Abstract

This study aimed to determine the effect of different uncommon tempura formulations (incubated with CO2 and with added ethanol) on physical, chemical and sensory characteristics of fried coated squids, immediately after frying and also after 48 h of refrigeration storage and subsequent oven reheating. Ethanol addition led to lower levels of moisture and higher of fat in the fried coating, regardless the use of CO2. There were no difference in instrumental colour parameters among all four battered samples. Ethanol added tempuras showed higher crispness and lower maximum force than their water counterparts in an instrumental texture evaluation. Fried squids coated with ethanol added tempuras were rated as crispier and crunchier, even after 2 days of storage and further reheating. Overall, partial substitution of water by ethanol appears as an interesting strategy to increase crispness in tempura coated fried products, especially when the products are stored and reheated before consumption.

Keywords: Deep fat-frying, Oven reheating, Tempura, Crispness, Ethanol

Introduction

Deep fried coated foodstuffs are known and appreciated worldwide (Fiszman and Salvador 2003) constituting some of the most extensively consumed convenience food products (Varela et al. 2008). Coating preserves and enhances food quality, limiting moisture lost during frying and contributing to the generation of pleasant flavors (Firdevs Dogan et al. 2005; Varela and Fiszman 2011). The crusts of fried products exhibit a characteristic crunchy texture and a golden yellow color (Chen et al. 2009). A crunchy and crispy crust with a tender and moist inside, are to a great extent, responsible for their great acceptance (Fiszman and Salvador 2003).

Crispness is a highly valued textural characteristic in breaded and battered fried foods, such as fish, poultry or vegetables (Firdevs Dogan et al. 2005). In fact, it has been reported as the most critical property determining their consumer acceptance (Maskat and Kerr 2002; Primo-Martín and van Deventer 2011). Consequently, extensive research has been conducted to investigate the influence of batter ingredients on crispness (Fiszman and Salvador 2003). In fact, tempura-type batter mixtures widely vary depending on the type of food being batter-coated and the specific characteristics desired for the final products (Salvador et al. 2005). Numerous industrial and culinary attempts to produce crispy and crunchy tempura crusts have been assayed.

A batter can be defined as a liquid mixture composed of water, flour, starch, salt, leavening and other minor ingredients, into which food products are dipped prior to deep-frying (Fiszman 2009). Flour functionality in batter systems largely depends upon the two major constituents of all flours: starch and protein. The proteins in batter provide structure and increase the coating pick-up values and final yield in fried products (Fiszman and Salvador 2003). The main protein in wheat flour responsible for such functionality is gluten. Gluten is a tough, elastic substance that acts as a net, trapping and holding air bubbles in the batter, and contributing to the coherence of the batter and to the adhesion to the battered products (Mallikarjunan et al. 2009). Depending on the quantity, quality and extent of hydration of gluten, the resultant structure can range from a crispy and brittle structure as in bread crust, to an elastic one, as it happens in bread loafs, or even a flowing one, as in a tempura, thus determining the products final texture (Schiffmann 2011).

Tempura coated fried foods are crispy right after frying, due to the formation of a mostly dehydrated gluten network layer. As moisture increases, it plasticizes the structural matrix, eventually leading to an elastic structure that results soggy and not crispy (Schiffmann 2011). Such moisture may come from the surrounding atmosphere during storage or holding after frying, or from the coated food, during reheating in the oven or in the microwave.

There have been numerous attempts to keep crispness in coated fried foods, by modifying the formula, using hydrocolloids or different types of flours (Fiszman 2009), with very limited success, especially when it comes to reheating. Blumenthal (2006) developed a tempura, which principle is based on the substitution of part of the water in the batter with ethanol. More specifically, he suggested mixing wheat flour with vodka and beer. Moreover, in such a recipe it was indicated that the tempura should be infused with CO2 into a siphon, in order to achieve more bubbles in the batter, that will eventually lead to more layers in the coating of the fried product. The author also claimed that during storage and further reheating, the fried tempura remains crispy.

Thus, the objective of this study was to shed some light on the effect of modifying tempuras by partially substituting water with ethanol and by infusing the liquid tempura with CO2, on several physical, chemical and sensory characteristics of tempura fried calamari, right after the deep-frying process and after storage and further reheating in the oven, with special attention to crispness.

Materials and methods

Experimental design

Frozen squid rings were purchased in a local supermarket and were thawed before coated with four different tempura formulations. The tempuras were produced using a regular wheat flour for frying. The four different formulations corresponded to the use of (1) either only mineral water (groups named as “H2O”) or a mixture of water with ethanol (named as “Eth”) for food use (National Distillery, Riachos, Portugal) and (2) to the incubation or not of the tempuras in a siphon charged with CO2 (Isi- Consumer Products, Vienna, Austria), (groups named respectively as either “no-CO2" or “CO2”).

Tempuras were produced by manually mixing 250 g of flour with 375 mL of either water or a water/ethanol mixture (225 mL water/150 mL ethanol) with a spoon for 2 min. Right after, those tempuras subjected to CO2 incubation were poured into a siphon and incubated with 4 charges of CO2 for 180 min. Thereafter, the content was siphoned onto a bowl. Tempuras non containing CO2 were also left to rest for the same time.

Around 60 squid rings were dipped into each type of tempura for 4–6 s. Battered squid rings were deep-fried on sunflower oil at 190 ± 5 °C during 210 s in a domestic fryer (Philips, Germany). Half of the fried tempura squids from each batch were kept in a tray covered with transparent film at 4 °C for 48 h. After this time, the four different battered type of samples were reheated at 130 ± 5 °C during 15 min in a conventional domestic convection oven (UFESA, Maxi-Grill BSHTAESL). The full experiment was replicated three times.

Sensory analysis of the full fried tempura squid (crust and squid ring) immediately after frying or oven reheating. In 30–40 samples, coating and squid were separated in order to proceed to analyse the coating (3 squid rings gave aprox 10 g of coating). In both cases, temperature of coating or battered squid rings were continuously controlled with the intention of never being less than 45 ± 5 °C.

Moisture content

Moisture content of the coating was determined by drying the samples (aprox. 1 g) at 102 °C into an oven (AOAC 2000). Five replicates were performed for each kind of formulated batter.

Fat content

The total oil content of the crusts was determined by extraction with petroleum ether using a Soxtec Avanti 2050 extraction system (Foss Tecator, Sweden). Previous hydrolysis of samples was carried out with HCl and fat was calculated as a percentage. Five replicates per sample were used.

Color parameters

Color measurements were made on each of four randomly selected battered squid rings from each formulation for each storage time (0 and 2 days). The Comission Internationale d’Eclairage (CIE) L*, a* and b* values were determined using a portable spectrophotometer (Konica Minolta CM-600d, Osaka, Japan) that was calibrated with a standard white calibration tile. Fifteen replicates were performed for each batch of samples.

Instrumental texture analysis

A TA-HDi Texture Analyser (Stable Micro Systems, Godalming, UK) equipped with the Kramer Shear Cell with 5 blades (HDP/KS5), was used for the compression tests with a 25 kg load cell. Kramer analysis was made just after the cooking process (deep-frying or oven convection reheating), in order to assure crust temperature to be around 45 ± 5 °C.

The following settings were used for the analysis: test speed 2 mm/s, trigger force 0.05 N, travel distance of the blades 15 mm and acquisition points per second 400 pps. Ten replications with approximately 10 g of fried tempura were performed for each type.

The following parameters were calculated from the force versus time curves: maximum force (N) respective work force or area (Ns), number of peaks above in the curve or fracture events (drop in force higher than 0.049 N), and initial slope (N/s) or gradient (slope of the curve up to the first major peak) (Sanz et al. 2007).

Scanning electron microscopy (SEM)

Samples for scanning electron microscope (SEM) observations were first washed with ether diethyl and then dried with a nitrogen stream, and afterwards were sectioned and the surface was coated with gold using a gold coater under vacuum, before taking the micrographs. SEM Quanta 3D FEG (FEI Company) micrographs were taken with a secondary electrons (SE) detector, at an accelerating voltage of 2 or 5 kV, a working distance varying from 10 to 11.4 mm and an average magnification of 150–5000 times.

Sensory analysis

A panel of 15 assessors with experience in the descriptive evaluation of crispy products was used to evaluate the four samples of battered squid rings at production day and with 48 h at reheated oven samples. Panellists were trained for 6 months in group sessions; in a first stage, group discussion with a variety of samples showing a wide range of crispness and crunchiness were carried out, in order to achieve a consensus on the meaning and intensity of these attributes (hardness, crispness, crunchiness). Thereafter, assessors were trained in sessions in individual booths in which the repeatability was addressed.

Testing was carried out in a sensory laboratory equipped with individual booths (NP ISO 8586, 2012) in different sessions in function of the production day (day 0 or reheated after 48 h). Surface temperature of the samples was controlled by using an infrared thermometer (Testo, Germany) in order to ensure 45 ± 5 °C. Four samples were given to each panellist in each session, corresponding to the four formulas of batters evaluated, either right after frying or after 48 h of refrigeration storage and further regeneration in the oven. Samples were given in random order on plastic plates and identified with a random letter code. Panellists were instructed to rinse their mouths with water between sample evaluations.

The intensities of sensory attributes were scored on 9 cm unstructured line scales labelled from “low” (0) to “high” (9). Color intensity and its homogeneity were considered as the color ranging from yellow to gold to brown and how uniform is the surface of the coating of the fried tempura squid after the thermal process (Albert et al. 2009). Adherence of tempura to squid was visually evaluated along the crust perimeter of the cutting surface after biting (Albert et al. 2009). To evaluate hardness, the instruction was to bite the whole sample with the incisor teeth until fracture and score the material resistance (Vincent 2004). To score crunchiness the instruction was to evaluate the intensity and pitch of the sound produced during mastication (first three bites) (Dijksterhuis et al. 2007). To evaluate crispness, the instruction was to score the number of layers with incorporated air during chewing (Dijksterhuis et al. 2007). Crumbliness was evaluated as the degree to which the sample fractures into pieces (Pascua et al. 2013). Oiliness was assessed as the amount of fat and oil in the mouth during chewing (Albert et al. 2009). Flavour intensity was evaluated as the strength of flavour perception during chewing and right after swallowing.

Statistics

The effects of partial substitution of water with ethanol and of either incubate or not the tempura with CO2 on chemical, instrumental colour and instrumental texture parameters were analysed by a two-way analysis of variance (ANOVA) using the GLM procedure of SPSS 12.0.1 (SPSS Inc., Chicago, Illinois, US). Differences between mean values were evaluated at the 0.05 level using the Tukey pair-wise comparison test. In order to evaluate the effect of refrigeration and subsequent oven reheating, a one-way ANOVA considering time as the only factor within each type of fried tempura squids, was also performed.

For the data reported by the panellists, a mixed analysis of variance was used, with ethanol addition and CO2 or storage time as fixed effects, plus the random factors of tasting session and panellist.

Results and discussion

Moisture and fat content

Moisture content on freshly fried tempura samples (day 0) and on oven reheated samples after 48 h refrigeration (day 2), in samples processed with four different formulations (either only with water or partially substituted with ethanol, and either or not incubated with CO2) are shown on Table 1.

Table 1.

Moisture and fat content (%) on fried tempura squids right after frying (day 0) and on samples reheated in the oven after 2 days of storage (day 2), processed with the four studied formulations: with just water or with added ethanol, and with or without CO2

| H2O | Eth | SEM | p eth | p CO2 | p eth × CO2 | |||

|---|---|---|---|---|---|---|---|---|

| No-CO2 | CO2 | No-CO2 | CO2 | |||||

| Moisture | ||||||||

| Day 0 | 43.4a | 38.9b | 11.6d | 18.4c | 3.1 | 0.001 | 0.026 | 0.001 |

| Day 2 | 40.9a | 34.7b | 15.1c | 14.9c | 2.6 | 0.001 | 0.001 | 0.001 |

| ptime | 0.001 | 0.001 | 0.001 | 0.001 | ||||

| Fat | ||||||||

| Day 0 | 12.9b | 18.1b | 31.7ª | 32.0ª | 2.1 | 0.001 | 0.151 | 0.159 |

| Day 2 | 16.3d | 25.8c | 29.4b | 36.3ª | 1.6 | 0.001 | 0.001 | 0.011 |

| ptime | 0.150 | 0.001 | 0.010 | 0.001 | ||||

Cells in the same row with different superscript are significantly different (p < 0.05) in the Tukey’s test

SEM standard error of the mean

Substitution of water with ethanol, CO2 incorporation and their interaction significantly affected moisture content of the fried coated tempura. Samples produced with just water showed lower moisture content when incubated with CO2 (43.4 and 38.9%, no-CO2 and CO2, respectively), while those elaborated with ethanol showed higher levels due to CO2 (11.6 and 18.4%, no-CO2 and CO2, respectively). The same trend was shown for reheated samples after 2 days of refrigerated storage, with fried tempura samples made just with water showing higher moisture contents when not incubated with CO2 (40.9 and 34.7%, no-CO2 and CO2, respectively), while those made with added ethanol showed no effect due to CO2 (15.1 and 14.9%, no-CO2 and CO2, respectively). CO2 seemed to differently affect moisture content of tempura made just with water or with added ethanol, both, right after frying and after 2 days of storage and further reheating. We find no clear explanation for that. To our knowledge, this is the first study in which these two factors are considered, and there is no previous scientific literature on the matter. A structure with more bubbles due to the presence of CO2 could ease dehydration during frying, but if this were the case, it would be difficult to understand why it did not behave in the same way in the ethanol added tempura on day 0.

Formulations with added ethanol, with or without CO2, showed lower moisture content than those just containing water. This is most likely due the far lower water content of the original batter before frying in the tempuras that had added ethanol. Water loss in both types of tempuras during frying was similar: the initial calculated water content of both batters were 60 and 36% (for H2O and Eth tempuras, respectively), while the content after frying was between 43.4 and 38.9% in H2O tempuras, and between 11.6 and 18.4% in Eth ones. This means that water loss during frying was around 20% for both types.

All four type of samples had significant differences from day 0 to day 2 in moisture content, but with an opposite behaviour in H2O and Eth ones: while in H2O ones there was a decrease in water content (both in CO2 and no-CO2 ones), fried tempuras with added ethanol showed a decrease in moisture due to storage and further reheating only in CO2 samples, while no-CO2 ones, that were those showing the lowest moisture content, showed an increase. During refrigeration, the water content equilibrates between the food and the surrounding atmosphere (Mercier et al. 2015), which would explain why samples with higher water content tended to lose moisture, while those with a lower water content showed an increase.

On top of that, water transfer between different ingredients or parts of the food unit also takes place if their water activities are different (fried batters and squid core). Depending on the temperature and relative humidity at which the product is exposed, the final moisture content at equilibrium will be defined by the sorption isotherms, and thus the kinetics of equilibration will again depend on water diffusion rate (Mekprayoon and Tangduangdee 2012). In the case of those tempuras containing just water this seemed to be not enough to counteract the evaporative loss during refrigeration and heating, while in Eth/No-CO2 ones could have contributed to the gain in water content.

As far as fat content is concerned (Table 1) addition of ethanol to the tempura significantly (p < 0.001) increased fat content of the fried tempura, both at day 0 and after 48 h of refrigeration storage and reheating. However, in this second case, there was a significant interaction (p < 0.001) between ethanol addition and CO2. At any rate, those tempuras containing ethanol showed far higher fat content right after frying (12.9–18.1% for H2O ones and 31.7–32.0% for Eth ones, with and without CO2 respectively), and after storage and reheating (16.3 and 25.8% for H2O ones and 29.4–36.3% for Eth ones, with and without CO2 respectively). Overall, these effects were in agreement with moisture content results, so that a decrease or increase in water content was paralleled with an increase or decrease, respectively, in fat content. But on top of this, there might be an effect of ethanol on increasing the oil uptake. After immersion into hot oil, the temperature of the surface layers rises rapidly. Water starts boiling at 100 °C and it is released from the surface as steam bubbles. As frying proceeds, the thickness of the formed crust continues to increase. It seems that during the cooling phase, the superheated steam in the bubbles on the surface of the product cools down, leading to a pressure drop that sucks the oil into the void spaces (Achir et al. 2008). In the case of ethanol containing tempura samples, the faster evaporation of ethanol and its higher diffusivity would have probably led to a higher number of empty voids in the surface, which could eventually lead to a higher oil uptake.

Such an increasing effect of ethanol containing tempura on the final fat content of fried battered foodstuff poses clear consequences on the nutritional outcome of the product, leading to a higher caloric value, which might be not adequate in those consumers aiming to reduce such. However, given that fried battered food are intrinsically of high caloric content, this might be not relevant.

The increase or decrease in fat content from day 0 to day 2 was most likely due to the variations in the moisture content, so that if there was a decrease in water, there occurred a proportional increase in the other components.

Textural analysis

Force versus time parameters obtained after crushing fried tempura samples in a Kramer cell are shown on Table 2. All studied parameters (maximum force, work load and number of fracture events) showed a significant interaction between ethanol addition and CO2, both on day 0 and on day 2, except for the maximum force on day 2 and the number of breaking events on day 0.

Table 2.

Parameters from the force displacement curves obtained by compression on fried tempura right after frying (day 0) and on samples reheated in the oven after 2 days of storage (day 2), processed with the four studied formulations: with just water or with added ethanol, and with or without CO2

| H2O | Eth | SEM | p eth | p CO2 | p eth × CO2 | |||

|---|---|---|---|---|---|---|---|---|

| No-CO2 | CO2 | No-CO2 | CO2 | |||||

| Max. force (N) | ||||||||

| Day 0 | 2.0a | 1.5b | 1.4b | 1.4b | 0.06 | 0.020 | 0.041 | 0.022 |

| Day 2 | 1.9a | 1.4b | 1.4b | 1.3b | 0.06 | 0.001 | 0.001 | 0.081 |

| ptime | 0.827 | 0.394 | 0.885 | 0.108 | ||||

| Work load (N s) | ||||||||

| Day 0 | 10.0a | 7.3b | 8.5ab | 8.6ab | 0.33 | 0.898 | 0.035 | 0.048 |

| Day 2 | 10.8a | 6.7b | 10.5a | 9.4a | 0.37 | 0.031 | 0.001 | 0.005 |

| ptime | 0.269 | 0.311 | 0.110 | 0.326 | ||||

| No. of fracture events | ||||||||

| Day 0 | 100.2b | 114.4b | 243.3a | 220.4ª | 11.53 | 0.001 | 0.877 | 0.392 |

| Day 2 | 80.6b | 44.1c | 217.2a | 247.3a | 14.11 | 0.001 | 0.707 | 0.001 |

| ptime | 0.148 | 0.001 | 0.524 | 0.196 | ||||

Cells in the same row with different superscript are significantly different (p < 0.05) in the Tukey’s test

SEM standard error of the mean

H2O/no-CO2 samples showed higher maximum force values than all the other groups, both on day 0 and on day 2. H2O/CO2 fried tempura samples had lower values on work load than any of the other groups on day 2, while on day 0 such a difference was only significant with the H2O/no-CO2 samples. Neither maximum force, nor work load, showed any significant variation after 48 h storage and oven reheating.

Eth samples showed significant higher number of fracture events than H2O ones right after frying and also after 48 h storage and further re-heating in the oven. Reheated H2O/CO2 samples showed lower number of breaking events than their H2O/no-CO2 counterparts, but CO2 showed no effect on Eth samples on any of the day tested. Only H2O/CO2 samples showed a significant reduction in the number of breaking events from day 0 to day 2, while the other groups experimented no variation in this parameter.

Mechanical properties obtained after compression tests allow inferring the structural properties of the product and how they will be perceived during chewing (Saeleaw and Schleining 2011). Compression tests using different probes and parameters have shown good correlations with crispness and crunchiness for some products, but not for others. Compression in a Kramer cell has been extensively used for measuring crispness in different types of dry snacks (Chaunier et al. 2005; Sandoval et al. 2008). Some authors have shown that both, maximum force and work load to failure, show an inverse correlation with sensory crispness (Van Hecke et al. 1998). Usually, a brittle product will also exhibit numerous fracture events, followed by sudden drops in force as the crack propagates (Miranda and Aguilera 2006), so that the higher the number of fracture events, the higher the crispness (Saeleaw and Schleining 2011).

In our samples, the use of ethanol in the tempura led to a clear increase in the indicators for crispness: lower maximum force and work load, and higher number of fracture events. This last fact is notable, since the average number of events outnumbered the regular fried tempura in more than 100%. And even more interesting, such indicators remained quite stable after 2 days of storage and further reheating. This is remarkable, since one of the main problems with storage and reheated fried coated foodstuff is the loss of crispness. The retention of crispness for some time after frying is an important quality factor in fried battered products (Baixauli et al. 2003). We could objectively detect the effect of ethanol on fried tempura crispness claimed by Blumenthal (2006). Nevertheless, it could be seen that there was not any significant modification in the indicators for crispness in samples not containing ethanol, with the exception of the significant decrease in the number of breaking events of H2O/CO2 fried tempuras.

A potential explanation for the effect of ethanol on the mechanical indicators of crispness could be the fact that, during frying, alcohol evaporation is faster and more violent than that of water, which might lead to the formation of a higher number of bubbles. Usually, the number of bubbles has been positively linked to crispness (Miranda and Aguilera 2006). However, in our study, those samples containing CO2, that are supposed to have a larger number of bubbles, did not show a clear tendency to show better indicators for crispness. Therefore, it seems that the increased crispness in ethanol added tempura is not only related to the larger number of bubbles as a consequence of sudden evaporation of ethanol during frying. Actually, crispness in snacks and other dry crispy products is very much related to the extent of dehydration (Katz and Labuza 1981). In our case, the Eth samples got much more dehydrated than H2O ones, and this could also contribute to their higher values for crispness indicators. Moreover, in the specific case of wheat, such a lower amount of available moisture could help to reach the glass state of the dried gluten network (Kokini et al. 1994), and this effect could last in time even after storage and reheating. During this processes, the water from the core (squids in this study) plasticizes the gluten network, reaching again the rubbery state, which eventually leads to an elastic structure and loss of crispness, as it happens during the staling of bread (Primo-Martín and van Deventer 2011). The use of ethanol seems to prevent such a process, either due to the very low levels of moisture achieved in the fried tempura, or to the lack of initial moisture to reach a complete development of the gluten network.

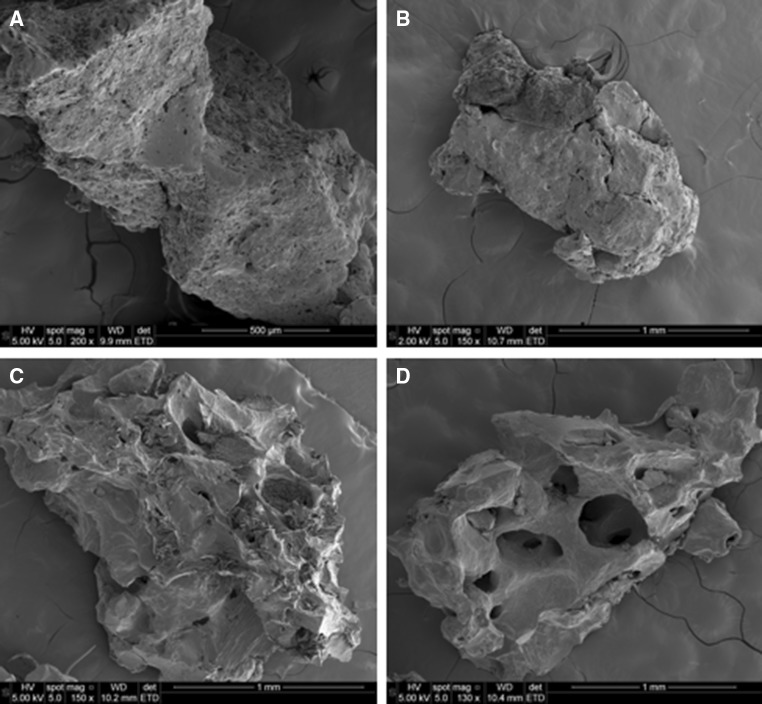

SEM

Images taken using SEM are shown in Fig. 1. Both ethanol addition and CO2 led to a less compact structure, with more bubbles and tiny holes. Also, ethanol samples showed a smoother surface regardless the presence of CO2. Such a structure agrees with the obtained results on the instrumental texture analysis tests, showing a more aerated structure as a result of the sudden evaporation of ethanol and the presence of CO2 bubbles.

Fig. 1.

SEM images of different types of fried tempuras: (a H2O/no-CO2; b H2O/CO2; c eth/no-CO2; d eth/CO2)

Pores development is one of the main structural changes during deep-fat frying. Evaporation of moisture from the tempura due to the high temperature during frying creates capillary paths on its way out of the product. These can even be large cavities and crevasses due to explosive evaporation, especially if there is quick formation of crust (Ngadi et al. 2008). This is actually what seemed to happen in our samples, since the ethanol added ones showed the sign of larger cavities and crevasses, probably as a result of (1) the sudden and more violent evaporation of ethanol and (2) the faster formation of the crust, as a result of the lower amount of water that needed to be evaporated to reach the glass state.

Color parameters

Colour parameters L*, a*, b* for fried tempura samples processed with the four different studied formulations (either with just water or with added ethanol, and with or without CO2) on day 0 and after 2 days of storage and further reheating in the oven (day 2), are shown in Table 3.

Table 3.

Instrumental colour parameters (L*, a* and b*) on fried tempuras right after frying (day 0) and on samples reheated in the oven after 2 days of storage (day 2), processed with the four studied formulations: with just water or with added ethanol, and with or without CO2

| H2O | Eth | SEM | p eth | p CO2 | p eth × CO2 | |||

|---|---|---|---|---|---|---|---|---|

| No-CO2 | CO2 | No-CO2 | CO2 | |||||

| L* | ||||||||

| Day 0 | 66.9a | 57.3b | 57.8b | 57.1b | 1.02 | 0.018 | 0.007 | 0.021 |

| Day 2 | 60.8a | 57.1ab | 52.4b | 55.2b | 0.90 | 0.001 | 0.685 | 0.018 |

| ptime | 0.136 | 0.789 | 0.019 | 0.147 | ||||

| a* | ||||||||

| Day 0 | − 2.8a | − 1.8ab | − 0.4c | − 0.8bc | 0.25 | 0.004 | 0.613 | 0.435 |

| Day 2 | − 1.2b | − 1.0b | 1.0a | − 0.2ab | 0.27 | 0.001 | 0.207 | 0.067 |

| ptime | 0.074 | 0.185 | 0.061 | 0.418 | ||||

| b* | ||||||||

| Day 0 | 22.7ab | 23.5a | 20.3ab | 19.3b | 0.58 | 0.007 | 0.468 | 0.603 |

| Day 2 | 21.6ab | 23.7a | 18.0b | 19.7ab | 0.67 | 0.002 | 0.076 | 0.904 |

| ptime | 0.545 | 0.952 | 0.206 | 0.923 | ||||

Cells in the same row with different superscript are significantly different (p < 0.05) in the Tukey’s test

SEM standard error of the mean

The interaction of ethanol and CO2 significantly influenced L* values of fried tempura samples on day 0 and after storage and reheating of the samples (p = 0.021 and p = 0.018, respectively). Overall, H2O samples showed higher L* values than their ethanol added counterparts, especially in those without CO2. However, CO2 did not show any effect on the L* values of samples right after frying, and the opposite one on samples stored and reheated.

As compared to other studies on tempura fried squids (Salvador et al. 2005; Sanz et al. 2004), the L* values were similar, although different factors not directly related to those evaluated in the present study could lead to small differences (type of oil, ingredients in the tempura and so on). As far as the effect of storage and reheating is concerned, only Eth/no-CO2 samples showed a significant decrease in L* values (p = 0.019), while the other types remained unaffected. So, overall, it seems that the presence of ethanol led to a darker surface. Within H2O tempuras, CO2 also led to darker colours on day 0, but not on day 2. In the case of ethanol, such an effect could be related to a lower water activity, which in turn could have positively influenced the development of browning reactions (van Boekel 2001). However, such a hypothesis does not support the effect of CO2 on lightness. It could be that the higher number of bubbles on the crust may lead to a different reflection of the light, which could also explain the lower lightness values on ethanol added samples Changes during the storage and reheating (dehydration and further browning reactions) seemed to affect only samples with added ethanol and without CO2.

Colour parameters a* and b* showed a significant effect of ethanol addition, both in day 0 and in day 2 (p = 0.004 and p = 0.001 for a* on days 0 and 2, respectively; p = 0.007 and p = 0.002 for b* on days 0 and 2, respectively). Neither CO2, nor its interaction with Eth showed a significant effect on these two parameters.

It was expected that a* and b* values were higher in samples at day 2, since undergoing two thermal processes (frying and oven) most likely to a stronger development of browning reactions than just a single one (frying). Also, dehydration of the surface may have also caused higher a* and b* values after storage and reheating. However, these processes seem to be not enough to make any difference between freshly fried and reheated products.

Sensory analysis

Results from the sensory analysis of fried squid rings battered with either a water or ethanol based tempura, incubated or not with CO2, and freshly fried or reheated after 2 days of refrigeration storage, are shown in Table 4. Ethanol addition and CO2 showed a significant interaction on colour homogeneity, crispness, crunchiness, crumbliness and oiliness on day 0, but not on day 2. As individual factors, CO2 did not affect any of the sensory parameters assessed, while the addition of ethanol significantly modified adherence of the tempura to the squid on day 2, hardness on both days, crispness, crunchiness and crumbliness on day 2 and flavour intensity on both days. Storage and further reheating significantly decreased the adherence of the tempura to the squids on H2O/no-CO2 samples, the crunchiness on ethanol added tempura samples and the crispness and crumbliness in both types of CO2 incubated samples. On the other hand, oiliness was lower in H2O/no-CO2 samples as a result of storage and reheating.

Table 4.

Average scores for the evaluated sensory parameters of the fried tempura squids right after frying (day 0) and on samples reheated in the oven after 2 days of storage (day 2), processed with the four studied formulations: with just water or with added ethanol, and with or without CO2

| H2O | Eth | SEM | p eth | p CO2 | p eth × CO2 | |||

|---|---|---|---|---|---|---|---|---|

| No-CO2 | CO2 | No-CO2 | CO2 | |||||

| Colour intensity | ||||||||

| Day 0 | 4.1 | 3.7 | 5.2 | 5.2 | 0.3 | 0.051 | 0.727 | 0.694 |

| Day 2 | 4.5 | 4.8 | 5.7 | 5.0 | 0.2 | 0.142 | 0.703 | 0.293 |

| p time | 0.663 | 0.232 | 0.454 | 0.691 | ||||

| Colour homogeneity | ||||||||

| Day 0 | 5.5ab | 6.3a | 5.2ab | 4.8b | 0.2 | 0.008 | 0.451 | 0.035 |

| Day 2 | 5.8 | 5.5 | 4.8 | 5.1 | 0.2 | 0.109 | 0.977 | 0.446 |

| ptime | 0.597 | 0.154 | 0.333 | 0.384 | ||||

| Tempura adherence | ||||||||

| Day 0 | 4.8 | 4.3 | 4.9 | 4.6 | 0.1 | 0.574 | 0.187 | 0.627 |

| Day 2 | 3.7b | 4.3ab | 4.9a | 5.0a | 0.2 | 0.001 | 0.068 | 0.287 |

| ptime | 0.007 | 0.982 | 0.986 | 0.178 | ||||

| Hardness | ||||||||

| Day 0 | 3.4b | 3.9b | 5.4a | 5.3a | 0.3 | 0.001 | 0.461 | 0.219 |

| Day 2 | 3.8b | 4.3ab | 5.4a | 5.4a | 0.3 | 0.002 | 0.405 | 0.390 |

| ptime | 0.563 | 0.381 | 0.987 | 0.414 | ||||

| Crunchiness | ||||||||

| Day 0 | 3.1b | 4.1b | 7.1a | 6.8a | 0.5 | 0.001 | 0.181 | 0.039 |

| Day 2 | 2.7b | 3.0b | 5.8a | 5.4a | 0.4 | 0.001 | 0.805 | 0.276 |

| ptime | 0.401 | 0.062 | 0.049 | 0.005 | ||||

| Crispness | ||||||||

| Day 0 | 3.0c | 4.6b | 6.7a | 6.8a | 0.5 | 0.001 | 0.007 | 0.019 |

| Day 2 | 2.8b | 3.0b | 5.6a | 5.2a | 0.4 | 0.001 | 0.812 | 0.374 |

| ptime | 0.667 | 0.025 | 0.098 | 0.003 | ||||

| Crumbliness | ||||||||

| Day 0 | 2.7c | 3.6b | 5.8a | 6.0a | 0.43 | 0.001 | 0.007 | 0.029 |

| Day 2 | 2.5b | 2.8b | 4.8a | 4.6a | 0.33 | 0.001 | 0.891 | 0.414 |

| ptime | 0.587 | 0.024 | 0.067 | 0.009 | ||||

| Oiliness | ||||||||

| Day 0 | 4.5b | 5.8a | 5.7a | 6.0a | 0.19 | 0.001 | 0.001 | 0.008 |

| Day 2 | 5.1 | 5.7 | 5.5 | 5.7 | 0.11 | 0.242 | 0.094 | 0.339 |

| ptime | 0.012 | 0.692 | 0.645 | 0.322 | ||||

| Flavour intensity | ||||||||

| Day 0 | 3.3b | 3.8ab | 5.7a | 5.7a | 0.39 | 0.002 | 0.661 | 0.622 |

| Day 2 | 3.6b | 4.1ab | 5.5a | 5.2a | 0.27 | 0.002 | 0.675 | 0.270 |

| ptime | 0.736 | 0.743 | 0.482 | 0.275 | ||||

Cells in the same row with different superscript are significantly different (p < 0.05) in the Tukey’s test

SEM standard error of the mean

As long as the external colour of the samples is concerned, sensory results only partially confirmed instrumental colour results: samples with added ethanol tended to have higher colour intensities on day 0, but not on day 2. The mentioned positive effect of lower water activity values on browning could be the reason for this effect. Nevertheless, such an effect is not dramatic in terms of scores. The homogeneity of the colour showed an interaction effect, so that samples without ethanol and with CO2 showed the highest values, while Eth/CO2 showed the lowest.

There was a better adherence of the coating to the squid in the ethanol based tempuras on day 2, while this effect was not detected on samples right after frying. It could be that the lower elasticity of the crust in ethanol added samples might have led to a more stable interaction between the coating and the squid, while the plasticiser effect of water in the non-ethanol ones, leading to a more elastic coating, might have eased their separation.

Hardness scores of samples with ethanol added tempura were clearly higher than their water counterparts on both days, while CO2 did not show a clear effect. This evidences that the perception of hardness in products that are intrinsically crunchy is not related to the maximum instrumental force, since the latter parameter can actually be very high as a consequence of a highly elastic structure. In fact, as commented before, maximum force and work load have been previously related to lower values of crunchiness. This was confirmed with the evaluation of crispness and crunchiness of tempura fried squids: ethanol addition boosted the scores of both parameters, confirming the results obtained for the instrumental texture evaluation. The fact that both crispness and crunchiness resulted higher in ethanol based fried tempuras points out to the occurrence of the previously discussed phenomena in samples containing ethanol: violent evaporation leading to a higher number of bubbles and formation of a stable glassy state due to lower moisture content (Ngadi et al. 2008; Primo-Martín and van Deventer 2011). CO2 incubation, which is supposed to lead to a higher number of bubbles, only have a significant effect on the crispness of freshly fried squids on water based tempuras, while it showed no effect on day 2, nor on ethanol ones in any of the days. It might be that the potential effect of CO2 on crispness is masked due to the overwhelming effect of ethanol on the same parameter. On the water based samples, its effect might be dependent upon the presence of a glassy structure in the walls of the bubbles: when such a structure becomes rubbery, the crispness is impaired despite of the number of bubbles. Accordingly, H2O/CO2 samples were crispier than their no-CO2 counterparts on day 0, but not after 2 days of storage and further reheating.

Crumbliness showed a similar trend to that of crispness. The higher crumbliness of ethanol based fried tempuras might be related with the vitreous state attained during frying, due to a more intense dehydration: the vitreous structure would be more difficultly to get rehydrated by saliva while chewing, so that the pieces of crust formed during mastication will be larger, glassier, will produce a louder noise upon breaking and will be not so easy to swallow. On the other hand, the plasticiser effect of water and saliva would have made the water based samples soggier during chewing,

After storage and reheating, ethanol based tempuras showed, or tended to show, lower values of crispness, crunchiness and crumbliness, but they were still showing much higher values than water based ones.

Both ethanol types (with and without CO2) and H2O/CO2 showed higher scores for oiliness than the plain traditional tempura samples on day 0. On day 2 the trend was similar, but not significant. Indeed, ethanol based tempura samples were those presenting higher fat contents (Table 1), while within water based ones, CO2 incorporation also led to an increase in fat content. Therefore, it seems that changes in oiliness perception were mostly due to a different oil content in tempuras, as a result of a higher absorption of oil due to a more porous structure and to a lower moisture content.

Fried tempura squids with ethanol showed higher flavour intensity scores than water based ones. This could be somehow related to the more intense development of Maillard reactions during frying due to lower water contents in these samples, as it was pointed out for colour intensity. However other factors should not be dismissed: ethanol based samples absorbed more oil, which itself is a rich source of flavour compounds in deep-fat fried products (Warner 2008). Moreover, the presence of a higher amount of fat can also affect the release of volatile flavour compounds (Guichard 2002), modifying the profile of compounds reaching the sensitive epithelium in the nose.

Conclusion

Substitution of water with ethanol in tempura fried squids promotes a more porous, dehydrated and glassy crust structure, which in turn makes the coating crispier and crunchier. Remarkably, these effects on texture remain after storage and reheating. Besides, ethanol based tempuras absorb more oil during frying and seem to develop stronger browning reactions, both facts determining a more intense flavour. On the other hand, incubation of tempuras with CO2 has not a marked influence on the physical or structural features of the fried coating, although in those in which no ethanol is added, the higher number of bubbles due to the presence of CO2 seems to improve the crunchiness of the fried coating.

Overall, the addition of ethanol to tempura is an interesting tool for improving crispness and crunchiness of coated fried products, especially in catering or central kitchens, in which storage and reheating are common procedures.

Acknowledgements

This research was supported by the 3rd Regional Programme for Research, Development, and Innovation (Junta de Extremadura, Spain (3PR05B032)). Authors thank Ana Mostazo for her technical assistance.

Compliance with ethical standards

Conflict of interest

Authors declare no conflict of interest.

References

- Achir N, Vitrac O, Trystram G. Heat and mass transfer during frying. In: Sahin S, Sumnu SG, editors. Advances in deep-fat frying of foods contemporary food engineering. Boca Raton: CRC Press; 2008. pp. 5–32. [Google Scholar]

- Albert Á, Varela P, Salvador A, Fiszman SM. Improvement of crunchiness of battered fish nuggets. Eur Food Res Technol. 2009;228:923–930. doi: 10.1007/s00217-008-1005-9. [DOI] [Google Scholar]

- AOAC (2000) Official methods of analysis. AOAC INTERNATIONAL, Gaithersburg, MD (USA)

- Baixauli R, Sanz T, Salvador A, Fiszman SM. Effect of the addition of dextrin or dried egg on the rheological and textural properties of batters for fried foods. Food Hydrocoll. 2003;17:305–310. doi: 10.1016/S0268-005X(02)00091-7. [DOI] [Google Scholar]

- Blumenthal H. In search of perfection. London: Bloomsbury Publishing Plc; 2006. [Google Scholar]

- Chaunier L, Courcoux P, Della Valle G, Lourdin D. Physical and sensory evaluation of cornflakes crispness. J Texture Stud. 2005;36:93–118. doi: 10.1111/j.1745-4603.2005.00007.x. [DOI] [Google Scholar]

- Chen S-D, Chen H-H, Chao Y-C, Lin R-S. Effect of batter formula on qualities of deep-fat and microwave fried fish nuggets. J Food Eng. 2009;95:359–364. doi: 10.1016/j.jfoodeng.2009.05.016. [DOI] [Google Scholar]

- Dijksterhuis G, Luyten H, de Wijk R, Mojet J. A new sensory vocabulary for crisp and crunchy dry model foods. Food Qual Prefer. 2007;18:37–50. doi: 10.1016/j.foodqual.2005.07.012. [DOI] [Google Scholar]

- Firdevs Dogan S, Sahin S, Sumnu G. Effects of soy and rice flour addition on batter rheology and quality of deep-fat fried chicken nuggets. J Food Eng. 2005;71:127–132. doi: 10.1016/j.jfoodeng.2004.10.028. [DOI] [Google Scholar]

- Fiszman SM. Coating ingredients. In: Tarté R, editor. Ingredients in meat products: properties, functionality and applications. New York: Springer; 2009. pp. 253–289. [Google Scholar]

- Fiszman SM, Salvador A. Recent developments in coating batters. Trends Food Sci Tech. 2003;14:399–407. doi: 10.1016/S0924-2244(03)00153-5. [DOI] [Google Scholar]

- Guichard E. Interactions between flavor compounds and food ingredients and their influence on flavor perception. Food Rev Int. 2002;18:49–70. doi: 10.1081/FRI-120003417. [DOI] [Google Scholar]

- Katz EE, Labuza TP. Effect of water activity on the sensory crispness and mechanical deformation of snack food products. J Food Sci. 1981;46:403–409. doi: 10.1111/j.1365-2621.1981.tb04871.x. [DOI] [Google Scholar]

- Kokini JL, Cocero AM, Madeka H, de Graaf E. The development of state diagrams for cereal proteins. Trends Food Sci Tech. 1994;5:281–288. doi: 10.1016/0924-2244(94)90136-8. [DOI] [Google Scholar]

- Mallikarjunan P, Ngadi MO, Chinnan MS. Properties of batters and breadings. In: Mallikarjunan P, Ngadi MO, Chinnan MS, editors. Breaded fried foods. Boca Raton: CRC Press; 2009. pp. 97–112. [Google Scholar]

- Maskat MY, Kerr WL. Coating characteristics of fried chicken breasts prepared with different particle size breading. J Food Process Preserv. 2002;26:27–38. doi: 10.1111/j.1745-4549.2002.tb00475.x. [DOI] [Google Scholar]

- Mekprayoon R, Tangduangdee C. Influence of Nusselt number on weight loss during chilling process. Procedia Eng. 2012;32:90–96. doi: 10.1016/j.proeng.2012.01.1241. [DOI] [Google Scholar]

- Mercier S, Marcos B, Moresoli C, Mondor M, Villeneuve S. Effect of the water content measurements on the estimation and identifiability of water diffusion and convection mass transfer coefficients. Int J Heat Mass Trans. 2015;90:480–490. doi: 10.1016/j.ijheatmasstransfer.2015.06.082. [DOI] [Google Scholar]

- Miranda ML, Aguilera JM. Structure and texture properties of fried potato products. Food Rev Int. 2006;22:173–201. doi: 10.1080/87559120600574584. [DOI] [Google Scholar]

- Ngadi M, Adedeji A, Kassama L. Microstructural changes during frying of foods. In: Sumnu SG, Sahin S, editors. Advances in deep-fat frying of foods. Contemporary food engineering. Boca Raton: CRC Press; 2008. pp. 169–200. [Google Scholar]

- Pascua Y, Koç H, Foegeding EA. Food structure: roles of mechanical properties and oral processing in determining sensory texture of soft materials. Curr Opin Colloid Interface. 2013;18:324–333. doi: 10.1016/j.cocis.2013.03.009. [DOI] [Google Scholar]

- Primo-Martín C, van Deventer H. Deep-fat fried battered snacks prepared using super heated steam (SHS): crispness and low oil content. Food Res Int. 2011;44:442–448. doi: 10.1016/j.foodres.2010.09.026. [DOI] [Google Scholar]

- Saeleaw M, Schleining G. A review: crispness in dry foods and quality measurements based on acoustic–mechanical destructive techniques. J Food Eng. 2011;105:387–399. doi: 10.1016/j.jfoodeng.2011.03.012. [DOI] [Google Scholar]

- Salvador A, Sanz T, Fiszman SM. Effect of the addition of different ingredients on the characteristics of a batter coating for fried seafood prepared without a pre-frying step. Food Hydrocoll. 2005;19:703–708. doi: 10.1016/j.foodhyd.2004.07.003. [DOI] [Google Scholar]

- Sandoval AJ, Chaunier L, Courcoux P, Valle GD. Bulk mechanical behavior of commercial particle food foams. J Texture Stud. 2008;39:405–425. doi: 10.1111/j.1745-4603.2008.00150.x. [DOI] [Google Scholar]

- Sanz T, Salvador A, Fiszman SM. Innovative method for preparing a frozen, battered food without a prefrying step. Food Hydrocoll. 2004;18:227–231. doi: 10.1016/S0268-005X(03)00067-5. [DOI] [Google Scholar]

- Sanz T, Primo-Martín C, van Vliet T. Characterization of crispness of French fries by fracture and acoustic measurements, effect of pre-frying and final frying times. Food Res Int. 2007;40:63–70. doi: 10.1016/j.foodres.2006.07.013. [DOI] [Google Scholar]

- Schiffmann RF. Technology of microwavable coated foods. In: Kulp K, Loewe R, Lorenz K, Gelroth J, editors. Batters and breadings in food processing. Minnesota: AACC International; 2011. pp. 207–218. [Google Scholar]

- Van Boekel MAJS. Kinetic aspects of the Maillard reaction: a critical review. Food/Nahrung. 2001;45:150–159. doi: 10.1002/1521-3803(20010601)45:3<150::AID-FOOD150>3.0.CO;2-9. [DOI] [PubMed] [Google Scholar]

- Van Hecke E, Allaf K, Bouvier JM. Texture and structure of crispy-puffed food products part II: mechanical properties in puncture. J Texture Stud. 1998;29:617–632. doi: 10.1111/j.1745-4603.1998.tb00189.x. [DOI] [Google Scholar]

- Varela P, Fiszman SM. Hydrocolloids in fried foods. A review. Food Hydrocoll. 2011;25:1801–1812. doi: 10.1016/j.foodhyd.2011.01.016. [DOI] [Google Scholar]

- Varela P, Salvador A, Fiszman SM. Methodological developments in crispness assessment: effects of cooking method on the crispness of crusted foods. Food Sci Technol LEB. 2008;41:1252–1259. doi: 10.1016/j.lwt.2007.08.008. [DOI] [Google Scholar]

- Vincent JFV. Application of fracture mechanics to the texture of food. Eng Fail Anal. 2004;11:695–704. doi: 10.1016/j.engfailanal.2003.11.003. [DOI] [Google Scholar]

- Warner K. Flavor changes during frying. In: Sumnu SG, Sahin S, editors. Advances in deep-fat frying of foods. Contemporary food engineering. Boca Raton: CRC Press; 2008. pp. 201–213. [Google Scholar]