Abstract

Objectives

To evaluate the mechanical properties and metallurgical characteristics of the M3 Rotary and M3 Pro Gold files (United Dental).

Materials and Methods

One hundred and sixty new M3 Rotary and M3 Pro Gold files (sizes 20/0.04 and 25/0.04) were used. Torque and angle of rotation at failure (n = 20) were measured according to ISO 3630-1. Cyclic fatigue resistance was tested by measuring the number of cycles to failure in an artificial stainless steel canal (60° angle of curvature and a 5-mm radius). The metallurgical characteristics were investigated by differential scanning calorimetry. Data were analyzed using analysis of variance and the Student-Newman-Keuls test.

Results

Comparing the same size of the 2 different instruments, cyclic fatigue resistance was significantly higher in the M3 Pro Gold files than in the M3 Rotary files (p < 0.001). No significant difference was observed between the files in the maximum torque load, while a significantly higher angular rotation to fracture was observed for M3 Pro Gold (p < 0.05). In the DSC analysis, the M3 Pro Gold files showed one prominent peak on the heating curve and 2 prominent peaks on the cooling curve. In contrast, the M3 Rotary files showed 1 small peak on the heating curve and 1 small peak on the cooling curve.

Conclusions

The M3 Pro Gold files showed greater flexibility and angular rotation than the M3 Rotary files, without decrement of their torque resistance. The superior flexibility of M3 Pro Gold files can be attributed to their martensite phase.

Keywords: Cyclic fatigue, Differential scanning calorimeter, Heat-treatment, M3 Pro Gold, M3 Rotary, Torsional resistance

INTRODUCTION

The introduction of nickel-titanium (NiTi) rotary instruments has been beneficial for endodontic practice [1,2]. Despite the good mechanical properties of NiTi alloys, the possibility of instrument separation is still a major concern during the clinical use of NiTi files [3]. Many variables contribute to file separation, but the 2 main causes are cyclic fatigue and torsional stress [4]. Cyclic flexural fatigue of an instrument occurs when the instrument is rotated in a curved canal by repeated compressive and tensile stresses, while torsional failure occurs when the tip of the instrument binds in the canal, but the motor continues to rotate. The elastic limit of the instrument is exceeded, causing plastic deformation and, subsequently, failure [5].

The variables that contribute to file separation include instrument size and cross-sectional area [6,7], design [8], metal surface treatments [1], and the metallurgical characteristics of the NiTi alloy, among others [9]. Therefore, several manufacturers have developed special forms of thermomechanical processing, with the aim of producing a superelastic NiTi alloy that primarily contains a stable martensitic phase under clinical conditions [10]. In recent years, NiTi rotary instruments made from a NiTi controlled memory wire (CM wire, DS Dental, Johnson City, TN, USA) have been introduced. The manufacturer claims that these instruments have superior flexibility and fatigue resistance to conventional NiTi rotary instruments made from superelastic wire [11].

The M3 Rotary file (M3, United Dental, Shanghai, China) is a newly introduced NiTi instrument that was designed to be used in continuous rotation with an inactive tip and a convex triangular cross-section; it consists of 3 instruments with sizes 20, 25, and 30 tip sizes and a 0.04 taper. In addition, opener and glide path files are also provided [12]. According to the producer, it is manufactured using an advanced memory alloy technology that can increase cyclic fatigue resistance. The manufacturer claims that this instrument allows quick and safe preparation of root canals, especially of curved root canals [12]. Recently, M3 Rotary has been upgraded to M3 Pro Gold (United Dental). These files have the same geometrical and design features as the M3 Rotary files, but undergo a different heat treatment. M3 Pro Gold files are manufactured with a CM wire associated with a gold treatment, which allows greater flexibility [13].

To date, no data are available on the mechanical properties of the M3 Pro Gold file, such as torsional stress and cyclic fatigue resistance. Hence, the aim of this work was to investigate the cyclic fatigue, maximum torque load, angular rotation, and metallurgical characteristics of the M3 Pro Gold file and to compare these findings with those of the M3 Rotary file.

MATERIALS AND METHODS

Sample size estimation was calculated a priori with G*Power 3.1.9.2 software (Heinrich-Heine-Universität Düsseldorf, Düsseldorf, Germany) [14]. The M3 Rotary size 20, 0.04 taper; M3 Rotary size 25, 0.04 taper; M3 Pro Gold size 20, 0.04 taper; and M3 Pro Gold size 25, 0.04 taper were used in this study. All tested files were 25 mm long, with 20 instruments each consumed in cyclic fatigue and torsional resistance tests. Every instrument was inspected for defects or deformities before the experiment under a stereomicroscope (SZR-10, Optika, Bergamo, Italy); none was discarded. The torsional load was applied until fracture to estimate the mean ultimate torsional strength, and the angle of rotation of the instruments was tested using a custom-made device produced following ISO 3630-1 [4].

Each file was clamped at 3 mm from the tip using a chuck connected to a torque-sensing load cell, after which the shaft of the file was fastened into an opposing chuck able to be rotated with a stepper motor. All tested files were rotated in the clockwise direction at a speed of 2 revolutions per minute until file separation. The torque load (N·cm) and angular rotation (°) were monitored continuously using a torsiometer (Sabri Dental Enterprises, Downers Grove, IL, USA) at room temperature (21°C ± 1°C), and the ultimate torsional strength and angle of rotation at failure were recorded.

The cyclic fatigue tests were performed using a custom-made device that allowed a reproducible simulation of an instrument confined in an artificial curved canal, as described previously [15,16]. The artificial canal was manufactured by reproducing the instrument size and taper, thus providing the instrument with a suitable trajectory with a 60° angle of curvature and a 5-mm radius of curvature. The instruments were rotated at a constant speed of 300 rpm using a 6:1 reduction handpiece (Sirona, Bensheim, Germany) powered by a torque-controlled endodontic motor (Silver, VDW, Munich, Germany). To reduce the friction of the file as it contacted the artificial canal walls, a special high-flow synthetic oil designed for the lubrication of mechanical parts (Super Oil, Singer Co. Ltd., Elizabethport, NJ, USA) was applied. All instruments were rotated until fracture occurred. After positioning the instrument into the artificial canal, as soon as rotation started, timing was initiated. Timing was stopped when instrument breakage was observed. For each instrument, the time to fracture in seconds was recorded by the same operator with a chronometer. The number of cycles to failure for each instrument was calculated by multiplying the time (seconds) to failure by the number of rotations or cycles per second. The length of the fractured file tip was measured using a digital microcaliper (Mitutoyo, Kawasaki, Japan). The fracture surfaces of all fragments were examined under a scanning electron microscope (ZEISS Supra 35VP, Oberkochen GmBH, Oberkochen, Germany) to investigate the topographic features of the fractured instruments.

Differential scanning calorimetry (DSC)

To investigate the thermal properties of the M3 Rotary and M3 Pro Gold files, DSC analysis (TA Instruments, New Castle, DE, USA) was also carried out [17]. For the DSC analysis, small segments of each file were placed in an aluminum pan on a platinum holder inside the measuring chamber of the DSC instrument. An empty pan was included as reference. The chamber was filled with argon gas with high purity to minimize any oxidation. The exothermic or endothermic energy flow was then recorded by raising the temperature to 100°C, lowering it to −100°C, and then re-raising it to 100°C. Liquid nitrogen was used as a coolant in this experiment. The heating and cooling rate was 0.17 °C/s. The martensite transformation starting point (Ms), martensite transformation finishing point (Mf), R-phase transformation starting point (Rs), R-phase transformation finishing point (Rf), austenite transformation starting point (As), and austenite transformation finishing point (Af) were determined.

Statistical analysis

The data were first checked using the Kolmogorov-Smirnov test for normality of the distribution and using the Levene test for the homogeneity of variance. Then, the data were statistically evaluated by the analysis of variance test and the Student-Newman-Keuls test for multiple comparisons (Prism 5.0, GraphPad Software, Inc., La Jolla, CA, USA) with the significance level established at 5% (p < 0.05).

RESULTS

The mean and standard deviation values of cyclic fatigue resistance, maximum torque load, and angle of rotation until fracture for each instrument are presented in Table 1.

Table 1. Cyclic fatigue, torque, and angle of rotation of the instruments tested.

| Instrument | Cyclic fatigue (NCF) | Torque (N·cm) | Angle of rotation (°) |

|---|---|---|---|

| M3 Rotary 20/0.04 | 564 ± 2a | 0.53 ± 0.02a | 295 ± 1a |

| M3 Pro Gold 20/0.04 | 961 ± 2b | 0.56 ± 0.01a | 494 ± 2b |

| M3 Rotary 25/0.04 | 452 ± 2c | 0.71 ± 0.02b | 392 ± 2c |

| M3 Pro Gold 25/0.04 | 836 ± 2d | 0.75 ± 0.01b | 596 ± 1d |

Data were shown with means ± standard deviations. Different superscript letters in the same column indicate statistically significant differences among groups (p < 0.05).

NCF, number of cycles to failure.

When comparing the same size of the 2 different instruments, a statistically significant difference in terms of cyclic fatigue resistance (p < 0.001) was noted. In particular, the M3 Pro Gold files exhibited higher cyclic fatigue resistance than the M3 Rotary files (p < 0.001). In addition, when comparing different sizes of the same instrument, tip size 20 and 0.04 taper showed higher cyclic fatigue resistance than tip size 25 and 0.04 taper (p < 0.05). Moreover, the M3 Pro Gold size 20/0.04 exhibited the highest values of cyclic fatigue resistance of all tested instruments (p < 0.05).

Regarding the maximum torsional strength, no statistically significant difference was observed when the same size of the 2 different instruments was compared, while there was a significant difference between the different sizes of the same instrument (p < 0.05). In particular, tip size 25 and 0.04 taper showed a higher maximum torsional strength than tip size 20 and 0.04 taper (p < 0.05).

Comparing the same size of the 2 different instruments, the M3 Pro Gold files showed significantly higher angular rotation to fracture (and therefore significantly higher time before torsional fracture) than the M3 Rotary files (p < 0.001). In addition, when comparing different sizes of the same instrument, tip size 25 and 0.04 taper was associated with a higher angular rotation to fracture (p < 0.05). In particular, M3 Pro Gold size 25/0.04 exhibited the highest angular rotation to fracture of all tested files (p < 0.05).

The mean length of the fractured fragment (3 mm and 5.1 mm for instruments tested for torsional and cyclic fatigue, respectively) was not significantly different for any of the instruments tested.

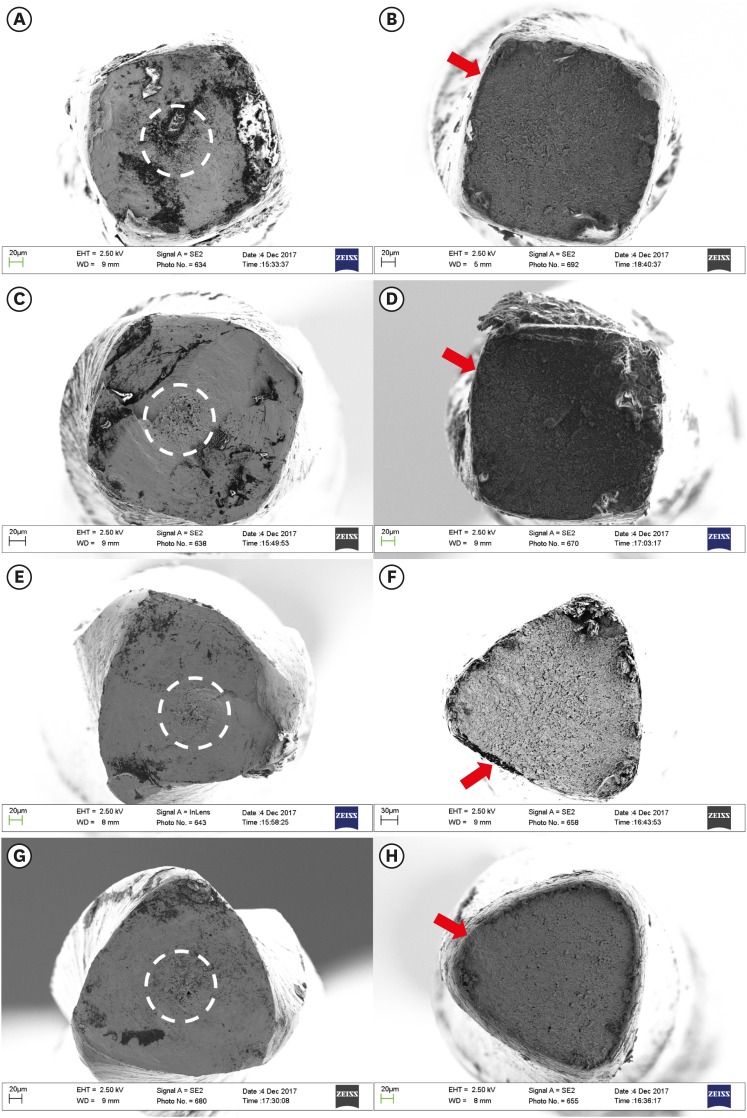

Scanning electron microscopy of the fracture surface showed similar and typical features of cyclic fatigue and torsional failure for all instruments. The crack initiation area and overload fast fracture zone for cyclic fatigue fractures and concentric abrasion marks and the fibrous dimple marks at the center of rotation for torsional failure are shown in Figure 1.

Figure 1.

Scanning electron micrographs of the fracture surface of the separated fragments. (A, B) M3 Rotary size 20/0.04; (C, D) M3 Pro Gold size 20/0.04; (E, F) M3 Rotary size 25/0.04; (G, H) M3 Pro Gold size 25/0.04. (A, C, E, G) The left column shows the images after the torsional test, with the circular box indicating the concentric abrasion mark; the skewed dimples near the center of rotation are typical features of torsional failure. (B, D, F, H) The right column shows images after the cyclic fatigue test, with red arrows indicating the crack initiation origin; the surface pattern shows dimples and cones observed in the same fracture plane.

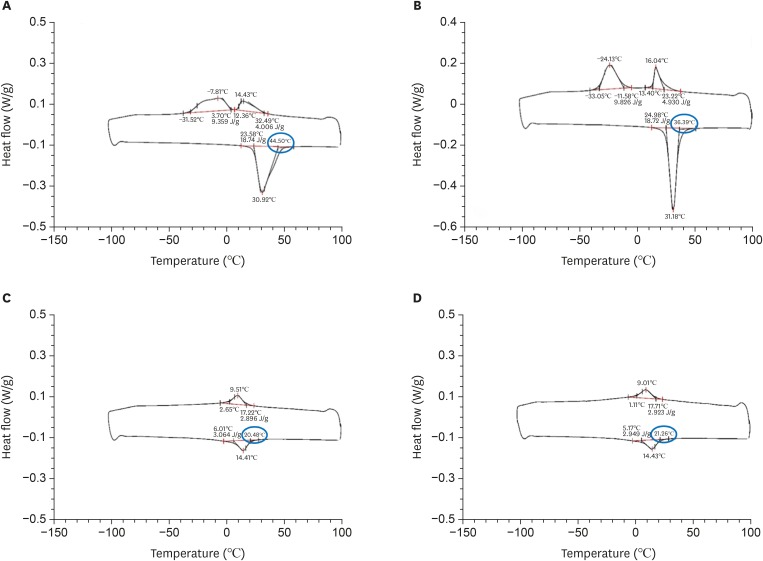

The results of DSC analysis (As, Af, Rs, Rf, Ms, and Mf) are shown in Table 2. M3 Pro Gold showed 1 prominent peak on the heating curve and 2 prominent peaks on the cooling curve. In contrast, the M3 Rotary files showed 1 small peak on the heating curve and 1 small peak on the cooling curve. The peaks observed for the M3 Rotary files were much less intense that those observed for the M3 Pro Gold files, as shown in Figure 2.

Table 2. Transformation temperatures (°C) for the nickel-titanium rotary instruments that were tested for 3 samples of each instrument.

| Instrument | Cooling | Heating | ||||||

|---|---|---|---|---|---|---|---|---|

| Rs | Rf | Ms | Mf | Rs | Rf | As | Af | |

| M3 Pro Gold size 20/0.04 | 32.49 ± 0.20 | 12.36 ± 0.22 | 3.70 ± 0.17 | −31.52 ± 0.23 | - | - | 23.58 ± 0.12 | 44.50 ± 0.18 |

| M3 Pro Gold size 25/0.04 | 23.22 ± 0.19 | 13.40 ± 0.24 | −11.58 ± 0.16 | −33.05 ± 0.22 | - | - | 24.98 ± 0.15 | 36.39 ± 0.17 |

| M3 Rotary size 20/0.04 | - | - | 17.22 ± 0.16 | 2.65 ± 0.22 | - | - | 6.01 ± 0.14 | 20.48 ± 0.16 |

| M3 Rotary size 25/0.04 | - | - | 17.71 ± 0.18 | 1.11 ± 0.21 | - | - | 5.17 ± 0.12 | 21.26 ± 0.19 |

Data were shown with mean ± standard deviations.

Ms, martensite transformation starting point; Mf, martensite transformation finishing point; Rs, R-phase transformation starting point; Rf, R-phase transformation finishing point; As, austenite transformation starting point; Af, austenite transformation finishing point.

Figure 2.

Typical differential scanning calorimetry (DSC) diagram obtained from (A) an M3 Pro Gold size 20/0.04 file, (B) an M3 Pro Gold size 25/0.04 file, (C) an M3 Rotary size 20/0.04 file, and (D) an M3 Rotary size 25/0.04 file. Blue circles indicate the austenite transformation finishing point (Af) temperatures for each file.

In particular, Figure 2A and 2B shows a typical DSC curve obtained from the M3 Pro Gold files. In the DSC diagram, the exothermic reaction in the upper curve indicates the martensitic transformation in the cooling process, while the endothermic reaction in the lower curve is caused by the reverse transformation from the martensitic phase to the rhombohedral phase (R-phase) and/or austenitic phase in the heating process. There was a clear endothermic peak on the heating curve. On the cooling curve, there were 2 exothermic peaks. The peaks at approximately −8°C and −25°C for the M3 Pro Gold size 20/0.04 and size 25/0.04, respectively, corresponded to the initial transformation from the martensitic phase to the R-phase, and the peaks at approximately 15°C and 20°C for the M3 Pro Gold size 20/0.04 and size 25/0.04, respectively, corresponded to the transformation from the R-phase to the austenitic phase. The DSC diagrams for the M3 Rotary file (Figure 2C and 2D) showed a single and defined peak upon cooling and heating. This peak represents the martensitic and reverse transformation between austenite and martensite.

DISCUSSION

Several variables, such as instrument size, taper, cross-sectional design, and manufacturing techniques, affect the clinical performance of endodontic files and their resistance to fracture by torsion and/or cyclic fatigue [18,19].

In this study, cyclic fatigue, maximum torque load, and the angular rotation of the M3 Rotary and new M3 Pro Gold files were evaluated. The M3 Rotary files and M3 Pro Gold files were compared because they have an identical design and geometrical features, but differ only in the heat treatment used in their manufacturing process; thus, the influence of other variables was eliminated in the present study. Moreover, only 2 sizes (sizes 20 and 25 with 0.04 taper) of both instruments were tested because these sizes are commonly used during instrumentation.

According to our results, when the same size of the 2 different instruments was compared, the M3 Pro Gold files exhibited higher cyclic fatigue resistance and angular rotation to fracture than the M3 Rotary files, while no significant difference was observed between the 2 instruments for the maximum torsional strength. These results are probably due to the different NiTi alloys and manufacturing processes [20,21]. In fact, according to the manufacturer, M3 Rotary instruments are made by an advanced memory alloy technology, which increases cyclic fatigue resistance [12]. No data are available on the metallurgical characteristics of this alloy. However, the DSC analysis conducted in this study revealed that the M3 Rotary files seem to be made with an alloy similar to the traditional NiTi. Indeed, M3 Rotary files, as conventional superelastic NiTi [22], have an austenite structure at room and oral temperature, while the M3 Pro Gold files, as CM wire, have a mixture of martensite and austenite at room temperature. In particular, the Af of the M3 Pro Gold sizes 20 and 25 files were measured to be 44.50°C and 36.39°C, respectively, from their heating curves. This means that at human body temperature (around 37°C) [23], the M3 Pro Gold files are in a mixed austenite and martensite phase. In contrast, the Af of the sizes 20 and 25 M3 Rotary files were measured to be 20.48°C and 21.26°C, respectively, from their heating curves, which means that M3 Rotary files are in a state of only austenite at human body temperature. Since martensite is less stiff than austenite [24], it is likely that shape memory files present lower stiffness than conventional or M-wire files [25].

Shen et al. [11,26] observed increased fatigue resistance in files manufactured via proprietary CM wire processing. The reason for this may be that for a given strain, a more flexible file would experience less stress, allowing for a longer fatigue lifetime [25]. Moreover, there was no significant difference between the M3 Rotary and M3 Pro Gold files in terms of maximum torsional strength. The type of metal alloy, consequently, does not appear to affect torsional strength. These results are in agreement with previous studies [20,21]. However, some previous studies reported that CM wire instruments were associated with a lower torque to failure than conventional or M-wire instruments [25,27]. These differences can be attributed to the different type and size of the tested instruments.

In addition, the angular rotation to fracture of a NiTi file is associated with its ability to be plastically deformed under stress without failing [21]. In this study, the M3 Pro Gold files were significantly more plastic than the M3 Rotary files. In particular, the M3 Pro Gold size 25/0.04 file exhibited the highest angular rotation to fracture. The increase in the plasticity of thermally treated files is thought to be due to the increase of the proportions of the R-phase and martensite. The R-phase has the lowest shear modulus among the 3 phases [28]. Martensite is more likely to deform than austenite since martensite has a twinning process, which refers to an internal movement of lattices without breaking atomic bonds by absorbing stress [22].

To explain the mechanical behavior observed in both fracture resistance tests, the effects of the size, as well as the cross-section, should not be ignored. The results of the present study show that the size 25 diameter instruments had significantly higher torsional (ultimate) strength than the size 20 diameter instruments. These findings imply that the diameter play an important role in torsional resistance, as previously reported [29,30]. In contrast, size 20 diameter files showed higher cyclic fatigue resistance than size 25 diameter files. These results are in agreement with previous studies reporting that smaller instruments usually showed high flexibility and fatigue resistance [6,10]. In particular, the M3 Pro Gold size 20 file with a 0.04 taper exhibited the highest values of cyclic fatigue resistance. These results are probably due to the benefits of metal treatment associated with the reduced dimensions of the instrument.

Moreover, in a supplementary study, the M3 Rotary size 20 file with a 0.04 taper was found to have a smaller area (71,665 µm2) than the M3 Rotary size 25 file with a 0.04 taper (80,841 µm2), based on a measurement of their cross-sectional area at 5 mm from the tip (D5) under scanning electron microscopy by software (AutoCAD, Autodesk Inc., San Rafael, CA, USA). The same results were found when the cross-sectional area was measured at 5 mm from the tip (D5) of the M3 Pro Gold size 20 file with a 0.04 taper and the M3 Pro Gold size 25 file with a 0.04 taper, considering that M3 instruments with the same tip size and taper had the same cross-sectional area regardless of the heat treatment received (M3 Rotary or Pro Gold). The present findings agree with those of previous studies reporting that a reduced cross-sectional area increased cyclic fatigue resistance but negatively affected torsional resistance [31,32].

The clinical implications of these observations are as follows. A high angle of rotation before fracture in controlled memory files may be beneficial because it may provide clinicians with an indication that plastic/permanent deformation has taken place and that fracture is imminent [25]. In addition, greater flexibility could be useful in clinical situations with high flexural fatigue (e.g., in curved canals).

CONCLUSIONS

Within the limitations of this study, it was observed that the M3 Pro Gold files showed greater flexibility than the M3 Rotary files, with no decrement of other mechanical properties such as torque resistance or angular rotation.

Footnotes

Conflict of Interest: No potential conflict of interest relevant to this article was reported.

- Conceptualization: Pedullà E, Gambarini G.

- Data curation: Pedullà E, Gambarini G, Rapisarda E, Chang SW, Testarelli L.

- Formal analysis: Pedullà E, La Rosa GRM, Rapisarda S, Bruno E.

- Investigation: Rapisarda E, Testarelli L, Miccoli G.

- Methodology: Pedullà E, La Rosa G, Lo Savio F.

- Project administration: Gambarini G, Pedullà E.

- Resources: Gambarini G, La Rosa G, Lo Savio F, Bruno E, Testarelli L.

- Software: Chang SW, La Rosa G, Lo Savio F.

- Supervision: Gambarini G, Rapisarda E, Chang SW.

- Validation: La Rosa G, Lo Savio F, Rapisarda E, Rapisarda S.

- Visualization: Gambarini G, Testarelli L, Miccoli G, La Rosa GRM.

- Writing - original draft: Pedullà E, La Rosa GRM, Miccoli G, Lo Savio F, Rapisarda S, Miccoli G.

- Writing - review & editing: Chang SW, Bruno E, Gambarini G, La Rosa G, Rapisarda E, Testarelli L.

References

- 1.Gavini G, Pessoa OF, Barletta FB, Vasconcellos MA, Caldeira CL. Cyclic fatigue resistance of rotary nickel-titanium instruments submitted to nitrogen ion implantation. J Endod. 2010;36:1183–1186. doi: 10.1016/j.joen.2010.03.032. [DOI] [PubMed] [Google Scholar]

- 2.Yum J, Cheung GS, Park JK, Hur B, Kim HC. Torsional strength and toughness of nickel-titanium rotary files. J Endod. 2011;37:382–386. doi: 10.1016/j.joen.2010.11.028. [DOI] [PubMed] [Google Scholar]

- 3.Parashos P, Messer HH. Rotary NiTi instrument fracture and its consequences. J Endod. 2006;32:1031–1043. doi: 10.1016/j.joen.2006.06.008. [DOI] [PubMed] [Google Scholar]

- 4.Pedullà E, Lo Savio F, Boninelli S, Plotino G, Grande NM, Rapisarda E, La Rosa G. Influence of cyclic torsional preloading on cyclic fatigue resistance of nickel - titanium instruments. Int Endod J. 2015;48:1043–1050. doi: 10.1111/iej.12400. [DOI] [PubMed] [Google Scholar]

- 5.Cheung GS. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endod Topics. 2007;16:1–26. [Google Scholar]

- 6.Pruett JP, Clement DJ, Carnes DL., Jr Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod. 1997;23:77–85. doi: 10.1016/S0099-2399(97)80250-6. [DOI] [PubMed] [Google Scholar]

- 7.Haïkel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J Endod. 1999;25:434–440. doi: 10.1016/S0099-2399(99)80274-X. [DOI] [PubMed] [Google Scholar]

- 8.Bryant ST, Thompson SA, Al-Omari MA, Dummer PM. Shaping ability of Profile rotary nickel-titanium instruments with ISO sized tips in simulated root canals: part 1. Int Endod J. 1998;31:275–281. doi: 10.1046/j.1365-2591.1998.00153.x. [DOI] [PubMed] [Google Scholar]

- 9.Ounsi HF, Al-Shalan T, Salameh Z, Grandini S, Ferrari M. Quantitative and qualitative elemental analysis of different nickel-titanium rotary instruments by using scanning electron microscopy and energy dispersive spectroscopy. J Endod. 2008;34:53–55. doi: 10.1016/j.joen.2007.09.009. [DOI] [PubMed] [Google Scholar]

- 10.Plotino G, Grande NM, Cotti E, Testarelli L, Gambarini G. Blue treatment enhances cyclic fatigue resistance of vortex nickel-titanium rotary files. J Endod. 2014;40:1451–1453. doi: 10.1016/j.joen.2014.02.020. [DOI] [PubMed] [Google Scholar]

- 11.Shen Y, Qian W, Abtin H, Gao Y, Haapasalo M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37:997–1001. doi: 10.1016/j.joen.2011.03.023. [DOI] [PubMed] [Google Scholar]

- 12.United Dental (CN) M3 Rotary brochure [Internet] Shangai: United Dental; 2016. [updated 2016 Dec 20]. [cited 2016 Sep 20]. Available from: http://www.m3-endo.com/col.jsp?id=110. [Google Scholar]

- 13.United Dental (CN) M3 Pro Gold brochure [Internet] Shangai: United Dental; 2016. [updated 2016 Dec 20]. [cited 2016 Sep 20]. Available from: http://www.m3-endo.com/col.jsp?id=111. [Google Scholar]

- 14.Pedullà E, Genovesi F, Rapisarda S, La Rosa GRM, Grande NM, Plotino G, Adorno CG. Effects of 6 single-file systems on dentinal crack formation. J Endod. 2017;43:456–461. doi: 10.1016/j.joen.2016.10.038. [DOI] [PubMed] [Google Scholar]

- 15.Gambarini G, Gergi R, Grande NM, Osta N, Plotino G, Testarelli L. Cyclic fatigue resistance of newly manufactured rotary nickel titanium instruments used in different rotational directions. Aust Endod J. 2013;39:151–154. doi: 10.1111/j.1747-4477.2012.00353.x. [DOI] [PubMed] [Google Scholar]

- 16.Pedullà E, Plotino G, Grande NM, Scibilia M, Pappalardo A, Malagnino VA, Rapisarda E. Influence of rotational speed on the cyclic fatigue of Mtwo instruments. Int Endod J. 2014;47:514–519. doi: 10.1111/iej.12178. [DOI] [PubMed] [Google Scholar]

- 17.Chang SW, Shim KS, Kim YC, Jee KK, Zhu Q, Perinpanayagam H, Kum KY. Cyclic fatigue resistance, torsional resistance, and metallurgical characteristics of V taper 2 and V taper 2H rotary NiTi files. Scanning. 2016;38:564–570. doi: 10.1002/sca.21301. [DOI] [PubMed] [Google Scholar]

- 18.Gao Y, Shotton V, Wilkinson K, Phillips G, Johnson WB. Effects of raw material and rotational speed on the cyclic fatigue of ProFile Vortex rotary instruments. J Endod. 2010;36:1205–1209. doi: 10.1016/j.joen.2010.02.015. [DOI] [PubMed] [Google Scholar]

- 19.Kramkowski TR, Bahcall J. An in vitro comparison of torsional stress and cyclic fatigue resistance of ProFile GT and Profile GT Series X rotary nickel-titanium files. J Endod. 2009;35:404–407. doi: 10.1016/j.joen.2008.12.003. [DOI] [PubMed] [Google Scholar]

- 20.Ha JH, Kim SK, Cohenca N, Kim HC. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J Endod. 2013;39:389–393. doi: 10.1016/j.joen.2012.11.028. [DOI] [PubMed] [Google Scholar]

- 21.Choi J, Oh S, Kim YC, Jee KK, Kum K, Chang S. Fracture resistance of K3 nickel-titanium files made from different thermal treatments. Bioinorg Chem Appl. 2016;2016:6374721. doi: 10.1155/2016/6374721. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Shen Y, Zhou H, Zheng Y, Campbell L, Peng B, Haapasalo M. Metallurgical characterization of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37:1566–1571. doi: 10.1016/j.joen.2011.08.005. [DOI] [PubMed] [Google Scholar]

- 23.de Vasconcelos RA, Murphy S, Carvalho CA, Govindjee RG, Govindjee S, Peters OA. Evidence for reduced fatigue resistance of contemporary rotary instruments exposed to body temperature. J Endod. 2016;42:782–787. doi: 10.1016/j.joen.2016.01.025. [DOI] [PubMed] [Google Scholar]

- 24.Kusy RP. A review of contemporary archwires: their properties and characteristics. Angle Orthod. 1997;67:197–207. doi: 10.1043/0003-3219(1997)067<0197:AROCAT>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 25.Ninan E, Berzins DW. Torsion and bending properties of shape memory and superelastic nickel-titanium rotary instruments. J Endod. 2013;39:101–104. doi: 10.1016/j.joen.2012.08.010. [DOI] [PubMed] [Google Scholar]

- 26.Shen Y, Qian W, Abtin H, Gao Y, Haapasalo M. Effect of environment on fatigue failure of controlled memory wire nickel-titanium rotary instruments. J Endod. 2012;38:376–380. doi: 10.1016/j.joen.2011.12.002. [DOI] [PubMed] [Google Scholar]

- 27.Pedullà E, Lo Savio F, Boninelli S, Plotino G, Grande NM, La Rosa G, Rapisarda E. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J Endod. 2016;42:156–159. doi: 10.1016/j.joen.2015.10.004. [DOI] [PubMed] [Google Scholar]

- 28.Wu SK, Lin HC, Chou TS. A study of electrical resistivity, internal friction and shear modulus on an aged Ti49Ni51 alloy. Acta Metall Mater. 1990;38:95–102. [Google Scholar]

- 29.Peters OA, Barbakow F. Dynamic torque and apical forces of ProFile 0.04 rotary instruments during preparation of curved canals. Int Endod J. 2002;35:379–389. doi: 10.1046/j.0143-2885.2001.00494.x. [DOI] [PubMed] [Google Scholar]

- 30.Bahia MG, Buono VT. Decrease in the fatigue resistance of nickel–titanium rotary instruments after clinical use in curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2005;100:249–255. doi: 10.1016/j.tripleo.2004.10.013. [DOI] [PubMed] [Google Scholar]

- 31.Plotino G, Grande NM, Testarelli L, Gambarini G. Cyclic fatigue of Reciproc and WaveOne reciprocating instruments. Int Endod J. 2012;45:614–618. doi: 10.1111/j.1365-2591.2012.02015.x. [DOI] [PubMed] [Google Scholar]

- 32.Park SY, Cheung GS, Yum J, Hur B, Park JK, Kim HC. Dynamic torsional resistance of nickel-titanium rotary instruments. J Endod. 2010;36:1200–1204. doi: 10.1016/j.joen.2010.02.016. [DOI] [PubMed] [Google Scholar]