Abstract

Effect of pulsed electric field (PEF) strength, pulse duration and temperature used during PEF assisted blanching pretreatment on energy input, cell disintegration index and drying time of apple slices was studied. A central composite rotatable design was used for designing the experiment and to visualize the effect of variables on responses. The level of variables used in the design varied from 1 to 2 kV cm−1, 25 to 75, and 60 to 80 °C for electric field strength, number of pulses and temperature of water during PEF assisted blanching pretreatment, respectively. The variables affected significantly the responses and polynomial quadratic models employed to visualize the effect of variables on different responses were found to fit well with high R2 values (0.84–0.99) indicating fitness of the models in describing the effect of variables on responses. An optimized condition for variables was derived at 1.25 kV cm−1, 50, and 80 °C for electric field strength, number of pulses temperature during PEF assisted blanching pretreatment, respectively with a desirability value of 0.85. High correlations were recorded between predicted and actual values for responses at optimized conditions of variables and the same can be used for production of dehydrated apple slices with low energy input.

Keywords: PEF, Blanching, Dehydration, Cell disintegration index

Introduction

Pulsed electric field (PEF) processing is a novel non-thermal method of food preservation that uses electric current for microbial inactivation. It has been found to cause minimal or no detrimental effect on the quality of food materials (Dermesonlouoglou et al. 2016). This technique is mainly used for processing of liquid and semi-liquid food products (Toepfl et al. 2005). In recent years, this technology has found newer applications in several fields, though, initially it was considered for processing of only pumpable foods having low electrical conductivities. It has found applications as a pretreatment for increase in extraction of plant pigments and colorants from plant sources (Fincan et al. 2004; López et al. 2009; Loginova et al. 2011; Puertolas et al. 2011), oil extraction from seeds (Zeng et al. 2010), extraction of phenolic compounds (Puértolas et al. 2010), increase in juice yield from fruits and vegetables (Bouzrara and Vorobiev 2000; Bazhal et al. 2001; Grimi et al. 2007; Jemai and Vorobiev 2006; Lebovka et al. 2007), sugar extraction from sugar beet (Katrokha and Kupchik 1984), as pretreatment before freezing (Jalte et al. 2009), inulin extraction from artichokes (Marchal et al. 2004), etc.

Pulsed electric field treatment of plant cells leads to increased permeabilization of cell membranes leading to increased movement of cell content from the cells (Knorr and Angersbach 1998). This phenomenon is called electroporation. This principle can be used for increased removal of moisture from the plant tissues during dehydration processes at enhanced drying rates. Application of pulsed electric field as a pretreatment during dehydration of plant materials has been studied in various products. Several reports exist with regards to increased mass transfer during dehydration of apples (Lebovka et al. 2004a), potato (Lebovka et al. 2007; Janositz et al. 2011), radish (Bajgai and Hashinaga 2001), rice (Cao et al. 2004), red beet roots (Shynkaryk et al. 2008), etc., as well as osmotic dehydration of apples (Amami et al. 2006), bell pepper (Ade-Omowaye et al. 2003), and carrots (Amami et al. 2007a, b). The level of electric field strength, time of treatment and temperature of treatment can affect the cell permeabilization thereby affecting the drying rate. Several workers have utilized pulsed electric field as a pretreatment along with temperature during dehydration processes for increase in mass transfer. However, effect of electric field strength, pulse numbers and temperature on cell disintegration, drying time and product quality has not been studied. Pulsed electric field assisted dehydration also had been found to be less energy intensive as compared to dehydration alone (Toepfl and Knorr 2006). Therefore, present work was undertaken with an objective to study the effect of pulsed electric field strength, time of treatment in the form of number of pulses and temperature during treatment of apple slices and to optimize these variables on the basis of energy input, cell disintegration index and drying time.

Materials and methods

Experimental design

Response Surface Methodology (RSM) with Central Composite Rotatable Design (CCRD) was used for designing the experiment. Pulsed electric field treatment, number of pulses and temperature during pulsed electric field strength were selected as independent variables and effect of these variables were studied on energy input during blanching, cell disintegration index and drying time of apple slices. The level of variables varied from 0.66 to 2.34 kV cm−1 for electric field strength, 8 to 92 for number of pulses and 53.18 to 86.82 °C for temperature of water during PEF treatment (Table 1). A total number of 20 experiments were carried out, 5 levels for each variable and six experiments at central point of the experimental design (Table 1).

Table 1.

Process variables and experimental design

| Factors | Variables | − 1.68 | − 1 | 0 | + 1 | + 1.68 |

|---|---|---|---|---|---|---|

| X1 | Electric field strength (kV cm−1) | 0.66 | 1.00 | 1.50 | 2.00 | 2.34 |

| X2 | Number of pulses | 7.96 (8a) | 25 | 50 | 75 | 92.04 (92) |

| X3 | Temperature (°C) | 53.18 | 60 | 70 | 80 | 86.82 |

| X1 | X2 | X3 | Runs |

|---|---|---|---|

| ± 1 | ± 1 | ± 1 | 8 |

| 1.68 | 0 | 0 | 2 |

| 0 | 1.68 | 0 | 2 |

| 0 | 0 | 1.68 | 2 |

| 0 | 0 | 0 | 6 |

aValues in parenthesis for pulse numbers are actual values used in the study

The data were recorded for each set of experimental design and the variables were standardized for ease in computation and to reduce their relative effect on the responses. The coefficients of second-order polynomial models were generated after multiple regression of the responses and they depict the effect of a particular variable on the response. The response values obtained at various experimental combinations of variables are given in Table 1. For the analysis of experimental design by the response surface methodology, it was assumed that n-mathematical functions, fk (where, k = 1, 2…, n), Yk in terms of m independent factors Xi (where, i = 1, 2,…, m) existed for each response variable.

The function was assumed to be approximated by following second-order polynomial equation.

where, βk0 is the value of the fitted response at the central point of the design, i.e. point (0,0) and βki, βkii and βkij are the linear, quadratic and interactive regression terms, respectively.

Surface plots were generated from the fitted quadratic polynomial regression equations in order to visualize the relationship among the variables and responses and to obtain the numerical solution for optimum conditions for variables at desired response levels. Response surface analysis was done using the statistical software (Design Expert software, Version 8.0.6, Statease, Minneapolis, MN, USA). The response surface plots for the models were plotted as a function of the two variables, while keeping the other one at its central point.

Optimization

Optimization of fitted polynomials for the response variables was carried out following nonlinear mathematical optimization method using Design Expert software (Version 8.0.6, Statease, Minneapolis, MN, USA). The experimental variables were set to be within experimental domain. The response variables for energy input and cell disintegration index were minimized and maximized, respectively. A weight was assigned to each response to obtain the goal within the desirability level.

Validation of the process

Experiments were carried out at optimized level of variables and data were recorded for the responses. Correlations were drawn between predicted and actual response values. The results were also compared with the apple samples blanched in water at 90 °C for 60 s with or without addition of ascorbic acid (200 mg kg−1) in the blanching medium. Apples slices were prepared at optimized conditions of process variables with and without addition of ascorbic acid (200 mg kg−1) in the blanching solution and the results were compared with those blanched in water.

Raw material and precutting

Apples (Jonagold var) were procured from local market of Quakenbruck, Germany and those without any blemishes or injury were selected for the study. The average weight of apples varied from 147 to 166 g. The apples were stored at 4 °C in the laboratory prior to experimental study. The apples were taken out from the cold room, washed in tap water and sliced using a mechanical slicer (Graef, DVE GS, Quakenbrück, Germany). The thickness of the slices was maintained uniform at 3 mm. The apple slices were treated with pulsed electric field immediately after cutting.

Pulsed electric field treatment and dehydration

The apple slices (100–110 g) were put in the pulsed electric field treatment chamber (18 × 13 × 20 cm dimensions) filled with water (3 L) of specific temperatures. The treatment chamber was connected with a batch type pulsed electric field equipment (Elcrack, DIL, Quakenbruck, Germany). The PEF system provided mono-polar pulses of near-rectangular shape. The duration between pulses was 25 µs. Two stainless steel electrodes were fitted in the treatment chamber at a distance of 13 cm.

The apple slices were treated at specific electric field strength and pulse numbers at specific temperatures as per experimental design (Table 1). The PEF treated slices were immediately taken out of the water drained on a wire mesh and spread on tissue paper to remove the surface moisture. The slices were dehydrated up to a moisture content of 6–7% in hot air dehydration unit (Heraeus D6450, Hanau, Germany) maintained at 60 °C and at a hot air velocity of 12 m s−1.

Measurements

Total energy input

Total energy input during pulsed electric field treatment was calculated based on electric field strength, number of pulses employed and capacitance of the electric field chamber using modified equation of Knorr and Angersbach (1998):

where, WTotal = Total energy input (kJ kg−1), C = Capacitance = 0.05 µF, U = Electric field strength (kV cm−1), n = Number of pulses.

Cell disintegration index

The electrical conductivity was measured with an impedance measurement equipment (DIL, Quakenbruck, Germany) in the frequency range of 0.5 kHz to 5 MHz. Impedance was measured in intact apple tissue and PEF pretreated samples (cylindrical) (diameter 2 cm, length 3 cm) and the data were recorded in a computer using a software (DIL, Quakenbruck, Germany). Cell disintegration index was calculated from the impedance data using following equation as described by Knorr and Angersbach (1998):

where,

KI and KI′ are electrical conductivity of untreated and treated materials, respectively, in low frequency field (1–5 kHz); and, Kh and Kh′ are electrical conductivity of untreated and treated materials, respectively, in high frequency field (1–5 MHz). The value of Zp varies from 0 to 1; for intact cells Zp = 0, and for total disintegration, Zp = 1.

Drying time and moisture ratio

Drying time was recorded for the PEF pretreated samples in the drying chamber (Heraeus D6450, Hanau, Germany) which was maintained at 60 °C temperature and hot air velocity was kept at 12 m s−1. The samples were dried up to 6–7% moisture content from an initial moisture content of 87.50% and time taken to dry the samples was reported in min. Moisture content in treated and untreated slices were recorded at definite time intervals (10 min) and moisture ratio (MR) was calculated using the following equation:

where, M, Mo and Me are the moisture content at any time, initial moisture content and equilibrium moisture content, respectively. The moisture ratio was plotted against drying time to see the efficacy of PEF pretreatment process.

Results and discussion

Effect of variables on energy input

The energy input due to pulsed electric field treatment is a derivative of electric field strength, capacitance of the electric field chamber and number of pulses. Therefore, the temperature of water used during the electric field treatment have not been considered during calculation of the energy input and the same is represented in the behavior of response on energy input due to electric field strength, pulse numbers and temperature. The energy input during PEF treatment varied from 0.25 to 4.23 kJ kg−1 among different experimental combinations of variables (Table 1). The energy input was maximum (4.23 kJ kg−1) in the case when number of pulses are high (75) at higher (2 kV cm−1) electric field strength. The minimum energy input was recorded for the experimental combination of 1.5 kV cm−1 electric field strength and 7.96 pulses. The following quadratic model was found to fit well in describing the effect of variables on energy input:

It is evident from above equation and from Table 2 that electric field strength as well as number of pulses had positive effect on energy input during PEF processing, however, temperature did not affected energy input. The positive signs for these variables show that with increase in the level of these variables, the value for energy input will increase. The electric field strength and number of pulses affected the energy input response significantly (p < 0.001) at linear and interactive levels, however, the effect of number of pulses was found to be non-significant at quadratic levels. The electric field strength showed significantly (p < 0.0001) higher effect on energy input as compared to number of pulses (Table 3). The quadratic model used to describe the effect of process variables on energy input showed high R2 (0.99%) indicating fitness of the model. Hot air dehydration proves to energy intensive process and energy required for evaporation of water depends on temperature and pressure applied during dehydration and it is in the range of 2.5–2.7 MJ kg−1. The total energy input required for conventional hot air drying generally ranges from 4 to 6 MJ kg−1 of water removed and depends on thermal efficiency of drying system (Toepfl and Knorr 2006). Taking into account the low energy required during PEF treatment of plant or animal tissues, it is clear that there is potential to reduce total energy input during the dehydration process. Toepfl (2011) also opinioned that electric field strength, specific energy input and temperature are the major processing parameters during PEF treatment. Whereas, the field strength has a threshold effect and the specific energy input can be applied as a dose parameter. The specific energy input required for permeabilization of plant tissue is in a range of 5–10 kJ kg−1 and for preservation of liquid media it is in the range of 50–200 kJ kg−1. Energy efficiency is considered to be one of the most critical factors for commercial introduction of PEF processes as an alternative to heat preservation techniques (Heinz et al. 2003). Therefore, amalgamation of techniques is required for its commercial success. In the present study also emphasis was laid on use of low electric field strength in combination of thermal treatment for achieving higher drying rates at low energy input.

Table 2.

Coefficients of second order regression model of responses

| Coefficient | Energy input (kJ kg−1) | Cell disintegration index | Drying time (min) |

|---|---|---|---|

| Intercept | 1.58 | 0.90 | 140.21 |

| X1 | 1.06 | 0.01 | − 4.06 |

| X2 | 0.85 | 0.15 | − 15.34 |

| X3 | 0.00 | 0.09 | − 17.92 |

| X1X2 | 0.53 | 0.003 | 0.63 |

| X1X3 | 0.00 | − 0.005 | 1.88 |

| X2X3 | 0.00 | − 0.05 | − 6.88 |

| X21 | 0.18 | − 0.15 | 10.99 |

| X22 | 0.005 | − 0.08 | 5.69 |

| X23 | 0.00 | − 0.05 | 10.11 |

Table 3.

Analysis of variance showing effect of variables on responses

| Source | Sum of squares | ||

|---|---|---|---|

| Energy input (kJ kg−1) | Cell disintegration index | Drying time (min) | |

| Model (β0) | 27.76**** | 0.82**** | 11369.81** |

| X1(β1) | 15.25**** | 0.002** | 225.17 |

| X2 (β2) | 9.83**** | 0.30**** | 3215.12** |

| X3 (β3) | 0.00 | 0.11**** | 4386.99*** |

| X1X2 (β1β2) | 2.23**** | 0.0001 | 3.13 |

| X1X3 (β1β3) | 0.00 | 0.0002 | 28.13 |

| X2X3 (β2β3) | 0.00 | 0.02**** | 378.13 |

| X21 (β21) | 0.46**** | 0.31**** | 1740.55* |

| X22 (β22) | 0.0003 | 0.09**** | 466.02 |

| X23 (β23) | 0.00 | 0.04**** | 1471.84* |

| Combined effect of variables at | |||

| Linear | 2.71**** | 0.40** | 5627.72** |

| Interactive | 0.49**** | 0.38 | 5218.34 |

| Quadratic | 0.02**** | 0.002**** | 2085.19* |

| R2 (%) | 99.92 | 99.74 | 84.50 |

****Significant (p < 0.0001), ***significant (p < 0.001), **significant (p < 0.01), *significant (p < 0.05)

Effect of variables on cell disintegration index

Cell disintegration index has become an important parameter in drying experiments as cell permeabilization is directly linked with movement of water molecules from tissues during dehydration of plant materials. Increase in cell disintegration means more openings in the cell wall of plant tissues causing increased mobility of solute or water molecules through the cell wall (Knorr and Angersbach 1998). Pulsed electric filed assisted blanching has led to increase in cell disintegration in apple slices also and it was found that treatment time in the form of number of pulses and temperature played major role towards cell disintegration as compared to electric field strength alone. The cell disintegration index varied from 0.34 to 0.95 among samples prepared at different experimental combinations of electric field strength, number of pulses and temperature of treatment (Table 1). The time taken during PEF treatment showed significantly (p < 0.0001) higher effect on cell disintegration index followed by temperature in the range of 60–80 °C and electric field strength in the range of 1–2 kV cm−1 (Tables 2, 3). It suggests that PEF treatment for longer duration at higher temperature will cause higher cell disintegration leading to higher drying rates. The quadratic model which describes the effect of variables on cell disintegration index can be written as:

All the variables affected significantly the cell disintegration index response at linear and quadratic levels. The interactive effect of electric field strength with number of pulses as well as temperature were found to be non-significant, however, the interactive effect of number of pulses and temperature showed significant (p < 0.0001) effect on cell disintegration index. The positive interactive effect shows that for getting a desired value of response, one variable has to be increased while lowering the other one and keeping the third variable as constant.

Janositz et al. (2011) observed similar impact of pulsed electric fields on the diffusion characteristics of potato slices. Bazhal et al. (2003) also observed an increase from 63 to 69% in cell porosity after PEF treatment of apple slices after 60 pulses at 1 kV cm−1. Pulsed electric field can cause both reversible and irreversible cell permeabilization in plant cells. However, quantitative data with regards to the degree of permeabilization and consequences of such disintegration of cells on the quality, functionality as well as stress and wound responses of plant tissues are still not available. Measurement of the frequency dependent passive electrical properties of biological cell systems (for the vegetable and muscle tissues characterized frequency ranges from 103 to 107 Hz) allows the simple quantification of the degree of membrane disintegration. Measuring conductivity–frequency spectra from differently treated (mechanical disruption, heat, freeze–thaw) plant tissues confirmed the validity and the effectiveness of the method developed (Angersbach et al. 1997). In the low frequency ranges, the change in conductivity occurs due to dramatic membrane conductivity increase as a result of irreversible membrane poration in the field direction and subsequent disruption. Whereas, in the high frequency ranges (5–10 MHz), the conductivity value from intact cells and cells with ruptured membranes practically remain the same. So it can be suggested that in high frequency range, the cell membrane does not present resistance to the electric current measured. According to Ade-Omowaye et al. (2001), PEF offers the advantages of low energy input, short time processing and eliminates the danger of loss in quality that could occur with thermal treatment during processing of plant tissues for achieving higher cellular disintegration. The cell disintegration increases sharply with increase in electric field strength and number of pulses and after which it further increases only marginally. Therefore, in the present study the pulsed electric field treatment was given at lower field strengths for shorter durations so that it could facilitate the cell disintegration sufficiently and at the same time energy expenditure is less.

Effect of variables on drying time

The time taken during dehydration is directly related to cell disintegration and energy input. It has been observed that at higher energy input there will be higher cell disintegration due to higher rate of membrane permeabilization. If membrane permeabilization is increased, it will lead to higher rates of movement for water leading to higher drying rates. The water molecules will have the more mobility through the pores and time taken to reach the surface of tissue through capillaries will be reduced and thus drying rate will be enhanced. Similar results have been observed in the present study. The samples, given high energy inputs causing higher cell disintegration index, had taken less time to dry. Temperature used at the time of PEF treatment also had great impact on drying rates as it also leads to cell disintegration. It is clear from the results that all the three variables affected the drying time which varied from 120 to 220 min among different experimental combinations (Table 1). The effect of temperature used during PEF treatment had significantly (p < 0.001) higher effect on drying rate followed by number of pulses and electric field strength. Shynkaryk et al. (2008) observed similar effect of temperature during pulsed electric field treatment on drying and subsequent rehydration of red beetroots. Lebovka et al. (2004b) also studied combined effect of pulsed electric fields and moderate temperatures and found that heating during PEF treatment improved the dehydration rate of apple slices.

The effect of electric field strength was found to be non-significant on drying rate (Table 3). However, number of pulses during PEF treatment and temperature of medium showed significant effect on drying time. In the present study low electric field strength range was selected for treating apple slices which may be reason for non-significant effect on drying time. Whereas, Increase in number of pulses increased the total time of treatment and made the apple slices to remain in hot water for more time which ultimately resulted in higher cell disintegration causing reduction in drying time. The variables affected significantly the drying time at linear (p < 0.01) and quadratic (p < 0.05) levels. However, the effect of variables at interactive levels was found to be non-significant. R2 value of 0.84 was recorded for the quadratic model suggesting suitability of the following polynomial model used to describe the effect of variables on drying time:

Toepfl and Knorr (2006) have suggested pulsed electric field pretreatment can significantly reduce the total energy input during dehydration process by means of opening the cells due to PEF and thereby increasing the rate of water removal during dehydration, and thus reducing the drying time. Similar results have been observed during PEF treated osmotic dehydration of apples (Amami et al. 2006), bell pepper (Ade-Omowaye et al. 2003), carrots (Amami et al. 2007a, b) etc., where PEF pretreatment was found to improve the dehydration process.

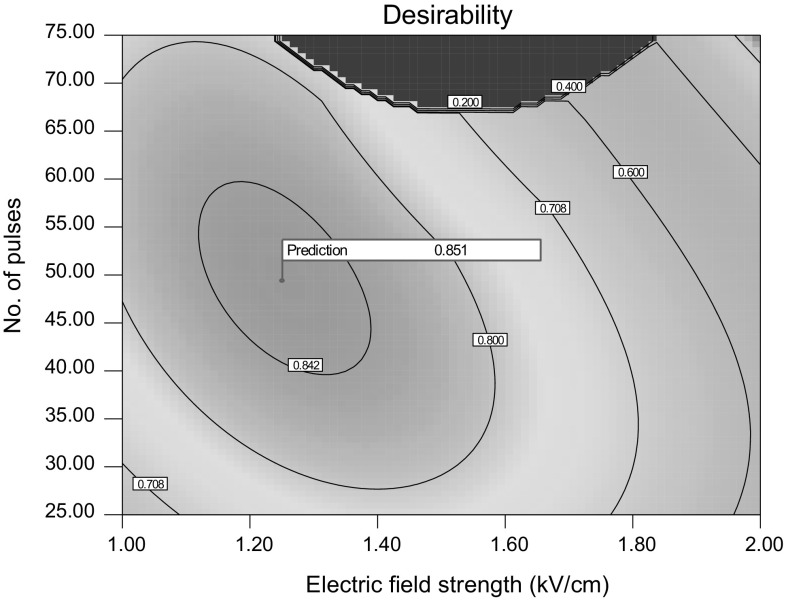

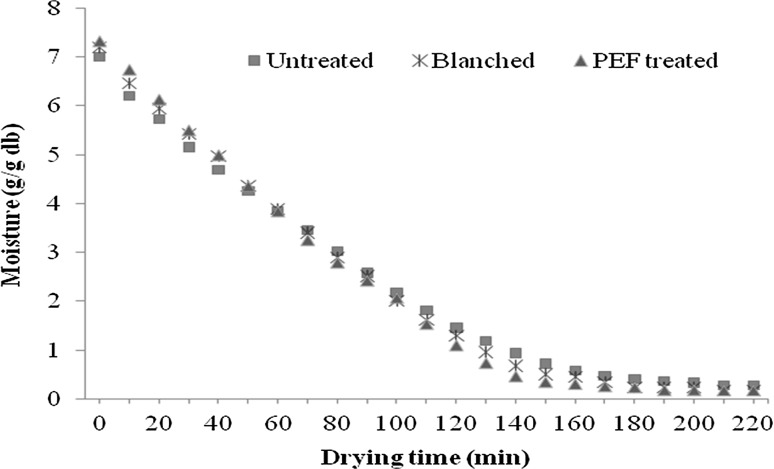

Optimization of process variables

The variables, electric field strength, number of pulses and temperature during PEF treatment, were optimized using multiple regression techniques keeping the variables in the range; whereas, the response for energy input during PEF treatment was minimized and cell disintegration index was maximized to reduce the dehydration time and thus to make the process less energy intensive. The drying time was kept in the range. The optimum value was arrived at 1.25 kV cm−1, 49.38 and 79.47 °C, for electric field strength, number of pulses and temperature during PEF treatment, respectively. The obtained predicted value for energy input, cell disintegration index and drying time were found to be 1.08 kJ kg−1, 0.90 and 136.73 min, respectively with an overall desirability of 0.85 (Fig. 1). Experiment was carried out at optimum conditions of variables and responses were studied and high correlations were observed between predicted values and actual response values. Data pertaining to weight loss during dehydration of apple slices were recorded and compared with untreated and conventional blanched samples. The blanched and PEF treated samples initially showed faster drying rates compared to untreated ones (Fig. 2). Though, there was slight increase in the moisture content during blanching and PEF treatments, this moisture probably was loosely attached to the sample surfaces and, therefore, easily removable showing higher drying rates at the beginning. These higher drying rates continued further till the end the maximum being in the case of PEF treated followed by blanched samples. The untreated samples showed lower drying rates throughout entire drying period which may be attributed to case hardening phenomenon occurring on the surface of the untreated samples. The higher drying rates in the case of PEF treated samples may be attributed to higher permeabilization of cells due to PEF treatment.

Fig. 1.

Desirability plot at optimum level of variables (at 79.47 °C)

Fig. 2.

Drying curves for untreated, blanched and PEF treated (125 kV cm−1, 50 pulses, 80 °C) apple slices

Conclusion

The response surface methodology used in this study can be employed in optimization of process variables during PEF treatment. The electric field strength, number of pulses and temperature during treatment significantly affected the cell disintegration index and drying time of apple slices. The polynomial quadratic models employed to visualize the effect of variables on different responses fit well with high R2 values indicating fitness of the models in describing the effect of variables on responses. The samples prepared at optimized conditions of electric field strength, number of pulses and temperature during treatment showed high correlations between predicted and actual values and thus the optimized conditions of process variables (i.e. 1.25 kV cm−1 electric field strength, 50 pulses, and 80 °C processing temperature) are recommended for production of dehydrated apple slices of good quality.

References

- Ade-Omowaye BIO, Angersbach A, Eshtiaghi NM, Knorr D. Impact of high intensity electric field pulses on cell permeabilisation and as pre-processing step in coconut processing. Innov Food Sci Emerg Technol. 2001;1:203–209. doi: 10.1016/S1466-8564(00)00014-X. [DOI] [Google Scholar]

- Ade-Omowaye BIO, Rastogi NK, Angersbach A, Knorr D. Combined effects of pulsed electric field pre-treatment and partial osmotic dehydration on air drying behaviour of red bell pepper. J Food Eng. 2003;60:89–98. doi: 10.1016/S0260-8774(03)00021-9. [DOI] [Google Scholar]

- Amami E, Vorobiev E, Kechaou N. Modelling of mass transfer during osmotic dehydration of apple tissue pre-treated by pulsed electric field. LWT. 2006;39:1014–1021. doi: 10.1016/j.lwt.2006.02.017. [DOI] [Google Scholar]

- Amami E, Fersi A, Khezami L, Vorobiev E, Kechaou N. Centrifugal osmotic dehydration and rehydration of carrot tissue pre-treated by pulsed electric field. LWT. 2007;40:1156–1166. doi: 10.1016/j.lwt.2006.08.018. [DOI] [Google Scholar]

- Amami E, Fersi A, Vorobiev E, Kechaou N. Osmotic dehydration of carrot tissue enhanced by pulsed electric field, salt and centrifugal force. J Food Eng. 2007;83:605–613. doi: 10.1016/j.jfoodeng.2007.04.021. [DOI] [Google Scholar]

- Angersbach A, Heinz V, Knorr D. Elektrische Leitfahigkeit als Maß des Zellaufschlußgrades von zellularen Materialien durch Verarbeitungsprozesse. Lebensmittel und Verpackungstechnik (LVT) 1997;42:195–200. [Google Scholar]

- Bajgai TR, Hashinaga F. High electric field drying of Japanese radish. Dry Technol. 2001;19:2291–2302. doi: 10.1081/DRT-100107499. [DOI] [Google Scholar]

- Bazhal MI, Lebovka NI, Vorobiev EI. Pulsed electric field treatment of apple tissue during compression for juice extraction. J Food Eng. 2001;50:129–139. doi: 10.1016/S0260-8774(00)00235-1. [DOI] [Google Scholar]

- Bazhal M, Ngadi MO, Raghavan GSV. Influence of pulsed electro-plasmolysis on the porous structure of apple tissue. Biosyst Eng. 2003;86:51–57. doi: 10.1016/S1537-5110(03)00111-9. [DOI] [Google Scholar]

- Bouzrara H, Vorobiev E. Beet juice extraction by pressing and pulsed electric fields. Int Sugar J CII. 2000;1216:194–200. [Google Scholar]

- Cao W, Nishiyama Y, Koide S, Lu ZH. Drying enhancement of rough rice by an electric field. Biosyst Eng. 2004;87:445–451. doi: 10.1016/j.biosystemseng.2003.12.007. [DOI] [Google Scholar]

- Dermesonlouoglou E, Zachariou I, Andreou V, Taoukis PS. Effect of pulsed electric fields on mass transfer and quality of osmotically dehydrated kiwifruit. Food Bioprod Process. 2016;100:535–544. doi: 10.1016/j.fbp.2016.08.009. [DOI] [Google Scholar]

- Fincan M, DeVito F, Dejmek P. Pulsed electric field treatment for solid–liquid extraction of red beetroot pigment. J Food Eng. 2004;64:381–388. doi: 10.1016/j.jfoodeng.2003.11.006. [DOI] [Google Scholar]

- Grimi N, Praporscic I, Lebovka N, Vorobiev E. Selective extraction from carrot slices by pressing and washing enhanced by pulsed electric fields. Sep Purif Technol. 2007;58:267–273. doi: 10.1016/j.seppur.2007.03.020. [DOI] [Google Scholar]

- Heinz V, Toepfl S, Knorr D. Impact of temperature on lethality and energy efficiency of apple juice pasteurization by pulsed electric fields treatment. Innov Food Sci Emerg Technol. 2003;4:167–175. doi: 10.1016/S1466-8564(03)00017-1. [DOI] [Google Scholar]

- Jalte M, Lanoiselle JL, Lebovka NI, Vorobiev E. Freezing of potato tissue pre-treated by pulsed electric fields. LWT-Food Sci Technol. 2009;42:576–580. doi: 10.1016/j.lwt.2008.09.007. [DOI] [Google Scholar]

- Janositz A, Noack AK, Knorr D. Pulsed electric fields and their impact on the diffusion characteristics of potato slices. LWT-Food Sci Technol. 2011;44:1939–1945. doi: 10.1016/j.lwt.2011.04.006. [DOI] [Google Scholar]

- Jemai AB, Vorobiev E. Pulsed electric field assisted pressing of sugar beet slices: towards a novel process of cold juice extraction. Biosyst Eng. 2006;93:57–68. doi: 10.1016/j.biosystemseng.2005.09.008. [DOI] [Google Scholar]

- Katrokha IM, Kupchik MP. Intensification of sugar extraction from sugar beet cossettes in an electric field. Sakharn. Prom-sti. 1984;7:28–31. [Google Scholar]

- Knorr D, Angersbach A. Impact of high-intensity electric field pulses on plant membrane permeabilization. Trends Food Sci Technol. 1998;9:185–191. doi: 10.1016/S0924-2244(98)00040-5. [DOI] [Google Scholar]

- Lebovka NI, Praporscic I, Vorobiev E. Effect of moderate thermal and pulsed electric field treatments on textural properties of carrots, potatoes and apples. Innov Food Sci Emerg Technol. 2004;5:9–16. doi: 10.1016/j.ifset.2003.12.001. [DOI] [Google Scholar]

- Lebovka NI, Praporscic I, Vorobiev E. Combined treatment of apples by pulsed electric fields and by heating at moderate temperature. J Food Eng. 2004;65:211–217. doi: 10.1016/j.jfoodeng.2004.01.017. [DOI] [Google Scholar]

- Lebovka NI, Praporscic I, Vorobiev E, Mietton-Peuchot M. Pulsed electric field enhanced expression and juice quality of white grapes. Sep Purif Technol. 2007;52:520–526. doi: 10.1016/j.seppur.2006.06.007. [DOI] [Google Scholar]

- Loginova KV, Lebovka NI, Vorobiev E. Pulsed electric field assisted aqueous extraction of colorants from red beet. J Food Eng. 2011;106:127–133. doi: 10.1016/j.jfoodeng.2011.04.019. [DOI] [Google Scholar]

- López N, Puértolas E, Condón S, Raso J, Alvarez I. Enhancement of the extraction of betanine from red beetroot by pulsed electric fields. J Food Eng. 2009;90:60–66. doi: 10.1016/j.jfoodeng.2008.06.002. [DOI] [Google Scholar]

- Marchal L, Muravetchi V, Vorobiev E, Bonhoure JP (2004) Recovery of inulin from Jerusalem Artichoke Tubers: development of a pressing method assisted by pulsed electric field. In: International congress on engineering and food, Montpellier, 7–11 Mar, p 6

- Puértolas E, López N, Saldaña G, Álvarez I, Raso J. Evaluation of phenolic extraction during fermentation of red grapes treated by a continuous pulsed electric fields process at pilot-plant scale. J Food Eng. 2010;98:120–125. doi: 10.1016/j.jfoodeng.2009.12.017. [DOI] [Google Scholar]

- Puértolas E, Saldana G, Alvarez I, Raso J. Experimental design approach for the evaluation of anthocyanin content of rose wines obtained by pulsed electric fields. Influence of temperature and time of maceration. Food Chem. 2011;126:1482–1487. doi: 10.1016/j.foodchem.2010.11.164. [DOI] [Google Scholar]

- Shynkaryk MV, Lebovka NI, Vorobiev E. Pulsed electric fields and temperature effects on drying and rehydration of red beetroots. Dry Technol. 2008;26:695–704. doi: 10.1080/07373930802046260. [DOI] [Google Scholar]

- Toepfl S. Pulsed electric field food treatment—scale up from lab to industrial scale. Procedia Food Sci. 2011;1:776–779. doi: 10.1016/j.profoo.2011.09.117. [DOI] [Google Scholar]

- Toepfl S, Knorr D. Pulsed electric fields as a pretreatment technique in drying processes. Stewart Postharv. Rev. 2006;4:1–6. [Google Scholar]

- Toepfl S, Heinz V, Knorr D. Overview of pulsed electric field processing for food. In: Sun DW, editor. Emerging technologies for food processing. Oxford: Elsevier; 2005. pp. 67–97. [Google Scholar]

- Zeng X, Han Z, Zi Z. Effects of pulsed electric field treatments on quality of peanut oil. Food Control. 2010;21:611–614. doi: 10.1016/j.foodcont.2009.09.004. [DOI] [Google Scholar]