Abstract

Conventional water resources in many regions are insufficient to meet the water needs of growing populations, thus reuse is gaining acceptance as a method of water supply augmentation. Recent advancements in membrane technology have allowed for the reclamation of municipal wastewater for the production of drinking water, i.e., potable reuse. Although public perception can be a challenge, potable reuse is often the least energy-intensive method of providing additional drinking water to water stressed regions. A variety of membranes have been developed that can remove water contaminants ranging from particles and pathogens to dissolved organic compounds and salts. Typically, potable reuse treatment plants use polymeric membranes for microfiltration or ultrafiltration in conjunction with reverse osmosis and, in some cases, nanofiltration. Membrane properties, including pore size, wettability, surface charge, roughness, thermal resistance, chemical stability, permeability, thickness and mechanical strength, vary between membranes and applications. Advancements in membrane technology including new membrane materials, coatings, and manufacturing methods, as well as emerging membrane processes such as membrane bioreactors, electrodialysis, and forward osmosis have been developed to improve selectivity, energy consumption, fouling resistance, and/or capital cost. The purpose of this review is to provide a comprehensive summary of the role of polymeric membranes in the treatment of wastewater to potable water quality and highlight recent advancements in separation processes. Beyond membranes themselves, this review covers the background and history of potable reuse, and commonly used potable reuse process chains, pretreatment steps, and advanced oxidation processes. Key trends in membrane technology include novel configurations, materials and fouling prevention techniques. Challenges still facing membrane-based potable reuse applications, including chemical and biological contaminant removal, membrane fouling, and public perception, are highlighted as areas in need of further research and development.

Keywords: Potable reuse, polymeric membranes, nanocomposite membranes, reverse osmosis, filtration, fouling

1. Introduction

Dwindling water supplies and growing populations have made planned potable reuse an increasingly important component of water resource management for many urban areas around the world [1–3]. Although reuse can only be a portion of a water supply portfolio due to intrinsic water losses, reuse of wastewater can augment the supply of water for agriculture, industry, and potable use, even in regions where climate change and cyclical droughts make traditional supplies unreliable. Membranes, particularly polymeric membranes, play a crucial role in the purification of municipal wastewater to potable quality, and are the core part of almost all of these systems [1, 2]. However, despite the technologies available, several challenges including membrane fouling, contaminant permeation, energy consumption, high pretreatment costs, managing treatment residuals, membrane integrity, and public perception limit widespread implementation of potable reuse [1, 3–5]. For example, as of 2010, only about 0.1% of treated municipal wastewater was directed to planned potable reuse in the U.S. [6]. The purpose of this review is to summarize recent developments for polymeric membrane that relate to potable water reuse, and also to identify areas in which future research and innovation are needed.

1.1 Reuse Terminology

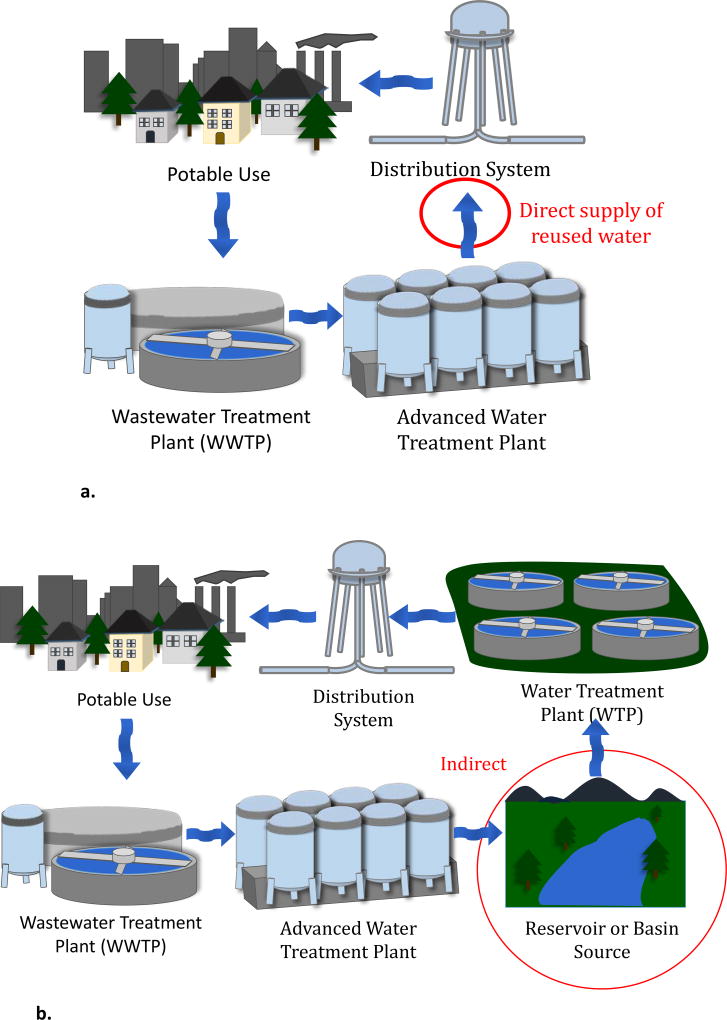

Planned potable reuse projects can be categorized as direct or indirect [3]. Direct potable reuse (DPR) is the direct addition of reclaimed wastewater to a drinking water treatment plant’s influent (referred to as “raw water augmentation”) or a drinking water distribution system (“treated drinking water augmentation”, Figure 1a). Indirect potable reuse (IPR) is the planned addition of purified wastewater (i.e., reclaimed wastewater) to an environmental buffer, namely a surface water reservoir (“reservoir water augmentation”) or groundwater aquifer (“groundwater augmentation”) [7], that is subsequently used for a drinking water supply (Figure 1b). In addition, de facto potable reuse (i.e., unplanned potable reuse) refers to the production of drinking water from wastewater-impacted water resources (Figure 1c). De facto potable reuse is common [8] and often unavoidable in major river systems such as adjacent to the Mississippi and Nile River (in the U.S. and Egypt, respectively).

Figure 1.

a. Schematic diagram of direct potable reuse (DPR). Treated water is sent directly back into the distribution system.

b. Schematic diagram of indirect potable reuse (IPR). An intermediate potable water source (bottom right, in red circle) acts as an environmental buffer and makes the process indirect.

c. Schematic diagram of de facto potable reuse (unplanned potable reuse). Note the discharge into a water source without as thorough treatment.

As one implementation of IPR, water agencies may also inject or infiltrate reclaimed water at locations in between the ocean and drinking water production wells to slow or reverse seawater intrusion into coastal aquifers. While de facto potable reuse and IPR have been practiced for some time, DPR has more recently become a technically and (to a lesser extent) socially viable reuse option in many geographies world-wide [4].

1.2 Potable Reuse History

The purification of wastewater has been examined as a means of augmenting conventional drinking water supplies for over 100 years [1]. In the 1920s, the Los Angeles Department of Water and Power constructed a wastewater purification plant to accommodate increased water demand due to rapid development and the lack of additional water supplies prior to access to Colorado River water [6]. By the 1930s, spreading basins were being used to augment groundwater with the effluent of a wastewater treatment in Southern California [1]. In 1968, the first DPR scheme was constructed in Windhoek, Namibia; in the years following, numerous IPR projects were established globally [7]. It was not until 1977 that membranes became an integral component of potable water reuse applications, when RO membranes were first used to purify wastewater at Orange County Water District’s Water Factory 21 [7].

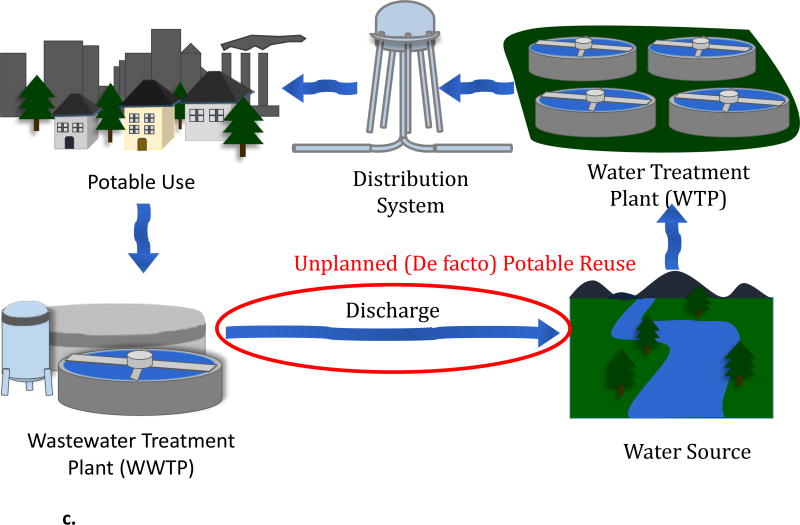

As treatment technologies for potable reuse have evolved over 50 years, there has been a gradual shift away from traditional processes, such as lime softening, toward membrane filtration [6]. As the cost and performance of membrane products have improved, polymeric membranes played an increasingly important role in potable reuse [9]. Polymeric membranes are now used to remove colloidal and dissolved materials in most potable reuse facilities. In the last 20 years, the number of IPR and DPR projects employing membrane technologies has increased significantly in the U.S., Australia, Singapore, and South Africa (Table 1). Globally, water reuse for potable and non-potable applications continues to be a critical water resource (Figure 2.), and has reached approximately 32 million m3/day [10].

Table 1.

Summary of major potable water reuse projects [11].

| Utility | Location | Membrane processes |

Additional treatment processes |

Capacity | Began operating |

Purpose |

|---|---|---|---|---|---|---|

| Orange County Water District/Orange County Sanitation District | Fountain Valley, CA, U.S. | MF-RO | Prescreening, UV-AOP, decarbonation, stabilization | 3.8E5 m3/d (100 MGD) | 2008 in current form | Seawater intrusion barrier, groundwater augmentation |

| City of Scottsdale | Scottsdale, AZ, U.S. | MF-RO | Pre-ozonation, UV disinfection, decarbonation, stabilization | 9.5E4 m3/d (25 MGD) | 1998 | Groundwater augmentation |

| West Basin Municipal Water District | Carson, CA, U.S. | MF-RO | Prescreening, pre-ozonation, UV-AOP, decarbonation, stabilization | 5.6E4 m3/d (15 MGD) | 1995 | Seawater intrusion barrier, groundwater augmentation, boiler feed water |

| Water Replenishment District of Southern California | Lakewood, CA, U.S. | MF-RO with secondary RO | UV-AOP, decarbonation, stabilization | 3E4 m3/d (8 MGD) | 2003 | Seawater intrusion barrier, groundwater augmentation |

| Los Angeles Department of Public Works | Los Angeles, CA, U.S. | MF-RO | Decarbonation, stabilization | 1.7E4 m3/d (4.5 MGD) | 2002 | Seawater intrusion barrier, groundwater augmentation |

| Singapore Public Utility Board | Singapore | MF-RO | UV disinfection, decarbonation, stabilization | >1.9E5 m3/d (>50 MGD) | 2003 | Reservoir augmentation |

| Colorado River Municipal Water District | Big Spring, TX, U.S. | MF-RO | UV-AOP | 7.6E3 m3/d (2 MGD) | 2014 | Direct potable reuse |

| Southeast Queensland Water (SEQ) | Queensland, AU | MF-RO | Pre-sedimentation, UV-AOP, stabilization | 6.4E4 m3/d (17 MGD) | 2007 | Reservoir augmentation, industrial use |

| Southeast Queensland Water (SEQ) | Queensland, AU | MF-RO | Pre-sedimentation, UV-AOP, stabilization | 7E4 m3/d (18.5 MGD) | 2008 | Reservoir augmentation, industrial use |

| Southeast Queensland Water (SEQ) | Queensland, AU | MF-RO | Pre-sedimentation, UV-AOP, stabilization | 9.8E4 m3/d (26 MGD) | 2008 | Reservoir augmentation, industrial use |

| Beaufort West Municipality | Western Cape, S.A. | UF-RO | Coagulation, media filtration, UV-AOP | 2.2E3 m3/d (0.6 MGD) | 2010 | Direct potable reuse |

| George Municipality | Western Cape, S.A. | UF | Unknown | 9.8E3 m3/d (2.6 MGD) | 2010 | Drinking water augmentation |

| Mossel Bay Municipality | Western Cape, S.A. | UF-RO | Unknown | 4.9E3 m3/d (1.3 MGD) | 2010 | Industrial water production |

| City of San Diego | San Diego, CA, U.S. | MF/UF-RO | UV-AOP, ozone | 3.8E3 m3/d (1 MGD) | 2011 | Drinking water augmentation |

| Cloudcroft Water and Wastewater Department | Cloudcroft, NM, U.S. | MBR-RO + UF | UV-AOP, GAC | 3.8E2 m3/d (0.1 MGD) | 2007 | Direct potable reuse |

Figure 2.

Planned water reuse share of market. Data from [10].

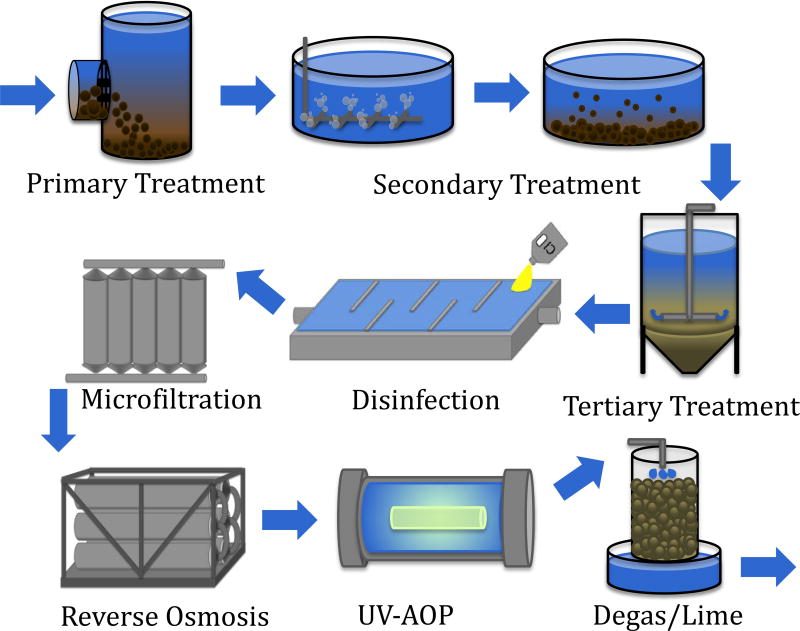

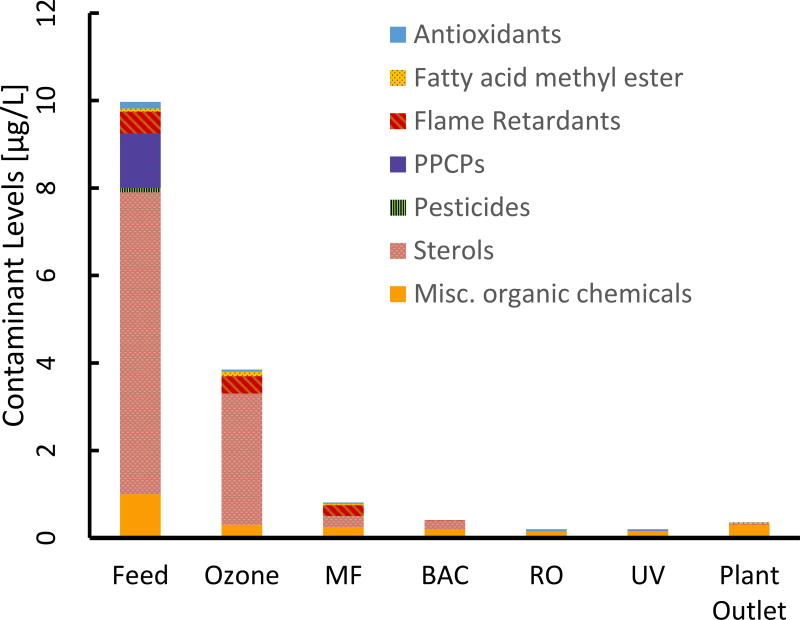

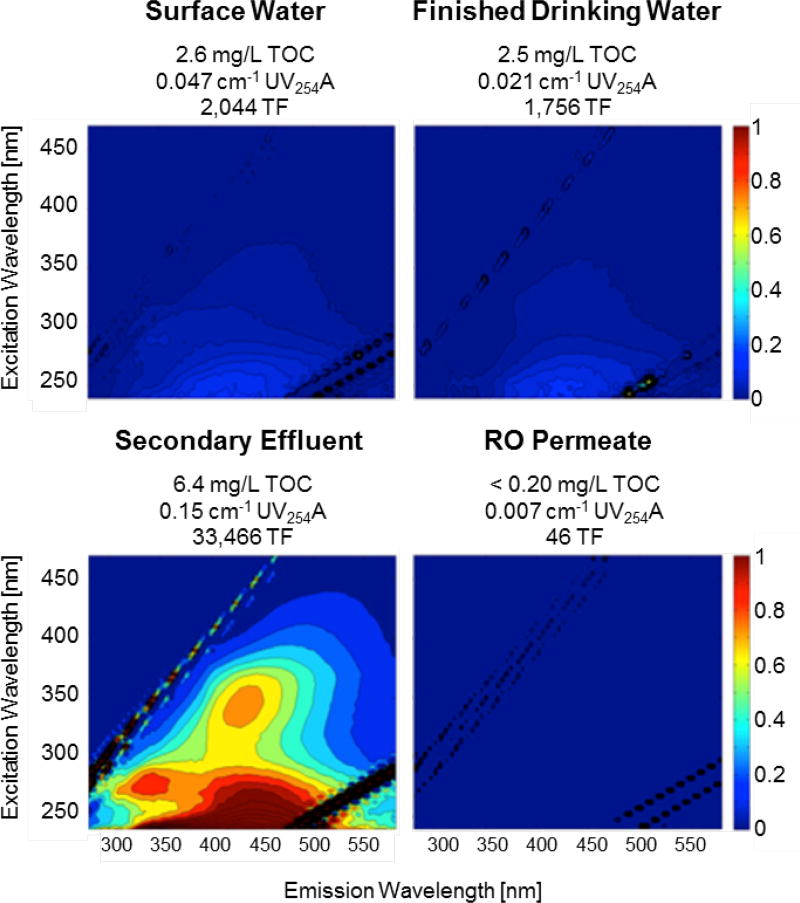

1.3 Treatment Processes

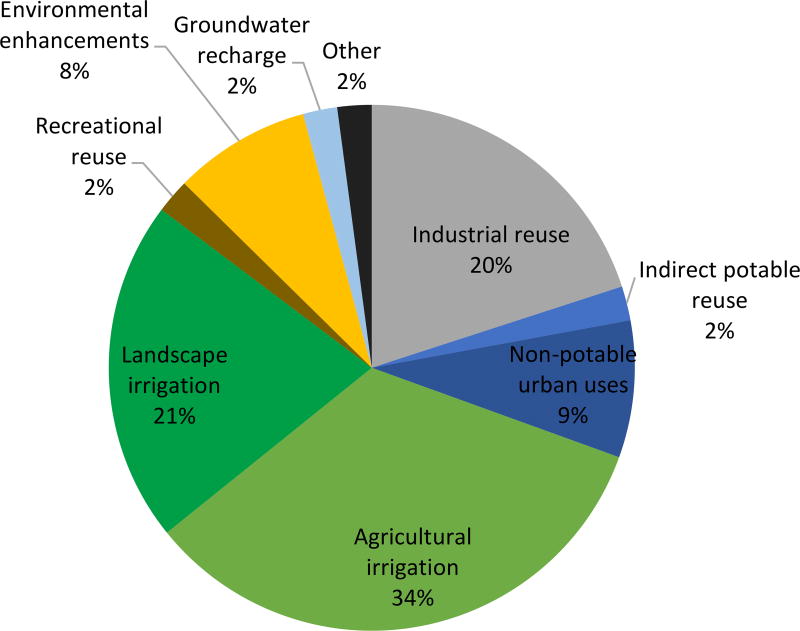

Years after the first application of reverse osmosis (RO) for wastewater purification at Orange County Water District, California, a treatment train consisting of microfiltration (MF) or ultrafiltration (UF) followed by RO and an advanced oxidation process (AOP) has emerged as an industry standard for many potable reuse applications Figure 3 [8]. The RO and AOP components are referred to as “full advanced treatment” (FAT), which is defined as the treatment of an oxidized wastewater using RO and an oxidation treatment process (e.g., UV/AOP). The use of MF/UF in front of RO is referred to as an integrated membrane system (IMS) where MF/UF acts as pretreatment to RO [7]. In Figure 3, the steps shown prior to membrane treatment help reduce membrane fouling, and the steps after (e.g., AOP) break down small neutral organic compounds that pass through the RO process. FAT and IMS are favored for many potable reuse projects due to high removal efficiencies of microbial pathogens, organic and inorganic contaminants, and other constituents relative to potable water production (e.g., particles, inorganic nitrogen, and dissolved solids; see Table 1) [11]. Post-treatment disinfection at current IPR and DPR facilities may be accomplished through the UV or UV-AOP processes. For groundwater and reservoir augmentation systems, post-treatment chlorine disinfection is generally not implemented as the water is sent to an environmental buffer. Primary disinfection for current DPR systems is typically performed downstream at the water treatment plant treating potable reuse treatment system effluent [11]. Additionally, chloramine residual is often applied before the RO membranes in order to minimize membrane biofouling, and is used instead of the stronger biocide chlorine due to polyamide RO membrane sensitivity [3]. Water stabilization (adding chemicals like calcium hydroxide) as a final step is often done to minimize distribution pipe corrosion.

Figure 3.

Schematic diagram of an industry standard potable reuse plant with MF-RO-UV-AOP, which employs low-pressure filtration (MF) followed by RO and UV advanced oxidation. To represent other conventional wastewater treatment processes, before the membrane steps, are settling tanks (primary treatment), aeration followed by settling for biological activated sludge (secondary treatment), and sand filtration (tertiary). The step UV-AOP (ultraviolet and advanced oxygenation processes) includes hydrogen peroxide or alternative oxidants, and the final step for water stabilization includes processes such as degassing and lime dosing (shown) intended to increase the water’s pH and alkalinity.

Compared to alternative unconventional water resources such as seawater desalination and water importation, potable water reuse generally requires less energy and is less costly [12, 13]. Although the FAT has become the backbone of most planned potable reuse projects and many consider it the standard for potable reuse worldwide, a number of drawbacks are associated with its implementation. Thus, alternative treatment trains may be used [14]. One such variation is to omit biologically activated carbon (BAC) from tertiary treatment plant, instead using other means for biological nutrient removal, which is often combined with ultrafiltration (UF) instead of microfiltration (MF). As another variation, biologically activated filtration may be used after RO and UV to remove byproducts of disinfection. Some trains even lack salinity control, omitting RO membranes. However, RO membranes are rarely omitted for direct potable reuse. Overall, several aims are always accomplished regardless of whether FAT or an alternative treatment train is used for potable reuse: physical removal, oxidation, and chemical inactivation [15].

Overall, the widespread use of RO membranes in potable reuse applications is due to: 1) demonstrated success in multiple installations worldwide enabling technology familiarity in a risk-averse industry responsible for protecting public health; 2) ability to handle variable input (i.e., operational reliability); 3) modularity; and 4) the very high quality of the product water, particularly with respect to pathogens, dissolved salts characterized as total dissolved solids (TDS; typically >99% removal), and wastewater-derived organic contaminants such as pharmaceuticals (removal varies, but typically >90%) [16–18]. While high pathogen removal is expected, current regulatory structures often give little or no disinfection credit for RO due to limitations in monitoring membrane integrity. Major advantages of membrane-based treatment systems over conventional processes for potable reuse include small footprints, modular designs, synergistic combinations with other treatment processes [19], fewer treatment stages and the ability to reject compounds that other processes cannot eliminate [20].

2. Membrane Technologies

Although the secondary or tertiary treated wastewater used as a source water for potable reuse applications may be of acceptable quality for environmental discharge and non-potable uses, it may still contain a wide range of undesirable constituents including [21]:

Conventional pollutants, e.g., suspended solids, colloids, nitrogen, metals, phosphorus, inorganic salts and pathogens

Unconventional pollutants, e.g., oxyhalides and refractory organics

Emerging contaminants, e.g., pharmaceuticals, plasticizers, pesticides, degradation by-products of detergents, and endocrine disrupting compounds (EDC’s).

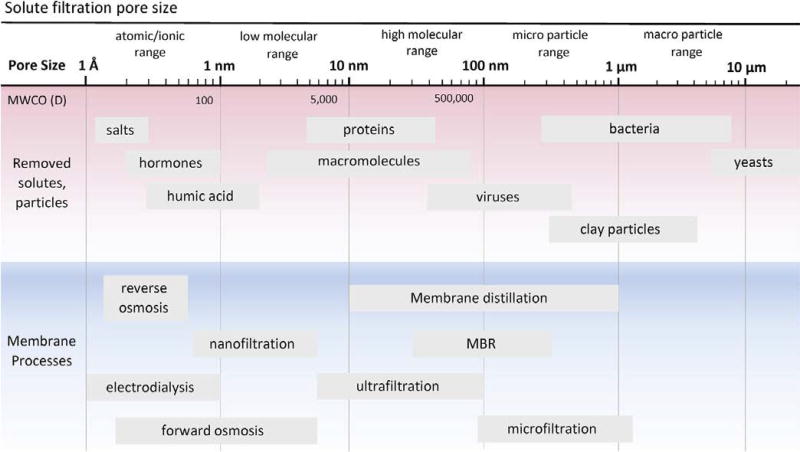

The principle of most membrane separations is the selective filtration of influent through pores of different sizes [22]. Figure 4 summarizes the separation performance of these membrane types based on the size ranges of certain common constituents found in water and the effective pore size of the membrane [23]. As the practice of potable reuse becomes more common, removal of pathogens and chemical contaminants will be an ongoing area of focus, and new treatment requirements may be on the regulatory horizon. The removal of target constituents from an aqueous solution by polymeric membrane systems can vary significantly and depends on many factors including constituent physicochemical properties, membrane type, and operational conditions [23]. The World Health Organization guidance document for potable water reuse provides recommended contaminant removal criteria [24].

Figure 4.

Membrane separation processes, pore sizes, molecular weight cut-off (MWCO) and examples of sizes of solutes and particles. (modified from [20], Copyright 2009 Reproduced with permission from Elsevier)

Membrane processes can be classified into different categories, based on different criteria including membrane configuration, type of membrane materials, driving force, separation mechanism, and size range of constituents removed. The latter is dictated by the membrane’s pore size or molecular weight cut-off (MWCO) [22]. Four main membrane types, as noted previously, are commonly used to treat wastewater to potable standards and are classified in order of decreasing pore size [22, 25]. As the pores get smaller the processes need more driving force. The technologies are often classified as low pressure (MF, UF) and high pressure (NF, RO) [22, 26].

For easier reference, a schematic diagram summarizing the most important constituents rejected by each membrane type is shown in Figure 4. For a better understanding of the role of membranes in potable water reuse, the fundamentals of the most important membrane technologies used within the context of advanced wastewater treatment are briefly discussed in the following sections.

2.1 Microfiltration and Ultrafiltration

Microfiltration (MF) and ultrafiltration (UF) are classified as low-pressure (<2 bar) processes. Separation by MF mainly occurs through sieving and, due to the relatively large pore size (approximately 0.1 to 1.0 µm), is mainly limited to the removal of suspended solids or particles, bacteria and, to lesser extent, organic colloids [16]. UF membranes also mainly operate through sieving but have a wider separation range than MF and depending on the pore size (generally between 0.01 and 0.1 µm), can remove particles, pathogens, viruses, and colloids. Potable reuse treatment (as shown in Table 1) commonly employs MF or UF for pathogen removal and as pretreatment for the NF or RO process. This pretreatment is critical to maintaining the integrity of the NF/RO system. The rejection achieved by MF and UF membranes depends on the properties of the membrane as well as the hydrodynamic conditions [27]. Additionally, disruptions in the upstream wastewater treatment processes can negatively affect the performance of a MF/UF unit and can cause significant fluctuations in MF/UF filtrate water quality [21], as well as increasing the required frequency of backwashing and chemical cleaning.

In potable reuse systems, MF membranes are commonly relied on to remove most fine suspended solids (more than 99% rejection) and some colloidal material. They can also provide 3 to 6 log removal (order of magnitude reduction for every increase of 1, i.e., 99.9 to 99.9999% removal) of protozoan cysts and coliform bacteria [21, 28]. MF pores typically range between 0.1 and 1.0 µm in diameter, providing limited removal of viruses (up to 2-log), although virus disinfection credit is rarely awarded [25]. The MF filtrate in potable reuse treatment schemes will subsequently be treated by RO and UV-AOP, each of which independently provides a very high level of disinfection. However, the incentive for virus removal at the pretreatment (MF/UF) stage remains high particularly since pathogen removal regulatory credit for RO is currently limited, as described in the section 2.2.2 [25]. In contrast, MF and UF system integrity can be confirmed daily via pressure decay testing (see section 7.2), thus allowing the cyst removal disinfection credits (e.g., 4-log credit for Giardia cysts and Cryptosporidium oocysts in the California regulatory framework).

UF membranes can typically reject all suspended solids, remove organic matter, reduce BOD5 (Biological Oxygen Demand over a 5 day test) by at least 95%, and greatly reduce turbidity. In addition to the contaminants removed by MF, UF can provide up to 6-log removal of bacteria, and if the membrane modules are intact, they can completely eliminate protozoan cysts and coliform bacteria from the filtrate [21]. However, practical experience has shown that typical UF membranes operated at reuse facilities do not always perform as a complete barrier to bacterial contamination, such as indicated by positive coliform results from the literature [25]. Membrane surface defects, deterioration of membrane due to biofouling, or imperfections in the packing of membrane modules or elements are the most probable causes of bacteria permeation [25]. UF membranes also provide an improved barrier to viruses (with up to 7-log removal) compared to MF [21]. Retention of viruses is enhanced at lower transmembrane pressures. As observed in MF membranes, virus and solids aggregates can form a cake layer on the membrane surface. The presence of turbidity and/or biomass in the feed water can enhance this adsorptive removal of viruses due to additional surface area [25].

Phosphorus, nitrogen, and total organic carbon constituents in soluble and colloidal form can also be partially removed through UF (and less with MF) but the achieved rejection can vary widely, 10 to 85%, depending on the phase of the contaminants (soluble or particulate). Increased removal can be achieved if chemical coagulants are dosed into the feed water [21]. Neither MF nor UF remove dissolved constituents such as salts and organic chemicals [21, 29]. In Table 2, the rejection ranges for MF and UF membranes for tertiary effluent are tabulated. It should be noted that the actual performance of a particular installation can vary according to the system’s specifications and operating practices [26, 29].

Table 2.

Tertiary effluent water quality and rejection characteristics of microfiltration and ultrafiltration membranes [26].

| Constituent | Concentrationa | MF rejection % |

UF rejection % |

|---|---|---|---|

| TSS (mg/L) | 2–8 | 95–98 | 96–99.9 |

| BOD5 (mg/L) | < 5–20 | 75–90 | 80–90 |

| COD (mg/L) | 30–70 | 70–85 | 75–90 |

| TOC (mg/L) | 8–30 | 45–65 | 50–75 |

| NH3-N (mg/L) | 1–6 | 5–15 | 5–15 |

| NO3-N (mg/L) | 0-trace | 0–2 | 0–2 |

| TDS | 500–700 | 0–2 | 0–2 |

| Total coliform (no./100 mL) | 103–105 | 2–5b | 3–6b |

| Protozoan cysts and oocysts (no./100 mL) | 0–10 | 2–5b | > 6b |

| Viruses (PFU/100 mL) | 101–103 | 0–2b | 2–7b |

. Conventional activated sludge system with nitrification

. Log removal

In all membrane technologies, fouling prevention and mitigation can be challenging. Fouling prevention measures for MF and UF usually include regular backwashing (cleaning every ~30 minutes for large-scale applications) and chemical cleaning [20]. For cleaning, the type of chemical used depends on the membrane’s chemical tolerance, and the cleaning frequency can vary from as much as once per day to once per month in potable reuse applications depending on the membrane type and quality of wastewater treated. Polymeric UF and MF membranes are less tolerant to chemical cleaning than their inorganic (e.g., ceramic) counterparts [30].

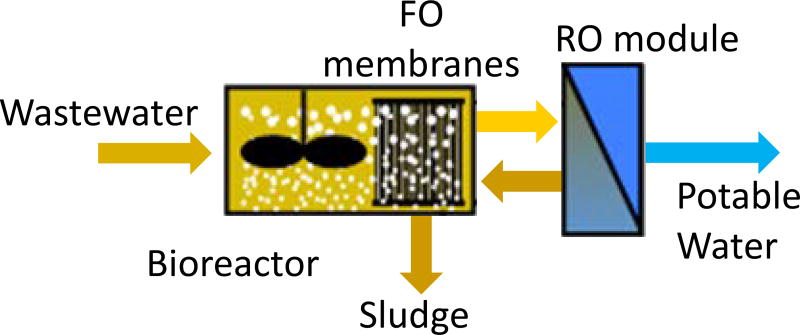

2.1.1. Membrane Bioreactor (MBR)

A common way to utilize MF and UF membranes for wastewater treatment in various industries is to combine them into an activated sludge process termed a membrane bioreactor (MBR). In MBRs, typically the membrane is submerged inside the bioreactor and vacuum is used to permeate the treated water while solids are retained in the bioreactor. This configuration not only reduces energy consumption, but also lower the amount of membrane fouling compared to a traditional side stream configuration [31]. The membrane is usually provided as a flat-sheet or hollow fiber configuration. Typical polymeric membrane materials for MBR applications include polyvinylidene fluoride (PVDF) (which accounts for approximately 45% of polymeric MBR membranes), polyethylene (PE), polyacrylonitrile (PAN), and Polyethersulfone (PES); of which the PAN membrane is most likely the most fouling resistant due to its lower affinity with extracellular polymeric substances [32]. The nomical pore size of MBR membranes is usually between 0.03 and 0.4 µm. In addition, the versatility of PDVF membrane manufacturing makes them available in the whole range of pore sizes, while, for example, PES and PE membranes seems to be mostly available only with 0.03 and 0.2 – 0.4 µm nominal pore sizes, respectively [33]. Notably, MBR membranes often have lower integrity than UF membranes.

The MBR replaces the two-stage conventional activated sludge (CAS) process (biotreatment and clarification) with a single, integrated process. There are several advantages of MBRs compared to conventional treatment, the most important being product consistency, reduced footprint, reduced sludge production, and nearly complete suspended solids separation from the effluent [34]. MBR technology more efficiently removes a wide range of biodegradable and hydrophobic trace organics than CAS processes, as MBR systems operate at a much higher mixed liquor suspended solids (MLSS) concentration [35]. During MBR treatment, hydrophobic trace organic contaminants can be adsorbed to MLSS, increasing retention time in the bioreactor and thus enhancing removal efficiency. Furthermore, unlike a CAS treatment process, MBRs provide a definitive boundary layer that provides complete suspended solids retention. Because of these features, MBR effluent may be suitable for use as irrigation water, process water, or as a pretreatment for potable reuse applications [36].

2.2 Nanofiltration and Reverse Osmosis

Nanofiltration and reverse osmosis processes are very similar in that they are designed to remove dissolved chemical contaminants including salts. Both require high hydraulic pressures and utilize similar membrane materials. NF removes many of the same solutes as RO but to a lesser degree (see Table 3). Although NF is rarely used in potable reuse processes, treatment plants are considering it as a lower-energy alternative to RO.

Table 3.

Expected rejection values of nanofiltration and reverse osmosis membranes on tertiary effluent [37].

| Constituent | Nanofiltration rejection rate (%) |

Reverse osmosis rejection rate (%) |

|---|---|---|

| TDS | 40–60 | 90–98 |

| TOC | 90–98 | 90–98 |

| Hardness | 80–85 | 90–98 |

| NaCl | 10–50 | 90–99 |

| NaSO4 | 80–95 | 90–99 |

| CaCl2 | 10–50 | 90–99 |

| MgSO4 | 80–95 | 95–99 |

| NO3− | 80–85 | 84–96 |

| Fluoride | 10–50 | 90–98 |

| Atrazine | 85–90 | 90–96 |

| Proteinsb | log 3–5 | log 4–7 |

| Bacteriaa,b | log 3–6 | log 4–7 |

| Protozoaa,b | log >6 | log >7 |

| Virusesa,b | log 3–5 | log 4–7 |

Theoretically, all microorganisms should be removed. The presented values reflect integrity concerns.

Refers to log removal, where log 2 is 99%, log 3 is 99.9% etc.

2.2.1 Nanofiltration

NF membranes were introduced in the late 1980s as an alternative “loose” RO membrane for applications wherein some ionic solutes in the feed water are selectively and purposely passed into the permeate [22]. The pore size of NF membranes is approximately 1–5 nm, which allows passage of neutral solutes of that size or smaller as well as some passage of monovalent salts such as Cl− [22, 27]. Compared to RO membranes, NF membranes have higher water permeability and allow operation at lower pressures, thus reducing the specific energy consumption [22].

In NF, solute rejection occurs as a result of several exclusion and transport mechanisms. Solutes are excluded from the membrane through steric, dielectric, and Donnan exclusion [38] and, in some cases, by adsorption to the membrane surface [4]. Solute rejection is also a function of the relative transport resistances of solutes and water. Solute transport occurs through three mechanisms, according to the extended Nernst-Planck equation (see Ref [38]): (1) convection of solute with the flowing water, (2) diffusion down the concentration gradient across the membrane, (3) electro-migration down the potential gradient that develops across the membrane due to the unequal diffusion rates of different ions. Water transport is generally modeled using a modified Hagen–Poiseuille equation (see Refs. [4, 39]).

Typically, NF rejects more than 95% of divalent ions of the same charge as the NF membrane, whereas the rejection of monovalent ions ranges from approximately 20 to 80% [4]. For uncharged solutes, however, the rejection as a function of molecular weight is represented as a sigmoidal curve, indicating differential separation between different compounds on the basis of molecular mass [40]. Therefore, the typical NF permeate could contain molecules of size varying below and above the claimed pore size of the membrane [23]. Models of the rejection of organic micropollutants by NF membranes have been proposed by various researchers [41, 42]. As an alternative to RO, NF membranes are appealing for potable water reuse applications in which the source wastewater TDS level is relatively low (i.e., <500 mg/L) and/or where hardness (rather than monovalent salt rejection) is the primary challenge. In addition, recent research has indicated that higher recovery from NF systems can be achieved through non-thermal crystallization [43] and/or ozone pre-treatment to reduce second stage membrane fouling [44]. Recent studies have been undertaken to further demonstrate the viability of NF within a multi-barrier potable reuse treatment process [42, 45].

2.2.2 Reverse Osmosis

RO membranes consist of a homogeneous polymer layer (e.g., polyamide), which preferentially permeates water, on top of a hierarchal polymeric support material (e.g., polysulfone and polyethersulfone) [22, 46]. Pressure is applied to drive the solvent (water) through the membrane while retaining most solutes on the feed side [22]. In order to produce fresh water, the applied pressure exceeds the osmotic pressure of the feed solution [47–49]. RO is the key treatment step of FAT, the current industry standard for potable reuse [11]. The FAT train has been demonstrated to be an effective and efficient process for potable reuse, largely because RO highly purifies water through rejection of most dissolved salts and organic molecules that are common contaminants in wastewater (e.g., organics like CECs), as well as larger particulates if not already removed by upstream pre-treatment membranes (MF or UF). For example, at the Torreele IPR plant in Belgium, the RO step effectively reduces hardness, TDS, organic carbon, nitrogen, and phosphorus, and removes approximately 98% of pesticides at an energy consumption of just 0.63 kWh/m3 [50]. RO energy consumption has decreased significantly since 1970, primarily due to improvements in membrane permeability and energy recovery efficiency [47–49]. RO uses highly-selective membranes to reject salts, colloids, biological materials, and most dissolved organics [22].

With RO, salts are generally highly-rejected; commercial seawater RO membranes reject 99.5–99.8% of sodium chloride. Brackish water RO membranes commonly used for potable reuse have approximately 99.5% salt rejection, despite their high water permeability [51]. Even higher rejections are reported for divalent and multivalent ions such as sulfate and phosphate, at ranges of 99.7– 99.98% and 99.7 – 99.99%, respectively [52].

Due to the sub-nanometer scale of RO pores, RO is considered to be a complete barrier for pathogens. For example, in a pilot study of RO treatment of wastewater, neither E. coli nor viruses were detected in the RO permeate with either MBR or MF pretreatment [53]. At the Orange County Water District’s (California, USA) advanced water purification facility, currently the largest potable reuse plant in the world (IPR via groundwater recharge), twice weekly monitoring for the indicator organisms’ total coliform and E. coli and monthly monitoring for virus indicators (coliphage) in RO permeate since the plant came online in 2008 has never resulted in a detection. Nevertheless, regulatory credit in the United States for pathogen removal by RO at advanced treatment facilities for reuse is currently limited to 2-logs, based on the approximately 2-log salt removal across RO that can be continuously monitored via conductivity analyzers [27]. To obtain higher credit closer to known performance (e.g., virus log removal of 4–7 per Table 3), a permitted method/technology (e.g., fluorescent dyes) is needed for continuous or frequent demonstration of an RO system’s integrity (e.g., due to possible malfunctions, operator error, or unnoticed leakages via glue strips or permeate seals in the spiral-wound elements) [25] at greater than 2-log.

RO membranes have been found to be effective in removing high molecular weight organic constituents (such as humic and fulvic acids) [28]. The BOD and chemical oxygen demand (COD) can be reduced up to 98% and 96%, respectively, and TOC can be rejected at 96% or higher [28]. The removal of EDCs can be as high as 95 to 99% [28]. Removal of organic solutes, such as wastewater-derived pharmaceuticals, is crucial in potable reuse, but the rejection varies between solutes and membranes [33]. Urtiaga et al. [54] performed pilot-scale testing of pharmaceuticals rejection by UF and RO treatment of wastewater effluent. In this study, all 12 compounds tested had rejection values greater than 99.3%. Radjenovic et al. [55] studied rejection of pharmaceuticals in a full-scale drinking water treatment plant using RO and NF treatment of groundwater. Most compounds were rejected by 85% or more by RO, but few solutes (both neutral and charged) were rejected poorly by 30–70%. Lower removal of neutral organic solutes was observed for lower molecular weight compounds. Additionally, incomplete rejection of certain DBPs, such as nitrosamines, and some micro-pollutants, such as 1,4-dioxane, of low molecular weight (less than 1001 Da) has been observed during full and pilot scale tests of high-pressure membrane applications [28]. However, detection of the low molecular weight compounds in product water has been reported only at trace concentrations, well below health significance [28, 56].

Despite low rejection for certain organic compounds, RO generally removes most compounds to a very high degree and better than other engineered or natural alternatives. For example, Drewes et al. [57] examined the efficacy of soil-aquifer treatment (SAT), NF and RO at removing organic carbon including dissolved organic carbon (DOC), polysaccharides, and humic substances, among other types. In almost every metric, RO removed the greatest fraction, followed by NF and SAT. SAT was still moderately effective, as shown by a 77% DOC removal over 12–18-month residence time of tertiary effluent. TOC rejection by RO and NF were 94–96.4% and 91.3–94.5%, respectively. Lower-molecular weight compounds were less rejected by the RO and NF membranes. Of 36 pharmaceuticals and EDCs chosen to represent a range of contaminant types and structures, another study showed that RO removed most to below detection limits, and double-pass RO removed all but two compounds to below detection limits [58].

Although there is experimental evidence of sub-nanometer pores in the active layer of polymeric thin film composite (TFC) RO membranes [59] (see Section 3.1.3), the passage of water and rejection of dissolved matter by RO is commonly simulated with the solution–diffusion model (which neglects transport by convection; see [60]) and variations thereof (see [52]). In the solution–diffusion model, both water and solutes are considered to dissolve into the membrane and diffuse through it. The chemical potential gradients inside the membrane’s active layer depend on the feed and permeate concentrations, membrane sorption coefficients, and applied pressure. For a given membrane, the solution–diffusion model predicts that solute rejection increases with increasing flux (i.e., the amount of permeate generated per unit area of membrane surface per unit time). Other RO membrane transport models including pore-flow models are reviewed in [61]. These models are divided into pore-flow, irreversible thermodynamics, and nonporous membrane models.

Various configurations of RO modules have been developed with the intent to minimizing energy consumption and contaminant permeation. In RO plants, multi-pass design (i.e., permeate from first stage is treated in a second stage) can be used to improve rejection of potentially harmful solutes such as borate, although this is uncommon in potable reuse applications. In reuse plants, multiple stages (i.e., concentrate from one stage is treated in the following stage) are commonly used to increase recovery and improve energy efficiency. As an example of multiple RO membrane passes, Israel’s Ashkelon seawater desalination plant uses multiple passes to meet stringent water quality standards and multiple stages within the 2nd and 3rd pass to improve recovery [62]. However, multiple RO passes are uncommon in potable reuse applications. In reuse plants, multiple stages (i.e., concentrate from one stage is treated in the following stage) are commonly used to increase recovery and in some cases, can improve energy efficiency Multiple stages with inter-stage pumps improve energy efficiency by minimizing the applied pressure in the first module(s) [63].

At typical potable reuse recovery percentages (50–85%) [7], 15–50% of the feed volume is converted into concentrate that must be disposed of or reused. The RO concentrate from a reuse plant is typically disposed through surface water (e.g., ocean) discharge, recycled to the wastewater treatment plant, deep well injected, or sent to an evaporation ponds, and may require treatment beforehand [2, 19, 64]. The vast majority of large-scale RO-based potable water reuse facilities are located in coastal areas, thus concentrate disposal is most commonly achieved by discharge to the ocean. However, some regions have restrictions or prohibitions on ocean outfalls. For instance, in 2008 the Governor of Florida signed into law a requirement that wastewater utilities in southeast Florida cease to use ocean outfalls by 2025 [65]: this may require membrane and system designs for much higher recovery ratios and thus solute tolerance (fouling, etc.). Inland water utilities often have few, if any, capabilities to discharge the concentrate, which is highly enriched in salts, emerging contaminants, pathogens, and other materials rejected by the RO system. Thus, further treatment of RO concentrate may be advantageous to increase the overall water production of a water reclamation facility while at the same time minimizing the volume of concentrate that requires disposal [43].

3. Membrane Materials

Development of novel membrane materials is a major research thrust for academia, industry, and national laboratories because membrane performance is often challenged by fouling, low permeability, and high contaminant permeation relative to stringent selectivity requirements. There are unique needs for membranes made for potable reuse. Reuse applications, as opposed to industrial applications, face a diversity of contaminants of concern. Such contaminants range from microorganisms (e.g., viruses) to molecular organics (e.g., pesticides) and inorganic compounds (e.g., heavy metals). These membranes, where possible, also need to be tolerant to relatively extreme chemical cleaning processes [30]. This translates into a number of different materials that may be effectively used within potable reuse treatment trains.

3.1 Polymeric Membranes

3.1.1 Membrane Comparison

Numerous polymers are used in the creation of membranes, although a select few have emerged as leading choices for potable reuse applications. Like any other application, two main design considerations drive potable reuse membrane technologies: membrane material properties and membrane formation mechanisms. Driving factors for which material is used include pore size distribution, wetting susceptibility, porosity, mechanical strength, cost, polymer flexibility, fouling resistance, stability, durability, and chemical resistance [64]. The latter may include resistance to pH, oxidants, and chlorination (Which is of particular importance for potable reuse membranes given the high levels of dangerous microorganisms, with little tolerance for their presence) [64]. Other desirable properties that also relate to the fabrication itself include low tortuosity and surface properties that influence rejection (e.g., surface charge). Additional characteristics may influence performance as well, such as improved regeneration/fouling recovery, which results from many things including low surface roughness, poorly adhering materials, and resistance to cleaning agents [66].

Potable reuse membranes share much in common with other processes such as desalination, but have notable differences. Salt-selective potable reuse membranes gain more benefit from high permeability due to reduced concentration polarization. Such membranes also need superior solute rejection and reliability, due to the wide variety and variability of solutes in the wastewater feed, with larger toxicity concerns. Still, many reuse systems use modules and technologies borrowed from desalination and municipal water treatment.

Many reviews of membrane materials have been previously reported published, so the present discussion is intended to be concise and comparative, focusing on membrane design than individual polymers. A list of common membrane materials and properties is displayed in Table 4.

Table 4.

| Material | Acronym | Most common use |

Advantages | Disadvantages | Mechanical strength & durability |

Hydrophillicity & WCA |

pH | Chlorine resistance |

|---|---|---|---|---|---|---|---|---|

| Polysulfone | PSF | MF/UF | Good mechanical strength, chemically resistant, |

|

|

1–13* |

|

|

| Polyether sulfone | PES | MF/UF | Good thermal properties, Rigid, compaction resistant, very permeable, oxidant tolerant, narrow pore size distribution |

|

|

1–13* |

|

|

| Polyacrilonitrile | PAN | MF/UF |

|

|

||||

| Polyvinylidie ne fluoride | PVDF | MF/UF | very oxidant tolerant, chlorine resistant | Broader pore size distribution |

|

|

2–11* |

|

| Polyethylene | PE | MF/UF (uncommon) | High resistance to organic solvents, Low cost, oxidant tolerant | Poor thermal properties, Weaker fouling resistance |

|

|

|

|

| Polypropylene | PP | MF/UF (uncommon) | High resistance to organic solvents, decent mechanical strength | Weaker fouling resistance, not oxidant tolerant |

|

|

2–13 |

|

| Polyvinyl chloride | PVC | occasionally MF/UF | Poor thermal stability, not oxidant tolerant |

|

|

|||

| Cellulose acetate | CA | RO, also MF/UF | Renewable source | Poor microbial degradation resistant |

|

|

5–8.5 |

|

| Polyamide | PA | RO (TFC active layer), NF, occasionally MF/UF | Small pores, excellent rejection, selectivity | Poor acid and alkali resistant Weak, experiences compaction |

|

|

1–13** |

|

Symbols are used as follows:

excellent,

excellent,

good

good

fair, and

fair, and

poor

poor

Poor long-term stability in basic conditions

Poor long-term stability in acidic or basic conditions

With respect to membrane materials used for MF/UF in potable reuse facilities, a variety of materials are used (see Table 4) [66–68]. As an example, currently polypropylene MF membranes (Evoqua S10T submerged, outside-in configuration) are used by Orange County Water District (OCWD), which operates the largest potable reuse facility in the world. This material choice is less common today for MF compared to alternatives that have emerged (such as PVDF) since the OCWD facility came online in 2008; regardless, the original polypropylene membranes operated successfully at OCWD for nine years (past a typically assumed life of approximately seven years) until their replacement in 2016 with the same product [69]. For potable reuse applications, the industry has moved largely toward PVDF as a material of choice, which is stated to have reduced capital cost, increased membrane life, and reduced nominal pore size compared to polypropylene [70]. Like polypropylene, PVDF is amenable to the outside-in configuration (i.e., direction of flow in a hollow fiber module – see later section on module types), air scour, and backwashing, but unlike polypropylene is chlorine resistant (enabling use of this effective oxidant during monthly membrane cleaning) [30]. Within the PVDF family of hollow fiber materials, modifications in manufacturing techniques have resulted in the development of two distinct classes of materials: non-solvent induced phase separation (NIPS) and thermally induced phase separation (TIPS) fibers. While new materials with performance advantages continue to emerge, consideration of alternate MF/UF materials (products) at an existing facility can require significant capital expense for a system retrofit, because unlike the RO industry, low-pressure membrane systems have not standardized around a common platform (e.g., size, design) which would (like RO) enable a new product to be directly installed (swapped in with no system modifications). Rather, MF/UF systems are unique to each supplier and are offered in a variety of configurations in both pressurized or submerged designs [71].

RO membranes are analyzed in this review in greater detail (see next section), as they are the most crucial to potable reuse and dominate cost, energy use, and R&D interest. Membrane materials may be modified to improve performance and mixed in composite membranes.

3.1.2 Membrane Fabrication

A variety of manufacturing techniques are used to fabricate membrane. Often, these methods depend more on the membrane material than the membrane class (e.g., UF, MF, etc.), although processes vary for controlling pore size, especially for composite membranes. Phase inversion and electrospinning are respectively the most and second most common techniques to fabricate mem- brane which is mostly used for fabricating potable reuse membranes. Notable phase inversion variants include non-solvent induced phase separation (NIPS) (a dominant technique), thermal phase separation, controlled evaporation, and finally vapor induced phase inversion (VIPS).

More complex methods are used for composite membranes and/or membrane surface modifications [72]. Other techniques used in membrane fabrication or modifications include in-situ polymerization, film casting, ion assisted deposition, aerosol deposition, ion exchange, dip coating, hydrothermal synthesis, sputtering and etching, surface adsorption, layer-by-layer deposition, and spray coating [73].

Chemical methods are also used to modify polymer membrane chemistry as a whole, depending on applications. These include hydrophilization treatment with plasma, radical grafting, and chemical coupling.

For more on self-assembled polymer nanostructures for filtration membranes, readers are referred to Asatekin and Vannucci [74]. For recent reviews on reverse osmosis membrane materials and nanomaterials readers are referred to Lee at al. [51], Maleb and Ayoub [61], Giwa et al.[3], and Lau et al. [75]. For reviews on NF membrane materials, Amirilargani et al. [76], for carbon nanomaterials, Goh et al [77], and for more general nanomaterials, Santhosh et al. [78]. Additional reviews include membrane fabrication by Lalia et al. [73], NF membrane fabrication by Cheng et al. [79], RO fouling by Pandey et al. [80], and for antifouling membranes, by Kang and Cao [81] and Saqib and Aljundi [82]. Additionally, chemical cleaning for potable reuse membranes has been reviewed by Porcelli and Judd [30]. A review of electrospun membranes was recently published by Kaur et al. [83], on phase inversion membranes by Wang et al.[84], and on track etching by Chakarvarti [85].

3.1.3 RO Membranes

RO membrane materials were reviewed in depth by Lee at al. [51] in 2011. Aspects of that review are summarized in this section, along with subsequent research. Although current potable reuse plants exclusively use thin-film composite (TFC) membranes, a range of RO membranes have historically been made from single polymers. Lee et al. [51] offer a brief history of cellulose acetate (CA) membrane development: After a symmetric CA membrane was found to have very low flux, asymmetric CA membranes were developed [51]; later, cellulose triacetate or diacetate–triacetate blends were also developed. CA has higher chlorine resistance, but it is prone to compaction (loss of permeability at high pressure) and hydrolysis in both acidic and alkaline environments, which reduces cleaning options. For CA membranes, significant acetylation (replacement of hydroxyl groups with acetyl groups using a catalyst such as H2SO4) improves salt selection but reduces permeability [86].

Other polymers including polyamide, polybenzimidazoline, and poly(piperazine-amide) have been evaluated for use in single-polymer asymmetric membranes, but none have the combination of permselectivity, compaction resistance, and chemical stability offered by the thin film composite membranes that currently dominate the RO membrane market [87].

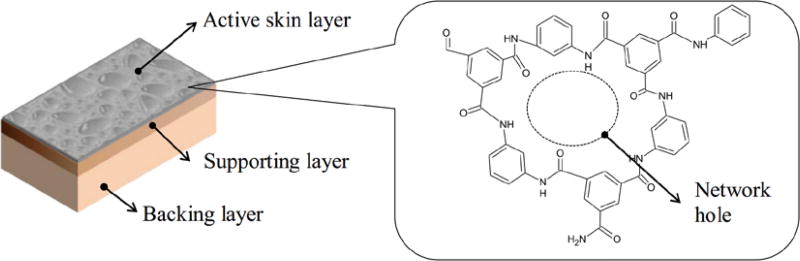

Most state-of-the-art commercial RO membranes today are TFCs. TFC membranes consist of a semi-permeable “active” layer, typically an aromatic polyamide, of around 50–200 nm thickness supported by a microporous polymer layer (typically polysulfone) roughly 40 µm thick, which is itself supported by a non-woven polyester web of approximately 100 µm thickness [51, 59] (Figure 5). These membranes achieve salt rejection around 99.5%, and good rejection of low molecular weight organics compared to CA [51, 59, 88, 89]. Lee et al. [51, 59, 88] reviewed the history of TFC membrane development and the various combinations of polymers used. Polysulfone was identified as the optimal material for the porous support layer because of its compaction resistance and stability under acidic and alkaline conditions making it compatible with interfacial polymerization. Various polymers have been used for the formation of active layer on membrane surface, but polyamides are most common. Notable commercial TFC membranes are listed in prior studies [51]. As an example, the OCWD potable reuse facility (100 MGD) utilizes three different types of TFC RO membranes – Hydranautics ESPA2-LD (previously used ESPA2 before membranes reached end-of-life), Dow XFRLE, and CSM FLR – which were selected at different times for installation into newly-built RO units as the plant expanded over time. Regardless of the fact that RO products are all TFC, OCWD testing complete prior to any product selection has indicated that product performance varies; namely, different manufacturer’s membranes can require significantly different feed pressures (affecting operational cost) to produce the same flux with similar permeate quality on the same feed water.

Figure 5.

Layers of typical TFC (thin film composite) RO membranes. The chemical structure of the polyamide active layer creates selectivity, from [59], Copyright 2015, reproduced with permission from Elsevier.

Modern TFC membranes are produced by interfacial polymerization, a process in which two immiscible liquids, each containing one monomeric or polymeric aromatic amine, are brought together, allowing polycondensation at the interface. Various manufacturing methods were explored before the industry settled on interfacial polymerization. Early TFC membrane manufacturing methods included float-casting, dip coating, and acid polycondensation [51].

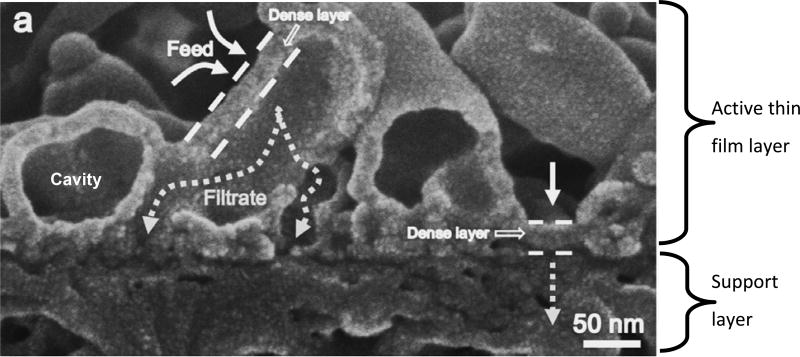

Recent studies have elucidated various aspects of the active layer structure. Fujioka et al. [59] reviewed positron annihilation spectroscopy and found that, for various RO membranes, free-volume holes (referred to as network holes in Figure 5) in the active layer have been measured in the range of 0.20–0.29 nm. Rejection of neutral species improves as the solute increases in size with respect to the free-volume holes. The active layer also exhibits roughness on a 100 nm scale [90] (Figure 6.). SEM images of the active layer surface show villi-like structures with a thin (~20 nm) skin and 50–200 nm cavities [59]. Permeability increases with increasing roughness (linearly, for the membranes tested) [90], a phenomenon ascribed to the increased cross-sectional area for diffusion.

Figure 6.

SEM of a thin film composite RO membrane, showing the larger scale roughness of the ESPA2 membrane by Hydranautics/Nitto, with a typical active layer pore radius of 0.267 nm. Modified from [59, 91], Copyright 2015, reproduced with permission from Elsevier.

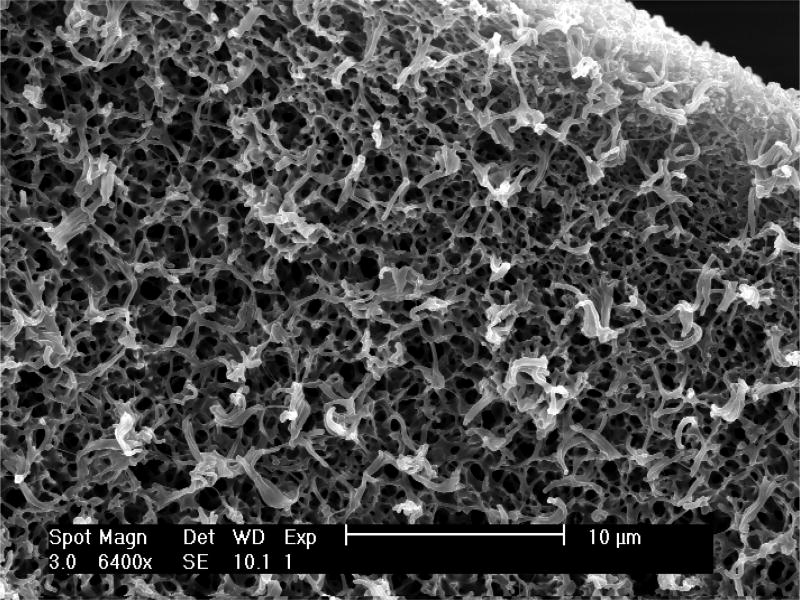

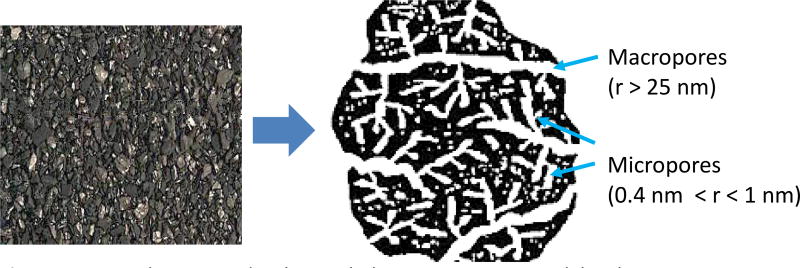

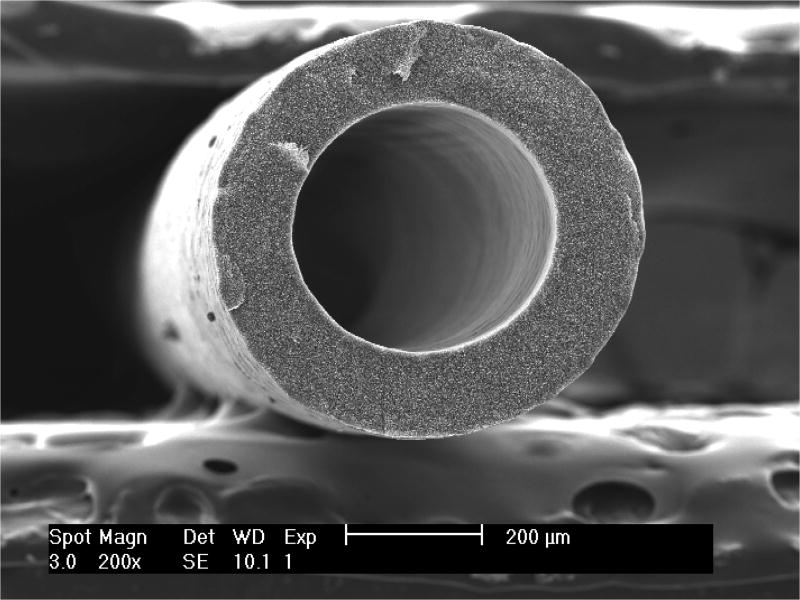

In contrast to RO and NF membranes, MF and UF membranes have much more porous structures, and do not have the tight relatively nonporous active layers seen in RO (Figure 7.). Because of the large particle size tolerance and high permeability, the MF/UF membranes are typically less complex than RO/NF membranes, and are thus easier and less costly to manufacture. Furthermore, their higher fluxes compared to RO membranes allows for a smaller surface area and corresponding investment, which further drives the research interest toward RO membranes over MF/UF.

Figure 7.

SEM of polypropylene MF membrane showing a highly porous structure (Advanced Water Purification Facility membranes imaged by the Orange County Water District at University of California-Irvine Materials Characterization Center).

3.2 Nanocomposite Membranes

Introduction of nanomaterials into polymer membrane matrices has focused less on salt removal and more on niche applications. Surface coatings have produced enhancements of many physical/chemical characteristics such as water permeability, fouling resistance, selectivity, increased mechanical strength and temperature resistance. Comprehensive reviews have been recently published outlining the impacts of incorporating nanomaterials into various types of membranes [3, 92, 93]. The nanomaterials that have attracted the most attention in wastewater treatment are carbon based nanomaterials (e.g., graphene oxide (GO) and carbon nanotubes (CNTs)), titanium dioxide (TiO2), and silver nanoparticles (nAg). This section highlights areas of particular interest to the reuse industry.

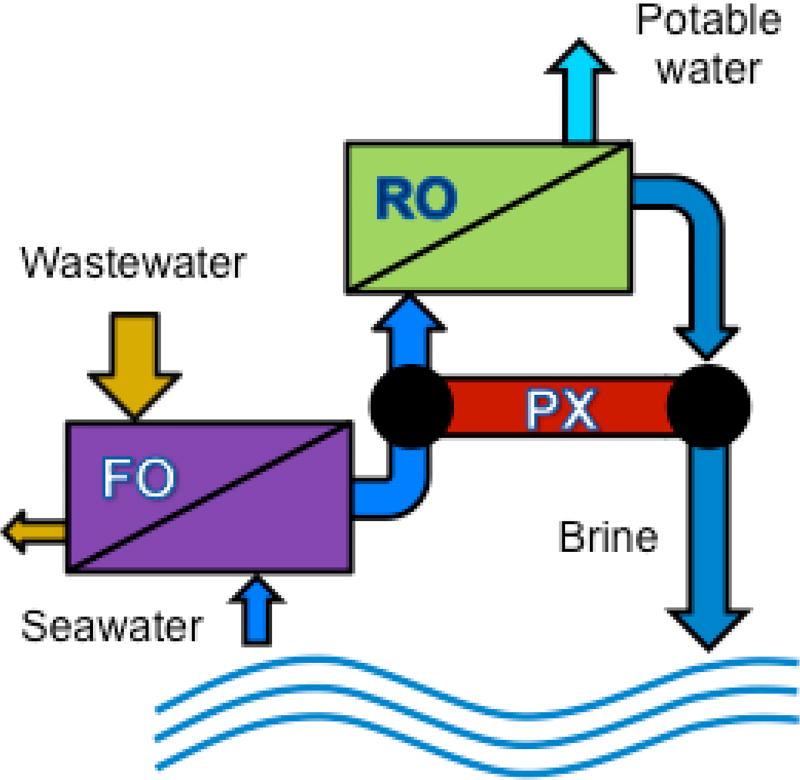

Promising results have been obtained for spiral wound flat membranes modified with inorganic additives used for improving the antifouling properties including nano-sized titanium dioxide, silica, nano-sized alumina, zirconium dioxide, and lithium perchlorate as well as antimicrobial additives such as copper or silver [94]. CNTs and GO have also been actively explored in efforts to develop ultrapermeable membranes [95]. Hu and Mi [96] integrated GO into a layer-by-layer assembly for forward osmosis (FO) applications and demonstrated water permeability an order of magnitude higher than commercial polymeric membranes [97]. Computational studies have claimed that a membrane comprised of single sheet graphene would produce water flux 250 times higher than current commercial RO membranes under the same conditions [98]. Notably, in contrast to potable water reuse applications, for seawater RO, resistance to the drive for ultrapermeability has emerged because concentration polarization will sharply limit the achievable flux increase for saline feeds. [99]. However, for lower salinities, the case in most reuse applications, they find that more significant performance gains are still possible. Apart from flux, Cohen-Tanugi et al. [100] showed that the energy savings possible from high permeability reach diminishing returns rapidly as permeability rises. More significant energy savings could potentially be realized in wastewater reclamation due to its lower feed salinity.

CNTs have garnered interest for membranes because their diameters can be controlled to, in theory, allow for higher selectivity [101]. TiO2 nanoparticles have been used to impart superhydrophilicity and photocatalytic properties that help prevent biofouling and improve permeability [102]. The photocatalytic nature of TiO2 has also been utilized for degradation of natural organic matter (NOM), trace levels of pharmaceuticals and personal care products, and polishing of wastewater effluent [103]. Most research in this area focuses on finding the optimal TiO2 concentration and method of incorporation into different polymer matrices rather than scalability to commercial applications. A remaining concern is the potential degradation of the host polymer matrix by the reactive species generated at the surface of embedded nanocatalyst. Silver nanoparticles, nAg, are incorporated into membrane materials to impart biocidal properties to the membrane and prevent or reduce biofouling. Incorporation and regeneration of nAg can prove challenging and researchers have taken different approaches. For example, nAg surface functionalization [104] and in situ formation [105] were both explored for TFC polyamide RO membranes. The surface functionalization approach achieved > 95% of inactivation of surface bacteria while in situ formation led to an inactivation of more than 75% of bacteria.

A new class of hollow fiber nanocomposite membranes is emerging as a promising solution for MF and UF [106]. Hollow fiber nanocomposite membranes have several advantages, including low cost, ease of fabrication, high mechanical stability, and combination of polymeric and inorganic material properties [107]. In addition, they have been observed to efficiently disinfect and adsorb/degrade organics in potable reuse feed if incorporated during hollow fiber membrane fabrication [108]. TiO2 nanoparticles have been found to be most useful in this respect and have also been found to increase thermal resistance, permeability, hydrophilicity, porosity, and tensile strength of hollow fiber membranes [109]. Similarly, hydrophilicity, permeability, and mechanical stability of hollow fiber membranes can be enhanced by embedding zinc oxide nanoparticles (ZnO), which also increase reversible fouling which is very much essential for potable reuse applications [110]. Ag has been shown to improve antibacterial properties, fouling resistance, and mechanical stability of hollow fiber membranes [71, 111].

Apart from the properties imparted to the membrane, the scalability of the manufacturing processes and regeneration once installed are essential to ensure commercial adoption. Manufacturing scalability still remains a serious hurdle for nanocomposite membranes. At this point, very few of these emerging technologies are competitive with polymeric membranes in terms of cost [51], and while the feasibility of nanocomposite membrane technology has been demonstrated at lab-scale, commercial realization is very limited. One commercially available RO membrane that includes a propriety nano zeolite additive is manufactured by LG Chem (originally NanoH2O). Their membranes have demonstrated only slightly lower salt rejection, but 140–200% higher water permeability when compared with standard commercial thin film membranes [92].

In general, the effects of the incorporation of nanomaterials varies greatly depending upon the specific material, base membrane material, and the manner in which the nanomaterial is incorporated (e.g., during casting versus grafted onto the surface) [77, 78]. To date, the goal of many studies in early stage research is to determine the optimal loading of the nanoparticles to maximize performance measured in terms of permeability, strength, wettability, and selectivity rather than pilot studies for field applications. Additionally, nanocomposite membrane parameters and challenge tests are primarily optimized for seawater desalination, not reuse. Overall, desalination and reuse applications need research to address challenges for both membranes (e.g., low water flux, membrane fouling and regular replacement) and the reuse industry (e.g., potentially high solids loading and matrices that may contain emerging contaminants). In summary, while most nanocomposite membranes are not yet commercially available, diverse and promising ongoing research may serve the potable reuse community in terms of target contaminant removal and energy/cost savings.

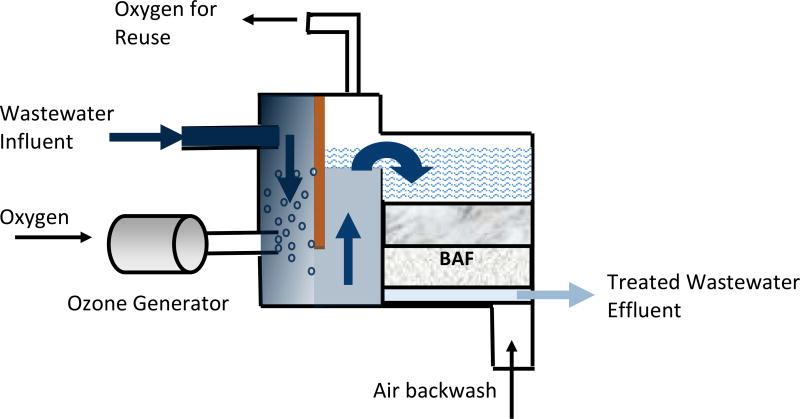

3.3 Ceramic Membranes

While polymeric membranes have been the staple in the suite of membranes used in water treatment applications for all pore ranges and operating modes, ceramic membranes have recently emerged as a broad classification of materials that show significant promise for applications to potable reuse. Contrasting polymeric and ceramic membranes is important for understanding the advantages and disadvantages of both. Ceramic MF/UF membranes have demonstrated potential for pretreatment to reduce fouling of RO membranes in combination with oxidation processes (e.g. ozone, UV) to degrade pollutants reducing membrane fouling, but their cost is high relative to polymeric membranes. Where ceramic membranes are employed, they are often used in combination with polymeric membranes later in the same treatment train (e.g., polymeric RO membranes) [112]. Although the present review focuses on polymeric membranes, ceramic membranes possess unique attributes relevant to wastewater reuse that should also be described. With further research, ceramic membranes might be improved to match the performance of polymeric membranes at a more feasible cost.

Ceramic membranes have the ability to be cleaned with harsh chemicals that would damage polymeric membranes. Thus, ceramic membranes have potential for treatment of high fouling feeds such as filter backwash [113]. Ceramic membranes employed in municipal water treatment are most commonly produced from alumina. Other common active layer materials include titanium dioxide and zirconia oxide. Since the use of ceramic membranes is uncommon, few studies directly evaluate potable reuse using ceramic membranes, but there are several areas where ceramics are particularly promising.

Various ceramic membranes ranging from MF to NF in pore size have been evaluated for use in treating secondary municipal wastewater effluent [114]. Materials including α-alumina, anatase, γ-alumina, amorphous titania, and amorphous organo-silica active layers on α-alumina supports have been evaluated. The γ-alumina NF membrane was deemed the most promising membrane for treatment of wastewater treatment plant effluent based on permeate flux (6.6 LMH) and selectivity (75% of UV254 absorbing compounds and 15% of ions). Most commercially available ceramic membranes lack pore sizes small enough for virus removal, but their tolerance for higher concentration of chlorine, oxidants, and coagulants allows them in theory to achieve high degrees of virus removal. Kramer et al. [115] studied the use of ceramic UF and NF membranes for pretreatment of typical municipal sewage prior to RO. After pretreatment by 6 mm screening and 0.5 mm sieving, the ceramic filters required less frequent cleaning than polymeric membranes [116]. Kramer et al. [109] also observed that biofouling of a RO membrane treating ceramic membrane permeate was very low. This study demonstrated that ceramic membranes may be considered for raw sewage reuse, where longer cleaning intervals are desired, and/or to prevent biofouling of RO membranes. Another membrane material that warrants further study is zeolite, which has demonstrated salt rejection in both molecular dynamics simulations and, to a lesser extent, in practice [51].

The oxidative resistance of ceramic membranes may provide more flexibility in the design of treatment processes for enhanced NOM removal. Ozone threatens the integrity of many polymers (although PTFE and, to a limited extent, PVDF are exceptions), but ceramic membranes are resistant to oxidation because they are already completely oxidized. If ozone is applied before a membrane, substantially more NOM, DBP precursors, and estrogenicity is removed, and a lower fouling propensity is observed in comparison to when ozone is used after MF/UF membrane processes [117, 118]. Catalytic ozonation on the surface and inside ceramic membrane pores can also prevent fouling [119]. The limited studies of ceramic membranes in reuse applications have highlighted their ability to handle high solid loadings and resist oxidation by ozone used for pretreatment. Therefore, due to their chemical resistance, ceramic membrane technology warrants continued research attention for water reuse applications. However, in comparison to polymeric membranes, ceramic membranes are less cost competitive, generally have larger pores and less permeable.

4. Membrane Module Types

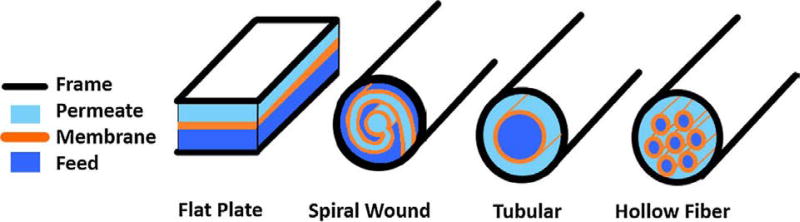

Membrane filtration technology has developed not only with respect to the membrane materials, but also how membranes are packaged in reactors and modules. Module types often place large constraints on membrane materials due to available fabrication processes. Thus, a wide range of membrane modules have been developed, suited to a variety of applications. The four conventional polymeric membrane module types are flat sheet, hollow fiber, spiral wound, and tubular (Figure 8) [120, 121]. However, flat sheet membranes and the rarer tubular modules (1–3 cm in diameter) have higher costs and lower practical packing density. These types are largely being replaced by hollow fiber or spiral wound membrane modules for water treatment and reuse applications. Some researchers have developed and tested novel configurations apart from those mentioned above. For example, one novel module configuration is a helical membrane configuration, where two pieces of membrane sheets are supported on a plastic spacer. Another is a fishbone or broom-like structured spacer, which has been examined by Liu et al. [122]. Other recent configurations, induce membrane vibrations to increase filtration rates [123, 124]. However, to date, none of these have proven to be cost competitive. Hence, the discussion below is focused on the three most commonly used polymeric membrane modules for potable water reuse applications: flat plate, hollow fiber and spiral wound. Relevant findings for each of these module configurations and challenges ahead are discussed in the following subsections.

Figure 8.

Schematic diagrams of module types for most membrane applications

Notably, flow configuration is another key distinction for membrane modules and consists of either dead-end or cross-flow (tangential flow) filtration. In dead-end configurations, all fluid passes through the membrane, perpendicular to its surface. In contrast, cross-flow systems are designed so that the flow is parallel to the membrane, and residual feed water is rejected as brine. Dead-end filtration is often used in experimental studies or when the particle loading in the feed is very low. While it has higher water recovery, dead-end filtration suffers faster fouling, requiring frequent backwashing [67, 125].

4.1 Flat Plate

Flat plate (plate and frame or flat sheet) membrane modules, also known as stacked membrane modules, are used in few water treatment applications where the feed streams to be treated contain high amount of foulants and/or have high viscosities. Modern flat plate membrane systems are built to tolerate very high pressures, in excess of 100 bar. They are used in the treatment of landfill leachates and for industrial textile wastewater reuse [126]. Even though tangential flow flat plate membranes have proved to be a popular MBR configuration for wastewater treatment (e.g., immersed flat sheet modules from Kubota®), their application is limited to advanced water treatment due to their low surface area to volume densities. Flat plate modules are predominantly used for MF and UF, with little industrial use for RO and NF. Extensive membrane fouling and low treatment efficiencies remain major challenges associated with flat sheet membrane modules in potable reuse applications [127].

To counter these challenges, recent research has focused on combining flat sheet membrane modules with embedded photo catalysts, such as TiO2, for the removal of organic matter from feed water [128, 129]. Hernandez et al. [130] showed that doping flat sheet membranes with Fe/Pd nanoparticles can enhance removal of contaminants due to an order of magnitude increase in catalytic activities on membrane surfaces. In addition, research has also shown that pretreatment of the feed water with polyaluminium chloride (PACl) and ozone can enhance the efficiency of flat sheet membranes used for potable reuse applications [131, 132]. Research in minimizing fouling of flat sheet membranes is also directed at hybrid forward osmosis (FO) systems for wastewater treatment/reuse, where FO membranes are first cast on hydrophilic glass plates and thermally annealed in water thereafter. These membranes have a highly porous sublayer sandwiched within and are termed as double-skinned membranes. They generally have less fouling propensity and mitigated internal concentration polarization (ICP) [133, 134].

4.2 Hollow Fiber

Hollow fiber (HF) membranes consist of several thousand hollow fibers with a small hollow portion called as lumen with various dimensions from of 0.5–1 mm in diameter. Due to its high surface area per volume, HF modules are mostly preferred over other configurations for large-scale operations. Generally, the hollow fiber modules used in potable reuse applications are manufactured to accommodate MF or UF membranes where they are common. However, this configuration has recently become commercially available again for RO (although it remains rare), and to some extent, for NF [135]. Challenges in making sufficiently permeable NF/RO membranes with sufficient structural strength have limited this applications, although fundamentally hollow fiber membranes have favorable mass transfer coefficients and packing densities for these processes [130]. The manufacturing of hollow fibers can be more limited than that of the flat membranes seen in flat plate or spiral wound systems, as roll-to-roll processes and coating techniques such as spray deposition or fabrication methods like polymer composites are more challenging. Due to technical limitations the technology and precision of making HF membranes and modules is still not widely explored. On the other HF membranes have higher packing density than that of other flat membranes so the separation efficiency is higher in this case for potable water reuse.

Filtration in HF membranes can operate from inside-out or vice versa, allowing for backwashing. HF membrane modules are increasingly used for wastewater potable reuse and desalination [136]. Hollow fibers are more resilient to small particulate fouling than spiral wound membranes for reuse applications, though they still benefit from pre-filtration if suspended solids are present in the feed water. Most HF membranes, even after surface modifications, are limited in their applications to pressures below 3.4 bar [70] whereas research on HF membrane with higher mechanical strength is ongoing which include inorganic additives.

Hollow fiber membranes for wastewater reuse are restricted by challenges including the trade-off relationship between permeability and rejection (related to membrane porosity), and low resistance to fouling [106]. Fouling issues are exacerbated by fiber clogging, and also by the small channels, which make high velocity cleaning difficult. Continuous efforts have been made to counter these challenges by modifying standard configurations, as in the case of spirally wound silicone rubber hollow fiber membranes and monofilament nylon [121], which display lower pressure drops and higher mass transfer rates due to combined advantages of both spirally wound and hollow fiber modules. Research has shown that inside-out hollow fiber modules, arranged in parallel configuration and operated in dead-end filtration mode, at some stage during cleaning need chlorinated water for backwashing if used for wastewater reuse [125]. Hence, tangential flow filtration is the most preferred hollow fiber membrane configuration due to reduction in fouling

Modifying membrane sometime called novel membrane surfaces is another alternative to counter the above-mentioned challenges of hollow fiber modules similar to using nanocomposite materials [71, 111]. Apart from metal nanoparticles, multi-walled carbon nanotubes (MWCNT) are increasingly being used during fabrication of hollow-fiber membranes [137] for either improved fouling resistance (carboxylated MWCNT) or increased permeabilities (hydroxylated MWCNT) [137] but the goal of high permeability and high selectivity is still a dream to fulfil.

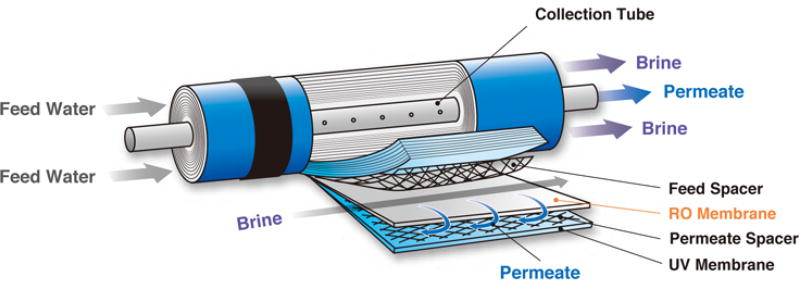

4.3 Spiral Wound

The most common membrane module used in NF/RO processes is spiral wound [120] which is also used for MF/UF. Spiral wound design success relates heavily to high packing densities and the relative ease of manufacturing the modules and the flat sheet membranes. Spiral wound modules contain a small-diameter tube tightly packed with flat sheet membranes separated by mesh spacers in the feed and permeate channels (Figure 10). This dense configuration means available surface area is higher for a filtration unit (example picture provided in Figure 11), thus overcoming the limitations of flat plate and tubular configurations. Most of these modules are composed of polymers (plastics), including the membranes, spacers, and other components, with the exception of the stainless steel pressure vessels and pipes. Spiral wound membranes have been found to be successful in not only removing traditional contaminants from feed [138, 139] but also emerging contaminants [140, 141] from wastewater sources. In the case of spiral wound RO, pretreatment is essential for water reuse applications [142]. Spiral wound membrane modules are highly sensitive to particulate fouling that can reduce process efficiency and reduce membrane lifetime (U.S.EPA, 2005). Hence, increasing fouling resistance remains the biggest challenge for spiral wound membranes.

Figure 10.

Spiral wound RO module design, Copyright 2016, reproduced with permission from Aquanext [143].

Figure 11.

Spiral wound RO membranes installed in Groundwater Replenishment System (GWRS) Advanced Water Purification Facility (Fountain Valley, California), taken at the Orange County Water District.

Ongoing research, through the last decade, focused on the optimization or complete removal of the feed spacer mesh from the spiral wound feed channels [144, 145]. Spacers in the feed can create dead regions that promote scaling, fouling, and particulate deposition. Successful spacer research has implement combinations of 3D printing with numerical modelling and experimental testing for reducing biofilms and improving flux recovery in RO and NF [146]. Limited lab-scale improvements are implemented however, because improved fabrication of complex geometries of these polymeric spacers (e.g. through 3D printing) remains expensive. Another area for innovation is higher-pressure tolerant modules composed of plastics, which can be cheaper, more chemically resistant, and less likely to induce salt nucleation than the typical stainless steel vessels and pipes.

The other significant breakthrough in this domain has been in surface modifications [147]. In addition, current research is focused on optimization of cleaning parameters for spiral wound membranes. To control biofouling and increase efficiency of the treatment, periodic cleaning of high-pressure RO/NF membranes is conducted as an effective operational strategy [148].

5. Alternative Membrane Technologies

5.1 Electrodialysis/Electrodialysis Reversal

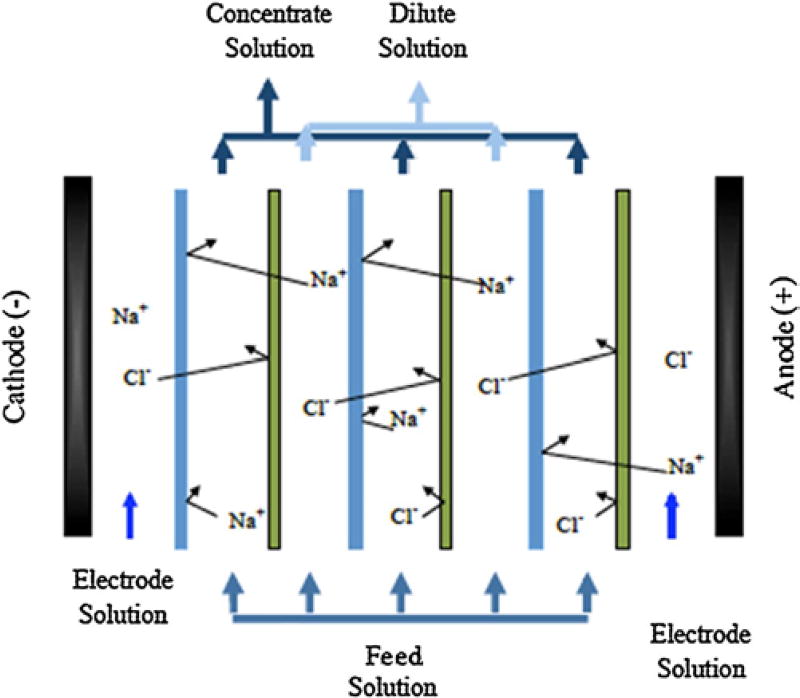

ED is a membrane-based desalination process in which ions transport through ion exchange membranes under the influence of an applied electrical field [149]. EDR was proposed by Meyer and Strauss in 1940, but its application at industrial scales started much later [150, 151]. ED was introduced and used in industrial applications before RO [150]. A schematic of an ED stack is shown in Figure 12. In EDR, the basic ED process is enhanced by periodically changing the direction of ion transport by reversing the polarity of the electrodes. This periodic change in polarity is done in order to prevent scaling and fouling problems and increase process efficiency [152, 153]. Additionally, when the polarity is reversed, automatic valves switch the flows of the dilute and concentrate streams through the cells [154].

Figure 12.

Schematic drawing of an electrodialysis stack. An applied voltage causes ions to move between electrodes, and membranes that either block negative or positive ions cause the ions to be trapped in concentrate channels.

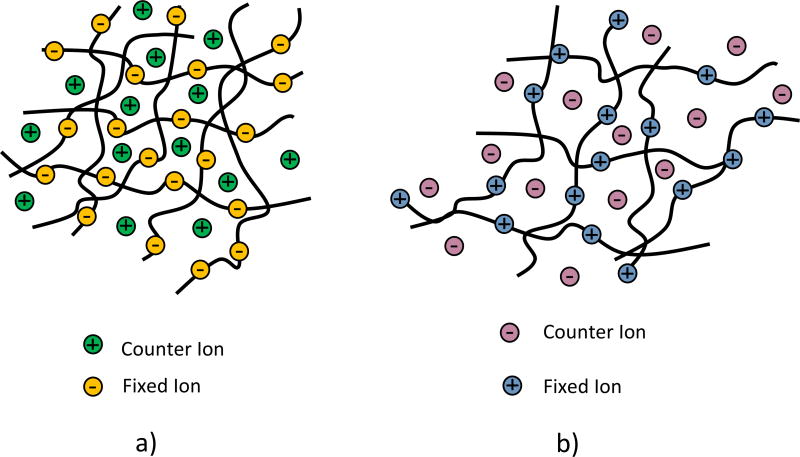

The ion exchange membranes used in ED/EDR processes can be considered as ion exchange resins in the polymeric matrix, and they are categorized into cation exchange membranes (CEMs) and anion exchange membranes (AEMs), as depicted in Figure 13. These ion exchange membranes have low electrical resistance, high pH stability, resistance to scaling, and fouling, robust structure for washing, cleaning, and long lifetime [155]. CEMs, which are negatively charged ion exchange membranes, can only pass cations. Most commercialized CEMs are composed of sulfonated cross-linked polystyrene that has a large number of sulphonate groups. In water, this ionic group is ionized to mobile H+ counter-ions and functional groups of –SO3− fixed in the structure [150]. AEMs, which are positively charged ion exchange membranes, only permeate anions. These ion exchange membranes typically have fixed quaternary ammonium groups, –NH4+ or quaternary –N-R3 in the polymeric structure [150].

Figure 13.

Schematic diagram of the structure of a) a cation exchange membrane and b) an anion exchange membrane.

Ion exchange membrane characteristics are especially important in the ED/EDR process, and these characteristics can be controlled to some extent in the manufacturing process. Ion exchange membranes are characterized by their properties of electrical resistance, ion exchange capacity, water content, ion transport number, solute permeability coefficient, electro-osmotic coefficient, water permeation coefficient, swelling ratio, and mechanical strength [156].