Abstract

Thraustochytrids, rich in docosahexaenoic acid (DHA, C22:6ω3), represent a potential source of dietary fatty acids. Yet, the effect of culture conditions on growth and fatty acid composition vary widely among different thraustochytrid strains. Two different thraustochytrid strains, Schizochytrium sp. PKU#Mn4 and Thraustochytriidae sp. PKU#Mn16 were studied for their growth and DHA production characteristics under various culture conditions. Although they exhibited similar fatty acid profiles, PKU#Mn4 seemed a good candidate for industrial DHA fermentation while PKU#Mn16 displayed growth tolerance to a wide range of process conditions. Relative DHA content of 48.5% and 49.2% (relative to total fatty acids), respectively, were achieved on glycerol under their optimal flask culture conditions. Maximum DHA yield (Yp/x) of 21.0% and 18.9% and productivity of 27.6 mg/L-h and 31.9 mg/L-h were obtained, respectively, in 5-L bioreactor fermentation operated with optimal conditions and dual oxygen control strategy. A 3.4- and 2.8-fold improvement of DHA production (g/L), respectively, was achieved in this study. Overall, our study provides the potential of two thraustochytrid strains and their culture conditions for efficient production of DHA-rich oil.

Keywords: Thraustochytrids, Glycerol, Polyunsaturated fatty acids, Docosahexaenoic acids, Batch culture

1. Introduction

Thraustochytrids are unicellular marine and fungus-like heterotrophic protists within the clade Stramenopiles [1], several strains of which are currently recognized for their high potential to produce polyunsaturated fatty acids (PUFAs) [2], and some of them have also been adopted for commercial production of an omega-3 PUFA – docosahexaenoic acid (C22:6, DHA) [3]. As one of the major structural lipids, DHA can be found as a key constituent of phospholipids, triacylglycerols, and free fatty acids in vertebrate animals [4]. Because of its myriad of benefits to human health [5], DHA has received substantial attention as an important functional food component with high demand on the global market [4,6]. Although fish oil is currently the major source of DHA, its supply is limited by the growing concerns over food security, the health of marine fish stocks, ecological disturbances from industrial fishing, and toxic impurities (PCBs, mercury, and dioxins) of some fish oils [[6], [7], [8]]. Of the single-celled microorganisms, thraustochytrids are advantageous because of their fast heterotrophic growth, high DHA content, ability to produce toxins-free oils, and suitability in commercial-scale fermentation [4,9].

DHA production by thraustochytrids, especially with some genera including Schizochytrium, Thraustochytrium, Aurantiochytrium, Thraustochytriidae, has been greatly improved in the last few decades [[10], [11], [12], [13], [14]]. Several attempts have been made to optimize the growth conditions and media components for improving DHA production in strains that belong to these genera [12,[15], [16], [17], [18], [19], [20], [21]]. These attempts highlight optimization of fermentation conditions as the single most effective means to improve the production of DHA and suggest optimal culture conditions can vary significantly among interspecific and/or intraspecific strains. In addition, growth characteristics and lipid profiles are known to vary widely across different thraustochytrid strains isolated from a biogeographic range of habitats (e.g., mangroves, sub-tropical to temperate region coastal waters etc.) [[22], [23], [24]]. For example, the strains from the genera Aurantiochytrium, Schizochytrium, Thraustochytrium, and Ulkenia showed different glucose utilization abilities and when grown on glycerol they yielded a different fatty acid composition of their lipids [25].

To date, only 13 genera of thraustochytrids are known with about 30 described species [26]; thus, our current understanding of the genetic and metabolic diversity of thraustochytrids is rudimentary. As one of the important marine bioresource, the isolation and characterization of better strains are now of prime importance that will expand our knowledge of their physiological responses to fermentation conditions. Nevertheless, much research is still needed to identify robust and efficient thraustochytrid strains for more economical commercial production of DHA. Because DHA production depends on several factors and their interactions including growth phase, culture mode, process conditions (e.g., pH, temperature, aeration etc.), and nutrition (e.g., carbon, nitrogen, phosphorous, medium supplements, etc.), it is thus essential that for each thraustochytrid strain, culture conditions are screened individually in order to derive the optimal process parameters that maximize their DHA yield.

In the present study, two thraustochytrid strains belonging to genera Schizochytrium and Thraustochytriidae, previously isolated from Shenzhen coastal waters of China [24], with potential for DHA production were investigated in detail. The aim of this study was to elucidate the distinct characteristics of these strains underlying the accumulation of DHA and determine the extrinsic (nutritional and environmental) factors that regulate their DHA yields. We conducted a comprehensive investigation to ascertain how extrinsic factors (carbon and nitrogen sources, the concentration of substrates, salinity, KH2PO4, pH, temperature, agitation speed) influence cell biomass, total fatty acids (TFAs) and its composition, and DHA production. In addition, fed-batch fermentation in a 5-L bioreactor using the optimal culture conditions with dual oxygen supply strategy was conducted to validate the flask culture results.

2. Materials and methods

2.1. Microorganism

Schizochytrium sp. PKU#Mn4 (CGMCC 8091) and Thraustochytriidae sp. PKU#Mn16 (CGMCC 8095) used in this study were previously isolated from mangrove of coastal waters in Shenzhen province [24]. These two strains were maintained at 28 °C on modified Vishniac's (MV) medium (Vishniac, 1956) (glucose·H2O 10 g/L, peptone 1.5 g/L, yeast extract 0.1 g/L, 100% artificial seawater (ASW) and agar 20 g/L) and subcultured every 25 days. The growth and PUFAs production profiles of the two strains prior to optimization are shown in Fig. S1.

2.2. Optimization of culture conditions

Nine growth parameters (carbon and nitrogen sources, temperature, pH, salinity, KH2PO4, agitation speed, carbon and nitrogen concentrations) were tested to evaluate their individual effect on the biomass and DHA production of PKU#Mn4 and PKU#Mn16. The carbon sources included glucose, glycerol, fructose, mannose, glucose-acetic acid, glucose-ethanol, glucose-citric acid, glucose-malic acid, glucose-potassium acetate, glycerol-citric acid, glycerol-malic acid, and glycerol-potassium acetate. The nitrogen sources were sodium glutamate, tryptone, peptone, yeast extract, peptone-yeast extract, ammonium sulfate, ammonium nitrate, and sodium nitrate. The range of best carbon source concentration was 5 g/L to 100 g/L while nitrogen concentrations were varied from 0.25 g/L to 10 g/L. The M4 medium (Jain et al., 2005) was used as the seed medium which contains glucose·H2O 20 g/L, peptone 1.5 g/L, yeast extract 1 g/L, KH2PO4 0.25 g/L and 100% ASW. The fermentation medium employed in the one-factor-at-a-time (OFAT) experiments was designed by varying the M4 medium. The optimal carbon concentration was studied with the best carbon source (glycerol) and the optimal nitrogen concentration with the best carbon source (glycerol) and nitrogen source (yeast extract). The experimental conditions are provided in Table S1.

For all experimental sets, the seed medium was incubated at 28 °C and 150 rpm. The seed inoculum was centrifuged and washed twice with sterile artificial seawater prior to culturing in 100 mL Erlenmeyer flasks containing 50 mL M4 medium for 96 h. All the experiments were conducted in triplicates.

2.3. Flask culture fermentation under optimal conditions

Flask culture batch fermentation of the two strains followed by the OFAT experiments was performed to assess the growth, DHA production, and fatty acid composition of PKU#Mn4 and PKU#Mn16 under their optimal conditions. Flask culture was performed in 500 mL Erlenmeyer flasks containing 300 mL optimized medium for 96 h at 28 °C.

2.4. Bioreactor (5 L) performance

For each of the two strains, fed-batch fermentation was performed in a 5 L fermenter (Model: SY-9000-V9, Shanghai Dong Ming Industrial Co. Ltd.) with working volume of 3 L at 28 °C for 8 days. The fermenter was equipped with DO and pH electrodes, temperature sensor, impeller, and air pump. The agitation speed was altered to maintain a dissolved oxygen (DO) level at 50% of saturation from day 0 to day 2 and then at 10% until the end of fermentation. A 24 h grown seed culture (300 mL) in the M4 medium was transferred to fermentation broth to make the final volume to 3 L. The initial fermentation medium was composed of 0.25 g/L KH2PO4 and 40% artificial seawater. The initial carbon and nitrogen for each strain were similar to their optimal medium composition. On each day 2 and 3, 100 mL feed medium accounting for 1/3 of the optimal glycerol and yeast-extract concentrations for DHA production was added to the 3 L culture broth. The culture broth was harvested at a regular interval of 24 h to determine the dry cell weight (DCW) and lipid production.

2.5. Analytical methods

At the end of each experiment, 15 mL broth was used to determine the DCW by gravimetric method. Thraustochytrid cells were harvested by centrifuging at 12,000 rpm for 5 min, washed twice with sterile distilled water, and then lyophilized for 48 h with a freeze-drying system (Christ, USA). The freeze-dried cells were stored at −20 °C for subsequent processing. Glycerol concentration was measured using a kit based on the enzymatic determination in a liquid sample (Applygen Technologies). Fatty acid methyl esters were prepared using the direct transesterification method [27]. Freeze dried biomass (50–100 mg), 100 μL of 1 mg/mL internal standard (nonadecanoic acid, C19:0) solution, and 2 mL of 4% sulfuric acid in methanol were placed into 5 mL screw-top glass tubes. The acid catalyzed trans-esterification started at 80 °C water bath for 1 h. One mL water and 1 mL hexane were added to the mixtures at room temperature, vortexed and centrifuged at 4000 rpm for 2 min. The fatty acid methyl esters (FAME) in the hexane layer were collected and analyzed by a gas chromatography Agilent 7890B (Agilent, USA) equipped with a DB-WAX column (60 m × 320 μm × 0.15 μm). A sample volume of 1 μL was injected in split mode with the split ratio 50:1. Nitrogen was used as the carrier gas. The injection port temperature was set at 250 °C. The column temperature was set to 50 °C for 1 min followed by programming at 25 °C/min to 175 °C, 3 °C/min to 220 °C and held for 5 min, then 2 °C/min to 230 °C and held for 11 min. The FAME peaks were identified by comparing with retention times of the standard mixtures (Sigma-Aldrich, USA).

2.6. Statistical analysis

One-way analysis of variance (one-way ANOVA) and Duncan analysis was carried out to test the significance of different treatments on fermentation parameters using SPSS Statistic 19 software.

3. Results

3.1. Effect of culture conditions on the growth and production of DHA

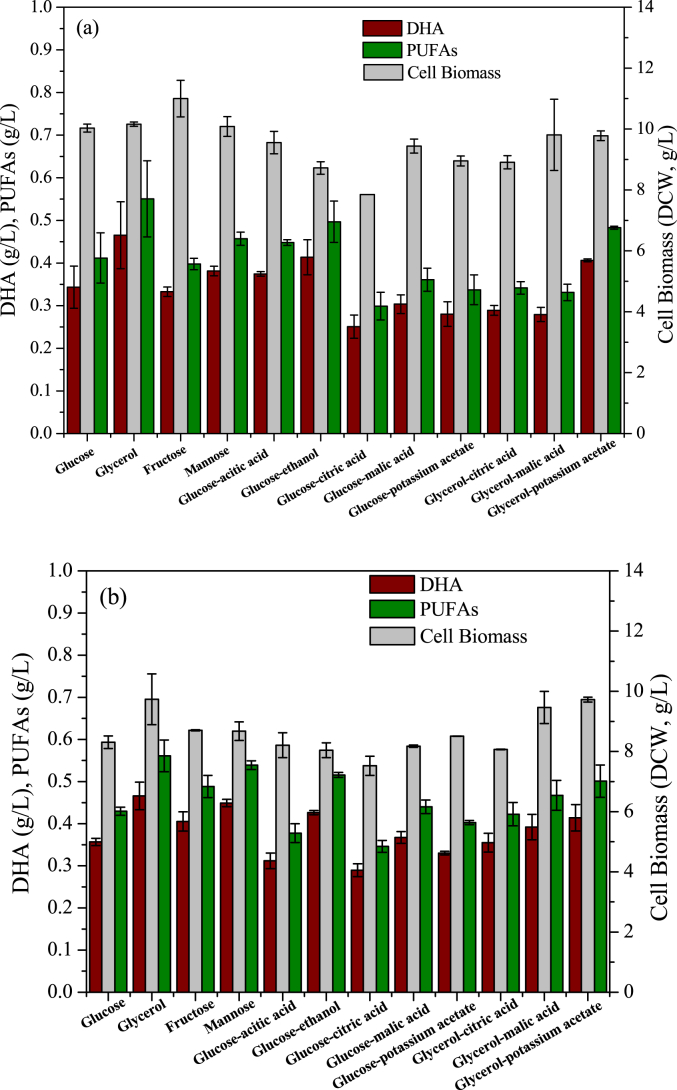

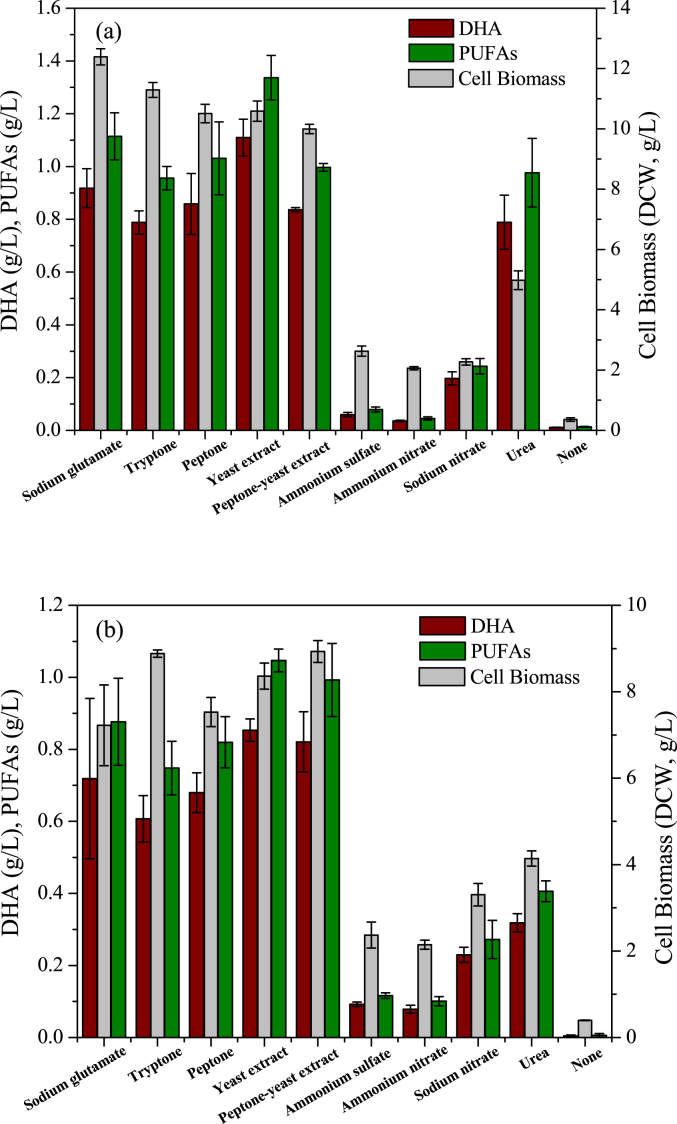

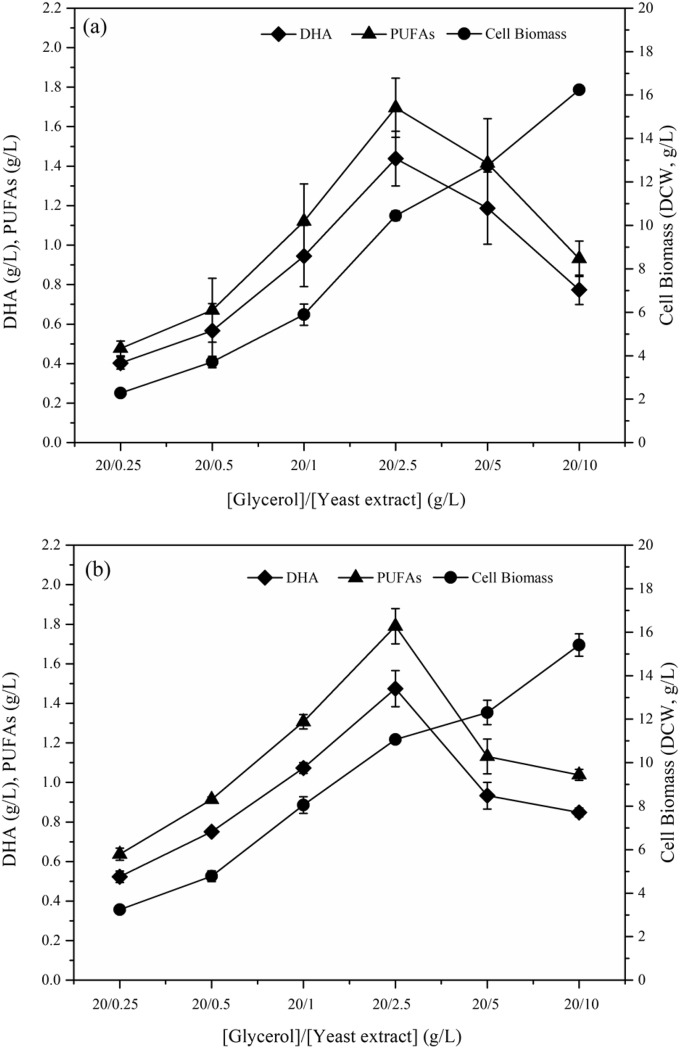

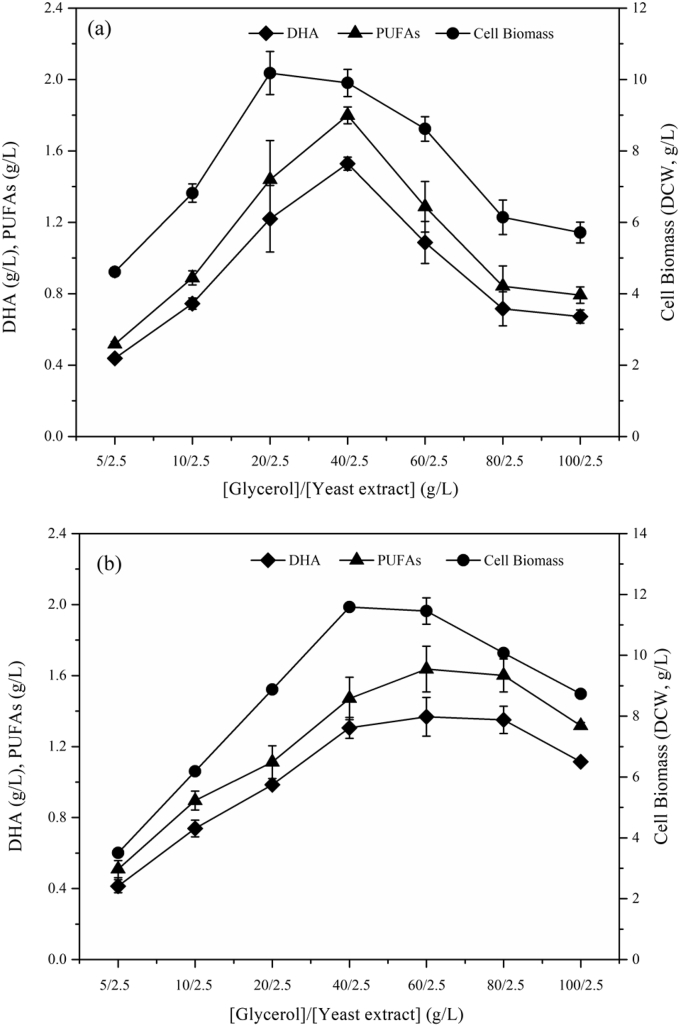

The strains PKU#Mn4 and PKU#Mn16 reached the early stationary phase with concomitant PUFAs production when cultured for 72 h (Fig. S1) under the initial growth conditions described in Table S1. The effect of culture medium components including carbon and nitrogen sources, substrate concentration, KH2PO4, and salt concentration, at different levels, were evaluated for DHA production in flask culture (Table S1). Of all the carbon and nitrogen sources tested, glycerol and yeast extract were best for PUFAs production (Fig. 1, Fig. 2, Table S2). Notably, both the strains yielded much higher growth and PUFAs production with organic nitrogen sources than with inorganic sources (Table 1). In addition, PKU#Mn4 showed an increase in DHA production when the concentrations of glycerol and yeast extract were increased up to 40 g/L and 2.5 g/L, respectively (Fig. 3, Fig. 4a, Table S3). Comparatively, the strain PKU#Mn16 could tolerate much higher concentration of glycerol than PKU#Mn4, in growth and concomitant DHA production (Fig. 3, Fig. 4b, Table S3). Although high C/N ratio is known to enhance DHA production, high C/N ratio resulting from a decrease in yeast extract level did not increase the DHA production in both the strains. On the contrary, an increase of the C/N ratio by increasing glycerol level improved the DHA production (Fig. 3, Fig. 4, Table S3).

Fig. 1.

Effects of various carbon sources on cell biomass, DHA and PUFAs production in the culture of (a) Schizochytrium PKU#Mn4 and (b) Thraustochytriidae PKU#Mn16.

Fig. 2.

Effects of various nitrogen sources on DCW, DHA and PUFAs production in the culture of (a) Schizochytrium PKU#Mn4 and (b) Thraustochytriidae PKU#Mn16.

Table 1.

Parameters with a significant effect (P < 0.05) on cell biomass, PUFAs, and DHA production in cultures of Schizochytrium sp. PKU#Mn4 and Thraustochytriidae sp. PKU#Mn16. Data are analyzed by one-way analysis of variance (one-way ANOVA).

| Schizochytrium sp. PKU#Mn4 | Thraustochytriidae PKU#Mn16 | |

|---|---|---|

| Cell biomass (g/L) | Carbon source | Carbon source |

| Nitrogen source | Nitrogen source | |

| Glycerol concentration | Glycerol concentration | |

| Yeast extract concentration | Yeast extract concentration | |

| pH | pH | |

| salinity | salinity | |

| Temperature | Temperature | |

| Agitation speed | ||

| PUFAs (g/L) | Carbon source | Carbon source |

| Nitrogen source | Nitrogen source | |

| Glycerol concentration | Glycerol concentration | |

| Yeast extract concentration | Yeast extract concentration | |

| pH | Agitation speed | |

| salinity | ||

| KH2PO4 | ||

| Temperature | ||

| Agitation speed | ||

| DHA (g/L) | Carbon source | Carbon source |

| Nitrogen source | Nitrogen source | |

| Glycerol concentration | Glycerol concentration | |

| Yeast extract concentration | Yeast extract concentration | |

| pH | Agitation speed | |

| KH2PO4 | ||

| Temperature |

Fig. 3.

Effects of varying yeast-extract concentrations on DCW, DHA and PUFAs production in the culture of (a) Schizochytrium PKU#Mn4 and (b) Thraustochytriidae PKU#Mn16.

Fig. 4.

Effects of varying glycerol concentrations on DCW, DHA and PUFAs production in the culture of (a) Schizochytrium PKU#Mn4 and (b) Thraustochytriidae PKU#Mn16.

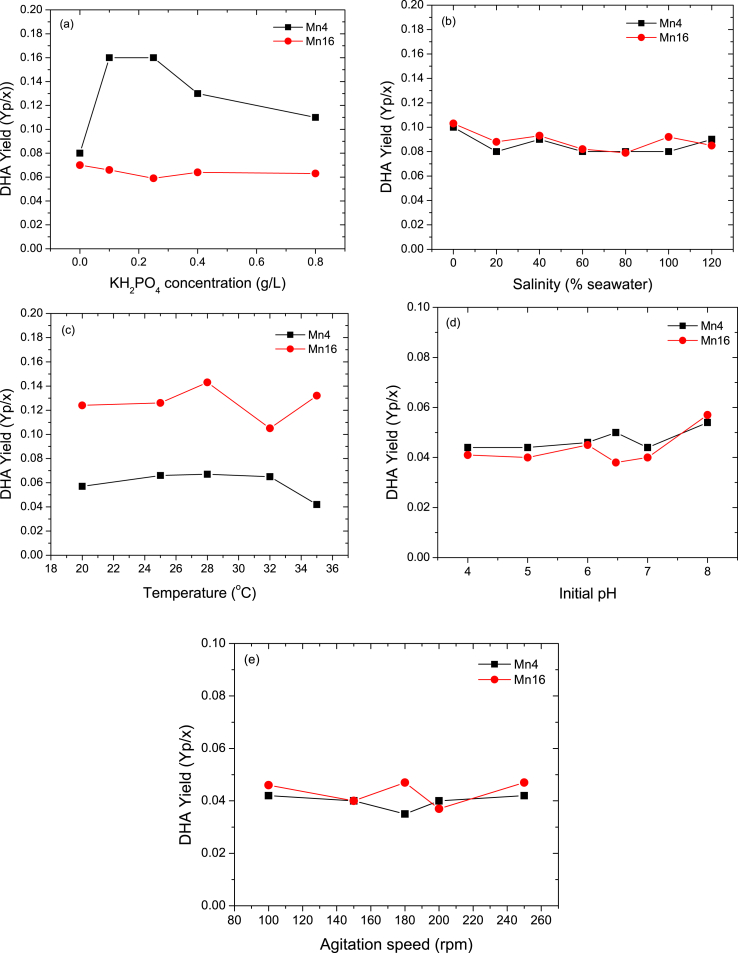

The effect of KH2PO4 and salt concentration on cell biomass and DHA production was examined over a range of 0–0.8 g/L and 0 to 120% salt (% seawater), respectively. The production of PUFAs and DHA by PKU#Mn4, but not by PKU#Mn16, was significantly affected by KH2PO4, and the maximum production was achieved at 0.25 g/L of KH2PO4 (Table 1). Notably, PKU#Mn4 exhibited distinct DHA yields in response to changes in KH2PO4 concentrations (Fig. 5a). Both the strains could grow well on a wide range of salinity (up to 120%) and their DHA yields varied within a range of 0.08–0.10 g/g biomass (Fig. 5b). Interestingly, even at low salt concentrations, both the strains presented a good potential for high DHA production.

Fig. 5.

Effects of different process conditions (KH2PO4, salinity, temperature, initial pH, and agitation speed) on the DHA yields (Yp/x) in Schizochytrium PKU#Mn4 and Thraustochytriidae PKU#Mn16 cultures.

A variety of environmental conditions including temperature, pH, and agitation speed were separately tested on each strain. Among these conditions, pH and temperature showed significant impact on DHA fermentation by PKU#Mn4 while only agitation speed affected DHA production in PKU#Mn16 culture (Table 1). These results indicated high oxygen transfer rate as an important factor to enhance DHA production in PKU#Mn16. Temperature changes resulted in different DHA yield profiles (Fig. 5c), and this seemed to be the most crucial controlling factor in industrial DHA fermentation using either of the two thraustochytrid strains. Although pH and agitation speed influenced DHA production (Table 1), it did not result in any significant change of DHA yields in the two strains (Fig. 5d and e).

Overall, the effect of carbon and nitrogen sources and their concentrations on the DHA fermentation by the two strains were similar. However, the effects of other fermentation conditions varied among the two strains. Notably, KH2PO4 concentration and temperature resulted in wide-ranging DHA yields compared to the other factors. Nevertheless, both the strains provided similar DHA yields when cultured within broad ranges of salinity, initial pH, and agitation speed and thus seemed better suited for industrial fermentation.

3.2. DHA production in flask culture under optimal conditions

The optimal conditions for DHA production in the two strains were 40–60 g/L glycerol, 2.5 g/L yeast extract, 0.25 g/L KH2PO4, 100% salinity, pH 6.47, 28 °C, and 150 rpm agitation speed. The results of flask (0.5 L) fermentation under the optimal conditions for both strains are presented in Table 2. At day 4, cell biomass of the two strains on glycerol was comparable (11.27 g/L and 10.75 g/L) and fatty acid profiles for 7 saturated fatty acids (SFAs) and 6 PUFAs were also similar. The major fatty acids produced by the two strains were palmitic acid (C16:0), docosapentaenoic acid (DPA, C22:5), and DHA, accounting for ca. 89% of the TFAs. The total PUFAs produced by PKU#Mn4 and PKU#Mn16 was 1.9 g/L and 2.7 g/L (57.5% and 58.8% of the TFAs), respectively. DHA production by PKU#Mn4 and PKU#Mn16 reached up to 1.61 g/L and 2.25 g/L with the yield (Yp/x) of 0.14 g/g and 0.21 g/g, respectively. Production of the second major PUFA, docosapentaenoic acid (C22:5ω6, DPA), reached 8.11% and 8.67% of TFAs in the two strains, respectively. By comparison, PKU#Mn16 showed slightly higher production of fatty acids, including PUFAs and SFAs, than PKU#Mn4 under their respective optimal medium and process conditions.

Table 2.

Yield and fatty acids composition of lipids from Schizochytrium sp. PKU#Mn4 and Thraustochytriidae sp. PKU#Mn16 cultures grown for 96 h under optimal conditions in flask culture. The data are expressed as the mean ± standard deviation.

| Parameters | Schizochytrium sp. PKU#Mn4 | Thraustochytriidae sp. PKU#Mn16 |

|---|---|---|

| DCW (g/L) | 11.27 ± 0.88 | 10.75 ± 0.55 |

| DHA (g/g) | 0.14 ± 0.01 | 0.21 ± 0.02 |

| DHA (g/L) | 1.61 ± 0.04 | 2.25 ± 0.24 |

| PUFA (g/L) | 1.90 ± 0.04 | 2.70 ± 0.38 |

| C12:0 | 0.09 ± 0.01 | 0.10 ± 0.02 |

| C14:0 | 2.29 ± 0.12 | 1.20 ± 0.12 |

| C15:0 | 1.95 ± 0.11 | 2.55 ± 0.06 |

| C16:0 | 33.29 ± 0.10 | 31.51 ± 0.93 |

| C17:0 | 0.20 ± 0.01 | 0.25 ± 0.04 |

| C18:0 | 0.85 ± 0.01 | 0.85 ± 0.01 |

| C18:3 | 0.14 ± 0.01 | 0.17 ± 0.02 |

| C20:0 | 0.11 ± 0.00 | 0.07 ± 0.00 |

| C21:0 | 0.33 ± 0.05 | 0.36 ± 0.06 |

| C20:3 | 0.45 ± 0.02 | 0.51 ± 0.11 |

| C20:4 | 0.15 ± 0.01 | 0.21 ± 0.01 |

| C20:5 | 0.12 ± 0.01 | 0.09 ± 0.01 |

| DPA (% of TFAs) | 8.11 ± 0.02 | 8.67 ± 0.02 |

| DHA (% of TFAs) | 48.52 ± 0.19 | 49.19 ± 0.41 |

| Sum of PUFAs | 57.50 ± 1.71 | 58.83 ± 1.59 |

3.3. Bioreactor DHA production

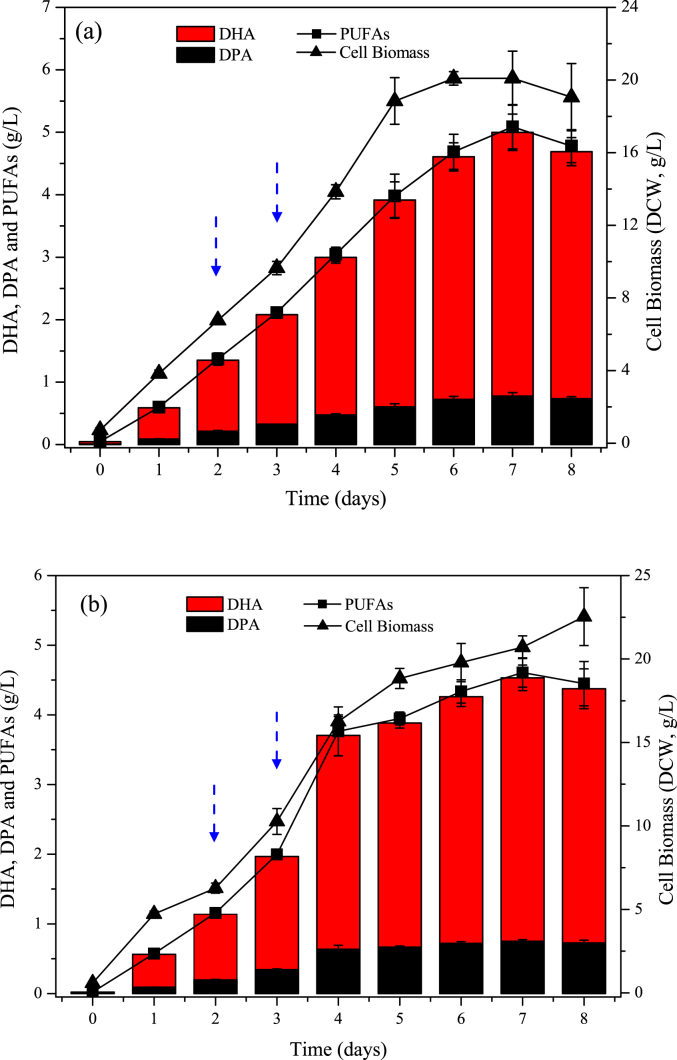

Fed-batch fermentation in a 5 L bench-top bioreactor with a working volume of 3 L was conducted to assess the applicability and reproducibility of the optimized medium and process conditions on a larger scale. The results of fed-batch bioreactor fermentation are presented in Table 3 and Fig. 6. Maximum DHA production of 4.42 g/L and 3.78 g/L, respectively, were achieved at day 7 with PKU#Mn4 and PKU#Mn16, which were 3.4- and 2.8- fold greater than those under un-optimized conditions. The peak DHA yields (Yp/x) were 21.0% (day 7) and 18.9% (day 4), and peak DHA productivities were 27.6 mg/L-h (day 5) and 24.1 mg/L-h (day 4) in the two strains, respectively. The TFAs production reached up to 64.2% (day 7) and 48.3% (day 4) of biomass, constituting 41.8% (day 8) and 50.8% (day 7) as PUFAs, respectively. The glycerol consumption rate varied from 47.6 to 5038.6 mg/L-h and 249.2 to 3681.7 mg/L-h, respectively, and increased dramatically at the end of the fermentation process. Overall, the bioreactor fermentation results provided much higher production of DHA compared to the flask culture and demonstrated reproducible optimized process performance under dual oxygen control strategy.

Table 3.

Time course of growth parameters in the 5-L bioreactor fed-batch fermentation process operated under optimal conditions.

| Strain | Time (days) | Biomass (X, g/L) | Glycerol consumption rate (mg/L-h) | TFAs (%Biomass) | PUFAs (%TFAs) | DHA (P, g/L) | DHA (%Biomass) | DHA (%TFAs) | DHA productivity (mg/L-h) |

|---|---|---|---|---|---|---|---|---|---|

| PKUaMn4 | 0 | 0.72 ± 0.12 | n.d | 20.21 ± 1.44 | 32.81 ± 2.21 | 0.04 ± 0.01 | 5.59 ± 0.05 | 27.73 ± 1.72 | n.d |

| 1 | 3.83 ± 0.20 | 47.6 | 43.48 ± 3.61 | 36.07 ± 0.54 | 0.50 ± 0.02 | 13.10 ± 1.28 | 30.11 ± 0.43 | 20.86 ± 0.93 | |

| 2 | 6.77 ± 0.01 | 678.2 | 58.71 ± 2.50 | 36.43 ± 0.49 | 1.14 ± 0.08 | 16.82 ± 1.16 | 30.19 ± 0.45 | 23.71 ± 1.69 | |

| 3 | 9.65 ± 0.37 | 420.3 | 58.82 ± 2.23 | 38.27 ± 1.43 | 1.75 ± 0.05 | 18.20 ± 1.24 | 31.70 ± 1.34 | 24.35 ± 0.73 | |

| 4 | 13.85 ± 0.39 | 124.3 | 59.77 ± 0.20 | 37.28 ± 0.74 | 2.52 ± 0.09 | 18.21 ± 0.17 | 30.76 ± 0.61 | 26.27 ± 0.97 | |

| 5 | 18.84 ± 1.28 | 553.3 | 55.46 ± 0.10 | 37.55 ± 0.49 | 3.31 ± 0.29 | 17.56 ± 0.35 | 31.02 ± 0.36 | 27.59 ± 2.43 | |

| 6 | 20.09 ± 0.37 | 209.9 | 60.79 ± 4.09 | 38.91 ± 0.12 | 3.89 ± 0.23 | 19.35 ± 1.29 | 32.22 ± 0.07 | 26.98 ± 1.57 | |

| 7 | 20.10 ± 1.49 | 5038.6 | 64.19 ± 1.71 | 40.85 ± 1.40 | 4.22 ± 0.29 | 21.03 ± 0.91 | 33.85 ± 1.22 | 25.14 ± 1.74 | |

| 8 | 19.05 ± 1.85 | 4846.6 | 61.42 ± 2.94 | 41.84 ± 0.56 | 3.96 ± 0.23 | 20.82 ± 1.11 | 34.53 ± 0.42 | 20.60 ± 1.17 | |

| PKUaMn16 | 0 | 0.59 ± 0.02 | n.d | 12.93 ± 0.37 | 28.49 ± 0.12 | 0.02 ± 0.00 | 3.11 ± 0.09 | 24.07 ± 0.02 | n.d |

| 1 | 4.72 ± 0.18 | 378.6 | 29.29 ± 1.02 | 41.49 ± 2.81 | 0.47 ± 0.00 | 9.99 ± 0.33 | 34.14 ± 2.32 | 19.65 ± 0.09 | |

| 2 | 6.28 ± 0.30 | 608.1 | 42.62 ± 2.64 | 46.77 ± 1.65 | 0.94 ± 0.03 | 14.99 ± 0.72 | 38.02 ± 1.61 | 19.58 ± 0.69 | |

| 3 | 10.27 ± 0.78 | 1014.17 | 42.81 ± 3.41 | 48.39 ± 1.56 | 1.62 ± 0.04 | 15.88 ± 1.46 | 39.18 ± 1.30 | 22.55 ± 0.53 | |

| 4 | 16.25 ± 0.30 | 249.18 | 48.31 ± 3.98 | 50.45 ± 1.07 | 3.07 ± 0.29 | 18.88 ± 1.77 | 41.04 ± 0.95 | 31.97 ± 3.07 | |

| 5 | 18.83 ± 0.61 | 679.82 | 43.23 ± 1.35 | 49.88 ± 0.37 | 3.22 ± 0.07 | 17.09 ± 0.66 | 40.53 ± 0.35 | 26.80 ± 0.62 | |

| 6 | 19.78 ± 1.15 | 906.80 | 44.68 ± 0.77 | 50.76 ± 1.50 | 3.54 ± 0.14 | 17.91 ± 0.71 | 41.38 ± 1.33 | 24.58 ± 0.97 | |

| 7 | 20.71 ± 0.68 | 1424.26 | 45.62 ± 1.72 | 50.78 ± 2.07 | 3.78 ± 0.18 | 18.28 ± 1.34 | 41.57 ± 1.98 | 22.50 ± 1.09 | |

| 8 | 22.53 ± 1.73 | 3681.70 | 40.96 ± 1.39 | 49.99 ± 1.40 | 3.65 ± 0.29 | 16.18 ± 0.22 | 40.80 ± 1.25 | 18.99 ± 1.49 |

n.d = not determined.

Fig. 6.

Time course of cell biomass, PUFAs, DHA, and DPA yields in the culture of (a) Schizochytrium sp. PKU#Mn4 and (b) Thraustochytriidae sp. PKU#Mn16 under optimal conditions in 5 L bioreactor fermentation. Arrows (blue) indicates the point of feed addition into the bioreactor.

4. Discussion

For efficient production of DHA in thraustochytrids, screening of culture conditions that are generally species-specific is vital [4]. We studied the effects of medium components and process conditions on the batch production of DHA using two isolated thraustochytrid strains, PKU#Mn4 and PKU#Mn16. The optimal medium composition and process conditions for the two strains were almost identical except for the concentration of glycerol. Of particular interest, PKU#Mn16 showed promising DHA production even at the high glycerol concentration of 80 g/L. In comparison, PKU#Mn4 was susceptible to substrate inhibition. This indicates that increased glycerol concentration does not necessarily increase its uptake rate and consumption even though glycerol enters the cell by facilitated diffusion [28]. PKU#Mn4 showed better glycerol utilization efficiency than PKU#Mn16. As illustrated in Table S4, several thraustochytrids strains have different capabilities in glycerol utilization and DHA production in batch fermentation under various culture conditions. Many studies used glycerol for DHA production in Schizochytrium spp., but not with Thraustochytriidae sp.; this is the first report of glycerol utilization by Thraustochytriidae sp. In our strains, biomass and DHA production were not very high probably due to the use of single carbon source for cell growth. Previous studies indicated that the use of mixed carbon sources (glucose and glycerol) and control of the dissolved oxygen level significantly improved the DHA production in thraustochytrid strains [10,11,14,29]. In future studies, these two parameters should be carefully investigated in both the strains. Nevertheless, we obtained high DHA/TFAs percent comparable to those obtained by previously reported efficient strains [9].

Apart from the concentration of carbon source, nitrogen limitation also enhances lipid yields in oleaginous microorganisms [30]. The high carbon to nitrogen ratio in the culture medium is known to induce high cellular lipid content [17,18,31]. Inorganic nitrogen may be used as a sole nitrogen source; yet, the addition of amino acids such as glutamate can improve biomass yield and lipid accumulation [32]. Similarly, we found that the organic nitrogen sources are more effective than the inorganic nitrogen for higher cell biomass and DHA production. In our study, the initiation of the lipid accumulation is attributed to low levels of oxygen and limitation of nitrogen and phosphorous sources used. Generally, nitrogen limitation leads to a reduction in protein and nucleic acid synthesis and promotes the conversion of the carbon sources into storage lipids [9]. The optimal C/N ratio of ca. 27 that yielded highest DHA content (Table S3) in our study was in close agreement with Fan and Chen (2007).

Phosphorous is known to play a vital role in cell growth, nucleic acid formation, and the formation of phospholipid layer. Previous studies have shown that phosphorous, in the form of KH2PO4, could significantly increase DHA production when their level is increased, but optimal levels of KH2PO4 were different among thraustochytrid strains [15,16]. For example, optimal KH2PO4 concentration for Thraustochytrium roseum ATCC 28210 was 0.2 g/L [15]; in comparison, for Schizochytrium limacinum SR21 and Ulkenia sp. SAM 2179, the optimal concentration was 3 g/L [16,33]. The optimal concentration for Schizochytrium sp. PKU#Mn4 was 0.25 g/L which was in close agreement with the previous report on Thraustochytrium roseum ATCC 28210 [15]. Notably, KH2PO4 did not show any effect on cell biomass and DHA yield in Thraustochytriidae sp. PKU#Mn16. These results demonstrate the inconsistency of the optimal KH2PO4 for DHA production in different thraustochytrid strains and indicate the significance of screening culture conditions for each species and strain of thraustochytrids.

Several lines of evidence suggested the tolerance of thraustochytrid strains to a wide range of salinity of culture medium [12,17,19,34,35]. Few reports have shown that a medium with 50% of seawater salinity is effective for defined medium [4,21,36]; yet, some other studies found 100% of seawater as the optimal salinity for DHA production [12,17]. In the present study, both the strains could grow over a wide range of salinity with concomitant DHA production and similar %PUFAs/TFAs and %DHA/TFAs. The ability of the two strains to grow and produce DHA even at low salinity may benefit the cost saving and quality control aspects of large-scale fermentation.

Although thraustochytrid strains grow over a wider range of temperature from 5 to 37 °C [4], several studies have reported the temperature range of 25–30 °C as optimal for cell biomass and DHA production [12,17,19,20,31,35,37]. Lower temperatures promote synthesis of PUFAs which increase cell membrane fluidity; therefore, higher DHA yield is observed at low temperatures but with reduced cell biomass. A similar phenomenon was noted with PKU#Mn4: relatively higher DHA yield with lower biomass at the low temperature of 20 °C (Fig. 5c). However, temperature change did not significantly influence cell biomass and DHA production in PKU#Mn16. Previous studies suggested that temperature effects on PUFAs and DHA yields along with their percentage in TFAs are different among thraustochytrid strains [12,38]. We also confirmed that the two strains respond differently to temperature alteration (Fig. 5c). Thus, our results suggest that optimal temperature to obtain maximal DHA yield is 28 °C for the two strains.

The growth of the two strains was significantly influenced by pH change; yet, they generally tolerated a wide pH range of 4–8 that agreed with the previous reports [35]. Of the two strains, PKU#Mn4 showed an optimal growth and DHA production at pH 6.47, which was in close agreement with other studies that suggested optimal pH condition range of pH 6–7 [4,12,19,21]. Although %DHA/TFAs varied between the two strains when cultured at different pH values, their %DHA/TFAs were relatively higher than the previously reported values [12]. Notably, the PUFAs and DHA yields were not affected by the pH change in case of PKU#Mn16 but rather significantly in PKU#Mn4 (Table 1).

The agitation speed of culture flask modulates the mass transfer rates of oxygen and thereby influences the cell growth and lipid yield [39]. Several studies have shown that oxygen is essential for the growth of thraustochytrids [10,11,32]; yet, the role of oxygen on altering DHA yield in different thraustochytrid strains remains unclear. As facultative aerobes, thraustochytrids can grow under microaerobic and anaerobic conditions [40,41]. The report on polyketide synthases (PKS) in Schizochytrium sp. provides clear evidence on the presence of an oxygen-independent pathway for fatty acid biosynthesis, in addition to the aerobic fatty acid synthase (FAS) pathway. Because of the PKS pathway, low level of oxygen (<1%) after high aeration level was found to favor DHA production in some thraustochytrid species [10,42,43]. Similar to these previous studies, we also observed a significant increase in DHA production when the DO level was set at 10% of saturation after an initially high level (50%) during the bioreactor fed-batch fermentation process. However, without a DO control during flask culture experiments, the strains displayed different behaviors when subjected to different agitation speeds. Schizochytrium sp. PKU#Mn4 grew very well and also produced similar levels of DHA across all the agitation speeds. On the contrary, Thraustochytriidae sp. PKU#Mn16 showed drastically reduced cell biomass and DHA production when the agitation speed was very low (100 rpm). The fact that Schizochytrium sp. PKU#Mn4 was able to produce DHA at even low agitation speed suggests the involvement of an anaerobic PKS pathway. PKU#Mn4 can be more advantageous in industrial fermentation since low agitation can reduce operation cost.

The high production of C16:0 fatty-acid (31.5–33.3% of TFAs) next to DHA by both the strains suggests their high potential as efficient organisms for biodiesel production. Similar relative C16:0 content were also reported in Schizochytrium sp. and Thraustochytrium sp. which were cultured on pure glycerol [13]. The PUFAs profiles of thraustochytrid strains are generally simple when grown on glucose [12] than on glycerol [13,44]. In our study, both the strains cultured in glycerol medium produced high DHA relative to TFAs, and the DHA content is much higher than that of many previous studies [12,13,44] or at the least similar to that of the most efficient strains [9,45]. This suggests that, although not fully optimized for the DHA production, our strains have high biotechnological potential. In addition, we characterized the distinct physiologies of the two phylogenetically close strains to explore their potential for DHA production and speculated that phylogenetically related thraustochytrid strains occupy mostly similar physiological characteristics and DHA production potentials. Finally, the 5 L bioreactor fermentation conducted under the optimal conditions and with dual oxygen control strategy showed higher DHA production compared to the flask culture experiments, which was in close agreement with the previous studies [12]. Nevertheless, further efforts to optimize the oxygen transfer rate with fermentation time [11,43] should be undertaken in the future studies.

5. Conclusions

Schizochytrium sp. PKU#Mn4 and Thraustochytriidae sp. PKU#Mn16 revealed different physiological responses to culture conditions. The optimal conditions were similar for these strains except for the glycerol concentration and yielded a high relative DHA content comparable to the best results in the mainstream literature. Although their lipid profiles were similar, PKU#Mn4 showed potential in industrial fermentation. DHA production was enhanced in oxygen-controlled 5 L bioreactor fermentation. To date, our study is the first report of a detailed investigation of DHA fermentation conditions for two newly-isolated thraustochytrid strains. The findings are anticipated to provide the basis for further process design and scale-up.

Conflicts of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Acknowledgements

This work was partially supported by National Key R&D Program of China (2016YFA0601400) and National Science Foundation of China (31670044, 91751115, and 31602185). The views expressed herein are those of the authors and do not necessarily reflect the views of the funding agencies or any of its subagencies.

Footnotes

Peer review under responsibility of KeAi Communications Co., Ltd.

Supplementary data related to this article can be found at https://doi.org/10.1016/j.synbio.2018.04.001.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Leyland B., Leu S., Boussiba S. Are thraustochytrids algae? Fungal Biol. 2017;121(10):835–840. doi: 10.1016/j.funbio.2017.07.006. [DOI] [PubMed] [Google Scholar]

- 2.Marchan L.F., Lee Chang K.J., Nichols P.D., Mitchell W.J., Polglase J.L., Gutierrez T. Taxonomy, ecology and biotechnological applications of thraustochytrids: a review. Biotechnol Adv. 2017 doi: 10.1016/j.biotechadv.2017.09.003. https://doi.org/10.1016/j.biotechadv.2017.09.003 [DOI] [PubMed] [Google Scholar]

- 3.Spolaore P., Joannis-Cassan C., Duran E., Isambert A. Commercial applications of microalgae. J Biosci Bioeng. 2006;101(2):87–96. doi: 10.1263/jbb.101.87. [DOI] [PubMed] [Google Scholar]

- 4.Fan K.W., Chen F. Elsevier; Amsterdam: 2007. Chapter 11-production of high-value products by marine microalgae thraustochytrids A2-Yang, Shang-Tian. Bioprocessing for value-added products from renewable resources; pp. 293–323. [Google Scholar]

- 5.Horrocks L.A., Yeo Y.K. Health benefits of docosahexaenoic acid (DHA) Pharmacol Res. 1999;40(3):211–225. doi: 10.1006/phrs.1999.0495. [DOI] [PubMed] [Google Scholar]

- 6.Puri M., Thyagarajan T., Gupta A., Barrow C.J. 2015. Omega-3 fatty acids produced from microalgae. Springer Handbook of Marine Biotechnology; pp. 1043–1057. [Google Scholar]

- 7.Kralovec J.A., Zhang S., Zhang W., Barrow C.J. A review of the progress in enzymatic concentration and microencapsulation of omega-3 rich oil from fish and microbial sources. Food Chem. 2012;131(2):639–644. [Google Scholar]

- 8.Jacobs M.N., Covaci A., Gheorghe A., Schepens P. Time trend investigation of PCBs, PBDEs, and organochlorine pesticides in selected n−3 polyunsaturated fatty acid rich dietary fish oil and vegetable oil supplements; nutritional relevance for human essential n−3 fatty acid requirements. J Agric Food Chem. 2004;52(6):1780–1788. doi: 10.1021/jf035310q. [DOI] [PubMed] [Google Scholar]

- 9.Gupta A., Barrow C.J., Puri M. Omega-3 biotechnology: thraustochytrids as a novel source of omega-3 oils. Biotechnol Adv. 2012;30(6):1733–1745. doi: 10.1016/j.biotechadv.2012.02.014. [DOI] [PubMed] [Google Scholar]

- 10.Huang T.Y., Lu W.C., Chu I.M. A fermentation strategy for producing docosahexaenoic acid in Aurantiochytrium limacinum SR21 and increasing C22:6 proportions in total fatty acid. Bio Technol. 2012;123:8–14. doi: 10.1016/j.biortech.2012.07.068. [DOI] [PubMed] [Google Scholar]

- 11.Chang G., Gao N., Tian G., Wu Q., Chang M., Wang X. Improvement of docosahexaenoic acid production on glycerol by Schizochytrium sp. S31 with constantly high oxygen transfer coefficient. Bio Technol. 2013;142:400–406. doi: 10.1016/j.biortech.2013.04.107. [DOI] [PubMed] [Google Scholar]

- 12.Liu Y., Tang J., Li J., Daroch M., Cheng J.J. Efficient production of triacylglycerols rich in docosahexaenoic acid (DHA) by osmo-heterotrophic marine protists. Appl Microbiol Biotechnol. 2014;98(23):9643–9652. doi: 10.1007/s00253-014-6032-9. [DOI] [PubMed] [Google Scholar]

- 13.Lee Chang K.J., Paul H., Nichols P.D., Koutoulis A., Blackburn S.I. Australian thraustochytrids: potential production of dietary long-chain omega-3 oils using crude glycerol. J Funct Foods. 2015;19:810–820. [Google Scholar]

- 14.Li J., Liu R., Chang G., Li X., Chang M., Liu Y. A strategy for the highly efficient production of docosahexaenoic acid by Aurantiochytrium limacinum SR21 using glucose and glycerol as the mixed carbon sources. Bio Technol. 2015;177:51–57. doi: 10.1016/j.biortech.2014.11.046. [DOI] [PubMed] [Google Scholar]

- 15.Singh A., Ward O.P. Production of high yields of docosahexaenoic acid by Thraustochytrium roseum ATCC 28210. J Ind Microbiol. 1996;16(6):370–373. doi: 10.1007/BF01569755. [DOI] [PubMed] [Google Scholar]

- 16.Yaguchi T., Tanaka S., Yokochi T., Nakahara T., Higashihara T. Production of high yields of docosahexaenoic acid by Schizochytrium sp. strain SR21. J Am Oil Chem Soc. 1997;74(11):1431–1434. [Google Scholar]

- 17.Yokochi T., Honda D., Higashihara T., Nakahara T. Optimization of docosahexaenoic acid production by Schizochytrium limacinum SR21. Appl Microbiol Biotechnol. 1998;49(1):72–76. [Google Scholar]

- 18.Bowles R.D., Hunt A.E., Bremer G.B., Duchars M.G., Eaton R.A. Long-chain n-3 polyunsaturated fatty acid production by members of the marine protistan group the thraustochytrids: screening of isolates and optimisation of docosahexaenoic acid production. J Biotechnol. 1999;70(1–3):193–202. [Google Scholar]

- 19.Zhu L., Zhang X., Ren X., Zhu Q. Effects of culture conditions on growth and docosahexaenoic acid production from Schizochytrium limacinum. J Ocean Univ China. 2008;7(1):83–88. [Google Scholar]

- 20.Taoka Y., Nagano N., Okita Y., Izumida H., Sugimoto S., Hayashi M. Influences of culture temperature on the growth, lipid content and fatty acid composition of Aurantiochytrium sp. Strain mh0186. Mar Biotechnol. 2009;11(3):368–374. doi: 10.1007/s10126-008-9151-4. [DOI] [PubMed] [Google Scholar]

- 21.Arafiles K.H.V., Alcantara J.C.O., Cordero P.R.F., Batoon J.A.L., Galura F.S., Leaño E.M. Cultural optimization of thraustochytrids for biomass and fatty acid production. Mycosphere. 2011;2(5):521–531. [Google Scholar]

- 22.Lee Chang K.J., Dunstan G.A., Abell G.C.J., Clementson L.A., Blackburn S.I., Nichols P.D., Koutoulis A. Biodiscovery of new Australian thraustochytrids for production of biodiesel and long-chain omega-3 oils. Appl Microbiol Biotechnol. 2012;93(5):2215–2231. doi: 10.1007/s00253-011-3856-4. [DOI] [PubMed] [Google Scholar]

- 23.Marchan L.F., Lee Chang K.J., Nichols P.D., Polglase J.L., Mitchell W.J., Gutierrez T. Screening of new British thraustochytrids isolates for docosahexaenoic acid (DHA) production. J Appl Phycol. 2017 doi: 10.1007/s10811-017-1149-8. https://doi.org/10.1007/s10811-017-1149-8 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Liu Y., Singh P., Sun Y., Luan S., Wang G. Culturable diversity and biochemical features of thraustochytrids from coastal waters of Southern China. Appl Microbiol Biotechnol. 2014;98(7):3241–3255. doi: 10.1007/s00253-013-5391-y. [DOI] [PubMed] [Google Scholar]

- 25.Lee Chang K.J., Nichols C.M., Blackburn S.I., Dunstan G.A., Koutoulis A., Nichols P.D. Comparison of thraustochytrids Aurantiochytrium sp., Schizochytrium sp., Thraustochytrium sp., and Ulkenia sp. for production of biodiesel, long-chain Omega-3 oils, and exopolysaccharide. Mar Biotechnol. 2014;16(4):396–411. doi: 10.1007/s10126-014-9560-5. [DOI] [PubMed] [Google Scholar]

- 26.Raghukumar S. The marine environment and the role of fungi. In: Raghukumar S., editor. Fungi in coastal and oceanic marine ecosystems: marine fungi. Springer International Publishing; Cham: 2017. pp. 17–38. [Google Scholar]

- 27.Lepage G., Roy C.C. Improved recovery of fatty acid through direct transesterification without prior extraction or purification. J Lipid Res. 1984;25(12):1391–1396. [PubMed] [Google Scholar]

- 28.Makri A., Fakas S., Aggelis G. Metabolic activities of biotechnological interest in Yarrowia lipolytica grown on glycerol in repeated batch cultures. Bio Technol. 2010;101:2351–2358. doi: 10.1016/j.biortech.2009.11.024. [DOI] [PubMed] [Google Scholar]

- 29.Chang G., Luo Z., Gu S., Wu Q., Chang M., Wang X. Fatty acid shifts and metabolic activity changes of Schizochytrium sp. S31 cultured on glycerol. Bio Technol. 2013;142:255–260. doi: 10.1016/j.biortech.2013.05.030. [DOI] [PubMed] [Google Scholar]

- 30.Xie Y., Wang G. Mechanisms of fatty acid synthesis in marine fungus-like protists. Appl Microbiol Biotechnol. 2015;99(20):8363–8375. doi: 10.1007/s00253-015-6920-7. [DOI] [PubMed] [Google Scholar]

- 31.Burja A.M., Radianingtyas H., Windust A., Barrow C.J. Isolation and characterization of polyunsaturated fatty acid producing Thraustochytrium species: screening of strains and optimization of omega-3 production. Appl Microbiol Biotechnol. 2006;72:1161–1169. doi: 10.1007/s00253-006-0419-1. [DOI] [PubMed] [Google Scholar]

- 32.Jakobsen A.N., Aasen I.M., Josefsen K.D., Strøm A.R. Accumulation of docosahexaenoic acid-rich lipid in thraustochytrid Aurantiochytrium sp. strain T66: effects of N and P starvation and O2 limitation. Appl Microbiol Biotechnol. 2008;80(2):297–306. doi: 10.1007/s00253-008-1537-8. [DOI] [PubMed] [Google Scholar]

- 33.Tanaka S, Yaguchi T, Shimizu S, Sogo T, Fujikawa S. Process for preparing docosahexaenoic acid and docosapentaenoic acid with ulkenia. US Patent No. 06509178 B1, 2003.

- 34.Chatdumrong W., Yongmanitchail W., Limtong S., Worawattanamateekul W. Optimization of docosahexaenoic acid (DHA) production and improvement of astaxanthin content in a mutant Schizochytrium limacinum isolated from mangrove forest in Thailand. Kasetsart J/Nat Sci. 2007;41:324–334. [Google Scholar]

- 35.Fan K.W., Vrijmoed L.L.P., Jones E.B.G. Physiological studies of subtropical mangrove thraustochytrids. Bot. Mar 2002;45(1):50–57. [Google Scholar]

- 36.Perveen Z., Ando H., Ueno A., Ito Y., Yamamoto Y., Yamada Y., Takagi T., Kaneko T., Kogame K., Okuyama H. Isolation and characterization of a novel thraustochytrid-like microorganism that efficiently produces docosahexaenoic acid. Biotechnol Lett. 2006;28(3):197–202. doi: 10.1007/s10529-005-5335-4. [DOI] [PubMed] [Google Scholar]

- 37.Taoka Y., Nagano N., Okita Y., Izumida H., Sugimoto S., Hayashi M. Effects of cold shock treatment on total lipid content and fatty acid composition of Aurantiochytrium limacinum strain mh0186. J Oleo Sci. 2011;60(5):217–220. doi: 10.5650/jos.60.217. [DOI] [PubMed] [Google Scholar]

- 38.Jain R., Raghukumar S., Tharanathan R., Bhosle N.B. Extracellular polysaccharide production by thraustochytrid protists. Mar Biotechnol. 2005;7(3):184–192. doi: 10.1007/s10126-004-4025-x. [DOI] [PubMed] [Google Scholar]

- 39.Cheirsilp B., Suwannarat W., Niyomdecha R. Mixed culture of oleaginous yeast Rhodotorula glutinis and microalga Chlorella vulgaris for lipid production from industrial wastes and its use as biodiesel feedstock. N Biotech. 2011;28(4):362–368. doi: 10.1016/j.nbt.2011.01.004. [DOI] [PubMed] [Google Scholar]

- 40.Cathrine S.J., Raghukumar C. Anaerobic denitrification in fungi from the coastal marine sediments off Goa, India. Mycol Res. 2009;113(1):100–109. doi: 10.1016/j.mycres.2008.08.009. [DOI] [PubMed] [Google Scholar]

- 41.Raghukumar S., Ramaiah N., Raghukumar C. Dynamics of thraustochytrid protists in the water column of the Arabian sea. Aquat Microb Ecol. 2001;24(2):175–186. [Google Scholar]

- 42.Bailey RB, Dimasi D, Hansen JM, Mirrasoul PJ, Ruecker CM, Veeder GT, et al. Enhanced production of lipids containing polyenoic fatty acid by very high density cultures of eukaryotic microbes in fermentors. US Patent No. 6607900, 2003.

- 43.Chi Z., Liu Y., Frear C., Chen S. Study of a two-stage growth of DHA-producing marine algae Schizochytrium limacinum SR21 with shifting dissolved oxygen level. Appl Microbiol Biotechnol. 2009;81(6):1141–1148. doi: 10.1007/s00253-008-1740-7. [DOI] [PubMed] [Google Scholar]

- 44.Scott S.D., Armenta R.E., Berryman K.T., Norman A.W. Use of raw glycerol to produce oil rich in polyunsaturated fatty acids by a thraustochytrid. Enzym Microb Technol. 2011;48(3):267–272. doi: 10.1016/j.enzmictec.2010.11.008. [DOI] [PubMed] [Google Scholar]

- 45.Raghukumar S. Thraustochytrid marine protists: production of PUFAs and other emerging technologies. Mar Biotechnol. 2008;10(6):631–640. doi: 10.1007/s10126-008-9135-4. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.