Abstract

Efficacy of spinosad and malathion loaded in eco-friendly biodegradable formulations was evaluated for controlling Culex pipiens larvae. Malathion (organophosphorus larvicide) and spinosad (naturally derived insecticide) were loaded on chitosan/alginate/gelatin capsules. Capsules were characterized by size measurement, scanning electron microscopy, Fourier transform infrared spectroscopy, and water uptake. In vitro release kinetics of the larvicides was studied in the running and stagnant water. Biochemical studies on the larvae treated with technical and formulated insecticides were also demonstrated. The results indicated that the released spinosad was active for a long time up to 48 and 211 days in the running and stagnant water, respectively. However, the capsules loaded with malathion showed larvicidal activity for 20 and 27 days in the running and stagnant water, respectively. Technical and formulated malathion and spinosad had an inhibition effect on acetylcholinesterase, carboxylesterase, and glutathione S-transferase. The results proved that the prepared capsules consisting of biodegradable polymers containing larvicides could be effective as controlled-release formulation against C. pipiens larvae for a long period.

Keywords: chitosan capsules, larvicide, controlled-release formulation, swelling, mosquitocidal activity, Culex pipiens, biochemical study

Video abstract

Introduction

Mosquitoes are considered to be the essential vector of many pathogens and parasites such as viruses, protozoans, bacteria, and nematodes, which cause dangerous diseases, for example, malaria, yellow fever, dengue, chikungunya fever, Zika fever, and filariasis, in tropical and subtropical areas. Culex, Aedes, and Anopheles are considered as the responsible vector of these diseases.1–3 In all the governorates of Egypt, the common house mosquito is Culex pipiens which causes infections and disability in persons.4 It is the main vector of Bancroftian filariasis (infects ~120 million persons per year, leaving several disabled),5 Rift Valley fever, and diseases caused by other viruses.6–8

Mosquito control represents an important strategy for prevention of disease transmission and epidemic outbreaks. Insecticides commercially used for mosquito control belong to four major chemical groups including chlorinated hydrocarbons, organophosphorus, carbamates, and pyrethroids, according to the World Health Organization Pesticide Evaluation Scheme and the Egyptian Ministry of Health.9 Synthetic insecticides are most commonly used in mosquito control programs.10 However, extensive use of an insecticide for generations increases the risk of mosquitoes developing resistance accompanied by dangerous effects on human, nontarget organism, and the environment.1,11–14 Organophosphates are insecticides which accumulate at low levels in the environment and are hydrolyzed at high or low pH.15,16 These were first developed as nerve gases, and their insecticidal effectiveness was discovered shortly thereafter.16,17 They have become widely used as replacements for organochlorine insecticides because they do not persist in organism tissues or the environment.16,18 Malathion is the most widely used within this group and was used as the main insecticide for vectors control until pyrethroids were introduced to the country between 1995 and 1997.19

Spinosad can be described as a macrocyclic lactone containing a unique tetracyclic ring to which two different sugars are attached. It consists of isomers A and D of spinosyn and is a naturally occurring product of an aerobic fermentation by Saccharopolyspora spinosa.20–22 Spinosad is also a highly effective bioinsecticide against all mosquito larval species tested thus far such as Aedes aegypti, Anopheles stephensi, and C. pipiens.23 It causes stomach and contact toxicity and degrades in the environment rapidly24 and has an excellent toxicological profile for human and environment.4,23,25–27 So, the Environmental Protection Agency has recorded spinosad as a low-risk material.28

Extensive use of insecticides in integrated control programs causes hazards to both humans and the environment.29,30 In addition, as much as 90% of the used conventional pesticides are lost or degraded, which not only increases the cost but also increases the environmental risks.30–32 The failure of the synthetic insecticides to control the insects and growing public concern for safe food and a healthy environment have encouraged the search for more environmentally benign vector control ways such as controlled-release formulations (CRFs).33,34 CRFs of pesticides can remarkably reduce the consumption of pesticides and their effect on the environment. They can prolong the pesticide’s activity, reduce the loss of pesticide by leaching, evaporation, and degradation, and minimize the danger of percutaneous poisoning.30,35,36 Usually, CRFs of insecticides are preferably prepared using biopolymer materials such as alginate, carboxymethyl cellulose, agarose, starch, and chitosan due to their low cost, good biological activity, free availability, nontoxicity to mammals, and high biodegradability.35,37,38

Among these materials, chitosan, a deacetylated derivative of chitin (N-acetyl-d-glucosamine), is a naturally occurring polysaccharide and found abundantly in marine crustaceans, exoskeletons, and fungal cell walls. Chitosan is a cationic, biocompatible (in animal tissues), nontoxic, odorless, and biodegradable polymer having many applications in different fields.39–43 Alginate gels are widely used as matrices for CRFs in agricultural applications due to their biodegradability and the ease of incorporation of pesticides using an aqueous system at ambient temperatures. However, alginate has inherent drawbacks, such as low mechanical strength, uncontrolled degradation, and extensive water uptake properties which can result in uncontrolled and unpredicted release rates of the active pesticides.44–46 The leaching of pesticides during the preparation of alginate beads has been improved by synthesizing bi-polymeric beads of alginate with other natural polysaccharides.36,47–50

Therefore, the current study aimed to prepare eco-friendly capsules based on chitosan, alginate, and gelatin loaded with malathion and spinosad as a promising formulation against C. pipiens larvae. The capsule characterization including scanning electron microscopy (SEM), Fourier transform infrared (FT-IR) spectroscopy, physical properties, and swelling capacities is demonstrated in detail. In addition, the in vivo effects of both insecticides on biochemical parameters such as acetylcholinesterase (AChE), carboxylesterase (CaE), and glutathione S-transferase (GST) were also examined.

Materials and methods

Materials and reagents

Low-molecular weight acid-soluble chitosan (3.60×105 Da and 89% degree of deacetylation), sodium alginate, gelatin (type A, from porcine skin, 300 bloom), glutaraldehyde (25%), bovine serum albumin, acetylthiocholine iodide (ATChI), 1-chloro-2,4-dinitrobenzene, 5,5′-dithiobis (2-nitrobenzoic acid), 4-nitrophenyl acetate (NPA), l-glutathione (GSH), and ethylenediaminetetraacetic acid (EDTA) were purchased from Sigma-Aldrich Co. (St Louis, MO, USA). Technical malathion 90%, diethyl 2-(dimethoxyphosphorothioyl) sulfanyl butanedioate, and formulated form (57% EC, Malasion®) were obtained from Kafr El Zayat Pesticides & Chemicals Co. (Gharbia, Egypt). Technical-grade spinosad (95%) and formulated form (25% G, Spintor®) were purchased from the Dow Chemical Company (Midland, MI, USA). All other reagents and solvents were of analytical grade and used as received.

Test insect and rearing

The C. pipiens larvae were obtained from susceptible reared strain provided by the Research Institute of Medical Entomology (Ministry of Health, Dokki, Gizva, Egypt) and reared under insectary conditions. Approximately, 400–600 C. pipiens larvae were reared in white enameled and shallow dishes containing 2–3 L of dechlorinated water. These trays were covered with mesh screen to prevent oviposition by escaped adult mosquitoes and were maintained at a room temperature (26°C±2°C) and relative humidity (70%±5%) with a 14-hour:10-hour (light:dark) photoperiod. The larvae were daily fed on biscuits and yeast power in the ratio of 3:1 until pupation. The pupae were transported from the dishes to plastic cups containing dechlorinated water and were maintained in netting cages with wood frames (30×30×30 cm) until adults emerged. Adults were provided with 10% solution of sucrose, and females were fed on pigeon blood four times a week.51

Dose–response larval bioassay of malathion and spinosad

The toxicity of technical and formulated malathion and spinosad was evaluated at different concentrations (0.25–10 and 0.0005–0.20 mg/L for malathion and spinosad, respectively) in dechlorinated tap water. The test cups were kept at 25°C±2°C and preferably under a photoperiod of 12 hours:12 hours (light:dark). Larval mortality was recorded after 24 and 48 hours of the exposure. The log dose–response curves were used for the determination of the lethal concentration causing 50% mortality (LC50) values according to the probit analysis.52 If the control mortality was between 5% and 20%, the mortalities of treated groups were corrected according to Abbott’s formula.53

Preparation of capsules loaded with malathion and spinosad

Chitosan/alginate/gelatin capsules were prepared by cross-linking with glutaraldehyde according to the technique previously described by Badawy et al.54 The best type of capsules from previous study (chitosan:alginate:gelatin:gluta raldehyde =0.25%:0.5%:0.625%:1%) was selected for loading the two tested technical-grade larvicides malathion and spinosad. These capsules were characterized by less swelling ratio, less diameter, spherical shape, and highest number per gram, which will give higher controlled release. The capsules were prepared following the same method mentioned earlier, in addition to mixing each insecticide (dissolved in acetonitrile) with 1% chitosan solution (w/v) and then pipetting to the alginate with glutaraldehyde solution.54

Capsules characterization

Size measurement

The size of ten replicates of dried capsule formulations was measured using LCD Digital Vernier Caliper/Micrometer (6 inch) Gauge 150 mm (Jingkewang Technology Co., Ltd, Shenzhen, People’s Republic of China) with an accuracy of ±0.02 mm/0.001 inch.

Surface morphology

SEM analysis was done using a JEOL JSM-5300 microscope (JEOL, Tokyo, Japan) to examine the capsules’ surface morphology. The observations were performed at an accelerating voltage of 25 kV. The dried capsules were sputtered with gold, mounted on metal stubs with double-sided tape, and examined under a scanning electron microscope. The cross-sections of the dried capsules were also scanned.

FT-IR spectroscopy

To study the functional groups of loaded and unloaded capsules and their components, the capsules were analyzed by FT-IR spectroscopy with KBr discs in the range of 4,000–400 cm−1 with a resolution of 4.0 cm−1 on a Perkin Elmer FT-IR Spectrophotometer (PerkinElmer Inc., Waltham, MA, USA).

Swelling properties

The swelling capacity of the loaded and unloaded capsules was demonstrated by the following method. The water uptake ability of capsules was estimated by immersing certain weight of dried capsules (0.05 g) into water and then by recording the water gain at different periods up to 10 days. Excess surface water was removed by drying with soft paper, and the swelling percentage was calculated by the following equation:

| (1) |

where Wt and Wo are the weights of swollen sample at time (t) and that of the original sample, respectively. Experiments were conducted in triplicate, and the obtained data were averaged.

Spectral analysis and estimation of malathion and spinosad content in controlled-release capsules

Absorption scan was performed in the range of 190–340 nm on 50 mg/L malathion and 25 mg/L spinosad in acetonitrile using UV/visible spectrophotometer (Alpha-1502; Laxco Inc, Bothell, WA, USA). Solvent was used as blank. The maximum wavelength appeared at 200 and 203 nm for spinosad and malathion, respectively. Therefore, all absorbance measurements were recorded at these wavelengths. For estimation of the malathion and spinosad content in capsules, a weight of 0.02 g of capsules was immersed in acetonitrile (5 mL) and grinded to disintegrate the capsules. The vial was left under room condition for 2 hours and then purified by Whatman filter paper no. 1. The filtrate of acetonitrile was used for UV analysis at a λmax of 200 nm for spinosad and 203 nm for malathion. The concentration of each insecticide in the product was estimated from the calibration curve. Calibration curves were obtained by using different concentrations of each insecticide (5–100 mg/L).

In vitro release study in stagnant and running water

Four weights of capsules (0.005, 0.01, 0.02, and 0.05 g) were immersed in distilled water (100 mL) and stored at 25°C±2°C. An aliquot of each sample was daily taken from each bottle at different periods and analyzed by UV spectroscopy at 200 and 203 nm until spinosad and malathion, respectively, became undetectable. The distilled water sample was used as a blank. The measured water samples were poured back into the dissolution cell to keep the volume constant. This technique was done for both stagnant and running water. In the running water technique, the water was removed and daily discharged. However, in the stagnant water technique, the measured water samples were poured back into the cups to keep the volume constant.

Larvicidal activity of controlled-release capsules loaded with malathion and spinosad

Larvicidal activity of malathion and spinosad released from prepared capsules against C. pipiens larvae was assayed using two techniques. First, bioassay in stagnant water was conducted as follows: Capsules (0.005, 0.01, 0.02, and 0.05 g) were placed in 100 mL of water containing ten C. pipiens larvae, and their death was monitored as a function of time daily for a period without change of water but with fresh larvae.55,56 The experiments were demonstrated in three replicates, and a control sample was obtained by keeping larvae in water under the same conditions but with unloaded beads. Second, the bioassay was performed in running water where the solution and larvae were discharged daily without capsules. Then, the water was replenished, fresh larvae were added, and a new death/survival count was carried out daily. The trial was repeated until a negligible mortality was obtained. The mortality was recorded in two experiments.

Biochemical studies

Specific activities of AChEs, CaEs, and GSTs were estimated in surviving larvae after 1 day of exposure to LC50 of malathion and spinosad. Larvae were homogenized by a glass/Teflon homogenizer in 40 mM sodium phosphate buffer (pH 7.4), 10 mM NaCl (1%, w/v), and Triton X-100 at 4°C. The homogenate was filtered through cheesecloth followed by centrifugation at 5,000 rpm (20 minutes) at 4°C. The supernatant was used immediately for assaying AChEs, CaEs, and GSTs. All the experiments were performed in triplicate. Crude protein was determined using bovine serum albumin for standard curve.57 AChE activity was estimated using 0.075 M ATChI as a substrate in colorimetric method.58 The assay medium (1.5 mL total) consisted of 10 μL of 0.075 M ATChI, 20 μL of the crude enzyme, 50 μL of 0.01 M 5,5′-dithiobis(2-nitrobenzoic acid), and 1,420 μL phosphate buffer (pH 8). After a 10-minute incubation at 37°C, the reaction was monitored at 412 nm by using UV/visible spectrophotometer (Alpha-1502; Laxco Inc). The specific activity was expressed as ΔOD412 min−1×mg protein−1. CaEs activity was assayed by spectrophotometer using the substrate NPA.59 The assay medium consisted of 1,925 μL of 20 mM Tris–HCl buffer (pH 8.0) containing 1 mM (EDTA), 50 μL of enzyme extract, and 25 μL of 5 mM NPA. In this method, after incubation (5 minutes) at 25°C, the formation of yellow 4-nitrophenol was recorded at 405 nm. The specific activity was expressed as ΔOD405 min−1×mg protein−1. GSTs activity was estimated by mixing 1,650 μL of 100 mM phosphate buffer (pH 7.4) containing 1 mM EDTA, 200 μL of 2.5 mM GSH, 50 μL of enzyme extract, and 100 μL of 1 mM 1-chloro-2,4-dinitrobenzene as a substrate.60 The absorbance was recorded at 340 nm. One unit of the activity corresponded to the quantity of enzyme conjugating 1 mmol of GSH per minute. The specific activity was expressed as ΔOD340 min−1×mg protein−1. Blanks (same as previous experiments without crude enzyme sample) were periodically measured for nonenzymatic activities; however, no significant activity was observed for all enzymes.

Statistical analysis

Statistical analysis was performed using the SPSS software, version 21.0 (IBM Corporation, Armonk, NY, USA). Mortality percentages were recorded for all treatment bioassays and corrected using Abott’s equation.53,61 Mean values and standard error were determined using three independent replications performed for each treatment. The LC50 value for the insect bioassay was recorded using log dose–response curves according to probit analysis.52 The least-square regression analysis was used for measuring 95% confidence limits. Data were analyzed by analysis of variance, and mean values were separated (P≤0.05) using Student–Newman–Keuls test.

Results and discussion

Preparation of capsules loaded with malathion and spinosad

The reaction between chitosan (0.25%), sodium alginate (0.5%) cross-linked with glutaraldehyde (1%), and gelatin (0.625%) was achieved to produce spherical capsules loaded with 16.05% malathion and 18.85% spinosad which were analyzed by UV spectrophotometer at a λmax of 203 and 200 nm, respectively (Table 1). Capsules were yellowish brown in color before drying and brown in color after drying. The properties of loaded and unloaded capsules are shown in Table 1. It was noted that the unloaded capsules were having higher diameter (1,004 μm) than the capsules loaded with malathion (932 μm), and hence, there were 820 and 2,170 capsules per gram, respectively. Likewise, spinosad-loaded capsules were 771 μm in diameter, and hence, there were 3,240 capsules per gram.

Table 1.

Properties of loaded and unloaded capsules

| Parameters | Unloaded capsules | Capsules loaded with malathion | Capsules loaded with spinosad |

|---|---|---|---|

| Components ratio (Ch:Alg:Gel:Glut:larvicide) | 0.25:0.5:0.625:1.0:0.0 | 0.25:0.5:0.625:1.0:16.05 | 0.25:0.5:0.625:1:18.85 |

| Capsule color | Yellow | Brown | Brown |

| Weight before drying (g) | 17.68 | 8.37 | 7.50 |

| Weight after drying (g) | 1.53 | 0.68 | 0.61 |

| Capsule no/g | 820 | 2,170 | 3,240 |

| Diameter ± SE (μm) | 1,004±32 | 931.82±24.46 | 770.91±15.85 |

| Flexibility before drying | Flexible | Flexible | Flexible |

| Flexibility after drying | Hard | Hard | Hard |

Abbreviations: Ch, chitosan; Alg, alginate; Gel, gelatin; Glut, glutaraldehyde; SE, standard error.

In this work, it was necessary to modify chitosan structure with alginate and to cross-link with glutaraldehyde as it has been proved that the mechanical strength of chitosan capsules is low, which limits its use as a CRF.62,63 Chitosan and alginate react via ionic interaction between the carboxyl residues of alginate and the amino terminals of chitosan.64 The interaction could also be via intermolecular hydrogen bonding.65 This complexation reduces the leakage of the encapsulated substances, and decreases the porosity of the alginate capsules. Similarly, Suave et al66 loaded the malathion in microspheres of pure polymers (3-hydroxybutyrate and poly-e-caprolactone) to evaluate its performance as a CRF.

Our results are in agreement with Yan et al35 who prepared alginate–chitosan–bentonite beads loaded with pesticides as a CRF and characterized them by FT-IR spectroscopy, SEM, thermogravimetry, water uptake tests, and release studies. Singh et al67 studied thiram fungicide’s dynamics of release from starch–alginate beads to control environmental pollution. In addition, Işiklan loaded insecticide carbaryl in sodium alginate, sodium alginate/gelatin, and sodium alginate/sodium carboxymethyl cellulose beads by cross-linking with glutaraldehyde and characterized them by FT-IR spectroscopy and SEM.68 The author found that the preparation conditions, such as carbaryl/sodium alginate ratio, time of exposure to glutaraldehyde, blend ratio, and temperature of release medium, impacted significantly on the release of the insecticide. Likewise, Huang et al69 loaded spinosad into microspheres using poly lactic acid as a coating material by emulsion solvent evaporation method. These microspheres were observed by SEM. The results proved that the microspheres were round beads with relatively smooth surfaces.

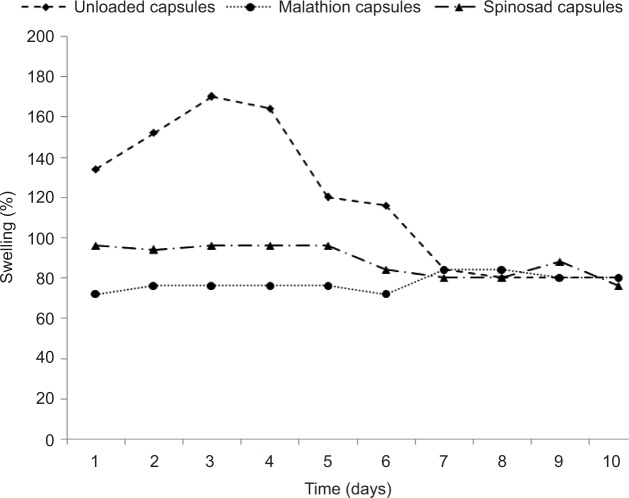

Swelling properties

The swelling kinetics of loaded and unloaded capsules observed during 10 days of the experiment is summarized in Figure 1. The weight of the unloaded capsules gradually increased, and the capsules exhibited a higher water absorption rate than both the loaded capsules for the first 6 days. After 24 hours, the unloaded capsules swelled rapidly. The highest degree of swelling was observed on the day 3 (170%), but the swelling reduced to 80% on day 7, and then remained constant until day 10. However, it was noted that the swelling kinetics of the capsules loaded with malathion and spinosad tended to be more stable along the experiment (70%–85% for malathion and 96% for spinosad).

Figure 1.

Swelling kinetics of loaded and unloaded capsules during 10 days.

Since sodium alginate and chitosan have a large number of hydrophilic groups, they are capable of extensive water uptake, so the capsules rapidly swelled at the first 3 days because of their hydrophilic contents. Later, they swelled slowly and continued to swell until they ruptured. All the capsules showed >70% of swelling instantly within the day 1, and later, the swelling became slow. This proved that only water might have transported within the porous polymer matrix. Our results are in agreement with those obtained by Agnihotri and Aminabhavi39 who prepared chitosan microparticles loaded with clozapine and found that the particles swelled to a maximum of 180% of their dry mass. All the particles showed >50% swelling immediately within the first minute, and later, the swelling became slow.

The swelling property of capsule is an effective factor that controls the release of active ingredient into the water for a long period. Swelling occurs due to the hydrophilic groups, and more positively charged amino groups along the biopolymer chain are responsible for an expanding polymer network.70,71 In addition, the swelling behavior of the capsules mainly results from the electrostatic discord between the negatively charged carboxyl groups on alginate and gelatin. Paula et al56 prepared chitosan/cashew gum (CH/CG) beads loaded with insecticide dichlorvos. They confirmed that the unloaded and loaded beads did not differ significantly in their swelling characteristics. However, in this study, we proved that the unloaded capsules recorded high swelling degree than the loaded capsules. This result may be referring to the complexation between the polymers, which decreases the capsules porosity and the sorption of the water into capsules.

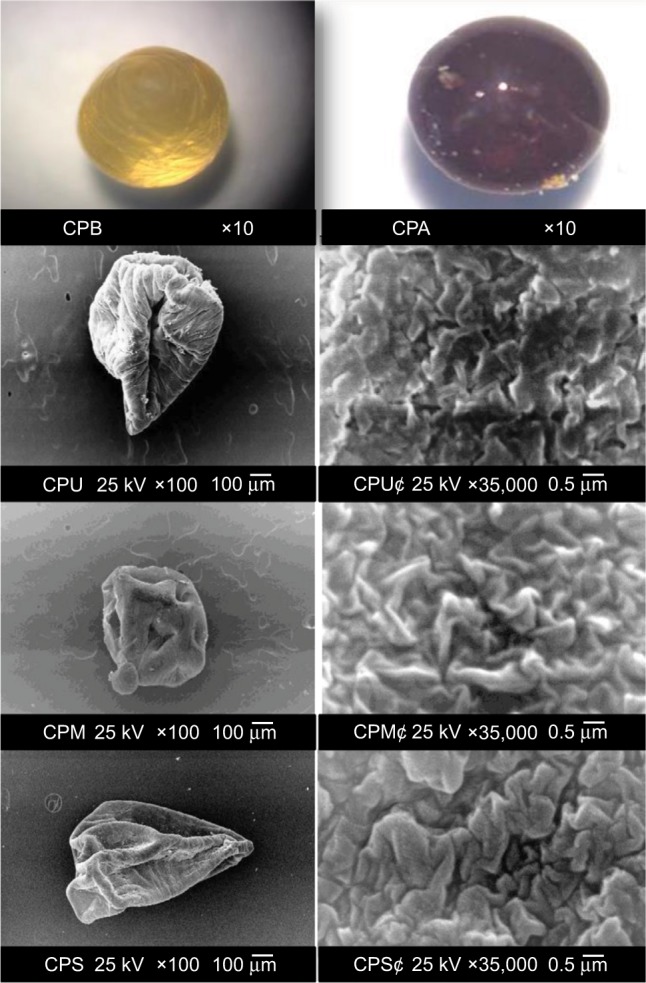

SEM analysis

The capsules initially were studied under a light stereo microscope before and after (Figure 2, CPB and CPA, respectively) drying to distinguish their characteristics. They appeared spherical in shape and yellowish gold in color before drying and turned to brown after drying. The general shape and surface morphology of the loaded and unloaded capsules were evaluated by SEM (Figure 2). The unloaded capsules were found to be irregular in shape with a longitudinal cavity (Figure 2, CPU), and their surface morphology was examined under a power of magnification of ×35,000 and appeared with a lot of pores and wrinkles (Figure 2, CPU¢). After loading with malathion, the capsules appeared under SEM as regular and oval shaped with a lot of wrinkles and pores (Figure 2, CPM), and their diameter ranged from 900 to 950 μm. However, the loading with spinosad made the capsules appear under SEM as irregularly shaped with many wrinkles, and their diameter ranged from 750 to 800 μm (Figure 2, CPS). The surface morphology of malathion- and spinosad-loaded capsules under a power of magnification of ×35,000 appeared more clearly with wrinkles and roughness (Figure 2, CPM¢and CPS¢). That might have been due to the hydrophilic nature of sodium alginate and chitosan, which resulted in a high degree of dehydration after drying.

Figure 2.

SEM images of loaded and unloaded capsules.

Notes: Stereo optical microscope morphology of whole shape (magnification, ×10) of the capsules prepared from chitosan (1%), alginate (1%), glutaraldehyde (2%), and gelatin (2.5%), before (CPB) and after (CPA) drying. SEM photograph of unloaded capsules (CPU) and their surface morphology (CPU¢), capsules loaded with malathion (CPM) and their surface morphology (CPM¢), and capsules loaded with spinosad (CPS) and their surface morphology (CPS¢). Scale bar is 100 μm and magnification is ×100 for whole capsules, and scale bar is 0.5 μm and magnification is ×35,000 for their surface morphologies.

Abbreviation: SEM, scanning electron microscopy.

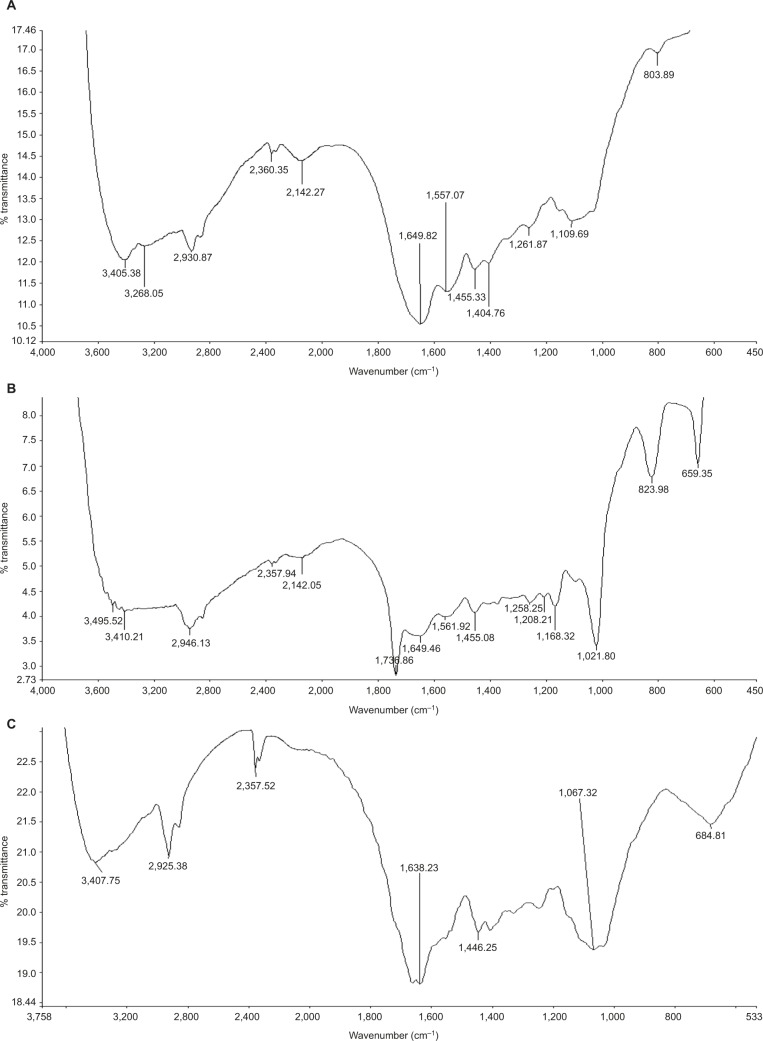

FT-IR spectroscopy

Figure 3 shows the FT-IR spectra of the unloaded capsules (Figure 3A) and capsules loaded with malathion (Figure 3B) and spinosad (Figure 3C). In all spectra, the absorption band at 3,405, 3,495, and 3,407 cm−1 was recorded due to the hydroxyl group −OH stretching vibrations which are characteristic of natural polysaccharides. The weak absorption bands at 2,930 (Figure 3A), 2,946 (Figure 3B), and 2,925 cm−1 (Figure 3C) represented −OH stretching vibration. The strong asymmetric stretching absorption band at 1,649 cm−1 in spectra of unloaded and malathion-loaded capsules and that at 1,638 cm−1 in spectra of spinosad-loaded capsules were due to the presence of carboxylate anions in chitosan and sodium alginate.

Figure 3.

Fourier transform infrared spectra.

Notes: Unloaded capsules (A). Capsules loaded with malathion (B) and spinosad (C).

In the spectrum of the malathion-loaded capsules, new strong absorption bands were noted at 1,021, 659, 1,736, and 823 cm−1. The strong stretching absorption band at 1,021 cm−1 appeared only in spectra of loaded capsules due to P=S of malathion. The absorption band at 823 cm−1 was assigned to P−O−C, and the absorption band at 1,455 cm−1 was assigned to CH3 asymmetric stretching in the malathion structure. Absorption band at 1,736 cm−1 was assigned to C=O (esters), and the band at 659 cm−1 was assigned to alkyl groups.66,72,73

In the spectrum of the spinosad-loaded capsules, new strong absorption bands at 1,446, 1,067, and 684 cm−1 were noted. The medium stretching absorption band at 1,067 cm−1 appeared only in spectra of loaded capsules due to C–N of spinosad. The absorption band at 684 cm−1 was assigned to alkyl groups. The absorption band at 1,446 cm−1 was assigned to CH3 asymmetric stretching in the spinosad structure.72

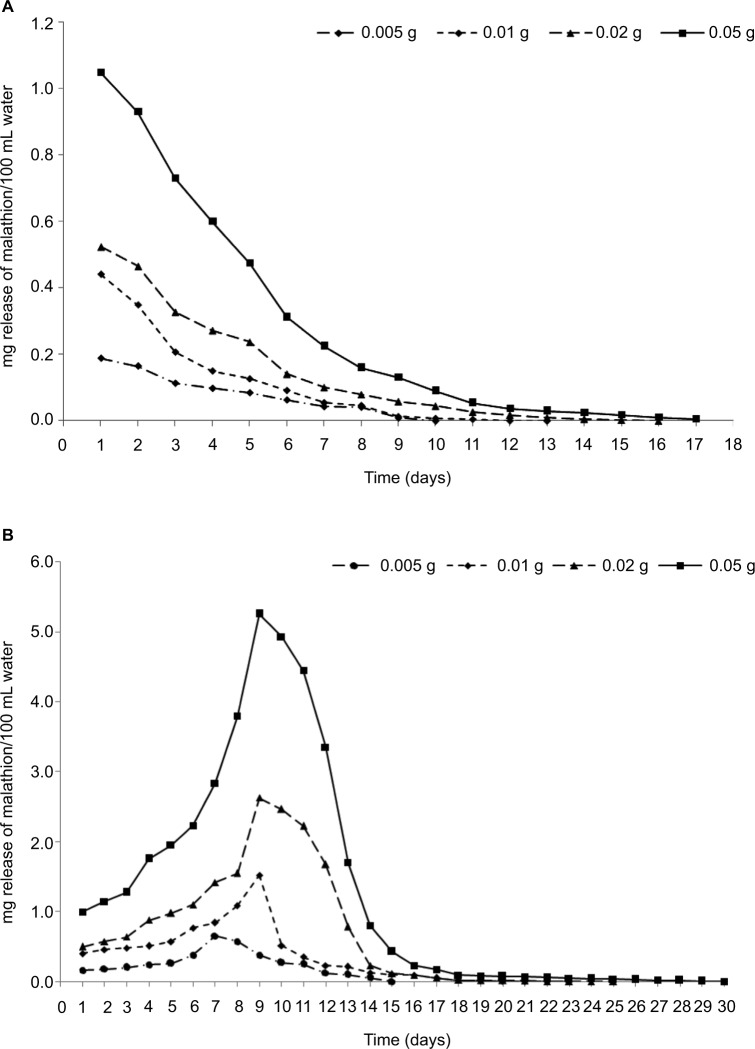

Malathion and spinosad in vitro release kinetics

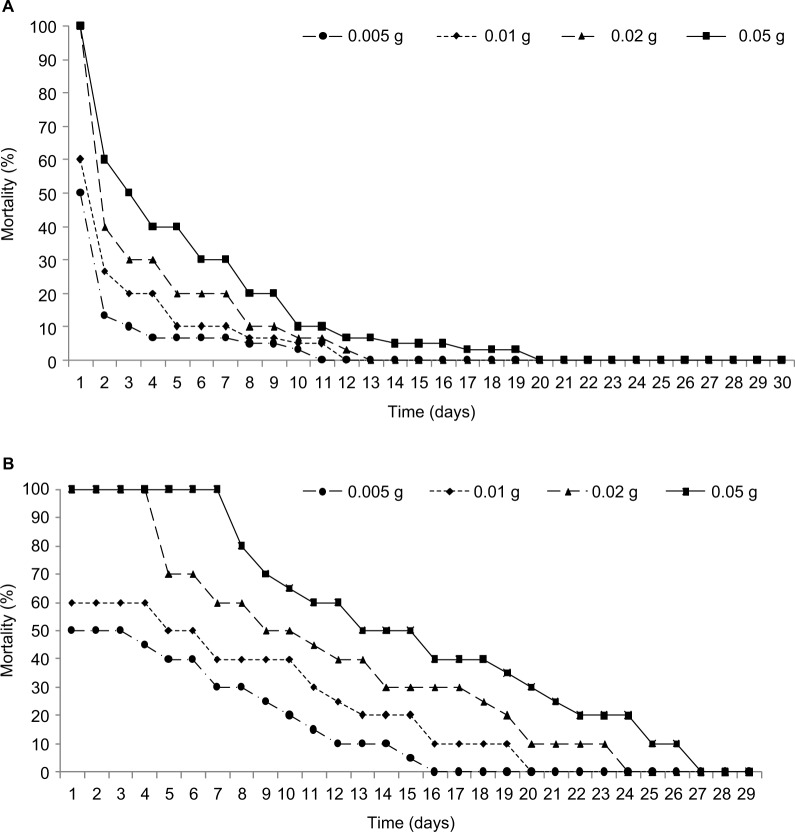

The capsules were loaded with 16.05% of malathion and analyzed by UV spectrophotometer at a λmax of 203 nm. A calibration curve given by the following equation: absorbance = +0.011C (mg/L), with 0.980 correlation coefficient, was used for malathion determination in acetonitrile. Figure 4 shows the in vitro release of malathion (mg/100 mL water) from prepared capsules in the running (Figure 4A) and stagnant water (Figure 4B) daily during 18 and 30 days, respectively. After 24 hours, in the running water, 0.05 g of capsules released the highest quantity of malathion (1.074 mg) in 100 mL water, while 0.02, 0.01, and 0.005 g capsules released 0.524, 0.440, and 0.188 mg, respectively, of malathion in 100 mL water (Figure 4A). Then, the quantities of the malathion released from all samples (0.005, 0.01, 0.02, and 0.05 g) significantly decreased with change of water daily. The malathion release became undetectable under UV spectroscope on days 10 and 13 for 0.005 and 0.01 g capsules, respectively, while with 0.02 and 0.05 g of capsules, malathion continued to be detected on days 15 and 17, respectively.

Figure 4.

In vitro release kinetics of the larvicide malathion determined by UV spectrophotometric assay.

Notes: Running water (A). Stagnant water (B).

Abbreviation: UV, ultraviolet.

The kinetics of release of malathion from the capsules observed in the stagnant water experiment is summarized in Figure 4B. After 24 hours, 0.005, 0.01, 0.02, and 0.05 g of capsules rapidly released increased quantities of malathion (0.159, 0.402, 0.794, and 0.993 mg/100 mL, respectively). Moreover, the accumulated release increased to the maximum values at days 7 (0.652 mg/100 mL for 0.005 g) and 9 (1.523, 2.628, and 5.256 mg/100 mL for 0.01, 0.02, and 0.05 g of capsules, respectively). Then, the release decreased gradually and became undetectable at days 15, 22, 25, and 30 for 0.005, 0.01, 0.02, and 0.05 g of capsules, respectively.

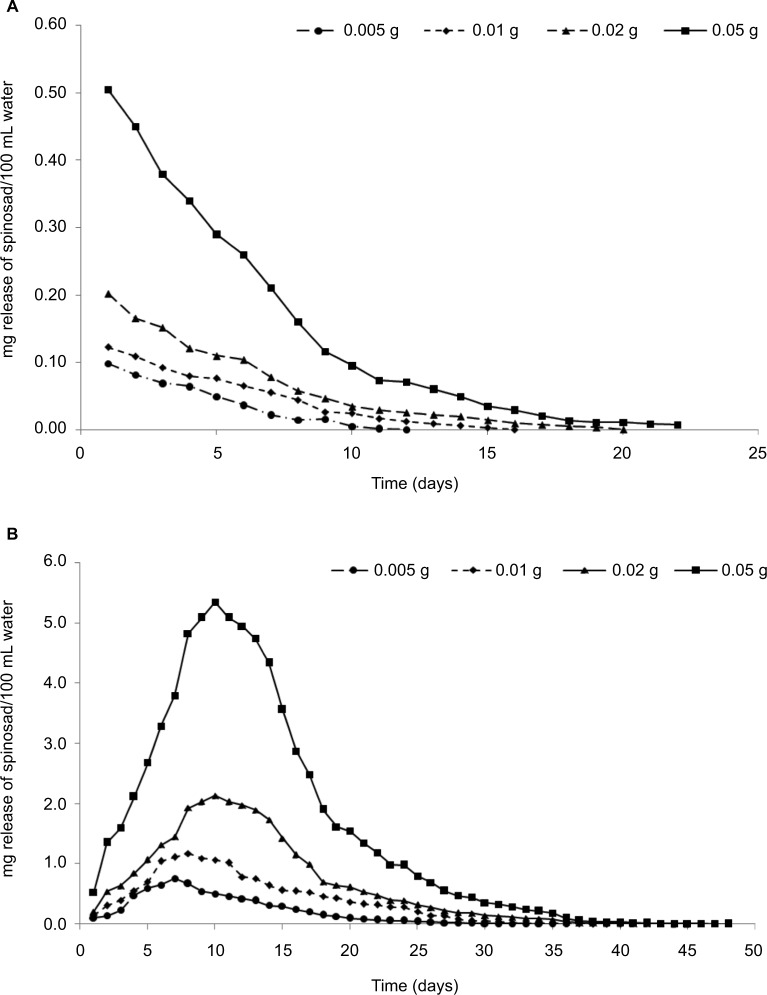

Likewise, prepared capsules of spinosad were loaded with 18.85% technical active ingredient and were analyzed by UV spectrophotometer at a λmax of 200 nm. A calibration curve given by the following equation: absorbance = +0.024C (mg/L), with 0.979 correlation coefficient, was used for spinosad determination in acetonitrile. Figure 5 shows the in vitro release of spinosad (mg/100 mL water) from prepared capsules in the running (Figure 5A) and stagnant water (Figure 5B) daily for 24 and 47 days, respectively. After the day 1, the highest quantity of spinosad (0.505 mg) released in 100 mL from the capsules with the highest weight (0.05 g) in the running water followed by 0.202, 0.122, and 0.098 mg/100 mL water from 0.02, 0.01, and 0.005 g of capsules, respectively (Figure 5A). Then, the quantities of the spinosad gradually released from all samples (0.005, 0.01, 0.02, and 0.05 g) significantly decreased with change of water daily. The spinosad release became undetectable as determined by the UV spectroscopy on the days 12, 16, 20, and 24 for 0.005, 0.01, 0.02, and 0.05 g of capsules, respectively.

Figure 5.

In vitro release kinetics of the larvicide spinosad determined by UV spectrophotometric assay.

Notes: Running water (A). Stagnant water (B).

Abbreviation: UV, ultraviolet.

The kinetics of release of spinosad from the capsules observed in the stagnant water experiment is shown in Figure 5B. The quantities of spinosad released from the capsules (0.005, 0.01, 0.02, and 0.05 g) rapidly increased on the day 1 (0.103, 0.144, 0.212, and 0.529 mg/100 mL, respectively). Moreover, the release increased to maximum values at day 7 (0.756 mg/100 mL) for 0.005 g, day 8 (1.171 mg/100 mL) for 0.01 g, and day 10 (2.140 and 5.394 mg/100 mL) for 0.02 and 0.05 g of capsules, respectively. Then, the release decreased gradually and became undetectable at days 36, 39, 46, and 49 for 0.005, 0.01, 0.02, and 0.05 g of capsules, respectively. It was noted that the malathion and spinosad releases were highly accumulated in stagnant water than running water. Our results were similar to those obtained by Paula et al56 who loaded chitosan and CH/CG beads with 5.15%–71.4% of 2,2-dichlorovinyldimethyl phosphate and studied in vitro release behavior of this larvicide. They found that the in vitro release was similar for CH and CH/CG beads, and faster release being observed after 5 hours for CH/CG beads at an equilibrium (30 hours), such that CH and CH/CG beads released up to 55% and 66% of the larvicide, respectively.

Larvicidal activity of controlled-release capsules

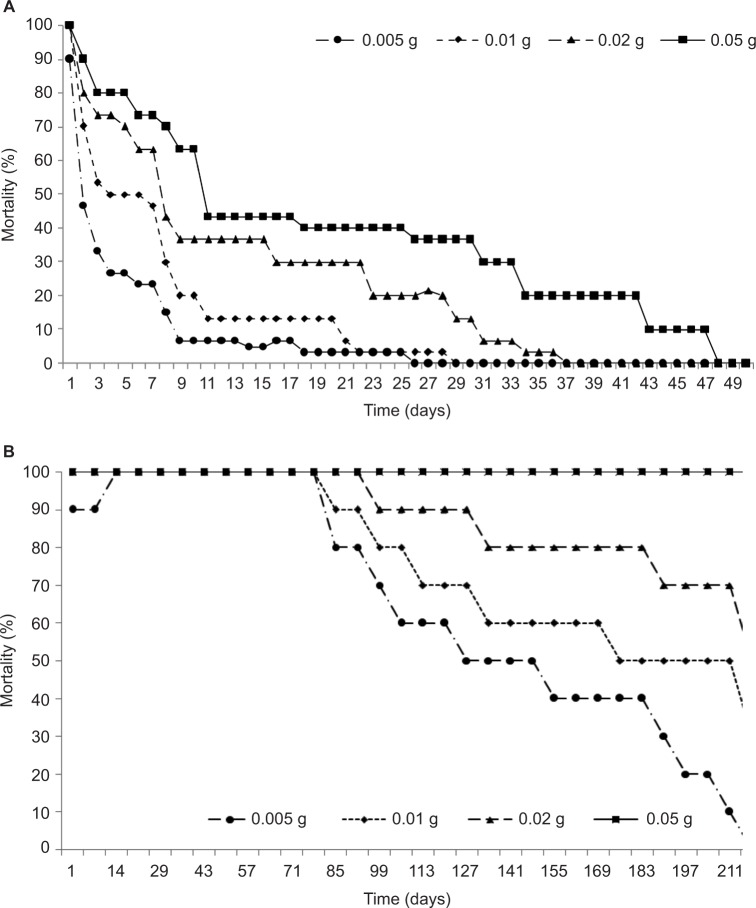

Larvicidal activity of controlled-release capsules loaded with malathion and spinosad against the third-instar larvae of C. pipiens according to the larval mortality percentages for different weights of capsules (0.005, 0.01, 0.02, and 0.05 g) is shown in Figures 6 and 7, respectively, as observed in running water (Figures 6A and 7A) and stagnant water (Figures 6B and 7B) experiments. After 24 hours, in the running and stagnant water experiments, mortality percentage was recorded as 100% for 0.05 and 0.02 g of capsules, and 60% and 50% for 0.01 and 0.005 g of capsules, respectively, for malathion product. In running water, larval mortality percentage decreased rapidly with change of water daily for all weights of capsules and reached 0% on days 11, 12, and 13 for 0.005, 0.01, and 0.02 g of capsules, respectively (Figure 6A). Quantity of malathion released from 0.05 g of capsules caused the larval mortality percentage to decrease to 0% on day 20. In stagnant water, the quantity of accumulated malathion released from 0.05 g of capsules exhibited 100% mortality up to the day 7, and this amount exhibited larval mortality for a long period (50% on 15 days). Then, the larval mortality gradually decreased to 0% on days 16 and 20 for capsule weights of 0.005 and 0.01 g, respectively. At the weights of 0.02 and 0.05 g, the larval mortality gradually decreased from 100% to 0% on days 24 and 27, respectively (Figure 6B).

Figure 6.

Larvicidal activity of controlled-release capsules according to mortality percentage for different weights of capsules (0.005, 0.01, 0.02, and 0.05 g) loaded with malathion (16.05% calculated by UV spectroscopy) for a period of time.

Notes: Running water (exchange of larvae and water together) (A). Stagnant water (exchange of larvae only) (B).

Abbreviation: UV, ultraviolet.

Figure 7.

Larvicidal activity of controlled-release capsules according to mortality percentage for different weights of capsules (0.005, 0.01, 0.02, and 0.05 g) loaded with spinosad (18.85%) calculated by UV spectroscopy for a period.

Notes: Running water (exchange of larvae and water together) (A). Stagnant water (exchange of larvae only) (B).

Abbreviation: UV, ultraviolet.

In the case of spinosad capsules (Figure 7), in the stagnant and running water experiments, after 24 hours, larval mortality percentage was recorded as 90% for 0.005 g of capsules and 100% for 0.01, 0.02, and 0.05 g of capsules. In the running water, with change of water daily, larval mortality percentage decreased to 40% on day 25 with 0.05 g of capsules and then to 0% on day 48 (Figure 7A). In stagnant water, the accumulated spinosad released from 0.05 g of capsules exhibited 100% mortality up to 7 months. The 0.02 g of capsules exhibited 100% larval mortality till day 92, and then the mortality percentage decreased gradually to 50% on day 218, while the 0.01 and 0.005 g of capsules exhibited 30% and 0% larval mortality, respectively, on the same day (Figure 7B).

This result is in agreement with those obtained previously by Paula et al56 who reported that the dichlorvos (2,2-dichlorovinyldimethyl phosphate) loaded in CH/CG beads resulted in the highest larval mortality of Aedes sp. with high masses of beads used. However, their data differed from ours as CH/CG beads showed only 50% mortality after 7 days. Mulla et al74 studied the in vivo release of Bti tablets and a zeolite granules formulation of temephos (1%) against Ae. aegypti for 6 months. They reported that 0.37 g of Bti/50 L of water provided control for ~90–112 days, whereas the temephos formulations at 5 g/50 L of water (100,000 ppm) yielded ~100% control for >6 months. On the contrary, Toma et al75 prepared a Bti tablet formulation (34,000 ppm) and reported that it induced 100% larval mortality of A. albopictus after 24 hours; however, the larvicidal activity lasted for only ~48 hours. Our study is also in agreement with Bhan et al76 who studied the formulation of temephos and imidacloprid based on biodegradable and biocompatible polyethylene glycol in different ratios. They studied this formulation against Culex quinquefasciatus and found that the temephos capsules were more toxic than the imidacloprid capsules with LC50 values of 0.013, 0.010, and 0.003 mg/L after 24, 48, and 72 hours, respectively.

Biochemical studies

The dose–response test evaluating the efficacy of the technical insecticide malathion against C. pipiens showed an LC50 value of 1.108 mg/L (Table 2). These results confirmed the results obtained by Selvi et al77 who found the LC50 values at the range from 0.8763 to 1.5788 mg/L against C. quinquefasciatus. On the contrary, the results recorded by Zahran and Abdelgaleil78 showed that this value was 2.2×10−3 mg/L against C. pipiens, and those by Rawash et al79 found that the value ranged between 0.0027 and 0.0043 mg/L. However, the technical spinosad showed an LC50 value of 0.075 mg/L against C. pipiens (Table 2). On the contrary, the results obtained by Kovendan et al80 reported that spinosad has less effect against third-instar larvae of Ae. aegypti with an LC50 of 74.070 mg/L.

Table 2.

Larval bioassay for technical and formulation malathion and spinosad against Culex pipiens

| Insecticide | Time (hours) | LC50 (mg/L) | 95% confidence limits (mg/L)

|

Slopea ± SE | Interceptb ± SE | χ2c | |

|---|---|---|---|---|---|---|---|

| Lower | Upper | ||||||

| Malathion (technical) | 24 | 1.108 | 0.508 | 2.209 | 1.403±0.111 | –0.063±0.058 | 22.686 |

| 48 | 0.750 | 0.255 | 1.568 | 1.476±0.112 | 0.184±0.059 | 30.094 | |

| Malathion (formulation) | 24 | 4.407 | 4.071 | 4.760 | 4.239±0.348 | –2.730±0.242 | 3.997 |

| 48 | 3.397 | 2.790 | 4.044 | 4.207±0.299 | –2.234±0.188 | 13.801 | |

| Spinosad (technical) | 24 | 0.075 | 0.059 | 0.102 | 2.741±0.251 | 3.080±0.3 | 13.310 |

| 48 | 0.048 | 0.023 | 0.072 | 2.331±0.218 | 3.084±0.275 | 25.926 | |

| Spinosad (formulation) | 24 | 0.008 | 0.006 | 0.01 | 2.725±0.227 | 5.764±0.449 | 10.203 |

| 48 | 0.001 | 0 | 0.003 | 1.951±0.425 | 5.543±0.898 | 7.727 | |

Notes:

Slope of the concentration–mortality regression line ± SE.

Intercept of the regression line ± SE.

Chi-square value.

Abbreviation: LC50, lethal concentration causing 50% mortality; SE, standard error.

To explore some biochemical actions, the effect of the LC50 values of technical and formulated malathion and spinosad on AChEs, CaEs, and GSTs isolated from C. pipiens larvae treated for 24 hours was studied. The data are recorded in Table 3 as specific activity (ΔOD min−1×mg protein−1) and as inhibition percentages for each enzyme. The untreated C. pipiens larvae had a specific activity of 5.49, 2.98, and 1.23 ΔOD min−1×mg protein−1 for AChEs, CaEs, and GSTs, respectively. However, technical malathion reduced the specific activities to 0.34, 0.00, and 0.17 ΔOD min−1×mg protein−1, respectively, for the same enzymes. In addition, technical spinosad reduced the specific activities to 0.69, 0.53, and 0.25 ΔOD min−1×mg protein−1, respectively, for the same enzymes. It was noted that the capsules loaded with technical malathion exhibited the highest inhibition percentage in the case of CaEs (100%) than AChEs (93.78%) and GSTs (86.10%). Likewise, technical spinosad exhibited the highest inhibition percentage in the case of AChEs (87.36%) than CaEs (82.12%) and GSTs (79.31%). In the case of the same mosquitocidal formulations, formulated malathion reduced the specific activities to 0.7, 1.17, and 0.44 ΔOD min−1×mg protein−1 for AChEs, CaEs, and GSTs, respectively, and exhibited the highest inhibition percentage in the case of AChEs (87.25%) more than GSTs (64.80%) and CaEs (60%). Likewise, formulated spinosad reduced the specific activities to 2.8, 0.6, and 0.35 ΔOD min−1×mg protein−1 for AChEs, CaEs, and GSTs, respectively. It was clear that formulated spinosad exhibited the highest inhibition percentage in the case of CaEs (79.86%) more than GSTs (72%) and AChEs (48.99%).

Table 3.

Biochemical effects of technical and formulated malathion and spinosad at their LC50 values on the AChE, CaE, and GST in Culex pipiens larvae after 24 hours of the treatment

| Treatment | Specific activity (ΔOD min−1×mg−1protein) ± SE

|

% Inhibition

|

||||

|---|---|---|---|---|---|---|

| AChE | CaE | GST | AChE | CaE | GST | |

| Control (untreated capsules) | 5.49±0.2a | 2.98±0.08a | 1.23±0.09a | 0.00 | 0.00 | 0.00 |

| Technical malathion (LC50 =1.108 mg/L) | 0.34±0.01d | 0.00±0.00d | 0.17±0.01d | 93.78 | 100 | 86.10 |

| Formulated malathion (LC50 =4.407 mg/L) | 0.7±0.02c | 1.17±0.02c | 0.44±0.02c,d | 87.25 | 60.73 | 64.80 |

| Technical spinosad (LC50 =0.075 mg/L) | 0.69±0.03c | 0.53±0.06b | 0.25±0.00b | 87.36 | 82.12 | 79.31 |

| Formulated spinosad (LC50 =0.008 mg/L) | 2.8±0.02b | 0.6±0.02c | 0.35±0.02b,c | 48.99 | 79.86 | 72.00 |

Note: Different letters in the same column indicate statistically significant differences according to Student–Newman–Keuls test (P≤0.05). The values indicated by the different letters in the same columns were compared, and that showed significant difference. On the contrary, the values indicated with the same letter in the same column showed that there is no significant difference between them.

Abbreviations: AChE, acetylcholinesterase; CaE, carboxylesterase; GST, glutathione S-transferase; LC50, lethal concentration causing 50% mortality; OD, optical density; SE, standard error.

This result proved that the malathion as an organophosphorus insecticide is a specific inhibitor of AChEs. Multiple forms of AChE, which confer varying degrees of resistance, have been found in a variety of arthropods.81–83 Our study is in agreement with the results obtained by Chen et al84 who studied the inhibitory effect of temephos (organophosphorus insecticide) on the nonspecific esterases, mixed function oxidases, GSTs, and AChEs, and reported that the specific activities of AChEs in Ae. aegypti larvae ranged from 0.08 to 0.13 ΔOD min−1×mg protein−1 for AChEs, from 0.19 to 0.2 ΔOD min−1×mg protein−1 for CaEs, and from 0.07 to 0.15 ΔOD min−1×mg protein−1 for GSTs at 10 mg/L formulated temephos. Vaughan et al85 found that paraoxon (an organophosphorus insecticide) caused 90% inhibition of AChEs in Ae. aegypti. In addition, spinosad affected unique sites on receptors for gamma-aminobutyric acid and nicotinic acetylcholine in the insect nervous system. Our study is in agreement with the results obtained by Kady et al4 who studied the toxicity of two bio-insecticides (Spinotoram 12% and Vertemic 1.8%) compared with Methomyl (Lannete 90% SP) against laboratory strain of mosquito species (C. pipiens and Anopheles multicolor).

Conclusion

The biopolymer capsules based on a combination of chitosan, alginate, and gelatin were successfully prepared to envelop the insecticides malathion and spinosad for controlling their release against larvae of C. pipiens. Release kinetics of both the insecticides was evaluated by in vivo and in vitro assays in running and stagnant water daily for a long period. The results proved that the capsules prepared with spinosad exhibited high residual activities against the larvae for a long period than those prepared with malathion. These results, together with a simple preparation technique, indicate the applicability of these biodegradable capsules as an eco-friendly formulation as carrier for different larvicides and controlling their release.

Acknowledgments

The authors acknowledge and cordially thank the Misr El Kheir Foundation: Science, Technology and Innovation Program for supporting and funding this work under the project code LGA05130114.

Footnotes

Disclosure

The authors report no conflicts of interest in this work.

References

- 1.Barbosa S, Black WC, 4th, Hastings I. Challenges in estimating insecticide selection pressures from mosquito field data. PLoS Negl Trop Dis. 2011;5(11):e1387. doi: 10.1371/journal.pntd.0001387. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Jang Y-S, Kim M-K, Ahn Y-J, Lee H-S. Larvicidal activity of Brazilian plants against Aedes aegypti and Culex pipiens pallens (Diptera: Culicidae) Agric Chem Biotechnol. 2002;45(3):131–134. [Google Scholar]

- 3.Park Y, Jung JK, Kim Y. A mixture of Bacillus thuringiensis subsp. israelensis with Xenorhabdus nematophila-cultured broth enhances toxicity against mosquitoes Aedes albopictus and Culex pipiens pallens (Diptera: Culicidae) J Econ Entomol. 2016 Mar 27; doi: 10.1093/jee/tow063. Epub. [DOI] [PubMed] [Google Scholar]

- 4.Kady GAE, Kamel NH, Mosleh YY, Bahght IM. Comparative toxicity of two bio-insecticides (Spinotoram and Vertemic) compared with methomyl against Culex pipiens and Anopheles multicolor. World J Agric Sci. 2008;4(2):198–205. [Google Scholar]

- 5.Yadav S. Dose optimization of thermal fogging trials for household insecticide formulation (EC) against Aedes aegypti (L.) Curr Biotica. 2012;6(1):71–79. [Google Scholar]

- 6.Abdel-Hamid YM, Soliman MI, Allam KM. Spatial distribution and abundance of culicine mosquitoes in relation to the risk of filariasis transmission in El Sharqiya Governorate, Egypt. Egypt Acad J Biol Sci. 2009;1:39–48. [Google Scholar]

- 7.Hoogstraal H, Meegan JM, Khalil GM, Adham FK. The Rift Valley fever epizootic in Egypt 1977–1978 2. Ecological and entomological studies. Trans R Soc Trop Med Hyg. 1979;73(6):624–629. doi: 10.1016/0035-9203(79)90005-1. [DOI] [PubMed] [Google Scholar]

- 8.Darwish M, Hoogstraal H. Arboviruses Infecting Humans and Lower Animals in Egypt: A Review of Thirty Years of Research. Egypt: Egyptian Public Health Association; 1981. [Google Scholar]

- 9.Becker N, Petrić D, Zgomba M, et al. Chemical control. In: Becker N, editor. Mosquitoes and Their Control. Berlin: Springer; 2010. pp. 441–475. [Google Scholar]

- 10.Rozendaal JA. Vector Control: Methods for Use by Individuals and Communities. Geneva: World Health Organization; 1997. [Google Scholar]

- 11.Joseph CC, Ndoile MM, Malima RC, Nkunya MH. Larvicidal and mosquitocidal extracts, a coumarin, isoflavonoids and pterocarpans from Neorautanenia mitis. Trans R Soc Trop Med Hyg. 2004;98(8):451–455. doi: 10.1016/j.trstmh.2003.10.008. [DOI] [PubMed] [Google Scholar]

- 12.Yang P, Ma Y, Zheng S. Adulticidal activity of five essential oils against Culex pipiens quinquefasciatus. J Pestic Sci. 2005;30(2):84–89. [Google Scholar]

- 13.Gill HK, Garg H. Pesticide: Environmental Impacts and Management Strategies. Croatia: Pesticides-Toxic Effects Intech Rijeka; 2014. pp. 187–230. [Google Scholar]

- 14.Mahyoub JA, Rehman H, Saggu S, et al. Insecticide susceptibility in larval populations of the West Nile vector Culex pipiens L.(Diptera: Culicidae) in Saudi Arabia. Asian Pac J Trop Biomed. 2016;6(5):390–395. [Google Scholar]

- 15.Trebše P, Arčon I. Degradation of organophosphorus compounds by X-ray irradiation. Radiat Phys Chem. 2003;67(3–4):527–530. [Google Scholar]

- 16.Manjarres-Suarez A, Olivero-Verbel J. Chemical control of Aedes aegypti: a historical perspective. Rev Costarric Salud Pública. 2013;22(1):68–75. [Google Scholar]

- 17.Grue CE, Gibert PL, Seeley ME. Neurophysiological and behavioral changes in non-target wildlife exposed to organophosphate and carbamate pesticides: thermoregulation, food consumption, and reproduction. Am Zool. 1997;37(4):369–388. [Google Scholar]

- 18.Williams PL, James RC, Roberts SM. Principles of Toxicology: Environmental and Industrial Applications. New York: John Wiley & Sons; 2000. [Google Scholar]

- 19.Karunaratne SH, Hemingway J. Malathion resistance and prevalence of the malathion carboxylesterase mechanism in populations of mosquito vectors of disease in Sri Lanka. Bull World Health Organ. 2001;79(11):1060–1064. [PMC free article] [PubMed] [Google Scholar]

- 20.Athanassiou CG, Kavallieratos NG, Chintzoglou GJ. Effectiveness of spinosad dust against different European populations of the confused flour beetle, Tribolium confusum Jacquelin du Val. J Stored Prod Res. 2008;44(1):47–51. [Google Scholar]

- 21.Arthurs SP, Lacey LA, Miliczky ER. Evaluation of the codling moth granulovirus and spinosad for codling moth control and impact on non-target species in pear orchards. Biol Control. 2007;41(1):99–109. [Google Scholar]

- 22.Paulraj MG, Kumar PS, Ignacimuthu S, Sukumaran D. Natural insecticides from actinomycetes and other microbes for vector mosquito control. In: Vijay V, Gopalakrishnan R, editors. Herbal Insecticides, Repellents and Biomedicines: Effectiveness and Commercialization. New Delhi: Springer; 2016. pp. 85–99. [Google Scholar]

- 23.Hertlein MB, Mavrotas C, Jousseaume C, et al. A review of spinosad as a natural product for larval mosquito control. J Am Mosq Control Assoc. 2010;26(1):67–87. doi: 10.2987/09-5936.1. [DOI] [PubMed] [Google Scholar]

- 24.Cisneros J, Goulson D, Derwent LC, Penagos DI, Hernández O, Williams T. Toxic effects of spinosad on predatory insects. Biol Control. 2002;23(2):156–163. [Google Scholar]

- 25.Romi R, Proietti S, Di Luca M, Cristofaro M. Laboratory evaluation of the bioinsecticide spinosad for mosquito control. J Am Mosq Control Assoc. 2006;22(1):93–96. doi: 10.2987/8756-971X(2006)22[93:LEOTBS]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 26.Bahgat IM, El Kady GA, Temerak SA, Lysandrou M. The natural bio-insecticide spinosad and its toxicity to combat some mosquito species in Ismailia Governorate, Egypt. World J Agric Sci. 2007;3(4):396–400. [Google Scholar]

- 27.Williams T, Valle J, Viñuela E. Is the naturally derived insecticide Spinosad® compatible with insect natural enemies? Biocontrol Sci Technol. 2003;13(5):459–475. [Google Scholar]

- 28.Thompson GD, Dutton R, Sparks TC. Spinosad – a case study: an example from a natural products discovery programme. Pest Manag Sci. 2000;56(8):696–702. [Google Scholar]

- 29.Li Z-Z, Xu S-A, Wen L-X, et al. Controlled release of avermectin from porous hollow silica nanoparticles: influence of shell thickness on loading efficiency, UV-shielding property and release. J Control Release. 2006;111(1–2):81–88. doi: 10.1016/j.jconrel.2005.10.020. [DOI] [PubMed] [Google Scholar]

- 30.Yi Y, Xu S, Sun H, et al. Gelation of photocrosslinkable carboxymethyl chitosan and its application in controlled release of pesticide. Carbohydr Polym. 2011;86(2):1007–1013. [Google Scholar]

- 31.Margni M, Rossier D, Crettaz P, Jolliet O. Life cycle impact assessment of pesticides on human health and ecosystems. Agric Ecosyst Environ. 2002;93(1–3):379–392. [Google Scholar]

- 32.Peppas NA, Langer R. New challenges in biomaterials. Science. 1994;263(5154):1715–1720. doi: 10.1126/science.8134835. [DOI] [PubMed] [Google Scholar]

- 33.Elango G, Rahuman AA, Kamaraj C, Bagavan A, Zahir AA. Adult emergence inhibition and adulticidal activity of leaf crude extracts against Japanese encephalitis vector, Culex tritaeniorhynchus. J King Saud Univ Sci. 2012;24(1):73–80. [Google Scholar]

- 34.Durán N, Islan GA, Durán M, Castrod GR. Nanobiotechnology solutions against Aedes aegypti. J Braz Chem Soc. 2016;27(7):1139–1149. [Google Scholar]

- 35.Yan H, Feng Y, Hu W, et al. Preparation and evaluation of alginate-chitosan-bentonite based beads for the delivery of pesticides in controlled-release formulation. Asian J Chem. 2013;25(17):9936–9940. [Google Scholar]

- 36.Nnamonu LA, Sha’Ato R, Onyido I. Alginate reinforced chitosan and starch beads in slow release formulation of imazaquin herbicide—preparation and characterization. Mater Sci Appl. 2012;3(8):566–574. [Google Scholar]

- 37.Roy A, Singh SK, Bajpai J, Bajpai AK. Controlled pesticide release from biodegradable polymers. Cent Eur J Chem. 2014;12(4):453–469. [Google Scholar]

- 38.Benelli G, Canale A, Higuchi A, Murugan K, Pavela R, Nicoletti M. The recent outbreaks of Zika virus: mosquito control faces a further challenge. Asian Pac J Trop Dis. 2016;6(4):253–258. [Google Scholar]

- 39.Agnihotri SA, Aminabhavi TM. Controlled release of clozapine through chitosan microparticles prepared by a novel method. J Control Release. 2004;96(2):245–259. doi: 10.1016/j.jconrel.2004.01.025. [DOI] [PubMed] [Google Scholar]

- 40.Hou W, Miyazaki S, Takada M, Komai T. Sustained release of indomethacin from chitosan granules. Chem Pharm Bull (Tokyo) 1985;33(9):3986–3992. doi: 10.1248/cpb.33.3986. [DOI] [PubMed] [Google Scholar]

- 41.Miyazaki S, Ishii K, Nadai T. The use of chitin and chitosan as drug carriers. Chem Pharm Bull (Tokyo) 1981;29(10):3067–3069. doi: 10.1248/cpb.29.3067. [DOI] [PubMed] [Google Scholar]

- 42.Borzacchiello A, Ambrosio L, Netti PA, et al. Chitosan-based hydrogels: synthesis and characterization. J Mater Sci Mater Med. 2001;12(10–12):861–864. doi: 10.1023/a:1012851402759. [DOI] [PubMed] [Google Scholar]

- 43.Soppirnath KS, Aminabhavi TM. Water transport and drug release study from cross-linked polyacrylamide grafted guar gum hydrogel microspheres for the controlled release application. Eur J Pharm Biopharm. 2002;53(1):87–98. doi: 10.1016/s0939-6411(01)00205-3. [DOI] [PubMed] [Google Scholar]

- 44.Connick WJ, Jr, Bradow JM, Wells W, Steward KK, Van TK. Preparation and evaluation of controlled-release formulations of 2,6-dichlorobenzonitrile. J Agric Food Chem. 1984;32(5):1199–1205. [Google Scholar]

- 45.Zhang Z, Luo Y, Chen J, et al. Formation of linear supramolecular polymers that is driven by C–H⋅⋅⋅π interactions in solution and in the solid state. Angew Chem Int Ed Engl. 2011;123(6):1433–1437. doi: 10.1002/anie.201006693. [DOI] [PubMed] [Google Scholar]

- 46.Fernández-Pérez M, Villafranca-Sanchez M, Gonzalez-Pradas E, Martinez-Lopez F, Flores-Cespedes F. Controlled release of carbofuran from an alginate-bentonite formulation: water release kinetics and soil mobility. J Agric Food Chem. 2000;48(3):938–943. doi: 10.1021/jf981296j. [DOI] [PubMed] [Google Scholar]

- 47.Johnson RM, Pepperman AB. Leaching of alachlor from alginate-encapsulated controlled-release formulations. Pestic Sci. 1996;48(2):157–164. [Google Scholar]

- 48.Zohuriaan-Mehr MJ, Pourjavadi A. New polysaccharide-g-polyacrylonitrile copolymers: synthesis and thermal characterization. Polym Adv Technol. 2003;14(7):508–516. [Google Scholar]

- 49.Kumbar SG, Aminabhavi TM. Preparation and characterization of interpenetrating network beads of poly(vinyl alcohol)-grafted-poly(acrylamide) with sodium alginate and their controlled release characteristics for cypermethrin pesticide. J Appl Polym Sci. 2002;84(3):552–560. [Google Scholar]

- 50.Yeom CK, Lee KH. Characterization of sodium alginate membrane crosslinked with glutaraldehyde in pervaporation separation. J Appl Polym Sci. 1998;67(2):209–219. [Google Scholar]

- 51.El-Bokl MM, Moawad HM. Evaluation of some plant extracts as mosquito larvicides. Ain Ahams Sci Bull. 1996;34:351–362. [Google Scholar]

- 52.Finney DJ. Probit Analysis. 3rd ed. Cambridge and New York: Cambridge University Press; 1971. [Google Scholar]

- 53.Abbott WS. A method of computing the effectiveness of an insecticide. J Econ Entomol. 1925;18(2):265–267. [Google Scholar]

- 54.Badawy MEI, Taktak NEM, Awad OM, Elfiki SA, El-Ela NEA. Larvicidal activity of temephos released from new chitosan/alginate/gelatin capsules against Culex pipiens. Int J Mosq Res. 2015;2(3):45–55. [Google Scholar]

- 55.Momin RA, Nair MG. Mosquitocidal, nematicidal, and antifungal compounds from Apium graveolens L. seeds. J Agric Food Chem. 2001;49(1):142–145. doi: 10.1021/jf001052a. [DOI] [PubMed] [Google Scholar]

- 56.Paula HCB, de Paula RCM, Bezerral SKF. Swelling and release kinetics of larvicide-containing chitosan/cashew gum beads. J Appl Polym Sci. 2006;102(1):395–400. [Google Scholar]

- 57.Lowry OH, Rosebrough NJ, Farr AL, Randall RJ. Protein measurement with the Folin phenol reagent. J Biol Chem. 1951;193(1):265–275. [PubMed] [Google Scholar]

- 58.Ellman GL, Courtney KD, Featherstone RM. A new and rapid colorimetric determination of acetylcholinesterase activity. Biochem Pharmacol. 1961;7(2):88–95. doi: 10.1016/0006-2952(61)90145-9. [DOI] [PubMed] [Google Scholar]

- 59.Chanda SM, Mortensen SR, Moser VC, Padilla S. Tissue-specific effects of chlorpyrifos on carboxylesterase and cholinesterase activity in adult rats: an in vitro and in vivo comparison. Toxicol Sci. 1997;38(2):148–157. [PubMed] [Google Scholar]

- 60.Saint-Denis M, Labrot F, Narbonne JF, Ribera D. Glutathione, glutathione-related enzymes, and catalase activities in the earthworm Eisenia fetida andrei. Arch Environ Contam Toxicol. 1998;35(4):602–614. doi: 10.1007/s002449900422. [DOI] [PubMed] [Google Scholar]

- 61.Abbott WS. A method of computing the effectiveness of an insecticide. J Am Mosq Control Assoc. 1987;3(2):302–303. [PubMed] [Google Scholar]

- 62.Murata Y, Maeda T, Miyamoto E, Kawashima S. Preparation of chitosan-reinforced alginate gel beads—effects of chitosan on gel matrix erosion. Int J Pharm. 1993;96(1–3):139–145. [Google Scholar]

- 63.Shu XZ, Zhu KJ. A novel approach to prepare tripolyphosphate/chitosan complex beads for controlled release drug delivery. Int J Pharm. 2000;201(1):51–58. doi: 10.1016/s0378-5173(00)00403-8. [DOI] [PubMed] [Google Scholar]

- 64.Wong TW, Chan LW, Kho SB, Sia Heng PW. Design of controlled-release solid dosage forms of alginate and chitosan using microwave. J Control Release. 2002;84(3):99–114. doi: 10.1016/s0168-3659(02)00237-7. [DOI] [PubMed] [Google Scholar]

- 65.Wan Ngah WS, Kamari A, Koay YJ. Equilibrium and kinetics studies of adsorption of copper (II) on chitosan and chitosan/PVA beads. Int J Biol Macromol. 2004;34(3):155–161. doi: 10.1016/j.ijbiomac.2004.03.001. [DOI] [PubMed] [Google Scholar]

- 66.Suave J, Dall’Agnol E, Pezzin A, Meier M, Silva D. Biodegradable microspheres of poly (3-hydroxybutyrate)/poly (ε-caprolactone) loaded with malathion pesticide: preparation, characterization, and in vitro controlled release testing. J Appl Polym Sci. 2010;117(6):3419–3427. [Google Scholar]

- 67.Singh B, Sharma DK, Gupta A. A study towards release dynamics of thiram fungicide from starch–alginate beads to control environmental and health hazards. J Hazard Mater. 2009;161(1):208–216. doi: 10.1016/j.jhazmat.2008.03.074. [DOI] [PubMed] [Google Scholar]

- 68.Işiklan N. Controlled release of insecticide carbaryl from sodium alginate, sodium alginate/gelatin, and sodium alginate/sodium carboxymethyl cellulose blend beads crosslinked with glutaraldehyde. J Appl Polym Sci. 2006;99(4):1310–1319. [Google Scholar]

- 69.Huang B-b, Yang F-m, Zhang X-x, Zhong J-b, Wu Z-j, Wu G. Study on key process of preparation of spinosad microsphere: II. Chin J Pestic Sci. 2011;4:013. Chinese. [Google Scholar]

- 70.Zhao S-P, Li L-Y, Cao M-J, Xu W-L. pH- and thermo-sensitive semi-IPN hydrogels composed of chitosan, N-isopropylacrylamide, and poly (ethylene glycol)-co-poly (ε-caprolactone) macromer for drug delivery. Polym Bull. 2011;66(8):1075–1087. [Google Scholar]

- 71.Efentakis M, Stamoylis K. A study of dimensional, swelling, and gel changes in hydrophilic and hydrophobic polymer mixtures of chitosan and their possible use as carriers for sustained release drug delivery. Adv Polym Technol. 2011;30(2):110–121. [Google Scholar]

- 72.Silverstein RM, Webster FX, Kiemle D, Bryce DL. Spectrometric Identification of Organic Compounds. 6th ed. New York: John Wiley & Sons; 1968. [Google Scholar]

- 73.Singha RK, Gangadhar B, Basu H, Manisha V, Naidu GRK, Reddy AVR. Remediation of malathion contaminated soil using zero valent iron nano-particles. Am J Anal Chem. 2012;3:76–82. [Google Scholar]

- 74.Mulla MS, Thavara U, Tawatsin A, Chompoosri J. Procedures for the evaluation of field efficacy of slow-release formulations of larvicides against Aedes aegypti in water-storage containers. J Am Mosq Control Assoc. 2004;20(1):64–73. [PubMed] [Google Scholar]

- 75.Toma L, Severini F, Di Luca M, Bella A, Romi R. Seasonal patterns of oviposition and egg hatching rate of Aedes albopictus in Rome. J Am Mosq Control Assoc. 2003;19(1):19–22. [PubMed] [Google Scholar]

- 76.Bhan S, Mohan L, Srivastava CN. Relative larvicidal potentiality of nano-encapsulated Temephos and Imidacloprid against Culex quinquefasciatus. J Asia Pac Entomol. 2014;17(4):787–791. [Google Scholar]

- 77.Selvi S, Edah MA, Nazni WA, Lee HL, Azahari AH. Characterization on malathion and permethrin resistance by bioassays and the variation of esterase activity with the life stages of the mosquito Culex quinquefasciatus. Trop Biomed. 2007;24(1):63–75. [PubMed] [Google Scholar]

- 78.Zahran HE-DM, Abdelgaleil SAM. Insecticidal and developmental inhibitory properties of monoterpenes on Culex pipiens L.(Diptera: Culicidae) J Asia Pac Entomol. 2011;14(1):46–51. [Google Scholar]

- 79.Rawash IA, Gaaboub IA, El-Gayar EM, El-Shazli AY. Standard curves for nuvacron, malathion, sevin, DDT and kelthane tested against the mosquito Culex pipiens L. and the microcrustacean Daphnia magna Straus. Toxicology. 1975;4(2):133–144. doi: 10.1016/0300-483x(75)90092-x. [DOI] [PubMed] [Google Scholar]

- 80.Kovendan K, Murugan K, Kumar AN, Vincent S, Hwang J-S. Bioefficacy of larvicidal and pupicidal properties of Carica papaya (Caricaceae) leaf extract and bacterial insecticide, spinosad, against chikungunya vector, Aedes aegypti (Diptera: Culicidae) Parasitol Res. 2012;110(2):669–678. doi: 10.1007/s00436-011-2540-z. [DOI] [PubMed] [Google Scholar]

- 81.Badawy MEI, Nasr HM, Rabea EI. Toxicity and biochemical changes in the honey bee Apis mellifera exposed to four insecticides under laboratory conditions. Apidologie. 2015;46(2):177–193. [Google Scholar]

- 82.Devonshire AL, Moores GD. Different forms of insensitive acetylcholinesterase in insecticide-resistant house flies (Musca domestica) Pestic Biochem Physiol. 1984;21(3):336–340. [Google Scholar]

- 83.Pralavorio M, Fournier D. Drosophila acetylcholinesterase: characterization of different mutants resistant to insecticides. Biochem Genet. 1992;30(1–2):77–83. doi: 10.1007/BF00554429. [DOI] [PubMed] [Google Scholar]

- 84.Chen CD, Nazni WA, Lee HL, Seleena B, Sofian-Azirun M. Biochemical detection of temephos resistance in Aedes (Stegomyia) aegypti (Linnaeus) from dengue-endemic areas of Selangor state, Malaysia. Proc ASEAN Congr Trop Med Parasitol. 2008;3:6–20. [Google Scholar]

- 85.Vaughan A, Chadee DD, French-Constant R. Biochemical monitoring of organophosphorus and carbamate insecticide resistance in Aedes aegypti mosquitoes from Trinidad. Med Vet Entomol. 1998;12(3):318–321. doi: 10.1046/j.1365-2915.1998.00111.x. [DOI] [PubMed] [Google Scholar]