Abstract

The peak particle velocity datasets recorded during quarry blasts in the neighborhood villages and towns in Ibadan and Abeokuta were processed and analyzed in order to recommend a safe blast design for each of the quarries. The minimum peak particle velocity of 48.27 mm/s was recorded near the foundation of the nearest residence at the shot to monitored distance of 500 m. The tendency of ground vibration emanating from the quarry sites to cause damage to the structures in the nearby dwelling areas is very high. The peak particle velocity datasets recorded were not within the safe limit. Therefore the peak particle velocity that will not exceed 35 mm/s is recommended for a safe blast design.

Keywords: Quarry blasts, Ground vibration, Peak particle velocity data, Blast seismograph

Specifications Table

| Subject area | Physics |

| More specific subject area | Solid Earth Physics |

| Type of data | Tabular text files |

| How data was acquired | Field surveys using GPS, Blast seismograph (V9000 Seismograph) manufactured by Vibrock Limited, |

| Data format | Processed and analyzed |

| Experimental factors | N/A |

| Experimental features | Processing of raw data into the tabular text files and linear regression lines with brief description of the experiment |

| Data source location | Field surveys were conducted at five major quarry sites each in Ibadan and Abeokuta Areas, Nigeria. Ibadan Quarry Sites are: Ladson, 7.37°N,3.97°E; Offa, 7.38°N, 3.95°E; Seedvest,7.32°N, 3.92°E; Wetipp ,7.35°N, 3.87°E and Ratcon, 7.33°N,3.87°E. Abeokuta Quarry Sites are: Equation, 7.08°N,3.67°E; Verytaces, 7.15°N, 3.74°E; Phoenix, 7.18°N,3.73°E; Associated, 7.05°N,3.33°E and United, 7.06°N, 3.33°E. |

| Data accessibility | Data are available within this article |

Value of the data

-

•

The data could be used as a source of information for quarry blasters to determine the relationship between the peak particle velocity and ground vibration.

-

•

The data could be used to monitor the level of damage on structures in the neighborhood of the quarry sites.

-

•

The data revealed Shot - Monitored distances (the distance between the shot points at the quarry sites and Building Monitored Station Points in the neighborhood of quarry sites which is very useful to quarry blasters to ensure the safety of lives and properties of residents.

-

•

The data could serve as a measuring indicator that can be used by the Environmental protection Agency to ensure that the Peak Particle Velocity values do no exceed 50.8 mm/s recommended by the United State Bureau of Mine.

1. Data

The datasets presented here were recorded, using blast seismograph, during the blast induced earthquake triggered at ten quarry sites in Ibadan and Abeokuta areas, Nigeria. The data comprise peak particle velocity (longitudinal, vertical and transverse components), shot-monitored distance, charge weight and scaled distance. Of all the parameters in the datasets, the peak particle velocity dataset is the blast induced earthquake predictor. Blair [1] indicated that the peak particle velocity was strongly dependent upon the maximum charge weight in the near field and the total charge in the very far-field. On the contrary, Singh et al. [2], Singh and Vogt [3] stated that the charge weight could affect the ground vibration only at distances close to the blasts with the effects that diminish quickly with distance. And ultimately it is the charge weight that controls the ground vibration. Olofsson [4] and Persson [5] stated that the magnitude of ground vibrations depended on the quantity of explosives, characteristics of the rock, distance from the blasting site and geology of the deposits.

Pal Roy [6] carried out field investigations with blasting having charge weight varying from 0.5 to 220 t to study the influence of blast duration on ground vibrations. The results signified Charge weight (quantity of explosives) distinctively as the parameter responsible for the persistence of ground movement. However, Zhang [7] observed that the duration of the seismic waves is directly proportional to the charge weight in a blast and inversely proportional to the distance.

The components of these datasets were considered to minimize the complaints of the residents in the neighborhood of the quarry sites. In recent years, one of the problems encountered by technical personnel who are responsible for excavation with blasting is the rightful or unjustifiable complaints of people or organizations in the neighborhood of quarry sites [8], [9]. The number of these kinds of real or psychological disturbances has gradually increased with the increase in the population and urbanization. Therefore, an economical and safe blasting data should eliminate these kinds of problems at the same time. For this reason, one of the significant aspects of good blasting is safety in terms of environmental effects. One of the requirements to be met by blasting design is to determine the maximum amount of explosive per delay for a certain distance, especially in large blasts, and to be able to perform controlled blasting for the elimination of these environmental problems [10], [11]. Experimental studies by explosive producers and users are being continued to determine the effects of ground vibrations and air blast induced by blasting and to be able to take necessary precautions. Legal regulations related to this subject are being developed [12], [13], [14]. Rock blasting in urban areas creates annoying ground vibrations and also may inflict structural damage when excess quantity of explosives is used. Only about 20–30% of the energy expended, during the blasting, is utilized to fragment the rock [15]. Rock breakage process continues after the fracturing of the rock is initiated until the useful energy level becomes less than the strength of the rock [16], [17]. The seismic energy released after the explosion creates a rock deformation through the particle motion. This particle motion generates ground vibrations [18], [19]. The vibration problem may be minimized through the use of proper blast design techniques. The intensity of ground vibration is influenced by a number of factors such as the quantity of explosives, distance from the blast, blast geometry, etc. [20], [21]. Peak particle velocity (PPV) value which is the key for the damage level prediction has been used to develop specification in several countries [22]. Particle velocity is the primary concept for investigating the damage potential of blast-induced vibrations [3].

2. Experimental design, materials and methods

The data were generated during the survey of residential buildings in the neighborhood of the quarry sites. A Global Positioning System (GPS) was used to measure Shot-Monitored distances (the distance between the shot points at the quarry sites and Building Monitored Station Points (BMSP) in the neighbourhood of quarry sites). Shot-Monitored distances (D) were recorded from GPS. 3-component blast Seismographs were positioned at twenty BMSP in the dwelling areas surrounding each site. Longitudinal, vertical and transverse PPV datasets associated with the blast-induced earthquakes were recorded from the Seismograph.

Twenty PPV datasets were obtained for each site (as shown in Table 1, Table 2, Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10).

Table 1.

Datasets of ground vibration measurements and design parameters for blasting at Ladson Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1850 | 110.50 | 109.45 | 108.20 | 189.46 | 6.97 |

| 2 | 350 | 1850 | 86.25 | 85.95 | 86.15 | 149.16 | 8.14 |

| 3 | 400 | 1875 | 70.45 | 71.25 | 69.65 | 122.17 | 9.24 |

| 4 | 450 | 1950 | 60.20 | 60.35 | 60.10 | 104.30 | 10.20 |

| 5 | 500 | 1950 | 50.90 | 50.20 | 49.75 | 87.10 | 11.32 |

| 6 | 550 | 1950 | 43.70 | 43.85 | 43.15 | 75.46 | 12.46 |

| 7 | 600 | 1950 | 39.50 | 40.50 | 38.95 | 68.68 | 13.59 |

| 8 | 650 | 1875 | 32.35 | 32.75 | 32.45 | 56.32 | 15.01 |

| 9 | 700 | 1875 | 28.80 | 27.50 | 28.10 | 48.74 | 16.17 |

| 10 | 750 | 1875 | 25.75 | 24.95 | 24.85 | 43.62 | 17.32 |

| 11 | 800 | 1912.5 | 23.60 | 22.65 | 23.85 | 40.48 | 18.29 |

| 12 | 850 | 1912.5 | 21.45 | 21.15 | 20.95 | 36.69 | 19.44 |

| 13 | 900 | 1912.5 | 19.55 | 19.15 | 19.85 | 33.81 | 20.58 |

| 14 | 950 | 1900 | 17.85 | 18.95 | 17.25 | 31.23 | 21.79 |

| 15 | 1000 | 1875 | 16.25 | 16.85 | 15.75 | 28.21 | 23.09 |

| 16 | 1050 | 2950 | 21.65 | 20.75 | 21.15 | 36.70 | 19.33 |

| 17 | 1100 | 1800 | 13.50 | 13.05 | 13.25 | 22.98 | 25.93 |

| 18 | 1150 | 2750 | 17.65 | 18.75 | 17.25 | 30.99 | 21.93 |

| 19 | 1200 | 2150 | 13.55 | 13.05 | 13.95 | 23.42 | 25.88 |

| 20 | 1250 | 2050 | 12.20 | 11.75 | 12.55 | 21.08 | 27.61 |

Table 2.

Datasets of ground vibration measurements and design parameters for blasting at Offa Quarry.

| Data monitoring points | Shot to monitored distance [metre] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1450 | 90.85 | 90.75 | 90.25 | 156.95 | 7.88 |

| 2 | 350 | 1450 | 71.05 | 71.30 | 70.95 | 100.94 | 9.19 |

| 3 | 400 | 1400 | 55.75 | 55.75 | 55.08 | 96.18 | 10.69 |

| 4 | 450 | 1450 | 47.50 | 47.40 | 47.35 | 82.13 | 11.82 |

| 5 | 500 | 1400 | 39.05 | 39.15 | 38.95 | 67.64 | 13.36 |

| 6 | 550 | 1500 | 35.45 | 35.55 | 35.75 | 60.63 | 14.20 |

| 7 | 600 | 1200 | 25.70 | 25.85 | 27.45 | 45.63 | 17.32 |

| 8 | 650 | 1850 | 32.05 | 32.00 | 32.05 | 55.48 | 15.11 |

| 9 | 700 | 1850 | 28.40 | 28.45 | 28.35 | 49.19 | 16.27 |

| 10 | 750 | 950 | 14.95 | 14.90 | 14.85 | 25.81 | 24.33 |

| 11 | 800 | 1350 | 17.80 | 17.70 | 17.85 | 30.80 | 21.77 |

| 12 | 850 | 1250 | 15.25 | 15.20 | 15.15 | 26.33 | 24.04 |

| 13 | 900 | 1250 | 13.95 | 13.80 | 12.95 | 23.51 | 25.46 |

| 14 | 950 | 1500 | 14.75 | 14.85 | 14.25 | 25.32 | 24.53 |

| 15 | 1000 | 1500 | 13.50 | 13.25 | 13.35 | 23.30 | 25.82 |

| 16 | 1050 | 1750 | 14.25 | 13.95 | 14.05 | 24.39 | 25.10 |

| 17 | 1100 | 2350 | 16.75 | 16.05 | 16.25 | 28.32 | 22.69 |

| 18 | 1150 | 1350 | 10.00 | 9.85 | 10.05 | 17.26 | 31.30 |

| 19 | 1200 | 1450 | 9.90 | 9.85 | 9.25 | 16.75 | 31.51 |

| 20 | 1250 | 2755 | 15.50 | 15.20 | 14.95 | 26.36 | 23.81 |

Table 3.

Datasets of ground vibration measurements and design parameters for blasting at Seed Vest Quarry.

| Data monitoring points | Shot to monitored distance [metre] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1650 | 100.75 | 101.05 | 99.85 | 174.16 | 7.39 |

| 2 | 350 | 1550 | 74.90 | 73.45 | 73.95 | 128.35 | 8.89 |

| 3 | 400 | 1355 | 54.30 | 54.95 | 53.85 | 94.17 | 10.89 |

| 4 | 450 | 1555 | 50.25 | 49.75 | 50.05 | 86.63 | 11.22 |

| 5 | 500 | 1850 | 48.75 | 48.35 | 48.05 | 83.80 | 11.62 |

| 6 | 550 | 1900 | 35.95 | 36.15 | 36.95 | 62.24 | 12.62 |

| 7 | 600 | 1400 | 29.15 | 29.75 | 28.85 | 50.67 | 16.03 |

| 8 | 650 | 1100 | 21.15 | 20.55 | 20.95 | 36.17 | 19.60 |

| 9 | 700 | 1250 | 20.80 | 21.05 | 20.10 | 34.77 | 19.80 |

| 10 | 750 | 1500 | 21.55 | 20.45 | 21.05 | 36.41 | 19.30 |

| 11 | 800 | 1800 | 22.45 | 22.10 | 21.95 | 38.42 | 18.86 |

| 12 | 850 | 1950 | 21.75 | 20.65 | 20.05 | 36.85 | 19.25 |

| 13 | 900 | 1250 | 13.90 | 13.10 | 13.55 | 23.42 | 25.46 |

| 14 | 950 | 1250 | 12.75 | 11.95 | 12.10 | 21.25 | 26.87 |

| 15 | 1000 | 1200 | 10.75 | 11.05 | 10.45 | 18.62 | 28.88 |

| 16 | 1050 | 1950 | 15.50 | 14.55 | 15.95 | 26.58 | 23.78 |

| 17 | 1100 | 1800 | 13.05 | 13.55 | 12.75 | 22.73 | 25.93 |

| 18 | 1150 | 1800 | 12.55 | 11.85 | 12.25 | 21.17 | 27.11 |

| 19 | 1200 | 1800 | 11.75 | 10.65 | 11.25 | 19.44 | 28.28 |

| 20 | 1250 | 1950 | 10.25 | 11.75 | 10.55 | 18.83 | 28.31 |

Table 4.

Datasets of ground vibration measurements and design parameters for blasting at Wetipp Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1600 | 110.44 | 110.42 | 109.98 | 191.01 | 7.50 |

| 2 | 350 | 1450 | 82.24 | 82.26 | 82.22 | 142.44 | 9.19 |

| 3 | 400 | 1850 | 80.85 | 80.81 | 80.83 | 140.00 | 9.30 |

| 4 | 450 | 1700 | 64.10 | 64.15 | 64.12 | 111.06 | 10.91 |

| 5 | 500 | 1300 | 45.30 | 44.95 | 45.35 | 78.29 | 13.87 |

| 6 | 550 | 1750 | 48.94 | 48.85 | 48.98 | 84.74 | 13.15 |

| 7 | 600 | 1950 | 46.66 | 46.65 | 46.62 | 80.79 | 13.59 |

| 8 | 650 | 1800 | 39.20 | 39.25 | 39.40 | 68.04 | 15.32 |

| 9 | 700 | 1200 | 26.24 | 26.15 | 26.32 | 45.44 | 20.21 |

| 10 | 750 | 1150 | 23.02 | 22.95 | 23.05 | 39.85 | 22.12 |

| 11 | 800 | 1650 | 27.24 | 27.15 | 27.20 | 47.11 | 19.69 |

| 12 | 850 | 1050 | 17.98 | 17.85 | 17.25 | 30.65 | 26.23 |

| 13 | 900 | 1850 | 24.95 | 24.55 | 24.85 | 42.93 | 20.92 |

| 14 | 950 | 1300 | 17.86 | 17.65 | 17.95 | 28.87 | 26.35 |

| 15 | 1000 | 1950 | 22.25 | 22.05 | 22.15 | 38.37 | 22.65 |

| 16 | 1050 | 1100 | 13.69 | 13.45 | 13.65 | 23.55 | 31.66 |

| 17 | 1100 | 1250 | 14.03 | 13.85 | 13.95 | 24.15 | 31.11 |

| 18 | 1150 | 1350 | 13.91 | 13.45 | 13.85 | 23.80 | 31.30 |

| 19 | 1200 | 1500 | 14.12 | 13.90 | 14.05 | 24.29 | 30.98 |

| 20 | 1250 | 1750 | 14.88 | 14.80 | 14.90 | 25.74 | 29.88 |

Table 5.

Datasets of ground vibration measurements and design parameters for blasting at Ratcon Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1500 | 105.61 | 104.95 | 105.24 | 182.33 | 7.75 |

| 2 | 350 | 1950 | 101.52 | 101.32 | 101.55 | 175.74 | 7.93 |

| 3 | 400 | 1850 | 77.11 | 77.00 | 69.88 | 129.45 | 9.30 |

| 4 | 450 | 1100 | 40.27 | 40.15 | 40.33 | 69.715 | 13.57 |

| 5 | 500 | 1050 | 32.28 | 31.98 | 32.17 | 55.67 | 15.43 |

| 6 | 550 | 1750 | 42.51 | 42.02 | 42.45 | 73.31 | 13.15 |

| 7 | 600 | 1200 | 26.46 | 26.39 | 26.42 | 45.77 | 17.32 |

| 8 | 650 | 1400 | 26.33 | 26.30 | 26.35 | 45.60 | 17.37 |

| 9 | 700 | 1700 | 27.39 | 27.32 | 27.43 | 47.42 | 16.98 |

| 10 | 750 | 1350 | 19.95 | 19.75 | 19.84 | 34.38 | 20.41 |

| 11 | 800 | 1800 | 22.86 | 22.84 | 22.79 | 39.54 | 18.86 |

| 12 | 850 | 1300 | 15.57 | 15.45 | 15.52 | 26.87 | 23.57 |

| 13 | 900 | 1550 | 16.42 | 16.35 | 16.40 | 28.39 | 22.86 |

| 14 | 950 | 1200 | 12.00 | 12.05 | 12.02 | 20.83 | 27.42 |

| 15 | 1000 | 1950 | 16.69 | 16.66 | 16.62 | 28.85 | 22.65 |

| 16 | 1050 | 1900 | 15.00 | 15.05 | 15.02 | 26.02 | 24.09 |

| 17 | 1100 | 1100 | 8.66 | 8.59 | 8.62 | 13.94 | 33.17 |

| 18 | 1150 | 1400 | 8.87 | 8.89 | 8.84 | 15.36 | 30.74 |

| 19 | 1200 | 1550 | 10.01 | 10.05 | 10.08 | 17.40 | 30.48 |

| 20 | 1250 | 1650 | 9.85 | 9.79 | 9.81 | 15.01 | 30.77 |

Table 6.

Datasets of ground vibration measurements and design parameters for blasting at Equation Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1400 | 114.70 | 114.75 | 114.72 | 198.71 | 8.02 |

| 2 | 350 | 1250 | 84.85 | 84.82 | 83.97 | 146.44 | 9.90 |

| 3 | 400 | 1600 | 83.63 | 82.98 | 83.45 | 144.37 | 10.00 |

| 4 | 450 | 1150 | 55.81 | 55.78 | 55.84 | 96.67 | 13.27 |

| 5 | 500 | 1000 | 43.44 | 43.41 | 43.52 | 75.27 | 15.81 |

| 6 | 550 | 2050 | 63.32 | 63.25 | 63.30 | 109.62 | 12.15 |

| 7 | 600 | 1350 | 41.48 | 41.35 | 41.44 | 71.75 | 16.33 |

| 8 | 650 | 1250 | 35.01 | 34.85 | 34.96 | 60.52 | 18.38 |

| 9 | 700 | 1650 | 38.40 | 38.38 | 34.42 | 64.28 | 17.23 |

| 10 | 750 | 1250 | 28.53 | 28.49 | 28.51 | 49.38 | 21.21 |

| 11 | 800 | 1900 | 35.10 | 35.03 | 35.06 | 60.73 | 18.35 |

| 12 | 850 | 1350 | 25.21 | 25.14 | 25.26 | 43.65 | 23.13 |

| 13 | 900 | 1300 | 22.61 | 22.63 | 22.58 | 39.16 | 24.96 |

| 14 | 950 | 1700 | 25.35 | 25.29 | 25.31 | 43.85 | 23.04 |

| 15 | 1000 | 1550 | 22.05 | 22.12 | 22.09 | 38.26 | 25.40 |

| 16 | 1050 | 1650 | 21.51 | 21.46 | 21.54 | 37.24 | 25.85 |

| 17 | 1100 | 1500 | 18.80 | 18.75 | 18.72 | 32.49 | 28.40 |

| 18 | 1150 | 1250 | 15.48 | 15.39 | 15.43 | 26.73 | 32.53 |

| 19 | 1200 | 1450 | 16.20 | 16.08 | 16.13 | 27.95 | 31.51 |

| 20 | 1250 | 1750 | 17.48 | 17.42 | 17.51 | 30.26 | 29.88 |

Table 7.

Datasets of ground vibration measurements and design parameters for blasting at Verytaces Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1050 | 142.91 | 142.94 | 142.89 | 247.53 | 9.26 |

| 2 | 350 | 1150 | 125.71 | 125.69 | 125.74 | 217.742 | 10.32 |

| 3 | 400 | 1250 | 112.80 | 112.72 | 112.77 | 195.31 | 11.31 |

| 4 | 450 | 1400 | 104.95 | 104.91 | 103.89 | 181.15 | 12.03 |

| 5 | 500 | 1450 | 94.62 | 94.58 | 94.53 | 163.81 | 13.13 |

| 6 | 550 | 1300 | 79.28 | 79.34 | 79.38 | 137.41 | 15.25 |

| 7 | 600 | 1450 | 76.31 | 75.95 | 76.26 | 131.94 | 15.76 |

| 8 | 650 | 1350 | 66.56 | 66.51 | 66.62 | 115.29 | 17.69 |

| 9 | 700 | 1650 | 68.65 | 67.93 | 68.62 | 118.47 | 17.23 |

| 10 | 750 | 1500 | 59.83 | 59.87 | 59.68 | 103.57 | 19.36 |

| 11 | 800 | 1100 | 46.17 | 46.10 | 46.05 | 79.86 | 24.12 |

| 12 | 850 | 1000 | 40.63 | 40.57 | 40.53 | 70.28 | 26.88 |

| 13 | 900 | 1300 | 44.34 | 44.39 | 44.42 | 76.87 | 24.96 |

| 14 | 950 | 1200 | 39.68 | 39.60 | 39.65 | 68.66 | 27.42 |

| 15 | 1000 | 1700 | 45.87 | 45.83 | 45.78 | 79.37 | 24.25 |

| 16 | 1050 | 1600 | 41.78 | 41.66 | 41.72 | 72.26 | 26.25 |

| 17 | 1100 | 1100 | 31.71 | 31.70 | 31.64 | 54.88 | 33.17 |

| 18 | 1150 | 1050 | 29.27 | 29.15 | 29.21 | 50.59 | 35.49 |

| 19 | 1200 | 1350 | 32.29 | 32.35 | 32.19 | 55.90 | 32.66 |

| 20 | 1250 | 1250 | 29.40 | 29.34 | 29.31 | 50.84 | 35.36 |

Table 8.

Datasets of ground vibration measurements and design parameters for blasting at Phoenix Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1550 | 79.83 | 79.80 | 79.88 | 138.28 | 7.62 |

| 2 | 350 | 1600 | 61.13 | 61.22 | 61.18 | 105.96 | 8.75 |

| 3 | 400 | 1650 | 48.67 | 48.53 | 48.62 | 84.19 | 9.85 |

| 4 | 450 | 1450 | 34.23 | 34.15 | 34.20 | 59.22 | 11.82 |

| 5 | 500 | 1950 | 37.17 | 37.32 | 37.24 | 64.51 | 11.32 |

| 6 | 550 | 1750 | 27.86 | 27.91 | 27.83 | 48.27 | 13.15 |

| 7 | 600 | 1550 | 20.95 | 20.87 | 20.90 | 36.21 | 15.24 |

| 8 | 650 | 1250 | 14.59 | 14.50 | 14.63 | 25.24 | 18.38 |

| 9 | 700 | 1350 | 13.62 | 13.57 | 13.51 | 23.50 | 19.05 |

| 10 | 750 | 1450 | 12.77 | 12.70 | 12.82 | 22.11 | 19.70 |

| 11 | 800 | 1450 | 11.27 | 11.22 | 11.19 | 19.45 | 21.01 |

| 12 | 850 | 1500 | 10.36 | 10.42 | 10.39 | 18.00 | 21.95 |

| 13 | 900 | 1600 | 9.88 | 9.75 | 9.82 | 17.00 | 22.5 |

| 14 | 950 | 1350 | 7.55 | 7.48 | 7.61 | 13.07 | 25.86 |

| 15 | 1000 | 1250 | 6.35 | 6.27 | 6.40 | 10.98 | 28.28 |

| 16 | 1050 | 1050 | 4.89 | 4.81 | 4.76 | 8.35 | 32.40 |

| 17 | 1100 | 1100 | 4.67 | 4.55 | 4.63 | 8.00 | 33.17 |

| 18 | 1150 | 1250 | 4.85 | 4.80 | 4.78 | 8.33 | 32.53 |

| 19 | 1200 | 1600 | 5.67 | 5.59 | 5.62 | 9.75 | 30.00 |

| 20 | 1250 | 1750 | 5.71 | 5.76 | 5.82 | 9.98 | 29.88 |

Table 9.

Datasets of ground vibration measurements and design parameters for blasting at Associated Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 1200 | 106.00 | 106.12 | 106.04 | 183.69 | 8.66 |

| 2 | 350 | 1150 | 83.21 | 83.12 | 83.19 | 144.06 | 10.32 |

| 3 | 400 | 1800 | 94.28 | 94.15 | 94.22 | 163.19 | 9.43 |

| 4 | 450 | 1850 | 81.66 | 81.58 | 81.52 | 141.31 | 10.46 |

| 5 | 500 | 1950 | 73.22 | 73.27 | 73.31 | 126.90 | 11.32 |

| 6 | 550 | 1450 | 52.33 | 52.26 | 52.20 | 90.52 | 14.44 |

| 7 | 600 | 1350 | 44.18 | 44.25 | 44.09 | 76.51 | 16.33 |

| 8 | 650 | 1450 | 41.56 | 41.48 | 41.61 | 71.97 | 17.07 |

| 9 | 700 | 1500 | 38.40 | 38.35 | 38.46 | 66.52 | 18.07 |

| 10 | 750 | 1750 | 38.83 | 38.79 | 38.88 | 67.26 | 17.93 |

| 11 | 800 | 1650 | 34.11 | 33.92 | 34.19 | 59.02 | 19.69 |

| 12 | 850 | 1700 | 32.03 | 32.11 | 31.98 | 55.49 | 20.62 |

| 13 | 900 | 1750 | 30.20 | 30.32 | 30.27 | 52.42 | 21.51 |

| 14 | 950 | 1600 | 26.34 | 26.25 | 26.30 | 45.55 | 23.75 |

| 15 | 1000 | 1850 | 27.13 | 26.85 | 27.02 | 46.77 | 23.25 |

| 16 | 1050 | 1400 | 20.93 | 20.79 | 20.84 | 36.12 | 28.06 |

| 17 | 1100 | 1450 | 20.11 | 20.23 | 20.16 | 34.93 | 28.89 |

| 18 | 1150 | 1350 | 18.00 | 18.19 | 18.11 | 31.35 | 31.30 |

| 19 | 1200 | 1800 | 20.70 | 20.81 | 20.62 | 35.87 | 28.28 |

| 20 | 1250 | 1950 | 20.68 | 20.52 | 20.60 | 35.68 | 28.31 |

Table 10.

Datasets of ground vibration measurements and design parameters for blasting at United Quarry.

| Data monitoring points | Shot to monitored distance [metres] | Charge weight (in 50 holes) [kg] | Peak Particle velocity (mm/s) |

Scaled distance | |||

|---|---|---|---|---|---|---|---|

| Vertical [mm/s] | Longitudinal [mm/s] | Transversal [mm/s] | Vectoral Sum [mm/s] | ||||

| 1 | 300 | 850 | 83.56 | 83.47 | 83.66 | 144.74 | 10.29 |

| 2 | 350 | 750 | 61.96 | 61.84 | 61.75 | 107.13 | 12.78 |

| 3 | 400 | 1300 | 75.32 | 75.40 | 74.28 | 129.91 | 11.09 |

| 4 | 450 | 1100 | 57.05 | 57.22 | 57.15 | 98.97 | 13.57 |

| 5 | 500 | 650 | 34.31 | 34.38 | 34.43 | 59.54 | 19.61 |

| 6 | 550 | 1500 | 53.57 | 53.48 | 53.65 | 92.78 | 14.20 |

| 7 | 600 | 1750 | 52.84 | 52.72 | 52.90 | 91.49 | 14.34 |

| 8 | 650 | 950 | 31.04 | 31.15 | 31.24 | 53.94 | 21.09 |

| 9 | 700 | 1000 | 29.03 | 29.12 | 28.86 | 50.24 | 22.14 |

| 10 | 750 | 1300 | 31.63 | 31.56 | 31.72 | 54.80 | 20.80 |

| 11 | 800 | 950 | 23.31 | 23.42 | 23.38 | 40.48 | 25.96 |

| 12 | 850 | 950 | 21.44 | 21.56 | 21.49 | 37.23 | 27.58 |

| 13 | 900 | 1200 | 23.27 | 23.08 | 23.16 | 40.13 | 25.98 |

| 14 | 950 | 1550 | 25.77 | 25.62 | 25.70 | 44.51 | 24.13 |

| 15 | 1000 | 850 | 15.86 | 15.92 | 15.80 | 27.47 | 34.30 |

| 16 | 1050 | 1400 | 20.93 | 20.85 | 20.77 | 36.11 | 28.06 |

| 17 | 1100 | 1400 | 19.63 | 19.75 | 19.81 | 34.17 | 29.40 |

| 18 | 1150 | 700 | 11.44 | 11.29 | 11.38 | 19.69 | 43.47 |

| 19 | 1200 | 1600 | 19.08 | 19.22 | 18.97 | 33.07 | 30.00 |

| 20 | 1250 | 1000 | 13.04 | 13.17 | 13.29 | 22.81 | 39.53 |

The patterns and protocols applied by the quarry blasters during the shots were followed in obtaining these data. For blasting operations at these sites, Ammonium Nitrate Fuel Oil (ANFO) was used as explosive. The explosives were detonated using magnadet detonator. Scaled distance (SD) data were obtained for each BMSP (as shown in Table 1, Table 2, Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10) using:

| (1) |

Charge weight of explosive, W, tends to Wm, when the quantity of explosive is maximum.

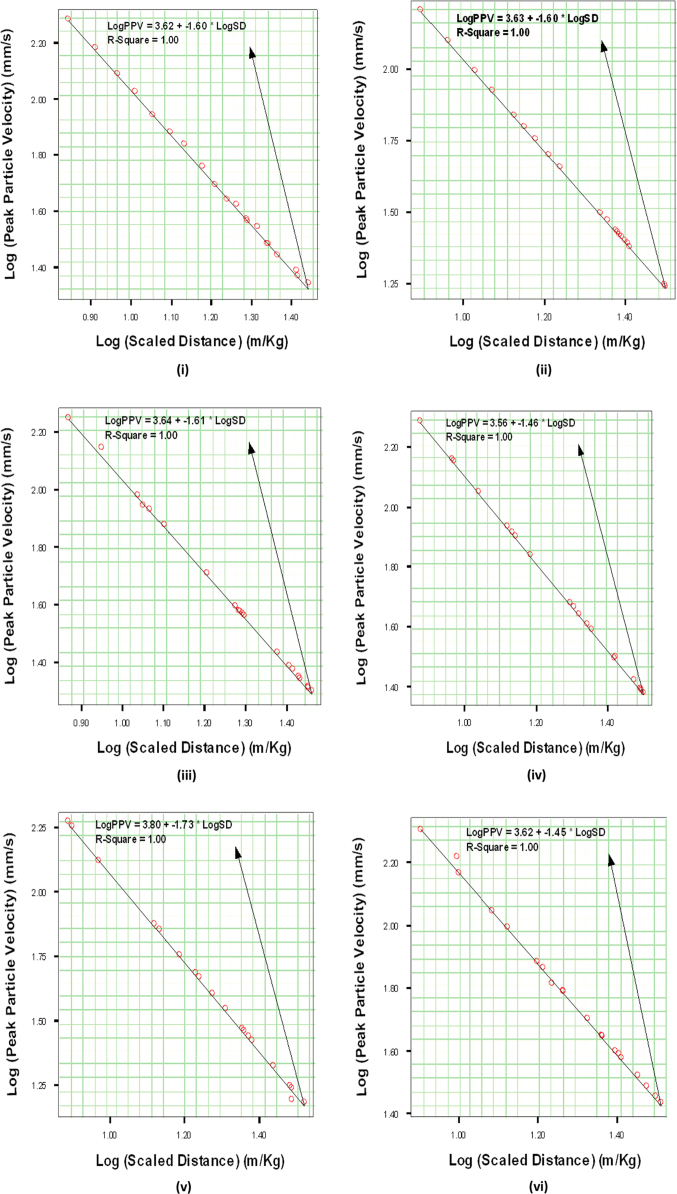

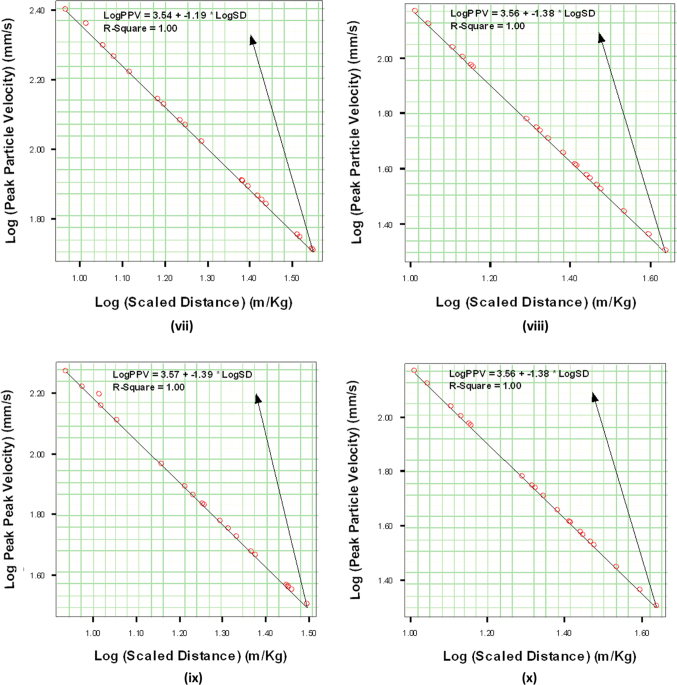

In order to establish a useful relationship between PPV and SD, as shown in Eq. (2), the PPV against SD data pairs obtained for each site was plotted using linear regression lines (Fig. 1).

| (2) |

Fig. 1.

Logarithmic plot of Peak Particle Velocity against Scaled Distance datasets at Five major Quarry Sites each in Ibadan and Abeokuta, Nigeria. Ibadan quarry sites are: (i) Ladson (ii) Offa (iii) Seedvest (iv) Wetipp and (v) Ratcon. Abeokuta quarry sites are: (vi) Equation, (vii) Verytaces, (viii) Phoenix, (ix) Associated and (x) United.

and are rock energy transfer and attenuation constants of the sites determined from the log PPV versus log SD linear regression graphs.

The maximum quantity of explosives (Wm) that can be detonated safely was determined using Eqs. (1), (2).

The PPV datasets obtained from ground vibrations at all the monitored stations recorded ranged from 9.98 to 247.53 mm/s. The PPV exceeded 50.8 mm/s recommended by the United States Bureau of Mine (USBM) at 55% of BMSP. The PPV data revealed that the vibration intensities were not bearable at most of the monitored stations. The analysis of data signifies that there is a correlation between the exceeded or large PPV recorded and the cracked walls of buildings in the vicinity of quarry sites.

A combination of scaled distance and geological constants, k and β parameters obtained from the regression lines in Fig. 1, could be used to predict the exact PPV associated with the vibration intensities of the quarry sites. Combination of these parameters with the PPV could also be used to determine the maximum quantity of the explosive to be detonated that will not cause damage to the buildings and structures around the sites.

Acknowledgements

We acknowledge the unflinching support of quarry owners in providing us all necessary information for the acquisition of these data.

Footnotes

Supplementary data associated with this article can be found in the online version at doi:10.1016/j.dib.2018.04.103.

Transparency document. Supplementary material

Supplementary material

.

References

- 1.D.P. Blair, Some problems associated with standard charge weight vibration scaling laws, in: Proceedings of the 3rd International Symposium on Fragmentation by Blasting, Brisbane, 1990, pp. 149–158.

- 2.P.K. Singh, R.B. Singh, D.P. Singh, A study on the effect of total charge versus charge per delay on ground vibration due to blasting. FOSMIN’98, India, 1998, pp. 128–133.

- 3.Singh P.K., Vogt W. Ground vibration: prediction for safe and efficient blasting. Erzmetall. 1998;51(10):677–684. [Google Scholar]

- 4.Olofsson S.O. APPLEX AB; Ärla: 2002. Blasters׳ Manual. [Google Scholar]

- 5.Persson P.A., Holmberg R., Lee J. CRC; USA: 1994. Rock Blasting and Explosives Engineering. [Google Scholar]

- 6.Pal Roy P. Vibration control in an opencast mine based on improved blast vibration predictors. Min. Sci. Technol. 1991;12 [Google Scholar]

- 7.Zhang J. In: Explosives and Blasting Technique. Holmberg R., editor. Balkema; Rotterdam: 2000. pp. 335–341. [Google Scholar]

- 8.J.J. Felice, Applications of modeling to reduce vibration and airblast levels. Paper presented at Fourth International Symposium on Rock Fragmentation by Blasting, Vienna, 5–8 July 1993, 1993.

- 9.Kahriman A., Ozer U., Aksoy M., Karadogan A., Tuncer G. Environmental impacts of bench blasting at Hisarcik Boron open pit mine in Turkey. International. J. Geosci. Environ. Geol. 2006:1015–1023. [Google Scholar]

- 10.G.J. Johnston and S. Durucan, The numerical prediction, analysis and modelling of ground vibration induced by blasting. Paper presented 3rd International Symposium on Mine Planning and Equipment Selection, Istanbul, 18–20 October 1994.

- 11.U. Ozer, A. Kahriman, A. Karadogan, G. Tuncer, M. Aksoy and K. Ozdemir, Investigation of the environmental effects of ground vibration induced by blasting in various quarries located at northern Cyprus. Paper presented 5th International Conference: Modern Management of Mine Producing Geology and Environment Protection, Albena Resort, Varna, Bulgaria, 13–17 June 2005, pp. 257–271.

- 12.Singh B., Pal Roy P.P. Balkema Publisher; Rotterdam: 1993. Blasting in Ground Excavation and Mines; p. 188. [Google Scholar]

- 13.A. Kahriman, G. Tuncer, S. Gorgun, A. Karadogan, Monitoring and analyzing ground vibration induced by different blasting excavation activities. Paper presented at Seventh International Symposium on Environmental Issues and Waste Management in Energy and Mineral Production, Cagliari, Italy, 7–10 October 2002, pp 385–394.

- 14.Kahriman A. Analysis of ground vibrations caused by bench blasting at can open-pit lignite mine in Turkey. Int. J Geosci. Environ. Geol. 2002;41(6):653–661. [Google Scholar]

- 15.Anonym . Atlas Powder Company; Dallas: 1987. Explosives and Rock Blasting. [Google Scholar]

- 16.A. Ghosh, A New Analytical Predictor of Ground Vibrations Induced by Blasting. M.Sc. Thesis of the University of Arizona, 1983.

- 17.R. Guha, Ground Vibrations from Surface Mine Blasting-an Investigation. M.Tech.Thesis of Mining Engineering Department of Indian School of Mines, 1984.

- 18.Singh B., Pal Roy P.P. Balkema Publisher; Rotterdam: 1993. Blasting in Ground Excavation and Mines; p. 188. [Google Scholar]

- 19.Konya C.J., Walter E.J. Prentice Hall; New Jersey: 1990. Surface Blast Design. [Google Scholar]

- 20.Venkatesh H.S. Influence of total charge in a blast on the intensity of ground vibrations-field experiment and computer simulation. Fragblast. 2005;9(3):127–138. [Google Scholar]

- 21.Kahriman A., Ozer U., Aksoy M., Karadogan A., Tuncer G. Environmental impacts of bench blasting at Hisarcik Boron open pit mine in Turkey. Environ. Geol. 2006;50(7):1015–1023. [Google Scholar]

- 22.Nicholls, H.R., Johnson, C.F., Duvall, W.I., Blasting vibration effects on structures. United State Bureau of Mines Report of Investigation 656, 1971.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material