Summary

The production of γ-linolenic acid (GLA) by the fungus Cunninghamella elegans CFR C07 in submerged fermentation was studied. Culture parameters such as carbon source and incubation time were optimized. Four different extraction methods using solvents with acid washed sand, glass beads, lyophilization and Soxhlet extraction were evaluated for improved extraction of lipids from the fungal biomass after fermentation. The GLA production was initially optimized in 250-mL flask and the process was demonstrated in a 3-litre fermentor. The maximum GLA production was 882 mg/L in shake flask culture and 733 mg/L in the fermentor. The study shows that Cunninghamella elegans CFR C07 is a potent organism for the production of GLA under submerged conditions.

Key words: γ-linolenic acid, submerged fermentation, Cunninghamella elegans, fatty acid production

Introduction

γ-Linolenic acid (GLA; 6,9,12-octadecatrienoic acid) is one of the essential fatty acids (EFA) in polyunsaturated fatty acid (PUFA) family that can reverse the symptoms of the lack of n-6 EFA in diet (1, 2). The role of GLA in metabolism is various; dihomo-γ-linolenic acid (DGLA) is the active form of GLA that mediates most of its physiological actions including cell to cell communication, synthesis of prostagladins, anti-inflammatory, vasodilatory and anti-aggregatory actions (3). However, it has been found that in vivo conversion of linolenic acid into GLA is hindered by ageing, consumption of alcohol and vitamin deficiency (4). The demand for dietary supplementation of GLA is increasing (5, 6) and microbial route for the production of GLA has more advantages than production from plant sources.

The present study evaluates the production of GLA in submerged fermentation by Cunninghamella elegans CFR C07 isolated at CSIR – Central Food Technological Research Institute (CFTRI), Mysore, India. The advantages of using fungal species for production of GLA are: high growth rate, easy manipulation of fatty acid profile by varying growth conditions instead of genetic manipulations or extensive breeding efforts, simple culture conditions and consistency of production (7). Fermentation has many benefits over the isolation from plant and animal sources because it is devoid of seasonal or climatic dependence, and microbial PUFAs are the oil types with higher value than low-priced oils (soybean, palm and sunflower oil). The extremely high growth rates of microbes, especially fungi, on wide varieties of substrates allow utilizing cheap materials. Microbial sources can supply more concentrated pharmaceutical grade PUFAs than other sources, with controlled quality (8). In fermentation studies, several parameters need to be optimized since they affect the fatty acid production (9). One of the important variables is C/N ratio. In the present study, optimization of inorganic carbon sources for the production of GLA was carried out. Downstream processing is one of the major factors determining the feasibility of the process and suitable extraction method of lipids from the biomass is very important in lipid fermentations (10, 11). The aim of this study is to optimize the carbon source, incubation time and extraction methods, and scale up the GLA production using Cunnighamella elegans CFR C07 in submerged fermentation.

Materials and Methods

Chemicals

The medium components were obtained from HiMedia Laboratories (Mumbai, India) and solvents used in this study were all of reagent grade. Fatty acid standard and Sudan black B were obtained from Sigma-Aldrich, Bangalore, India.

Fungal strains

Cunnighamella elegans CFR C07 isolated from the Western Ghats of Karnataka and Nilgiris region, India, is used in the study. The strain was stored on potato dextrose agar (PDA) plates (HiMedia Laboratories) at 4 °C. Culture was maintained by repeated subculturing.

Medium and culture conditions

The culture medium designed by Somashekar et al. (12) contained (in g/L): KNO3 1.00, KH2PO4 2.50, ZnSO4·7H2O 0.01, CuSO4·5H2O 0.002, MnSO4 0.01, MgSO4·7H2O 0.50, FeSO4·7H2O 0.02, yeast extract 5.00, glucose 30.0 and CaCl2 0.10, pH=5.5. Seed culture was prepared in potato dextrose broth (PDB) using spore solution (104 spores per mL). A volume of 20 mL of the spore solution was added to 80 mL of PDB and incubated for 2 days at 30 °C and 200 rpm. A volume fraction of 20% of the inoculum was added to the medium and the culture was grown in Erlenmeyer flasks (250 mL) incubated with shaking at 200 rpm for 5 days at (28±2) °C.

Optimization of carbon source

Four inorganic carbon sources (30 g/L each), namely maltose, galactose, sucrose and fructose were evaluated in the fermentation medium and the production of biomass from different carbon sources was determined on dry mass basis by separating the biomass by centrifugation at 6000×g (model C-24BL; REMI, Maharashtra, India) and drying at 60 °C in a hot air oven (model 101; RRT NC, Trivandrum, Kerala, India).

Staining method

The fungal strains were stained with Sudan black B according to the method of Burdon (13) and du Preez et al. (14) in order to check the oil accumulation. The fungal biomass was separated after fermentation by centrifugation at 6000×g (model C-24BL; REMI), suspended in 1 mL of Sudan black B staining solution and washed with distilled water. A smear of culture solution was made on a clear glass slide. The cells were then washed with 70% alcohol 3-4 times to remove excess stain and observed under optical microscope with oil immersion objective (model DM 2000; Leica, Wetzlar, Germany).

Optimization of incubation time

In order to study the effect of incubation period on GLA production, fungal culture was fermented for varying incubation time (3 to 5 days). Biomass was collected, oil was extracted and GLA was estimated by gas chromatography (model GC1000; Chemito Instruments Pvt. Ltd., Nashik, India) after converting it into methyl esters.

Evaluation of GLA production in the fermentor

The previously described medium (12) was used for studies in the fermentor. The medium was transferred into 3-litre submerged bioreactor (Infors HT, Bottmingen, Switzerland) and sterilized. The pH was maintained in the fermentor using 1 M HCl and 1 M NaOH and frothing was controlled using antifoam. Pre-inoculum was prepared in PDB. Fermentation was continued for 4 days and the fermentor conditions were: total volume 1.5 L, temperature 28 °C, pH=5.5, aeration 1 vvm, shaking speed of 200 rpm and inoculum size 20%. GLA production was evaluated by GC as described previously.

Determination of dry cell mass

For dry cell mass determination, cell samples in the liquid medium were harvested by centrifugation at 6000×g (model C-24BL; REMI) for 15 min. The obtained cell pellet was then kept for freeze drying in a lyophilozer (ScanVac; Labogene, Allerød, Denmark).

Optimization of solvent extraction methods

Biomass obtained after 4 days of incubation was subjected to four different solvent extraction methods (11). In method 1, biomass and acid washed sand (1:2, by mass) were homogenized for 1 h. Lipids were extracted by chloroform/methanol (2:1, by volume), centrifuged at 6000×g (model C-24BL; REMI) to get a clear supernatant, and anhydrous sodium sulphate was added to remove any residual moisture. Solvent was removed by flushing with nitrogen. In method 2, biomass was lyophilised and extracted three times by chloroform/methanol (2:1, by volume) using automatic solvent extraction system B-811 (BÜCHI Labortechnik AG, Flawil, Switzerland).

Method 3 was Soxhlet extraction (11). Lipids were extracted with 250 mL of hexane for 8 h in automatic solvent extraction system B-811 (BÜCHI Labortechnik AG). In method 4, biomass and glass beads (1:2, by mass) were homogenised for 1 h and lipids were extracted by chlorofom/methanol (2:1, by volume). The extracted lipids were centrifuged at 6000×g (model C-24BL; REMI) to give a clear supernatant, and anhydrous sodium sulphate was added to remove the residual moisture. Solvent was removed by flushing with nitrogen.

Thin layer chromatography (TLC) of lipids was done after the extraction and the bands were evaluated. The samples were spotted on TLC plates coated with silica gel (HiMedia), which were run in a solvent system containing n-hexane and ethyl acetate in a volume ratio of 9:1. After air drying the plates, the fractions were observed in an iodine chamber containing silica gel. For identification of triacylglycerol (TG) and free fatty acid (FFA), corresponding standards (Sigma-Aldrich) were used.

Fatty acid methyl ester preparation

Before the estimation of GLA by gas chromatography (GC), the extracted lipids were converted to methyl esters. The extracted lipids (500 µL) were mixed with 2% H2SO4 and 10 mL of methanol and refluxed for 5 h (at approx. 60 °C) in rotavapor (model R-210; BÜCHI Labortechnik AG). After 5 h, the methanol was evaporated and 10 mL of ethyl acetate were added and transferred into separating funnel. Distilled water (10 mL) was added to the separating funnel and it was shaken gently. The aqueous layer was separated from the organic layer and washing was repeated twice. The ethyl acetate layer was separated and dried over sodium sulphate. It was then filtered, evaporated and resuspended in ethyl acetate/hexane (1:1). Then these samples were analysed by TLC to confirm the presence of free fatty acid methyl esters and then used for GC analysis.

Gas chromatographic conditions

The samples were analyzed using gas chromatograph equipped with flame ionization detector (model GC1000; Chemito Instruments Pvt. Ltd) and Stabilwax capillary column (Restek Corporation, Bellefonte, PA, USA). The analysis started at 40 °C for 1 min and the temperature was increased to 240 °C at the rate of 40 °C/min. After reaching 240 °C, the temperature was held stable for 5 min before the analysis was terminated. The column temperature was 140 °C and the injection volume was 1 μL with split injection ratio of 1:100. The injector temperature was 240 °C and the carrier gas was nitrogen at rate of approx. 5 mL/min. The peak area percentages were recorded. Individual fatty acid methyl esters were identified by comparing their retention times with fatty acid standards.

Results and Discussion

Effect of carbon source

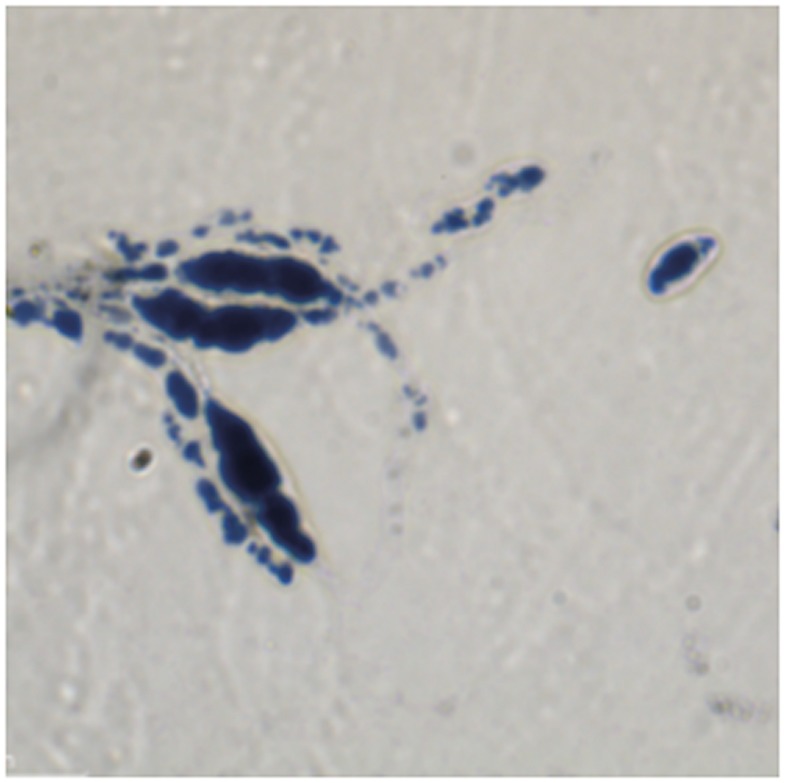

Glucose was found to be a good carbon source for the production of biomass with a yield of (20.5±1.2) g/L, whereas galactose and maltose were found to be poor substrates with yields of 9.7 and 10 g/L, respectively. Fructose and sucrose gave almost similar yields (19.8 and 20 g/L, respectively) of biomass as that of glucose. Studies by Shrivastava et al. (7) and Ahmed et al. (9) reported glucose as the major carbon source for the production of GLA. Previous studies showed an increased yield of GLA after the addition of glucose (15). After staining with Sudan black B, the presence of blue or greyish oil globules was observed within the mycelium under microscope (Fig. 1). Medium with glucose gave oilier mycelia than other carbon sources. Glucose was selected as the carbon source in the production medium to increase oil accumulation and biomass yield.

Fig. 1.

Cunninghamella elegans CFR C07 under optical microscope with oil immersion objective (at 40× magnification)

Effect of incubation time

Optimum incubation period for Cunninghamella elegans CFR C07 was found to be 4 days, with GLA production of (882±10.8) mg/L from (20.5±1.2) g/L of biomass. In incubation period longer than 4 days, GLA production seemed to decrease even though biomass increased (Fig. 2). The peak at retention time of 21.8 min indicates the GLA. The GLA production decreased to 866 mg/L on the 5th day of incubation. Earlier studies on Cunninghamella sp. also reported optimum incubation period of 4-5 days (4, 16) and other fungal strains like Mucor sp. take 7 days (9).

Fig. 2.

Gas chromatogram showing the fatty acid methyl ester profile at different stages of incubation. The γ-linolenic acid (GLA) peak at retention time of 21.8 min on the 3rd, 4th and 5th day of incubation, respectively: a) not observed, meaning that there were no lipids, b) γ(GLA)=882 mg/L, and c) γ(GLA)=866 mg/L

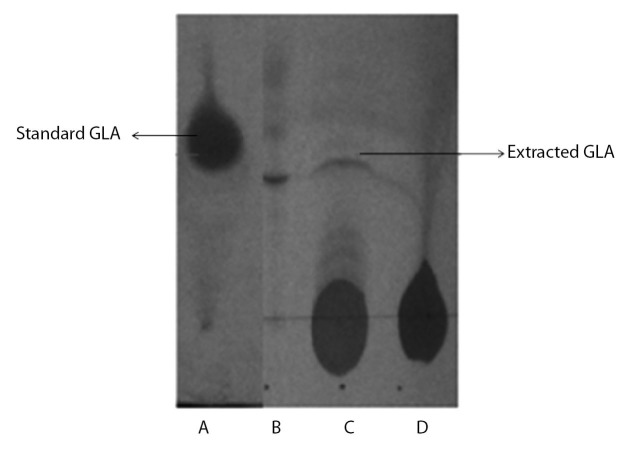

Selection of extraction methods

Biomass obtained after 4 days of incubation was subjected to different solvent extraction methods. Among them, hexane used as a solvent for 8 h in automatic extraction system gave the best oil yield, so this method was selected for further studies. Microbial oils are considered to be used for human consumption, so the solvent used in the extraction must be acceptable in terms of toxicity, handling, safety and cost (8). Therefore, hexane was selected, as being less toxic than chloroform/methanol mixture (11). The presence of GLA in the extracted oil was confirmed by TLC in which a clear band of GLA was observed against standard (Fig. 3).

Fig. 3.

Comparison of isolated γ-linolenic acid (GLA) with standard GLA by thin layer chromatography: A=standard GLA, B=extraction method 3, C=extraction method 1 and D=extraction method 4

Evaluation of biomass and GLA production

In flask cultivation, 20.5 g/L of biomass were obtained after 4 days and glucose was used as the carbon source. The results obtained here were better than those obtained by Manoh and Seto (4) with C. elegans NRRL 1378 and the medium containing more glucose, malt extract, yeast extract and peptone. In the study done by Murad et al. (17), 12 g/L of biomass were obtained using C. baineri 2A1. In another study by Shrivastava et al. (7) on Cunninghamella echinulata var. elegans MTCC552, 10.90 g/L of biomass were produced. In a study by Gema et al. (18) on Cunninghamella echinulata, 8.9 g/L of biomass were obtained.

In the present study, 882 mg/L of GLA were obtained using the strain after 4 days of incubation, which was higher than the yields reported by Murad et al. (17), Shrivastava et al. (7) and Gema et al. (18), i.e. 650, 209.5 and 720 mg/L, respectively.

Production in a 3-litre fermentor was evaluated and maximum GLA production of 733 mg/L was observed. Fermentation studies by Saad et al. (16) resulted in 747.72 mg/L of GLA with the optimization of aeration and agitation. The optimization of physical parameters such as aeration and agitation in the fermentor used in this study may give even better results, but it can still be concluded that Cunninghamella elegans CFR C07 can be used for the production of GLA and that it could be a potent organism for further scale-up studies and commercialization.

Conclusions

Cunninghamella elegans CFR C07 is a good microbial source of γ-linolenic acid (GLA). Glucose was selected as the carbon source for the production of GLA under submerged conditions. Maximum GLA production was observed on the 4th day of cultivation. Medium containing fructose and sucrose gave good biomass yield (20 g/L), but the GLA content was lower than that of other tested carbon sources. The maximum GLA production at optimized conditions in shake flask was 882 mg/L, while in 3-litre fermentor it was 733 mg/L. The study shows that the isolated strain of Cunninghamella elegans CFR C07 is a potent producer of GLA. Further studies on the scale-up of fermentation by this organism may result in a viable commercial process for the production of GLA via microbial route.

Acknowledgements

We are thankful to CSIR network project CSC0112 (CSIR, New Delhi, India) for funding this work.

References

- 1.Rajendra GN, Ujjwal N, Ruchi S. Fungal production of omega-6 fatty acid: Gamma-linolenic acid. Intl J Biol Chem. 2007;1:127–30. 10.3923/ijbc.2007.127.130 [DOI] [Google Scholar]

- 2.Horrobin DF. Nutritional and medical importance of gamma-linolenic acid. Prog Lipid Res. 1992;31:163–94. 10.1016/0163-7827(92)90008-7 [DOI] [PubMed] [Google Scholar]

- 3.Kapoor R, Huang YS. Gamma linolenic acid: An antiinflammatory omega-6 fatty acid. Curr Pharm Biotechnol. 2006;7:531–4. 10.2174/138920106779116874 [DOI] [PubMed] [Google Scholar]

- 4.Manoh Y, Seto A. Process for preparing a lipid composition having a high γ-linolenic acid content. US patent 5026644. 1991.

- 5.Kennedy MJ, Reader SL, Davies RJ. Fatty acid production characteristics of fungi with particular emphasis on gamma linolenic acid production. Biotechnol Bioeng. 1993;42:625–34. 10.1002/bit.260420511 [DOI] [PubMed] [Google Scholar]

- 6.Ward OP, Singh A. Omega-3/6 fatty acids: Alternative sources of production. Process Biochem. 2005;40:3627–52. 10.1016/j.procbio.2005.02.020 [DOI] [Google Scholar]

- 7.Shrivastava A, Bajaj I, Saudagar P, Singhal R. Media optimization for the production of γ-linolenic acid by Cunninghamella echinulata var. elegans MTCC 552 using response surface methodology. Int J Food Eng. 2008;4:1–32. 10.2202/1556-3758.1178 [DOI] [Google Scholar]

- 8.Arjuna A. Production of polyunsaturated fatty acids by fungi: A review. Int J Pharma Bio Sci. 2014;5:931–54. [Google Scholar]

- 9.Ahmed SU, Singh SK, Pandey A, Kanjilal K, Prasad RBN. Effects of various process parameters on the production of γ-linolenic acid in submerged fermentation. Food Technol Biotechnol. 2006;44:283–7. [Google Scholar]

- 10.Čertík M, Andráši P, Šajbidor J. Effect of extraction methods on lipid yield and fatty acid composition of lipid classes containing γ-linolenic acid extracted from fungi. J Am Oil Chem Soc. 1996;73:357–65. 10.1007/BF02523431 [DOI] [Google Scholar]

- 11.Somashekar D, Venkateshwaran G, Srividya C. Krishnanand, Sambaiah K, Lokesh BR. Efficacy of extraction methods for lipid and fatty acid composition from fungal cultures. World J Microbiol Biotechnol. 2001;17:317–20. 10.1023/A:1016792311744 [DOI] [Google Scholar]

- 12.Somashekar D, Venkateshwaran G, Sambaiah K, Lokesh BR. Effect of culture conditions on lipid and gamma-linolenic acid production by mucoraceous fungi. Process Biochem. 2003;38:1719–24. 10.1016/S0032-9592(02)00258-3 [DOI] [Google Scholar]

- 13.Burdon KL. Fatty material in bacteria and fungi revealed by staining dried, fixed slide preparations. J Bacteriol. 1946;52:665–78. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.du Preez JC, Immelman M, Kock JLF, Kilian SG. The effect of acetic acid concentration on the growth and production of gamma-linolenic acid by Mucor circinelloides CBS 203.28 in fed-batch culture. World J Microbiol Biotechnol. 1997;13:81–7. 10.1007/BF02770812 [DOI] [Google Scholar]

- 15.de Oliveira Carvalho P, de Oliveira JG, Pastore GM. Enhancement of gamma-linolenic acid production by the fungus Mucor sp. LB-54 by growth temperature. Rev Microbiol. 1999;30:170–6. 10.1590/S0001-37141999000200016 [DOI] [Google Scholar]

- 16.Saad N, Abdeshahian P, Kalil MS, Yusoff WMW, Hamid AA. Optimization of aeration and agitation rate for lipid and gamma linolenic acid production by Cunninghamella bainieri 2A1 in submerged fermentation using reponse surface methodology. Sci World J. 2014;•••:280146 10.1155/2014/280146 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Murad AMA, Karim NAA, Hashim NHF, Adnan AM, Zainal Z, Hamid AA, et al. Identification and characterisation of an oleaginous fungus producing high γ-linolenic acid. Internet J Microbiol. 2010;9:1–9. [Google Scholar]

- 18.Gema H, Kavadia A, Dimou D, Tsagou V, Komaitis M, Aggelis G. Production of γ-linolenic acid by Cunninghamella echinulata cultivated on glucose and orange peel. Appl Microbiol Biotechnol. 2002;58:303–7. 10.1007/s00253-001-0910-7 [DOI] [PubMed] [Google Scholar]