Abstract

In the past two decades, a considerable amount of research has focused on the determination of the digestible (DE) and metabolizable energy (ME) contents of feed ingredients fed to swine. Compared with the DE and ME systems, the net energy (NE) system is assumed to be the most accurate estimate of the energy actually available to the animal. However, published data pertaining to the measured NE content of ingredients fed to growing pigs are limited. Therefore, the Feed Data Group at the Ministry of Agricultural Feed Industry Centre (MAFIC) located at China Agricultural University has evaluated the NE content of many ingredients using indirect calorimetry. The present review summarizes the NE research works conducted at MAFIC and compares these results with those from other research groups on methodological aspect. These research projects mainly focus on estimating the energy requirements for maintenance and its impact on the determination, prediction, and validation of the NE content of several ingredients fed to swine. The estimation of maintenance energy is affected by methodology, growth stage, and previous feeding level. The fasting heat production method and the curvilinear regression method were used in MAFIC to estimate the NE requirement for maintenance. The NE contents of different feedstuffs were determined using indirect calorimetry through standard experimental procedure in MAFIC. Previously generated NE equations can also be used to predict NE in situations where calorimeters are not available. Although popular, the caloric efficiency is not a generally accepted method to validate the energy content of individual feedstuffs. In the future, more accurate and dynamic NE prediction equations aiming at specific ingredients should be established, and more practical validation approaches need to be developed.

Keywords: Heat production, Ingredients, Maintenance, Net energy, Prediction equations, Validation

Background

Most pigs are fed diets based on cereal (corn, wheat, barley, etc.) and protein sources (soybean meal, etc.). However, less-expensive, alternative feed ingredients either rich in dietary fiber or protein, such as corn by-products and oil-seed meals, have been increasingly included in swine diets in order to decrease feed costs [1]. In addition, using the net energy (NE) system may help to reduce feed cost because it takes the heat increment (HI) into consideration. Therefore, it is a more precise evaluation of the true energy value of the feed compared to the metabolizable energy (ME). In most situations, the NE content of ingredients is predicted from equations. The most widely used prediction equations were developed more than 20 years ago and include NE prediction equations for growing pigs [2], fattening pigs [3], maintenance-fed adult sows [4], and growing boars [5]. These studies covered wide range of ingredients and demonstrated that NE contents of ingredients or diets can be estimated based on their chemical compositions or digestible nutrients. Nevertheless, some highly processed ingredients (or by-products) that have become more available nowadays (corn germ meal, cottonseed meal, rice bran, etc) were not included. Therefore, these prediction equations may not be suitable for these new feedstuffs.

Nine open-circuit respiration chambers were established at Ministry of Agriculture Feed Industry Centre (MAFIC) according to the design of van Milgen et al. [6]. Since 2012, many research projects have been conducted in MAFIC to determine the maintenance energy requirements for pigs and the NE content of individual ingredients. All data were determined using the same methods and procedures [1, 7–14]. The objective of this review is to summarize the NE-related work conducted at MAFIC and compare these results with those from other research groups on methodological aspect, which included estimating the energy requirements for maintenance as well as the determination, prediction, and validation of the NE content of various ingredients.

Some concepts about energy

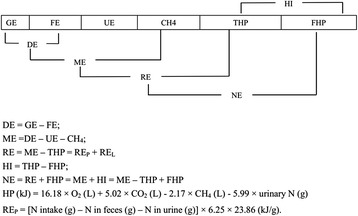

When measuring NE by the indirect calorimetry method, heat production (HP) can be calculated from gas exchanges (open-circuit respiration chambers) and the urinary nitrogen according to Brouwer [15]. The utilization of the energy in a feed by pigs is a multi-level system (Fig. 1). The ME can be partitioned into two parts: NE and HI. HI is the heat produced during the process of nutrient ingestion, digestion, and metabolism, and is thought to be useless [16]. However, it is difficult to separate the HI from total heat production (THP), and HI is typically calculated as THP minus NE requirements for maintenance (NEm). The NEm also cannot be determined directly, and fasting heat production (FHP), which is measured in the fasted animal, is frequently used to estimate the NEm [2, 5, 17]. As a result, HI is calculated as THP minus FHP. In growing animals, NE is usually estimated as the sum of NEm and retained energy (RE), and RE is usually evaluated as ME intake minus THP. In growing pigs, RE corresponds to the sum of RE as protein (REP) and RE as lipid (REL). The REP is typically calculated using nitrogen retention (g) = N × 6.25 × 23.86 (kJ/g) [18] and REL is calculated as the difference between RE and REP (Fig. 1).

Fig. 1.

Scheme of energy utilization in pigs. The utilization of energy in a feed by pigs is a multi-level system. GE, gross energy; DE, digestible energy; ME, metabolizable energy; RE, retained energy; NE, net energy; FE, fecal energy; UE, urinary energy, THP, total heat production; FHP, fasting heat production; HI, heat increment

Information on intake and output for pigs

Modern pig production contributes to many environmental problems that relate to excretion from pigs, especially in areas with highly intensive production systems. Therefore, measurement of intake and output data is very useful for the global design of manure management systems for swine [19].

In our NE trials, the inputs including feed intake, gross energy (GE) intake and O2 consumption as well as the outputs including feces, urine, CO2, CH4, and HP have been summarized according to diet characteristics (Table 1). Although pigs were fed in crates and feed intake was lower than ad libitum, these data may still be useful as a reference for the actual production situation. Almost half of the GE consumed is used for HP and only one third of the GE is retained. Approximately 14% of the GE is excreted in the feces, 3% of the GE is excreted in the urine and 0.7% of the GE is excreted as methane.

Table 1.

Information on intake and output for pigsa

| Diets | n | Mean BW, kg | Intake | Output | Gas exchange, L/d | Digestibility, % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed, kg/d | GE, MJ/d | Feces | Urine | CH4 energy, MJ/d | HP, MJ/d | O2 | CH4 | CO2 | DM | GE | |||||||

| Weight, g/d | GE, MJ/d | Volume, L/d | GE, MJ/d | THP | FHP | HI | |||||||||||

| Corn-soybean meal | 30 | 45.53 | 1.46 | 24.31 | 380.4 | 2.57 | 2.64 | 0.57 | 0.19 | 12.73 | 7.66 | 5.07 | 606.4 | 4.9 | 660.8 | 73.9 | 89.4 |

| Oil-seed mealsb | 66 | 44.78 | 1.45 | 24.51 | 576.6 | 3.80 | 3.19 | 0.81 | 0.14 | 12.26 | 7.50 | 4.76 | 587.8 | 3.6 | 619.6 | 60.2 | 84.5 |

| Fibrous ingredientsc | 24 | 44.70 | 1.54 | 24.62 | 766.6 | 4.47 | 2.33 | 0.74 | 0.16 | 12.04 | 7.22 | 4.82 | 593.8 | 4.1 | 634.1 | 50.2 | 81.8 |

| Corn DDGS | 36 | 47.08 | 1.68 | 28.09 | 622.1 | 4.09 | 3.08 | 1.02 | 0.26 | 13.69 | 7.78 | 5.91 | 651.7 | 6.6 | 735.5 | 63.0 | 85.4 |

| Meand | 168 | 45.07 | 1.50 | 25.22 | 558.2 | 3.62 | 2.89 | 0.78 | 0.18 | 12.61 | 7.53 | 5.08 | 604.8 | 4.5 | 654.9 | 62.8 | 85.6 |

aData from NE trials conducted at MAFIC; pigs were fed in crates with a feed intake lower than ad libitum; GE, gross energy; HP, heat production; THP, total heat production; FHP, fasting heat production; HI, heat increment

bIncludes rapeseed meal, peanut meal, sunflower meal, and cottonseed meal

cIncludes rice bran, corn germ meal, corn gluten feed, and wheat bran

dExcluding corn-SBM, oil-seed meals, high-fiber meals, and corn DDGS but including wheat and corn diets

Estimation of the energy requirements for maintenance

Estimation of the energy requirement for maintenance is very important when conducting research on energy metabolism, which will influence the absolute NE value of a feedstuff [8, 20]. The energy requirements for maintenance can be expressed as ME (MEm) or NE (NEm). The choice of methodologies and measuring conditions are very important for estimating these energy values.

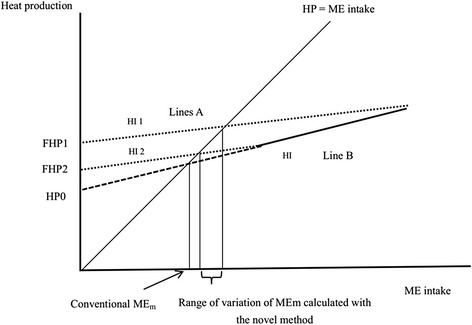

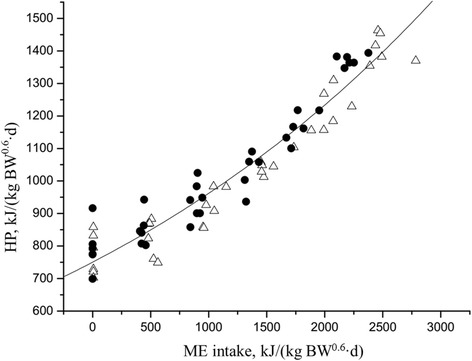

The NEm cannot be determined directly but there are mainly 2 methods which have been used to estimate NEm. Firstly, the FHP can be measured directly in fasted animals and it is then used as an estimate of NEm [2, 5, 17]. This method is affected by the length of fasting, previous feeding level, and differences in activity between fasting and fed status [7, 8, 21]. Additionally, FHP is affected by both the ATP requirement at the cellular level and heat produced from the generation of ATP from body nutrient stores [22]. The second approach for estimating NEm which has been widely used in the past is the regression method, in which THP is calculated through extrapolating HP measured at different ME intake levels to zero ME intake (HP0). The commonly used regression models include linear model and curvilinear model. For linear regression [5, 16], the hypothesis is that the HP increased linearly with the ME intake. However, this method has great limitations. Firstly, the ME intake levels selected for HP extrapolating typically range from 60% to 100% of ad libitum intake, thus there is a lack of information on the relationship between HP and ME intake below the energy requirements for maintenance [8, 20]. In this method, the efficiencies of energy utilization for maintenance (km) and growth (kg) are assumed to be constant. However, recent research reported that this traditional assumption may be incorrect [8, 9, 20, 23]. Secondly, the FHP value measured throught direct method is variable and is affected by the previous feeding level [8, 9, 23, 24]. These authors also reported that the HP0 was lower than the actual measured FHP value (Fig. 2). The curvilinear regression model to estimate the NEm was proposed at MAFIC [8], which uses exponential regression between HP and a wide range of ME intakes both above and below energy requirements for maintenance (Fig. 3). In this method, the Y-intercept was thought to be the NEm and takes into account the difference between kg and km as well as the effect of previous feeding level on FHP. However, both the linear and curvilinear models provide only one estimate of NEm, while pigs fed at different feeding levels have different NEm.

Fig. 2.

Relationship between heat production and metabolizable energy (ME) intake. HP0 = Extrapolated total heat production at zero energy intake. FHP 1 corresponds to the FHP measured with animals receiving the highest feed level and FHP2 corresponds to the FHP measured with animals receiving the lowest feed level. The slope of line B = HI:ME. The complement of the slope of line B is kg (NE:ME). The slope of line A = (HIi:ME). The complement of the slope of line A is km (NEm: ME), km > kg (adapted from Labussière et al. [23]; Noblet and van Milgen, [20]). FHP: Fasting heat production; HI: Heat increment; km: Efficiencies of energy utilization for maintenance; kg: Efficiencies of energy utilization for growth; MEm: Metabolizable energy requirements for maintenance; NE: Net energy; NEm: Net energy requirements for maintenance

Fig. 3.

Exponential relationship between heat production and metabolizable energy (ME) intake for all pigs. HP = 749 × e (0.0002 × ME intake), R2 = 0.91, P < 0.001. Data are from growing (●), and finishing (△) pigs (Zhang et al. [8]). HP: heat production

The MEm was estimated by assuming that the HP is equal to ME intake at maintenance. Therefore, based on the NEm estimation, the MEm was conventionally calculated by solving the regression quations (linear regression model, HP = a + b ME intake; exponential regression model, HP = a eb×ME intake). A novel method to estimate MEm was proposed by Labussière et al. [23], in which the estimated MEm ranged from the MEm calculated at the lowest feeding level to MEm calculated at the highest feeding level (Fig. 2). MEm is affected by feeding levels and estimated MEm decreases in growing pigs when ME intake is reduced [23]. Several hypotheses have been suggested to explain the results, including the effect of the gastrointestinal tract size [6, 25], or the changed muscle protein turnover rate [26].

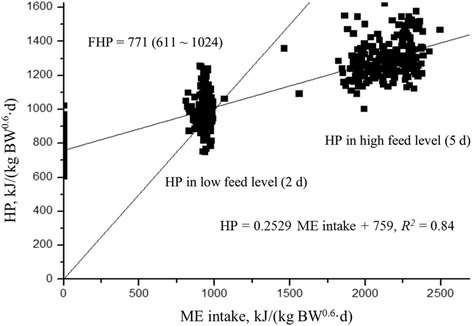

In our NE trials, where FHP was considered as the HP measured for 8 h after 31 h fasting from the last meal, the HP0 (759 kJ ME/ (kg BW0.6·d)) linearly regressed on HP and ME intake was in the range of the FHP (611 to 1,024 kJ ME/ (kg BW0.6·d), a few of extreme outliers existed, and most FHP values ranged around 700 to 800, Table 2 and Fig. 4). The following regression equation was established based on all data in our NE trials: HP = 0.2529 ME intake + 759 (R2 = 0.84). Consequently, the MEm = 1,016 kJ ME/ (kg BW0.6·d).

Table 2.

Comparison of extrapolated total heat production at zero energy intake (HP0) and FHP.a All works listed were conducted in MAFIC

| No. | Authors | Experiments (diets) | HP0 | FHP | Range of FHP |

|---|---|---|---|---|---|

| 1 | Liu et al. (2015) [10] | Complete diets | 768 | 781 | 605–901 |

| 2 | Li et al. (2015) [1] | Corn DDGS diets | 783 | 795 | 611–971 |

| 3 | Li et al. (2017) [13] | Rapeseed meal | 768 | 789 | 692–1,024 |

| 4 | Li et al. (2018) [14] | Five ingredients | 717 | 770 | 615–973 |

| 5 | Li et al. (unpublished) | Corn | 737 | 716 | 648–869 |

| 6 | Li et al. (2017) [12] | Rapeseed meal | 798 | 775 | 651–866 |

| Summary | 759 | 771 | 611–1,024 |

aIncludes 6 experiments with 34 diets and 26 ingredients, 204 replications, 408 heat production and 204 fasting heat production

Fig. 4.

Regression of heat production on metabolizable energy (ME) intake. 16 experiments, 34 diets, 26 ingredients, 204 replications with 408 heat production and 204 fasting heat production data were included in the figure. FHP: Fasting heat production; HP: heat production

The estimated energy requirements for maintenance among different research projects are shown in Table 3. These values depend on the methods used, growth stage, conditions of measurement (e.g. procedure, activity), feeding levels and the composition of the diet; they should then be interpreted with caution and are not directly comparable. Accounting for the effect of feeding level on FHP, the measurement of FHP immediately after a fed period is highly preferable [20]. The MEm (1,016 kJ ME/ (kg BW0.6·d), summarized in MAFIC) was very close to the value (1,020 kJ ME/ (kg BW0.6·d)) obtained from different breeds and variable BW [27].

Table 3.

Comparison of the estimation of energy requirements for maintenance among different experimentsa

| Reference | Methods | BW, kg | MEm | NEm (HP0) |

|---|---|---|---|---|

| Noblet et al. (1999) [27] | Linear regression | Variable | 1,020b | 750c |

| Labussière et al. (2011) [23] | Ranged values based on feeding levels | 60–90 | 822–1028 | 608–771 |

| Zhang et al. (2014) [8] (MAFIC work) | Linear regression | 30–60 | 893 | 590 |

| Linear regression | 60–90 | 815 | 532 | |

| Exponential regression | 30–60 | 973 | 758 | |

| Exponential regression | 60–90 | 921 | 732 | |

| Li et al. (2017) [13] (MAFIC work) | Linear regression | 30–60 | 1,016 | 759 |

| Measured FHP | 30–60 | – | 771 |

aEnergy unit: kJ / (kg BW0.6·d)

bThe average value for different breeds, variable BW

cData from Noblet et al. [5]: all pigs were fed at a high FL and immediately fed a reduced FL

In conclusion, estimating the energy requirements for maintenance is a complex project. Future research should focus more on biochemical mechanisms and use new technologies to find more meaningful criteria which are representative of the maintenance condition for pigs.

Net energy content of ingredients

Previous studies have shown that the DE and ME systems systematically underestimate the energy concentration of feeds high in starch or fat and overestimate the energy concentration of feeds high in protein or crude fibre [5, 28]. Therefore, the NE system should be the most appropriate system by now to estimate the true energy value of feed ingredient, which is theoretically independent of the feed characteristics [28–31]. Large amounts of data pertaining to the determination of NE value of ingredients were published during the past decade (Table 4). Indirect calorimetry and comparative slaughter are the two main methods used to determine the NE content of ingredients. The indirect calorimetry consists of measuring oxygen consumption, and carbon dioxide and methane production [20]. These measurements combined with the urinary energy production are then used to calculate HP based on equations from Brouwer [15]. The comparative slaughter technique, on the other hand, directly measures energy gain based on chemical analysis of samples collected after slaughter, and HP is calculated as the difference between ME intake and energy gain [20]. Due to differences in experimental procedures, the chemical composition of ingredients, animals, and errors in analysis, it is difficult to compare these two methods for a given ingredient, and determine which method should be used to estimate the true energy available to an animal. Ayoade et al. [32] reported that the NE in wheat and corn DDGS diets obtained with indirect calorimetry and comparative slaughter method did not differ. However, many other results indicated that the NE values measured by indirect calorimetry were greater than values calculated with the comparative slaughter method [33–36], which may be attributed to the fact that in studies using comparative slaughter technique, pigs were housed in a more practical facility and then can move freely with more heat production related to physical activity. Moreover, pigs in studies using comparative slaughter technique may sometimes be raised below their critical temperature with again an increased heat production. Therefore, heat production measured using comparative slaughter method may be highly increased in connection with increased maintenance energy and FHP values, while the FHP value used in indirect calorimetry procedure is obtained under minimal activity and at thermo-neutrality, which leads to the greater NE value [37, 38].

Table 4.

Summary of research on the net energy content of ingredients conducted in the past decade (MJ/kg DM)

| Authors | Ingredients | Pigs | NE | NE/ME | Methods |

|---|---|---|---|---|---|

| Hinson et al. (2009) [53] | Soybean meal | Growing | 7.66 | – | Comparative slaughter |

| Finishing | 10.08 | – | |||

| Low-oligosaccharide soybean meal | Growing | 9.14 | – | ||

| Finishing | 11.73 | – | |||

| Glycerol | Growing | 13.44 | – | ||

| Finishing | 16.98 | – | |||

| Kil et al. (2011) [34] | Soybean oil | Growing | 20.19 | – | Comparative slaughter |

| Finishing | 19.33 | – | |||

| Choice white grease | Growing | 25.05 | – | ||

| Finishing | 24.99 | – | |||

| Kil et al. (2013) [35] | Corn | Growing | 9.06 | – | Comparative slaughter |

| Finishing | 11.08 | – | |||

| Stewart et al. (2013) [54] | Soybean hulls | Growing | 1.67 | – | Comparative slaughter |

| Finishing | 4.01 | – | |||

| Wheat middlings | Growing | 4.46 | – | ||

| Finishing | 4.72 | – | |||

| Heo et al. (2014) [55] | Canola meal (Brassica napus) | Growing | 8.80 | 69.8 | Indirect calorimetry |

| Canola meal (Brassica juncea) | 9.80 | 72.6 | |||

| Graham et al. (2014) [39] | Corn DDGS-high oil (12.1% oil)a | Finishing | 12.99 | 81.7 | Estimating NE efficiency from a growth study |

| Corn DDGS-high oil (9.6% oil) | 11.85 | 74.7 | |||

| Corn DDGS-high oil (9.4% oil) | 11.60 | 71.0 | |||

| Corn DDGS-medium oil (7.6% oil) | 10.61 | 75.3 | |||

| Corn DDGS-low oil (5.4% oil) | 9.61 | 66.0 | |||

| Gutierrez et al. (2014) [36] | Corn DDGS-BPXb | Growing | 8.78 | – | Comparative slaughter |

| Finishing | 8.46 | – | |||

| Corn DDGS (13.0% oil) | Growing | 9.10 | – | ||

| Finishing | 11.57 | – | |||

| High protein DDG | Growing | 9.68 | – | ||

| Finishing | 9.17 | – | |||

| Liu et al. (2014 and 2015) [9, 10] (MAFIC work) | Corn | Growing | 13.21 | 81.0 | Indirect calorimetry |

| Soybean meal | 10.62 | 64.3 | |||

| Wheat bran | 7.78 | 71.6 | |||

| Wheat | 11.44 | 74.6 | |||

| Corn DDGS-high oil (10.6% oil) | 10.21 | 66.5 | |||

| Canola meal | 8.38 | 72.0 | |||

| Cottonseed meal | 7.32 | 72.9 | |||

| Li et al. (2017) [11] (MAFIC work) | Corn DDGS-high oil (11.2% oil) | Growing | 10.47 | 70.0 | Indirect calorimetry |

| Corn DDGS-high oil (10.7% oil) | 10.98 | 77.0 | |||

| Corn DDGS-medium oil (7.6% oil) | 10.96 | 70.8 | |||

| Corn DDGS-low oil (4.7% oil) | 9.49 | 67.7 | |||

| Corn DDGS-low oil (3.6% oil) | 9.28 | 69.0 | |||

| Velayudhan et al. (2015) [42] | Dry extruded expelled SBM | Growing | 10.64 | 75.7 | Indirect calorimetry |

| Li et al. (2018) [14](MAFIC work) | Rice bran | Growing | 12.33 | 77.9 | Indirect calorimetry |

| Corn germ meal | 8.75 | 72.4 | |||

| Corn gluten feed | 7.51 | 78.5 | |||

| Peanut meal | 10.75 | 75.3 | |||

| Sunflower meal | 6.49 | 67.2 | |||

| Li et al. (2017) [13](MAFIC work) | Rapeseed meal-expeller press | Growing | 10.14 | 72.2 | Indirect calorimetry |

| Rapeseed meal-expeller press | 11.46 | 80.1 | |||

| Rapeseed meal-solvent extracted | 7.98 | 65.3 | |||

| Rapeseed meal-solvent extracted | 9.47 | 75.1 | |||

| Rapeseed meal-solvent extracted | 7.91 | 72.7 | |||

| Li et al. (2017) [12] (MAFIC work) | Corn | Growing | 12.46 | 78.3 | Indirect calorimetry |

| Soybean meal | 11.34 | 70.2 | |||

| Rapeseed meal-expeller press | 11.71 | 74.7 | |||

| Rapeseed meal-solvent extracted | 8.83 | 76.5 |

aOil content as-fed basis;

bCorn DDGS-BPX, uncooked corn distillers dried grains with solubles

Although questionable, Graham et al. [39] developed a new method to calculate the NE value of ingredients which estimates NE based on regression analysis determined by estimating NE efficiency (NEE) from growth studies. In this method, the NE of a corn-soybean meal control diet was calculated based on literature data and then the NEE (NE intake: ADG) was calculated according to actual pig growth. The NE of the test diet was calculated based on the hypothesis that the NEE of pigs fed a test diet was equal to that of pigs fed the control diet. The NE of the test ingredient was calculated according to the percentage of the test ingredient in the test diet.

From a practical point of view, and to avoid bias in the calculation of NE for different feedstuffs, it is necessary to use similar animals and maintain these animals under similar and standardized conditions [20]. In our laboratory, the NE trials (data shown in Tables 2, 5, and 6) were conducted in the same location (Fengning, Hebei, China) and using standardized conditions, including similar animals from same breed (Duroc × Large White × Landrace, BW ranged from 30 to 60 kg), similar chambers, a constant temperature and humidity and using the same experimental procedures. In these experiments, pigs were individually housed in metabolic crates for 16 d, which included 7 d to adapt to the feed and environmental conditions. On d 8, pigs were transferred to the open-circuit respiration chambers for measurement of O2 consumption as well as CO2 and CH4 production. During this time, pigs were fed their diet at 2,400 kJ ME/ (kg BW0.6·d). Feces and urine were collected from d 9 to d 13, and HP was measured. From d 14 to d 15, pigs were fed at the maintenance requirement (MEm = 893 kJ ME/ (kg BW0.6·d)) obtained from the results of Zhang et al. [8] in order to adapt the pigs from the fed to the fasting state. On the last day of each period, pigs were fasted and FHP was estimated as the averaged HP of 8 h after 31 h fasting. Even not quantifying physical activity, the FHP in our trials was measured under minimum expected activity (during the night, in the dark, and adjustment of the cage, etc.) and after a long period of fasting. The FHP values measured in different studies using the same procedure conducted in MAFIC close to each other (Table 2) [1, 8–12], and also close to those obtained by the INRA group according to a specific methodology or those used in the large scale NE measurements [5].

Table 5.

Levels of ingredients in the dietsa

| Ingredients | No. of diets | Inclusion level,% | |

|---|---|---|---|

| Max | Mean | ||

| Corn | 33 | 97.03 | 66.12 |

| Soybean meal | 26 | 25.00 | 17.58 |

| Wheat bran | 5 | 33.00 | 15.40 |

| Wheat | 4 | 58.37 | 20.59 |

| Corn DDGS | 9 | 29.25 | 17.53 |

| Rapeseed meal | 11 | 20.00 | 14.68 |

| Cottonseed meal | 4 | 10.00 | 5.75 |

| Full-fat rice bran | 1 | 29.25 | 29.25 |

| Corn germ meal | 1 | 29.25 | 29.25 |

| Corn gluten feed | 1 | 24.38 | 24.38 |

| Peanut meal | 1 | 19.50 | 19.50 |

| Sunflower meal | 1 | 29.25 | 29.25 |

| Dicalcium phosphate | 33 | 1.20 | 0.89 |

| Limestone | 34 | 1.46 | 0.83 |

| Salt | 34 | 0.40 | 0.36 |

| Vitamin and mineral premix | 34 | 0.50 | 0.50 |

| Lysine HCl | 10 | 0.71 | 0.40 |

| DL-methionine | 8 | 0.14 | 0.09 |

| L-threonine | 10 | 0.17 | 0.08 |

| L-tryptophan | 5 | 0.04 | 0.03 |

aIncludes 6 experiments, 34 diets and 26 ingredients

Table 6.

Chemical composition of dietsa (as-fed basis)

| Chemical composition | Minimum | Maximum | Mean |

|---|---|---|---|

| Dry matter | 85.96 | 90.11 | 87.94 |

| Crude protein | 6.87 | 23.79 | 16.59 |

| Neutral detergent fiber | 8.52 | 24.33 | 14.33 |

| Acid detergent fiber | 1.56 | 9.59 | 4.52 |

| Ether extract | 2.18 | 5.52 | 3.05 |

| Starch | 31.57 | 63.10 | 43.07 |

| Ash | 2.97 | 5.91 | 4.43 |

| Gross energy | 15.48 | 16.90 | 16.12 |

aIncludes 6 experiments with 34 diets and 26 ingredients

Based on the above methodologies, a series of studies were conducted in MAFIC to evaluate the NE values of 26 ingredient samples, including 2 corn samples, 2 soybean meal samples, 1 wheat sample, 1 wheat bran sample, 8 rapeseed meal samples, 1 cottonseed meal sample, 6 corn DDGS samples, 1 rice bran sample, 1 corn germ meal sample, 1 corn gluten feed sample, 1 peanut meal sample and 1 sunflower meal sample. The estimated NE values were summarized in Table 4, and our NE values were comparable with those in feeding tables by Sauvant et al. [40] or NRC [41].

Net energy prediction equations

The NE prediction equations have been proposed for growing pigs (Just, 1982) and growing boars [5] with the latter have being widely used during the past two decades [32, 42–44].

The NE in wheat-corn DDGS diets [28] or corn-DDGS [1] measured by indirect calorimetry is similar to values obtained with prediction equations of Noblet et al. [5]. However, Kil [45] reported that NE values for diets and ingredients predicted from the equations of Noblet et al. [5] fed to growing pigs were greater than the values measured by comparative slaughter. It should be mentioned that the measured NE values were obtained with a FHP value (536 kJ/(kg BW0.6·d)) markedly lower than the value (750 kJ/(kg BW0.6·d)) used in the prediction equations of Noblet et al. [5]. There are differences in methodology used to estimate the energy requirements for maintenance. Therefore, caution should be essential when comparing the measured values with predicted values. It is also difficult to compare NE values obtained by different methods using statistical procedures. A possible reason is the relatively large standard error of the mean for the NE of ingredients compared with diets when the NE values of ingredients are calculated according to the difference procedure. The inherent problems associated with using the difference procedure were also found by Kil et al. [34]. In the present review, the NE value of 26 ingredients and 34 diets measured at MAFIC were compared with values predicted by the equations of Noblet et al. [5] and Just [2]. From the present review, the equations of Noblet et al. [5] can be used to predict the NE value of most ingredients (Fig. 5), except for those ingredients containing high fiber content, such as sunflower meal or cottonseed meal. The NE of 34 diets can be accurately predicted by the equations of Noblet et al. [5] (Fig. 5). The equation proposed by Just [2] underestimate the NE value of the 26 ingredients and 34 diets (Fig. 6). Generally, the prediction equations proposed by Noblet et al. [5] can be used to predict NE in situations where calorimeters are not available. However, more accurate NE prediction equations should be established with those equations aimed at specific ingredients such as oil-seed meals and fibrous ingredients. Future research at MAFIC will focus on such projects.

Fig. 5.

Comparison of net energy (NE) values measured at MAFIC with those predicted by equations from INRA. NE values of 26 ingredients or 34 diets measured at MAFIC or predicted based on an INRA prediction eq. (NE = (0.7 × DE) + [(1.61 × EE) + (0.48 × Starch) –(0.91 × CP)–(0.87 × ADF)]/1000 × 4.184) were illustrated. ADF: Acid detergent fiber; CP: crude protein; DE: Digestible energy; EE: Ether extract

Fig. 6.

Comparison of net energy (NE) values measured at MAFIC with thosed predicted by equations by Just. NE values of 26 ingredients or 34 diets measured at MAFIC or predicted based on a prediction equation by Just [2] (NE = 0.75× ME – 1.88) were illustrated. ME: Metabolizable energy

Validation

As mentioned above, the NE value of feedstuffs can be directly determined by either comparative slaughter or indirect calorimetry technique, or can be predicted from equations. However, only a few studies have been conducted to validate these estimated NE values [46]. The recent published literatures on NE value validation have been summarized in Table 7. Among these studies, caloric efficiency is the most popular parameter used to determine whether the NE value of the ingredient was accurately estimated [12, 28, 39, 47–49]. The caloric efficiency was calculated as the daily energy intake (ADFI×dietary energy, MJ/kg) divided by ADG [39, 48, 49]. The validation approach using caloric efficiency is established based on the fact that pigs tend to consume their feed according to their energy requirements, and thus if the other nutrients such as amino acids are maintained constant, similar growth performance of pigs are expected [49, 50]. Therefore, the test ingredient was included in experimental diets in gradient levels in these validation trials, and similar caloric efficiency among the dietary treatments were expected if the assigned energy value is accurate. The NE values of tallow, soybean oil, wheat middlings, medium-oil corn DDGS, and rapeseed meal have been validated through this method [12, 28, 39, 47, 48]. Moreover, some studies used gain to feed ratio instead of caloric efficiency as a parameter to validate the estimated energy value. The underlying theories and experimental procedures of such experiments are the same as those using caloric efficiency. The NE value of flaxseed meal and canola meal have been validated through this method [46, 51].

Table 7.

Summary of validation research published in the past decade

| Authors | Ingredients | BW, kg | Methods | Experimental designa | Conclusion |

|---|---|---|---|---|---|

| Wu et al. (2007) [28] | Tallow | 23–98 | Caloric efficiency | Keep the NE to SID Lys ratio constant | The NE efficiency was not influenced by fat level, but DE and ME efficiency decreased |

| Eastwood et al. (2009) [51] | Flaxseed meal | 32–115 | Gain to feed ratio | Keep NE and SID Lys constant | The NE of flaxseed meal was correctly estimated |

| Montoya et al. (2010) [46] | Canola meal and full-fat canola seeds | 30–60 | Gain to feed ratio | Keep NE and SID Lys constant | The NE of canola meal was correctly estimated, but slightly underestimated for full fat canola seed. |

| Adeola et al. (2013) [47] | Soybean oil and tallow | 6–25 | Caloric efficiency | Keep the ME to SID Lys ratio constant | The NE of soybean oil from the 2012 NRC was accurate. NE of tallow were underestimated |

| De Jong et al. (2014) [48] | Wheat middlings | Nursery pigs | Caloric efficiency | Keep the SID Lys constant and isocaloric | The INRA NE of wheat midds appears to be a more accurate energy value than the ME obtained from the NRC |

| Graham et al. (2014) [39] | Medium-oil corn DDGS | 69–126 | Caloric efficiency | Keep the SID Lys constant and isocaloric | The NE of corn DDGS was accurate |

| Nitikanchana et al. (2015) [49] | Medium-oil corn DDGS and fat | 57–124 | Caloric efficiency | Keep the SID Lys constant and isocaloric | The NE of corn DDGS was overestimated and fat was underestimated |

| Wu et al. (2016) [52] | 4 corn DDGS sources | 22–115 | NRC growth model; prediction error and bias | Keep NE to SID Lys ratio similar | The NE predicted by a commercial service resulted in suboptimal prediction of NE among corn DDGS sources |

| Li et al. (2017) [12] (MAFIC work) | Corn, SBM, rapeseed meal | 36 | Caloric efficiency | Keep NE to SID Lys ratio similar | The NE measured was correctly estimated |

aDE: Digestiable energy; ME: Metabolizable energy; NE: Net energy; SID Lys: Standardized ileal digestible lysine

In the validation trials mentioned above, a key step in experimental design is to set up the constant values, usually the standardized ileal digestible lysine (SID Lys), among the dietary treatments when formulating treatment diets. In this situation, the net energy contents of the treatment diets tend to be slightly different due to the different inclusion levels of the test ingredients [39, 48, 49]. Some researchers then adjusted the energy-supplying parts of the diets to keep the NE value constant among the dietary treatments at the same time [46, 51]. Therefore, the gain to feed ratio was equal with the caloric efficiency in these experiments. In many other studies, the NE to SID Lys ratio was kept constant among the dietary treatments when formulating treatment diets [12, 28, 47]. There is still no evidence showing which experimental design is more accurate in validation. The caloric efficiency can combine with other techniques, e.g. meta-analysis, to validate the NE content of ingredients as well as the prediction equations for growth performance established based on meta-analysis [49].

However, the actual NE value of the ingredients, especially the high-fiber ingredients, rely on the inclusion level of the ingredients in diets [2]. It was emphasized that the NE value of ingredients can be greatly affected at a high inclusion level in diets [48]. Furthermore, it is more common that no significant difference were observed among dietary treatments using the caloric efficiency approach, especially when the number of replications is insufficient. Under such conditions, it is difficult to conclude that the assigned energy value is accurate, because we can only infer that the value is not wrong from statistical point of view. As a result, there are some drawbacks to use the caloric efficiency method to validate the energy content of ingredients. In a more recent study, the target NE values of corn DDGS were compared with the estimated NE contents of DDGS based on the NRC growth model. Prediction error and bias between these two datasets were calculated and used to validate the target NE values [52]. This approach avoids to use caloric efficiency in energy content validation, but the choice of an appropriate model is vital to get convincing results.

Conclusions and perspectives for future

The NE system provides a good foundation to increase the utilization of alternative feedstuffs in swine diets. However, research on NE is time-consuming, expensive, and complex and depends heavily on methodology. This review summarizes the NE research in swine conducted at MAFIC from methodological aspect. The net energy requirements for maintenance were estimated in MAFIC using both the fasting heat production method and the nonlinear regression method. The NE value of feedstuffs were determined using indirect calorimetry through standard experimental procedure in MAFIC, and the prediction equation from INRA (NE = (0.7 × DE) + [(1.61 × EE) + (0.48 × Starch) - (0.91 × CP) - (0.87 × ADF)]/1000 × 4.184) can be used to predict NE in situations where calorimeters are not available. Although with drawbacks, caloric efficiency is still the most popular parameter to validate the estimated NE content. In the future, new criteria established on biochemical mechanisms can be used to describe the maintenance condition for pigs. NE prediction equations based on individual ingredients should be established to improve the accuracy of prediction. More generally accepted approach is needed to further validate the estimated NE values of feedstuffs.

Acknowledgements

We thank Dr. Jean Noblet and Dr. Philips A. Thacker for excellent assistance in editing the manuscript. We also thank our colleagues of the Ministry of Agricultural Feed Industry Centre for collaboration on net energy research.

Funding

This project was financially supported by the Modern Agricultural Industry Technology System (CARS-36), Developing key equipment for digital management and monitoring environment in animal production (2013AA10230602), National Natural Science Foundation of China (31372317), the 111 Project (B16044) and China Postdoctoral Science Foundation. The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Availability of data and materials

All the data were presented in the main manuscript and available to readers.

Abbreviations

- ADFI

Average daily feed intake

- ADG

Average daily gain

- BW

Body weight

- DE

Digestible energy

- DM

Dry matter

- FHP

Fasting heat production

- GE

Gross energy

- HI

Heat increment

- HP

Heat production

- kg

Efficiencies of energy utilization for growth

- km

Efficiencies of energy utilization for maintenance

- ME

Metabolizable energy

- MEm

Metabolizable energy requirements for maintenance

- N

Nitrogen

- NE

Net energy

- NEE

Net energy efficiency

- NEm

Net energy requirements for maintenance

- RE

Retention energy

- REL

Retention energy as lipid

- REP

Retention energy as protein

- THP

Total heat production

Authors’ contributions

ZL summarized all of the net energy experiments conducted at MAFIC and wrote the manuscript. HL and YL participated in the experiments. CL, FW, DL and SZ critically evaluated the manuscript. All authors read and approved the final manuscript.

Ethics approval and consent to participate

All procedures used in this study were performed according to the guidelines for the ethical treatment of animal by the Institutional Animal Care and Use Committee of China Agricultural University (Beijing, China).

Competing interests

The authors declare that they have no competing interests.

Contributor Information

Zhongchao Li, Email: lizhongchao2012@163.com.

Hu Liu, Email: 624279480@qq.com.

Yakui Li, Email: liyakui@163.com.

Zhiqian Lv, Email: 2434390936@qq.com.

Ling Liu, Email: liul@mafic.ac.cn.

Changhua Lai, Email: laichanghua999@163.com.

Junjun Wang, Email: jkywjj@hotmail.com.

Fenglai Wang, Email: wangfl@cau.edu.cn.

Defa Li, Email: defali@mafic.ac.cn.

Shuai Zhang, Email: zhangshuai16@cau.edu.cn.

References

- 1.Li P, Li DF, Zhang HY, Li ZC, Zhao PF, Zeng ZK, et al. Determination and prediction of energy values in corn distillers dried grains with solubles sources with varying oil content for growing pigs. J Anim Sci. 2015;93:3458–3470. doi: 10.2527/jas.2014-8782. [DOI] [PubMed] [Google Scholar]

- 2.Just A. The net energy value of crude (catabolized) protein for growth in pigs. Livest Prod Sci. 1982;9:349–360. doi: 10.1016/0301-6226(82)90041-0. [DOI] [Google Scholar]

- 3.Schiemann R, Nehring K, Hoffmann L, Jentsch W, Chudy A. Energetische Futterbevertung und Energienormen. Berlin: VEB Deutscher Landwirtschatsverlag; 1972. [Google Scholar]

- 4.Noblet J, Shi X, Dubois S. Metabolic utilization of dietary energy and nutrients for maintenance energy requirements in sows: basis for a net energy system. Br J Nutr. 1993;70:407–419. doi: 10.1079/BJN19930135. [DOI] [PubMed] [Google Scholar]

- 5.Noblet J, Fortune H, Shi XS, Dubois S. Prediction of net energy value of feeds for growing pigs. J Anim Sci. 1994;72:344–354. doi: 10.2527/1994.722344x. [DOI] [PubMed] [Google Scholar]

- 6.van Milgen J, Bernier JF, Lecozler Y, Dubois S, Noblet J. Major determinants of fasting heat production and energetic cost of activity in growing pigs of different body weight and breed/castration combination. Br J Nutr. 1998;79:509–517. doi: 10.1079/BJN19980089. [DOI] [PubMed] [Google Scholar]

- 7.Hu Q, Wang FL, Piao XS, Ni JJ, Zhang XM, Li DF. Effects of fasting duration and body weight on fasting heat production in growing pigs. J Anim Vet Adv. 2012;11:2333–2341. doi: 10.3923/javaa.2012.2333.2341. [DOI] [Google Scholar]

- 8.Zhang GF, Liu DW, Wang FL, Li DF. Estimation of the net energy requirements for maintenance in growing and finishing pigs. J Anim Sci. 2014;92:2987–2995. doi: 10.2527/jas.2013-7002. [DOI] [PubMed] [Google Scholar]

- 9.Liu DW, Jaworski NW, Zhang GF, Li ZC, Li DF, Wang FL. Effect of experimental methodology on fasting heat production and the net energy content of corn and soybean meal fed to growing pigs. Arch Anim Nutr. 2014;68:281–295. doi: 10.1080/1745039X.2014.931016. [DOI] [PubMed] [Google Scholar]

- 10.Liu DW, Liu L, Li DF, Wang FL. Determination and prediction of the net energy content of seven feed ingredients fed to growing pigs based on chemical composition. Anim Prod Sci. 2015;55:1152–1163. [Google Scholar]

- 11.Li ZC, Li P, Liu DW, Li DF, Wang FL, Su YB, et al. Determination of the energy value of corn distillers dried grains with solubles containing different oil levels when fed to growing pigs. J Anim Physiol Anim Nutr. 2017;101:339–348. doi: 10.1111/jpn.12445. [DOI] [PubMed] [Google Scholar]

- 12.Li ZC, Li YK, Lv ZQ, Liu H, Zhao JB, Noblet J, et al. Net energy of corn, soybean meal and rapeseed meal in growing pigs. J Anim Sci Biotechnol. 2017;8:44. doi: 10.1186/s40104-017-0169-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Li ZC. Net energy prediction of plant protein ingredients to growing pigs. PhD thesis. Beijing: China Agricultural University; 2017.

- 14.Li Y, Li Z, Liu H, Noblet J, Liu L, Li D, et al. Net energy content of rice bran, corn germ meal, corn gluten feed, peanut meal, and sunflower meal in growing pigs. Asian-Australas J Anim Sci. 2018. 10.5713/ajas.17.0829. [Epub ahead of print]. [DOI] [PMC free article] [PubMed]

- 15.Brouwer E. Report of sub-committee on constants and factors. Proceedings of the 3rd EAAP symposium on energy metabolism; Troonn, Publ. 11. London: Academic Press; 1965. pp. 441–443. [Google Scholar]

- 16.Ewan RC. Energy utilization in swine nutrition. In: Lewis AJ, Southern LL, editors. Swine nutrition. 2. New York: CRC Press; 2001. pp. 903–916. [Google Scholar]

- 17.Kil DY, Kim BG, Stein HH. Feed energy evaluation for growing pigs. Asian-Australas J Anim Sci. 2013;26:1205–1217. doi: 10.5713/ajas.2013.r.02. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Chwalibog A, Jakobsen K, Tauson A-H, Thorbek G. Energy metabolism and nutrient oxidation in young pigs and rats during feeding, starvation and re-feeding. Comp Biochem Physiol A Mol Integr Physiol. 2005;140:299–307. doi: 10.1016/j.cbpb.2005.01.010. [DOI] [PubMed] [Google Scholar]

- 19.Jørgensen H, Prapaspongsa T, Poulsen HD. Models to quantify excretion of dry matter, nitrogen, phosphorus and carbon in growing pigs fed regional diets. J Anim Sci Biotechnol. 2013;4:42. doi: 10.1186/2049-1891-4-42. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Noblet J, van Milgen J. Energy and energy metabolism in swine. In: Chiba LI, editor. Sustainable swine nutrition. Ames, IA: Wiley-Blackwell; 2013. pp. 33–35. [Google Scholar]

- 21.Labussière E, Dubois S, van Milgen J, Noblet J. Partitioning of heat production in growing pigs as a tool to improve the determination of efficiency of energy utilization. Front Physiol. 2013;4:146. doi: 10.3389/fphys.2013.00146. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Birkett S, Lange KD. Limitations of conventional models and a conceptual framework for a nutrient flow representation of energy utilization by animals. Br J Nutr. 2001;86:647–659. doi: 10.1079/BJN2001441. [DOI] [PubMed] [Google Scholar]

- 23.Labussiere E, van Milgen J, de Lange CF, Noblet J. Maintenance energy requirements of growing pigs and calves are influenced by feeding level. J Nutr. 2011;141:1855–1861. doi: 10.3945/jn.111.141291. [DOI] [PubMed] [Google Scholar]

- 24.de Lange K, van Milgen J, Noblet J, Dubois S, Birkett S. Previous feeding level influences plateau heat production following a 24 h fast in growing pigs. Br J Nutr. 2006;95:1082–1087. doi: 10.1079/BJN20061748. [DOI] [PubMed] [Google Scholar]

- 25.Koong LJ, Nienaber JA, Pekas JC, Yen JT. Effects of plane of nutrition on organ size and fasting heat production in pigs. J Nutr. 1982;112:1638–1642. doi: 10.1093/jn/112.8.1638. [DOI] [PubMed] [Google Scholar]

- 26.Gerrits W, Schrama JW, Tamminga S, Verstegen M. Effect of protein and protein-free energy intake on myofibrillar protein degradation in preruminant calves of 120 and 200 kilograms of live weight. J Anim Sci. 1998;76:1364–1370. doi: 10.2527/1998.7651364x. [DOI] [PubMed] [Google Scholar]

- 27.Noblet J, Karege C, Dubois S, van Milgen J. Metabolic utilization of energy and maintenance requirements in growing pigs: effects of sex and genotype. J Anim Sci. 1999;77:1208–1216. doi: 10.2527/1999.7751208x. [DOI] [PubMed] [Google Scholar]

- 28.Wu Z, Li DF, Ma YX, Yu Y, Noblet J. Evaluation of energy systems in determining the energy cost of gain of growing-finishing pigs fed diets containing different levels of dietary fat. Arch Anim Nutr. 2007;61:1–9. doi: 10.1080/17450390601106614. [DOI] [PubMed] [Google Scholar]

- 29.Noblet J. Digestive and metabolic utilization of energy in swine: application to energy evaluation systems. J Appl Anim Res. 2000;17:113–132. doi: 10.1080/09712119.2000.9706295. [DOI] [Google Scholar]

- 30.Noblet J, Henry Y. Energy evaluation systems for pig diets: a review. Livest Prod Sci. 1993;36:121–141. doi: 10.1016/0301-6226(93)90147-A. [DOI] [Google Scholar]

- 31.Noblet J, Van Milgen J. Energy value of pig feeds: effect of pig body weight and energy evaluation system. J Anim Sci. 2004;82:E229–E238. doi: 10.2527/2004.8213_supplE229x. [DOI] [PubMed] [Google Scholar]

- 32.Ayoade DI, Kiarie E, Neto MAT, Nyachoti CM. Net energy of diets containing wheat-corn distillers dried grains with solubles as determined by indirect calorimetry, comparative slaughter, and chemical composition methods. J Anim Sci. 2012;90:4373–4379. doi: 10.2527/jas.2011-4858. [DOI] [PubMed] [Google Scholar]

- 33.Quiniou N, Dubois S, Noblet J. Effect of dietary crude protein level on protein and energy balances in growing pigs: comparison of two measurement methods. Livest Prod Sci. 1995;41:51–61. doi: 10.1016/0301-6226(94)00030-B. [DOI] [Google Scholar]

- 34.Kil DY, Ji F, Stewart LL, Hinson RB, Beaulieu AD, Allee GL, et al. Net energy of soybean oil and choice white grease in diets fed to growing and finishing pigs. J Anim Sci. 2011;89:448–459. doi: 10.2527/jas.2010-3233. [DOI] [PubMed] [Google Scholar]

- 35.Kil DY, Ji F, Stewart LL, Hinson RB, Beaulieu AD, Allee GL, et al. Effects of dietary soybean oil on pig growth performance, retention of protein, lipids, and energy, and on the net energy of corn in diets fed to growing or finishing pigs. J Anim Sci. 2013;91:3283–3290. doi: 10.2527/jas.2012-5124. [DOI] [PubMed] [Google Scholar]

- 36.Gutierrez NA, Kil DY, Liu Y, Pettigrew JE, Stein HH. Effects of co-products from the corn-ethanol industry on body composition, retention of protein, lipids and energy, and on the net energy of diets fed to growing or finishing pigs. J Sci Food Agric. 2014;94:3008–3016. doi: 10.1002/jsfa.6648. [DOI] [PubMed] [Google Scholar]

- 37.Bray HJ, Giles LR, Gooden JM, Black JL. Energy expenditure in growing pigs infected with pleuropneumonia. In: KJ MC, Unsworth EF, ARG W, editors. Energy metabolism of farm animals. Northern Ireland: Newcastle: Proc. 14th Symp. Energy Metab; 1997. pp. 291–294. [Google Scholar]

- 38.Verstegen MWA. Proc. Saskatoon, SK: Western Nutr. Conf; 2001. Developments towards net energy systems in feeds and animals; pp. 170–184. [Google Scholar]

- 39.Graham AB, Goodband RD, Tokach MD, Dritz SS, DeRouchey JM, Nitikanchana S, et al. The effects of low-, medium-, and high-oil distillers dried grains with solubles on growth performance, nutrient digestibility, and fat quality in finishing pigs. J Anim Sci. 2014;92:3610–3623. doi: 10.2527/jas.2014-7678. [DOI] [PubMed] [Google Scholar]

- 40.Sauvant D, Perez JM, Tran G. Tables of composition and nutritional value of feed materials: pigs, poultry, cattle, sheep, goats, rabbits, horses and fish. 2004. [Google Scholar]

- 41.NRC . Nutrient requirements of swine. 11th. Ed. Washington: National Academy Press; 2012. [Google Scholar]

- 42.Velayudhan DE, Heo JM, Nyachoti CM. Net energy content of dry extruded-expelled soybean meal fed with or without enzyme supplementation to growing pigs as determined by indirect calorimetry. J Anim Sci. 2015;93:3402–3409. doi: 10.2527/jas.2014-8514. [DOI] [PubMed] [Google Scholar]

- 43.Rojas OJ, Stein HH. Concentration of digestible, metabolizable, and net energy and digestibility of energy and nutrients in fermented soybean meal, conventional soybean meal, and fish meal fed to weanling pigs. J Anim Sci. 2013;91:4397–4405. doi: 10.2527/jas.2013-6409. [DOI] [PubMed] [Google Scholar]

- 44.Sotak-Peper KM, Gonzalez-Vega JC, Stein HH. Concentrations of digestible, metabolizable, and net energy in soybean meal produced in different areas of the United States and fed to pigs. J Anim Sci. 2015;93:5694–5701. doi: 10.2527/jas.2015-9281. [DOI] [PubMed] [Google Scholar]

- 45.Kil DY. Digestibility and energetic utilization of lipids by pigs. PhD thesis. Urbana, IL: University of Illinois; 2008. [Google Scholar]

- 46.Montoya CA, Leterme P. Validation of the net energy content of canola meal and full-fat canola seeds in growing pigs. Can J Anim Sci. 2010;90:213–219. doi: 10.4141/CJAS09054. [DOI] [Google Scholar]

- 47.Adeola O, Mahan DC, Azain MJ, Baidoo SK, Cromwell GL, Hill GM, et al. Dietary lipid sources and levels for weanling pigs. J Anim Sci. 2013;91:4216–4225. doi: 10.2527/jas.2013-6297. [DOI] [PubMed] [Google Scholar]

- 48.De Jong J, DeRouchey J, Tokach M, Dritz S, Goodband R. Effects of dietary wheat middlings, corn dried distillers grains with solubles, and net energy formulation on nursery pig performance. J Anim Sci. 2014;92:3471–3481. doi: 10.2527/jas.2013-7350. [DOI] [PubMed] [Google Scholar]

- 49.Nitikanchana S, Dritz SS, Tokach MD, DeRouchey JM, Goodband RD, White BJ. Regression analysis to predict growth performance from dietary net energy in growing-finishing pigs. J Anim Sci. 2015;93:2826–2839. doi: 10.2527/jas.2015-9005. [DOI] [PubMed] [Google Scholar]

- 50.Quiniou N, Noblet J. Effect of the dietary net energy concentration on feed intake and performance of growing-finishing pigs housed individually. J Anim Sci. 2012;90:4362–4372. doi: 10.2527/jas.2011-4004. [DOI] [PubMed] [Google Scholar]

- 51.Eastwood L, Kish PR, Beaulieu AD, Leterme P. Nutritional value of flaxseed meal for swine and its effects on the fatty acid profile of the carcass. J Anim Sci. 2009;87:3607–3619. doi: 10.2527/jas.2008-1697. [DOI] [PubMed] [Google Scholar]

- 52.Wu F, Johnston LJ, Urriola PE, Hilbrands AM, Shurson GC. Evaluation of NE predictions and the impact of feeding maize distillers dried grains with solubles (DDGS) with variable NE content on growth performance and carcass characteristics of growing-finishing pigs. Anim Feed Sci Technol. 2016;215:105–116. doi: 10.1016/j.anifeedsci.2016.02.023. [DOI] [Google Scholar]

- 53.Hinson RB, Kil DY, Beaulieu AD, Stewart LL, Fi J, Pettigrew JE, et al. Net energy content content of commercial and low-oligosaccharide soybean meal. J Anim Sci. 2009;87(E-Suppl. 3):99. [Google Scholar]

- 54.Stewart LL, Kil DY, Ji F, Hinson RB, Beaulieu AD, Allee GL, et al. Effects of dietary soybean hulls and wheat middlings on body composition, nutrient and energy retention, and the net energy of diets and ingredients fed to growing and finishing pigs. J Anim Sci. 2013;91:2756–2765. doi: 10.2527/jas.2012-5147. [DOI] [PubMed] [Google Scholar]

- 55.Heo JM, Adewole D, Nyachoti M. Determination of the net energy content of canola meal from Brassica napus yellow and Brassica juncea yellow fed to growing pigs using indirect calorimetry. Anim Sci J. 2014;85:751–756. doi: 10.1111/asj.12196. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

All the data were presented in the main manuscript and available to readers.