Abstract

The aim of this paper was to study, step by step, the effect of ingredients and storage conditions on several properties of both the maize-based dough and the final product, during the new polenta-based snack food developing. Two different maize flours were characterized through water activity determination, particle size analysis, scanning electronic microscopy; then, dough made with different ratio of these were evaluated for mechanical properties and microstructure. According to the preliminary physicochemical characterization of both flour and dough, the final formulation was chosen for the polenta-based snacks. Thus, mechanical and sensory analyses, as well as microstructure determination, were performed on the final product. Results showed that the two maize flours presented different particle size distribution and gelatinization enthalpy, and affected the mechanical properties of intermediate products. The storage conditions dramatically affected the characteristics of the final products. Sensory results demonstrated that breading improves the crispness of external part but keeping creamy the product inside. The chosen approach was useful for understanding that flour particle size and storage are the critical factors that should be considered for this type of snack. The best formulation was made by mixing coarse and fine maize flours and by adding a batter.

Keywords: Maize flour, Food rheology, Sensory analysis, Product development, Food structure, Gelatinization

Introduction

The innovation process does not consist only in the development of a new product for the global market, but also in reformulation, simplifying, accelerating or improving products already present in the market (Lambin 2000). Therefore, the development of a product based on a traditional food recipe could be also considered an innovation.

Polenta is a porridge-like dish, generally made by mixing cornmeal, especially yellow maize cornmeal but also buckwheat, white maize or a mixture of the two flours, with water, salt, and constantly stirring the mixture while cooking over a low heat. It can be eaten alone or topped with various ingredients (cheese, meat, sausages, fish, etc.). It is most popular in the north of Italy but it can be also found in other countries in Europe and South America. In literature, there is only one study regarding its characterization (Zeppa et al. 2012), which was carried out to define the lexicon for a sensory profile of polenta and the relationships among sensory properties and maize cultivars. The authors showed that the descriptors chosen were useful to differentiate sensory quality among samples and that the defined lexicon could be used to describe the sensory qualities of polenta obtained by fresh maize flour both for basic research and product development. More recently a preliminary paper on dynamic sensory evaluation of polenta-based sticks (Di Monaco et al. 2016) has been published. The authors studied the effect of preparation method, storage condition and serving temperature on dominant sensory attributes of samples and on consumer liking over the time. They found an effect of those variables on some dominant attributes, but they underlined that consumer liking scores did not significantly change during consumption for all the samples. Fried samples received the highest liking scores, but they should be improved. In order to do that, the effect of ingredients on the structure and mechanical properties of the final product should also be considered.

Maize is the main ingredient in polenta formulation. The major component of the maize granules is the starch, involved in different processes, such as gelling, retrogradation, viscosity, pasting properties, that affect sensory and physical properties of many foods (Serna-Saldivar 2012; Eliasson 2004).

When starch is heated in excess of water, its granules swell up to several times their original size, the water is absorbed and the crystalline order is lost. During heating, the viscosity increases with temperature increasing, due to the swelling of the starch granules and then it decreases because of the starch granules rupturing and fragmentation. Meanwhile, during cooling, a gel structure is formed because amylose molecules aggregate to form a network. Pasting properties are consequently affected by the constituents that leached out from the granules during heating and the interactions between the chains (Singh et al. 2011).

A different starch organization or different damage starch content, due to different milling, can affect the pasting and gel properties of different maize flours (Agama-Acevedo et al. 2008).

Food properties could be affected not only by used ingredients but also by storage conditions and cooking procedures, therefore, even these factors should be considered in order to improve the quality of the final product.

Food based on gelatinized starch may undergo important textural changes during freezing and frozen storage. If the freezing rate is too slow or the storage temperature is higher than − 5 °C, a spongy structure could be formed due to water release that increases the interaction between molecular chains. However, during frozen storage, the main physical changes are due to the moisture migration and ice recrystallization, related to the stability of the water inside and outside the food. Indeed, when frozen tissues are stored without an adequate moisture barrier packaging a surface desiccation defect, called freeze burn, could appear on the surface (Zaritzky 2012). If one or more of those defects appear, the consumer may consider the food unacceptable.

The general growing trend to spend less time on cooking and food preparation has led to a great demand for time-saving “ready-to-eat” frozen products. Thus, breaded foods are very popular today, and their consumption has increased in recent years both in high convenience consumer societies and in developing countries (Miranda et al. 2010). These products are generally pre-fried, as deep-fat frying is the most common way to prepare breaded frozen foods, and then they could be consumed at home after a frying, microwave or oven cooking process. A deep fat frying technique often makes foods more pleasant with distinctive sensory qualities, including flavor, texture, and appearance (Gamonpilas et al. 2013).

The aim of this study was to develop a new polenta-based snack. The effect of maize flour, storage conditions and cooking procedure on polenta-based snack properties have been investigated. Two different maize flours were characterized by water activity, relative humidity, particle size distribution, microstructure and gelatinization transition. Polenta samples prepared with a mixture of the two maize flours, at different mixing ratios, were evaluated for their mechanical properties and microstructure. According to the preliminary physicochemical characterization of both flour and polenta, the best formulation was defined and final products, both chilled and frozen, were evaluated for their mechanical and sensory properties and microstructure.

Materials and methods

Maize flour

Two types of maize flours were used: “Bramata” (B), and “Crema” (C) produced by Geovita (Milano, Italy).

Water activity and moisture content determination. Water activity was measured through an AcquaLab device (Decagon Devices, Inc., 4TE series) at 20 ± 3 °C that uses the chilled-mirror dew-point technique. The moisture content of flours was determined by AACC method 44-19 (AACC 2000).

Particle size measurement. Flours particle size distribution was measured by light scattering Mastersizer 3000 (Mastersizer S, Malvern Instruments, UK). The flour samples were analyzed with a dry sampler, the sample was dispersed into the air, through a sonic jet and then it was sent to the laser beam, at a controlled rate. The procedure was performed according to the AACC 55-40 official method (AACC 2012). The size distribution was quantified as relative volume of particles in size bands and presented as size distribution curves using Mastersizer 3000 Software (Malvern Instruments, Worcestershire, UK). Particle size distribution (PSD) parameters were: weighted average volume D [4,3], the largest particle size (D90), average particle volume (D50), the smallest particle size (D10). Each result represented the average of 5 replications.

Thermal analysis. Differential scanning calorimetry was used to study starch gelatinization transition. Maize flour (≈ 5 mg) was placed in 40μL aluminum hermetic pan and distilled water was added with the help of a Hamilton microsyringe to achieve different flour–water suspensions (40/60; 30/70; 20/80). The pan was sealed and held at room temperature for 24 h before the analysis. Thermal analysis was carried out in triplicate using a differential scanning calorimeter (DSC TA Instruments QSC Q200). Each sample was held at 20 °C for 1 min, then was heated up to 95 °C, at 10 °C/min. Indium was used for calibration, and an empty aluminum pan was used as a reference. Onset temperature (Tonset), peak temperature (Tpeak), endset temperature (Tendset) and enthalpy of gelatinization (ΔHg) were calculated.

Microstructure. The maize flour was lyophilized and then mounted on a stub, coated with gold using a DC Sputter Coater (AGAR B7340, Agar Scientific Ltd, Stansted, UK) and observed using an electronic scanning microscope (SEM) (LEO EVO 40SEM phase angle 0°, electronic flow 20 kV).

Dough

Sample preparation. Four dough samples were prepared using 80% (w/w) water and 20% (w/w) maize flour: samples were coded as B dough (water + B flour), C dough (water + C flour); BC and CB dough (water + mixed flours, at different mixing ratios).

Dough samples were cooked, for 20 min at 100°Cin a cooking device (“Cooking Chef Kenwood”, De’Longhi Appliances s.r.l., Italy) After cooking dough samples were molded into cylinders (16 mm of diameter and 16 mm in height), cooled at 4 °C and stored in a fridge at 4 °C (chilled samples) or in blast chilling at − 18 °C and kept in the freezer for 7 days (frozen samples).

Mechanical analysis. Cylindrical samples, both frozen and chilled, were first equilibrate at room temperature then were submitted to uniaxial compression tests using a dynamometer Instron 4467 (Instron Int., England) with a 100 N load cell. Compression was applied at a crosshead speed of 10 mm/min up to the strain of 50%. Measurements were performed at room temperature (23 ± 1 °C). Five or more replications for each sample were performed.

Microstructure. Chilled samples were put in 4% glutaraldehyde solution for 2 h at 4 °C. Then the samples were gradually dehydrated using ethanol solutions at 25, 50, 75 and 90%. The samples were immersed for 30 min in the first three solutions, while they were kept for 24 h in the 90% solution. The samples were finally dried until critical point through CO2. Microstructure acquisition have been made as describe for flour.

Polenta-based snack

Materials. In addition to maize flour (Geovita, Asti, Italy) and water (S. Stefano, Salerno, Italy), the polenta-based snack recipe had other ingredients: butter (Galbani, Pavia, Italia), extra virgin olive oil (Carapelli, Firenze, Italy), grana Padano cheese (Agriform spa, Verona, Italy), salt (Italkari, Palermo, Italy), black pepper (Cerreto Srl, Reggio Emilia, Italy), rosemary flavor (Puglia Aromi, Foggia, Italy).

For breaded samples, a commercial roasted maize flour (De Cecco, Chieti, Italy) was used. Pre-gelatinized rice flour (Lo Conte, Avellino, Italia) and water were used to prepare the batter. For the frying procedure, sunflower oil (“Friggibene”, Carapelli, Firenze, Italia) was used.

Sample preparation. Polenta- based snack samples were prepared with a mixture of B and C maize flours, at two different ratios (F1 and F2). The C/B flour ratio was chosen based on the previous results. F1 and F2 samples were molded in stick shape (2 × 2 × 1 cm). The breading was obtained using just roasted maize flour (B1), or using first a batter, then the roasted maize flour (B2).

Two different storage conditions were investigated, chilled for 24 h at 4 °C (FS) and frozen at − 18 °C (FR) for 7 days.

Two different cooking procedures were chosen: oven cooking (O) performed at 180 °C for 15 min, deep-frying (F) at 180 °C for 90 s.

Mechanical analysis and microstructure. Mechanical analysis and microstructure image acquisition of polenta-based snack were performed as for the dough samples.

Sensory evaluation. Seven expert assessors evaluated the polenta-based snacks using a modified approach of the Flash profile method, as proposed by Liu et al. (2016). The two formulations (F1 and F2) were treated with breading (F1B1 and F2B1) or batter and breading (F1B2 and F2B2); each of them were chilled (F1B1CH, F2B1CH, F1B2CH, F2B2CH) or frozen stored (F1B1FR, F2B1FR, F1B2FR, F2B2FR); the applied cooking method was oven-cooking (O) or deep-frying (F), for all the samples. Then a total of sixteen samples were evaluated.

With the flash profile method, the entire sample set was evaluated into 3 sessions. In the first session, after the judges were trained on the procedure, they performed an Ultra Flash Profile (UFP) by focusing on differences/similarities among samples and naming differences on the map (Varela and Ares 2012). In the second session, judges compared their attributes list with that from others and tested the samples to choose the most relevant 10 attributes. Also, they were asked to give a definition for each attribute. In the third session, judges ranked the samples according to their individual vocabulary. Two replications of the ranking phase were performed on two consecutive days.

Data analysis

Maize flour

Water activity, moisture content, PSD parameters, temperatures and enthalpy of gelatinization data were submitted to t test (p < 0.05) using SPSS v17 software (IBM, USA).

Dough

Mechanical data were collected by INSTRON Series IX software v.8.25.00. Stress (σc) − strain (εc) curves were derived from load–displacement curves.

Polenta-based snack

Mechanical data were analysed as for the dough samples. Sensory data were recorded using a computerized data system (Fizz Acquisition ver. 2:45 G, Biosystemes, Couternon, Paris). Ranking data given by each judge for each individual attribute were used to build individual matrices (samples × attributes). For samples with equal rank orders (tied samples), a mean value was used. The FP data set was also averaged over the two individual repetitions. Individual matrices were assembled and analysed by Generalized Procrustes analysis (GPA) in order to obtain the sample consensus map and the loadings of individual attributes configurations (XLSTAT vers. 2014 5.03).

Results

Maize flour characterization

The water activity in the samples was about 50% with slightly lower values for flour C. The moisture content ranged 9.3–11.2% for both flours.

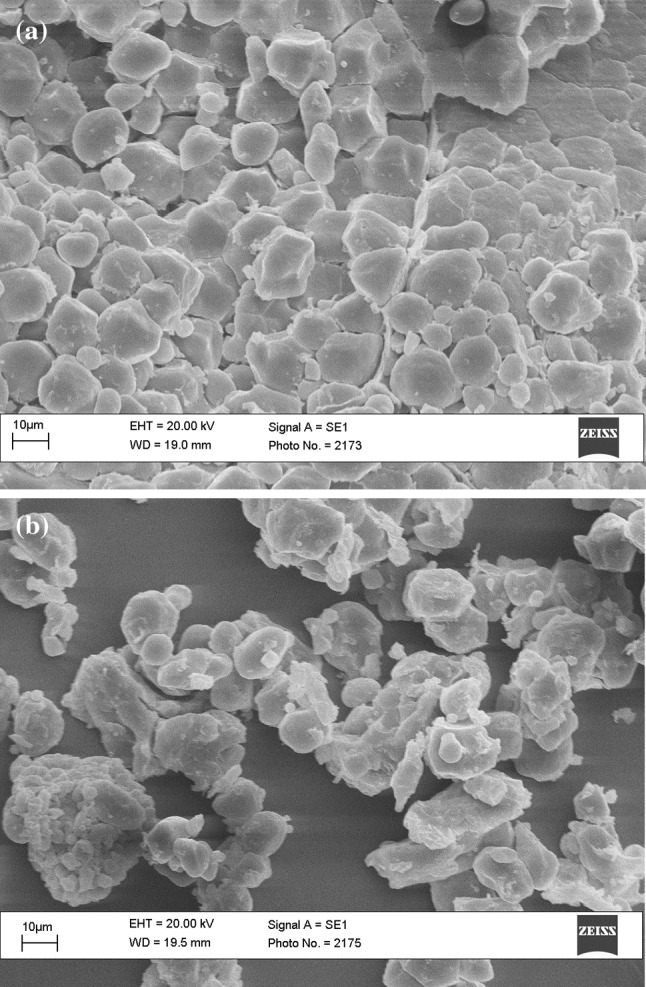

Maize flours micrographs were shown in Fig. 1. Figure 1a shows particles of flour B, the surfaces of mechanical breakage, due to milling, and the high number of starch granules are well distinguishable, moreover the cell walls seemed to be intact. In Fig. 1b different particles of flour C can be observed. They are very inhomogeneous, both in shape and size; some flour particles corresponded to a single or a few starch granules.

Fig. 1.

Micrographs of two different flours at ×2000 magnification (flour: a “Bramata” (B). b “Crema” (C))

Particle size analysis (Table 1) clearly showed that the two maize flours had different particle size distribution. In fact, B flour presented a more homogeneous particle distribution size, quite high, from 450 μm to 1300 μm (D90). On the contrary, particle size distribution of C flour was varied between 10 μm (D10) to 170 μm (D90), ten times lower than the particles of flour B.

Table 1.

Particle size distribution parameters, temperatures and enthalpy of starch gelatinization of Bramata (B) and Crema (C) maize flours

| Parameters | B flour | C flour | p value |

|---|---|---|---|

| Granulometric parameters | |||

| D10 | 472.28 ± 23.105 | 12.045 ± 0.168 | ≪0.001 |

| D50 | 759.33 ± 24.302 | 57.1 ± 1.588 | ≪0.001 |

| D90 | 1227.8 ± 41.806 | 170.52 ± 2.530 | ≪0.001 |

| D4.3 | 809.22 ± 27.682 | 75.814 ± 1.465 | ≪0.001 |

| Gelatinization enthalpy and temperatures | |||

| Flour/water ratio = 40/60 | |||

| ΔH | 2.52 ± 1.41 | 9.28 ± 0.17 | 0.006 |

| Tonset | 66.77 ± 0.49 | 62.29 ± 0.38 | 0.004 |

| Tpeak | 72.45 ± 1.53 | 71.71 ± 0.43 | 0.02 |

| Tendset | 85.80 ± 0.98 | 88.44 ± 0.27 | 0.8 |

| Flour/water ratio = 30/70 | |||

| ΔH | 3.47 ± 0.17 | 9.25 ± 0.46 | 0.009 |

| Tonset | 65.77 ± 0.87 | 63.04 ± 0.43 | 0.03 |

| Tpeak | 72.39 ± 0.47 | 71.65 ± 0.27 | 0.04 |

| Tendset | 82.55 ± 0.74 | 85.01 ± 0.76 | 0.06 |

| Flour/water ratio = 20/80 | |||

| ΔH | 3.24 ± 1.15 | 9.54 ± 0.40 | 0.007 |

| Tonset | 64 ± 0.69 | 61.88 ± 0.14 | 0.07 |

| Tpeak | 71.28 ± 0.11 | 71.49 ± 0.88 | 0.1 |

| Tendset | 82.20 ± 3.56 | 84.91 ± 1.23 | 0.08 |

At each line p value lower than 0.05 are reported in bold

The gelatinization enthalpy of flour C was significantly higher than flour B, at each flour/water ratio considered (p < 0.05). For flour B the gelatinization enthalpy varied from 2.52 (at the lower flour/water ratio) to about 4.0 J/gstarch (at intermediate and higher flour/water ratio). For flour C the gelatinization enthalpy was always of about 9.5 J/gstarch. La Tonset of flour C was significantly lower than flour B (Table 1) both at low and intermediate water content.

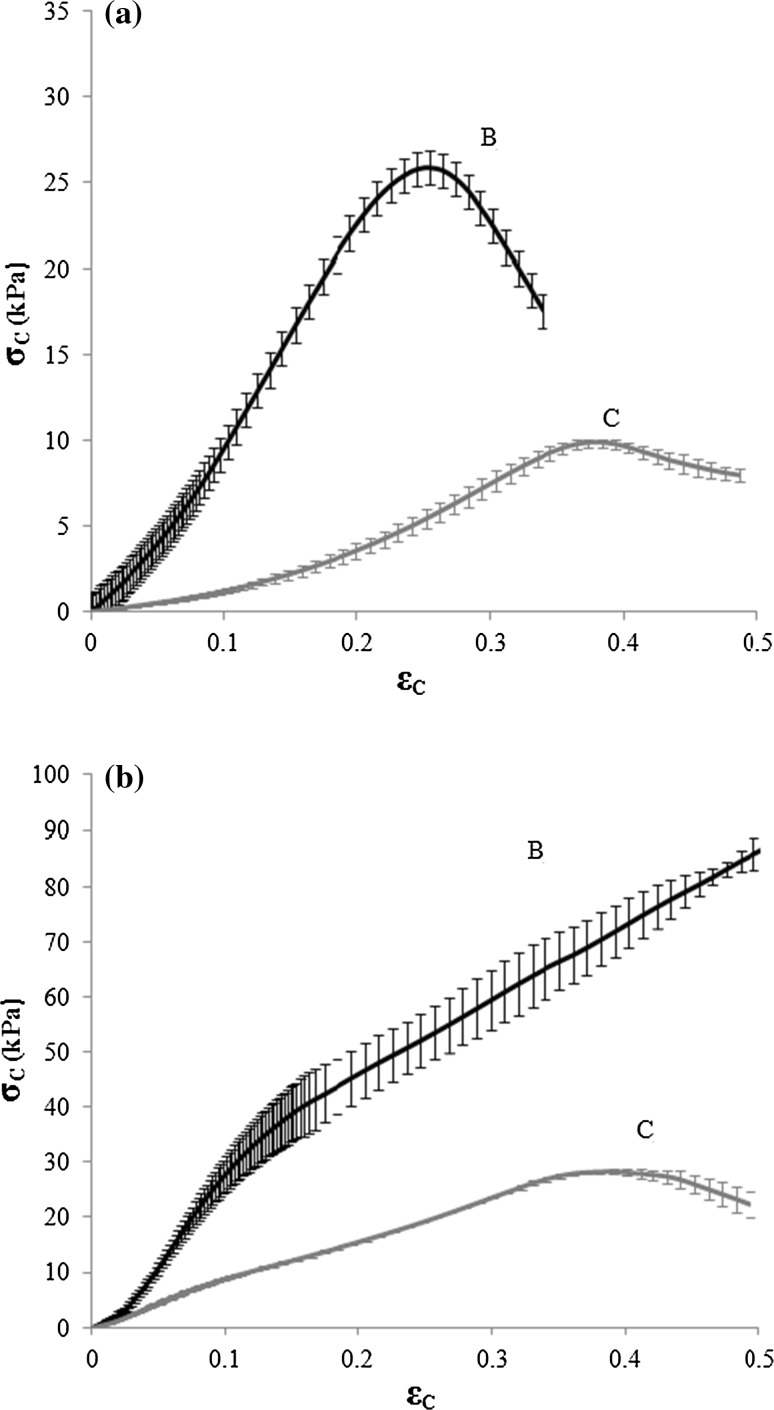

Dough characterization

Figure 2 shows the stress–strain curves of chilled and frozen dough, made with water and B and C maize flour, respectively. On the chilled product, the average stress–strain curves of 100% B dough were higher than those of 100% C dough (Fig. 2a). The maximum stress value before breaking was around 25 kPa and 10 kPa for B and C, respectively. The fracture strain was around 0.4 for 100% B dough and around 0.2 for 100% C dough.

Fig. 2.

Stress (σc) versus strain (εc) curves of B and C doughs (B dough = 80% water + 20% B flour; C dough = 80% water + 20% + C flour) (storage condition: a chilled samples; b frozen samples)

After freezing higher stress values were observed and mechanical behavior of B-based dough dramatically changed, as underlined by the sigmoidal shape of stress–strain curve characteristic of aerated food products (Fig. 2b).

Regardless of storage method, i.e. refrigeration or freezing, samples obtained with B flour had higher stress values than those obtained with C flour. However, on the frozen product, several differences between the two flours were highlighted.

Based on the previous results, it was decided to mix the two flours. Two different doughs were prepared and characterized: BC (80% water + 20% mixed flours, 70% of B and 30% of C) and CB dough (80% water + 20% mixed flours, 30% of B and 70% of C). An intermediate dough, with a 50% of B and 50% of C as mixed flours, was prepared but not characterized because it was too much inhomogeneous.

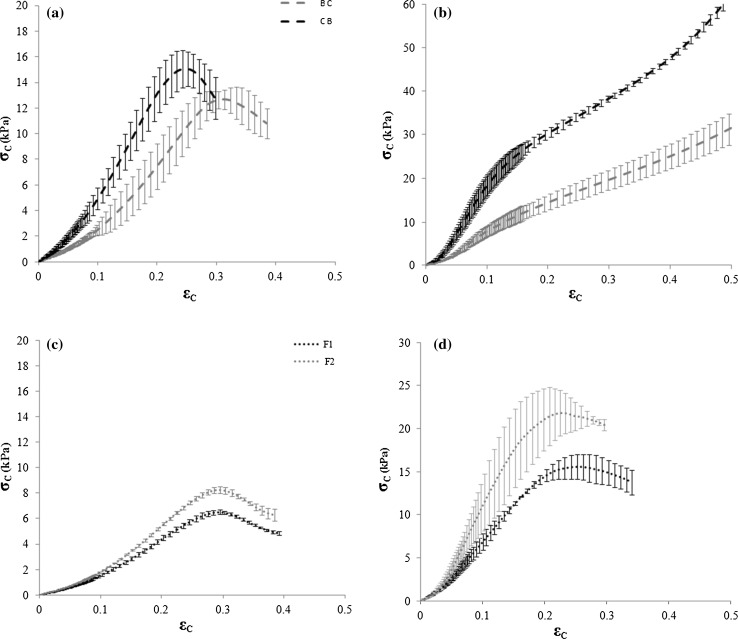

Figure 3 showed the shear stress–strain curves of chilled (Fig. 3a–c) and frozen dough (Fig. 3b–d) formulated with a different mixture of B and C flour. BC and CB shear stress–strain curves are reported in Fig. 3a, b.

Fig. 3.

Stress (σc) versus strain (εc) curves of different dough formulations, both chilled (a–c) and frozen (b–d) stored. BC sample (80% water + 20% mixed flours, 70% of B and 30% of C); CB dough (80% water + 20% mixed flours, 30% of B and 70% of C); F1 (80% water + 15% mixed flours, 30% of B and 70% of C, + 5% other ingredients); F2 (80% water + 15% mixed flours,70% of B and 30% of C, + 5% other ingredients) (dough formulation: a, b BC and CB; c, d F1 and F2)

For the chilled samples, when higher concentration of B flour (70% of B) was used the stress/strain curves seemed to be slightly higher than when a higher concentration of C flour was used (Fig. 3a), even if they did not differ concerning the maximum stress values (13 ± 3 kPa) and those values were intermediate between the maximum stress of C-made dough and B-made dough (Fig. 2a).

Fracture strain values were lower for samples with a lower percentage of B flour (0.25) than C flour (0.35). For the unfrosted samples (Fig. 3b), the mechanical behavior was closer to the dough made with only B flour, in particular when higher ratios of B flour were used.

Considering the different mechanical behavior of B and C-based dough, it was decided to add other ingredients only to the dough made with a maize flour mix and a 5% of maize flour was replaced by other ingredients, so the following formulations were prepared: F1 (80% water + 15% mixed flours, 30% of B and 70% of C, + 5% other ingredients) and F2 (80% water + 15% mixed flours, 70% of B and 30% of C, + 5% other ingredients). F1 and F2 curves are reported in Fig. 3 c-d. When other ingredients were used to partially substitute maize flour the mechanical behavior of the dough drastically changed. In particular, the addition of other ingredients in the chilled samples seemed to affect only fracture strain values and small differences were observed between the two final snack formulations (Fig. 3c). The unfrosted dough had similar behavior to the chilled ones, but with higher fracture stress and strain values (Fig. 3d), therefore the spongy structure was lost with respect to the same product formulated with only water and maize flour.

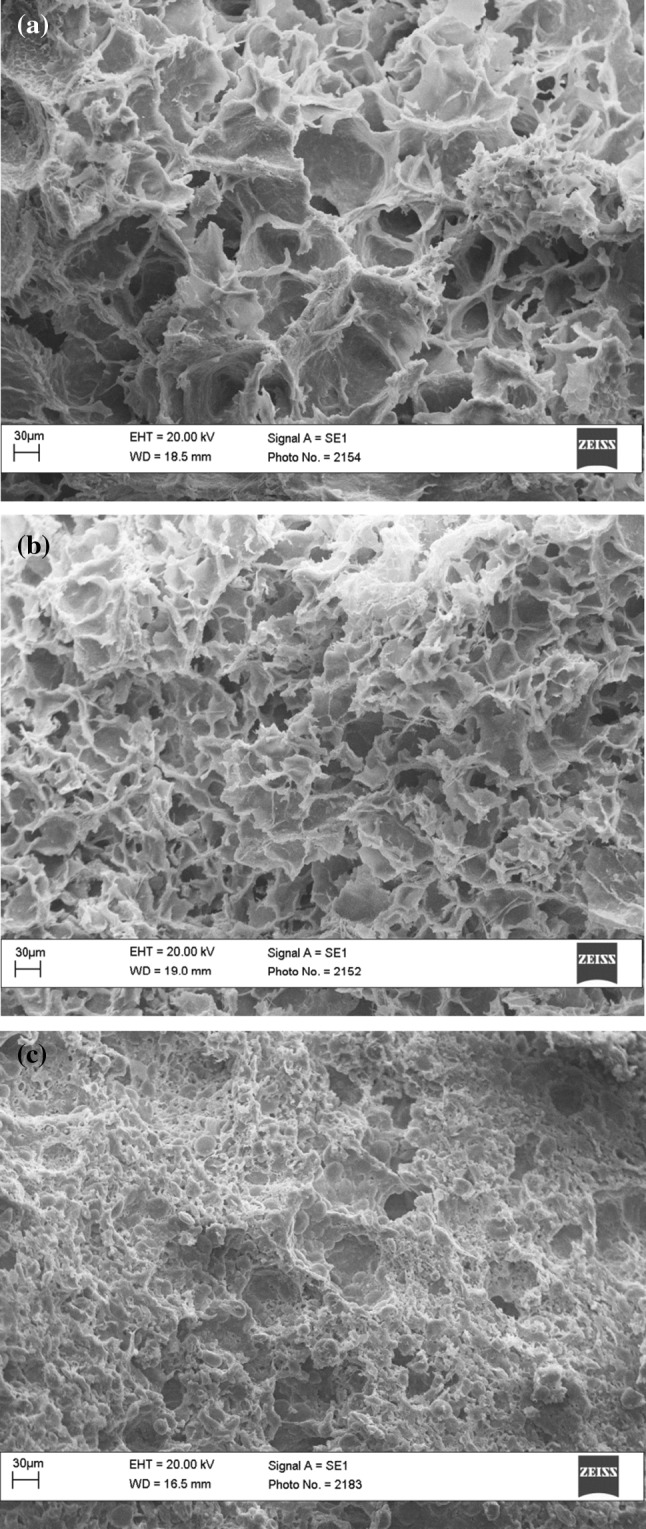

Micrographics of simple dough and complex dough were obtained, as reported in Fig. 4. The simple dough formulated using B and C presented different microstructures; samples made with B had a sponge-like structure (Fig. 4a), with pores of higher dimensions and a less compact structure and more firm cellular walls than samples made with C (Fig. 4b), even if both presented a spongy structure. These results were in accordance with the mechanical behavior of different dough. In both samples, starch granules were not observed and this is an indication that all the starch has been gelatinized. Meanwhile, micrographs at the same magnification of one complex dough (Fig. 4c), i.e. F2 with more ingredients than the only water and flour, revealed that the microstructure was more complex than those of simple dough, and a continuous network was observed and it included also spherical particles, probably lipid particles due to the addition of other ingredients. The structure was more compact than that observed for the simple dough and the cell walls were not very firm.

Fig. 4.

Micrographs of BC (a), CB (b), F2 (c) at ×500 magnification

Polenta-based snack characterization

Sensory evaluation

During the Ultra flash profile session, each judge generated 5–13 attributes for a total of 74 descriptors. The number of different attributes was 31. The most frequently used attributes were the following: external crunchiness, oiliness, creaminess, softness, yellow color, graininess, breading cohesiveness, pepper flavor, breading thickness and internal cohesiveness.

During the first Flash Profile session, each judge generated 4–10 attributes for a total of 59 attributes so they used relatively fewer attributes than UFP. Comparing the number of attributes elicited from each judge during each step, the number decreased due to the limitation of attributes to use (maximum 10). The number of different attributes was quite similar to that of UFP. Crunchiness and greasiness were the most frequent attributes, followed by a creaminess and fried odor. Afterward, color homogeneity was used 3 times, other attributes, such as breading thickness, gumminess, and graininess, were selected by only two judges.

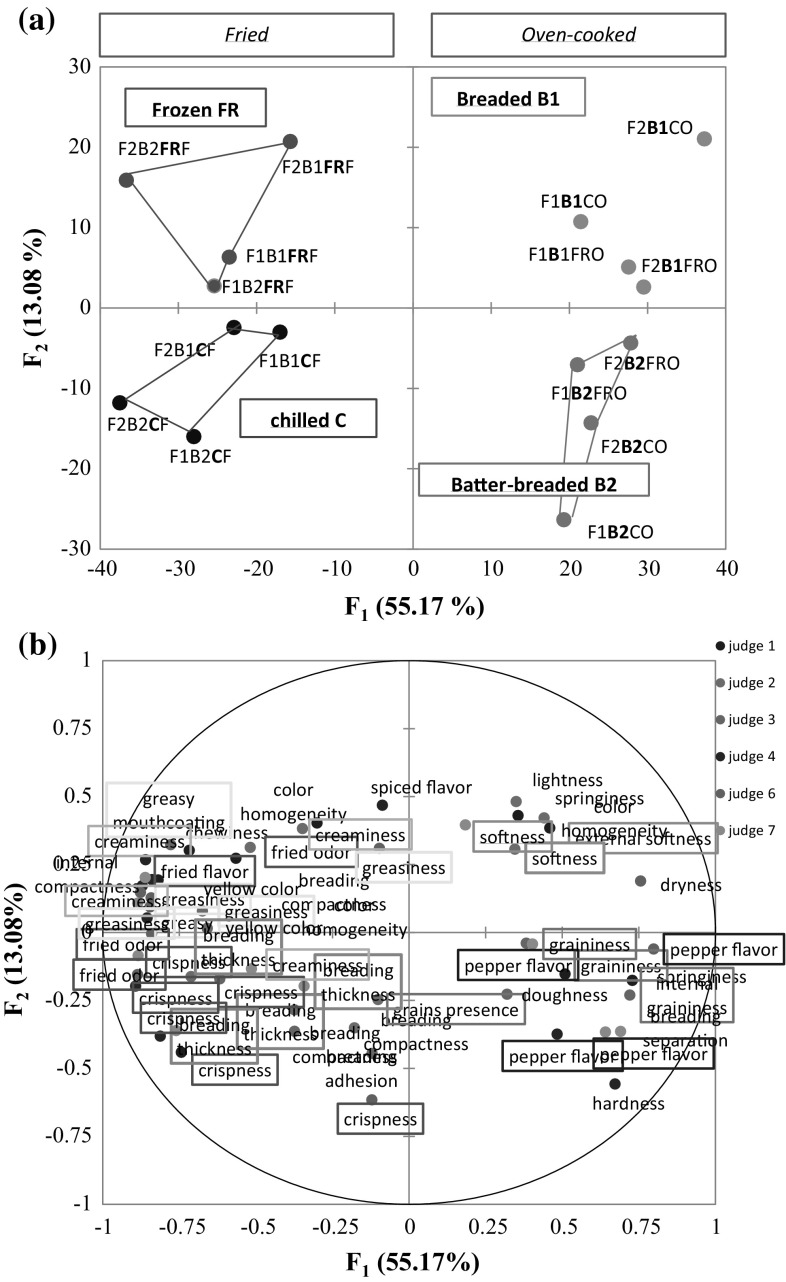

In Fig. 5 the sample consensus map and the loadings of individual attributes configurations were respectively shown.

Fig. 5.

Generalized Procrustes Analysis (GPA) on Flash Profile of the 16 polenta-based snacks: consensus configuration of samples (a) and configuration of individual attributes on the map (b). F1 and F2 axis are the first and the second dimension (factor), respectively, from GPA accounted for 74% of the total variation

The first two components accounted for about 68% of the total variance, with 55 and 13% for F1 and F2, respectively.

By sample consensus map (Fig. 5a), it is possible to observe that judges were able to discriminate between cooking methods; all the oven cooked samples were placed on the right side of the map opposed to the fried samples along the first component.

For the oven cooked samples it seemed that samples were discriminated for breading type; breading type 1 samples were located in the first quarter meanwhile the others were in the fourth quarter. There was not a clear separation between fresh and frozen samples for the oven cooked ones, meanwhile, for the fried samples there was a separation for storage condition but not for breading type. Two formulations (F1 and F2) were not easily distinguished by judges.

Regarding all attributes elicited by each judge, from Fig. 5b it seemed that some attributes had the same meaning for some judges but not for all. Looking at the configuration map, axis 1 appeared to define color attributes. Regarding crunchiness, that was the most frequent attribute, six of the crunchiness attributes appeared together on the third quartile showing that fried products were more assembled with crunchiness. Also in terms of greasiness, creaminess, and fried odor, judges were in agreement on the meaning of the attribute. Additionally, flavor attributes were mostly appearing close to X-axis as pepper flavor on the positive side and fried flavor on the negative side. In the second axis, texture attributes appeared on the negative side and it was possible that negative values implied compact and adhesive polenta samples, while positive values were associated with creamy and soft samples.

Discussion

Milling can affect the pasting and gel properties of different maize flours (Agama-Acevedo et al. 2008). The particle diameter of 10 μm, reported for C flour, corresponded to the particle size of the maize starch granules, according to Aguilera and Stanley (1999). Milling process could be responsible for the leak of starch granules, so the starch was more available to gelatinization, as also reported by Carvalho et al. (2010) for C than B sample.

Gelatinization enthalpies of B flour were much more lower than those found in literature, and it was possible that the starch did not completely gelatinize during the analysis due to the bigger size of maize flour. On the contrary, the gelatinization enthalpy values of C flour were in line with the values reported in the literature (Cornejo-Villegas et al. 2013), even if some differences could be due to different varieties of flour used (Sandhu et al. 2007).

The main difference between the two flours could be due to a higher amount of small free particles in flour C than flour B, as also underlined by granulometry and micrography. Particles of C flour were of similar size to those of the starch granules, so water diffusion was much more promoted into the individual flour particles than in the case of bigger aggregates.

The difference in gelatinization temperature between the two flours was in agreement with what already stated for the enthalpy: to a coarser particle size corresponded a slower kinetics of diffusion of water and the time at which the gelatinization started shifted towards higher temperatures.

In previous studies from the literature, an effect of particle size on gelatinization temperatures in maize flours was reported, in particular as the size of the starch particles tended to increase, there is also an increase in initial and final gelatinization temperatures (Cornejo-Villegas et al. 2013). High gelatinization temperatures could also be due to the presence of additional interactions between the components that hindered the process of gelatinization (Guzmán et al. 2009).

In addition, differences also in terms of distribution, the shape of the starch granules and the different arrangement of the fractions of starch in the granule may affect both the temperatures of gelatinization and the enthalpies of gelatinization (Sandhu et al. 2007).

Dough made with two different flours showed different mechanical properties. It could be due to different phenomena that occurred during the storage, such as starch retrogradation, water crystallization, and gel syneresis which led to a spongy structure and a sigmoidal curve. These results were in accordance with the literature (Charoenrein and Preechathammawong 2010).

In general, when the freezing process of a starch-based product was slow and the product was kept around 0 °C for long period, it tended to form a spongy structure due to the amylose retrogradation. Although the rigidity of the starch gel depended both on the retrogradation of gelatinized starch granules, and on the syneresis from amylopectin crystallization (Matalanis et al. 2009).

The results obtained suggested that when a coarse flour (B) was used alone, it gave a product that once defrosted behaved like a sponge. During the compression tests the water tended to leak from the pores and at the end of the test, samples tended to absorb most of the released water. This phenomenon was not observed for the other dough.

The formation of a spongy structure during freezing may be due to the different capacity of the coarse flour to interact with the water, a phenomenon also evidenced by calorimetric analysis. In the dough based on fine flour (C), the water was well incorporated into the structure and this caused a more compact structure which underwent to rupture at certain deformation. On the contrary, the defrosted product, prepared only with B flour, tended to lose water and did not reach the breaking point. Considering all the obtained results it was necessary to mix the two maize flour, because a coarse flour determined a higher consistency to the dough than a fine flour, but a spongy structure was not required for a product that should be frosted. Both flour ratios (30% B and 70% C and the inverse ratio) could be used for final product formulations. The final choice could depend on consumers’ preferences.

When other ingredients were used to partially substitute maize flour, mechanical properties of the final dough changed. The addition of other components, such as polysaccharides or proteins, caused the decrease of starch retrogradation and the creation of a spongy structure, with effects on the mechanical properties (Charoenrein and Preechathammawong 2010; Zaritzky 2008).

Different rapid sensory techniques have been developed in the last years in order to characterize different products in short times. Among them, Flash profile (FP) was a fast, descriptive, sensory method based on the combination of free choice terms selection and comparative ranking evaluation (Delarue 2014). In order to increase the development of individual vocabularies and to increase the interpretability of the results, some modifications have been applied to FP as reported by Liu et al. (2016) and Di Monaco et al. (2015). Those modifications consisted of a preliminary session, called Ultra Flash Profile (UFP) used in order to allow the judges to focus on differences or similarities among samples, and naming differences on a rectangular sheet.

In the present study, judges were able to elicit more attributes that distinguished the products during Flash Profile using UFP technique. Judges distinguished samples for cooking modes, but not for formulation. These results were expected because the baking and deep frying were two different cooking modes. In particular, the density and thermal capacity of the oil determined a rate of heat transfer much higher compared to other carriers, as the hot air in the oven during cooking, and also during deep-frying heat was evenly transferred to the entire product (Achir et al. 2009). Results demonstrated the effectiveness of the addition of the breading to the product in order to obtain a product crisp on the outside and creamy inside, as reported in the literature for several other products consumed after frying (Sanz and Salvador 2008). Crispness was lower in the case of frozen products for which an overwhelming and persisted sensation of oily and greasy was perceived. The crispness of the final product affected the acceptability of this product (Di Monaco et al. 2016).

Conclusion

The present work aimed to characterize an innovative polenta-based snack using two maize flours which were first characterized. In particular the impact of the type and the amount of maize flour, and also storage conditions on the properties of intermediate and final polenta-based products has been investigated. The results showed that maize flour type affected the mechanical properties of intermediate products but the addition of other ingredients reduced this effect. As well storage conditions dramatically influenced characteristics of samples, before and after cooking. For the sensory characterization of final products, the method applied was useful for obtaining rapidly the information about the characteristics that were actually perceived by consumers as well as to study the effect of dough formulation, batter type and storage condition on sensory properties. So the chosen approach was useful for understanding which are the critical factors that should be considered for this innovative polenta-based snack: flour particle size and storage type. So a frozen polenta-based snack should therefore be made of a mixture of coarse and fine maize flours (30 and 70%), because a coarse flour determined a higher consistency to the dough than a fine flour, but a spongy structure was not required for a product that should be frosted. Eventually, the snack could be also battered both to reduce the oil content and to improve sensory properties of the final product.

Acknowledgements

The present research was partially funded by the project MISE maisfood Industria 2015.

References

- AACC (2000) Approved methods of the American Association of Cereal Chemists, 10th edn, Method 44-19. The American Association of Cereal Chemists, St. Paul

- AACC (2012) Approved methods of the American Association of Cereal Chemists, 11th edn, Method 55-40.01. American Association of Cereal Chemists, St. Paul

- Achir N, Vitrac O, Trystram G. Heat and mass transfer during frying. In: Sahin S, Gulum Sumnu S, editors. Advances in deep-fat frying of foods. Boca Raton: CRC Press; 2009. pp. 5–32. [Google Scholar]

- Agama-Acevedo E, de la Rosa APB, Méndez-Montealvo G, Bello-Pérez LA. Physicochemical and biochemical characterization of starch granules isolated of pigmented maize hybrids. Starch Starke. 2008;60:433–441. doi: 10.1002/star.200800206. [DOI] [Google Scholar]

- Aguilera JM, Stanley DW. Microstructural principles of food processing and engineering. 2. Gaithersburg: Aspen Publishers Inc.; 1999. [Google Scholar]

- Carvalho CW, Takeiti CY, Onwulata CI, Pordesimo LO. Relative effect of particle size on the physical properties of corn meal extrudates: effect of particle size on the extrusion of cornmeal. J Food Eng. 2010;98:103–109. doi: 10.1016/j.jfoodeng.2009.12.015. [DOI] [Google Scholar]

- Di Monaco R, Cavella S, Miele NA, Liu J, Bredie WLP (2015) The use of ultra flash profiling as enhancer of flash profile method. In: Abstract book of the 11th Pangborn sensory science symposium, The Swedish Exhibition & Congress Centre, Gothenburg, Sweden

- Charoenrein S, Preechathammawong N. Undercooling associated with slow freezing and its influence on the microstructure and properties of rice starch gels. J Food Eng. 2010;100:310–314. doi: 10.1016/j.jfoodeng.2010.04.014. [DOI] [Google Scholar]

- Cornejo-Villegas Á, Gutiérrez-Cortez E, Rojas-Molina I, Real-López D, Zambrano-Zaragoza L, Martínez-Vega V, Rodríguez-García ME. Physicochemical, morphological, and pasting properties of nixtamalized flours from quality protein maize and its particle distribution. LWT Food Sci Technol. 2013;53:81–87. doi: 10.1016/j.lwt.2013.01.023. [DOI] [Google Scholar]

- Delarue J. Flash Profile, its evolution and uses in sensory and consumer science. In: Delarue J, Lawlor B, Rogeaux M, editors. Rapid sensory profiling techniques: applications in new product development and consumer research. 1. Cambridge: Woodhead Publishing; 2014. pp. 121–151. [Google Scholar]

- Di Monaco R, Miele NA, Volpe S, Masi P, Cavella S. Temporal dominance of sensations and dynamic liking evaluation of polenta sticks. Brit Food J. 2016;118:749–760. doi: 10.1108/BFJ-07-2015-0236. [DOI] [Google Scholar]

- Eliasson AC. Starch in food: Structure, function and applications. Boca Raton: CRC Press; 2004. [Google Scholar]

- Gamonpilas C, Pongjaruvat W, Methacanon P, Seetapan N, Fuongfuchat A, Klaikherd A. Effects of cross-linked tapioca starches on batter viscosity and oil absorption in deep-fried breaded chicken strips. J Food Eng. 2013;114:262–268. doi: 10.1016/j.jfoodeng.2012.08.008. [DOI] [Google Scholar]

- Guzmán AQ, Flores MEJ, Escobedo RM, Guerrero LC, Feria JS. Changes on the structure, consistency, physicochemical and viscoelastic properties of corn (Zea mays sp.) under different nixtamalization conditions. Carbohydr Polym. 2009;78:908–916. doi: 10.1016/j.carbpol.2009.07.024. [DOI] [Google Scholar]

- Lambin JJ. Market‐driven management, strategic and operational marketing. London: Macmillan; 2000. [Google Scholar]

- Liu J, Grønbeck MS, Di Monaco R, Giacalone D, Bredie WL. Performance of flash profile and napping with and without training for describing small sensory differences in a model wine. Food Qual Prefer. 2016;48:41–49. doi: 10.1016/j.foodqual.2015.08.008. [DOI] [Google Scholar]

- Matalanis AM, Campanella OH, Hamaker BR. Storage retrogradation behavior of sorghum, maize and rice starch pastes related to amylopectin fine structure. J Cereal Sci. 2009;50:74–81. doi: 10.1016/j.jcs.2009.02.007. [DOI] [Google Scholar]

- Miranda JM, Martínez B, Pérez B, Antón X, Vázquez BI, Fente CA, Cepeda A. The effects of industrial pre-frying and domestic cooking methods on the nutritional compositions and fatty acid profiles of two different frozen breaded foods. LWT Food Sci Technol. 2010;43:1271–1276. doi: 10.1016/j.lwt.2010.03.013. [DOI] [Google Scholar]

- Sandhu KS, Singh N, Malhi NS. Some properties of corn grains and their flours I: physicochemical, functional and chapati-making properties of flours. Food Chem. 2007;101:938–946. doi: 10.1016/j.foodchem.2006.02.040. [DOI] [Google Scholar]

- Sanz T, Salvador A. Rheology of batters used in frying. In: Sumnu SG, Sahin S, editors. Advances in deep-fat frying of foods. Boca Raton: CRC Press; 2008. pp. 216–230. [Google Scholar]

- Serna-Saldivar SO. Cereal grains: laboratory reference and procedures manual. Boca Raton: CRC Press; 2012. [Google Scholar]

- Singh N, Singh S, Shevkani K. Maize: composition, bioactive constituents, and unleavened bread. In: Preedy VR, Watson RR, Patel VB, editors. Flour and breads and their fortification in health and disease prevention. London: Academic Press; 2011. pp. 89–100. [Google Scholar]

- Varela P, Ares G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Res Int. 2012;48:893–908. doi: 10.1016/j.foodres.2012.06.037. [DOI] [Google Scholar]

- Zaritzky N. Frozen storage. In: Evans JA, editor. Frozen food science and technology. Oxford: Blackwell Publishing Ltd; 2008. pp. 224–247. [Google Scholar]

- Zaritzky N. Physical-chemical principles in freezing. In: Sun Da-Wen., editor. Handbook of Frozen food processing and packaging. 2. Boca Raton: CRC Press; 2012. pp. 19–20. [Google Scholar]

- Zeppa G, Bertolino M, Rolle L. Quantitative descriptive analysis of Italian polenta produced with different corn cultivars. J Sci Food Agric. 2012;92:412–417. doi: 10.1002/jsfa.4593. [DOI] [PubMed] [Google Scholar]