Abstract

The nutritional composition of bran from four rice varieties namely, Jyothi/IR64, Basmati and Agonibora representing high amylose, intermediate amylose and waxy, respectively were evaluated with friction and abrasive mills at different degrees of milling (DOM). Fat and protein content of the bran inversely correlated to amylose content of rice variety. The fat and fibre contents reduced with increased DOM due to increasing starch influx from the endosperm. Abrasive milling produced bran with higher protein content and total dietary fibre, resulting in superior quality bran, while friction milling led to higher fat. Agonibora bran was found to be superior in terms of nutritional quality. Industrial milling resulted in higher protein content in bran, and Jyothi variety had a better amino acid profile.

Keywords: Grain, Amylose, Rice bran, Nutritional composition, Oryzanol, Amino acids

Introduction

The rice varieties are classified into eight distinct groups based on the total and insoluble amylose contents, viscogram pattern and other physicochemical properties (Bhattacharya et al. 1982). Milling of paddy produces husk, dehusked rice (brown rice), white rice, broken rice and bran. Among the by-products, rice bran has several potential applications.

Rice bran has a highly nutritious chemical composition, containing 12–17% protein, 13–23% fat, 34–54% carbohydrates, 6–14% fibre and 8–18% ash (Saunders 1985). The oil from bran is valued for its bioactive phytochemicals like γ-oryzanol, tocopherols and tocotrienols (Orthoefer 1996). Further, defatted bran is an inexpensive source of protein and suitable for food applications provided some anti-nutritional factors (high ash content and presence of phytate) are removed. However, protein extractability is relatively rather low as it is bound with cell walls (Fabian and Ju 2011). Higher silica content in the bran could also affect the protein extractability, as the crystalline lattice tends to bind some of the nutrients. Currently, rice bran is widely used as animal feed owing to post-milling handling and processing difficulties.

Bran is mainly valued for its protein and fibre in its potential use in food applications. Because 35% of the protein in bran are indigestible cell wall-bound proteins (Maust et al. 1972), it may be desirable to use extracted proteins in specifically targeted applications. The concentration of major nutrients of rice grain decreases from the outermost layer to the centre of the grain, but the contrary was true for starch content (Bhattacharya 2011). Apart from varieties of rice, the bran composition varies considerably due to factors like environmental variability, distribution of chemical composition, anatomy and geometry of grains, resistance of grains to breakage and the milling process (Rosniyana et al. 2007).

Milling is performed either by abrasive or friction mill or in combination to remove the bran. The extent of removal of bran from brown rice is called ‘Degree-of-Milling’ (DOM). According to FAO (1992), DOM has been categorised into four classes such as under-milled (3–4%), medium-milled (5–6%), fully-milled (7–8%) and over-milled (> 8%). DOM significantly influences the bran composition where excess milling leads to breakage of kernels resulting in a higher degree of admixing with starchy endosperm, necessitating prudent milling approach (Sotelo et al. 1990; Amissah et al. 2003; Schramm et al. 2007; Deepa and Singh 2010). These laboratory scale studies were executed at any fixed DOM with a random selection of rice varieties. Few studies (Palipane and Swarnasiri 1985; Rosniyana et al. 2007) have also been performed at industrial scale but on a single rice variety.

A comparative analysis of bran composition obtained from two conventional milling systems at different DOM under laboratory and industrial scale milling would provide a comprehensive understanding of the influence of milling. Hence, the present study is undertaken to evaluate the distribution of bran nutrients in four different rice varieties representing high amylose, intermediate amylose and waxy groups of quality classification of rice, with different DOM using laboratory friction and abrasive mills. The study was also extended to industrial scale milling for a practical assessment of bran composition from these representative varieties.

Materials and methods

Materials

Four rice varieties viz., Jyothi (pigmented), IR64, Taraori Basmati (HBC-19) and Agonibora were selected for the study. Former two varieties of rice were purchased from the Agricultural Produce Market Committee (APMC), Mysuru, (India) while Taraori Basmati (HBC-19) and Agonibora varieties were purchased from M/s G.D. Overseas, Karnal and Assam Agricultural Research Station, Titabar, (India), respectively. The paddy samples were cleaned and stored at 4 °C until use. Heat stable α-amylase from Bacillus licheniformis, amyloglucosidase from Aspergillus niger, pepsin from porcine gastric mucosa, pancreatin from porcine pancreas and standards used in the amino acid analysis were purchased from M/s Sigma-Aldrich Chemicals Co., St. Louis, USA. Potato amylose was purchased from M/s ICN Biomedicals Inc., Cleveland, USA. All other chemicals used were of analytical grade obtained from M/s Sisco Research Laboratories Pvt. Ltd., Mumbai, India.

Methods

Laboratory milling

The stored paddy varieties were brought to room temperature (RT) of 25 ± 2 °C and equilibrated for 24 h before processing. Dehusking of paddy was performed using a laboratory rubber roller sheller (M/s Satake Corporation, Hiroshima, Japan) and similarly, the brown rice obtained was also stored and used. The brown rice was subjected to 5, 7 and 10% DOM by varying the duration of milling in laboratory friction (McGill No. 2, M/s H.T. McGill, Texas, USA) and abrasive (M/s Satake Corporation, Hiroshima, Japan) mills. The moisture content of the brown rice of all the varieties was 12 ± 1% before milling. Preliminary experimental runs were carried out to determine the approximate duration required to achieve the desired DOM. Friction milling was performed by charging 150 g of brown rice in the milling chamber, and the necessary pressure was applied by placing a weight (456 g) on the lever arm at 23 cm from the centre of the shaft. The machine was driven by a direct driven motor at 1450 RPM. Abrasive milling was performed by normal (straight) and successive methods, by charging 200 g of brown rice in the milling chamber, and the rice was milled against a rotating emery disc at 1430 RPM. The milled fraction obtained was passed through 22 mesh (B.S.S) sieve (710 μm) to separate bran from brokens. The DOM was calculated using Eq. (1). The bran (throughs) obtained after sieving was stored at − 2 to 2 °C until further use.

| 1 |

The milled rice obtained was ground into flour using a laboratory mill (M/s IKA-Werke GmbH & Co., Staufen, Germany) for analysis.

Industrial milling

The selected paddy varieties (~ 400 kg of each of Jyothi, IR64 and Basmati, and ~ 150 kg of Agonibora) were thoroughly cleaned and dehusked with a rubber roll sheller (M/s Sree Maradi Ranganatha rice mill, Mysuru, India). The brown rice obtained was milled to fully milled condition sequentially first in an abrasive mill followed by a friction mill. Under the conditions employed, the DOM was found to be between 6 and 8% for these varieties.

Moisture content

The moisture content of brown rice, milled rice flour and rice bran were determined by drying the samples at 130 °C for 2 h (Method 930.15; AOAC 2016). The nutrient contents were expressed on moisture free basis.

Nutritional composition of brown rice, milled rice and bran

The fat was extracted with hexane, using a Soxhlet apparatus and determined gravimetrically (Method 2003.06; AOAC 2016). The protein content was determined by the micro-Kjeldahl method (Method 2001.11; AOAC 2016) by estimating the total nitrogen content of the defatted samples and multiplying it using a factor of 5.95 (N × 5.95). The ash content was determined by incinerating defatted bran at 550 °C (Method 942.05; AOAC 2016). The total carbohydrate in defatted bran was estimated by the difference using the Eq. (2).

| 2 |

Amylose equivalent

The total and soluble amylose contents in rice (measured as amylose equivalent) were determined using the method described by Bhattacharya (2011). The milled rice (10% DOM), ground to pass through 60 mesh (B.S.S) sieve (250 μm), was defatted with 85% methanol.

Starch content

The starch estimation was carried out by hydrolysing the bran according to the method described by Holm et al. (1986) and subsequently estimating the glucose concentration in the hydrolysed bran using the dinitrosalicylic acid (DNS) method (Miller 1959). The defatted rice bran (100 mg) was dispersed in 15 ml of distilled water, treated with heat stable α-amylase (100 μl; 1870 units), incubated in a boiling water bath for 10 min, and cooled to RT. The starch was further hydrolysed by adding amyloglucosidase (45 μl; 14 units in 15 ml acetate buffer, pH 4.8) and incubating in a shaking water bath at 60 °C for 90 min followed by cooling to RT and centrifuging (M/s Thermo Scientific, Osterode am Harz, Germany) at 7435×g for 15 min. The supernatant was made up to 100 ml, and the glucose concentration in the supernatant was determined using the DNS reagent. The starch content was obtained by multiplying the glucose content by a factor of 0.9.

Dietary fibre content

Dietary fibre (insoluble and soluble) content was estimated using the method described by Asp et al. (1983) by a series of enzymatic digestion of defatted bran with heat stable α-amylase in boiling water, followed by pepsin and pancreatin treatments. The digested sample was vacuum filtered through a Gooch crucible. The insoluble fibre was retained in the crucible while the filtrate containing soluble fibre was collected separately. The soluble fibre in the filtrate was precipitated by the addition of four volumes of warm ethyl alcohol and recovered by vacuum filtration. Both soluble and insoluble fibre fractions obtained as retentate were separately dried at 105 °C and weighed. The protein and ash content in the dried fractions were estimated as described earlier. Blank assays were run in parallel. The insoluble and soluble dietary fibre contents were determined using the Eq. (3).

| 3 |

The total dietary fibre content was the sum of insoluble and soluble fibre fractions.

When the sample size was smaller, the total dietary fibre content was calculated using the Eq. (4).

| 4 |

Amino acid composition

The amino acid composition of the industrially milled bran was determined by hydrolysing the samples, equivalent to 5 mg protein, using constant boiling 6 M hydrochloric acid containing 1% phenol under vacuum at 110 °C for 24 h (Bidlingmeyer et al. 1984). The amino acids were converted to phenylthiocarbamyl (PTC) derivatives and analysed by reverse-phase ultra-fast liquid chromatography (M/s Shimadzu Corporation., Kyoto, Japan).

Oryzanol estimation

Oryzanol content in the oil extracted from industrially milled rice bran samples was determined by a spectrophotometric method at 315 nm wavelength using petroleum ether (60–80 °C) as solvent (Seetharamaiah and Prabhakar 1986).

Statistical analysis

The experiments were done in triplicates, and the average values were reported. The results obtained with each variety were analysed using one-way Analysis of Variance (ANOVA), and means of each pair were compared at 5% significance level by Tukey–Kramer multiple comparison test (SPSS Statistics software, Version 25, 2017, New York, USA). Besides, the effects of experimental factors such as variety and DOM, and their interaction on the nutritional composition were analysed using two-way ANOVA.

Results and discussion

Amylose content of rice varieties

Amylose content is the key determinant of the cooking and processing qualities of rice (Bhattacharya 2011). In the present study, the rice varieties were selected to represent the quality types based on the earlier reports (Guha and Ali 2002; Deepa et al. 2008; Srivastava and Jaiswal 2013). But amylose content of rice could vary depending upon the geographical location and seasonal changes.

Jyothi contained the highest total amylose of 29.7% followed by IR64, Basmati and Agonibora containing 29.3, 26.1 and 3.6%, respectively. The insoluble amylose content was also of the same trend (14.2, 9.3, 9.1 and 2.6%, respectively) among the varieties. There were some minor variations in the total amylose content between the present and the earlier studies (Guha and Ali 2002; Deepa et al. 2008; Srivastava and Jaiswal 2013), yet their basic classification such as Jyothi and IR64 being high amylose varieties, Basmati as an intermediate variety and Agonibora as a waxy variety.

Milling and nutritional composition of bran

Industrial milling is a combination of both abrasive and friction mill where the brown rice kernels are passed through a series of stages. Conventionally applying either friction or abrasive process to remove the bran part of the grain, may simply tear the grain leading to removal of only external bran layers and very little subaleurone layer in the former process (Juliano et al. 1973; Shams-Ud-Din and Bhattacharya 1978) or removal of both outer and inner layer including subaleurone layers in the latter process (Resurreccion et al. 1979; www.knowledgebank.irri.org). Industrial milling is designed to reduce mechanical stresses and heat buildup in the grain, to minimise grain breakage and produce more uniformly polished grain. In any case, the milling process impacts the extent of bran removal and consequently its nutritional composition.

Nutritional composition of bran from laboratory milling

Nutritional composition of bran obtained from laboratory friction and abrasive milling are shown in Table 1. Two-way ANOVA of the nutritional composition of bran obtained from different rice varieties and DOM with friction and abrasive milling are shown in Table 2.

Table 1.

Influence of type of milling on protein, carbohydrate, starch, dietary fibre and ash content of bran from different rice varieties

| Rice variety | DOM (%) | Protein content (%) | Total carbohydrate content (%) | Starch content (%) | Total dietary fibre content (%) | Ash content (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Friction mill | Abrasive mill | Friction mill | Abrasive mill | Friction mill | Abrasive mill | Friction mill | Abrasive mill | Friction mill | Abrasive mill | ||

| Jyothi | 5 | 15.20 ± 0.07b | 15.75 ± 0.00a | 73.06 ± 0.01a | 70.06 ± 0.32b | 32.78 ± 0.73a | 20.01 ± 0.15a | 40.28 ± 0.72c | 50.05 ± 0.48c | 11.74 ± 0.06c | 14.19 ± 0.32b |

| 7 | 13.64 ± 0.00a | 16.90 ± 0.00b | 75.09 ± 0.08b | 69.18 ± 0.14a | 39.82 ± 0.72b | 25.48 ± 0.41b | 35.27 ± 0.65b | 43.70 ± 0.27b | 11.26 ± 0.08b | 13.92 ± 0.14b | |

| 10 | 13.72 ± 0.00a | 17.88 ± 0.00c | 76.12 ± 0.16c | 69.38 ± 0.07a | 54.59 ± 0.23c | 36.21 ± 0.20c | 21.53 ± 0.08a | 33.17 ± 0.13a | 10.16 ± 0.16a | 12.74 ± 0.07a | |

| IR64 | 5 | 16.68 ± 0.00c | 17.64 ± 0.06a | 72.65 ± 0.20a | 68.50 ± 0.07a | 36.37 ± 2.31a | 25.94 ± 0.23a | 36.28 ± 2.11c | 42.56 ± 0.30c | 10.67 ± 0.20b | 13.87 ± 0.13c |

| 7 | 15.75 ± 0.07b | 17.45 ± 0.06a | 73.57 ± 0.75a | 70.78 ± 0.05b | 42.36 ± 3.86b | 36.34 ± 0.05b | 31.21 ± 4.61b | 34.44 ± 0.10b | 10.68 ± 0.68b | 11.77 ± 0.11b | |

| 10 | 14.36 ± 0.07a | 17.32 ± 0.13a | 77.13 ± 0.17b | 73.04 ± 0.03c | 56.83 ± 3.96c | 49.00 ± 0.97c | 20.30 ± 3.79a | 24.04 ± 1.00a | 8.51 ± 0.10a | 9.63 ± 0.10a | |

| Basmati | 5 | 16.10 ± 0.07c | 18.79 ± 0.00a | 73.57 ± 0.03a | 67.79 ± 0.16a | 34.42 ± 3.55a | 16.30 ± 2.30a | 39.15 ± 3.52c | 49.19 ± 0.16c | 10.33 ± 0.04b | 13.42 ± 0.16c |

| 7 | 15.96 ± 0.00b | 20.01 ± 0.06b | 73.90 ± 0.09a | 67.65 ± 0.06a | 36.57 ± 1.02b | 25.79 ± 1.02b | 37.33 ± 1.11b | 41.86 ± 1.09b | 10.13 ± 0.09b | 12.33 ± 0.00b | |

| 10 | 15.42 ± 0.00a | 20.74 ± 0.13c | 76.91 ± 0.35b | 68.87 ± 0.00b | 57.00 ± 1.06c | 43.50 ± 1.18c | 19.91 ± 1.41a | 25.37 ± 1.18a | 7.67 ± 0.35a | 10.39 ± 0.12a | |

| Agonibora | 5 | 18.45 ± 0.15a | 20.09 ± 0.00a | 70.23 ± 0.14a | 66.57 ± 0.31a | 23.21 ± 0.50a | 19.46 ± 0.91a | 47.02 ± 0.64c | 47.11 ± 0.60c | 11.32 ± 0.29b | 13.34 ± 0.31c |

| 7 | 18.37 ± 0.00a | 20.38 ± 0.00b | 71.07 ± 0.61a | 67.37 ± 0.25b | 29.35 ± 1.71b | 26.00 ± 0.05b | 41.72 ± 2.31b | 41.37 ± 0.30b | 10.56 ± 0.61b | 12.25 ± 0.25b | |

| 10 | 16.77 ± 0.06b | 20.90 ± 0.06c | 74.24 ± 0.29b | 68.83 ± 0.26c | 36.66 ± 1.37c | 38.96 ± 1.02c | 37.58 ± 1.09a | 29.87 ± 1.27a | 9.00 ± 0.22a | 10.21 ± 0.26a | |

Values are expressed as mean ± standard deviation

Mean values, denoted by different superscripts along a column within the same variety are significantly different at p ≤ 0.05

Table 2.

Two-way ANOVA (F values) of the nutritional composition of rice bran

| Source | Fat | Protein | Total carbohydrate | Starch | Total dietary fibre | Ash |

|---|---|---|---|---|---|---|

| Friction mill | ||||||

| Variety | ND | 5119.672** | 171.169** | 90.718** | 54.425** | 44.985** |

| DOM | ND | 1771.847** | 418.866** | 256.353** | 155.200** | 167.727** |

| Interaction | ND | 193.684** | 10.449** | 5.323** | 5.252** | 3.517* |

| Abrasive mill | ||||||

| Variety | 257.856** | 7056.828** | 575.020** | 210.750** | 228.648** | 184.208** |

| DOM | 139.901** | 988.309** | 318.309** | 1570.522** | 2214.851** | 741.955** |

| Interaction | 8.258** | 248.886** | 113.753** | 20.312** | 19.420** | 28.590** |

ND not determined

**Significant at 1% (p < 0.01); *Significant at 5% (p < 0.05)

Fat content of bran

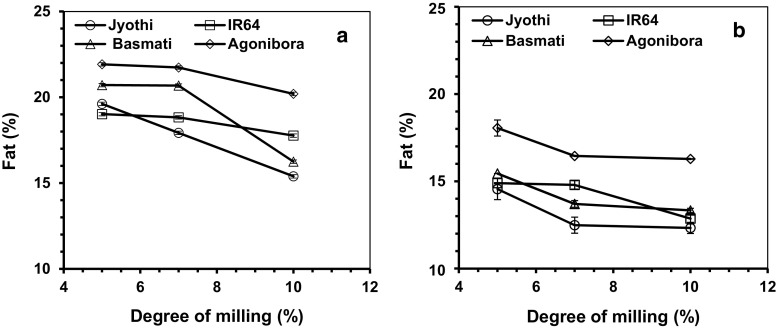

An interesting inverse relationship was observed between the amylose content of the rice and the bran fat content. From the three levels of DOM, the general trend showed that the Agonibora contained the highest fat content followed by Basmati or IR64 and Jyothi with both types of milling (Fig. 1). Choudhury and Juliano (1980) reported a similar trend in bran fat content with three rice varieties varying in amylose content.

Fig. 1.

Influence of milling on the fat content of bran from different rice varieties a friction mill, b abrasive mill

The fat content of the rice bran varied from 15.4 to 21.9% with friction milling (Fig. 1a) while it ranged between 12.3 and 18.1% with abrasive milling (Fig. 1b) over the range of DOM studied. The higher fat content in friction mill-bran could be attributed to the fact that friction milling is more efficient in removing the bran layers especially the fat rich aleurone layer (Rosniyana et al. 2007). Histological studies evidenced that most of the oil in rice is present as distinct globules in the aleurone layer (Bhattacharya 2011). The fat content decreased with increase in DOM in both friction and abrasive milling (Fig. 1) due to the increased influx of starch from endosperm at higher DOM. With a large increase in DOM from 0.3 to 9.0%, fat content in rice kernel reduced to the extent of ~ 84% by friction milling (Bhattacharya 2011).

Protein content of bran

The protein is concentrated in the embryo, aleurone and subaleurone layers of endosperm than the inner endosperm (Ellis et al. 1986). The bran constitutes more of the outer layers including aleurone layer, while the polish fraction contains relatively more of subaleurone layers. However, the bran produced in the mill would always be a composite mixture of outer and part of the endosperm layers. The distribution of protein across the layers seemed to be influenced by high or low protein rice variety.

The successive abrasive milling of selected rice varieties showed that the polish fraction (5–11% DOM) was the protein-rich fraction (Table 3). Resurreccion et al. (1979) classified the milling fractions as bran (0–6%), subaleurone-polish (6–12%) and subaleurone (12–20%) layers. The deep successive milling of rice grains showed that the highest protein fraction to be the subaleurone layer in high-protein rice in contrast to the bran layer in low-protein rice. In the present study, the protein content of rice varieties ranged between 8.0 and 9.6% (Table 3), which is less than the notional dividing limit (10%) of high- and low-protein rice (Cagampang et al. 1966). However, successive milling revealed that the protein distribution in these varieties was more concentrated in the subaleurone layer as compared to the aleurone layer reflecting in higher protein content in polish fraction (5–11% DOM) than the bran layer (0–5% DOM).

Table 3.

Protein content of various milled fractions obtained during successive abrasive milling of different rice varieties

| Rice fractions | Jyothi | IR64 | Basmati | Agonibora | ||||

|---|---|---|---|---|---|---|---|---|

| DOM (%) | Protein content (%) | DOM (%) | Protein content (%) | DOM (%) | Protein content (%) | DOM (%) | Protein content (%) | |

| Brown rice | 0 | 9.46 ± 0.00 | 0 | 8.03 ± 0.06 | 0 | 9.52 ± 0.00 | 0 | 9.62 ± 0.07 |

| Bran | 0–5.7 | 16.54 ± 0.00 | 0–5.7 | 16.49 ± 0.00 | 0–5.3 | 19.20 ± 0.06 | 0–5.6 | 19.26 ± 0.00 |

| Endosperm | ||||||||

| Sub-aleurone | ||||||||

| 5.7–7.8 | 19.37 ± 0.06 | 5.7–7.6 | 16.62 ± 0.06 | 5.3–7.1 | 22.00 ± 0.06 | 5.6–7.3 | 22.43 ± 0.07 | |

| 7.8–10.4 | 18.38 ± 0.06 | 7.6–10.2 | 16.29 ± 0.06 | 7.1–9.8 | 21.96 ± 0.00 | 7.3–10.6 | 22.03 ± 0.07 | |

| 10.4–13.2 | 17.79 ± 0.06 | 10.2–12.0 | 16.04 ± 0.00 | 9.8–11.4 | 19.77 ± 0.00 | 10.6–12.8 | 20.30 ± 0.07 | |

| 13.2–22.4 | 13.90 ± 0.00 | 12.0–17.3 | 13.01 ± 0.00 | 11.4–17.4 | 18.62 ± 0.13 | 12.8–21.3 | 13.79 ± 0.07 | |

| Starchy endosperm | ||||||||

| 22.4–25.4 | 12.34 ± 0.06 | 17.3–24.0 | 8.77 ± 0.06 | 17.4–24.1 | 14.25 ± 0.06 | 21.3–26.0 | 10.22 ± 0.07 | |

| 25.4–100 | 7.80 ± 0.13 | 24.0–100 | 5.79 ± 0.00 | 24.1–100 | 6.81 ± 0.06 | 26.0–100 | 6.87 ± 0.00 | |

Values are expressed as mean ± standard deviation

Normal milling of rice varieties showed that the highest protein content of bran was observed in Agonibora followed by Basmati, IR64 and Jyothi with both types of milling at different DOM (Table 1). These results exhibited a similar relationship observed with fat and amylose contents. The protein content of abrasive mill-bran ranged from 15.8 to 20.9%, which was higher (4–35%) compared to friction mill-bran that ranged between 13.6 and 18.5%. The difference could arise due to the milling principle involved in the mills. In an earlier comparative study (Ellis et al. 1986) the microscopic observation of transverse sections of milled rice samples (10% DOM) apparently showed that both types of milling removed the same amount of bran layers. However, Kjeldahl estimation revealed that friction milled rice contained relatively higher (1–5%) protein content compared to abrasive milled rice, with an expected opposite trend in bran. The above analysis affirms that abrasive mill-bran likely to contain a higher amount of protein than the friction mill-bran in rice varieties where protein concentration is higher in the subaleurone layer.

During abrasive milling, the bran protein content generally increased with increasing DOM except in the case of IR64 wherein there was no significant difference (Table 1). Abrasive milling removed the grain layers from the outer as well as inner layers including subaleurone layer, even at a lower DOM (< 11%). Thus, the observed pattern of protein content in the bran at different DOM could be attributed to the protein distribution in the grain as well as the type of milling.

In friction milling, the bran-protein content decreased with increase in DOM, as it usually removes the external bran layers and less of the subaleurone layer. Further, the reduced protein content could be related to the excess endosperm breakage during milling. The small brokens varied from 1.8 to 3.6% at 5% DOM and 8.6 to 13.8% at 10% DOM leading to progressive dilution of bran fraction with starch. Among the varieties, the reduction in bran protein content between 5 and 10% DOM (Table 1) was the least for Basmati (4%) and the highest for IR64 (14%). These results revealed that there could be a significant difference in the grain structure among the varieties and only an in-depth histological study may help to throw more light on this aspect.

Total carbohydrate and starch content of bran

The major carbohydrates in the bran are starch, celluloses and hemicelluloses (Saunders 1985). The carbohydrate content of the bran ranged from 70.2 to 77.1% with friction milling and 66.6–73.0% with abrasive milling in the range of study (Table 1). Ideally, friction mill-bran shall contain lower levels of carbohydrate owing to the milling principle involved. However, friction milling exerts relatively higher pressure and generate heat leading to a higher starch influx in the bran due to endosperm breakage, which is reflected in the carbohydrate and starch contents. Expectedly, an increase in the carbohydrate content was observed with increase in DOM. Among the varieties, bran from Agonibora had the least carbohydrate content (66.6–74.2%).

Starch is the major constituent of the rice endosperm, but lacking in the outer layers of rice. However, with the increase in DOM, starch appears in the bran because the endosperm also gets progressively removed and so also due to the increase in breakage (Saunders 1985). But it reduces the nutritional value of the bran. The total starch content in friction mill-bran varied between 23.2 and 57.0%, which was significantly higher than the abrasive mill-bran that ranged between 16.3 and 49.0% (Table 1). As described earlier, this increase can be attributed to higher kernel breakage during friction milling. Understandably, rising trend in starch content was observed with increase in DOM for both types of milling.

Among the varieties, Agonibora bran contained the least starch content (23.2–36.7%) owing to its superior milling quality while the other three varieties exhibited a similar range of values (32.8–57.0%) with friction milling. However, in the case of abrasive milling, Jyothi and Basmati (16.3–43.5%) showed a similar extent of starch content as that of Agonibora (19.4–39.0%) while IR64 exhibited the highest starch content (25.9–49.0%). The results revealed that Agonibora had relatively good resistance to any milling.

Dietary fibre content of bran

The majority of the researchers have looked at crude fibre, which is a measure of cellulose and lignin (Cummings 1973) while dietary fibre is the real measure of nutritional benefits. Dietary fibre comprises polysaccharides, oligosaccharides, lignin and associated plant substances (Elleuch et al. 2011). These are classified as soluble and insoluble, based on their water solubility. The total dietary fibre content of abrasive mill-bran ranged from 24.0 to 50.1%, which is much higher than the friction mill-bran that ranged between 19.9 and 40.3% at different DOM among Jyothi, IR64 and Basmati (Table 1). The higher fibre content in abrasive mill-bran can be attributed to the relatively lesser endosperm breakage and consequently lower contamination with starch. The dietary fibre content of bran from both types of milling showed a decreasing trend with the increase in DOM (Table 1) affirming the fact that fibre is higher in the outer (bran) layers of rice. Interestingly, the bran of pigmented variety, Jyothi contained 2–35% higher total dietary fibre content compared to non-pigmented varieties, Basmati and IR64 at all the levels of DOM with both types of milling. Pigmented rice varieties not only contained polyphenolic pigments but also contained higher amounts of dietary fibre (Deepa et al. 2008). In the case of Agonibora, the total dietary fibre content was similar with both types of milling at all levels of DOM (Table 1), once again indicating its superior milling quality.

The insoluble dietary fibre content has been reported to be several folds higher over soluble dietary fibre content in industrial defatted rice bran (Wan et al. 2014). In the present study, the insoluble dietary fibre content was nearly five–seven folds higher than the soluble dietary fibre content at 10% DOM in abrasive mill-bran (Table 4). Insoluble fibre acts as a laxative, increasing the faecal bulk and decreases the intestinal transit time (Elleuch et al. 2011). Soluble fibre has beneficial functional properties that include hypocholesterolemic, antioxidant, immune-modulation and antitumor activities (Wan et al. 2014). The waxy variety (Agonibora) contained higher soluble dietary fibre content (4.3%) closely followed by Jyothi (4.2%). Among the varieties, bran from pigmented variety Jyothi was rich in both soluble and insoluble dietary fibre.

Table 4.

Components of insoluble and soluble dietary fibre of bran from different rice varieties1

| Rice variety | Insoluble dietary fibre | Soluble dietary fibre | Total dietary fibre (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Residue (g/g-sample) | Protein (%) | Ash (%) | Fibre (%) | Residue (g/g-sample) | Protein (%) | Ash (%) | Fibre (%) | ||

| Jyothi | 0.3862 ± 0.01 | 31.30 ± 0.00 | 1.09 ± 0.07 | 30.26 ± 0.72d | 0.1224 ± 0.00 | 0.49 ± 0.00 | 70.59 ± 0.17 | 4.15 ± 0.50a | 34.41 ± 1.21 |

| IR64 | 0.2254 ± 0.01 | 16.62 ± 0.00 | 0.20 ± 0.03 | 21.87 ± 0.75a | 0.1072 ± 0.01 | 5.36 ± 0.00 | 66.88 ± 0.30 | 3.57 ± 0.93a | 25.44 ± 1.69 |

| Basmati | 0.2561 ± 0.01 | 16.30 ± 0.00 | 0.39 ± 0.01 | 24.83 ± 1.22c | 0.1147 ± 0.01 | 6.50 ± 0.00 | 69.22 ± 0.03 | 3.35 ± 0.82a | 28.17 ± 2.05 |

| Agonibora | 0.2446 ± 0.00 | 17.22 ± 0.11 | 0.37 ± 0.02 | 23.42 ± 0.52b,a,c | 0.1211 ± 0.00 | 6.14 ± 0.25 | 64.06 ± 0.05 | 4.25 ± 0.47a | 27.67 ± 0.99 |

1Bran from abrasive milling (10% DOM)

Mean values, denoted by different superscripts along a column are significantly different at p ≤ 0.05

Ash content of bran

The ash content of bran ranged from 7.7 to 11.7% with friction milling and at a slightly higher range, between 9.6 and 14.2% with abrasive milling in the range of DOM studied (Table 1). Ideally, friction mill-bran shall contain higher levels of ash/minerals as the bran layers are gradually and progressively removed. However, the ash content was lower which could be attributed to the higher amount of starch influx in friction mill-bran. The decreasing trend with increasing DOM can be correlated with increasing starch content in the bran. Studies have shown that the outer layers (bran) of the rice grain have the highest concentration of ash content and it decreases towards the centre of the grain (Resurreccion et al. 1979). The bran from the pigmented rice (Jyothi) contained marginally higher ash content (10.2–14.2%) while all the other three varieties showed a similar range (7.7–13.9%) with both types of milling. A previous study reported that the most minerals are abundant in the pigmented varieties (Deepa et al. 2008).

The two-way ANOVA results (Table 2) indicated that the effects of variety, DOM and their interaction parameters on the nutritional composition of bran were significant (p < 0.01). However, interaction parameter between variety and DOM on the ash content of friction milled bran was found to be significant, only at p < 0.05.

Nutritional composition of bran from industrial milling

Nutritional composition and amino acid profile of bran from different rice varieties obtained from industrial milling are shown in Table 5. Industrial milling was included in the study to understand the impact of composite (abrasive-friction) milling on bran quality at fully milled condition (~ 7% DOM).

Table 5.

Nutritional composition and amino acid profile of bran from different rice varieties obtained from industrial milling1

| Nutrients | Jyothi (%) | IR64 (%) | Basmati (%) | Agonibora (%) |

|---|---|---|---|---|

| Fat | 20.54 ± 0.93a | 20.63 ± 1.71a | 19.28 ± 1.15a | 20.63 ± 0.81a |

| Oryzanol2 | 1.29 ± 0.01a | 1.57 ± 0.02c | 1.81 ± 0.02d | 1.54 ± 0.01b,c |

| Protein | 16.64 ± 0.07a | 17.11 ± 0.24b | 17.64 ± 0.03c | 19.64 ± 0.03d |

| Amino acids | ||||

| Essential amino acids | ||||

| His | 2.16 ± 0.13 | 2.92 ± 0.06 | 2.74 ± 0.01 | 2.72 ± 0.09 |

| Ile3 | 4.54 ± 0.06 | 4.04 ± 0.12 | 4.11 ± 0.02 | 3.99 ± 0.25 |

| Leu3 | 9.10 ± 0.18 | 8.22 ± 0.24 | 8.43 ± 0.02 | 8.60 ± 0.15 |

| Lys | 4.56 ± 0.04 | 4.73 ± 0.07 | 4.34 ± 0.04 | 4.42 ± 0.05 |

| Met4 | 1.92 ± 0.01 | 1.87 ± 0.02 | 2.01 ± 0.00 | 1.93 ± 0.01 |

| Phe5 | 5.42 ± 0.05 | 5.15 ± 0.05 | 5.10 ± 0.03 | 5.51 ± 0.06 |

| Thr | 4.30 ± 0.02 | 4.06 ± 0.33 | 3.87 ± 0.23 | 3.52 ± 0.48 |

| Val3 | 7.17 ± 0.00 | 6.64 ± 0.02 | 6.19 ± 0.49 | 5.99 ± 0.15 |

| Non-essential amino acids | ||||

| Ala | 7.75 ± 0.03 | 7.82 ± 0.42 | 7.48 ± 0.20 | 7.28 ± 0.04 |

| Arg | 8.69 ± 0.06 | 7.90 ± 0.16 | 8.12 ± 0.30 | 7.48 ± 0.69 |

| Asp | 8.51 ± 0.04 | 9.27 ± 0.43 | 8.89 ± 0.05 | 8.86 ± 0.08 |

| Cys4 | 1.74 ± 0.00 | 1.74 ± 0.07 | 1.70 ± 0.00 | 1.62 ± 0.00 |

| Glu | 15.56 ± 0.04 | 15.21 ± 0.72 | 15.93 ± 0.02 | 16.21 ± 0.38 |

| Gly | 6.12 ± 0.04 | 6.74 ± 0.26 | 6.67 ± 0.20 | 6.59 ± 0.41 |

| Pro | 5.24 ± 0.13 | 6.35 ± 1.26 | 6.90 ± 0.22 | 7.55 ± 0.10 |

| Ser | 4.92 ± 0.06 | 4.95 ± 0.23 | 4.93 ± 0.15 | 5.07 ± 0.28 |

| Tyr5 | 2.29 ± 0.10 | 2.38 ± 0.02 | 2.59 ± 0.01 | 2.67 ± 0.07 |

| EAA | 39.2 | 37.6 | 36.8 | 36.7 |

| BCAA | 20.8 | 18.9 | 18.7 | 18.6 |

| SAA | 3.7 | 3.6 | 3.7 | 3.6 |

| AAA | 7.7 | 7.5 | 7.7 | 8.2 |

1Milled at ~ 7% DOM; 2Oryzanol content in oil

EAA essential amino acids, 3BCAA branched chain amino acids, 4SAA sulfur containing amino acids, 5AAA aromatic amino acids

Values are expressed as mean ± standard deviation

Mean values, denoted by different superscripts along a row are significantly different at p ≤ 0.05

The fat content in the industrial mill-bran ranged from 19.3 to 20.6% for the selected varieties, and the values were even higher than the lab-scale friction mill-bran (Fig. 1). Higher fat content indicated that industrial milling removed the fat rich aleurone layer more efficiently compared to lab-scale milling. Agonibora bran contained relatively higher fat content. However, significant differences were not observed among the varieties.

Among the industrial mill-bran, Agonibora bran contained the highest protein content followed by Basmati, IR64 and Jyothi in agreement with the pattern of protein-amylose inverse relationship observed during lab-scale milling. The protein content in the industrial bran of different varieties ranged from 17.1 to 19.6% (Table 5), which was similar to the values obtained during lab-scale abrasive milling except for Basmati wherein the protein content was slightly lower. The combination of abrasive and friction milling intended for greater head rice yield (HRY) in the industrial milling was also found to be efficient in removing aleurone and subaleurone layers leading to higher fat and protein contents in the bran.

Rice bran is the most abundant source of oryzanols those are associated with many physiological functions and health benefits (Orthoefer 1996). The oryzanol content ranged between 1.3 and 1.8% in the extracted oil from industrial mill-bran (Table 5). Among the varieties, the pigmented variety had least oryzanol content in agreement with a related study (Pradeep et al. 2014).

The amino acid profile of industrial mill-bran of the representative varieties is presented in Table 5. Rice bran contains the highest amount of lysine (essential for protein synthesis) which is generally deficient among all the cereal brans and mainly possesses hypoallergenic protein fractions with several beneficial nutritional properties (Fabian and Ju 2011). Stabilised rice bran can be directly incorporated into foods such as beverages, baked products and cereals snacks. The sum of essential amino acids (EAA) was marginally higher in Jyothi (39.2%) and IR64 (37.6%) while Basmati and Agonibora had slightly lower but comparable within both the varieties (~ 36.7%). One of the important class of EAA are the branched-chain amino acids (BCAA) which are considered to be essential for protein metabolism and responsible for increasing the rate of protein synthesis. Jyothi variety contained marginally higher BCAA content (21%) while other varieties had a similar level (19%). The EAA and BCAA contents in the selected varieties were comparable to the values reported for the industrial rice bran (Saunders 1985). Further, the other essential amino acids such as lysine, sulphur amino acid content (Met + Cys) and aromatic amino acid (Tyr + Phe) were similar among all the varieties. The amino acid profile of the rice bran samples of the present study could meet the amino acid requirements recommended for 6 months to 3-year-old children (FAO 2013) except the limiting amino acid lysine (5.7%). The amino acid profile of the high amylose pigmented variety, i.e., Jyothi with higher EAA, BCAA and SAA contents, was better than the other three varieties.

Conclusion

The present study indicated that nutritional composition of rice bran is dependent on rice variety and the milling process. Abrasive milling produced bran with higher protein, dietary fibre and minerals content while friction milling produced bran with higher fat content. A general trend of decrease in the nutritional content of bran with the increase in the DOM was observed owing to the influx of starch from the endosperm. Agonibora was found to be superior for bran nutrient with least starch content thus indicating its superior milling quality. The fat and protein content in bran from the selected varieties was according to quality classification such as waxy, intermediate and high amylose. Lysine was only the limiting amino acid in the bran. The industrial milling of rice varieties, as practised for higher HRY, also complemented well for obtaining better quality bran. Variety of rice had a greater impact on the nutrient-rich rice bran and its further use in food applications.

Acknowledgements

Authors thank K. Govindaraju, for his help in amino acid analysis. CK acknowledges Indian Council of Medical Research, New Delhi, India for the award of the fellowship.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

References

- Amissah JGN, Ellis WO, Oduro I, Manful JT. Nutrient composition of bran from new rice varieties under study in Ghana. Food Control. 2003;14:21–24. doi: 10.1016/S0956-7135(02)00047-6. [DOI] [Google Scholar]

- AOAC . Official methods of analysis of AOAC international. 20. Maryland: Association of Official Analytical Chemists; 2016. [Google Scholar]

- Asp NG, Johansson CG, Hallmer H, Siljestroem M. Rapid enzymatic assay of insoluble and soluble dietary fiber. J Agric Food Chem. 1983;31:476–482. doi: 10.1021/jf00117a003. [DOI] [PubMed] [Google Scholar]

- Bhattacharya KR. Rice quality: a guide to rice properties and analysis. New Delhi: Woodhead Publishing Limited; 2011. [Google Scholar]

- Bhattacharya KR, Sowbhagya CM, Indudhara Swamy YM. Quality profiles of rice: a tentative scheme for classification. J Food Sci. 1982;47:564–569. doi: 10.1111/j.1365-2621.1982.tb10124.x. [DOI] [Google Scholar]

- Bidlingmeyer BA, Cohen SA, Tarvin TL. Rapid analysis of amino acids using pre-column derivatization. J Chromatogr B Biomed Sci Appl. 1984;336:93–104. doi: 10.1016/S0378-4347(00)85133-6. [DOI] [PubMed] [Google Scholar]

- Cagampang GB, Cruz LJ, Espiritu SG, Santiago RG, Juliano BO. Studies on the extraction and composition of rice proteins. Cereal Chem. 1966;43:145–155. [Google Scholar]

- Choudhury NH, Juliano BO. Effect of amylose content on the lipids of mature rice grains. Phytochemistry. 1980;19:1385–1389. doi: 10.1016/0031-9422(80)80179-8. [DOI] [Google Scholar]

- Cummings JH. Dietary fibre. Gut. 1973;14:69–81. doi: 10.1136/gut.14.1.69. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Deepa C, Singh V. Shelling, milling, nutritional and functional properties of selected rice varieties. Oryza. 2010;47:110–117. [Google Scholar]

- Deepa G, Singh V, Naidu KA. Nutrient composition and physicochemical properties of Indian medicinal rice—Njavara. Food Chem. 2008;106:165–171. doi: 10.1016/j.foodchem.2007.05.062. [DOI] [Google Scholar]

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 2011;124:411–421. doi: 10.1016/j.foodchem.2010.06.077. [DOI] [Google Scholar]

- Ellis JR, Villareal CP, Juliano BO. Protein content, distribution and retention during milling of brown rice. Plant Foods Hum Nutr. 1986;36:17–26. doi: 10.1007/BF01091749. [DOI] [Google Scholar]

- Fabian C, Ju YH. A review on rice bran protein: its properties and extraction methods. Crit Rev Food Sci Nutr. 2011;51:816–827. doi: 10.1080/10408398.2010.482678. [DOI] [PubMed] [Google Scholar]

- FAO. Food and Agriculture Organization of the United Nations . The anatomy and physical properties of the rice grain. In: Semple RL, Hicks PA, Lozare JV, Castermans A, editors. Towards integrated commodity and pest management in grain storage. Rome: A REGNET (RAS/86/189) publication in collaboration with NAPHIRE; 1992. [Google Scholar]

- FAO. Food and Agriculture Organization of the United Nations (2013) Dietary protein quality evaluation in human nutrition. In: Report of an FAO expert consultation. FAO Food and Nutrition Paper- 92, Rome [PubMed]

- Guha M, Ali SZ. Molecular degradation of starch during extrusion cooking of rice. Int J Food Prop. 2002;5:509–521. doi: 10.1081/JFP-120015488. [DOI] [Google Scholar]

- Holm J, Bjorck I, Drews A, Asp NG. A rapid method for the analysis of starch. Starch-Starke. 1986;38:224–226. doi: 10.1002/star.19860380704. [DOI] [Google Scholar]

- IRRI. International Rice Research Institute. Philippines. Rice Milling. http://www.knowledgebank.irri.org/ericeproduction/PDF_&_Docs/Teaching_Manual_Rice_Milling.pdf. Accessed 5 Sept 2017

- Juliano BO, Antonio AA, Esmama BV. Effects of protein content on the distribution and properties of rice protein. J Sci Food Agric. 1973;24:295–306. doi: 10.1002/jsfa.2740240306. [DOI] [PubMed] [Google Scholar]

- Maust LE, Scott ML, Pond WG. The metabolizable energy of rice bran, cassava flour, and blackeye cowpeas for growing chickens. Poult Sci. 1972;51:1397–1401. doi: 10.3382/ps.0511397. [DOI] [Google Scholar]

- Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem. 1959;31:426–428. doi: 10.1021/ac60147a030. [DOI] [Google Scholar]

- Orthoefer FT. Rice bran oil. In: Hui YH, editor. Bailey’s industrial oil and fat products. 5. New York: Wiley; 1996. pp. 393–409. [Google Scholar]

- Palipane KB, Swarnasiri CD. Composition of raw and parboiled rice bran from common Sri Lankan varieties and from different types of rice mills. J Agric Food Chem. 1985;33:732–734. doi: 10.1021/jf00064a042. [DOI] [Google Scholar]

- Pradeep PM, Jayadeep A, Guha M, Singh V. Hydrothermal and biotechnological treatments on nutraceutical content and antioxidant activity of rice bran. J Cereal Sci. 2014;60:187–192. doi: 10.1016/j.jcs.2014.01.025. [DOI] [Google Scholar]

- Resurreccion AP, Juliano BO, Tanaka Y. Nutrient content and distribution in milling fractions of rice grain. J Sci Food Agric. 1979;30:475–481. doi: 10.1002/jsfa.2740300506. [DOI] [PubMed] [Google Scholar]

- Rosniyana A, Hashifah MA, Norin SS. The physico-chemical properties and nutritional composition of rice bran produced at different milling degrees of rice. J Trop Agric Food Sci. 2007;35:99–105. [Google Scholar]

- Saunders RM. Rice bran: composition and potential food uses. Food Rev Int. 1985;1:465–495. doi: 10.1080/87559128509540780. [DOI] [Google Scholar]

- Schramm R, Abadie A, Hua N, Xu Z, Lima M. Fractionation of the rice bran layer and quantification of vitamin E, oryzanol, protein, and rice bran saccharide. J Biol Eng. 2007;1:1–9. doi: 10.1186/1754-1611-1-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seetharamaiah GS, Prabhakar JV. Oryzanol content of Indian rice bran oil and its extraction from soap stock. J Food Sci Technol. 1986;23:270–273. [Google Scholar]

- Shams-Ud-Din MD, Bhattacharya KR. On the meaning of the degree of milling of rice. Int J Food Sci Technol. 1978;13:99–105. doi: 10.1111/j.1365-2621.1978.tb00783.x. [DOI] [Google Scholar]

- Sotelo A, Sousa V, Montalvo I, Hernandez M, Hernandez-Aragon L. Chemical composition of different fractions of 12 Mexican varieties of rice obtained during milling. Cereal Chem. 1990;67:209–212. [Google Scholar]

- Srivastava AK, Jaiswal HK. Grain characteristics and cooking quality of indigenous aromatic and non-aromatic genotypes of rice (Oryza sativa L.) Int J Sci Res Rev. 2013;2:36–41. [Google Scholar]

- Wan Y, Espinoza Rodezno LA, Solval KM, Li J, Sathivel S. Optimization of soluble dietary fiber extraction from defatted rice bran using response surface methodology. J Food Process Preserv. 2014;38:441–448. doi: 10.1111/j.1745-4549.2012.00792.x. [DOI] [Google Scholar]