Abstract

Celiac disease is an autoimmune disorder caused by a permanent intolerance of genetically susceptible persons to gluten proteins and intake of gluten-free diets throughout their life is the only treatment way. Therefore, studies dealing with the production and improvement of gluten-free food products, especially bakery products are of great importance. The aim of this study was to investigate the effect of adding pomegranate seed powder (0–50%) and transglutaminase enzyme (0–1.2%) on physicochemical, sensory and textural properties of gluten-free cake made from rice flour. The results showed that pomegranate seed powder and transglutaminase had positive effects on fiber and ash contents, and porosity; whilst, the incorporation reduced the weight loss, volume and specific volume. Optimization process was performed and optimum gluten-free formulation contained 25.75% pomegranate seed powder and 0.97% transglutaminase. The optimized gluten-free cake showed higher total antioxidant activity, ash, fiber, protein and moisture contents and lower peroxide value, volume index and porosity compared to the control one. The porosity decrement was confirmed in the optimized cake by scanning electron microscopy images.

Keywords: Celiac, Transglutaminase, Functional, Dietary fiber

Introduction

Celiac is a chronic inflammation of the small intestine triggered by increasing the sensitivity to gluten proteins founded in wheat, oat, and barley (Ghergherehchi et al. 2010). It has a wide range of clinical symptoms from asymptomatic individuals to a typical maladaptive syndrome with chronic diarrhea (Bafandeh et al. 2013). Celiac is the most common food intolerance disorder with increasing prevalence all over the world. Therefore, the use of gluten-free diet has been introduced as an effective treatment for celiac and other gluten-related disorders (Gobbetti et al. 2017). According to the Codex Alimentarius reports, the maximum amounts of gluten in natural gluten-free products and in wheat starch based products is 20 and 200 ppm, respectively (Susanna and Prabhasankar 2013). Replacing the gluten in gluten-free products is a major challenge for cereal technologists. The functionality of proteins in gluten-free flours can be modified in order to improve their baking properties through strengthening the protein network (Renzetti et al. 2008). Gluten-free cereals recommended for patients suffering from celiac disease are rice, corn, sorghum, and buckwheat. But, except for rice, they have negative effects on the quality of final products even at concentration levels of 10-20%. Rice flour has a sweet and desirable taste, white color, easy digestibility, and anti-allergenic properties. Rice flour has some unique properties such as low amounts of protein and sodium, lack of gliadin, and presence of easy digestible carbohydrates that make it an ideal diet for patients with celiac disease (Gujral et al. 2003). Transglutaminase enzyme has been successfully used in gluten-free products due to its ability to form protein cross-linking (Renzetti et al. 2008). Addition of fruit and vegetable by-products in gluten-free products is a way to increase the nutritional quality of these products due to their high contents of dietary fibers, vitamins, antioxidants, and proteins (Majzoobi et al. 2016). Dietary fibers are known as functional constitutes for humans due to their cholesterol reduction features and also protective activities against cardiovascular diseases, diabetes, and constipation. Fruit and vegetable wastes including tomato, carrot, and apple pomace have been successfully applied in production of wheat flour based bakery products, while their applications are still new and in their development stages in gluten-free products (Majzoobi et al. 2016). Pomegranate (Punica granatum), belonging to the Punicaceae family, is native to subtropical regions of Iran. According to the different literatures, various beneficial properties of pomegranate are related to different parts of the fruit. Pomegranate is a rich source of sodium, riboflavin, niacin, vitamin c, calcium, phosphorus, and also contains potent antioxidants such as polyphenolic compounds, tannins, anthocyanins, andellagic acid (Basiri et al. 2011). In recent years, pomegranate market has grown due to an increase in consumer awareness about its potential health promoting properties (Fischer et al. 2011). Pomegranate seed, a by-product of pomegranate process, allocate about 20% (w/w) of the whole fruit. Recent studies have shown that pomegranate seeds might be a potential source of antioxidants and nutrients. Furthermore, it has been suggested that food supplementation with pomegranate seeds may prevent DNA damage, reduce the risk of cancer, and also reduce the symptoms of menopause. The advantageous of pomegranate seeds are related to the presence of biologically active components especially polyphenols, which their antioxidant effects have been studied. In addition, significant amounts of compounds with polyphenolic structures were detected in pomegranate seeds (Jing et al. 2012). Therefore, the aim of the present study was to improve the nutritional value of gluten-free cakes using pomegranate seed powder (PSP) and transglutaminase enzyme (TGE).

Materials and methods

Materials

Rice flour was provided from Poodrineh Shomal Co. (Iran). Xanthan gum and microbial TGE were purchased from Rhodia Food Co. (France) and BDF Natural Ingredient Co. (Spain), respectively. Other materials used in this study were water, sugar, vegetable oil (Behshahr Industrial Co. Iran), baking powder (Afzoodaniha Co. Iran), fat-free dried milk (Parsian Sanat Shayan Co. Iran), and fresh eggs (Telavang Co. Iran). Pomegranates were purchased from a local market in Iran and then transferred to the laboratory. After washing and pressing, pomegranate seeds were collected and dried at ambient temperature (30 °C) for 2 days. In addition, the seeds were dried in an oven at the temperature of 50 °C for another 24 h to obtain a constant weight. Finally, they were grounded using an electrical mill (Perten Instruments, Sweden) and sieved by 100 mesh screen. The physicochemical properties of pomegranate powder and rice flour are shown in Table 1.

Table 1.

The physicochemical properties of pomegranate seed and rice flour

| Parameters | Pomegranate seed | Rice |

|---|---|---|

| pH | 5.85 | 6.32 |

| Moisture (%) | 3.95 | 5.10 |

| Protein (%) | 18.80 | 9.11 |

| Crude oil (%) | 19.20 | 1.25 |

| Total ash (%) | 1.70 | 0.70 |

| Crude fiber (%) | 20.00 | 4.07 |

| TTA (%) | 92.45 | 6.78 |

Methods

Cake making procedure

Gluten-free cakes were produced according to the method of Dhen et al. (2016). For this purpose, rice flour, PSP, xanthan gum, TGE, baking powder and dried milk powder were completely mixed together. Sugar and vegetable oil were completely mixed to form a cream-like color mixture. Then, fresh whipped eggs were added and the mixture was stirred for 5 min until complete mixing. Afterwards, water were added simultaneously to the later mixture and stirred at low speed for 3 min. The obtained dough was molded and divided into specified size and then baked in an oven for 40 min at 180 °C. The obtained gluten-free cakes were cooled in ambient temperature, packaged in polyethylene bags and then stored at room temperature until analyses.

Physical analyses

Specific volume of cake samples was measured according to the method of Yildiz and Dogan (2014) by dividing the volume of cake samples by the weight. Weight loss percentage of cakes was calculated according to the method of Sumnu et al. (2010). In order to examine the porosity of the crumb of cakes, several images were taken from three samples inside a black box by Canon digital camera (model SX60 HS, Japan) and stored as color form (24 bits). The obtained images were evaluated by the Image J software and gray level images were created through activation of the 8-bit part of the software. For converting gray level image to binary one, after improving the contrast of image, the image was segmented based on the Otsu algorithm followed by activation of the binary part of the software. Finally, the images were obtained as dark and light spots and the porosity parameter (total surface area to total image area ratio) was extracted from the binary images (Nouri et al. 2017).

Chemical analyses

Protein, ash and fat contents were measured in accordance with the AACC methods 46-12, 08-01, and 30-25, respectively (AACC 1999). Crude fiber content was determined according to the AOAC method 43/991 (AOAC 2000). DPPH radical scavenging activity was evaluated based on the method described by Brand-Williams et al. (1995). Mineral salts including iron, copper, zinc, manganese and calcium were measured using atomic absorption spectrometer (Analytic Jena; ContrAA300 Model, Germany) according to the Iranian National Standard number 9266. Peroxide value of the extracted oil was determined by titration method with sodium thiosulphate in accordance with AOCS methods cd-5-53.

Textural properties

Textural profile analysis (TPA) of the cake samples was evaluated for cohesiveness, gumminess, chewiness, and hardness according to the AACC method 74-09 by a texture analyzer (TA-XT-PLUS Texture Analyzer, Stable Micro System, UK). For scanning electron microscopy (SEM), the fresh cakes were cut into cubic sizes, frozen in liquid nitrogen and then dried under vacuum. Dried samples were coated with gold–palladium and then scanned by a Scanning Electron Microscopy apparatus (Philips XL30, Netherland). The outer and inner surfaces of the cakes were scanned at 100× magnification (Shyu and Sung 2010).

Sensory evaluation

Sensory analysis of samples was done by 10 well-trained panelists (ages 22–27) both male and female. All treatments were encoded randomly and evaluated for texture, hardness, flavor, Chewing ability, and overall acceptability according to the five-point hedonic scale; dislike extremely for score 1 and like extremely for score 5.

Shelf life of optimized cake

Staling of baked products is related to the migration of moisture from the crumb of the products to the crust (Tsatsaragkou et al. 2015). Therefore, the moisture content (AACC, 44-16) and Hardness (AACC, 74-09) of the optimized and control cakes were measured at 1, 7, and 14 days of storage. Also peroxide of samples evaluated during storage based on AOCS methods cd-5-53,

Statistical analysis

The statistical program used in this study to analyze the effect of two variables, PSP (0–50%) and TGE (0–1.2%) on the quality of treatments and finding optimized formulations was Central Composite Design via Minitab software version 16. The significant terms in the model were found by analysis of variance for each response. In addition, Lack of fit, (R2), adj-R2, CV and PRESS were calculated to check the model adequacy.

Results and discussion

Physical properties

Specific volume

Analysis of variance in Table 2, showed a significant negative interaction effects (P < 0.01) of PSP and TGE on the specific volume of cake samples. These variables affect specific volume via non-significant positive linear and quadratic effects. The results were in agreement with Yildiz and Dogan (2014), who used the mixture of potato starch and chestnut flour for making gluten-free cakes. They showed that the specific volume significantly decreased when the concentration of chestnut flour increased in the mixture. In another study, Nouri et al. (2017) stated that an addition of carrot pomace powder to low-fat donuts reduced their specific volume due to the presence of insoluble fibers in dough blend. Singh et al. (2016) developed gluten-free rice muffins and they reported that addition of black carrot fibers to the formulation reduced the specific volume of muffins due to the presence of black carrot fibers collapsing the carbon dioxide gas bubbles during baking. Therefore, the presence of PSP, a rich source of dietary fiber and TGE forming cross-link bindings between glutamine and lysine could prevent the expansion of gas cells, which consequently led to the reduction in specific volume.

Table 2.

Regression coefficients of the second-order polynomial equations for the physicochemical properties of cakes

| Sources | Ash (%) | Protein (%) | Fiber (%) | Weight loss (%) | Specific volume (ml g−1) | Porosity (%) |

|---|---|---|---|---|---|---|

| Model (P value) | 36.01**** | 6.92* | 124.38**** | 8.18** | 3.41ns | 5.11* |

| β0 | 74.22 | 10.59 | 2.92 | 7.92 | 0.85 | 23.3 |

| β1 | 0.02**** | − 0.0001** | 0.03**** | 0.11ns | 0.03ns | 0.001ns |

| β2 | 0.01**** | 0.31ns | 0.06ns | 16.42ns | 0.61ns | − 7.45ns |

| β1 β1 | − 2.86**** | − 6.11ns | 0.0006** | 0.001ns | 0.0003ns | − 0.002* |

| β2 β2 | 0.14ns | − 0.77* | − 0.0041ns | − 6.92** | 1.46ns | 2.08ns |

| β1 β2 | − 1.32ns | 0.02* | − 0.0012ns | − 0.28** | − 0.08** | 0.19** |

| Lack of fit (P value) | 5.60ns | 2.43ns | 14.23ns | 0.49ns | 28.49ns | 4.21ns |

| R2 | 96.26 | 83.18 | 98.89 | 85.38 | 75.88 | 78.51 |

| R2-adjust | 93.58 | 71.16 | 98.09 | 74.94 | 50.08 | 63.16 |

| CV (%) | 12.26 | 1.99 | 22.29 | 9.55 | 30.26 | 6.06 |

| PRESS | 0.04 | 0.46 | 0.82 | 17.83 | 6.77 | 23.51 |

ns not significant

β0 is the constant, β1 and β2 is the linear of PSP and TGE, β1,1 and β2,2 is the quadratic, and β1,2 is the interaction coefficients

*Significant at P < 0.05; **significant at P < 0.01; ***significant at P < 0.001; ****significant at P < 0.0001

Porosity

In general, porosity of crumb texture of baking products is affected by number and distribution of cavities in the crumb texture. Higher number cavities and gas cells as well as more uniform distribution cause the higher porosity of the final product. Table 2 indicated that incorporation levels of PSP and TGE significantly increased the porosity of cake samples (P < 0.01), while PSP had significant negative quadratic effects (P < 0.05). In accordance with the results of this study, Tsatsaragkou et al. (2015) showed that the porosity of the control cake was significantly higher than that of gluten-free ones containing different levels of resistant starch.

Weight loss

As it is shown in Table 2, higher levels of PSP and TGE had a non-significant positive effect on the weight loss. The quadratic effect of PSP was non-significant, but TGE had a significant negative quadratic effect (P < 0.01). The interaction effect between TGE and PSP on the weight loss of cake samples showed negative and significant effects (P < 0.01). The weight loss is due to the water evaporation during baking and it depends on the volume of the prepared cakes. In this case, increasing in the cakes’ volume caused an increase in the contact surface with air, which in turn leads to an increase in the water evaporation (Dhen et al. 2016). On the other hand, the weight loss decrement could be related to the decreased specific volume and also better cake texture due to the presence of TGE.

Chemical properties

Ash content

The analysis of ash content changes is presented in Table 2. The data showed significant positive linear effects of PSP and TGE on the ash content (P < 0.0001). Levent and Bilgiçli (2011) showed that adding lupine and buckwheat flours up to 2.02 and 1.98%, respectively, increased ash content of gluten-free cakes, which is in line with the results of the present study. The increased ash content of cakes could be explained by high contents of minerals such as potassium, phosphorus, magnesium, and calcium in pomegranate seed (Dadashi et al. 2013). Gularte et al. (2012a, b) evaluated the effect of legume flours (chickpea, peas, lentil, and bean) on starch and protein digestibility of gluten-free cakes. Their results similarly showed that the ash content increased by addition of legume flours.

Fiber content

The statistical analysis in Table 2 demonstrated that PSP had a significant positive linear (P < 0.0001) and quadratic (P < 0.01) effects on the fiber content of the cakes. But the TGE showed a non-significant effect on the fiber content of samples. Furthermore, the interaction between PSP and TGE affect this component in the non-meaningful negative form. The increased fiber content of gluten-free cakes could be explained by the presence of fibers in PSP. In this regard, Altindag et al. (2015) showed that crude fiber content of gluten-free cookies containing buckwheat-corn flour was higher than other formulations due to higher crude fiber content of buckwheat and corn than rice flour.

Protein

As shown in Table 2, PSP had a significant negative linear effect (P < 0.01) on the protein content of the samples. However, the linear effect of TGE was positive and non-significant. In addition, PSP and TGE showed non-significant and significant negative quadratic effects, respectively (P < 0.01). The interaction effect was also positive and significant (P < 0.05). In agreement with the results of the present research, Gularte et al. (2012a, b) investigated that the replacement of rice flour by fibers decreased the protein content of gluten-free cakes. Since the pomegranate seed is rich in fiber (Martinez et al. 2006), the partial replacement of PSP in the formulation, reduced the protein content of the product.

Textural properties

TPA results in Table 3, showed that PSP had a significant negative linear effect (P < 0.01) and a significant positive quadratic effect (P < 0.05) on the hardness of cakes. The interaction effect between the independent variables was positive and non-significant. In accordance with the results of this study, Yildiz and Dogan (2014) showed that chestnut flour and potato starch significantly decreased the hardness of gluten-free cakes. They also reported that the hardness of optimized gluten-free cake was less than that of control one. Negative effect of PSP on this characteristic could be related to its water binding capacity. A reverse relationship between volume and hardness of bakery foods has been shown in the previous studies. It is though that incorporating the PSP into formulation, negatively affected the quantity of air retained by dough thorough thickening of walls surrounding the gas cells, which consequently resulted in lower specific volume and higher crumb hardness (Nouri et al. 2017).

Table 3.

Regression coefficients of the second-order polynomial equations for the sensory and Textural properties cakes

| Sources | Chewiness (N mm) | Gumminess (N) | Cohesiveness | Hardness (N) | Overall acceptability | Chewing ability | Flavor | Texture |

|---|---|---|---|---|---|---|---|---|

| Model (P value) | 4.78* | 5.67* | 3.53ns | 5.09* | − 0.025ns | 0.006ns | − 0.03ns | 0.006ns |

| β0 | 0.55 | 0.59 | 0.59 | 1.02 | 6.44* | 6.12* | 4.31* | 4.89* |

| β1 | − .016** | − .019** | 0.005* | − .046** | 2.36 | 3.18 | 2.68 | 3.06 |

| β2 | 0.009ns | − 0.134ns | 0.185ns | − 0.458ns | 0.04* | − 0.01** | 0.04* | 0.02* |

| β1 β1 | 0.0003ns | 0.0004* | − 1.17* | 0.001* | 3.01ns | 0.93* | 2.35ns | 2.14ns |

| β2 β2 | − 0.29ns | − 0.17ns | 0.06ns | − 0.10ns | − 9.57* | 4.50ns | − 9.15* | − 8.31* |

| β1 β2 | 0.012ns | 0.012ns | − 0.003ns | 0.021ns | − 1.56* | − 0.24ns | − 1.05ns | − 1.85* |

| Lack of fit (P value) | 4.07ns | 2.99ns | 0.35ns | 2.01ns | 6.48ns | 2.21ns | 5.34ns | 0.58ns |

| R2 | 77.35 | 80.2 | 75.6 | 78.41 | 82.14 | 81.38 | 75.49 | 77.73 |

| R2-adjust | 61.17 | 66.06 | 51.31 | 62.99 | 69.38 | 68.09 | 57.98 | 61.83 |

| CV (%) | 43.79 | 45.15 | 8.89 | 63.09 | 13.37 | 8.99 | 13.82 | 12.98 |

| PRESS | 0.82 | 8.13 | 0.03 | 3.08 | 2.83 | 1.09 | 4.12 | 1.7 |

ns not significant

β0 is the constant, β1 and β2 is the linear of PSP and TGE, β1,1 and β2,2 is the quadratic, and β1,2 is the interaction coefficients

*Significant at P < 0.05; **significant at P < 0.01; ***significant at P < 0.001

Furthermore, Table 3 showed a significant positive linear effect (P < 0.05) and significant negative quadratic effect (P < 0.05) of PSP on the cohesiveness of cakes, while the interaction effect between the independent variables was negative and non-significant. Gularte et al. (2012a, b) showed that the cohesiveness of the gluten-free cakes increased soluble and insoluble fiber content increased. Yildiz and Dogan (2014) demonstrated that incorporation of different levels of TGE had different effects on the cohesiveness of samples based on the level of chestnut flour and potato starch.

On the other hand, the PSP had a significant negative linear effect (P < 0.01) and a significant positive quadratic effect (P < 0.05) on gumminess (Table 3). The TGE has also non-significant negative linear and quadratic effect. The interaction effect between PSP and TGE was not significant. The decreased gumminess could be related to the presence of TGE and consequently developed protein network, which acts as a barrier against leakage of starch and protein and finally lead to the lower gumminess of the product (Shokri et al. 2016).

Moreover, TPA results in Table 3 showed that the PSP had a significant negative effect (P < 0.01) and non-significant positive quadratic effect on the chewiness of gluten-free cakes. The TGE did not significantly affect the chewiness. There was also a non-significant interaction effect between PSP and TGE. In agreement with these results, Majzoobi et al. (2016) showed that the chewiness of gluten-free cakes improved with increasing levels of carrot pomace powder.

Sensory properties

The results of sensory analysis of treatments enriched with PSP are presented in Table 3. The PSP showed a significant positive linear effect (P < 0.05) on the texture of gluten-free cakes, while the linear effect of TGE was not significant. Both PSP and TGE had a significant negative quadratic effect (P < 0.05). The interaction effect between PSP and TGE was positive but not significant. Majzoobi et al. (2016) demonstrated that incorporation of hydrocolloids to the formula improved the texture of gluten-free cakes, which is congruent with the results of the present study.

Many factors can affect the flavor of food products. The results of analysis of variance revealed a significant positive linear effect on the flavor of the cakes (P < 0.05). In addition, the interaction effect between the independent variables was not significant on the flavor of the prepared cakes. In accordance with these results, Levent and Bilgiçli (2011) showed that addition of lupine seed flour up to 30% improved the flavor of gluten-free cakes.

The results of experimental data obtained from Chewing ability of the prepared cakes demonstrated a significant negative linear effect of PSP (P < 0.01) and a significant positive linear effect of TGE (P < 0.05) on the Chewing ability of gluten-free cakes. The PSP and TGE had non-significant positive and negative quadratic effects, respectively. The interaction effect between pomegranate powder and TGE was also positive and non-significant.

The findings of overall acceptability in Table 3, revealed the positive and significant linear effect of PSP (P < 0.05); whilst, the TGE had a non-significant positive linear effect. The quadratic effect of PSP and TGE was negative and significant (P < 0.05). In addition, the independent variables had a non-significant interaction effect. The results of Levent and Bilgiçli (2011) showed that addition of lupine seed flour up to 30% and buckwheat flour up to 10% increased the overall acceptability of the cake samples, which is in line with the results of the present research. It is worthy to note that the mean scores for all sensory attributes except chewiness was improved in enriched treatments.

Optimization of cakes formulation

Central composite design was used to determine the best conditions for production a suitable cake with maximum desirability. The numerical optimization was performed to obtain optimum levels of independent variables. The best formulation with the highest desirability (D = 0.82) was chosen to produce a gluten-free cake with high quality. Optimum conditions were 25.75 and 0.97% for PSP and TGE, respectively. In order to verify the model accuracy in predicting the optimum formulation, experimental samples were prepared and the values of the predicted indices of the responses were compared with the experimental values. The paired t test was conducted in order to measure how the experimental values are close to the predicted ones (obtained from the model). The results in, illustrated that the experimental values did not statistically differ from those predicted by model, signifying the adequacy of the model in predicting the optimum formulation.

Features of optimized cakes

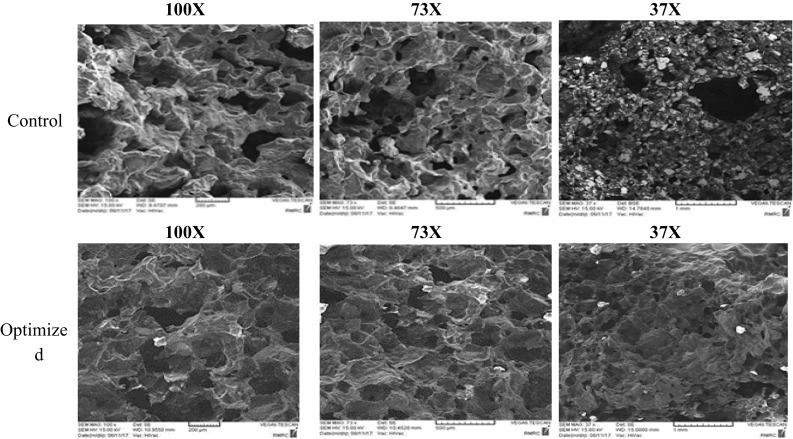

The general characteristics of the fresh optimized and control cakes are shown in Table 4. The results revealed that the volume index and porosity of the optimized cakes are significantly lower than the control ones, which is in line with the obtained results from the SEM images (Fig. 1). Analyzing the SEM images of gluten free cake fortified with pomegranate seed powder, showed that structure of crumb had smaller pores, Because of a continuous network formation between starch granules and protein of this seed led to worse texture with less porous. As revealed the porosity and pore sizes of the optimized cakes were different from the control ones, which have better porosity than the optimized ones. These results were in a good match with the results obtained from Image processing. On the other hand, SEM images results revealed that staling process accelerated in optimized cake due to the high amount of protein in this ingredient.

Table 4.

The general properties for control and optimized Gluten-free cake

| Properties | Control | Optimized |

|---|---|---|

| Index volume | 8.33 ± 0.11A | 7.36 ± 0.28B |

| Porosity (%) | 9.90 ± 0.99A | 7. 50 ± 0.14A |

| Weight loss (%) | 10.63 ± 0.02B | 19.40 ± 1.39A |

| Ash (%) | 0.64 ± 0.00B | 1.01 ± 0.05A |

| Protein (%) | 7.34 ± 0.04B | 9.11 ± 0.02A |

| Fiber (%) | 3.26 ± 0.09B | 4.14 ± 0.02A |

| TTA (%) | 11.93 ± 2.46B | 27.32 ± 6.43A |

| Texture | 3.75 ± 0.42A | 3.55 ± 0.68A |

| Hardness | 2.30 ± 0.82B | 3.25 ± 0.75A |

| Flavor | 3.07 ± 0.79B | 4.00 ± 0.62A |

| Chewing | 3.90 ± 0.65A | 3.45 ± 0.64A |

| Acceptability | 3.52 ± 0.71B | 4.02 ± 0.43A |

| Fe (mg/Lit) | 0.42 ± 0.05B | 0.85 ± 0.19A |

| Zn (mg/Lit) | 0.16 ± 0.01B | 0.28 ± 0.25A |

| Cu (mg/Lit) | 0.03 ± 0.01A | 0.15 ± 0.17A |

Different letters denote significant (P ≤ 0.05) in row

Fig. 1.

SEM image for control and optimized cakes

However, the weight loss of the optimized cakes was lower than that of the control ones, but the ash, protein, and fiber contents of the optimized cakes were significantly higher than those of the control ones, indicating their higher nutritional values. Similarly, the free radical inhibitory effect of the optimized samples was significantly higher that the control ones due to the presence of significant amounts of antioxidant compounds in pomegranate seed oil. The amount of mineral salts was also higher than the control cake.

As shown in Table 4, there is no significant differences between the texture and chewiness of the optimized and control cakes (P > 0.05). However, the hardness of the optimized cakes was significantly higher than the control samples (P < 0.05). There was a significant difference between the flavor of the cakes (P < 0.05). The optimized cakes had higher flavor score than the control ones. Yildiz and Dogan (2014) reported a non-significant difference between the flavor of control and gluten-free cakes based on chestnut flour and potato starch. However, the gluten-free cakes treated with TGE had higher flavor scores, which do not match the present results. The overall acceptance score of the optimized samples was non-significantly higher than the control ones. The results of Majzoobi et al. (2016) indicated that the control samples obtained lower scores in terms of flavor and overall acceptability than the optimized samples including carrot pomace powder, due to hard and dense texture, inferior mouth feel, and appearance.

Shelf life of optimized cake

The moisture, peroxide, and Hardness content of the optimized and control cakes during storage shows in Table 5. It is evident the moisture contents of the control and optimized cake as 18.56 and 21.30% at first day of storage, respectively. At seventh day of storage, the control cake had significantly lower moisture content than the optimized cake. At fourteenth day, the moisture content of the optimized cake was also non-significantly higher than the control cake. The results of statistical analysis indicated the high ability of TGE to forma protein network to retain the moisture in the structure of the prepared cakes.

Table 5.

Changes of the properties of control and Optimized gluten-free cake during storage

| Cake | Control | Optimized | ||||

|---|---|---|---|---|---|---|

| 1 | 7 | 14 | 1 | 7 | 14 | |

| Peroxide-value (m Eq Kg−1) | 1.52 ± 0.10Ba | 3.44 ± 0.51Aa | 3.80 ± 0.36Aa | 1.02 ± 0.04Cb | 2.73 ± 0.22Bb | 3.09 ± 0.07Aa |

| Hardness (N) | 1.80 ± 0.44Aa | 1.19 ± 0.07Ba | 1.44 ± 0.13Ab | 0.84 ± 0.22Ba | 2.55 ± 0.46Aa | 2.66 ± 0.13ABa |

| Moisture (%) | 18.56 ± 0.54Ab | 16.00 ± 0.58Bb | 12.63 ± 0.12Ca | 21.30 ± 0.41Aa | 17.78 ± 0.1Ba | 12.78 ± 0.02Ca |

Different capital letters in each row indicate a significant difference at the level of 5% during storage of each sample

Different small letters in each row indicate a significant difference at 5% level between control and the optimal sample on one day

The hardness of the optimized gluten-free cake increased over storage time (Table 5). The hardness of the control cake raised from an initial level of 1.19–1.80 g at 7th day, but declined and reached to the level of 1.44 at 14th days of storage. On the contrary, the fresh optimized cake had slightly lower hardness than the control cake at the beginning, while during storage period and at the end of storage, its value increased to the maximum level (2.66 N), which was significantly higher than control ones.

The peroxide values of the samples presented in Table 5, revealed the range of 10–20 m Eq Kg−1. Since rancidity more than 20 m Eq Kg−1is undesirable for consumers (Chahartagh et al. 2017), therefore food is acceptable in term of rancidity. The control and the gluten-free cakes did not show any significant difference in terms of peroxide value at first day of storage. However, the peroxide value of the gluten-free cakes was less than the control ones. The peroxide value of the samples was significantly different at seventh and fourteenth days of storage time and the gluten-free cake showed lower peroxide values than the control cake. Thus, this type of enrichment was suitable for control of rancidity during storage time.

Conclusion

The present study showed that the addition of PSP and TGE into gluten-free cake formulation had a positive effect on the porosity, fiber and ash contents and improved the textural and sensory properties. On the other hand, the independent variables decreased volume, specific volume, and L* value of the crust and crumb of the product. Finally, optimization process was performed and the best formulation containing 25.75% PSP and 0.97% TGE was obtained. The sensory evaluations indicated that the overall acceptability of the improved cakes was higher than the control ones. The enriched gluten-free and the control cakes during storage time showed significant and non-significant differences between control and the optimized cakes regarding the peroxide value and moisture content, respectively.

Acknowledgements

The authors acknowledge the financial support provided by Khuzestan Agricultural Sciences and Natural Resources University.

Contributor Information

Zainab Saeidi, Email: saeidyzainab@yahoo.com.

Behzad Nasehi, Phone: +98 (0) 5138683002-5/412, Email: Nasehi.b@pnum.ac.ir.

Hossein Jooyandeh, Email: Hosjooy@yahoo.com.

References

- AACC . Approved method of the American Association of Cereal Chemists. 9. Minnesota: American Association of Cereal Chemists Inc; 1999. [Google Scholar]

- Altındag G, Certel M, Erem F, İlknur Konak Ü. Quality characteristics of gluten-free cookies made of buckwheat, corn, and rice flour with/without transglutaminase. Rev Agaroquim Tecnol Alim. 2015;21:213–220. doi: 10.1177/1082013214525428. [DOI] [PubMed] [Google Scholar]

- AOAC . Official method of analysis. 17. Gaithersburg, MD: Association of Official Analytical Chemists Inc.; 2000. [Google Scholar]

- Bafandeh Y, Rezazadeh R, Ghavidel A, Moghadaszadeh M. Patient with chronic constipation with celiac disease: case report. Med J Tabriz Univ Med Sci Health Serv. 2013;35:98–101. [Google Scholar]

- Basiri SH, Shahidi F, Kadkhodaee R, Farhosh R. An investigation on the effect of ultrasound waves and pretreatment methods on the extraction of oil from pomegranate Seeds. J Food Sci Technol. 2011;8:115–122. [Google Scholar]

- Brand-Williams W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. LWT. 1995;28:25–30. doi: 10.1016/S0023-6438(95)80008-5. [DOI] [Google Scholar]

- Chahartagh F, Nasehi B, Barzegar H. Optimization characteristics of low calorie Cake enriched with stevia leaf powder. JFST. 2017;69:31–41. [Google Scholar]

- Dadashi S, Mousazadeh M, Mousavi SM, Yavari A. Study on quality properties and antioxidant activity of the pomegranate seeds of some Iranian commercial varieties. Iran J Med Aromat Plants. 2013;29:502–515. [Google Scholar]

- Dhen N, Román L, Rejeb IB, Martínez MM, Garogouri M, Gómez M. Particle size distribution of soy flour affecting the quality of enriched gluten-free cakes. LWT Food Sci Technol. 2016;66:179–185. doi: 10.1016/j.lwt.2015.10.032. [DOI] [Google Scholar]

- Fischer UA, Carle R, Kammerer DR. Identification and quantification of phenolic compounds from pomegranate (Punica granatum L.) peel, mesocarp, aril and differently produced juices by HPLC-DAD–ESI/MS (n) Food Chem. 2011;127:807–821. doi: 10.1016/j.foodchem.2010.12.156. [DOI] [PubMed] [Google Scholar]

- Ghergherehchi R, Rafeey M, Majidi J, Majidi S. Prevalence of celiac disease in Type 1 diabetic children and adolescents in East Azarbaijan. J Babol Univ Med Sci. 2010;11:40–45. [Google Scholar]

- Gobbetti M, Pontonio E, Filannino P, Rizzello CG, De Angelis M, Di Cagno R (2017) How to improve the gluten-free diet: the state of the art from a food science perspective. Food Res Int. 10.1016/j.foodres.2017.04.010 [DOI] [PubMed]

- Gujral HS, Guardiola I, Carbonell JV, Rosell CM. Effect of cyclodextrinase on dough rheology and bread quality from rice flour. J Agric Food Chem. 2003;51:3814–3818. doi: 10.1021/jf034112w. [DOI] [PubMed] [Google Scholar]

- Gularte MA, de la Hera E, Gómez M, Rosell CM. Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci Technol. 2012;48:209–214. doi: 10.1016/j.lwt.2012.03.015. [DOI] [Google Scholar]

- Gularte MA, Gómez M, Rosell CM. Impact of legume flours on quality and in vitro digestibility of starch and protein from gluten-free cakes. Food Bioprocess Technol. 2012;5:3142–3150. doi: 10.1007/s11947-011-0642-3. [DOI] [Google Scholar]

- Jing PU, Ye T, Shi H, Sheng Y, Slavin M, Gao B, Liu L, Yu LL. Antioxidant properties and phytochemical composition of China-grown pomegranate seeds. Food Chem. 2012;132:1457–1464. doi: 10.1016/j.foodchem.2011.12.002. [DOI] [PubMed] [Google Scholar]

- Levent H, Bilgiçli N. Enrichment of gluten-free cakes with lupine (Lupinus albus L.) or buckwheat (Fagopyrum esculentum M.) flours. Int J Food Sci Nutr. 2011;62:725–728. doi: 10.3109/09637486.2011.572546. [DOI] [PubMed] [Google Scholar]

- Majzoobi M, Poor ZV, Jamalian J, Farahnaky A. Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace powder. Int J Food Sci Technol. 2016;51:1369–1377. doi: 10.1111/ijfs.13104. [DOI] [Google Scholar]

- Martinez JJ, Melgarejo P, Hernández F, Salazar DM, Martinez R. Seed characterisation of five new pomegranate (Punica granatum L.) varieties. Sci Hortic. 2006;110:241–246. doi: 10.1016/j.scienta.2006.07.018. [DOI] [Google Scholar]

- Nouri M, Nasehi B, Samavati V, Mehdizadeh SA. Optimizing the effects of Persian gum and carrot pomace powder for development of low-fat donut with high fiber content. Bioact Carbohydr Diet Fibre. 2017;9:39–45. doi: 10.1016/j.bcdf.2017.01.001. [DOI] [Google Scholar]

- Renzetti S, Dal Bello F, Arendt EK. Microstructure, fundamental rheology and baking characteristics of batters and breads from different gluten-free flours treated with a microbial transglutaminase. J Cereal Sci. 2008;48:33–45. doi: 10.1016/j.jcs.2007.07.011. [DOI] [Google Scholar]

- Shokri F, Salehifar M, Azizi MH. Effect of hydroxy propyl methyl cellulose and microbial transglutaminase enzyme on farinograph and quality characteristics of gluten-free pasta. Food Sci Technol. 2016;59:123–132. [Google Scholar]

- Shyu YS, Sung WC. Improving the emulsion stability of sponge cake by the addition of γ-polyglutamic acid. J Mar Sci Technol. 2010;18:895–900. [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fiber concentrate and xanthan gum. J Food Sci Technol. 2016;53:1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sumnu G, Koksel F, Sahin S, Basman A, Meda V. The effects of xanthan and guar gums on staling of gluten-free rice cakes baked in different ovens. Int J Food Sci Technol. 2010;45:87–93. doi: 10.1111/j.1365-2621.2009.02107.x. [DOI] [Google Scholar]

- Susanna S, Prabhasankar P. A study on development of gluten free pasta and its biochemical and immunological validation. LWT Food Sci Technol. 2013;50:613–621. doi: 10.1016/j.lwt.2012.07.040. [DOI] [Google Scholar]

- Tsatsaragkou K, Papantoniou M, Mandala I. Rheological, physical, and sensory attributes of gluten-free rice cakes containing resistant starch. J Food Sci. 2015;80:E341–E348. doi: 10.1111/1750-3841.12766. [DOI] [PubMed] [Google Scholar]

- Yildiz Ö, Dogan IS. Optimization of gluten-free cake prepared from chestnut flour and transglutaminase: response surface methodology approach. Int J Food Eng. 2014;10:737–746. doi: 10.1515/ijfe-2014-0024. [DOI] [Google Scholar]