Abstract

The development of innovative rice products is a way to exploiting and adding value to low-grade African rice varieties. To this purpose, rice-based pasta was enriched with flours from soybean and orange-fleshed sweet potato, that are common ingredients in the African tradition. Four different formulations based on pre-gelatinized rice flour and liquid egg albumen, and containing soybean and/or sweet potato (up to 20%) were prepared and characterized via a multidisciplinary approach. Soybean and sweet potato enrichment leads to a decrease in the pasta consistency and in significant changes in the color of the resulting samples, likely due to Maillard-type reactions. E-sensing approaches indicated that the sensory profile of the various pasta products strongly depends on the type of enrichment. Data collected after cooking suggest that both soybean and sweet potato have a role in defining the firmness and water absorption, as well as the optimum cooking time. Structural characterization of proteins in the uncooked products indicates the presence of protein aggregates stabilized by hydrophobic interactions and disulfide bonds in all samples, although structural properties of the aggregates related to specific compositional traits.

Keywords: Gluten free pasta, Soybean, Sweet potato, Enriched rice pasta

Introduction

Gluten-free (GF) pasta has gained worldwide consumption, especially by people with various forms of gluten intolerance or suffering from celiac disease. The latter represent around 1% of the population in Europe and in the USA (Catassi et al. 2015). The demand for GF food has recently increased also in Africa, although the prevalence of celiac disease in Africa remains unknown (Catassi et al. 2015). Rice flour has been widely used as a raw material in the preparation of GF products, because of its bland taste, white color, high digestibility, and hypoallergenic properties (Fabian and Ju 2011). Compared to wheat, rice flour has low protein content and a relatively poor ability to develop a cohesive network, which impairs its technological performance (Marti and Pagani 2013).

Several studies have recently emphasized the need for improving the nutritional quality of cereal-based GF products, highlighting the low content in essential micronutrients of these products when compared with their wheat-based counterparts (Pellegrini and Agostoni 2015). This has prompted a search for additional and/or alternative raw materials—including minor cereals, psudocereals, and pulses—with high nutritional profile, that have been formulated into GF staple foods such as bread (Calderón de la Barca et al. 2010; Marti et al. 2017) and pasta (Cabrera-Chávez et al. 2012; Marengo et al. 2015). In this frame, the addition of egg albumen represents an effective strategy to improve GF pasta products (Marti et al. 2014; Phongthai et al. 2017). Addition of egg albumen provides a simple and effective way for forming within GF products a protein network capable of minimizing solid losses upon cooking and to improve some rheological traits (such as firmness) in the cooked pasta (Marti and Pagani 2013; Marti et al. 2014).

Soybean is an excellent source of proteins that may provide a number of desirable functional and technological beneficial effects, along with a balanced amino acid intake (Meinlschmidt et al. 2016). Orange-fleshed sweet potato is also an interesting ingredient for GF foods. Sweet potato is widely used to prevent vitamin A deficiency in Africa, due to its high content in β-carotene (Gurmu et al. 2014; Christides et al. 2015), and provides satisfactory sensory attributes and appropriate physical properties (Mahmoud and El Anany 2014). Additionally, sweet potato shows a relatively low amount of phytates and a high content of ascorbic acid, that positively affect micronutrient bioavailability (La Frano et al. 2014). However, preparation of rice-based GF pasta incorporating materials other than cereals may present difficulties, and much attention should be paid to the use of proper ingredients and of proper procedures in the pasta-making process (Cabrera-Chávez et al. 2012; Barbiroli et al. 2013; Phongthai et al. 2017).

In view of producing GF pasta with enhanced nutritional properties with minimal or no modifications in the pasta-making process, this work addresses the effects of soybean and/or orange-fleshed sweet potato added at nutritionally meaningful levels—alone or in combination—to rice flour-based GF pasta. The effects of the various supplementations on the properties of pasta from different formulations were assessed by a combination of physical, molecular, and instrumental sensory approaches. This combination of approaches was aimed at defining a molecular-based rationale for the properties of the various ingredients combinations and, eventually, of the final product.

Materials and methods

Raw materials and chemicals

Pregelatinized rice flour (protein: 7%; starch: 89%; ash 0.7%; moisture 3%) was kindly provided by Molino Favero (Padova, Italy). Flours from soybean, cv Jenguma (protein 37%; lipid 21%; fiber 7%; ash 3%; carbohydrate 26%; moisture 6%) and orange-fleshed sweet potatoes, cv Apomunden (protein 6%; lipid 0.5%; fiber 12%; ash 2%; carbohydrate 69%; moisture 10.5%) were provided by the Crops Research Institute of the CSIR (Accra, Ghana). Liquid egg albumen (11% protein) was purchased from Ovopel s.p.a. (San Giovanni in Croce, Cremona, Italy). Unless otherwise specified, all other chemicals were from Sigma (Sigma Chemical Co., St. Louis, MO, USA).

Pasta production

Experimental pasta samples were produced at the pilot-plant of DeFENS (University of Milan, Milan, Italy). Starting from a control formulation (R) made from pre-gelatinized rice flour (90% w/w) and liquid egg albumen (10% w/w, added during mixing), a portion of rice flour was replaced with sweet potato flour (10%; RP), or soybean flour (20%; RS), or a combination of both (10% sweet potato and 20% soybean; RPS), keeping constant the amount of liquid egg, used here as a structuring agent, in the absence of gluten (Marti et al. 2014). Dry ingredients and liquid egg albumen were blended with tap water in order to produce a mixture with a final moisture of 40%. Mixtures were formed into macaroni shape (7 mm external diameter, 40 mm length) in a lab scale extruder (20 kg/h; MAC 30, Italpast, Parma, Italy), as described by Marti et al. (2010), and dried to a final humidity of 12% by using a low-temperature cycle (50 °C for 14 h). All the dried pasta samples were stored at room temperature for no more than 6 weeks before use. For color measurements, protein solubility studies, and instrumental sensory analysis, uncooked pasta samples were ground to ≤ 0.500 mm with a laboratory mill (IKA Universalmühle M20, Staufen, Germany), fitted with a water cooling jacket in order to avoid overheating during grinding.

Color analysis

A portable colorimeter CR-300 (Minolta, Osaka, Japan) was used to determine the color of the various uncooked pasta samples in terms of L* (lightness), a* (redness), and b* (yellowness) values in the CIELAB color space. L*, a*, and b* were measured directly on finely ground samples (particle size ≤ 0.500 mm) homogenously distributed in a Petri dish, averaging 16 independent measurements.

Cooking behaviour

An aliquot of pasta (20 g) was cooked at the optimum cooking time (Marti et al. 2016) for each sample in boiling water (pasta:water = 1:10) with no salt added. Cooking loss was evaluated according to the AACC official method 66-50.01 (AACC 2001). The test was carried out in duplicate for two independent cooking runs. Results are expressed as grams of solid loss/100 g of dry pasta. Weight increase of pasta during cooking was evaluated by weighing pasta before and after cooking. The results of two independent cooking were expressed as the ratio between the weight increase and the weight of uncooked pasta. Textural characteristics of the cooked pasta were determined by using a Kramer cell on 20 g of sample (Marti et al. 2010). The analysis was repeated 10 times for each sample, to assess firmness (in Newtons).

Properties of the protein network

Protein aggregation studies were carried out by suspending 0.15 g of finely ground uncooked pasta in 5 ml of 50 mM phosphate buffer, 0.1 M NaCl, pH 7.0, in the presence of 6 M urea or of 6 M urea and 10 mM dithiothreitol (DTT) when indicated (Marengo et al. 2015). Suspensions were stirred for 60 min at room temperature. After centrifugation at 10,000×g for 20 min, the amount of protein in the supernatant was determined by a dye-binding method (Bradford 1976). Results are expressed as mg proteins/g pasta. Proteins solubilized from pasta were treated with denaturing buffer (0.125 M Tris–HCl, pH 6.8, 50% (v/v) glycerol, 1.7% SDS; 0.01% Bromophenol Blue), containing 1% (v/v) 2-mercaptoethanol when indicated, and boiled for 10 min. SDS-PAGE was carried out in a MiniProtein apparatus (BioRad, Richmond, VA, USA), by loading a volume of each sample corresponding to 0.015 mg protein per lane (Iametti et al. 2006). Gels were stained with Coomassie Brilliant Blue. Accessible thiols (expressed as micromol thiols/g pasta) were determined by suspending 0.15 g of finely ground uncooked pasta samples in 5 ml of 0.05 M sodium phosphate, pH 7.0, containing 0.1 M NaCl and 0.2 mM 5,5′-dithiobis-(2-nitrobenzoate) (DTNB), in the presence/absence of 6 M urea. After 1 h stirring at room temperature, samples were centrifuged (∼ 5000×g, 30 min, 25 °C), and the supernatant absorbance was read at 412 nm (Bonomi et al. 2012; Marengo et al. 2015).

Instrumental sensory analysis

The volatile profile of the various pasta samples was assessed by a Portable Electronic Nose (PEN2, Win Muster Airsense Analytics Inc., Schwerin, Germany), consisting of a sampling apparatus, a detecting unit with a sensor array, and an appropriate pattern-recognition software (Win Muster v.1.6) for data recording and elaboration. For electronic nose (e-nose) measurements, the sample headspace is exposed to the sensors that provide a signal pattern related to the volatile compounds in the headspace (Benedetti et al.2008; Marengo et al. 2017). For the determination of the aromatic profiles, 5 g of pasta, cooked at the optimum time and subsequently freeze-dried, were resuspended in 5 ml of distilled water and placed in a 40 ml airtight glass vial fitted with a pierceable silicon/Teflon® disk in the cap. After equilibration for 1 h at room temperature, headspace measurements were performed using the following conditions: flow rate 300 ml/min, injection time 60 s, flush time 180 s (during which the surface of the sensors was cleaned with air filtered through active carbon). All samples were analyzed in triplicate and the sensor responses were used for the subsequent statistical analysis.

Electronic tongue (e-tongue) is an analytical device that mimics the taste sensing mechanism of gustatory system comprising detecting sensors that are specific for liquids and able to evaluate tastes. Measurements were carried out by a Taste-Sensing System SA 402B (Intelligent Sensor Technology Co. Ltd, Japan). For this study a total of 5 detecting sensors and 2 reference electrodes were used, separated in two arrays according to membrane charge: hybrid (CT0; CA0; AAE) and positive (C00; AE1). Measurements are based on the capability of tasty compounds to modify sensors potential through electrostatic or hydrophobic interactions (Buratti et al. 2011). Ten grams of pasta, cooked at the optimum time and subsequently freeze-dried, were resuspended in 200 ml of distilled water, vortexed for about 5 min and centrifuged at 5000×g for 10 min at 20 °C. The supernatants were filtered, diluted 1:4 (v/v) with distilled water and placed in 40 ml cups for e-tongue analysis. Before each measurement, the detecting sensors and the reference electrodes were dipped into a reference solution (30 mM potassium chloride, 0.3 mM tartaric acid) and the electric potential was measured for each sensor (Vr). The sensors were then dipped for 30 s into the sample and the potential (Vs) was measured. For each sensor the “relative value” (Rv) was calculated as the difference between the potential of the sample and that of the reference solution (Vs–Vr). Sensors were rinsed with fresh reference solution for 6 s and then dipped into the reference solution again. The new potential of the reference solution was defined as Vr′. For each sensor, the difference between the potential of the reference solution before and after sample measurement (Vr′–Vr) is the CPA (Change of Membrane Potential caused by Absorption) value (CPAv) and corresponds to the e-tongue “aftertastes”. Before starting a new measurement cycle, sensors were rinsed for 90 s with washing solutions and then for 180 s with the reference solution. Each sample was evaluated in triplicate and sensor outputs were converted to taste information. The “taste values” were calculated by multiplying sensor outputs for appropriate coefficients based on the Weber–Fechner law, which gives the intensity of sensation considering the sensor properties with regard to specific tastes (Kobayashi et al. 2010; Marengo et al. 2017).

Statistical analysis

Analysis of variance (ANOVA) was performed on the data adopting the least significant difference (LSD). Data were processed by Statgraphic Plus for Windows v. 5.1. (StatPoint Inc., Warrenton, VA, USA). E-nose and e-tongue data were elaborated by Principal Component Analysis (PCA) using the MINITAB 14, version 12.0 software (Minitab Inc., State College, PA, USA) package. PCA was applied as an exploratory tool to uncover aroma and taste characteristics.

Results and discussion

Pasta quality

Color is one of the fundamental parameters in determining consumers’ choice, and may be affected by several factors that include processing conditions and formulations, and/or the presence of specific ingredients (Marti et al. 2016), including those added to improve nutritional value (Wood 2009; Petitot et al. 2010). In the case of pasta making the drying conditions play a key role in defining the product color due to the onset of Maillard reactions and of the ensuing formation of colored compounds (De Noni and Pagani 2010). The use of egg albumen as a structuring agent in rice-based pasta reportedly results in a lower luminosity and a higher b* index than albumen-free controls (Marti et al. 2014), also when a pre-gelatinization process is carried out on rice flour (Marti et al. 2013).

The addition of the various ingredients used in this study resulted in further significant color changes. In particular, enrichment with the carotenoid-rich orange-fleshed sweet potato flour (RP) gave in a decrease in lightness and a relevant increase of a* and b* indices. Enrichment with soybean flour alone (RS) had a major effect on b*. Previous studies have associated this increase with the high protein content of soybean (Marco and Rosell 2008).

Another fundamental index for pasta acceptability is its cooking behavior (Marti et al. 2016), that relates to the development of proper protein–protein and protein-starch matrices (Marti and Pagani 2013). Cooking indices of the rice-based pasta (Table 1) were significantly affected by the addition of soybean and/or of sweet potato flour to rice flour. Enrichment resulted in a relevant decrease of the cooking time. In the case of RP, the observed decrease might be attributed to the prompt capability of potato starch granules to absorb water and to a relevant fiber content, as potato skin is not removed before milling. Fibers reportedly promote moisture penetration into pasta and weaken the starch network (Marti et al. 2010). Soybean flour—regardless of the presence of sweet potato flour—gave a further decrease of cooking time that may be attributed to the lower amount of starch in the system and to the increased fat content. Indeed, Fat content in the various samples increased from ≤ 2% in the non-enriched control R to 3.4% (RP), reaching values of 6.3 and 6.6% in RS and RPS, respectively.

Table 1.

Quality index of pasta samples

| R | RP | RS | RPS | |

|---|---|---|---|---|

| Color indices of uncooked pasta | ||||

| Lightness (L*) | 48.0 ± 0.9a | 32.2 ± 1.2d | 43.6 ± 0.7b | 37.3 ± 1.1c |

| Redness (a*) | − 1.5 ± 0.7c | 5.3 ± 0.4a | 0.8 ± 0.2b | 5.1 ± 0.5a |

| Yellowness (b*) | 7.8 ± 0.5c | 17.1 ± 1.2b | 20.3 ± 0.9a | 20.1 ± 0.8a |

| Cooking behavior | ||||

| Optimum cooking time (min) | 13 | 10 | 8 | 8 |

| Cooking loss (g/100 g) | 9.8 ± 0.5b | 10.9 ± 0.4a | 9.2 ± 0.2b | 10.6 ± 0.3a |

| Water absorption capacity (g/100 g) | 65.4 ± 1.9c | 68.4 ± 1.4b | 71.0 ± 2.4a | 71.0 ± 2.6a |

| Firmness (N) | 520 ± 40a | 224 ± 10c | 343 ± 26b | 226 ± 18c |

Values are mean ± SD. Values with the same superscript letter in a given row are not significantly different (P ≤ 0.05)

Presence of soybean proteins in RS increased significantly the overall protein content (12.8%, as opposed to 6.8% in the non-enriched control) and limited the leaching of solids into cooking water (Table 1). Conversely, presence of potato starch (in RP and RSP) further weakened the solid matrix and resulted in high cooking losses, regardless of the presence of soybean proteins (total protein content was 6.6 in RP and 12.7 in RPS). The same molecular events commented above may explain the observed changes in water absorption capacity (WAC), a parameter that highlights the dynamics of the water interactions within a food matrix (Marti et al. 2016). The WAC value for the non-enriched pasta in this study was slightly lower than those reported by Marti et al. (2014), likely because a different rice variety and higher amount of albumen were used here.

The decreased textural firmness of RP and of RPS with respect to the non-enriched control may be attributed to an overall structural weakness ensuing from the intrinsic features of potato starch and from the increased fiber content, as discussed above. Once again, soybean proteins contribute to retain some of the firmness in RS, but their effect is no longer evident when with sweet potato flour is simultaneously present, as in RPS.

Structural features of the protein network

The role of covalent and non-covalent interactions in stabilizing protein aggregates in the various pasta samples was assessed by measuring the amount of protein solubilized in buffers with different dissociating ability towards protein–protein complexes (Marti et al. 2014). Saline buffer allows the solubilization of albumins and globulins, whereas the addition to the saline buffer of a chaotrope (urea) and/or of a disulfide reducing agent enables the dissociation of protein aggregates stabilized by hydrophobic interactions and by disulphide bonds, respectively (Bonomi et al. 2012).

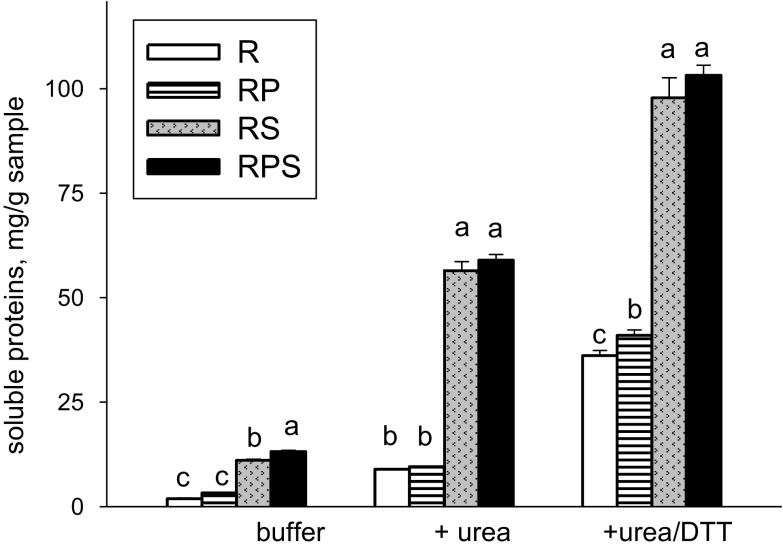

As shown in Fig. 1, the amount of proteins solubilized from the various pasta samples in saline buffer was low, and increased markedly when urea and urea/DTT were added, indicating that protein aggregates in all pasta samples are stabilized by hydrophobic interactions and disulfide bonds, as observed in other types of rice-based pasta (Barbiroli et al. 2013; Marti et al. 2014). The data in Fig. 1 also make it evident that the simultaneous addition of sweet potato flour has no significant effect on the overall structure of protein aggregates in soybean-enriched rice pasta.

Fig. 1.

Solubility of proteins from the various uncooked pasta samples in buffers of different dissociating capacity. Bars identified by the same letter in a given group are not significantly different (P ≤ 0.05)

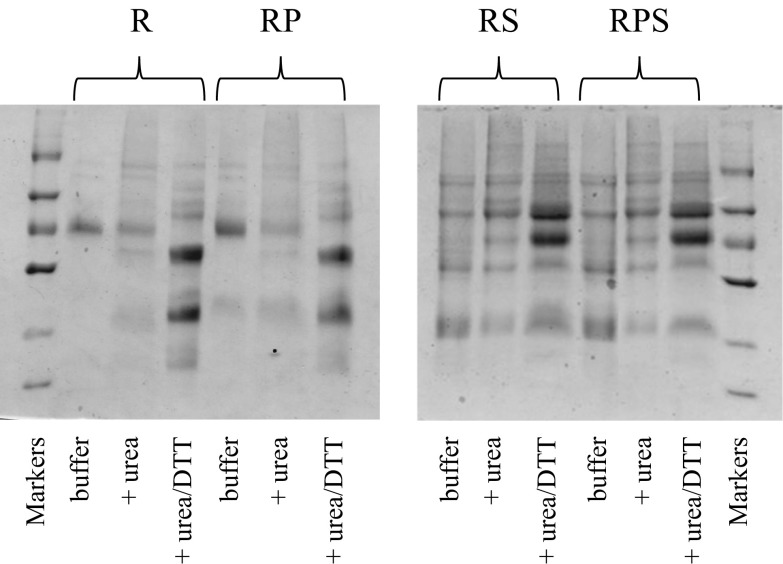

Figure 2 presents the SDS-PAGE tracings for the proteins solubilized from the various samples of uncooked pasta when using buffer systems of different dissociating ability. It is evident that most of the ovalbumin (visible as a band at 45 kDa in the SDS tracings) did not form aggregates and remained buffer-soluble in uncooked pasta, at least in the absence of soybean proteins. This suggest that the structuring effects of the added egg white (all pasta samples contain about 0.5% ovalbumin, the main structuring protein in egg white) is only exerted during cooking, as the SDS-PAGE tracings offer no evidence in ovalbumin being involved in the formation of a network in uncooked pasta with either rice proteins (4.9 and 4.2% of total dry matter in R and RP, respectively) or sweet potato proteins (1.2% of total dry matter in RP). Conversely, the SDS-PAGE tracings for proteins solubilized from samples enriched with soybean proteins (7.4% of total dry matter in RS and RPS) indicated that ovalbumin was involved in covalent and non-covalent interactions with other proteins in the system already during the pasta-making process.

Fig. 2.

SDS-PAGE tracings for proteins solubilized from the various uncooked pasta samples in the presence/absence of 6 M urea and 0.01 M DTT

In all samples, rice proteins (corresponding to the rather intense bands at 37 and 24 kDa (Barbiroli et al. 2013)) only became evident in the SDS-PAGE tracings of proteins solubilized in the presence of urea and DTT. This is consistent with previous reports on the formation of rice proteins aggregates upon thermal pre-treatments of rice, and on the nature of the interactions that stabilize these rice protein aggregates (Barbiroli et al. 2013).

Finally, SDS-PAGE tracings for the proteins solubilized in the various buffer systems from pasta enriched with soybean flour (RS and RPS) gave definite indication of the occurrence of inter-protein hydrophobic interactions and disulfide bonds in uncooked pasta. Although difficult to assess on quantitative basis in these complex systems, the interactions occurring in un-cooked soybean-enriched rice pasta appear to involve also some of the rice proteins, suggesting the participation of proteins from all the components (i.e., rice, soybean, and egg white) in the formation of an inter-protein network. However, the involvement of the modest amount of sweet potato proteins (1.2 and 0.6% of total dry matter in RP and RPS, respectively) in these inter-protein interactions remains elusive.

Thus, also in consideration of the cooking parameters for the various types of pasta (Table 1), it could be possible that the protein aggregates formed in soybean-enriched rice pasta—as hypothesized above—may have some ability as for forming a network capable of retaining the swollen starch granules formed upon cooking. However, it is also possible that some of these inter-protein interactions lead to formation of other types of aggregates among proteins of different origin, that have a much more compact structure and do not have starch-retaining capacity.

The compactness of protein structure may be assessed—even in the case of insoluble aggregates—by estimating the conditional reactivity of suitable amino acid side chains. In the case of cereal-based products, the accessibility of protein –SH groups to suitable reagents in the presence/absence of denaturants has been used to evaluate the extent and nature of process-related modifications (Bonomi et al. 2012; Cabrera-Chávez et al. 2012; Barbiroli et al. 2013).

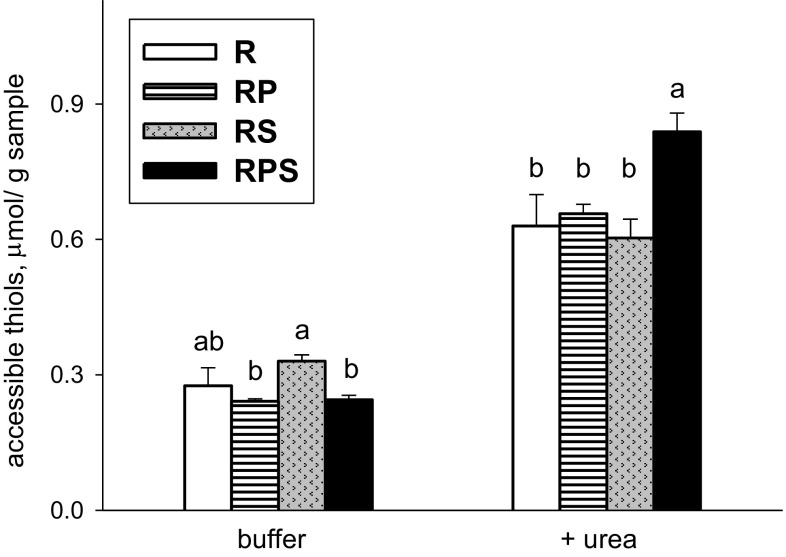

The data presented in Fig. 3 indicate that the number of readily accessible thiol groups in all pasta samples was essentially independent of their protein content and of the proteins’ origin. The number of accessible thiol groups increased to a comparable extent in all samples upon addition of urea, suggesting the presence of compact structures in all samples. However, the urea-dependent increase in accessible thiols was highest in pasta enriched with both sweet potato and soybean flours. This observation provides further evidence as for the role of starch in determining the type and extent of interactions among proteins in pasta (Cabrera-Chávez et al. 2012; Barbiroli et al. 2013).

Fig. 3.

Accessibility of cysteine thiols to thiol-specific reagents in the various uncooked pasta samples as a function of the presence/absence of 6 M urea. Bars identified by the same letter in a given group are not significantly different (P ≤ 0.05)

Instrumental sensory properties of pasta

E-nose and e-tongue were used to evaluate the aromatic and taste profile of the four different pasta formulations. Data collected were elaborated by PCA (in correlation matrix) to achieve a partial visualization of the data set in a reduced dimension. The sensor array of e-nose consists of 10 metal oxide semiconductor (MOS) type sensors: W1C (aromatic); W5S (broadrange); W3C (aromatics); W6S (hydrogen); W5C (aromatics–aliphatics); W1S (broad-methane); W1W (sulphur-containing compounds); W2S (broad-alcohol); W2W (sulphur-containing and chlorinated compounds); W3S (methane-aliphatics).

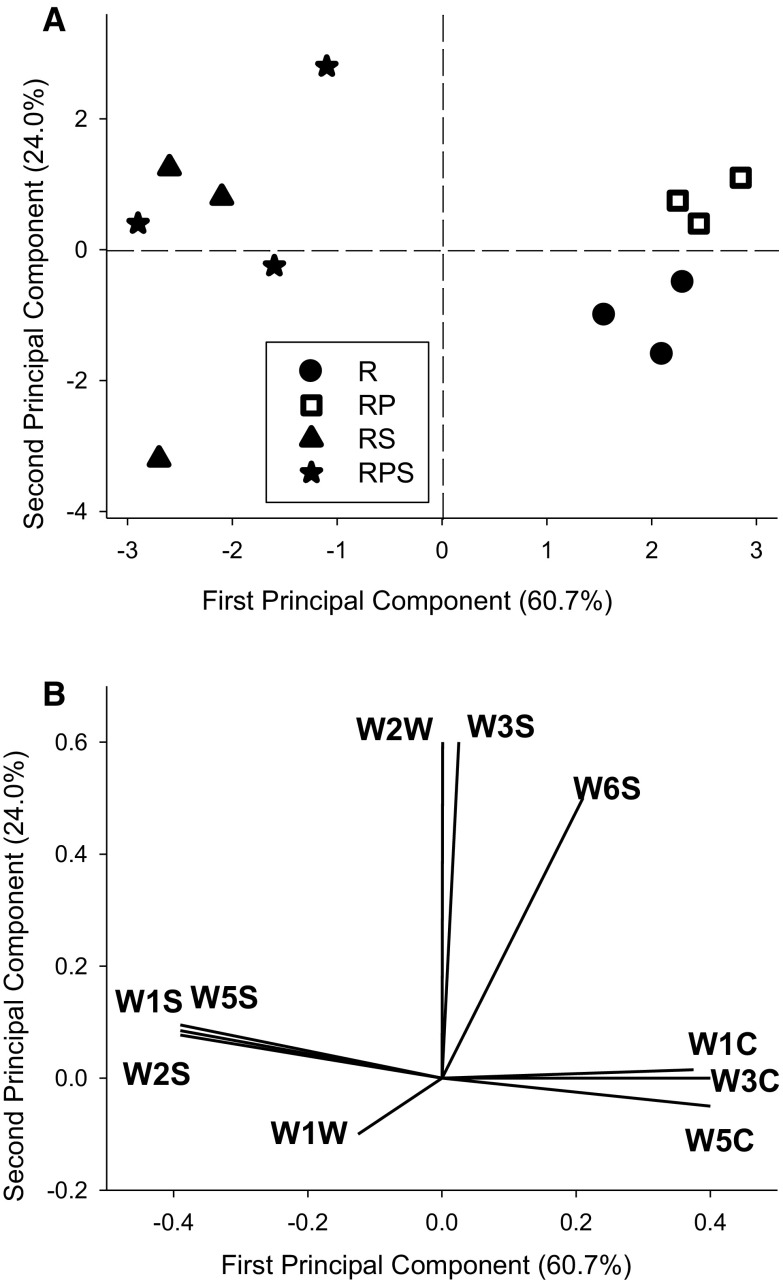

Figure 4 reports the PCA score plot (a) and loading plot (b) of e-nose data in the area defined by the first two Principal Components explaining 84.7% of total variance. The score plot (Fig. 4a) shows that samples are grouped into two clusters along the first Principal Component (60.7% of the total variance) according to their composition. Pasta samples enriched with soybean (RS and RPS) are grouped in the negative part of the first Principal Component, whereas the control (R) and pasta enriched with orange-fleshed sweet potato (RP) are grouped in the positive part of first Principal Component. Considering the loading plot (Fig. 4b), it is possible to notice that WC sensors, specific for the aromatic compounds, contribute to the discrimination of the aromatic profile of pasta between soybean-enriched pasta (RS) and the ones containing only rice or rice and sweet potato (R; RP). The same plot indicates that WS sensors (broadrange sensitivity) are relevant in the discrimination of pasta samples enriched with soybean (RS and RPS), regardless of the presence of sweet potato flour in the formulation.

Fig. 4.

PCA score plot (a) and loading plot (b) for the e-nose data collected on the various samples of cooked pasta

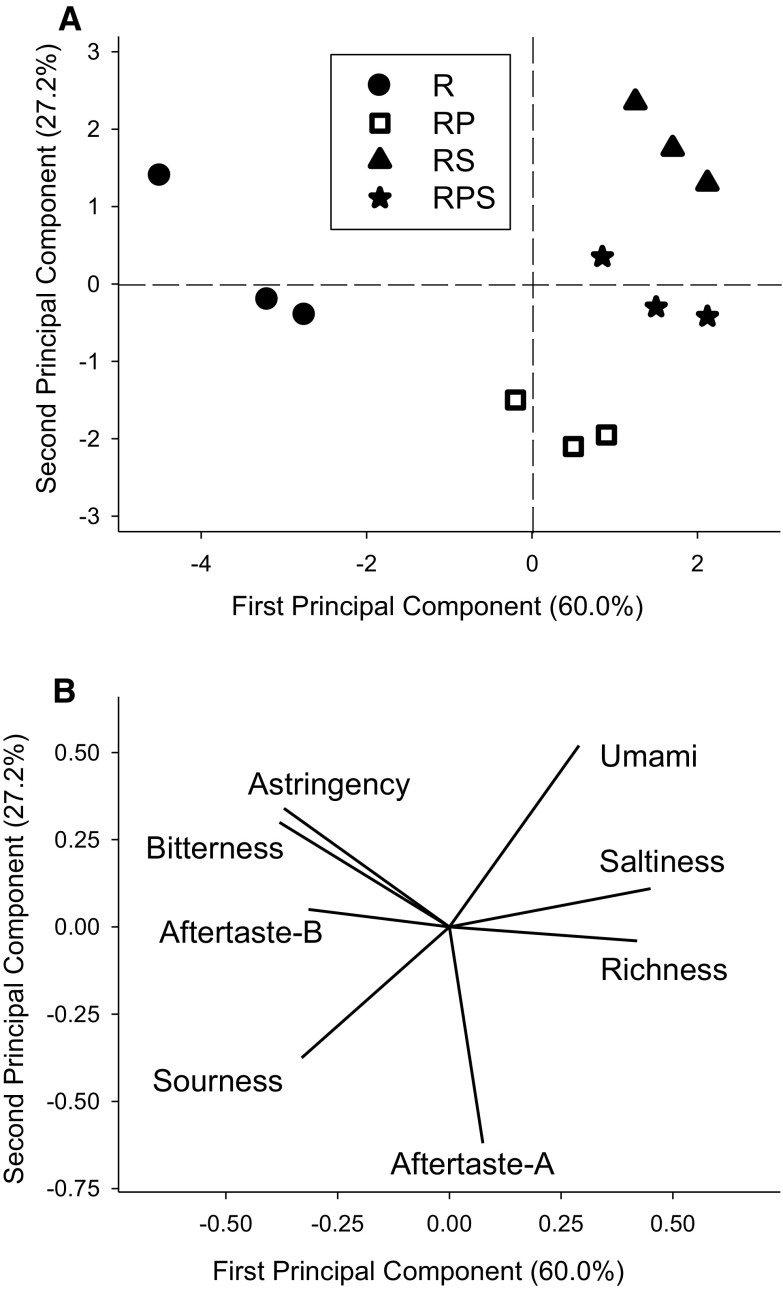

The e-tongue measurements allowed to estimate some “taste values” such as sourness, saltiness, bitterness, aftertaste-bitterness, astringency and aftertaste-astringency. Figure 5 reports the PCA score plot (Fig. 5a) and loading plot (Fig. 5b) of taste values collected by e-tongue, in the area defined by the first two Principal Components explaining 87.2% of total variance.

Fig. 5.

PCA score plot (a) and loading plot (b) for the e-tongue data collected on the various samples of cooked pasta

Considering the score plot (Fig. 5a) a clear separation of the samples is evident both on the first and second Principal Component. In particular, the control pasta (R) located to the left of the plot is discriminated by all the other samples, and is characterized by sourness, astringency and bitterness (Fig. 5b). The pasta enriched with orange-fleshed sweet potato (RP) lies to the right of the plot and is characterised by the astringency aftertaste, whereas samples enriched with soybean are more characterized by the Umami taste and richness (Fig. 5b).

Conclusion

The application of a multidisciplinary approach to the characterization of differently enriched rice-based pasta allowed to define the overall quality parameters of the samples and to understand some of the molecular determinants of their properties. This study underscores the relevance of a proper combination of ingredients in assessing specific features and in driving the behavior of specific molecules within the systems.

In particular, the data on protein aggregation point out that: (1) rice proteins may be themselves relevant in terms of aggregate formation; (2) the interplay between starch and proteins is of paramount relevance as for the formation of a proper protein network that includes proteins from the source used for enrichment; (3) protein-rich ingredients—such as soybean—provide additional components and strength to the inter-protein network generated during the pasta-making process.

From a practical standpoint, this investigation may offer some guidelines as for designing and producing pasta fit to the consumers’ expectations, that can eventually add value to local African raw materials. In this frame, it is worth noting that the procedures reported here do not involve sophisticated treatments or expensive equipment/ingredients, and therefore appear reasonably sustainable also form an economic standpoint.

Acknowledgements

This work was supported in part by the GRISP project “New Products”.

References

- AACC International . Approved methods of analysis, 11th edn. Method 66-50.01. Pasta and noodle cooking quality—firmness. St. Paul: AACC International; 2001. [Google Scholar]

- Barbiroli A, Bonomi F, Casiraghi MC, Iametti S, Pagani MA, Marti A. Process conditions affect starch structure and its interactions with proteins in rice pasta. Carbohyd Polym. 2013;92:1865–1872. doi: 10.1016/j.carbpol.2012.11.047. [DOI] [PubMed] [Google Scholar]

- Benedetti S, Buratti S, Spinardi A, Mannino S, Mignani I. Electronic nose as a non-destructive tool to characterise peach cultivars and to monitor their ripening stage during shelf-life. Postharvest Biol Technol. 2008;47:181–188. doi: 10.1016/j.postharvbio.2007.06.012. [DOI] [Google Scholar]

- Bonomi F, D’Egidio MG, Iametti S, Marengo M, Marti A, Pagani MA, Ragg EM. Structure-quality relationship in commercial pasta: a molecular glimpse. Food Chem. 2012;135:348–355. doi: 10.1016/j.foodchem.2012.05.026. [DOI] [PubMed] [Google Scholar]

- Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem. 1976;72:248–254. doi: 10.1016/0003-2697(76)90527-3. [DOI] [PubMed] [Google Scholar]

- Buratti S, Ballabio D, Giovanelli G, Zuluanga Dominguez CM, Moles A, Benedetti S, Sinelli N. Monitoring of alcoholic fermentation using near infrared and mid infrared spectroscopies combined with electronic nose and electronic tongue. Anal Chim Acta. 2011;697:67–74. doi: 10.1016/j.aca.2011.04.020. [DOI] [PubMed] [Google Scholar]

- Cabrera-Chávez F, Calderón de la Barca AM, Islas-Rubio AR, Marti A, Marengo M, Pagani MA, Bonomi F, Iametti S. Molecular rearrangements in extrusion processes for the production of amaranth-enriched, gluten-free rice pasta. LWT Food Sci Technol. 2012;47:421–426. doi: 10.1016/j.lwt.2012.01.040. [DOI] [Google Scholar]

- Calderón de la Barca AM, Rojas-Martínez ME, Islas-Rubio AR, Cabrera-Chávez F. Gluten-free breads and cookies of raw and popped amaranth flours with attractive technological and nutritional qualities. Plant Food Hum Nutr. 2010;65:241–246. doi: 10.1007/s11130-010-0187-z. [DOI] [PubMed] [Google Scholar]

- Catassi C, Gatti S, Lionetti E. World perspective and celiac disease epidemiology. Digest Dis. 2015;33:141–146. doi: 10.1159/000369518. [DOI] [PubMed] [Google Scholar]

- Christides T, Amagloh FK, Coad J. Iron bioavailability and provitamin A from sweet potato- and cereal-based complementary foods. Foods. 2015;4:463–476. doi: 10.3390/foods4030463. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Noni I, Pagani MA. Cooking properties and heat damage of dried pasta as influenced by raw material characteristics and processing conditions. Crit Rev Food Sci Nutr. 2010;50:465–472. doi: 10.1080/10408390802437154. [DOI] [PubMed] [Google Scholar]

- Fabian C, Ju YH. A review on rice bran protein; Its properties and extraction methods. Crit Rev Food Sci Nutr. 2011;51:816–827. doi: 10.1080/10408398.2010.482678. [DOI] [PubMed] [Google Scholar]

- Gurmu F, Hussein S, Laing M. The potential of orange-fleshed sweet potato to prevent vitamin A deficiency in Africa. Intl J Vitam Nutr Res. 2014;84:65–78. doi: 10.1024/0300-9831/a000194. [DOI] [PubMed] [Google Scholar]

- Iametti S, Bonomi F, Pagani MA, Zardi M, Cecchini C, D’Egidio MG. Properties of the protein and carbohydrate fractions in immature wheat kernels. J Agric Food Chem. 2006;54:10239–10244. doi: 10.1021/jf062269t. [DOI] [PubMed] [Google Scholar]

- Kobayashi Y, Habara M, Ikezazki H, Chen R, Naito Y, Toko K. Advanced taste sensors based on artificial lipids with global selectivity to basic taste qualities and high correlation to sensory scores. Sensors. 2010;10:3411–3443. doi: 10.3390/s100403411. [DOI] [PMC free article] [PubMed] [Google Scholar]

- La Frano MR, de Moura FF, Boy E, Lönnerdal B, Burri BJ. Bioavailability of iron, zinc, and provitamin A carotenoids in biofortified staple crops. Nutr Rev. 2014;72:289–307. doi: 10.1111/nure.12108. [DOI] [PubMed] [Google Scholar]

- Mahmoud AH, El Anany AM. Nutritional and sensory evaluation of a complementary food formulated from rice, faba beans, sweet potato flour, and peanut oil. Food Nutr Bull. 2014;35:403–413. doi: 10.1177/156482651403500402. [DOI] [PubMed] [Google Scholar]

- Marco C, Rosell CM. Breadmaking performance of protein enriched, gluten-free breads. Eur Food Res Technol. 2008;227:1205–1213. doi: 10.1007/s00217-008-0838-6. [DOI] [Google Scholar]

- Marengo M, Bonomi F, Marti A, Pagani MA, Elkhalifa AEO, Iametti S. Molecular features of fermented and sprouted sorghum flours relate to their suitability as components of enriched gluten-free pasta. LWT Food Sci Technol. 2015;63:511–518. doi: 10.1016/j.lwt.2015.03.070. [DOI] [Google Scholar]

- Marengo M, Akoto HF, Zanoletti M, Carpen A, Buratti S, Benedetti S, Barbiroli A, Johnson PNT, Sakyi-Dawson EO, Saalia FK, Bonomi F, Pagani MA, Manful J, Iametti S. Soybean-enriched snacks based on African rice. Foods. 2017;5:38–49. doi: 10.3390/foods5020038. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marti A, Pagani MA. What can play the role of gluten in gluten free pasta? Trends Food Sci Technol. 2013;31:63–71. doi: 10.1016/j.tifs.2013.03.001. [DOI] [Google Scholar]

- Marti A, Seetharaman K, Pagani MA. Rice-based pasta: a comparison between conventional pasta-making and extrusion-cooking. J Cereal Sci. 2010;52:404–409. doi: 10.1016/j.jcs.2010.07.002. [DOI] [Google Scholar]

- Marti A, Caramanico R, Bottega G, Pagani MA. Cooking behavior of rice pasta: effect of thermal treatments and extrusion conditions. LWT Food Sci Technol. 2013;54:229–235. doi: 10.1016/j.lwt.2013.05.008. [DOI] [Google Scholar]

- Marti A, Barbiroli A, Marengo M, Fongaro L, Iametti S, Pagani MA. Structuring and texturing gluten-free pasta: egg albumen or whey proteins? Eur Food Res Technol. 2014;238:217–224. doi: 10.1007/s00217-013-2097-4. [DOI] [Google Scholar]

- Marti A, D’Egidio MG, Pagani MA. Pasta: quality testing methods. In: Wrigley C, Corke H, Seetharaman K, Faubion F, editors. Encyclopedia of cereal grains. 2. London: Academic Press; 2016. pp. 161–165. [Google Scholar]

- Marti A, Marengo M, Bonomi F, Casiraghi MC, Franzetti L, Pagani MA, Iametti S. Molecular features of fermented teff flour relate to its suitability for the production of enriched gluten-free bread. LWT Food Sci Technol. 2017;78:296–302. doi: 10.1016/j.lwt.2016.12.042. [DOI] [Google Scholar]

- Meinlschmidt P, Sussmann D, Schweiggert-Weisz U, Eisner P. Enzymatic treatment of soy protein isolates: effects on the potential allergenicity, techno functionality, and sensory properties. Food Sci Nutr. 2016;4:11–23. doi: 10.1002/fsn3.253. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pellegrini N, Agostoni C. Nutritional aspects of gluten-free products. J Sci Food Agric. 2015;95:2380–2385. doi: 10.1002/jsfa.7101. [DOI] [PubMed] [Google Scholar]

- Petitot M, Boyer L, Minier C, Micard V. Fortification of pasta with split pea and faba bean flours: pasta processing and quality evaluation. Food Res Intl. 2010;43:634–641. doi: 10.1016/j.foodres.2009.07.020. [DOI] [Google Scholar]

- Phongthai S, D’Amico S, Schoenlechner R, Homthawornchoo W, Rawdkuen S. Effects of protein enrichment on the properties of rice flour based gluten-free pasta. LWT Food Sci Technol. 2017;80:378–385. doi: 10.1016/j.lwt.2017.02.044. [DOI] [Google Scholar]

- Wood JA. Texture, processing and organoleptic properties of chickpea-fortified spaghetti with insights to the underlying mechanisms of traditional durum pasta quality. J Cereal Sci. 2009;49:128–133. doi: 10.1016/j.jcs.2008.07.016. [DOI] [Google Scholar]