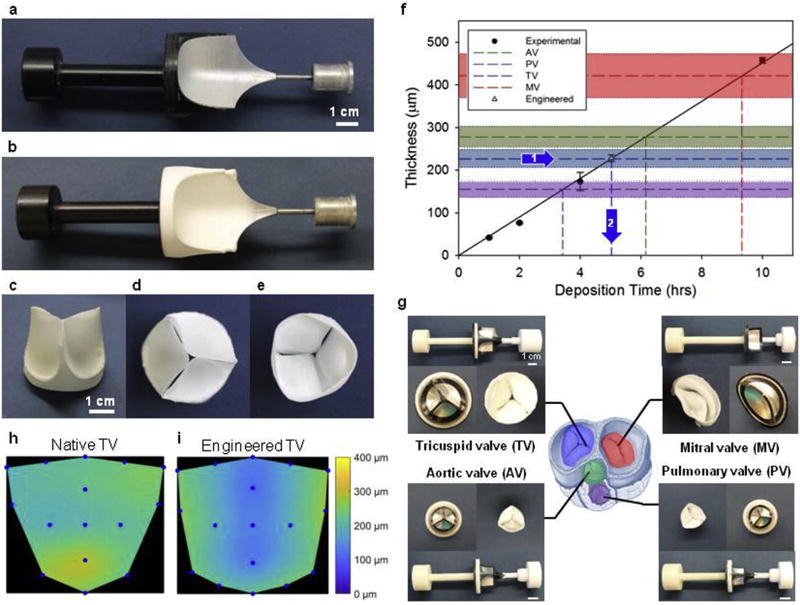

Fig. 1. Double component fiber deposition (DCD) process control of engineered heart valve morphology.

a) Double component mandrel full assembly before fiber deposition. Mandrel component 1: non-conductive shield of acrylonitrile butadiene styrene (in black). Component 2: main collecting target of aluminum alloy. b) Double component mandrel after polymer fiber deposition (Supplemental Video 1). c) Tri-leaflet valve removed from the mandrel and trimmed, showing leaflet coaptation at rest. d) View from the ventricular side and e) view from the atrial side of the tri-leaflet valve. f) Process scalability in terms of construct thickness was verified by monitoring the leaflet thickness vs. deposition time. A specific thickness of interest was then fabricated to approximate a native porcine tricuspid valve (average thickness 227 µm) from a prescribed fabrication time of 5 h and 2 min to obtain comparable thickness in the artificial leaflets. Leaflet fabrication was evaluated in a range of interest for tissue engineering applications: 0–500 µm. Different colors illustrate thickness ranges for porcine valves and fabrication times for the four valve types. g) DCD processing method applied to the four valve types, prototypes shown in the picture demonstrate the capacity of DCD to generate valves with variable macro-scale morphology and size (Fig. 2). Heart sketch adapted from Ref. [72]. In addition to a linear control over the valve thickness, DCD showed relatively homogeneous fiber deposition over the valve surface. h) Native porcine tricuspid valve thickness distribution over the leaflet area. i) Engineered tricuspid valve thickness distribution over the leaflet area after 5 h and 2 min of fabrication (thickness distribution comparison for the four valves provided in Fig. 3). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)