price, increase from $5.0 to $20.8, $47.8, and $76.1/tCO2 sequestered at $30, $60, $90, and $120/tCO2 sequestered, respectively. At $120/tCO2 sequestered, total profits are as much as $3.3 billion/y (Fig. S2). Profits are similar across abatement credit scenarios. While the distribution of such profits depends on contractual arrangements, there is nevertheless the potential for high profits for biorefineries or CO2 off-takers.

Discussion

Fermentation CO2 streams are a strategic early source for cost-effective CCS deployment in the United States. To assess the technical, economic, and institutional feasibility of CCS from existing biorefineries, we discuss (i) system economics, (ii) emissions impacts, (iii) producer coordination, (iv) additional revenue opportunities, and (v) implications for CCS and BECCS commercialization.

CCS is profitable at existing biorefineries at sequestration credits as low as $30/tCO2 (Fig. 2A). The current paradigm suggests that, although CCS from existing biorefineries has lower capture costs than for less-concentrated CO2 sources, like coal, it faces higher transport and sequestration costs due to their small scale (13, 14, 23). In contrast, our analysis shows that integrated pipeline networks allow sequestration of biorefinery CO2 emissions at low overall cost. Should supportive policy treat biogenic, industrial, and fossil CO2 emissions equally, ethanol is likely a low-cost entry point for CCS in the United States. In practice, consistent accounting for biogenic CO2 emissions and CO2 removal poses considerable challenges to policymakers (25).

Increasingly large sequestration and abatement credits increase producer profits but have declining returns for incremental emissions impacts (Fig. 2B). Declining incremental emissions reductions result from the prevalence of low-cost abatement across biorefineries. There are diminishing returns to CCS as sequestration credits exceed $75/tCO2: at this point, nearly 85% of all fermentation emissions can be sequestered cost-effectively. Beyond this credit price, the value of credits accrues primarily to producers as profit (Fig. S2). Plant or infrastructure operators can profit over $3 billion/y at a sequestration credit price of $120/tCO2.

CCS is effective at reducing the carbon intensity of existing ethanol production, positioning it as an important tool to reduce emissions in the transportation sector. Lifecycle assessment indicates that a typical dry mill ethanol plant in the midwestern United States can reduce overall carbon intensity by at least 40% via CCS (16). At scale, we estimate that biorefineries with CCS can contribute roughly 1.5 billion gallons/y of ethanol to the California market through 2030, providing 7–8 MtCO2/y of abatement on a lifecycle basis or 4–5% of California’s 2030 goal based on demand forecasts, fuel blending constraints, proposed standards, and lifecycle assessments (SI Text). Should biorefiners adopt CCS on corn ethanol production, it would likely qualify as one of the lowest-carbon intensity crop-based fuels produced in the United States. Nevertheless, CCS does not mitigate the detrimental impacts of large-scale corn ethanol production, including high water and fertilizer demands, nitrous oxide emissions, and potential effects on food prices.

Coordination and development of an integrated CO2 transport network are important for low-cost CCS implementation. An integrated approach to pipeline infrastructure offers the lowest average cost for operators over the life of the project if sufficient capacity utilization is achieved relatively early in the life of the pipeline (28). Across scenarios that we consider, the levelized cost of transport does not exceed $19/tCO2 (Fig. 4). While transport costs increase with quantity of CO2 sequestered, pipeline aggregation and the inherently low cost of CO2 capture allow 68% of the available resource to be sequestered at costs at or below $60/tCO2. At short transportation distances, truck transportation of CO2 may be more cost-effective than pipeline transport (14). Integrated pipelines also reduce the barriers to entry and are more likely to lead to faster development and deployment of CCS. There is early momentum for integrated pipeline infrastructure development in the United States: the Carbon Storage Assurance and Facility Enterprise initiative is intended to develop integrated CCS storage complexes constructed and permitted for operation in the 2025 timeframe, including in Nebraska and Kansas (29).

Similar opportunities exist for EOR using fermentation CO2, creating additional revenues. EOR is widely practiced in the United States and currently procures CO2 from biorefineries in Kansas (30). Basins in Texas, Oklahoma, Wyoming, Michigan, and Louisiana constitute current demand, but EOR could potentially expand to California, North Dakota, Colorado, and West Virginia among other states (31). Additional demand may come from EOR in Residual Oil Zones. However, many EOR sites are farther than saline aquifers from the Upper Midwest, where biorefineries are concentrated. Ultimately, the choice of CO2 sequestration in saline aquifers or via EOR will depend on economics, policy instruments, and storage regulations. Finally, our analysis suggests that other countries, including Brazil, China, Canada, and the European Union (EU), could adopt CCS at ethanol biorefineries at low costs (SI Text).

Sequestration and abatement credits can develop experience in carbon sequestration, project finance, and business models for CCS. The rate of fermentation CO2 emissions is an order of magnitude larger than existing dedicated-storage geologic injection rates and is twofold higher than rates of industrial CO2 sequestered via EOR (10, 30). Importantly, implementation does not rely on widespread deployment of costly or unproven solvents, sorbents, or membranes for commercial-scale CO2 capture (SI Text). Capture at existing biorefineries also provides valuable experience for future cellulosic biorefineries equipped with CCS, which will have similar scale and CO2 purity. Cellulosic biorefineries with CCS can achieve net negative lifecycle emissions, playing an important role in stringent climate change mitigation scenarios (17). Furthermore, there is a geographic overlap between existing ethanol biorefineries and potential cellulosic feedstocks, like agricultural residues and dedicated energy crops (6). As such, CO2 transportation infrastructure for existing biorefineries could support CCS at future cellulosic biorefineries in the United States. In this scenario, transport operators may wish to overbuild CO2 pipelines in anticipation of future CO2 supply from advanced BECCS technologies. Prior work has identified overbuilding as cost-effective when CO2 supply is expected to increase over time (32).

Policy Context

Recent financial incentives offered under state and national policy suggest a substantial near-term opportunity to permanently sequester biogenic CO2. Below, we highlight the opportunities and shortcomings of existing policies to incentivize CCS from biorefineries. We find that low-carbon fuel and CCS policies in the United States can likely incentivize CCS, but national and international quantity mandates fail to provide adequate incentives as currently designed.

Market-based incentives for CO2 abatement in the transportation sector, both in the United States and internationally, can incentivize CCS. For instance, several states and provincial jurisdictions (e.g., California, Oregon, British Columbia) have implemented low-carbon fuel standards (LCFSs), which are market-based policies to reduce the lifecycle carbon intensity of transportation fuels over time (33). These systems provide an economic incentive for emissions abatement in biofuel production. Their potential can be evaluated through the analogous abatement credits that we study. Average monthly abatement credit prices in California’s LCFS have ranged from ∼$75 to $125/tCO2 since late 2015, with a price ceiling of $200/tCO2. Political uncertainty surrounding California’s climate programs has recently been resolved, and analyses suggest that LCFS credit prices will remain high, particularly if post-2020 targets are tightened (34). Currently, California is developing a quantification methodology and permanence protocol for CCS that will enable its use in the LCFS and, potentially, cap and trade programs. Should these methodologies be adopted as part of the LCFS, biorefiners will be able to provide an additional source of low-carbon ethanol to California, helping fulfill the mandates of the LCFS.

Similar CCS opportunities exist in other jurisdictions implementing LCFSs. Oregon’s Clean Fuel Standard can adopt fuel pathways from California’s LCFS, easing regulatory implementation of CCS. Canada is currently developing a national Clean Fuels Standard to achieve 30 MtCO2 of annual reductions by 2030, which would extend LCFS policies beyond the province of British Columbia (35). Canada is currently the largest importer of United States ethanol: should it implement a Clean Fuels Standard, it could serve as an additional market driver for CCS deployment for ethanol (36).

Newly revised CCS tax policy in the United States can also produce revenues for existing ethanol biorefineries. The Bipartisan Budget Act of 2018 (H.R. 1892) includes a 12-y tax credit of up to $50/tCO2 sequestered in secure geologic storage, which is similar to the sequestration credits that we study (37). This proposal expands an existing tax credit for CO2 sequestration, which was previously $20/tCO2 (38). Smaller tax credits would also be available for EOR operations. We estimate that 99% of fermentation CO2 from biorefineries in the United States meets the minimum facility-level capture threshold of 25,000 tCO2 sequestered per year. While other sources of industrial CO2 would also qualify for this tax credit, our analysis suggests that biorefineries could be a cost-effective option for industrial CCS at the national scale.

In contrast to other policy instruments, biofuel quantity mandates fail to provide incentive for CCS at existing biorefineries as currently designed. For instance, the US Renewable Fuels Standard (RFS) provides limited support for CCS deployment on biofuels, as all corn ethanol production is statutorily mandated as a “conventional biofuel” and generates the lowest priced category of credit (39). Moreover, the binned structure of the RFS means that even producers of “advanced biofuels” from other feedstocks do not directly benefit from reductions in carbon intensity of their fuels. Nevertheless, the US Environmental Protection Agency has proposed registration, recordkeeping, and reporting requirements to allow CCS in the RFS. The EU is currently evaluating its post-2020 climate policy; however, it is unclear if the EU will eliminate its Fuel Quality Directive, which regulates the carbon intensity of transportation fuels, in favor of a quantity-based mandate (33). Without a carbon intensity regulation, European policy may not provide adequate incentive for CCS. Similarly, Canada’s Renewable Fuels Regulations do not currently require lifecycle emissions reductions (35). Quantity mandates are the primary driver of ethanol exports: as a result, international policy changes may be necessary to encourage further markets for ethanol with CCS (36). We also note that policy uncertainty, including evolving regulations, repeated expiration and renewal of policies, and lack of coordination between policymakers, can affect revenues and finance for CCS at existing biorefineries.

Conclusion

The challenge as well as the importance of meeting gigatonne-scale CO2 removal envisioned in stringent climate change mitigation scenarios cannot be overstated. However, CCS integration at biorefineries could catalyze the growth of carbon capture, transport, and sequestration in the United States. Such deployments would build critical experience with carbon sequestration, project finance, and business models for CCS, which would be applicable worldwide. Finally, existing and proposed policies seem poised to make CCS integration cost-effective. Deploying CCS at existing biorefineries is an important step forward toward understanding the potential for large-scale BECCS.

Methods

Data Development.

We estimate facility-level CO2 fermentation emissions based on current and under construction production and apply an emissions factor of 2,853 tCO2/million gallons ethanol production as in ref. 19. We estimate capital and operating costs for CO2 capture and compression using methods developed in ref. 40, with updates to fermentation CO2 parameters from ref. 13 and state-level industrial electricity prices from the Energy Information Administration. We assume that biorefineries use grid electricity for compression, which is priced at state-level industrial electricity prices, and have a carbon intensity equal to that of the North American Electric Reliability Corporation subregion. We estimate the cost and capacity of CO2 pipelines constructed from X80 steel with o.d. values of 3, 4, 6, 8, 10, 14, 18, 22, 26, and 30 inches based on data and methods in refs. 23 and 24. We assess site-specific sequestration costs, which include the cost of site characterization based on areal footprint, well drilling and completion, injection equipment, operating and maintenance costs, and ongoing monitoring and verification costs, based on methods in refs. 41 and 42 (SI Text). We include a fixed cost of $52 million per site to account for development costs. We calculate CO2 abatement costs by accounting for regional variation in the carbon intensity of electricity supplied for compression, adopting lifecycle assessment methods and data used by the State of California (43). We assume a 10% cost of capital and a 20-y project lifetime. We adjust capital costs of pipelines to 2014 using US Bureau of Labor Statistics cost indices and the costs of storage using the Information Handling Services (IHS) Upstream Capital Cost Index.

Candidate CO2 pipeline rights of way follow existing natural gas pipelines as reported by the National Pipeline Mapping System (44). Where existing pipelines do not exist, possible rights of way are added by following major roads. The lengths of portions of the candidate network that pass through urban areas (US Census Bureau) and/or mountainous regions (slope greater than 8%) are adjusted to reflect a 50% increase in total construction cost under these conditions.

Problem Statement and Scenarios.

We minimize the total cost of capture, compression, transportation, and sequestration using integer programming to identify cost-effective sequestration opportunities (6, 45) (SI Text). Our five decision variables consist of two positive continuous variables representing CO2 flow through each pipeline segment and the amount of CO2 injected into each aquifer resource as well as three binary variables that identify the activation of individual pipeline segments, aquifer resources, and CO2 capture at biorefineries. Our model is implemented in the General Algebraic Modeling System and solved using a branch-and-bound method. As a result of model complexity, solutions yield optimality gaps of 10–50%, which mean that solutions should be considered feasible but not necessarily optimal. As a result, implementation of CCS at each subsidy level is likely even more favorable than indicated by this study.

In each scenario, we assume a credit price for sequestration or abatement. System boundaries are described in detail in SI Text. Sequestration credits emulate existing CCS tax credits (37), while abatement credits emulate tradeable climate policy instruments, such as credit prices in an LCFS (33). In practice, price volatility, the availability of other low-carbon transportation fuels, lifecycle emissions accounting, tax equity availability, and policy duration will affect the cost-effectiveness of a CCS project incentivized by tax credits or tradeable permit systems. We do not explicitly assess other potential revenue streams, including utilization options, like EOR or beverage carbonation. We define profit as the difference between cost and credit price and do not formally consider ethanol production costs.

We generate supply curves both at the facility level and the system level. Facility-level supply curves depict capture, transport, and sequestration costs at each biorefinery for a given credit price (Fig. 2A and Fig. S1). System-level supply curves depict overall abatement or sequestration at the industry level for a given credit price (Fig. 2B). We calculate facility-level transportation costs by assigning the full cost of pipelines used by individual plants (e.g., feeder pipelines) to each respective plant and identifying a levelized cost of injection for each shared network, which is paid by each plant participating on that network. This approach simulates a scenario in which an independent pipeline operator charges a fixed rate for usage of the network. However, this does mean that each plant on an individual network pays the same rate regardless of their proximity to an injection site. Feeder pipelines are defined as pipelines that are used by only one plant, while trunk pipelines are shared among many plants.

Data Access.

Biorefinery data presented here are available online from the Renewable Fuels Association at www.ethanolrfa.org/resources/biorefinery-locations/. Existing pipeline rights of way are available at https://www.npms.phmsa.dot.gov/. National Carbon Sequestration database data on saline aquifers are available at https://www.netl.doe.gov/research/coal/carbon-storage/natcarb-atlas.

Supplementary Material

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1719695115/-/DCSupplemental.

References

- 1.Fuss S, et al. Betting on negative emissions. Nat Clim Chang. 2014;4:850–853. [Google Scholar]

- 2.Sanchez DL, Nelson JH, Johnston J, Mileva A, Kammen DM. Biomass enables the transition to a carbon-negative power system across western North America. Nat Clim Chang. 2015;5:230–234. [Google Scholar]

- 3.Sanchez DL, Kammen DM. A commercialization strategy for carbon-negative energy. Nat Energy. 2016;1:15002. [Google Scholar]

- 4.Fuss S, et al. Research priorities for negative emissions. Environ Res Lett. 2016;11:115007. [Google Scholar]

- 5.Anderson K, Peters G. The trouble with negative emissions. Science. 2016;354:182–183. doi: 10.1126/science.aah4567. [DOI] [PubMed] [Google Scholar]

- 6.Johnson N, Parker N, Ogden J. How negative can biofuels with CCS take us and at what cost? Refining the economic potential of biofuel production with CCS using spatially-explicit modeling. Energy Procedia. 2014;63:6770–6791. [Google Scholar]

- 7.Smith P, et al. Biophysical and economic limits to negative CO2 emissions. Nat Clim Chang. 2016;6:42–50. [Google Scholar]

- 8.SEAB CO2 Utilization Task Force 2016 SEAB task force report on CO2 utilization and negative emissions technologies (Secretary of Energy Advisory Board, Washington, DC). Available at https://www.energy.gov/sites/prod/files/2016/12/f34/SEAB-CO2-TaskForce-FINAL-with%20transmittal%20ltr.pdf.

- 9.Sanchez DL, Sivaram V. Saving innovative climate and energy research: Four recommendations for Mission Innovation. Energy Res Soc Sci. 2017;29:123–126. [Google Scholar]

- 10.Global CCS Institute 2016 The global status of CCS: Summary report Available at https://www.globalccsinstitute.com/publications/global-status-ccs-2016-summary-report. Accessed July 3, 2017.

- 11.Xu Y, Isom L, Hanna MA. Adding value to carbon dioxide from ethanol fermentations. Bioresour Technol. 2010;101:3311–3319. doi: 10.1016/j.biortech.2010.01.006. [DOI] [PubMed] [Google Scholar]

- 12.Greenberg SE, McKaskle R. Insights into Cost of CCS Gained from the Illinois Basin-Decatur Project. Carbon Sequestration Leadership Forum; Washington, DC: 2016. [Google Scholar]

- 13.Herron S, Zoelle A, Summers WM. Cost of Capturing CO2 from Industrial Sources. Natl Energy Technology Lab; Pittsburgh, PA: 2014. [Google Scholar]

- 14.Psarras PC, et al. Carbon capture and utilization in the industrial sector. Environ Sci Technol. 2017;51:11440–11449. doi: 10.1021/acs.est.7b01723. [DOI] [PubMed] [Google Scholar]

- 15.Bains P, Psarras P, Wilcox J. CO2 capture from the industry sector. Prog Energy Combust Sci. 2017;63:146–172. [Google Scholar]

- 16.McCoy S. 2016 Reducing lifecycle biofuel emissions with CCS. Available at https://www.cslforum.org/cslf/sites/default/files/documents/tokyo2016/McCoy-BiofuelsCCS-TG-Tokyo1016.pdf. Accessed September 3, 2017.

- 17.Muratori M, et al. Carbon capture and storage across fuels and sectors in energy system transformation pathways. Int J Greenhouse Gas Control. 2017;57:34–41. [Google Scholar]

- 18.Mueller S, Rushing SA. 2017 Ethanol industry provides critical CO2 supply. Ethanol Producer Magazine. Available at www.ethanolproducer.com/articles/14122/. Accessed April 5, 2017.

- 19.Hornafius KY, Hornafius JS. Carbon negative oil: A pathway for CO2 emission reduction goals. Int J Greenhouse Gas Control. 2015;37:492–503. [Google Scholar]

- 20.Finley RJ. An overview of the Illinois basin–Decatur project. Greenhouse Gases Sci Technol. 2014;4:571–579. [Google Scholar]

- 21.Gibson L. 2017 Red Trail Energy moves forward with carbon capture research. Ethanol Producer Magazine. Available at www.ethanolproducer.com/articles/14428/red-trail-energy-moves-forward-with-carbon-capture-research. Accessed July 3, 2017.

- 22.Davis SC, Williams SE, Boundy RG. Transportation Energy Data Book. 36th Ed Oak Ridge Natl Lab; Oak Ridge, TN: 2017. [Google Scholar]

- 23.Knoope MMJ, Guijt W, Ramírez A, Faaij APC. Improved cost models for optimizing CO2 pipeline configuration for point-to-point pipelines and simple networks. Int J Greenhouse Gas Control. 2014;22:25–46. [Google Scholar]

- 24.McCoy ST, Rubin ES. An engineering-economic model of pipeline transport of CO2 with application to carbon capture and storage. Int J Greenhouse Gas Control. 2008;2:219–229. [Google Scholar]

- 25.Lomax G, Lenton TM, Adeosun A, Workman M. Investing in negative emissions. Nat Clim Chang. 2015;5:498–500. [Google Scholar]

- 26.Corsten M, Ramírez A, Shen L, Koornneef J, Faaij A. Environmental impact assessment of CCS chains–Lessons learned and limitations from LCA literature. Int J Greenhouse Gas Control. 2013;13:59–71. [Google Scholar]

- 27.Middleton RS, Bielicki JM. A scalable infrastructure model for carbon capture and storage: SimCCS. Energy Policy. 2009;37:1052–1060. [Google Scholar]

- 28.Chrysostomidis I, et al. Assessing issues of financing a CO2 transportation pipeline infrastructure. Energy Procedia. 2009;1:1625–1632. [Google Scholar]

- 29.US Department of Energy 2016 DOE announces $68.4 million in funding to advance the safe and permanent storage of CO2. Energy.gov. Available at https://energy.gov/fe/articles/doe-announces-684-million-funding-advance-safe-and-permanent-storage-co2. Accessed July 7, 2017.

- 30.Wallace M, Kuuskraa VA. Near-Term Projections of CO2 Utilization for Enhanced Oil Recovery. Natl Energy Technology Lab; Pittsburgh, PA: 2016. [Google Scholar]

- 31.Advanced Resources International 2010. U.S. Oil Production Potential from Accelerated Deployment of Carbon Capture and Storage (Advanced Resources International, Arlington, VA)

- 32.Middleton RS, Kuby MJ, Wei R, Keating GN, Pawar RJ. A dynamic model for optimally phasing in CO2 capture and storage infrastructure. Environ Model Softw. 2012;37:193–205. [Google Scholar]

- 33.Yeh S, Witcover J, Lade GE, Sperling D. A review of low carbon fuel policies: Principles, program status and future directions. Energy Policy. 2016;97:220–234. [Google Scholar]

- 34.Christensen A, Hobbs B. A model of state and federal biofuel policy: Feasibility assessment of the California Low Carbon Fuel Standard. Appl Energy. 2016;169:799–812. [Google Scholar]

- 35.Environment and Climate Change Canada 2017 Clean fuel standard: Discussion paper. Available at https://www.canada.ca/en/environment-climate-change/services/canadian-environmental-protection-act-registry/clean-fuel-standard-discussion-paper.html. Accessed July 14, 2017.

- 36.Dickinson C. 2016. 2016 Top Markets Report: Renewable Fuels (International Trade Association Washington, DC)

- 37.Larson J. 2018 H.R.1892–115th Congress (2017–2018): Bipartisan Budget Act of 2018. Available at https://www.congress.gov/bill/115th-congress/house-bill/1892. Accessed February 10, 2018.

- 38. 26 USC § 45Q–Credit for carbon dioxide sequestration. (Legal Information Institute, Cornell Law School, Ithaca, NY). Available at https://www.law.cornell.edu/uscode/text/26/45Q. Accessed July 5, 2017.

- 39. 40 CFR Part 80, Subpart M–Renewable Fuel Standard. (Legal Information Institute, Cornell Law School, Ithaca, NY). Available at https://www.law.cornell.edu/cfr/text/40/part-80/subpart-M. Accessed July 5, 2017.

- 40.McCollum DL, Ogden JM. 2006 Techno-economic models for carbon dioxide compression, transport, and storage & correlations for estimating carbon dioxide density and viscosity (Institute of Transportation Studies). Available at https://cloudfront.escholarship.org/dist/prd/content/qt1zg00532/qt1zg00532.pdf. Accessed May 5, 2017.

- 41.Ogden J, Johnson N. 2010. Techno-economic analysis and modeling of carbon dioxide (CO2) capture and storage (CCS) technologies. Developments and Innovation in Carbon Dioxide (CO2) Capture and Storage Technology, Carbon Dioxide (CO2) Capture, Transport, and Industrial Applications, ed Maroto-Valer M (Woodhead Publ, Sawston, Cambridge, United Kingdom), Vol 1, pp 27–63.

- 42.McCoy ST. The Economics of CO2 Transport by Pipeline and Storage in Saline Aquifers and Oil Reservoirs. Carnegie Mellon Univ; Pittsburgh, PA: 2008. [Google Scholar]

- 43.California Air Resources Board 2018 CA-GREET 2.0 Model. Available at https://www.arb.ca.gov/fuels/lcfs/ca-greet/ca-greet.htm. Accessed May 5, 2017.

- 44.Johnson NAC. 2012 Detailed spatial modeling of coal-based hydrogen infrastructure deployment with carbon capture and storage: Methods, implications, and insights. Available at https://search.proquest.com/openview/32859dcc9dbeac35796e57c8a8abf73e/1?pq-origsite=gscholar&cbl=18750&diss=y. Accessed May 5, 2017.

- 45.Hasan MMF, Boukouvala F, First EL, Floudas CA. Nationwide, regional, and statewide CO2 capture, utilization, and sequestration supply chain network optimization. Ind Eng Chem Res. 2014;53:7489–7506. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.