Abstract

Sensory characteristics are important for the acceptance of thickened liquids, but those of liquids thickened to the new standards put forth by the International Dysphagia Diet Standardization Initiative (IDDSI) are unknown. This research sought to identify and rate the perception of important sensory properties of liquids thickened to levels specified in the IDDSI framework. Samples were made with water, with and without added barium sulfate, and were thickened with a cornstarch or xanthan gum based thickener. Samples were characterized using projective mapping/ultra-flash profiling to identify important sample attributes, and then with trained descriptive analysis panels to characterize those attributes in non-barium and barium thickened liquids. Three main groups of attributes were observed. Taste and flavor attributes decreased in intensity with increasing thickener. Thickener specific attributes included graininess and chalkiness for the cornstarch thickened samples, and slipperiness for the xanthan gum samples. Within the same type of thickener, ratings of thickness-related attributes (perceived viscosity, adhesiveness, manipulation, and swallowing) at different IDDSI levels were significantly different from each other. However, in non-barium samples, cornstarch samples were perceived as thicker than xanthan gum samples even though they had similar apparent viscosities at 50 s−1. On the other hand, the two thickeners had similar perceived thickness in the barium samples even though the apparent viscosities of cornstarch samples were higher than those of the xanthan gum samples. In conclusion, IDDSI levels can be distinguished based on sensory properties, but these properties may be affected by the type of thickener and medium being thickened.

Keywords: Dysphagia, thickened liquids, sensory evaluation, IDDSI, viscosity

Graphical Abstract

1. Introduction

Dysphagia, or swallowing impairment, is estimated to affect approximately 8% of the world’s population (Cichero et al., 2013). It commonly occurs after stroke, in individuals with neurodegenerative diseases, or following treatment for head and neck cancer (Cichero et al., 2013; Martino et al., 2005). Dysphagia may also occur in premature infants or children with congenital or developmental disorders (Cichero et al., 2013). Many individuals with dysphagia have difficulty swallowing thin liquids with turbulent and fast flow (Parkinson & Sherman, 1971). Without proper control, liquids can enter the airway; this is known as aspiration, and can result in an increased risk of pneumonia and even death (Martino et al., 2005). Dysphagia is also associated with dehydration and malnutrition, and has negative consequences for quality of life and participation in social activities involving eating and drinking (Olle Ekberg, Hamdy, Woisard, Wuttge-Hannig, & Ortega, 2002).

Dysphagia management can include compensatory measures such as changes in posture and different swallowing techniques, but the most common intervention is diet modification (Sura, Madhavan, Carnaby, & Crary, 2012). For individuals who experience aspiration with thin liquids, drinks are thickened with modified cornstarch, xanthan gum, carboxymethylcellulose, or guar gum, thus slowing bolus flow and providing additional time to achieve airway closure before the bolus arrives near the airway entrance (Hong, Sun, Yoo, & Yoo, 2012; Macqueen, Taubert, Cotter, Stevens, & Frost, 2003; Tashiro, Hasegawa, Kohyama, Kumagai, & Kumagai, 2010). Although thicker liquids are generally considered to be easier to control and safer to swallow, there are a few challenges with thickened liquids. Overly thick liquids are more likely to leave behind post swallow residue, which in turn becomes a risk for aspiration when breathing resumes (Cichero et al., 2013). In addition, thicker liquids are more satiating than thin liquids, and this can lead to reduced intake of fluids and dehydration (McCrickerd, Chambers, Brunstrom, & Yeomans, 2012; Sura et al., 2012). Thickened drinks are also often perceived as unpalatable, and patients prescribed overly thick liquids may have poor compliance (Garcia, Chambers IV, Matta, & Clark, 2005; Macqueen et al., 2003).

When treating an individual with dysphagia, it is important to first identify the cause of the swallowing issues, and then choose an appropriate management method. A videofluoroscopic swallowing study (or a modified barium swallow) is a dynamic swallowing x-ray that is widely considered the gold standard method of swallowing assessment, and this enables the clinician to observe swallowing safety and efficiency with boluses of different consistencies (Martin-Harris et al., 2008). In this test, barium sulfate is added to liquids to make them radiopaque (Jones & Donner, 1989). However, the addition of barium sulfate may impart textural properties that can affect the perception of liquids, such as slimy and gritty texture or increased apparent viscosity and density (O Ekberg et al., 2009; Stokely, Molfenter, & Steele, 2014). This may cause problems if the properties of the thickened liquids used in the modified barium swallow behave differently from those used in dysphagia management.

It is imperative that the level of thickness of a thickened liquid be adequately characterized so that the optimal thickness level can be provided to individuals. The National Dysphagia Diet (NDD) defines liquids by viscosity as thin (1–50 cP), nectar-thick (51–350 cP), honey-thick (351–1750 cP), and pudding-thick (>1750 cP), when measured at the shear rate of 50 s−1 (McCullough, Pelletier, & Steele, 2003). In this system, viscosity, or the resistance to flow, is measured by a viscometer or rheometer at the desired shear rate, and 1 cP is equivalent to 10−3 Pa·s (Macosko, 1994). Since it is acknowledged that the viscosity of non-Newtonian liquids changes with shear rate, by convention, a shear rate of 50 s−1 has been adopted as the standard at which the viscosity of liquids used in dysphagia management is reported (Force & Association, 2002). However, instrumental measurements of viscosity are impractical outside a research environment, and manufacturer guidelines using NDD terms are insufficient to predict the apparent viscosity of liquids (Garin et al., 2014; Steele, Van Lieshout, & Goff, 2003). Furthermore, there is often a lack of consistency between xanthan gum and cornstarch based thickeners, as apparent viscosities of the two thickeners are not equivalent (Garcia et al., 2005; Garin et al., 2014).

The International Dysphagia Diet Standardization Initiative (IDDSI) has recently published new standards for characterizing the thickness of liquids based on gravity flow through a 10 mL Becton Dickinson slip-tip syringe (manufacturer code 301604) over a fixed 10 second interval: thin (no liquid left after 10 s), slightly thick (1–4 mL of liquid left after 10 s), mildly thick (4–8 mL of liquid left after 10 s), moderately thick (flows, but >8 mL of liquid left after 10 s), and extremely thick (no flow or drip after 10 s) (IDDSI, 2016a). Notably, the IDDSI framework has chosen to use gravity flow rather than apparent viscosity as the primary parameter for classifying liquid thickness. A major motivation for this decision was the fact that gravity flow tests using a syringe are more accessible to end users including patients, clinicians, caregivers and food service professionals.

It is currently unknown whether the IDDSI Framework levels of gravity flow can be distinguished based on sensory attributes. An understanding of the sensory characteristics of products helps to ensure that the product will be acceptable and safe for consumers (Lotong, Chun, Chambers IV, & Garcia, 2003; Macqueen et al., 2003). While the former parameter is not explicitly tested during descriptive analyses, product characteristics can still give information about the palatability of the product. For example, slimy products are often unacceptable, and in the context of thickened liquids, consumers tend to prefer less thick liquids (Szczesniak, 2002; Vickers et al., 2015). Likewise, product safety is dependent on the perceived viscosity levels of the thickened liquid (Lotong et al., 2003). Thus, the objective of this research was to characterize the sensory properties of liquids thickened with xanthan gum and cornstarch in both non-barium and barium media, when thickened according to levels specified by the IDDSI framework. This was done by first performing projective mapping and ultra-flash profiling on the samples to identify important attributes, and then by characterizing those attributes in trained descriptive analysis panels. It was hypothesized that differences in perceived viscosity might be observed in the different gravity flow levels across non-barium and barium thickened liquids, and that the different concentrations of thickeners required to achieve the different IDDSI levels would result in changes in graininess and slipperiness across different gravity flow levels.

2. Materials and Methods

2.1. Preparation of thickened liquids

The same samples were used for both the projective mapping and ultra-flash profiling panels, and the trained descriptive analysis panels. Within these panels, two experiments (non-barium and barium) were conducted with nine samples of thickened liquid, ranging from thin to extremely thick, in each experiment. All samples were prepared at the University of Guelph, Canada. In the first experiment, a commercial thickening agent from Nestle Resource®: either Thicken Up® (TU; modified cornstarch) or Thicken Up Clear® (TUC; xanthan gum), was added to a base of Lemon Splash Water (Nestle Pure Life) according to the recipes shown in Table 1. In the second experiment, the same thickening agents were added to water (Nestle Pure Life) with 20% w/w added barium sulfate (E-Z-Paque®, 96%), in amounts shown in Table 1. The sample formulations were determined through preliminary trials and were confirmed to fall within the levels of the IDDSI framework and remain within those levels for a period of at least 3 hours post mixing.

Table 1.

Sample formulation for thickened liquids in non-barium and barium media

| IDDSI Level | Thickness | Water (g) | Barium Sulfate (g) | Thicken Upa (g) | Density (g/mL) | Thicken Up Cleara (g) | Density (g/mL) |

|---|---|---|---|---|---|---|---|

| ←———Liquids without added barium———→ | |||||||

| 0 | Thin | 200 | N/A | N/A | 1.00 | N/A | 1.00 |

| 1 | Slightly-Thick | 200 | N/A | 8.30 | 1.01 | 1.30 | 1.00 |

| 2 | Mildly-Thick | 200 | N/A | 9.54 | 1.02 | 2.50 | 1.02 |

| 3 | Moderately- Thick | 200 | N/A | 11.70 | 1.03 | 4.20 | 1.02 |

| 4 | Extremely- Thick | 200 | N/A | 15.60 | 1.04 | 15.00 | 1.03 |

| ←———Liquids with added barium———→ | |||||||

| 0 | Thin | 570 | 126 | N/A | 1.16 | N/A | 1.16 |

| 1 | Slightly-Thick | 570 | 126 | 18.00 | 1.16 | 2.10 | 1.17 |

| 2 | Mildly-Thick | 570 | 126 | 23.40 | 1.17 | 6.00 | 1.15 |

| 3 | Moderately- Thick | 570 | 126 | 30.60 | 1.17 | 12.00 | 1.16 |

| 4 | Extremely- Thick | 570 | 126 | 40.20 | 1.17 | 25.20 | 1.16 |

Thicken Up is a modified cornstarch consisting of 100% modified cornstarch. Thicken Up Clear is xanthan based and ingredients include corn and potato maltodextrin, xanthan gum, potassium chloride.

Samples for both experiments were made using the same protocol. Samples were made by whisking the weighed thickener and/or barium sulfate into 22°C moving water with a stand mixer (Bosch Compact MUM4405) for 2 minutes, and then left to rest for 1 hour prior to serving. Samples were always kept at room temperature (22°C).

2.2. Density Measurements

The density of each thickened liquid sample was determined from the mass measurements of 10 cm3 volumes of each sample at room temperature (22°C). Mass was measured on an Adventurer AX822/E digital scale (OHAUS, Parsippany), accurate to 0.01 g. Three replicates were taken of separate batches of all samples.

2.3. Viscosity Measurements

To further characterize the thickened liquids, viscosity measurements were taken with a Physica MCR 301 Rheometer (Anton Paar, Benelux) using concentric cylinder geometry. Viscosity was measured with a shear ramp test with controlled shear rate from 1 to 100 s−1 at 25°C, and three replicates were taken of separate batches of all samples. Because TU samples were found to increase in apparent viscosity over time, all viscosity measurements for TU samples were taken 1 hour after preparation to mimic the conditions of the sensory panels.

2.4. Panelists

All panels were approved by the University of Guelph Research Ethics Board (REB#15MY022 and REB#16SE020). Potential participants were recruited from the University of Guelph via email, and written consent was obtained from each panelist prior to their participation in the study. All panelists were given monetary remuneration for their time.

For the projective mapping and ultra-flash profiling panels, 30 healthy untrained panelists were recruited for the non-barium and barium experiments. This sample size was chosen based on sample sizes used in other research using the same technique (Kennedy & Heymann, 2008; King, Cliff, & Hall, 1998; Nestrud & Lawless, 2009). In total, 53 participants were recruited as seven participants took part in both the non-barium and barium experiments. Three sessions were held for each experiment with between 7 and 13 panelists per session.

For the trained descriptive analysis panel, 11 panelists were recruited for the first experiment, which evaluated samples without barium sulfate. For the second experiment (which evaluated thickened liquids with added barium sulfate), 12 panelists were recruited. Three panelists took part in both the non-barium and barium trained panels. The number of panelists were chosen as per a study done by Ross, Weller, & Alldredge, 2012.

2.5. Projective Mapping and Ultra-Flash Profiling

Two separate projective mapping and ultra-flash profiling experiments were conducted in the Human Nutraceutical Research Unit of the University of Guelph to rapidly assess product sensory attributes (Pagès, 2005). Panelists in the first experiment evaluated samples without barium sulfate while those in the second experiment evaluated samples containing barium sulfate. Thus, for each experiment, each panelist evaluated nine samples. Before each session, panelists were shown how to conduct projective mapping and ultra-flash profiling using paper cut outs of different shapes, sizes, and colors (Hopfer & Heymann, 2013). Projective mapping groups samples based on similarities and differences in order to gain an understanding of products characteristics while ultra-flash profiling generates ranks samples based on sample attributes chosen by panelists (Varela & Ares, 2012).

Samples were served in 30 mL portions in sample cups labelled with random three-digit blinding codes. Participants were instructed to taste all samples using the provided teaspoons. Unsalted soda crackers (Premium Plus®, Mondelez International, Toronto, ON, Canada) and filtered water were provided for oral cleansing between samples. A spit cup was also provided to panelists during the evaluation of samples with barium sulfate. Each panelist was provided with a 60 cm × 40 cm paper and was asked to place the samples on the paper based on how similar or different the samples were perceived to be (Hopfer & Heymann, 2013). Samples perceived to be similar would be placed close together while samples perceived to be different would be placed far apart. After samples had been placed on the paper, panelists were asked to write an “x” in the place of the sample cup and to record the blinding code of that sample. Panelists were then instructed to describe the characteristics of each sample by writing descriptors next to the position of each sample on the paper. Panelists were informed that descriptors needed to be objective and could include an intensity amount of the attribute, but no hedonic qualities were to be assessed. For the evaluation of the barium samples, participants were instructed to expectorate samples after tasting the product.

2.6. Trained Descriptive Analysis Panel

As with the projective mapping and ultra-flash profiling, two separate trained descriptive analysis panels were conducted to train panelists to evaluate the sensory attributes of liquid samples either with or without added barium sulfate (Meilgaard, Civille, & Carr, 1991). Attributes to be analyzed were selected in advance from words generated during the ultra-flash profiling, but they were discussed and modified during an hour-long training session at the beginning of each panel. The attributes generated and their techniques and definitions are shown in Table 2. As in the projective mapping experiment, samples were provided in 30 mL portions in cups labelled with random three-digit blinding codes. Panelists were instructed to taste all samples with the provided teaspoons, and to expectorate the barium samples after tasting and evaluating. Crackers and filtered water were provided for rinsing between samples. For each panel, panelists completed 10 h of training according to a procedure modified from Meilgaard et al. in 1991. Nevertheless, because all panelists completed less than 60 h of training, they were considered minimally trained (Chambers, Allison, Iv, & Hall, 2004). During training, panelists were presented with references for each attribute, and were taught to evaluate the intensity of each attribute. References included sweeteners (Aspartame/Acesulfame K and Sucralose) for sweetness, almond extract and citric acid for bitterness and sourness respectively, strawberry and lemon oil for their respective flavors, lotus root extract for adhesiveness, calcium carbonate and powdered mashed potatoes for chalkiness and graininess respectively, and TU and TUC for perceived viscosity, adhesiveness, manipulation, and swallowing. Panelists were taught to evaluate between two and three new attributes per session, and panelists practiced rating the sample attributes with increasing numbers of samples and attributes as sessions progressed. At the beginning of the training, panelists recorded their ratings on papers with 15 cm line scales, but after they had learned all the attributes, panelists evaluated the samples in sensory booths using computers. At the end of the training, panelists could evaluate all nine non-barium or barium stimuli and their corresponding attributes in a single session.

Table 2.

Sensory attributes, techniques, and definitions used to evaluate thickened liquids

| Attributea | Technique | Definition |

|---|---|---|

| Strawberryb | With nose blocked, place product in mouth, swirl for 5 seconds, release nose, measure the intensity of strawberry flavor coming through nose | The flavor associated with strawberry flavored cough syrup |

| Bitternessb | Place product in mouth, swirl for 5 seconds, measure the intensity of bitterness | The taste factor associated with bitter almond |

| Chalkinessb | Spit out sample from mouth, evaluate residue for sensation of chalkiness, which may present as a mouth drying effect | The degree to which the mouth surfaces feel chalky following expectoration of sample |

| Sweetnessb,c | Place product in mouth, swirl for 5 seconds, measure the intensity of sweetness | The taste factor associated with a sorbitol solution |

| Adhesivenessb,c | Place product in mouth, compress between tongue and palate, measure the amount of product that adheres to oral surfaces | The residual product that leaves a sticky feeling in the mouth, which is difficult to remove |

| Slipperinessb,c | Place product in mouth, rub the tongue against the palate, measure the force required to move tongue across palate | The amount in which the product elicits a slippery sensation when rubbing the tongue against the palate |

| Perceived Viscosityb,c | Place 1 tsp of product close to lips, slurp gently to measure the flow of liquid, measure the force required; once product is in mouth, allow to flow across tongue, measure the rate of flow | The force required to draw between lips and spoon and the rate of flow across tongue |

| Ease of manipulationb,c | Place product in mouth, move slowly to back of mouth, measure the effort required | The effort required to move the liquid from the front of the mouth to the back of the throat |

| Lemonc | With nose blocked, place product in mouth, swirl for 5 seconds, release nose, measure the intensity of lemon flavor coming through nose | The flavor associated with fresh lemon |

| Sournessc | With nose blocked, place product in mouth, swirl for 5 seconds, measure the intensity of sourness | The taste factor associated with a citric acid solution |

| Graininessc | Place product in mouth, move tongue parallel to palate, measure the concentration of small granules in sample | The concentration of small granules detected in the mouth and on the tongue |

| Ease of swallowingc | When product is at back of mouth, swallow slowly, measure the force required to pass the liquid completely from the mouth down the throat | The effort required for the throat muscles to swallow |

Attributes evaluated on a 15 cm line scale, 0 represents the absence of an attribute while 15 represents a strong presence of that attribute.

Attributes evaluated during the trained panel with added barium sulfate

Attributes evaluated during the trained panel without added barium sulfate

During data collection, panelists evaluated the attribute intensities of each sample on a continuous 15 cm line scale labelled with appropriate anchors. Panelists were given the products in a randomized complete block design, and each panelist conducted four replicates of each product. All responses were recorded on a computer using Compusense 5.8 software (Guelph, ON, Canada).

2.7. Statistical Analyses

Density and instrumental viscosity measurements were analyzed using SAS 9.4 (Cary, NC, USA). The MEANS procedure was used to calculate means, standard deviation, and the 95% confidence intervals for the samples.

To analyze the data from projective mapping, the x and y coordinates of sample placement by each panelist were measured with a ruler with the bottom left corner of the page as the origin. The descriptors used for each sample in the ultra-flash profiling were recorded in a contingency table with synonyms grouped together. The data were analyzed with Multiple Factor Analysis using XL Stat (Addinsoft SARL, New York, NY, USA), where descriptors were supplementary variables.

Data from the trained descriptive analysis panels were analyzed using SAS 9.4, and a type I error rate of α=0.05 was chosen for all tests. For each trained panel, the different attributes were analyzed with mixed model ANOVA using the GLIMMIX procedure, with the level and type of thickeners and panelists as fixed factors, and sessions as random factors to see if the thickeners had a significant effect on the perceived sensory attributes. Least squared means and standard errors were generated for each attribute and sample to compare samples. A separate covariance structure was fitted with different errors for panelists and thickeners if their variance was found to be heterogenous, and the best model was chosen based on AICC fit statistics. The two thickeners, TU and TUC, were compared using estimate statements to estimate their means and difference between means for each attribute. Kendall Tau’s test of concordance was used to test the thickener and panelist interaction for any cross-over effects. All means were compared with Tukey’s multiple means comparison to determine significant differences in effect. In addition, principal component analysis was used to analyze the data using the FACTOR procedure to have a better understanding of the relationship between the samples and the attributes.

3. Results

3.1. Density and Viscosity Measurements

Density measurements are shown in Table 1. In non-barium samples, densities of the samples at the same IDDSI levels were similar. In the barium samples, densities of the cornstarch samples were higher than those of the xanthan gum samples at IDDSI levels 2–4. The densities of barium samples were all higher than the non-barium samples.

Instrumental viscosity measurements of the thickened liquid samples at 50 s−1 are shown in Table 3. For non-barium samples, the apparent viscosity of cornstarch thickened liquids was higher than that of xanthan gum thickened liquids at the same IDDSI level. Nevertheless, the apparent viscosity of samples in the same IDDSI level never exceeded those of a higher IDDSI level. In the barium samples, the apparent viscosity of cornstarch thickened liquids was also higher than those of xanthan gum thickened liquids at the same IDDSI level. Notably, TU3 had a higher apparent viscosity than TUC4 at 50 s−1.

Table 3.

Apparent viscosity measurements of non-barium and barium thickened liquids at 50 s−1 and 25°C

| Non-barium | Barium | |||||||

|---|---|---|---|---|---|---|---|---|

|

|

||||||||

| Sample | Apparent Viscosity (cP) | NDDb Class | 95% CIc | STDd | Apparent Viscosity (cP) | NDD Class | 95% CI | STD |

| T0a | 1.015 | Thin | 0.869 – 1.161 | 0.059 | 3.20 | Thin | 2.65 – 3.744 | 0.22 |

| TU1a | 74.43 | Nectar | 69.63 – 79.24 | 1.93 | 116.75 | Nectar | 53.33 – 180.17 | 25.53 |

| TU2 | 140.7 | Nectar | 101.3 – 180.1 | 15.9 | 271.0 | Nectar | 243.6 – 298.41 | 11.03 |

| TU3 | 336.3 | Nectar | 312.0 – 360.6 | 9.8 | 844.3 | Honey | 762.1 – 926.6 | 33.1 |

| TU4 | 1392 | Honey | 1329 – 1454 | 25 | 2823 | Pudding | 2649 – 2997 | 70 |

| TUC1a | 47.68 | Thin | 46.24 – 49.12 | 0.58 | 50.45 | Thin | 39.76 – 61.14 | 4.30 |

| TUC2 | 126.3 | Nectar | 108.2 – 144.4 | 7.3 | 156.0 | Nectar | 142.2 – 169.8 | 5.6 |

| TUC3 | 287.0 | Nectar | 277.6 – 296.4 | 3.8 | 357.8 | Honey | 349.8 – 365.9 | 3.3 |

| TUC4 | 1050 | Honey | 1025 – 1075 | 10 | 775.2 | Honey | 759.4 – 790.9 | 6.3 |

T: no thickener added; TUC: Thicken Up Clear (xanthan gum); TU: Thicken Up (cornstarch); 0–4 indicate viscosity level on IDDSI scale

National Dysphagia Diet Classifications: thin (1–50 cP), nectar (51–350 cP), honey (351–1750 cP), pudding (>1750)

95% Confidence Interval

STD: standard deviation

Flow indices of thickened liquid samples were calculated from the viscosity measurements, and are shown in Table 4. The flow index (n) can be calculated from the power-law of fluids, η =Kγn−1, and is a representation of the shear-thinning behavior of non-Newtonian fluids where a smaller “n” represents a greater departure from non-Newtonian behavior (i.e. more shear-thinning) (Brito-de la Fuente, Ekberg, & Gallegos, 2012). The flow indices showed that the thickened liquids displayed greater shear-thinning behavior with increasing concentrations of thickener. Although TU1 was more shear-thinning than TUC1, TUC samples were more shear-thinning than TU samples for IDDSI levels 2–4.

Table 4.

Flow behavior index (n) of liquids thickened with Thicken Up (modified cornstarch) and Thicken Up Clear (xanthan gum), where η=Kγn-1

| Samples | Flow Index (n) | |||||||

|---|---|---|---|---|---|---|---|---|

|

| ||||||||

| TU1 | TU2 | TU3 | TU4 | TUC1 | TUC2 | TUC3 | TUC4 | |

| Non-Barium | 0.338 | 0.281 | 0.241 | 0.167 | 0.402 | 0.242 | 0.141 | 0.058 |

| Barium | 0.651 | 0.557 | 0.479 | 0.385 | 0.400 | 0.218 | 0.135 | 0.083 |

3.2. Projective Mapping and Ultra-Flash Profiling Panels

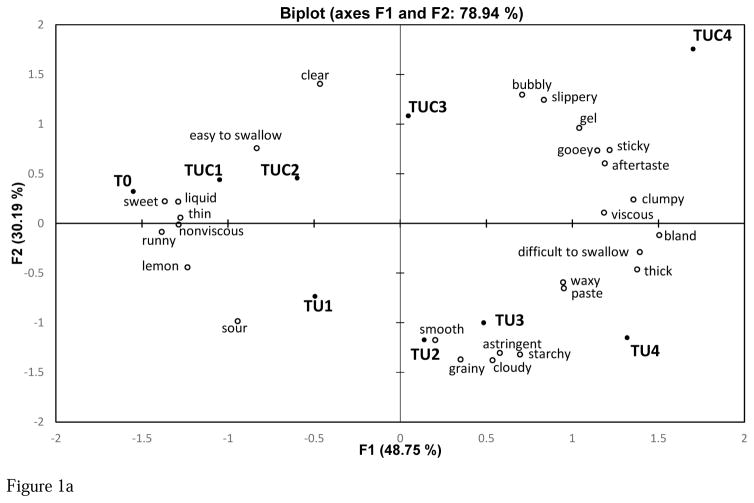

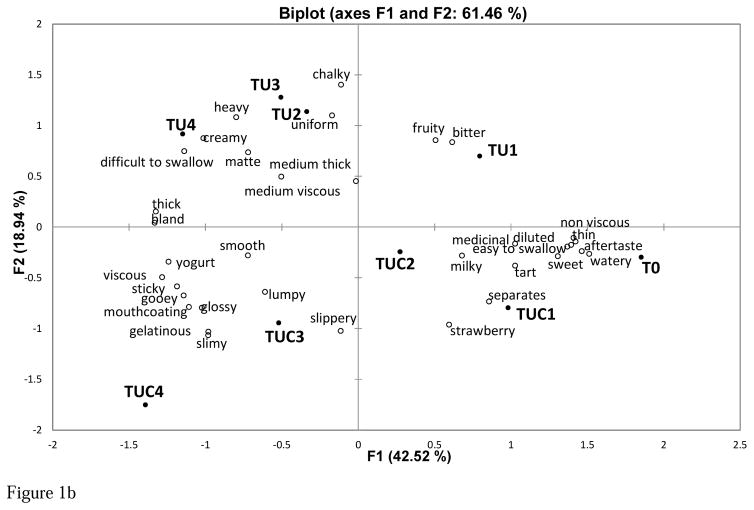

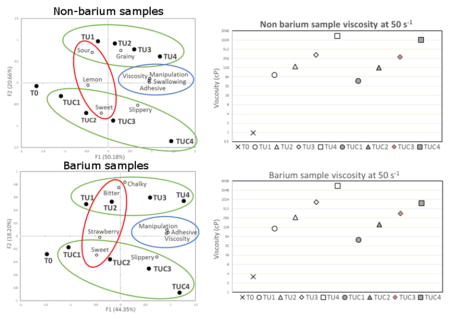

Projective mapping provided a preliminary analysis of the sensory characteristics of the thickened liquids and gave information about which attributes were important in distinguishing the liquids. The results for the non-barium and barium stimuli are displayed in biplots in Figures 1a and 1b respectively. Samples are bolded, and the two axes represent the two factors that were most influential to panelists when they were characterizing the samples.

Figure 1.

Figure 1a. Multiple factor analysis of napping and ultra-flash profiling data for samples without barium sulfate; T: no thickener added; TUC: Thicken Up Clear (xanthan gum; TU: Thicken Up (cornstarch); 0–4 indicate viscosity level on IDDSI scale

Figure 1b. Multiple factor analysis of napping and ultra-flash profiling data for samples with barium sulfate; T: no thickener added; TUC: Thicken Up Clear (xanthan gum; TU: Thicken Up (cornstarch); 0–4 indicate viscosity level on IDDSI scale

In both panels, factor 1 was influenced by IDDSI level. Samples T0, TU1, TUC1, and TUC2 were grouped in the same quadrants and described as thin and sweet. For those samples, non-barium stimuli were also described as lemon, while barium stimuli were described as fruity and strawberry. On the other hand, TU2, TU3, TU4, TUC3, and TUC4 were described as thick, viscous, and bland. Factor 2 in both panels represented the type of thickener, with TU samples grouped in the same quadrants and TUC and no thickener samples grouped in the remaining quadrants. For non-barium stimuli, TU samples were characterized as sour, smooth, grainy, and cloudy, while TUC and no thickener samples were characterized as clear, slippery, and sticky. For samples containing barium sulfate, TU samples were described as bitter, matte, chalky, and creamy while TUC and no thickener samples were characterized as glossy, slippery, and gelatinous.

3.3. Trained Descriptive Analysis Panels

Mixed model ANOVA of the effect of thickeners on the perception of sensory attributes found that the different thickeners produced a significant effect (P<0.0001) for all attributes in both non-barium and barium panels. Although both panels also showed a significant interaction (P<0.0001) effect between thickener and panelist for all attributes except strawberry, the Kendall Tau’s concordance test run on the attributes found that all panelists were concordant (P<0.0001), and there were no cross-over effects. Although both trained panels rated taste and flavor attributes, taste and flavor were only included to prevent a halo-dumping effect, where the absence of an attribute can result in increased rating of other attributes (Clark & Lawless, 1994). As the focus of the research is on texture perception, the taste and flavor attributes will not be discussed in detail except to note that they followed the same trends observed in the projective mapping and ultra-flash profiling panels.

Estimates of the mean rating of attributes in the TU and TUC samples showed that as with the projective mapping results, graininess and chalkiness were present predominantly in TU samples for non-barium and barium stimuli respectively (P<0.0001). Graininess was only present in TU samples, and was significantly lower in TU4 (Table 5). On the other hand, chalkiness did not change across different concentrations of thickener, but was significantly higher (P<0.0001) in TU samples than in TUC samples (Table 6).

Table 5.

Means, standard error, and mean comparisons of sensory attributes of thickened liquids (n=44; 11 panelists, 4 sessions)

| Attribute | Samples | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

| ||||||||||

| T0a | TU1a | TU2 | TU3 | TU4 | TUC1a | TUC2 | TUC3 | TUC4 | ||

| Sweet | Mean | 9.6z | 7.0x | 7.0x | 7.1xy | 6.5x | 8.6yz | 9.4z | 9.0z | 9.9z |

| SE | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | |

| Sour | Mean | 9.7yz | 10.1z | 8.9xyz | 8.3xy | 7.7wx | 7.6wx | 6.5vw | 5.9v | 3.7u |

| SE | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | |

| Lemon | Mean | 10.2z | 8.3xy | 6.4v | 6.9vwx | 6.8wx | 8.7yz | 8.4xy | 8.1wxy | 6.2v |

| SE | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | |

| Adhesiveness | Mean | 0.1u | 6.2w | 8.0x | 9.7y | 13.6z | 2.4v | 5.1w | 7.5x | 13.6z |

| SE | 0.12 | 0.26 | 0.27 | 0.51 | 0.17 | 0.19 | 0.29 | 0.34 | 0.16 | |

| Graininess | Mean | 0.0x | 9.0z | 9.2z | 8.7z | 6.0y | 0.0x | 0.2x | 0.1x | 0.1x |

| SE | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | |

| Slipperiness | Mean | 0.2u | 4.3w | 4.3w | 5.4wx | 5.6x | 2.7v | 6.5x | 10.0y | 14.3z |

| SE | 0.27 | 0.27 | 0.27 | 0.27 | 0.27 | 0.27 | 0.27 | 0.27 | 0.27 | |

| Perceived Viscosity | Mean | 0.0s | 6.4v | 8.0w | 10.8x | 14.2z | 2.3t | 4.9u | 7.4vw | 13.3y |

| SE | 0.14 | 0.24 | 0.24 | 0.26 | 0.17 | 0.19 | 0.29 | 0.29 | 0.26 | |

| Ease of Manipulation | Mean | 0.1t | 5.8v | 7.3x | 10.0y | 13.5z | 1.7u | 3.7v | 6.5wx | 12.8z |

| SE | 0.10 | 0.23 | 0.28 | 0.30 | 0.19 | 0.14 | 0.24 | 0.24 | 0.20 | |

| Ease of Swallowing | Mean | 0.2s | 5.9w | 7.5x | 9.6y | 12.1z | 2.2u | 4.3v | 7.2x | 13.1z |

| SE | 0.12 | 0.26 | 0.24 | 0.29 | 0.20 | 0.17 | 0.25 | 0.26 | 0.30 | |

T: no thickener added; TUC: Thicken Up Clear (xanthan gum); TU: Thicken Up (cornstarch); 0–4 indicate viscosity level on IDDSI scale

Means in the same row followed by the same superscript are not significantly different according to a Tukey’s multiple range test (P≥0.05)

Table 6.

Means, standard error, and mean comparisons of sensory attributes of thickened liquids (n=48; 12 panelists, 4 sessions)

| Attribute | Samples | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

| ||||||||||

| T0a | TU1a | TU2 | TU3 | TU4 | TUC1a | TUC2 | TUC3 | TUC4 | ||

| Sweet | Mean | 11.5z | 9.1xy | 9.2xy | 8.5x | 6.3w | 10.3yz | 9.7yz | 9.6xy | 8.4x |

| SE | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | |

| Bitter | Mean | 7.7yz | 8.6z | 8.5z | 8.7z | 7.9yz | 8.3yz | 7.8yz | 8.3yz | 6.7y |

| SE | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | |

| Strawberry | Mean | 9.0yz | 8.8xyz | 8.1xyz | 8.0xy | 6.3w | 9.5z | 8.4xyz | 8.4xyz | 7.3wx |

| SE | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | |

| Adhesiveness | Mean | 1.1t | 5.0v | 6.7w | 9.8x | 13.2z | 3.2u | 6.6w | 9.3x | 11.8y |

| SE | 0.18 | 0.20 | 0.25 | 0.29 | 0.23 | 0.17 | 0.22 | 0.19 | 0.15 | |

| Chalkiness | Mean | 6.8y | 9.7z | 10.2z | 10.4z | 9.8z | 6.8y | 6.9y | 6.5y | 6.0y |

| SE | 0.34 | 0.28 | 0.32 | 0.26 | 0.31 | 0.24 | 0.25 | 0.33 | 0.26 | |

| Slipperiness | Mean | 1.5t | 3.3u | 4.5v | 6.3wx | 6.1w | 3.5u | 7.4x | 11.6y | 13.6z |

| SE | 0.11 | 0.17 | 0.22 | 0.31 | 0.15 | 0.20 | 0.25 | 0.29 | 0.17 | |

| Perceived Viscosity | Mean | 0.7t | 4.1v | 6.9w | 10.9x | 13.6z | 2.5u | 6.1w | 10.2x | 12.6y |

| SE | 0.21 | 0.21 | 0.21 | 0.21 | 0.21 | 0.21 | 0.21 | 0.21 | 0.21 | |

| Ease of Manipulation | Mean | 0.8s | 3.8u | 6.9w | 11.3y | 14.2z | 2.6t | 5.6v | 9.4x | 11.8y |

| SE | 0.15 | 0.19 | 0.26 | 0.19 | 0.09 | 0.15 | 0.21 | 0.33 | 0.20 | |

T: no thickener added; TUC: Thicken Up Clear (xanthan gum); TU: Thicken Up (cornstarch); 0–4 indicate viscosity level on IDDSI scale

Means in the same row followed by the same superscript are not significantly different according to a Tukey’s multiple range test (P≥0.05)

The trends for slipperiness were similar in both experiments, where slipperiness was significantly higher (P<0.0001) in TUC samples than in TU samples. The ratings for slipperiness of TUC samples at different IDDSI levels were significantly different (P<0.05) from each other, and the ratings of the attribute increased with increasing concentrations of thickener (Tables 4 and 5). For the TU samples, the slipperiness of TU3 and TU4 were not significantly different from each other, but they were rated higher than TU1 and TU2. In both panels, the ratings for all TU samples fell between the ratings of TUC1 and TUC2.

While the previous attributes had similar trends across non-barium and barium media, the attributes of adhesiveness, perceived viscosity, ease of manipulation, and ease of swallowing differed across the two experiments. Nevertheless, the ratings for these four attributes followed similar trends, and the estimates of the mean rating of these attributes showed that the mean rating of cornstarch samples was significantly higher (P<0.0001) than that of xanthan gum samples in both experiments. Because of the similarity of these attributes, they will be grouped together as the thickness-related attributes. In the non-barium samples, ratings for the levels of the attributes were all significantly different from each other within the same type of thickener (Table 5). However, at lower IDDSI levels, TUC samples had lower perceived viscosity and adhesiveness ratings than TU samples, and at higher viscosities, TU and TUC samples had more similar ratings. TUC1 and TUC2 were rated lower than TU1, and TUC3 was rated lower than TU2 for all four attributes in the non-barium samples. Nevertheless, TUC4 and TU4 were rated as the two highest samples for those attributes, and they did not differ significantly in their ratings except for the attribute of perceived viscosity, where TU4 was rated as significantly higher than TUC4.

In samples containing barium sulfate, the scores for perceived adhesiveness, perceived viscosity, and ease of manipulation corresponded to those in the IDDSI framework. Not only were ratings for the IDDSI levels all significantly different from each other within the same type of thickener, but the scores of samples in the same IDDSI level also did not exceed those in a higher level (Table 6). For adhesiveness and perceived viscosity, TU1 was rated higher than TUC1, and TU4 was rated higher than TUC4, but TU and TUC samples in levels 2 and 3 did not differ significantly from each other within the same IDDSI level. For ease of manipulation, TU samples were always rated higher than TUC samples within the same IDDSI level.

The principal component analysis gave further information about which product characteristics influenced sample attributes and attributes related to each other. As with the projective mapping, factor 1 of both the non-barium and barium panels was influenced by IDDSI level, and factor 2 was influenced by the type of thickener used. Attributes influenced most by IDDSI level included flavor, perceived viscosity, adhesiveness, ease of manipulation, and ease of swallowing, and the latter four attributes were closely related to each other. TU samples were characterized as sour and grainy or bitter and chalky in non-barium and barium samples respectively. On the other hand, TUC samples were characterized as sweet and slippery for both non-barium and barium panels. Overall, the principal component analysis showed that both trained and untrained panelists observed the same attributes in the samples.

4. Discussion

The purpose of this research was to identify important sensory characteristics in liquids thickened with xanthan gum and cornstarch in non-barium and barium media to levels specified in the IDDSI framework, and to examine how these sensory properties were affected by the type of thickener, level of thickness, and medium being thickened. For non-barium thickened liquids, the attributes examined were sweet, sour, lemon, adhesiveness, graininess, slipperiness, perceived viscosity, ease of manipulation, and ease of swallowing. For the barium thickened liquids, the important attributes identified were sweet, bitter, strawberry, adhesiveness, chalkiness, slipperiness, perceived viscosity, and ease of manipulation.

The taste and flavor attributes in the product were due to the medium being thickened. In the non-barium samples, the sweet, sour, and lemon attributes came from the Lemon Splash Water (Nestlé Pure Life) used as the base for the samples. In the barium samples, the sweet, bitter, and strawberry attributes came from the barium sulfate mixture, which included its own flavorings. In both the projective mapping and ultra-flash profiling and trained descriptive analysis panels, ratings of taste and flavor attributes decreased with increasing IDDSI level. This inverse relationship agrees with previous research which shows decreased taste and flavor perception with increased viscosity (Ferry, Hort, et al., 2006; Ferry, Mitchell, et al., 2006; Hollowood, Linforth, & Taylor, 2002).

It was also found that certain taste attributes were more present in certain thickeners. The predominance of sourness and bitterness in the cornstarch samples was likely due to the structure of the matrix formed by the cornstarch granules, allowing for more efficient mixing with saliva (Ferry, Hort, et al., 2006). Tastants in the cornstarch would then be better solubilized and ready for interaction with taste receptor cells (Dransfield, 2008). In addition, xanthan gum has been found to decrease the perception of sourness and bitterness more than sweetness, which would explain why the xanthan gum did not have a similar masking effect on sweetness (Pangborn, Gibbs, & Tassan, 1979).

Other thickener specific attributes were also identified. Slipperiness was seen predominantly in the xanthan gum samples. This was expected, as xanthan gum has been found to contribute to slickness or slipperiness in samples (Matta, Chambers IV, Garcia, & Helverson, 2006; Vickers et al., 2015). Both graininess and chalkiness were rated higher in the cornstarch samples than the xanthan gum samples, and these attributes were likely due to the cornstarch and barium sulfate respectively. Thus, graininess was only present in the cornstarch thickened samples, and the rating for graininess decreased in the TU4, which was the cornstarch sample thickened to the highest IDDSI level. This could be a result of the increased lubrication and apparent viscosity of the sample, which have been found to lower the sensation of grittiness (Engelen & Van Der Bilt, 2008; Imai, Hatae, & Shimada, 1995).

Although barium sulfate was present in the same concentration in both cornstarch and xanthan gum samples, chalkiness was rated higher in cornstarch samples. This could be attributed to the structure of xanthan gum, which could have masked the chalkiness. In fact, other research has found that the chalky texture of barium sulfate can be hidden by gums, and that grittiness sensation is less perceived in gums than in other viscous suspensions (Imai et al., 1995; Katzbauer, 1998; Miller, 1966). However, the chalkiness ratings of the TUC samples were not significantly different from that of T0, which did not contain any thickener. Another explanation for the increased chalkiness ratings in the TU samples could be the presence of cornstarch particles in the samples, which could have compounded the sensation of grittiness. This is in line with other research that suggests that the sensation of graininess or grittiness increases with increasing particle concentration (Imai et al., 1995; Kilcast & Clegg, 2002).

In both non-barium and barium samples, thickness-related attributes of perceived viscosity, adhesiveness, ease of manipulation, and ease of swallowing were rated higher in cornstarch samples than the xanthan gum samples, and the ratings of these attributes increased with increased IDDSI level. It was expected that cornstarch samples would be perceived as more viscous than xanthan gum samples as the apparent viscosities obtained from instrumental measurements showed similar trends, but there were certain differences between the apparent viscosity measurements and the perceived viscosity ratings.

In the non-barium samples, while the cornstarch samples were more viscous than xanthan gum samples at the same IDDSI level, the apparent viscosity of samples at a certain level never exceeded that of a higher level (Table 3). However, the trained panel found that TU1 had higher perceived viscosity than TUC1 and TUC2, and that TU2 also had higher perceived viscosity than TU3 (Table 5). One explanation for this phenomenon could be the high slipperiness ratings of the xanthan gum samples, as slipperiness has been found to be negatively related with thickness and adhesive-related attributes (Vickers et al., 2015).

The discrepancies between the ratings for the thickness-related attributes and the apparent viscosity measurements of the samples may also suggest that the current shear rate standard of 50 s−1 as the oral shear rate is not appropriate. Because TU and TUC products differ in shear-thinning behavior (Table 4), their viscosities would show a greater departure from each other at other shear rates. This is especially an issue for TUC4, which displays highly shear-thinning behavior, so its viscosity will decrease rapidly at higher shear rates. This behavior may pose a problem during swallowing, as swallowing shear rates have been estimated to be between 100 to 400 s−1 (Brito-de la Fuente et al., 2012; Meng, Rao, & Datta, 2005; Yamagata, Izumi, Egashira, Miyamoto, & Kayashita, 2012; Zhu, Mizunuma, & Michiwaki, 2014). If the oral or swallowing shear rate were higher than 50 s−1, that would explain why the TUC products were perceived as less viscous than TU products, as their viscosity would drop faster than TU products at higher shear rates.

For the barium samples, cornstarch samples also had higher apparent viscosity measurements than xanthan gum samples, and the apparent viscosity of TU3 was higher than that of TUC4. This showed a departure from the ordering of the samples not only according to IDDSI levels, but also the National Dysphagia Diet Task Force levels (Table 3). Thus, the addition of barium sulfate changed the samples in such a way that the apparent viscosity did not match with the flow of the liquids. As stated previously, IDDSI has chosen to exclude viscosity from their classification parameters as flow rate can be influenced by other factors such as density, yield stress, and temperature (IDDSI, 2016b). As such, one hypothesis for the discrepancy between the flow rate and apparent viscosity could be the density difference between TU and TUC samples in the barium stimuli, as the densities of the cornstarch samples were slightly higher than that of the xanthan gum samples (Table 1).

Another explanation for this phenomenon could be the presence of xanthan gum in the E-Z-Paque barium sulfate powder. Xanthan gum has been shown to interact with cornstarch during the gelatinization and pasting processes of starch hydration by decreasing maximum and final viscosity during the heating process, but by increasing paste viscosity (Shi & BeMiller, 2002; Weber, Clerici, Collares-Queiroz, & Chang, 2009). In addition, xanthan gum interacts with cornstarch via hydrogen bonds and can delay or decrease the retrogradation process (Weber et al., 2009). This interaction could have caused a change in apparent viscosity without impacting gravity flow. It should be noted that research on the effect of xanthan gum on cornstarch gelatinization used unmodified cornstarch that had to be heated for the hydration process to commence. Nevertheless, modified cornstarch also undergoes similar gelatinization and pasting processes, and would likely interact similarly with xanthan gum. Furthermore, the barium sulfate itself could have interacted with xanthan gum and cornstarch to change the viscosities of the thickened liquids. Low levels of salt have been shown to decrease xanthan gum solution viscosity by converting the random coil form to the ordered form, which has lower viscosity (Garcia-Ochoa, Santos, Casas, & Gomez, 2000). On the other hand, the addition of salt can increase the viscosity of starch solutions by replacing the cations in solution for hydrogen bonds, thus increasing the volume of the starch granules, and xanthan gum can aid this process by promoting the cation exchange (Sudhakar, Singhal, & Kulkarni, 1995).

Further research could focus on the discrepancy between perceived viscosity ratings and apparent viscosity measurements. In the non-barium samples, it is hypothesized that the textural differences of the samples can affect the perceived viscosity, and that this caused the departure of perceived viscosity ratings from both the gravity flow levels and apparent viscosity measurements. In addition, it is hypothesized that the current shear rate standard of 50 s−1 may not be appropriate to model the oral shear rate. For the barium samples, perceived viscosity ratings related well to the gravity flow levels, but they departed from the apparent viscosity measurements. This has been proposed to be due to interactions between barium sulfate and the xanthan gum and cornstarch thickeners.

5. Conclusions

This study characterized the sensory attributes of liquids thickened according to IDDSI levels, and it was found that the attributes could be grouped into three major categories of taste and flavor attributes, thickener specific attributes, and thickness-related attributes.

Graininess and chalkiness were seen predominantly in TU samples for non-barium and barium stimuli respectively, while slipperiness was characteristic of TUC samples. The presence of these attributes appears to have been due to the cornstarch, barium sulfate, and xanthan gum in the products respectively.

The thickness-related attributes were perceived viscosity, adhesiveness, ease of manipulation, and ease of swallowing. Within the same type of thickener, the ratings of these attributes at different IDDSI levels were significantly different from each other. However, these attributes behaved differently in non-barium and barium media, and they also did not relate well to their apparent viscosities at 50 s−1. In the non-barium samples, the perceived viscosity of xanthan gum samples was lower than that of cornstarch samples even though the apparent viscosities of the thickeners at the same IDDSI level were similar. On the other hand, while results from the trained panel with barium samples showed that thickness-related attributes were within the boundaries established by the IDDSI levels, viscosity measurements revealed that the apparent viscosities of the cornstarch samples were much higher than those of the xanthan gum samples.

In conclusion, the IDDSI framework classifies liquids into gravity-flow defined thickness levels that can be distinguished based on sensory characteristics by individuals. However, within the same IDDSI level, further differences in sensory properties are distinguishable based on the thickener used and the medium being thickened.

Supplementary Material

Highlights.

Taste and flavor attributes decreased in intensity with increasing thickness level

Thickener specific attributes affected textural properties regardless of liquid matrix

Perceived viscosity attributes were not affected by the type of thickener but behaved differently in non-barium and barium mediums

Perceived viscosity of the samples did not relate well to apparent viscosity at 50 s−1

Acknowledgments

This study was funded by the National Institutes of Health on Deafness and Other Communication Disorders (NIH) for Grant Number 011020.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- Brito-de la Fuente E, Ekberg O, Gallegos C. Rheological Aspects of Swallowing and Dysphagia. In: Ekberg O, editor. Dysphagia: Diagnosis and Treatment. Berlin, Germany: Springer-Verlag; 2012. pp. 493–506. [Google Scholar]

- Chambers DH, Allison AA, Iv EC, Hall J. Training effects on performance of descriptive panelists. Journal of Sensory Studies. 2004;19:486–499. [Google Scholar]

- Cichero JAY, Steele C, Duivestein J, Clavé P, Chen J, Kayashita J, … Murray J. The Need for International Terminology and Definitions for Texture-Modified Foods and Thickened Liquids Used in Dysphagia Management: Foundations of a Global Initiative. Curr Phys Med Rehabil Rep. 2013;1:280–291. doi: 10.1007/s40141-013-0024-z. https://doi.org/10.1007/s40141-013-0024-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clark CC, Lawless HT. Limiting response alternatives in time-intensity scaling: an examination of the halo-dumping effect. Chemical Senses. 1994;19(6):583–594. doi: 10.1093/chemse/19.6.583. Retrieved from http://dx.doi.org/10.1093/chemse/19.6.583. [DOI] [PubMed] [Google Scholar]

- Dransfield E. The taste of fat. Meat Science. 2008;80(1):37–42. doi: 10.1016/j.meatsci.2008.05.030. https://doi.org/10.1016/j.meatsci.2008.05.030. [DOI] [PubMed] [Google Scholar]

- Ekberg O, Bulow M, Ekman S, Hall G, Stading M, Wendin K. Effect of barium sulfate contrast medium on rheology and sensory texture attributes in a model food. Acta Radiologica (Stockholm, Sweden : 1987) 2009;50(2):131–8. doi: 10.1080/02841850802555638. https://doi.org/10.1080/02841850802555638. [DOI] [PubMed] [Google Scholar]

- Ekberg O, Hamdy S, Woisard V, Wuttge-Hannig A, Ortega P. Social and psychological burden of dysphagia: Its impact on diagnosis and treatment. Dysphagia. 2002;17(2):139–146. doi: 10.1007/s00455-001-0113-5. https://doi.org/10.1007/s00455-001-0113-5. [DOI] [PubMed] [Google Scholar]

- Engelen L, Van Der Bilt A. Oral physiology and texture perception of semisolids. Journal of Texture Studies. 2008;39(1):83–113. https://doi.org/10.1111/j.1745-4603.2007.00132.x. [Google Scholar]

- Ferry ALS, Hort J, Mitchell JR, Cook DJ, Lagarrigue S, Valles Pamies B. Viscosity and flavour perception: Why is starch different from hydrocolloids? Food Hydrocolloids. 2006;20(6):855–862. https://doi.org/10.1016/j.foodhyd.2005.08.008. [Google Scholar]

- Ferry ALS, Mitchell JR, Hort J, Hill SE, Taylor AJ, Lagarrigue S, Vallès-Pàmies B. In-mouth amylase activity can reduce perception of saltiness in starch-thickened foods. Journal of Agricultural and Food Chemistry. 2006;54(23):8869–8873. doi: 10.1021/jf061607n. https://doi.org/10.1021/jf061607n. [DOI] [PubMed] [Google Scholar]

- Force, N. D. D. T., & Association, A. D. National dysphagia diet: standardization for optimal care. American Dietetic Association; 2002. [Google Scholar]

- Garcia-Ochoa F, Santos VE, Casas JA, Gomez E. Xanthan gum: production, recovery, and properties. Biotechnology Advances. 2000;18:549–579. doi: 10.1016/s0734-9750(00)00050-1. [DOI] [PubMed] [Google Scholar]

- Garcia JM, Chambers E, IV, Matta Z, Clark M. Viscosity measurements of nectar- and honey-thick liquids: Product, liquid, and time comparisons. Dysphagia. 2005;20(4):325–335. doi: 10.1007/s00455-005-0034-9. https://doi.org/10.1007/s00455-005-0034-9. [DOI] [PubMed] [Google Scholar]

- Garin N, De Pourcq JT, Martin-Venegas R, Cardona D, Gich I, Mangues MA. Viscosity differences between thickened beverages suitable for elderly patients with dysphagia. Dysphagia. 2014;29(4):483–488. doi: 10.1007/s00455-014-9533-x. https://doi.org/10.1007/s00455-014-9533-x. [DOI] [PubMed] [Google Scholar]

- Hollowood TA, Linforth RST, Taylor AJ. The effect of viscosity on the perception of flavour. Chemical Senses. 2002;27(7):583–91. doi: 10.1093/chemse/27.7.583. https://doi.org/10.1093/chemse/27.7.583. [DOI] [PubMed] [Google Scholar]

- Hong SR, Sun DS, Yoo W, Yoo B. Flow behaviors of commercial food thickeners used for the management of dysphagia: Effect of temperature. International Journal of Food Engineering. 2012;8(2) https://doi.org/10.1515/1556-3758.2215. [Google Scholar]

- Hopfer H, Heymann H. A summary of projective mapping observations - The effect of replicates and shape, and individual performance measurements. Food Quality and Preference. 2013;28(1):164–181. https://doi.org/10.1016/j.foodqual.2012.08.017. [Google Scholar]

- IDDSI. Complete IDDSI Framework Detailed Definitions. 2016a Retrieved March 22, 2017, from http://iddsi.org/wp-content/uploads/2016/10/Opt_CompleteFramework_IDDSI-Framework_updated_12October2016ZS-Edit_final.pdf.

- IDDSI. IDDSI Framework Testing Methods. 2016b Retrieved January 1, 2016, from http://iddsi.org/wp-content/uploads/2016/10/Opt_Testing_IDDSI-Framework_updated_10October2016ZS-Edit_final.pdf.

- Imai E, Hatae K, Shimada A. Oral perception of grittiness: Effect of particle size and concentration of the dispersed particles and the dispersion medium. Journal of Texture Studies. 1995;26:561–576. [Google Scholar]

- Jones B, Donner MW. How I do it: Examination of the patient with dysphagia. Dysphagia. 1989;4(3):162–172. doi: 10.1007/BF02408041. https://doi.org/10.1007/BF02408041. [DOI] [PubMed] [Google Scholar]

- Katzbauer B. Properties and applications of xanthan gum. Polymer Degradation and Stability. 1998;(97):81–84. [Google Scholar]

- Kennedy J, Heymann H. Projective mapping and descriptive analysis of milk and dark chocolates. Journal of Sensory Studies. 2008;24(2009):220–233. https://doi.org/10.1111/j.1745-459X.2008.00204.x. [Google Scholar]

- Kilcast D, Clegg S. Sensory perception of creaminess and its relationship with food structure. Food Quality and Preference. 2002;13(7–8):609–623. https://doi.org/10.1016/S0950-3293(02)00074-5. [Google Scholar]

- King MC, Cliff MA, Hall JW. Comparison of projective mapping and sorting data collection and multivariate methodologies for identification of similarity-of-use of snack bars. Journal of Sensory Studies. 1998;13(1056):347–358. [Google Scholar]

- Lotong V, Chun SS, Chambers E, IV, Garcia JM. Texture and flavor characteristics of beverages containing commercial thickening agents for dysphagia diets. Journal of Food Science. 2003;68(4):1537–1541. https://doi.org/10.1111/j.1365-2621.2003.tb09680.x. [Google Scholar]

- Macosko CW. Rheology: Principles, Measurements and Applications. Rheology Principles, Measurements, and Applications. New York, NY: Wiley-VCH; 1994. https://doi.org/10.1016/S0032-5910(96)90008-X. [Google Scholar]

- Macqueen CE, Taubert S, Cotter D, Stevens S, Frost GS. Which commercial thickening agent do patients prefer? Dysphagia. 2003;18(1):46–52. doi: 10.1007/s00455-002-0084-1. https://doi.org/10.1007/s00455-002-0084-1. [DOI] [PubMed] [Google Scholar]

- Martin-Harris B, Brodsky MB, Michel Y, Castell DO, Schleicher M, Sandidge J, … Blair J. MBS measurement tool for swallow impairment-MBSimp: Establishing a standard. Dysphagia. 2008;23(4):392–405. doi: 10.1007/s00455-008-9185-9. https://doi.org/10.1007/s00455-008-9185-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Martino R, Foley N, Bhogal S, Diamant N, Speechley M, Teasell R. Dysphagia after stroke: Incidence, diagnosis, and pulmonary complications. Stroke. 2005;36(12):2756–2763. doi: 10.1161/01.STR.0000190056.76543.eb. https://doi.org/10.1161/01.STR.0000190056.76543.eb. [DOI] [PubMed] [Google Scholar]

- Matta Z, Chambers E, IV, Garcia JM, Helverson JM. Sensory Characteristics of Beverages Prepared with Commercial Thickeners Used for Dysphagia Diets. Journal of the American Dietetic Association. 2006;106(7):1049–1054. doi: 10.1016/j.jada.2006.04.022. https://doi.org/10.1016/j.jada.2006.04.022. [DOI] [PubMed] [Google Scholar]

- McCrickerd K, Chambers L, Brunstrom JM, Yeomans MR. Subtle changes in the flavour and texture of a drink enhance expectations of satiety. Flavour. 2012;1(1):20. https://doi.org/10.1186/2044-7248-1-20. [Google Scholar]

- McCullough G, Pelletier C, Steele C. National Dysphagia Diet: What to Swallow? The ASHA Leader. 2003;8(20):16–27. Retrieved from http://dx.doi.org/10.1044/leader.FTR3.08202003.16. [Google Scholar]

- Meilgaard M, Civille GV, Carr TB. Sensory Evaluation Techniques. 2. Boca Raton, FL: CRC Press; 1991. [Google Scholar]

- Meng Y, Rao Ma, Datta aK. Computer Simulation of the Pharyngeal Bolus Transport of Newtonian and Non-Newtonian Fluids. Food and Bioproducts Processing. 2005;83(4):297–305. https://doi.org/10.1205/fbp.04209. [Google Scholar]

- Miller RE. Flavoring barium sulphate. American Journal of Roentgenology. 1966;96(2):484–487. doi: 10.2214/ajr.96.2.484. [DOI] [PubMed] [Google Scholar]

- Nestrud MA, Lawless HT. Perceptual mapping of apples and cheeses using projective mapping and sorting. Journal of Sensory Studies. 2009;25(2010):390–405. https://doi.org/10.1111/j.1745-459X.2009.00266.x. [Google Scholar]

- Pagès J. Collection and analysis of perceived product inter-distances using multiple factor analysis: Application to the study of 10 white wines from the Loire Valley. Food Quality and Preference. 2005;16(7):642–649. https://doi.org/10.1016/j.foodqual.2005.01.006. [Google Scholar]

- Pangborn RM, Gibbs ZM, Tassan C. Effect of Hydrocolloids on apparent viscosity and sensory properties of selected beverages. Journal of Texture Studies. 1979;9(1978):415–436. [Google Scholar]

- Parkinson C, Sherman P. The influence of turbulent flow on the sensory assessment of viscosity in the mouth. Journal of Texture Studies. 1971;2:451–459. doi: 10.1111/j.1745-4603.1971.tb00593.x. [DOI] [PubMed] [Google Scholar]

- Ross CF, Weller KM, Alldredge JR. Impact of Serving Temperature on Sensory Properties of Red Wine as Evaluated Using Projective Mapping by a Trained Panel. Journal of Sensory Studies. 2012;27(6):463–470. https://doi.org/10.1111/joss.12011. [Google Scholar]

- Shi X, BeMiller JN. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydrate Polymers. 2002;50(1):7–18. https://doi.org/10.1016/S0144-8617(01)00369-1. [Google Scholar]

- Steele CM, Van Lieshout PHHM, Goff HD. The rheology of liquids: A comparison of clinicians’ subjective impressions and objective measurement. Dysphagia. 2003;18(3):182–195. doi: 10.1007/s00455-002-0104-1. https://doi.org/10.1007/s00455-002-0104-1. [DOI] [PubMed] [Google Scholar]

- Stokely SL, Molfenter SM, Steele CM. Effects of barium concentration on oropharyngeal swallow timing measures. Dysphagia. 2014;29(1):78–82. doi: 10.1007/s00455-013-9485-6. https://doi.org/10.1007/s00455-013-9485-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sudhakar V, Singhal RS, Kulkarni PR. Studies on starch-hydrocolloid interactions: effect of salts. Food Chemistry. 1995;53(4):405–408. https://doi.org/10.1016/0308-8146(95)99835-N. [Google Scholar]

- Sura L, Madhavan A, Carnaby G, Crary MA. Dysphagia in the elderly: Management and nutritional considerations. Clinical Interventions in Aging. 2012 Jul;7:287–298. doi: 10.2147/CIA.S23404. https://doi.org/10.2147/CIA.S23404. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Szczesniak AS. Texture is a sensory property. Food Quality and Preference. 2002;13(4):215–225. https://doi.org/10.1016/S0950-3293(01)00039-8. [Google Scholar]

- Tashiro A, Hasegawa A, Kohyama K, Kumagai H, Kumagai H. Relationship between the rheological properties of thickener solutions and their velocity through the pharynx as measured by the ultrasonic pulse Doppler method. Bioscience, Biotechnology, and Biochemistry. 2010;74(8):1598–605. doi: 10.1271/bbb.100192. https://doi.org/10.1271/bbb.100192. [DOI] [PubMed] [Google Scholar]

- Varela P, Ares G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Research International. 2012;48(2):893–908. https://doi.org/10.1016/j.foodres.2012.06.037. [Google Scholar]

- Vickers Z, Damodhar H, Grummer C, Mendenhall H, Banaszynski K, Hartel R, … Robbins J. Relationships Among Rheological, Sensory Texture, and Swallowing Pressure Measurements of Hydrocolloid-Thickened Fluids. Dysphagia. 2015;30(6):702–713. doi: 10.1007/s00455-015-9647-9. https://doi.org/10.1007/s00455-015-9647-9. [DOI] [PubMed] [Google Scholar]

- Weber FH, Clerici MTPS, Collares-Queiroz FP, Chang YK. Interaction of guar and xanthan gums with Starch in the Gels Obtained from Normal, Waxy and High-amylose Corn starches. Starch/Staerke. 2009;61(1):28–34. https://doi.org/10.1002/star.200700655. [Google Scholar]

- Yamagata Y, Izumi A, Egashira F, Miyamoto K, Kayashita J. Determination of a Suitable Shear Rate for Thickened Liquids Easy for the Elderly to Swallow. Food Science and Technology Research. 2012;18(3):363–369. [Google Scholar]

- Zhu JF, Mizunuma H, Michiwaki Y. Determination of characteristic shear rate of a liquid bolus through the pharynx during swallowing. Journal of Texture Studies. 2014;45(6):430–439. https://doi.org/10.1111/jtxs.12094. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.