Abstract

Gluten-free muffins with squash seed flour (SSF) were developed for contribute to reduce nutritional deficiencies and improving the health of the celiac population. Physicochemical and sensory properties of muffins were evaluated. SSF was incorporated at two levels (10 and 20% w/w) in commercial gluten-free premix (control). Incorporation of SSF increased total dietary fiber content, protein and unsaturated fatty acids. The addition of SSF at 10% resulted in a muffin that did not differ significantly from the control muffin; and also that formulations with SSF at 20% caused an increase in the browning index. Browning was favored by the increase of SSF with higher levels of fiber content. Incorporation of SSF at 20% had a significant effect on the textural parameters (firmness and chewiness) of the muffin. Also, both formulations containing SSF showed a higher overall acceptability, particularly muffins with 20% of SSF that rendered the highest scores for sponginess, texture, taste and colour.

Keywords: Gluten-free, Muffins, Squash seed flour, Dietary fiber, Bake

Introduction

In recent years there has been an increasing demand of gluten-free foods as about 1% of the world population is suffering from celiac disease (CD) (Shevkani and Singh 2014; Singh et al. 2016). CD is an inflammatory disease of the small intestine triggered by gluten proteins from cereals, particularly wheat, barley and rye. Cereal proteins comprise up to 80% of gluten proteins which play an important role in the baking industry (Drabińska et al. 2016). Gluten is composed of two main protein fractions: gliadins, which contribute essentially to the viscosity of the batter, and glutenins, which are responsible for batter elasticity (Wieser 2007). The only known treatment for CD patients is strict lifelong gluten-free diet (Farrell and Kelly 2002; Fasano and Catassi 2001). Most of the gluten-free products are generally made from flours that are deficient in dietary fiber (DF) (Thompson et al. 2005; Majzoobi et al. 2016). Fiber supplements do not have the same health benefits as naturally occurring high-fiber foods. Several studies suggested that people should consume more natural fiber which is found in whole grains, seeds, fruits and vegetables (Parisi et al. 2002; Flint et al. 2009; Brownlee 2011). Reportedly, DF has been known to improve and maintain human health. According to Meghwal and Kadeppagari (2016) there is fair evidence that DF from whole foods lowers blood pressure, improves serum lipids and reduces inflammation. Another study reported a range of cardiovascular benefits associated with DF (Flint et al. 2009). Nevertheless, DF intake is commonly lower than recommended (Rubel et al. 2014).

Muffins are widely-consumed sweet, spongy breakfast or evening snacks prepared traditionally from wheat flour, sugar, oil/fat, milk and eggs, which means that people having CD cannot consume them (Ciesarová et al. 2016). However, gluten-free muffins are of interest in present time not only for people who have CD, also for people who are interested in gluten-free products (Singh et al. 2015). Squash (Cucurbita maxima) seeds are gluten-free and can be used by those with CD. Many of the health benefits of squash seeds have been attributed to the following factors: large amounts of lipids of the type of polyunsaturated and monounsaturated fatty acids, α-galactosides with prebiotic activity, proteins with well-balanced amino acids and high biological value, phenolic compounds, and high dietary fiber content (Stevenson et al. 2007; Habib et al. 2015; Palacio et al. 2014; Srbinoska et al. 2012; Alfawaz 2004). Squash seed flour (SSF) seems to be a potential source of natural and functional ingredients related to health-promoting and/or CD prevention and can be used for enriching fiber gluten-free muffins. There is no available published data on muffin formulation containing SSF blended with commercial gluten-free flour. So, the objective of the present study was to develop a gluten-free muffin containing various levels of SSF (0, 10 and 20%). Because the addition of fibers may cause a significant effect on the final muffin quality, the physicochemical and sensory properties were also evaluated and compared with those obtained using commercial gluten-free flours.

Materials and methods

Materials

Squash seeds (Cucurbita maxima) were purchased from “For Good” in a local gluten-free market (Tandil, Argentina), sealed and stored in polyethylene bags until used. The SSF was obtained from the milling of squash seeds to a fine powder in a cereal mill (Mod. TDMC, TecnoDalvo, Argentina) and sieved through a 32 mesh sieve (500 μm). The resulting flour showed the following characteristics: fats 40.16%; proteins 28.72%; total dietary fiber (TDF) 25.69%; ashes 3.63%; and carbohydrates 1.80%. A ready-to-bake dry chocolate gluten-free premix (GFP) (Kapac, Argentina) was used as control. The ready-to-bake dry GFP ingredients were: powdered sugar, cornstarch, rice flour, whole milk powder, cocoa powder, whole egg powder, whipping agent (INS 471, INS 477, milk proteins, glucose solids), and salt. Leavening agents: INS 500ii INS 541i. Thickener: INS 412. Flavoring: vanillin. Other ingredients used were vanilla essence (Castillo, Argentina) and water, both at the same volume for the three muffin formulations (1 and 50 ml, respectively).

Batter formulation and baking procedure

Three muffin formulations were prepared replacing GFP with 0, 10 and 20% of SSF, respectively, 50 mL of water and 1 mL of vanilla essence gluten-free. The sample without SSF was called control (C). Two samples with 10 and 20% of SSF, respectively, were called SSF-10 and SSF-20. The choice of these levels was based on the proximate composition of SSF and on the most common values used in other studies of fiber enriched baked products (Costantini et al. 2014; Bialek et al. 2015). Ingredients were individually weighed using electronic scale (Model V-350, ACCULAB, USA).

For the development of the muffins, the dry ingredients and the specified amount of water (50 mL) were placed into the mixer of a bread maker machine (HP4030E, ATMA, China) using the program “batter” during 10 min in order to standardize the mixing procedure for all formulations. Then, approximately 12 g of the resulting preparation were placed into individual paper cups. Muffins were baked at 190 °C for 10 min in a convection electric oven (DELI-4, Moretti, Argentina). Finally, muffins were cooled at room temperature for 1 h and packed individually in heat-sealed food grade plastic bags until used. Muffin parameters were assessed at 20 °C 3-h after baking.

Proximate composition

Moisture, protein, total fat, and ash content of muffin samples were done according to AACC (Methods: 44-19, Kjeldahl, 30-25.01, 08-01, 2000). Muffins were defatted with hexane and dried for analysis of and TDF. Soluble, insoluble and TDF was determined by commercial kit following AOAC method 985.29 (2000). Digestible carbohydrate content was obtained by difference method. Results were expressed as g/100 g of product (fresh basis). Calorie contents were also calculated using the following specific energy factors: 9 for fats, 2 for TDF, and 4 for carbohydrates and proteins, respectively (AAC 2004) and changed to kJ.

Muffin quality evaluation

The quality of the muffins obtained for each formulation was evaluated by determining parameters related to volume, moisture, crumb structure, alveoli, texture and colour:

Specific volume Specific volume (Vs) was determined as a ratio of volume and weight (AACC 2000). Four muffins of each formula were analyzed.

Moisture content Moisture content of the muffin crumb was determined by oven drying for 2 h at 135 °C. For each measurement, approximately 3 ± 0.001 g of crumb were taken from a central slice of the piece. Four muffins of each formula were analyzed.

Crumb structure Two central and vertical slices (12 mm thick) were cut from each muffin and placed in a light-box. Colour images of slices were acquired using a Nikon D3100 digital camera (35 mm, 1/8, f/5, ISO 100), with a resolution of 300 pixels per inch. A square field of view of 40 × 40 mm2 of the slice was considered for the structure analysis. The image was converted to 8-bits in grey scale (ranging from 0 to 255) and then was binarized (converted from gray-level to black and white) using the algorithm Isodata (ImageJ 1.47 v software, National Institute of Health, Bethesda, MD, USA). Black dots represent alveoli. Image imperfections were considered with an alveolar threshold of 0.005 cm2 (Salinas et al. 2015). The numbers of cell per area (N) (cells/mm2), mean cell area (AM) (mm2) and the void fraction or total area occupied by alveoli (AT) (%) were calculated.

Crumb texture Texture profile analysis (TPA) of muffin slices was performed using a texture analyzer INSTRON (Model 3343, USA) equipped with a 50 N load cell. From the middle part of each muffin two slices 2 cm high were obtained. Slices were subjected to a double compression cycle (deformation: 40%, crosshead speed: 0.5 mm/s) with a cylindrical probe (diameter: 25 mm). The parameters determined were firmness, cohesiveness, springiness and chewiness. Eight measurements were performed for each formulation sample (4 muffins × 2 slices).

Crumb colour Colour measurements were performed on the crumb using a tri-stimulus colour analyzer (Chroma Meter CR-400, Konica Minolta, Japan). Ten measurements per formula were analyzed. Reflected colour was measured at 10º-observer angle with D65 illuminant. Values of L*, a* and b* were measured and used to calculate the browning index (BI) parameter (Buera et al. 1985) with the following equations:

| 1 |

| 2 |

Sensory evaluation

Finally, muffins prepared from C, SSF-10 and SSF-20 formulations were subjected to sensory evaluation by an untrained panel of twenty celiac persons (12 females and 8 males with ages ranging from 16 to 74 years). Three muffins (one of each formulation, coded with three digits and presented in random order) were served to each panelist accompanied with water to cleanse their palates between sample tasting. Panelists were asked to evaluate attributes as crumb colour, taste, sponginess (defined as porosity), crumb texture and general acceptability. Also, they were asked about the possibility of buying the product or not. They were asked to score each attribute on a 9-point hedonic scale where one is Dislike Extremely and nine is Like Extremely (Watts et al. 1989). Friedman Test (paired data) was used to analyze sensory results (InfoStat Software).

Statistical analysis

Results were expressed as the mean ± standard deviation (SD) for each parameter. Differences were tested by one-way analysis of variance (ANOVA) followed by Tukey test to determine significant differences (p < 0.05) using Infostat version 2011. Different letters were used to label values with statistically significant differences among them.

Results and discussion

Proximate composition of muffins

The proximate composition of C, SSF-10 and SSF-20 is shown in Table 1. The addition of SSF to an all-purpose ready-to-bake dry premix in muffin formulation resulted in nutritional differences of the final products obtained. The ash contents of all the samples did not differ significantly (p < 0.05). Also the results showed that both SSF-10 and SSF-20 formulations presented significantly higher fat, protein and TDF contents as compared to C sample (p < 0.05). These increased values in muffins formulated with SSF occurred concomitantly with a decrease in assimilable carbohydrates compared to C (p < 0.05), giving rise to products with a higher protein content and a lipid fraction enriched with polyunsaturated and monounsaturated fatty acids (Stevenson et al. 2007; Habib et al. 2015). In addition, the observed increase in TDF in both formulations containing SSF compared to C, allows these foods to be included in the label the attributed “High in dietary fiber,” according to the current national legislation (for this claim the Argentinean Alimentarius Codex establishes that a solid food must contain a minimal of 6 g of dietary fiber per 100 g) (AAC 2004). The higher content of TDF in muffins formulated with SSF is mainly due to the higher proportion of insoluble fiber. On the other hand, in a previous study we have demonstrated that α-galactosides extracted from Cucurbita maxima seeds exhibited a positive in vitro prebiotic activity using L. paracasei as a probiotic microorganism (Palacio et al. 2014). From the above, it is clear that muffins made with SSF, in addition to providing compounds of α-galactoside type (soluble fiber) with prebiotic activity, have improved the nutritional profile with respect to the product obtained with the ready-to-bake premix (control), while maintaining the characteristic of being free from gluten-forming proteins.

Table 1.

Proximate composition (g/100 g dry weight) and energetic value of gluten-free muffins

| Parameter (g/100 g dry weight) | C | SSF-10 | SSF-20 |

|---|---|---|---|

| Ash | 3.44 ± 0.28 a | 3.60 ± 0.02 a | 3.70 ± 0.04 a |

| Fat | 3.70 ± 0.07 a | 8.62 ± 0.26 b | 13.68 ± 0.16 c |

| Total dietary fibre | 0 a | 9.04 ± 0.45 b | 11.11 ± 0.55 c |

| Soluble | 0 a | 2.92 ± 0.14 b | 2.89 ± 0.14 b |

| Insoluble | 0 a | 6.12 ± 0.37 b | 8.22 ± 0.41 c |

| Protein | 5.45 ± 0.14 a | 7.94 ± 0.20 b | 10.76 ± 0.04 c |

| Carbohydratesa | 87.41 ± 0.07 a | 70.80 ± 0.08 b | 60.75 ± 0.15 c |

| K caloriesb | 161 | 164 | 172 |

| kJb | 674 | 686 | 720 |

Mean ± SD of triplicate analysis. Different letters in the same file indicate significant differences between means (p < 0.05)

SSF squash seed flour, C control, SSF-10 (10 g SSF/100 g gluten-free premix (GFP)), SSF-20 (20 g SSF/100 g GFP)

aCalculated by difference method

bValues of 40 g of edible portion

In agreement with our results, Majzoobi et al. (2016) found that the replacement of gluten-free flour with carrot pomace poder at various levels (10, 20 and 30%) and two particle size (210 and 500 μm) increased fiber, ash and protein contents when compared to control samples. Other authors (Gularte et al. 2012) reported the same results in their studies, in which rice flour was substituted with different legumes (chickpea, pea, lentil and bean) on the development of gluten-free cake products.

Quality evaluation of muffins

Technological quality of muffins was evaluated by determining the Vs, crumb colour, crumb structure, and crumb properties such as moisture, alveoli and texture.

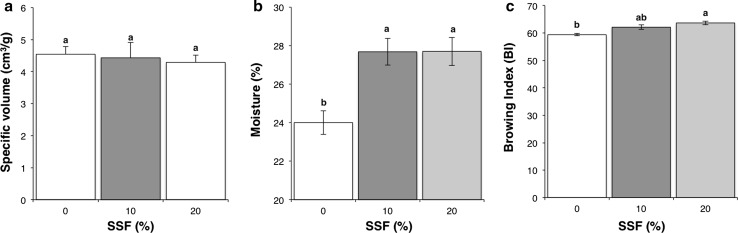

The Vs value represents the relationship between the volume and weight of the product, parameter generally recognized as useful for the evaluation of bread and bakery products (Capriles et al. 2016). Higher volumes exert positive economic effects for bakery product because products with higher volume often attract consumers. Final volume depends on batter expansion during baking procedure and on the ability of the matrix structure to retain gas. In this study, according to the Tukey test no statistical differences of Vs values for the three-sample muffin were observed (p < 0.05) (Fig. 1a). It can be thus concluded that the substitution of the premix by SSF up to a 20% does not alter the rheological properties of the muffins since it allows a level of expansion and gas retention comparable to that of the control formulation.

Fig. 1.

Parameter of muffin quality: a specific volume, b crumb moisture, c crumb browning index. Different letters in the same graphics indicate significant differences (p < 0.05)

The final crumb moisture content of the muffins is related to the water absorption during batter preparation and the water loss during baking procedure. In fact, it has been suggested that crumb morphology strongly affects the rate of water transport (Roca et al. 2006). As shown in Table 2, the control sample showed the highest cell/total area ratio. This probably sped up moisture migration and increased loss during baking. Smaller pore size is expected to be involved in slowing down the moisture migration on SSF-20 muffin with respect to C. The addition of SSF to muffin formulations increased the moisture content of samples. The differences in moisture content between C and the samples containing SSF, might also be due to the high fiber content (Uthumporn et al. 2014). Therefore, the C muffin crumb was the driest one and the addition of SSF caused a significant increase in crumb moisture (p < 0.05) (Fig. 1b).

Table 2.

Effect of squash seed flour addition (0, 10 and 20 g/100 g of ready-to-bake dry gluten-free premix) on the muffin crumb

| Samples | N (cells/cm2) | AM (mm2) | AT (%) |

|---|---|---|---|

| C | 26.4 b | 149 c | 66 b |

| SSF-10 | 24.2 ab | 136 b | 60 ab |

| SSF-20 | 22.8 a | 127 a | 57 a |

GFP gluten-free premix, SSF squash seed flour, C Control, SSF-10 (10 g SSF/100 g GFP), SSF-20 (20 g SSF/100 g GFP), N numbers of cells per area, AM mean cell area, AT void fraction

Different letters in the same column indicate significant differences between means (p < 0.05)

Colour of the muffin crumb is the most important parameter taken into account by the consumers when purchasing the product. The crumb colour depends mainly on the type of flour, the quality and quantity of the ingredients used, and the temperature and time of baking. The BI indicates the level of brown colour and was reported as an important parameter of quality related to Maillard reactions (Saricoban and Yilmaz 2010). The extent of browning also determines the flavor of the final product (Ureta et al. 2014). Figure 1c shows the BI obtained for all the formulations baked for the same time and at the same temperature. Since these variables were the same for all formulations, the results allow to conclude that the addition of SSF at 10% resulted in a muffin that did not differ significantly from the control muffin; and also that formulations with SSF at 20% caused an increase in the BI compared to the control formulation (p < 0.05). Browning was favored by the increase of SSF with higher levels of fiber content. This increase may be due to the pigments from the SSF that influenced the colour of the crumb. According to Salinas et al. (2015), the BI is favored by the presence of prebiotics on bakery products. Similarly, Frutos et al. (2008) also reported that the increase of over 12% of artichoke fiber caused darker bread colour.

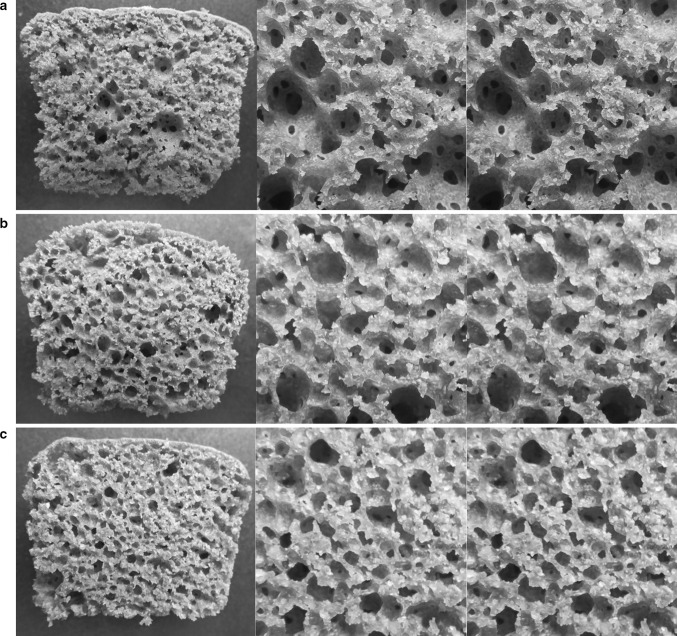

Images of the structure of the muffins and respective crumb centers of all formulations can be observed in Fig. 2. Values of the structure parameters (number of alveoli per area, mean alveolus area and percentage of total air trapped) of muffin crumb for C, SSF-10 and SSF-20 formulations are shown on Table 1. Anova results showed that muffin enrichment with SSF had a significant effect on the structure of the crumbs. The addition of 20% of SSF per 100 g of mix resulted in the crumb with the smallest mean cell area and cell density with significant differences compared to C (p < 0.05). Considering the sample with 10 g of SSF per 100 g of total mix, the crumb obtained had a significantly smaller mean cell area accompanied by non-significant differences in cell density, compared to the C muffin (p < 0.05). Finally, the addition of 20 g of SSF caused a significant decrease on the cell/total area ratio (void fraction) compared to the C sample.

Fig. 2.

Muffin crumb structure images: a control, b SSF-10, c SSF-20

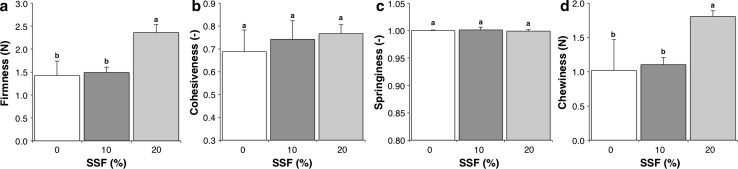

TPA consists of the double compression of a food sample imitating the action of the jaw. Figure 3 represents the TPA of crumb of the three experimental samples. Firmness was defined as the highest force required to compress the muffin crumb under a constant deformation. Another textural parameter considered was cohesiveness that quantifies the internal resistance of the muffin structure under some compression. A product with high cohesion is more tolerant to handling and packaging, and thus it will be presented to the consumers in its expected state (Singh et al. 2016). Springiness is also important in baked products, a measure that is defined as the elasticity of the muffins, calculated by measuring the extent of recovery between the first and second compression. This textural parameter is a desirable muffin property associated with an elastic and fresh aerated product (Shevkani and Singh 2014). Anova results showed that the addition of SSF at 20% had a significant effect on the firmness and chewiness textural parameters of the muffin crumb (p < 0.05). Beginning with firmness, we observed an increase in comparison to C sample. Secondly, the C muffin crumb had no significant differences with either SSF muffin formulation on values corresponding to cohesiveness and springiness, respectively. Finally, a significant increase on chewiness was observed for SSF-20 muffin (compared to C). These results showed the same trend as firmness:chewiness values increased at increasing fiber concentrations, with SSF-20% having a stronger effect than SSF-10%. It is worth to remind that chewiness is directly proportional to firmness. Possibly, the type and concentration of fiber used to produce the gluten-free product as well as its effects on moisture retention in the muffin might influence the specific effects observed on the texture of the products, a fact which requires further investigation.

Fig. 3.

Textural parameter of muffin crumb: a firmness, b cohesiveness, c springiness, d chewiness. Different letters in the same graphics indicate significant differences (p < 0.05)

The effect of the addition of different flours to gluten-free products on crumb textural properties has been dealt with in several studies. In agreement with our results, Shih et al. (2006) reported that the firmness and chewiness of the gluten-free cakes improved with the addition of up to 40% of sweet potato flour. However, Singh et al. (2016) develop a gluten-free rice muffin with black carrot pomace dietary fiber concentrate (three levels) and xanthan gum (0.5%) and observed a reduction in muffin firmness with the addition of 3, 6 and 9% of black carrot pomace fiber. Wang et al. (2002) also found an increase in breadcrumb chewiness with inulin addition and no significant effect on cohesiveness and springiness (in agreement with our results).

Sensory evaluation of muffins

Sensory evaluation results of muffins are shown in Table 3. The colour, taste and texture are important parameters for the acceptability of food products by consumers (Kaur et al. 2012). SSF-addition significantly increased the colour, sponginess, taste, texture and overall acceptability of gluten-free muffins. Colour scores of muffins containing 0, 10 and 20% of SSF ranged from 7 to 9; while sponginess, taste, texture and overall acceptability scores ranged from 5 to 9. Results analyzed by Friedman Test showed that celiac consumers indicated that the muffins prepared with 20% of SSF had the higher value scores with a higher overall acceptability when compared to C muffin. Panelists scores agree with the instrumental analysis that showed SSF-addition improved muffin quality by yielding better moisture content, browning index, firmness and chewiness; all of which enhance the sensory characteristics of gluten-free muffins containing SSF.

Table 3.

Sensory characteristics (maximum score of 9) of gluten-free muffin

| Samples | Colour | Friedman test | Sponginess | Friedman test | Taste | Friedman test | Texture | Friedman test | Overall acceptability | Friedman test |

|---|---|---|---|---|---|---|---|---|---|---|

| C | 9 (7–9) | 1.80 a | 7 (5–9) | 1.28 a | 7 (5–9) | 1.25 a | 7 (5–8) | 1.10 a | 7 (5–9) | 1.18 a |

| SF-10 | 9 (7–9) | 2.03 ab | 8 (7–9) | 2.18 b | 9 (7–9) | 2.33 b | 8 (7–9) | 2.33 b | 9 (8–9) | 2.43 b |

| SF-20 | 9 (7–9) | 2.18 b | 9 (8–9) | 2.55 b | 9 (8–9) | 2.43 b | 9 (8–9) | 2.58 b | 9 (9–9) | 2.40 b |

| p value | 0.0182 | < 0.0001 | < 0.0001 | < 0.0001 | < 0.0001 |

C control, SF-10 (10 g squash flour/100 g gluten-free premix (GFP)), SF-20 (20 g squash flour/100 g GFP)

Different letters in the same column indicate significant differences between means (minimum–maximum value) analyzed by Friedman test (p < 0.05)

Conclusion

In this study, the development of a gluten-free muffin with compounds of α-galactoside type (soluble fiber) with a functional and acceptable profile was obtained. Muffins enriched with SSF exhibited higher TDF, protein and unsaturated fat contents when compared to muffins prepared with GFP. Also, both formulations containing SSF showed higher overall acceptability, particularly muffins with 20% of SSF that rendered the highest scores for sponginess, texture, taste and colour. The enrichment with SSF can be used as a strategy to develop not only for celiac population, but also for other consumers.

Acknowledgements

Authors would like to thanks CONICET for the graduate fellowship granted to María I. Palacio, Celibrand (healthy food store) for the collaboration on the elaboration of gluten-free muffins for the sensory evaluation and to the Department of Food Technology-FCV (UNCPBA) for the collaboration on the use of the texturometer.

References

- AAC (2004) Argentinean Alimentarius Codex. Chapther V. (Art 235 fifth Joint Res. Nº 40 and 298) http://www.anmat.gov.ar/alimentos/codigoa/Capitulo_V.pdf. Accessed 24 Aug 2016

- Alfawaz MA. Chemical composition and oil characteristics of pumpkin (Cucurbita maxima) seed kernels. Food Sci Agric Res Center. 2004;129:5–18. [Google Scholar]

- Bialek M, Rutkowska J, Adamska A, Bajdalow E. Partial replacement of wheat flour with pumpkin seed flour in muffins offered to children. CyTA-J Food. 2015;14(3):391–398. [Google Scholar]

- Brownlee IA. The physiological roles of dietary fibre. Food Hydrocolloids. 2011;25(2):238–250. doi: 10.1016/j.foodhyd.2009.11.013. [DOI] [Google Scholar]

- Buera MP, Retriella C, Lozano RD. Definition of colour in the non-enzymatic browning. Die Farbe. 1985;33:316–326. [Google Scholar]

- Capriles VD, dos Santos FG, Aréas JAG. Gluten-free breadmaking: improving nutritional and bioactive compounds. J Cereal Sci. 2016;67:83–91. doi: 10.1016/j.jcs.2015.08.005. [DOI] [Google Scholar]

- Ciesarová Z, Basil E, Kukurová K, Marková L, Zieliński H, Wronkowska M. Gluten-free muffins based on fermented and unfermented buckwheat flour-content of selected elements. J Food Nutr Res. 2016;55(2):108–113. [Google Scholar]

- Costantini L, Lukšič L, Molinari R, Kreft I, Bonafaccia G, Manzi L, Merendino N. Development of gluten-free bread using tartary buckwheat and chia flour rich in flavonoids and omega-3 fatty acids as ingredients. Food Chem. 2014;165:232–240. doi: 10.1016/j.foodchem.2014.05.095. [DOI] [PubMed] [Google Scholar]

- Drabińska N, Zieliński H, Krupa-Kozak U. Technological benefits of inulin-type fructans application in gluten-free products—a review. Food Sci Technol. 2016;56:149–157. doi: 10.1016/j.tifs.2016.08.015. [DOI] [Google Scholar]

- Farrell RJ, Kelly CP. Celiac sprue. New Engl J Med. 2002;346(3):180–188. doi: 10.1056/NEJMra010852. [DOI] [PubMed] [Google Scholar]

- Fasano A, Catassi C. Current approaches to diagnosis and treatment of celiac disease: an evolving spectrum. Gastroenterology. 2001;120(3):636–651. doi: 10.1053/gast.2001.22123. [DOI] [PubMed] [Google Scholar]

- Flint AJ, Hu FB, Glynn RJ, Jensen MK, Franz M, Sampson L, Rimm EB. Whole grains and incident hypertension in man. Am J Clin Nutr. 2009;90(3):493–498. doi: 10.3945/ajcn.2009.27460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Frutos MJ, Guilabert-Antón L, Tomás-Bellido A, Hernández-Herrero JA. Effect of artichoke (Cynara scolymus L.) fiber on textural and sensory qualities of wheat bread. Food Sci Technol Int. 2008;14(5):49–55. doi: 10.1177/1082013208094582. [DOI] [Google Scholar]

- Gularte MA, Gómez M, Rosell CM. Impact of legume flours on quality and in vitro digestibility of starch and protein from gluten-free cakes. Food Bioprocess Technol. 2012;5:3142–3150. doi: 10.1007/s11947-011-0642-3. [DOI] [Google Scholar]

- Habib A, Biswas S, Siddique AH, Manirujjaman M, Uddin B, et al. Nutritional and lipid composition analysis of pumpkin seed (Cucurbita maxima Linn.) J Nutr Food Sci. 2015;5(4):374. [Google Scholar]

- Kaur G, Sharma S, Nagi HPS, Dar BN. Functional properties of pasta enriched with variable cereal brans. J Food Sci Technol. 2012;49(4):67–474. doi: 10.1007/s13197-011-0294-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Majzoobi M, Poor ZV, Jamalian J, Farahnaky A. Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace poder. Int J Food Sci Technol. 2016;51(6):1369–1377. doi: 10.1111/ijfs.13104. [DOI] [Google Scholar]

- Meghwal M, Kadeppagari RK (2016) Dietary fibers and their role as functional food for human health: food fibers and human health. In: examining the development, regulation, and consumption of functional foods, pp 29–44

- Palacio MI, Etcheverría AI, Manrique GD. Fermentation by Lactobacillus paracasei of galactooligosaccharides and low-molecular weight carbohydrates extracted from Squash (Cucurbita maxima) and lupin (Lupinus albus) seeds. J Microbiol Biotechnol Food Sci. 2014;3(4):329–332. [Google Scholar]

- Parisi GC, Zilli M, Miani MP, Carrara M, Bottona E, Verdianelli G, Leandro G, et al. High-fiber diet supplementation in patients with irritable bowel syndrome (IBS): a multicenter, randomized, open trial comparison between wheat bran diet and partially hydrolyzed guar gum (PHGG) Dig Dis Sci. 2002;47(8):1697–1704. doi: 10.1023/A:1016419906546. [DOI] [PubMed] [Google Scholar]

- Roca E, Guillard V, Guilbert S, Gontard N. Moisture migration in a cereal composite food at high water activity: effects of initial porosity and fat content. J Cereal Sci. 2006;43(2):144–151. doi: 10.1016/j.jcs.2005.08.008. [DOI] [Google Scholar]

- Rubel IA, Pérez EE, Manrique GD, Genovese DB. Fibre enrichment of wheat bread with Jerusalem artichoke inulin: effect on dough rheology and bread quality. Food Struct. 2014;3:21–29. doi: 10.1016/j.foostr.2014.11.001. [DOI] [Google Scholar]

- Salinas MV, Zuleta A, Ronayne P, Puppo MC. Wheat bread enriched with organic calcium salts and inulin. A bread quality study. J Food Sci Technol. 2015;53(1):491–500. doi: 10.1007/s13197-015-2008-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saricoban C, Yilmaz MT. Modelling the effects of processing factors on the changes in colour parameters of cooked meatballs using response surface methodology. World Appl Sci J. 2010;9(1):14–22. [Google Scholar]

- Shevkani K, Singh N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol. 2014;49(10):2237–2244. doi: 10.1111/ijfs.12537. [DOI] [Google Scholar]

- Shih FF, Truing VD, Daigle KW. Physicochemical properties of gluten-free pancakes from rice and sweet potato flours. J Food Qual. 2006;29(1):97–107. doi: 10.1111/j.1745-4557.2005.00059.x. [DOI] [Google Scholar]

- Singh JP, Kaur A, Shevkani K, Singh N. Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int J Food Sci Technol. 2015;50(5):1190–1197. doi: 10.1111/ijfs.12764. [DOI] [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53(2):1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Srbinoska M, Hrabovski N, Rafajlovska V, Sinadinović-Fišer S. Characterization of the seed and seed extracts of the pumpkins Cucurbita maxima D. and Cucurbita pepo L. from Macedonia. J Chem Chem Eng. 2012;31(1):65–78. [Google Scholar]

- Stevenson DG, Eller FJ, Wang L, Jane JL, Wang T, Inglett GE. Oil and tocopherol content and composition of pumpkin seed oil in 12 cultivars. J Agric Food Chem. 2007;55(10):4005–4013. doi: 10.1021/jf0706979. [DOI] [PubMed] [Google Scholar]

- Thompson T, Dennis M, Higgins LA, Lee AR, Sharrett MK. Gluten-free diet survey: are Americans with coeliac disease consuming recommended amount of fibre, iron, calcium and grain foods? J Hum Nutr Diet. 2005;18:163–169. doi: 10.1111/j.1365-277X.2005.00607.x. [DOI] [PubMed] [Google Scholar]

- Ureta MM, Olivera DF, Salvadori VO. Baking of muffins: kinetics of crust color development and optimal baking time. Food Bioprocess Technol. 2014;7(11):3208–3216. doi: 10.1007/s11947-014-1292-z. [DOI] [Google Scholar]

- Uthumporn U, Woo WL, Tajul AY, Fazilah A. Physico-chemical and nutritional evaluation of cookies with different levels of eggplant flour substitution. CyTA-J Food. 2014;13(2):220–226. doi: 10.1080/19476337.2014.942700. [DOI] [Google Scholar]

- Wang J, Rosell CM, Benedito de Barber C. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002;79(2):221–226. doi: 10.1016/S0308-8146(02)00135-8. [DOI] [Google Scholar]

- Watts BM, Ylimaki GL, Jeffery LE, Elias LG. Basic sensory methods for food evaluation. Ottawa: International Development Research Centre (IDRC); 1989. pp. 150–185. [Google Scholar]

- Wieser H. Chemistry of gluten proteins. Food Microbiol. 2007;24(2):115–119. doi: 10.1016/j.fm.2006.07.004. [DOI] [PubMed] [Google Scholar]