Abstract

Background and aims

The purpose of this study is to determine the effect of CO2 laser irradiation in comparison with sandblasting (Sb), hydrofluoric acid (Hf) and silane coupling agent (Si) on shear bond strength (SBS) of resin cement to CAD/CAM ceramics bonded to dentin.

Material and Methods

Forty-eight (CAD/CAM) ceramic discs were prepared and grouped by material, i.e. lithium disilicate (Emax CAD) and zirconia ceramic (Emax ZirCAD), distributed into four different groups: group A, lithium disilicate (Li) CO2/HF/Si; group B, Li: HF/Si; group C, zirconia (Zr) CO2/Sb/Si; group D, Zr: Sb/Si.

Results

It was shown significant difference between irradiated and non-irradiated groups in terms of shear bond strength for zirconia ceramics (p value = 0.039).

Conclusion

CO2 laser irradiation increases shear bond strength for both CAD/CAM ceramics bonded to dentin.

Keywords: CO2 laser, CAD/CAM ceramics, Shear bond strength, Dentin

Introduction

Ceramic restorations have become digitized processes, and now make use of CAD/CAM technology 1,2). This evolution has coincided with advances in bonding technology, and a growing demand for ceramic restorations. Several mechanical and chemical retention methods have been developed to improve the bonding strength of CAD/CAM ceramics. Successful strong adhesion between resin, dentin and ceramics requires surface pre-treatments 3). In ceramic bonding to tooth structure, two different interfaces need to be considered: dentin-resin and ceramic-resin 4).

On the dentin side, immediate dentin sealing technique (IDS) is employed to create an interaction between dentin and resin luting agent. Retention to dentin is due mainly to hybrid layer formation and micro-mechanical retention with the resin tags embedded in the dentinal tubules 5, 6).

On the ceramic side, various techniques have been reported that mechanically facilitate resin-ceramic bonding. Sandblasting and/or acid etching with hydrofluoric acid are common methods, increasing surface area for bonding and creating an irregular surface topography 7, 8).

In silica-based ceramics, hydrofluoric acid etches and dissolves the glass ceramic, which causes physical alteration of the ceramic surface, creating micro-mechanical retention. Silane acts as a coupling agent, which is essential for the intimate contact needed between different materials to promote and enhance resin penetration 9).

For this reason, hydrofluoric acid etching in combination with silane enhances the chemical bond strength of silicon dioxide (silica) in silica-based ceramics 10–14). Three clinical studies 15–17) on silica-based ceramics are available today that provide evidence in support of recommendations; reports from short-term clinical trials on single crowns showed survival rates between 97.4% 13) and 100% 18), after two years. It has been reported that silane treatment followed by hydrofluoric acid etching enhances micro tensile strength when ceramic is bonded to tooth structure.

These techniques do not improve the bond strength of zircon-based ceramics, owing to their high crystalline content, which m Addressee for Correspondence: akes them resistant to acid etching 19, 20). Some studies report that sandblasting increases surface roughness and successfully improves the bonding strength of zirconia-based ceramics 21). Chen et al. 22) did not recommend sandblasting in silica-based ceramics because of possible morphological change and volume loss in the ceramics.

In the literature, against a background of debate on various applications of lasers in dentistry, many authors have recommended laser irradiation as a promising method for ceramic surface treatment, for example with a carbon dioxide (CO2) laser 23, 24). El Gamal et al. showed that the CO2 laser could be a useful method for zirconia-based ceramic surface treatment, and that it increased the bond strength of resin cement applied to zirconia ceramics 25).

The aim of the present study was to determine the effect of a CO2 laser compared with (i) sandblasting and silane coupling agent on the bond strength of adhesive resin cement applied to a zirconia ceramic base and dentin, and (ii) hydrofluoric acid and silane coupling agent on the bond strength of adhesive resin cement applied to a lithium disilicate ceramic base and dentin.

Materials and Methods

Laser parameters

Based on previous studies on micromechanical adhesion 26, 27), CO2 laser parameters were selected as follows, bearing in mind its high absorption in ceramics. A CO2 laser (Dream Pulse Lasers, Daeshin Enterprise Corp., Seoul, Korea), wavelength 10,600 nm, was used with 5 W settings corresponding to a power density of 6.37 × 104 W/cm2. Irradiation was crossed on the surface in continuous mode for 40 seconds (working distance 2 mm, spot size of the aiming beam 0.1 mm) Fig. 1.

Fig. 1:

CO2 laser device

Dentinal discs

A total of 48 caries-free humans third molars were selected. Surface-cleaned teeth were stored in distilled water for < 6 months, pending further processing. Each tooth was fixed in a plastic fold with acrylic resin (EpoxiCure, Buehler, USA). The occlusal surfaces were sliced with a low-speed saw (ISOMET™, Buehler, USA) in wet conditions to expose the superficial dentin surfaces.

Ceramic materials

A total of 24 cubes of lithium disilicate (IPSe.max CADs, Ivoclar Vivadent, Liechtenstein) and 24 cubes of zirconia (IPSe.max ZirCADs, Ivoclar Vivadent, Liechtenstein) were prepared with a low-speed saw (ISOMET™, Buehler, USA) in wet conditions. These 5 mm thick ceramic cubes Fig. 2, were immersed in demineralized water and cleaned with an ultrasonic cleaner (Fischer Scientific FB15047®) for three minutes. All the surfaces were cleaned with 100% ethanol. These ceramic samples were then randomly distributed into four groups according to their surface treatment (Table 1), namely Group A: lithium disilicate samples were irradiated with the CO2 laser at 5W, etched with 9% hydrofluoric acid (Ultradent porcelain etch3, USA), rinsed with water for 15 s and dried with air; Scotchbond universal adhesive (3M ESPE, Germany) was applied to the surface for 20 s and then dried with air for 5 s according to the manufacturer's instructions, Group B: lithium disilicate samples were etched with 9% hydrofluoric acid (Ultradent porcelain etch3, USA), rinsed with water for 15 seconds and dried with air; Scotchbond universal adhesive (3M ESPE, Germany) was applied to the surface for 20 s and then dried with air for 5 s according to the manufacturer's instructions, Group C: zirconia samples were irradiated with the CO2 laser at 5 W, sandblasted (< 50 µm) and dried with air. Silane was applied to the surface for 20 s, and dried with air for 5 s according to the manufacturer's instructions, and Group D: zirconia samples were sandblasted (< 50 µm) and dried with air. Silane was applied to the surface for 20 s, and then dried with air for 5 s according to the manufacturer's instructions.

Fig. 2:

Ceramic cubes of lithium disilicate and zirconia ceramics

Table 1: Tested group.

| Group | Surface treatment |

|---|---|

| A (Lithium disilicate) | Irradiated with CO2 laser at 5W then etched with hydrofluoric acid 9% (Ultradent porcelain etch3,USA) and Scotchbond universal adhesive (3M ESPE, Germany) |

| B (Lithium disilicate) | Etched with hydrofluoric acid 9% (Ultradent porcelain etch3,USA) and scotchbond uni-versal adhesive (3M ESPE, Germany) |

| C (Zirconia) | Irradiated with CO2 laser at 5W then sandblasted (< 50 µm) and treated with scotch-bond universal adhesive (3M ESPE, Germany) |

| D (Zirconia) | Sandblasted (< 50 µm) and treated with scotchbond universal adhesive (3M ESPE, Germany) |

Bonding procedures

After the surface treatments, ceramic discs were cemented to dentinal disc surfaces using the “self-etch” resin cement (Relyx ultimate 3M ESPE, Germany) under a constant setting force of 10 N for 5 min under pressure (precision weight). The excess cement was removed, and samples were placed in distilled water at 37°C for 24 h before the shear strength test. All the bonding procedures were performed strictly according to the manufacturer's instructions.

Shear bond strength

Shear bond strength was tested in a universal testing machine (Zwick 2.5 kN, Germany) Fig. 3, at a crosshead speed of 1 mm/min. Shear loading was applied until failure occurred. Shear bond strength values (MPa) were calculated using the formula: bond strength = F/A, where F is the force at failure (N) and A is the surface area of the ceramic cube (mm2).

Fig. 3:

Universal testing machine (Zwick 2.5kN, Germany)

Fracture mode

All the debonded dentin surfaces were examined under a scanning electron microscope (JSM-5310LV, Jeol Ltd., Japan) after gold metallization (thickness 40 Å) (ion sputter Jeol JFC 1100E), to assess the mode of fracture. Fracture of bonding could occur in any of three modes: adhesive fracture (A) at the interface between the ceramic and resin cement or between the resin cement and dentin interface, cohesive fracture (C) within the ceramic, within the bonding material or within the dentin only, or mixed facture (M).

Statistical analysis

Shear bond strength data (MPa) was compared with a Mann-Whitney U-test. Shear bond was the dependent variable, and surface treatment was the influencing factor. Statistical significance was set at p < 0.01

Results

Shear bond strength

Lithium disilicate ceramic (Emax CAD)

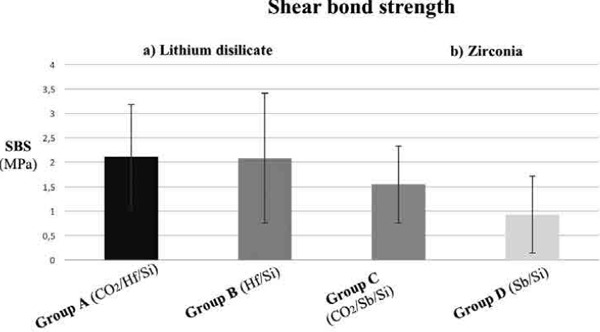

Surface preparation with CO2 laser, hydrofluoric acid and silane increased shear bond strength. There was no significant difference between irradiated and non-irradiated ceramic groups (p = 0.899).

Zirconia (Emax ZirCAD)

Irradiation with CO2 laser in combination with sandblasting and silane increased shear bond strength. The difference between irradiated and non-irradiated ceramics was significant (p = 0.039).

Mean shear bond strength values in the tested groups are reported in Table 2 and Fig. 4.

Table 2: Shear bond strength results.

| Group | Mean Bond strength (MPa) | Standard deviation | *P. value |

|---|---|---|---|

| Group A Lithium disilicate: CO2/HF/Si | 2,10 | 1,07 | 0,89 |

| Group B Lithium disilicate: HF/Si | 2,08 | 1,32 | |

| Group C Zirconia: CO2/Sb/Si | 1,54 | 0,79 | 0,039 |

| Group D Zirconia: Sb/Si | 0,92 | 0,78 |

Paired t-test

Fig. 4:

Statistical analyses of shear bond strength: (a) lithium disilicate, (b) zirconia

Discussion

Advances in CAD/CAM technology and development of high strength ceramics such as silica-based and zirconia-based ceramics have been instrumental in dental research 28, 29). Silica-based ceramic (lithium disilicate) has been recommended for use in fabricating inlays, onlays, veneers, anterior and posterior crowns and implant supported crowns 30). However, the use of zirconia-based ceramic (zirconia) has been limited to the posterior region as substructures for crowns or bridges with one pontic 31).

Despite their improved mechanical strength, the cementation of highly crystalline ceramic restorations is still a challenge for dentists. Previous investigations have focused on different surface treatments to improve the bond strength between cement and ceramic, such as tribochemical silica coating, hydrofluoric acid, sandblasting and laser irradiation 32–35).

This study follows on a previous study designed to investigate the influence of different surface treatments on the shear bond strength of lithium disilicate and zirconia-based ceramics 26).

The earlier study highlighted better bond strengths of lithium disilicate-based ceramics using hydrofluoric acid with silane due to their glass components, but it was found that this procedure had no significant influence when ceramic surfaces were irradiated with a CO2 laser. Also, CO2 has the ability to enhance shear bond strength in combination with sandblasting and silane between resin cement and zirconia.

In this study, the same methods were used for ceramic surface pre-treatment; the effect of a CO2 laser was compared with (i) sandblasting and silane coupling agent on bond strength of adhesive resin cement applied to a zirconia ceramic base and dentin, and (ii) hydrofluoric acid and silane coupling agent on bond strength of adhesive resin cement applied to a lithium disilicate ceramic base and dentin.

This study found that surface treatment with a CO2 laser, hydrofluoric acid and silane increased shear bond strength in lithium disilicate ceramics by siloxane network formation with silica 36). Etching with hydrofluoric acid dissolves the glassy or crystalline components of the ceramic and produces a porous irregular surface, increasing surface area and facilitating the penetration of the resin into the etched ceramic surface 37). Applying silane coupling agent to the ceramic surface provides a chemical covalent and hydrogen bond for a sufficient resin bond to silica-based ceramic 38). Comparison between irradiated and non-irradiated ceramic did not show any significant between-group differences, but confirmed the effect of hydrofluoric acid etching with silane in terms of bonding to dentin (p = 0.899).

As expected, CO2 irradiation in combination with sandblasting and silane increased shear bond strength, and the difference between irradiated and non-irradiated ceramics was significant (p = 0.039). This result confirms the efficiency of CO2 laser irradiation due to the absorption of the CO2 laser beam in zirconia ceramics 23).

This result can be attributed to the performance of CO2 laser irradiation in roughening ceramic surface through thermo-mechanical ablation, which increases micro- mechanical retention. This enhances the bond strength at the zirconia/cement interface 26, 39).

Currently, there is a strong demand for self-adhesive resin cements in dentistry due to their advantages, including fewer steps in the bonding protocol and less pre-treatment of the tooth structure. The bonding mechanism of self-adhesive resin cement relies more on chemical bonding than on micromechanical retention 40).

Bonding dentin surface with (RelyX™) self-adhesive resin cement does not require pre-treatment of the tooth surface. According to the manufacturer, this self-adhesive cement consists of phosphoric acid modified methacrylate monomers that demineralize the dentine by its acidity, while at the same time the resin infiltrates the dentine matrix, forming a hybrid layer with resin tags without prior removal of the smear layer 41–44). Also, Re et al. showed that sandblasting improved adhesion of Rely X Unicem on a zirconia surface due the roughening, which allows better micro-retention of the cement 45).

By contrast, Rodrigues et al. have shown that methacrylate phosphoric esters cannot penetrate parts of the dissolved smear layer retained on the dentin surface, resulting in interfacial gaps, and so lower bond strength, with a mean value of 0.34 MPa 46). This is in line with the low values of shear bond strength of the tested groups, with a mean value in group A of 2.10 MPa, in group B of 2.08 MPa, in group C of 1.54 MPa, and in group D of 0.92 MPa.

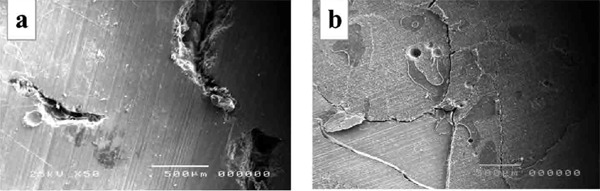

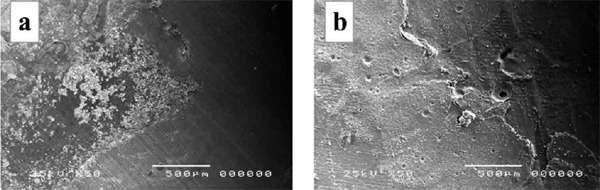

The failure types also showed an interesting pattern. SEM observations in the lithium disilicate groups (A and B) showed primarily cohesive fractures within the bonding resin cement between ceramic surfaces and dentin surfaces, leaving bonded cement on both surfaces Fig. 5. Similarly, the zirconia groups (C and D) displayed cohesive fractures within the bonding resin cement between ceramic surfaces and dentin surfaces, leaving bonded cement on both surfaces Fig. 6.

Fig. 5:

SEM images of fracture mode. Lithium disilicate: (a) irradiated surface (b) non-irradiated surface.

Fig. 6:

SEM images of fracture mode. Zirconia: (a) irradiated surface (b) non-irradiated surface.

This cohesive fracture can be explained by the mean values of resistance strength: that of self-adhesive resin cement (Relyx) is lower than that of the ceramic/cement and cement/dentin interfaces.

This study accounts for the bond strength of a self-adhesive resin cement applied to pre-treated CAD/CAM ceramics, with no dentin surface treatment, and long-term water storage which may be considered as limitations of this study. Our study also did not evaluate the combined effect of CO2 laser and zircon primer on SBS of zirconia-based ceramics. Further long-term studies will be needed to determine shear bond strength values of laser-irradiated zirconia in clinical situations.

Conclusion

This study prompts the following conclusions:

- Applying 5 W laser irradiation (CO2) increased shear bond strengths between zirconia-based ceramics and dentin compared with non-irradiated ceramic surfaces.

- Laser irradiation combined with HF acid and silane bonding seems not to offer an alternative method for improving the dentin-to-ceramic surface (lithium disilicate) bonding.

Acknowledgement

The authors thank Christophe Pradille and Gilbert Fiorucci from Mines-ParisTech Centre de Mise en Forme des Materiaux (CEMEF) for valuable technical assistance.

Compliance with ethical standards

Conflict of interest

The authors of this article certify that they have no proprietary, financial, or other personal interest of any nature or kind in any product, service and/or company that is presented in this article.

References

- 1: Christensen RP, Galan AD, Mosher TA. Clinical status of eleven CAD/CAM materials after one to twelve years of service. In: Mormann WH. editor. State of the art of CAD/ CAM restorations: 20 years of CEREC. Surrey: Quintessence Publishing: 2006 [Google Scholar]

- 2: Liu PR, Essig ME. (2008) Panorama of dental CAD/CAM restorative systems. Compend Contin Educ Dent 29(8):482-8 [PubMed] [Google Scholar]

- 3: Swift EJ, Jr, Perdigao J, Heymann HO. (1995) Bonding to enamel and dentin: a brief history and state of the art. Quintessence Int. 26(2):95-110 [PubMed] [Google Scholar]

- 4: Pashley DH, Sano H, Ciucchi B, Yoshiyama M, Carvalho RM. (1995) Adhesion testing of dentin bonding agents: a review. Dent Mater. 11(2):117-25 [DOI] [PubMed] [Google Scholar]

- 5: Magne P, So WS, Cascione D. (2007) Immediate dentin sealing supports delayed restoration placement. J Prosthet Dent. 98(3):166-74 [DOI] [PubMed] [Google Scholar]

- 6: Roberson M, Theodore M, Haymann OH, Swift EM, Sturdevant C. Sturdevant's art and science of operative dentistry, 4th edn. St. Louis: The C.V. Mosby Co., Chap 5 2002;177-9 [Google Scholar]

- 7: Ozcan M, Vallittu PK. (2003) Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 19(8):725-31 [DOI] [PubMed] [Google Scholar]

- 8: Ozcan M. (2002) The use of chairside silica coating for different dental applications: a clinical report. J Prosthet Dent. 87(5):469-72 [DOI] [PubMed] [Google Scholar]

- 9: Shahverdi S, Canay S, Sahin E, Bilge A. (1998) Effects of different surface treatment methods on the bond strength of composite resin to porcelain. J Oral Rehabil. 25(9):699-705 [DOI] [PubMed] [Google Scholar]

- 10: Della Bona A, Anusavice KJ, Hood JA. (2002) Effect of ceramic surface treatment on tensile bond strength to a resin cement. Int J Prosthodont. 15(3):248-53 [PubMed] [Google Scholar]

- 11: Derand P, Derand T. (2000) Bond strength of luting cements to zirconium oxide ceramics. Int J Prosthodont. 13(2):131-5 [PubMed] [Google Scholar]

- 12: Yoshida K, Yamashita M, Atsuta M. (2004) Zirconate coupling agent for bonding resin luting cement to pure zirconium. Am J Dent. 17(4):249-52 [PubMed] [Google Scholar]

- 13: Sun R, Suansuwan N, Kilpatrick N, Swain M. (2000) Characterisation of tribochemically assisted bonding of composite resin to porcelain and metal. J Dent. 28(5):441-5 [DOI] [PubMed] [Google Scholar]

- 14: Reich S, Fischer S, Sobotta B, Klapper HU, Gozdowski S. (2010) A preliminary study on the short-term efficacy of chairside computer-aided design/computer-assisted manufacturing- generated posterior lithium disilicate crowns. Int J Prosthodont. 23(3):214-6 [PubMed] [Google Scholar]

- 15: Ho GW, Matinlinna JP. (2011) Insights on porcelain as a dental material. Part II: chemical surface treatments. Silicon. 3(3):117-123 [Google Scholar]

- 16: Lung CY, Matinlinna JP. (2012) Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dent Mater. 28(5):467-77 [DOI] [PubMed] [Google Scholar]

- 17: Filho AM, Vieira LC, Araujo E, Monteiro S. (2004) Effect of different ceramic surface treatments on resin microtensile bond strength. J Prosthodont. 13(1):28-35 [DOI] [PubMed] [Google Scholar]

- 18: Fasbinder DJ, Dennison JB, Heys D, Neiva G. (2010) A clinical evaluation of chairside lithium disilicate CAD/CAM crowns: a two-year report. J Am Dent Assoc. 141:10S-4S [DOI] [PubMed] [Google Scholar]

- 19: Bertolotti RL, Lacy AM, Watanabe LG. (1989) Adhesive monomer for porcelain repair. Int J Prosthodont. 2(5):483-9 [PubMed] [Google Scholar]

- 20: Stangel I, Nathanson D, Hsu CS. (1987) Shear strength of the composite bond to etched porcelain. J Dent Res. 66(9):1460-5 [DOI] [PubMed] [Google Scholar]

- 21: He M, Zhang Z, Zheng D, Ding N, Liu Y. (2014) Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater.33(6):778-85 [DOI] [PubMed] [Google Scholar]

- 22: Chen TM, Brauer GM. (1982) Solvent effects on bonding organo- silane to silica surfaces. J Dent Res. 61(12):1439-43 [DOI] [PubMed] [Google Scholar]

- 23: Akyil MS, Uzun IH, Bayindir F. (2010) Bond strength of resin cement to yttrium-stabilized tetragonal zirconia ceramic treated with air abrasion, silica coating, and laser irradiation. Photomed Laser Surg. 28(6):801-8 [DOI] [PubMed] [Google Scholar]

- 24: Stubinger S, Homann F, Etter C, Miskiewicz M, Wieland M, Sader R. (2008) Effect of Er:YAG, CO(2) and diode laser irradiation on surface properties of zirconia endosseous dental implants. Lasers Surg Med. 40(3):223-8 [DOI] [PubMed] [Google Scholar]

- 25: El Gamal A, Rocca JP, Fornaini C, Muhammad O, Medioni E, Cucinotta A, Brulat-Bouchard N. (2016) The effect of CO2 and Nd:YAP lasers on CAD/CAM ceramics: SEM, EDS and thermal studies. Laser Ther. 25(1):27-34 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26: El Gamal A, Medioni E, Rocca JP, Fornaini C, Muhammad O, Brulat-Bouchard N. (2017) Shear bond, wettability and AFM evaluations on CO2 laser-irradiated CAD/CAM ceramic surfaces. Lasers Med Sci. 32(4):779-785 [DOI] [PubMed] [Google Scholar]

- 27: El Gamal A, Rocca JP, Fornaini C, Medioni E, Brulat-Bouchard N. (2017) Microhardness evaluations of CAD/CAM ceramics irradiated with CO2 or Nd:YAP laser. Laser Ther. 26(1):13-18 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28: Holand W, Schweiger M, Rheinberger VM, Kappert H. Bioceramics and their applications for dental restoration. Adv Appl Ceram 2009; 108:373-80 [Google Scholar]

- 29: Liu D, Matinlinna JP, Pow EHN. (2002) Insights into porcelain zirconia bonding. J Adhes Sci Technol. 26:1249-65 [Google Scholar]

- 30: Tysowsky GW. (2009) The science behind lithium disilicate: a metal-free alternative. Dent Today.28(3):112-3. [PubMed] [Google Scholar]

- 31: Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. (2002) Relative translucency of six all- ceramic systems. Part II: core and veneer materials. J Prosthet Dent. 88(1):10-5 [PubMed] [Google Scholar]

- 32: Della Bona A, Donassollo TA, Demarco FF, Barrett AA, Mecholsky JJ., Jr (2007) Characterization and surface treatment effects on topography of a glass-infiltrated alumina/zirconia-reinforced ceramic. Dent Mater. 23(6):769-75 [DOI] [PubMed] [Google Scholar]

- 33: Kern M, Strub JR. (1998) Bonding to alumina ceramic in restorative dentistry: clinical results over up to 5 years. J Dent. 26(3):245-9 [DOI] [PubMed] [Google Scholar]

- 34: Kern M, Thompson VP. (1994) Sandblasting and silica coating of a glass-infiltrated alumina ceramic: volume loss, morphology, and changes in the surface composition. J Prosthet Dent. 71(5):453-61 [DOI] [PubMed] [Google Scholar]

- 35: Ural C, Kulunk T, Kulunk S, Kurt M. (2010) The effect of laser treatment on bonding between zirconia ceramic surface and resin cement. Acta Odontol Scand. 68(6): 354-9 [DOI] [PubMed] [Google Scholar]

- 36: Corazza PH, Cavalcanti SC, Queiroz JR, Bottino MA, Valandro LF. (2013) Effect of post-silanization heat treatments of silanized feldspathic ceramic on adhesion to resin cement. J Adhes Dent. 15(5):473-9 [DOI] [PubMed] [Google Scholar]

- 37: Ozcan M, Alkumru HN, Gemalmaz D. (2001) The effect of surface treatment on the shear bond strength of luting cement to a glass-infiltrated alumina ceramic. Int J Prosthodont. 14(4):335-9. [PubMed] [Google Scholar]

- 38: Patel RKV, Agarwal A, Kalavathy N. (2011) The effect of surface conditioning methods on shear bond strength of resin luting cement to all ceramic coping material. An in-vitro study. Int J. Prosthetic Dentistry.3(1) :1-10. [Google Scholar]

- 39: Ahrari F, Boruziniat A, Alirezaei M. (2016) Surface treatment with a fractional CO2 laser enhances shear bond strength of resin cement to zirconia Laser Ther. 25(1):19-26 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40: Hikita K, Van Meerbeek B, De Munck J, Ikeda T, Van Landuyt K, Maida T, Lambrechts P, Peumans M. (2007) Bonding effectiveness of adhesive luting agents to enamel and dentin. Dent Mater. 23(1):71-80. [DOI] [PubMed] [Google Scholar]

- 41: Scaminaci Russo D, Pierleoni F, Buti J, Ferrari M, Giachetti L. (2014) In vitro comparison of bonding effectiveness of different adhesive strategies. Am J Dent. 27(6):323-9 [PubMed] [Google Scholar]

- 42: Zorzin J, Belli R, Wagner A, Petschelt A, Lohbauer U. (2014) Self-adhesive resin cements:adhesive performance to indirect restorative ceramics. J Adhes Dent. 16(6):541-6 [DOI] [PubMed] [Google Scholar]

- 43: Gerth HU, Dammaschke T, Zuchner H, Schafer E. (2006) Chemical analysis and bonding reaction of RelyX Unicem and Bifix composites: a comparative study. Dent Mater. 22(10):934-41 [DOI] [PubMed] [Google Scholar]

- 44: Abo-Hamar SE, Hiller KA, Jung H, Federlin M, Friedl KH, Schmalz G. (2005) Bond strength of a new universal self-adhesive resin luting cement to dentin and enamel. Clin Oral Investig. 9(3):161-7 [DOI] [PubMed] [Google Scholar]

- 45: Re D, Augusti D, Sailer I, Spreafico D, Cerutti A. (2008) The effect of surface treatment on the adhesion of resin cements to Y-TZP. Eur J Esthet Dent. 3(2):186-96. [PubMed] [Google Scholar]

- 46: Rodrigues RF, Ramos CM, Francisconi PA, Borges AF. (2015) The shear bond strength of self-adhesive resin cements to dentin and enamel: An in vitro study. J Prosthet Dent. 113(3):220-7 [DOI] [PubMed] [Google Scholar]