Abstract

The use of a starfruit dietary fiber concentrate (SDFC) as a novel ingredient in Vienna sausages was investigated. A constrained mixture design was followed to evaluate the effect of different proportions of SDFC (0–10%), pork meat (0–100%) and turkey meat (0–100%) on the shear force, shrinkage, color, residual nitrite, moisture and polyphenol contents of sausages. Moreover, a chemical, physical and sensory characterization of the optimized formulations was performed. The cubic model equations demonstrated that the SDFC in mixture with pork or turkey meat had a reducing effect on nitrites, moisture, shear force and shrinkage, while there was an increase on the polyphenol concentration as the increase of SDFC proportion in the formulations. The optimization resulted in Vienna-type sausages formulated with a ternary mixture of pork/turkey meat and high SDFC proportion (7.4–8.4%). These products had high total dietary fiber content (11.04–17.79%) and antioxidant polyphenols, low residual nitrite content, shrinkage and red color. They presented good taste, color and texture attributes, and were sensory acceptable. This study demonstrated that enrichment of Vienna-type sausages with SDFC in mixture with pork/turkey meat is a way to obtain potential functional meat products with high antioxidant dietary fiber content, reduced in nitrites, and good physical and sensory properties.

Keywords: Vienna-type sausages, Starfruit dietary fiber concentrate, Polyphenols, Residual nitrite, Physical characteristics, Sensory characteristics

Introduction

Meat is a highly nutritious food rich in high biological value proteins, fatty acids, vitamins (B and E), minerals and bioactive compounds (conjugated linoleic acid, L-carnitin, carnosine, etc.). The processing of meat into products represents one of the most economically significant food industries around the world because of the new consumer’s preference for ready-to-eat-foods (Mehta et al. 2015). Sausages such as Frankfurt, Bologna and mainly Vienna-type are popular consumed cooked meat products at all ages, which have high economical and commercial significance. However, as the most of meat products, sausages have high levels of saturated fatty acids, cholesterol, sodium chloride and curing salts (sodium nitrate-NaNo3 and sodium nitrite-NaNo2). The nitrite/nitrate salts are added to inhibit the spoilage bacterium growth and reduce the rancidity, even though they are considered precursors of carcinogenic nitrosamines (Mehta et al. 2015; Honikel 2008). Thus, the consumption of sausages is not recommended in a daily intake diet because they are considered a potential health hazard that somehow is associated to be a predisposing factor for cardiovascular diseases, colon cancer, obesity and diabetes mellitus (Mehta et al. 2015; Nisa et al. 2017). These facts have driven the research for modifying traditional meat formulation products through the incorporation of plant based ingredients with potential health benefits (Nisa et al. 2017). One of these ingredients is dietary fiber (DF), which has abundant evidence on its gastrointestinal improvement and physiological functions with several human health benefits such as lower risk for developing colorectal cancer, cardiovascular diseases, diabetes and obesity. Consequently, it has been recommended a daily intake level of 21–38 g per day for person aged 19 to older than 50 years, but most individuals consume less than half of the daily recommended dietary intakes of DF in several nations worldwide. Therefore, reformulation or design of new food products with added fiber has been considered important for the food industry (Li and Komarek 2017).

In this context, because the technological properties of DF such as water holding, swelling, solubility and oil holding capacities are related with their physiological effects, DF is considered a potential functional ingredient. In this regard, byproducts from fruits and vegetable has been proposed as raw materials for producing DF concentrates (DFCs) as functional ingredients. They are characterized to have high DF content (> 50%) and associate bioactive compounds such as polyphenols which has been recognized as potential antioxidants that protect against oxidative damage to human biomolecules (O’Shea et al. 2012; Pantaleón-Velasco et al. 2014; Sharma et al. 2016).

Recently, some studies have documented the addition of DFCs into some types of emulsified cooked sausages in order to achieve fiber-enriched meat products (Viuda-Martos et al. 2010; Sánchez-Zapata et al. 2011; Kim et al. 2011; Ktari et al. 2014; Díaz-Vela et al. 2017). These studies demonstrated that chemical, physical, physicochemical and sensory characteristics depend on the concentration, chemical composition and technofunctional properties of the DFC. Therefore, the research for the application of new DFCs as potential functional ingredients to obtain the best commercial meat products is underway (Verma and Banerjee 2010; Jiménez-Colmenero and Delgado-Pando 2013; Mehta et al. 2015).

In this regard, a DFC has been prepared from pomace of starfruit (Averroa carambola L.) in a previous work with high content of DF (84% db) and polyphenols with antioxidant activity, as well as technofunctional properties that suggest its use as ingredient in meat products (Pantaleón-Velasco et al. 2014). Therefore, the aim of this study was to evaluate the effect of starfruit DFC in mixture with pork and turkey meats on the chemical, physical and sensory properties of Vienna-type sausages.

Materials and methods

Raw materials and reagents

The DFC was obtained from starfruit pomace supplied by a fruit juice company from Veracruz, Veracruz, Mexico in January 2016. The DFC was prepared following the procedure described by Pantaleón-Velasco et al. (2014). Briefly, starfruit pomace was washed with water at 55 °C during 5 min (water-to-pomace mass ratio of 2:1), pressed, freeze dried (Labconco freeze Dry System/Free zone 4.5), milled and sieved at 0.500 mm using a 35 mesh (ASTM). Finally, the powder of starfruit DFC (SDFC) was packaged with a vacuum sealer (model VM-16; ORVED, Barcelona, Spain) into high-density polyethylene plastic food bags and stored in air-tight glass containers in refrigeration at 6 ± 1 °C.

The SDFC was characterized by analysis of proximate chemical composition, content of polyphenols and antioxidant activity according to the methods described in the following sections.

The pork loin and turkey leg meats were of Federal Inspection Type from Oaxaca (México). Pork meat was separated from exceeding fat while turkey leg meat was separated from connective tissues and cartilages. The pH and proximate chemical composition were determined in both meats.

Sausage preparation

Vienna sausages were manufactured according to a standard procedure, where proportions of pork meat, turkey meat and SDFC powder as a portion of a fixed sausage formulation were modified according to a mixture experimental design (Table 1). The fixed formula was prepared with 20% crushed ice (w/w), 15% pork backfat, 3% starch potato, 2% potassium chloride, 1% sugar, 0.3% cure salt which was composed of 94% sodium chloride and 6% sodium nitrite (180 NaNO2 mg/kg), 0.1% garlic powder, 0.1% humus flavor powder, 0.05% polyphosphates and 0.05% ascorbic acid powder. Each ingredient was weighted in grams for 100 g of meat.

Table 1.

Three-component mixture design of pork meat, turkey meat and SDFC powder in Vienna sausage formulations

| Blend | Component proportions (%) | ||

|---|---|---|---|

| X1 (pork) | X2 (turkey) | X3 (SDFC) | |

| A | 100 | 0 | 0 |

| B | 90 | 0 | 10 |

| C | 0 | 90 | 10 |

| D | 0 | 100 | 0 |

| E | 47.5 | 47.5 | 5 |

| F | 95 | 0 | 5 |

| G | 0 | 95 | 5 |

| H | 45 | 45 | 10 |

| I | 50 | 50 | 0 |

| J | 68.75 | 23.75 | 7.5 |

| K | 23.75 | 68.75 | 7.5 |

| L | 73.75 | 23.75 | 2.5 |

| M | 23.75 | 73.75 | 2.5 |

On the other hand, pork and turkey meats were ground using a meat mincer (Moulinex ME-625) and then mixed with the SDFC to obtain the desired composition for each treatment. The SDFC/pork meat/turkey meat mixture was homogenized with the fixed formula in a proportion of 1:0.416 (w/w), stuffed into artificial Viscofan casing at dimensions of 25.4 mm diameter/170 mm length, and linked at both ends into portions of 34 g. The sausages were submerged in a water bath at 80–85 °C during 15 min until reaching an internal temperature of 73 °C. The cooked sausages were kept in a cold bath until an internal temperature of 30 °C. Next, the exceeding water was removed and the cooked sausages were vacuum packed with a vacuum sealer (model VM-16; ORVED, Barcelona, Spain) in high-density polyethylene plastic food bags and refrigerated at 5 °C overnight until analysis.

Statistical design

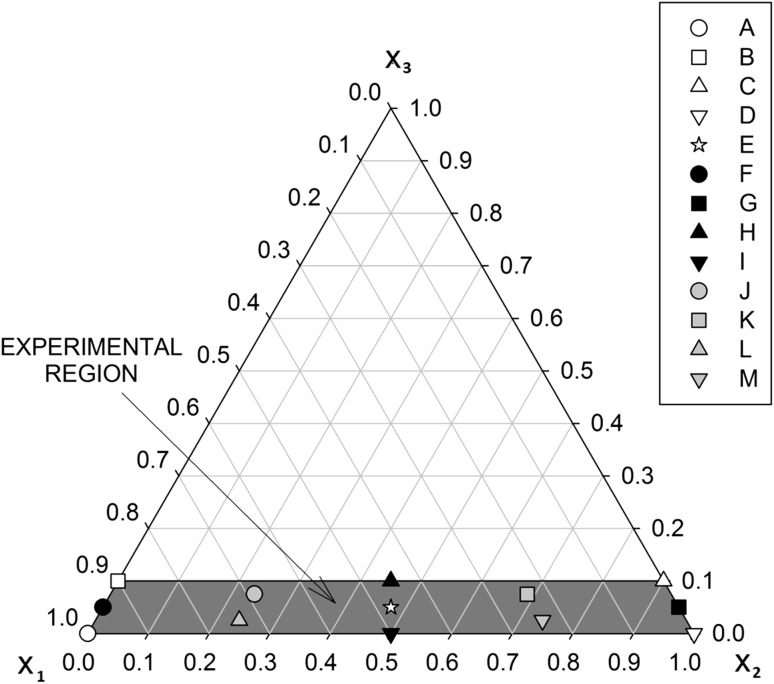

A constrained simplex mixture design with three factors and one center centroid (3,1) was used to study the mixture effect of different proportions of pork meat, turkey meat and SDFC on the chemical and physical characteristics of Vienna sausages (Table 1). This resulted in 13 formulations of Experimental treatments included formulations on corners, edges, centroid, and inner points of the trapezoid-shaped factor space (Fig. 1), where moisture content, residual nitrite content, polyphenol content, shear force, shrinkage, and color parameters of lightness (L*) redness/greenness (a*) and yellowness/blueness (b*) were measured as the response variables. All experiments were carried out by triplicate. Experimental results were related with pork meat (x1), turkey meat (x2) and SDFC (x3) components in a ternary mixture by the special cubic model:

| 1 |

Equation (1) was fitted to experimental data using ordinary linear regression to estimate model parameters b1, b2, b3, b12, b13, b23 and b123 for each one of the responses. Following data fitting, an analysis of variance was performed for each equation to identify significant predictor variables (p < 0.05). The fitness quality of the linear regression models was quantified by the determination coefficient (R2). Linear regression procedures were performed with the Matlab R2012a software and its Statistics Toolbox 7.5 (MathWorks Inc., Natick, MA, USA).

Fig. 1.

Diagram for the simplex mixture design with three factors and one center centroid (3,1) for ternary mixture of SDFC, pork meat and turkey meat in Vienna sausages

Selection and characterization of Vienna-type sausages

Numerical optimization of predicted values (previously obtained by the special cubic model) of nitrite content, polyphenol content, moisture content, shrinkage, shear force, and color parameters (L*, a* and b*) using the Excel Solver Tool (Microsoft Office 2007; Microsoft; Redmond, WA) was applied to obtain three optimal formulations of Vienna sausages formulated with SDFC based principally on the lowest nitrite content and the other chemical and physical desirable characteristics. After that, each optimized Vienna sausage formulation was prepared by triplicate and characterized through determination of their chemical, physical and sensory characteristics.

Chemical analyses

Proximate chemical composition

The samples were analysed by triplicate for their moisture, crude protein (N × 6.25), fat and ash contents according to the 934.01 (gravimetric method), 960.52 (Kjedahl method), 948.22 (Soxhlet apparatus using petroleum ether) and 942.05 (incineration at 525 °C) methods, respectively, (AOAC 2005). Insoluble, soluble and total DF contents were determined according to the 32-07.01 method (AACC 2009). The carbohydrate content was determined by the subtraction from the total sum value of the before components.

Residual nitrite content

The residual nitrite content was determined according to the Norma Oficial Mexicana NOM-213-SSA1-2002 (Norma Oficial Mexicana 2002). The fresh sample was ground, homogenized with water and heated at 80 °C during 1 h. Mercuric chloride solution was added until clumps disappeared. The mixture was filtered and Griess reactive was added to the supernatant to form a pink chromophore compound which was detected at 520 nm. Sodium nitrite was used as standard and results were reported as NaNO2 mg/kg fresh weight (FW).

Soluble polyphenols

A sequential organic aqueous extraction was used to evaluate the soluble polyphenols using acidic aqueous methanol (50:50 v/v) and acetone/water mixture (70:30 v/v) following the procedure described by Bravo and Saura-Calixto (1998). After centrifugation (15 min, 3000×g), the supernatants from each extraction step were combined and the soluble polyphenols were estimated using Folin–Ciocalteau’s reagent at 750 nm) with gallic acid as a standard in a spectrophotometer (Cary 60, Agilent Technologies, Inc., Australia). The content of soluble polyphenols was expressed as grams of gallic acid equivalents (GAE)/kg of dry weight (DW).

Antioxidant capacity

This property was evaluated in the extracts of soluble polyphenols by two in vitro methods. The capacity to scavenge the free radical cation 2,2′-azino-bis-(3-ethyl-benzothiazoline-6-sulfonic acid) (ABTS·+) was assessed using the decolorisation assay proposed by Re et al. (1999). The radical ABTS·+ was formed by oxidation with potassium persulfate. Decrease of ABTS·+ absorbance at 658 nm in the presence of the polyphenol extract was monitored for 6 min in a spectrophotometer (Cary 60, Agilent Technologies). Trolox was used for calibration and the results were expressed as μmol Trolox equivalents (TE)/g DW.

Ferric reducing antioxidant power (FRAP) assay was carried out as described by Pulido et al. (2000). FRAP reagent (containing 10 mM TPTZ in 40 mM HCl, 20 mM FeCl3∙6H2O and 0.3 M acetate buffer, pH 3.6) was either mixed with the corresponding sample, distilled water or Trolox. Absorbance readings were taken at 595 nm after 30 min in a spectrophotometer (Cary 60 Agilent Technologies). The results were expressed as μmol TE/g DW.

Physical analysis

Shear force

The shear force was determined using a Tester EZTest EZ-S Shimadzu Universal Texturometer (Shimadzu Corporation, Japon). Three sausages of each treatment were removed from the casing and cut in length of 3 cm. Each sample was placed on the rig and sheared in the direction of the axis of the sausage using a Warner–Bratzler probe. The full scale load was set at 0.4903 kN with the cross-head speed set at 120 mm/s. The shear force (N) was computed as the mean of the maximum cutting force.

Texture profile analysis (TPA)

TPA was performed using a Tester EZTest EZ-S Shimadzu Universal Texturometer. The sausages were removed from the casing, cut into slices of 1 cm. The sample was subjected to a 2-cycle compression test using a circular device at a compression load of 0.4903 kN and cross-head speed of 60 mm/min. Hardness, cohesiveness, gumminess, elasticity and masticability were determined from the TPA curve. Three batches of four sausages for each selected formulation were measured.

Shrinkage

Three sausages from each formulation were cooked at 150 °C in an oven (Felisa) to a core 72 °C determined by inserting a connector from thermocouple (Oakton thermometer) in the center of sausage. The diameter (in three locations per sausage) and length of sausage were measured before and after cooking using a vernier (Trupper). Dimensional changes (shrinkage) were determined considering that sausage is a right circular cylinder according to the following equation.

| 2 |

where is the uncooked sausage diameter, is the uncooked sausage length, is the cooked sausage diameter and is the cooked sausage length.

Color

The analysis of color was carried out using a tristimulus colorimeter Konica Minolta Model CR-400 (Konica Minolta Sensing Americas, Inc). The sample sausage was cross cut in three sections and the flat part was used for the lecture in the colorimeter. The L*, a* and b* parameters were used to determine the color characteristics of the samples.

Sensory evaluation

Training of sensory panel assessors

The persons were called to form the sensory panel assessors for meat products. The selected assessors were initially evaluated through recognition tests of odour and basic flavours, and test of intensity evaluation. For the first test, samples of common odours such as vanilla, apple, banana, lemon, meat, species (pepper, cumin), garlic were placed in amber glass jars with punched lids and panellists were asked to identify the odour, while the second test was carried out by a recognition test of basic flavours (sweet, salty, sour, bitter, umami). On the other hand, the intensity evaluation was carried out by an arrangement test using different concentrations of sucrose, sodium chloride, acetic acid, caffeine and monosodium glutamate as sweet, salty, sour, bitter, umami flavours.

After selection of sensory assessors, tests of differentiation and generation of attributes were carried out in order to train the panel assessors. Thus, a triangular test was used to evaluate the capacity of assessors to detect the minimum significant differences between the meat products with different composition. For the test of attribute generation was used commercial sausages and the assessors were asked to detect by triplicate the attributes of flavour (bitter, sour, salty and umami), texture (hardness, gumminess, fibrous), color (intensity and homogeneity) and odour (fish, meat, smoke, garlic and pepper).

Flash profile analysis of Vienna sausages

Each optimized Vienna sausage formulation was prepared by triplicate and subjected to cooking at 150 °C in an oven (Felisa) during 15 min. After that, cooked sausages were cut in slices (2.4 cm length) and kept warm in a closed glass vessel until the test (3–5 min). A Flash Profile was used to describe the sensory attributes of sausages which were conducted by trained sensory panellists. They evaluated the intensities of taste (sour and salty), texture (juiciness, gumminess, hardness and fibrous), odour (meat, smoke and garlic), and color (intensity and homogeneity). Each panelist evaluated three order replicates of each optimized formulation coded in randomized form. The attributes were measured through an unstructured lineal scale of 9 cm with descriptors at both ends from low (0 cm) to high intensity (9 cm).

Consumer acceptability test of Vienna sausages

The three optimized Vienna sausages formulated with SDFC were coded with three different digits and evaluated using an acceptability consumer test whit one hundred young (18–25 years old) untrained panellists. They were asked to score selected formulation sausages in terms of overall acceptability using a nine-point hedonic scale (from 1 = to dislike too mucho to 9 = I like too much).

Statistical analysis

Results of each analysis were recorded as the mean of three replicates ± standard deviation. A one-way ANOVA was run followed by a Fisher’s least-significant-difference (LSD) test at a confidence level of 95% using the Statgraphics Plus 5.1 statistical software (StatPoint Technologies, Inc., Warrenton, VA).

Results and discussion

The powder of SDFC obtained in this work had a moisture content of 9.5 ± 0.09% (FW), and a chemical composition (DW) in ash, fat and proteins of 1.3 ± 0.0, 11.4 ± 1.1, 1.9 ± 0.08%, respectively. In addition, the SDFC had high contents of total (78.03 ± 3.9% DW), insoluble (67.01 ± 2.3% DW) and soluble (11.0 ± 1.6% DW) DF, and 6.05 ± 0.01% DW of soluble polyphenols with 498.84 ± 9.69 and 255.4 ± 3.68 μmol TE/g of antioxidant capacity determined by FRAP and ABTS assays, respectively. The total DF and antioxidant polyphenol values of SDFC were similar to those (84% and 5.0–6.1 g GAE/100 g DW, respectively) reported by Pantaleón-Velasco et al. (2014).

On the other hand, pork and turkey meats had moisture contents of 71.47 and 73.42% FW, respectively; with high content of proteins (20.74 and 19.97% FW, respectively) followed by fat (5.81 and 4.75% FW, respectively) and ash (0.43 and 0.37% FW, respectively). The pH value of both meats was between 5.4 and 5.7 which is an optimum pH and indicated a good technological quality of meats (Brewer 2010).

Effect of SDFC on chemical characteristics of Vienna sausages

The results of the complete mixture experimental design for the response variables of the moisture content, residual nitrite level and soluble polyphenols are shown in Table 2. The moisture content of the treatments ranged from 64.49 to 71.83% FW, which are similar to the moisture contents reported for cooked sausages added with fruit dietary fiber ingredients such as citrus fiber washing water/rosemary essential oil (60.36–65.62%) (Viuda-Martos et al. 2010) and date flesh paste (63.68–68.14%) (Sánchez-Zapata et al. 2011). On the other hand, the range of residual nitrite content of the formulations was from 18.86 to 41.46 mg NaNO2/kg FW (Table 2). It can be highlighted that the highest values of residual nitrite and moisture contents was for the A formulation, followed by D and I formulations (Table 2), both without SDFC (Table 1). In this regard, there was a significant reduction of 76.97 and 78.51%, respectively, from the initial added sodium nitrite (180 NaNO2 mg/kg), which could be attributed to the reaction of this salt with myoglobin, proteins and sulfhydryl groups; or maybe oxidized to nitrates (Bazan-Lugo 2008).

Table 2.

Chemical characteristics in final product at studied formulations for response variables

| Blend | Nitrite (mg NaNO2/kg FW) | Polyphenols (g GAE/kg DW) | Moisture (% FW) |

|---|---|---|---|

| A | 41.46 ± 0.60a | 1.3 ± 0.02f | 71.02 ± 3.6abc |

| B | 21.39 ± 0.52f | 5.3 ± 0.04a | 64.49 ± 2.1e |

| C | 18.86 ± 0.86 g | 5. 5 ± 0.05a | 65.41 ± 2.3de |

| D | 38.69 ± 0.72b | 1.4 ± 0.05f | 71.83 ± 1.0a |

| E | 25.66 ± 0.66d | 3.4 ± 0.0c | 66.54 ± 3.4de |

| F | 26.43 ± 0.37d | 2.8 ± 0.0d | 66.92 ± 6.6de |

| G | 26.64 ± 0.52d | 3.2 ± 0.1c | 67.68 ± 4.8d |

| H | 20.79 ± 0.38f | 5.1 ± 0.1a | 65.96 ± 4.5de |

| I | 38.76 ± 0.94b | 1.1 ± 0.0f | 71.11 ± 1.2ab |

| J | 24.98 ± 0.43d | 4.3 ± 0.0b | 65.84 ± 1.4de |

| K | 23.19 ± 0.24e | 4.50 ± 0.1b | 66.36 ± 3.1de |

| L | 29.49 ± 0.26c | 2.2 ± 0.0e | 68.08 ± 1.4 cd |

| M | 29.01 ± 0.32c | 2.4 ± 0.0de | 68.37 ± 0.9bcd |

Data expressed as mean ± SD of three independent experiments. Means in a column followed by different superscript letters are significantly different by Fisher’s LSD method (p < 0.05)

On the other hand, Table 2 shows that the soluble polyphenol content of the formulations ranged from 1.25 to 5.45 g GAE/kg DW, noting the lowest values were for the formulations with the highest residual nitrite content. Conversely, the lowest significant values for the moisture and nitrite residual and the highest (p < 0.05) polyphenol content were for the formulations B, C and H (Table 2). In this regard, as is shown in Table 4, the cubic model equations which model the experimental and predicted values for the moisture, nitrite and polyphenols responses, had a high correlation coefficient (R2 = 0.8700) for the first one and very high correlation coefficients (R2 = 0.9695 and R2 = 0.9836) for residual nitrite and polyphenol contents. The ANOVA of the lineal regression model demonstrated that the mixture of either pork or turkey meat with the SDFC reduces (p < 0.05) the content of moisture and residual nitrite, while the polyphenol content increased with the proportion of SDFC in the mixture of sausages (Table 4). Related to this, an increase of 77% in polyphenol content and reduction of 54.5% in the residual nitrite content was obtained at the highest proportion of SDFC (10%) in the mixture of B, C, H formulations of Vienna-type sausages (Tables 1, 2) compared to sausage formulation without SDFC. These results suggest that polyphenols with antioxidant capacity contained in the SDFC may be related to residual nitrite level reduction. These findings are similar to those reported by Viuda-Martos et al. (2010) where reductions on residual nitrite level (40.15–46.16%) were observed after the incorporation of citrus fiber washing water and/or rosemary essential oil with in Bologna sausages, which was attributed to the polyphenols or flavonoids contained in the citrus fiber, and terpenes in the essential oil. Also, Li et al. (2013) reported a decreased residual nitrite content in dry-cured sausages added with green tea polyphenols in the final product at the first day of preparation. They explained that reduction of nitrite level are maybe caused by reactions between nitrites with bioactive compounds contained in the dietary fiber. Thus, the nitrite is possibly transformed into nitrous acid, which in turn reacts with the exogenous reducing substances such as ascorbic acid and polyphenols, especially flavonoids, and is transformed into nitric oxide, completing the dismutation reaction (Li et al. 2013). This fact could be beneficial because the formation of nitric oxide contributes to the reduction of Clostridium botulinum growth that causes botulism (Bazan-Lugo 2008). The reduced residual nitrite content in the sausage products has healthy effects because it reduces the possibility of nitrosamines formation with toxic and carcinogenic effects that has been considered as a risk by the consumption of meat products (Honikel 2008; Bazan-Lugo 2008). However, it is important to consider that high reduction of nitrites could affect the safety of Vienna-type sausages added with SDFC because they have the capacity to decrease harmful aerobic microorganisms.

Table 4.

Regression coefficients of special cubic models

| Response | Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Nitrites | 40.84 | 39.07 | 1269.91 | − 10.46 | − 1582.65 | − 1584.50 | 166.87 | 0.9695 |

| Soluble polyphenols x 102 | 11.15 | 13.57 | 700.10 | 1.92 | − 318.41 | − 308.22 | 17.04 | 0.9836 |

| Shear force | 7.65 | 8.35 | 453.68 | 4.91 | − 436.08 | − 459.02 | − 57.88 | 0.9041 |

| Moisture | 71.15 | 71.89 | 498.90 | − 3.56 | − 547.04 | − 544.42 | 67.30 | 0.8700 |

| Shrinkage | 14.74 | 14.49 | 337.88 | − 0.30 | − 483.59 | − 477.27 | − 8.29 | 0.9222 |

| * | 63.91 | 60.94 | 134.76 | 1.25 | − 79.78 | − 67.33 | − 38.85 | 0.3971 |

| * | 10.25 | 12.25 | 331.08 | 4.68 | − 393.81 | − 410.41 | − 9.44 | 0.7231 |

| * | 8.88 | 10.38 | − 836.64 | 0.22 | 1097.27 | 1078.42 | − 134.00 | 0.9487 |

Bold numbers indicate significant parameter estimates by Fisher’s LSD method (p < 0.05)

Effect of the mixture of SDFC, pork and turkey meats on the physical characteristics of Vienna sausages

The values of the complete mixture experimental design obtained for the response variables of shear force, shrinkage degree and color parameters (L*, a* and b*) are shown in Table 3. The shear force of the treatments ranged from 7.77 to 11.75 N and the shrinkage was from 3.40 to 15.20%. The sausage formulations with the highest proportion (100%) of pork or turkey meat in the mixture showed the lowest values of shear force and the highest shrinkage, but as the concentration of SDFC increased in the mixture, the shrinkage decreased (Table 3). In this regard, the cubic model equations showed a high correlation coefficients for shear force (R2 = 0.9041) and shrinkage (R2 = 0.9222) indicating a high relationship between the experimental and predicted values (Table 4). These equations demonstrated that shrinkage increased (p < 0.05) as the concentration of either pork meat or turkey meat increased in a pure mixture (b1 and b2) in Vienna-type sausage formulations. Also, the shear force increased (p < 0.05) as the increase in the proportion of pork meat, turkey meat or SDFC as unique component in the mixture. The model equations also confirmed that there was a trend to decrease the values of shear force and shrinkage in the formulations prepared with the mixture of either pork meat or turkey meat and SDFC (Table 4). Therefore, the sausages formulations composed by the highest concentration (10%) of SDFC and 90% of pork or turkey meat in the mixture had the lowest shrinkage values (Table 3) and a reduction up to 77.6%, while the shear force increases up to 68%. This could be due to DF causes structuration of the sausage emulsion matrix avoiding the shrinkage of sausages during the oven heating, making them harder.

Table 3.

Physical characteristics in final product at studied formulations

| Blend | Shear force (N) | Shrinkage (%) | |||

|---|---|---|---|---|---|

| A | 7.80 ± 0.20d | 15.20 ± 0.4a | 64.42 ± 1.04a | 9.19 ± 0.58b | 9.07 ± 1.13e |

| B | 13.10 ± 0.70a | 3.40 ± 0.4e | 64.83 ± 0.79a | 6.33 ± 0.71e | 22.96 ± 0.98a |

| C | 11.30 ± 0.40b | 3.80 ± 1.6e | 62.13 ± 0.47bcd | 6.99 ± 0.26cde | 22.94 ± 0.39a |

| D | 8.30 ± 0.30 cd | 14.00 ± 1.2a | 60.79 ± 0.58d | 12.63 ± 0.40a | 10.57 ± 0.28de |

| E | 9.20 ± 0.30c | 7.60 ± 0.30bcd | 63.79 ± 1.39ab | 8.14 ± 0.96bcd | 19.22 ± 1.13b |

| F | 8.90 ± 0.60 cd | 8.90 ± 0.61b | 62.99 ± 0.34abc | 8.76 ± 0.36bc | 19.42 ± 0.74b |

| G | 9.10 ± 0.40c | 7.31 ± 0.92bcd | 60.88 ± 0.46d | 9.18 ± 0.18b | 18.78 ± 1.00b |

| H | 11.80 ± 0.00b | 3.45 ± 0.40e | 62.44 ± 0.63bcd | 8.83 ± 0.78b | 19.87 ± 0.96b |

| I | 9.50 ± 0.20c | 14.82 ± 1.12a | 61.61 ± 0.19 cd | 13.07 ± 0.31a | 10.24 ± 0.36de |

| J | 11.10 ± 0.40b | 5.14 ± 0.39de | 60.80 ± 0.13d | 6.80 ± 0.50de | 19.83 ± 0.26b |

| K | 10.90 ± 0.30b | 6.00 ± 0.30cde | 62.45 ± 0.15bcd | 8.41 ± 1.07bcd | 20.16 ± 1.17b |

| L | 8.80 ± 0.90cd | 8.59 ± 1.79bc | 63.48 ± 0.49abc | 11.40 ± 0.63a | 12.24 ± 1.45 cd |

| M | 8.30 ± 0.40 cd | 12.69 ± 0.47a | 62.98 ± 0.54abc | 8.86 ± 0.22b | 14.15 ± 0.82c |

Data expressed as mean ± SD of three independent experiments. Means in a column followed by different superscript letters are significantly different by Fisher’s LSD method (p < 0.05)

The mathematical equations obtained for the color responses (Table 4) showed that the b* parameter had a very high coefficient correlation (R2 = 0.9487) and a* parameter had a high coefficient correlation (R2 = 0.7231), while L*parameter showed low coefficient correlation (R2 = 0.3971). This indicates that b* and a* values were the color parameters that represent de color characteristics of Vienna-type sausages. The regression analysis showed a positive and negative effects (p < 0.05) on the and parameter in formulations with the mixture of SDFC and pork or turkey meat, respectively (Table 4). Thus, the yellowness (positive values) increased as the proportion of SDFC increased in the mixture of sausage formulations (Table 3) and may be related to the polyphenol content (Table 2), and yellow carotenoid pigments maybe contained in the SDFC. The b* values of this work were higher than those of low-fat pork sausages (11.2–11.9) and cooked beef frankfurter sausages (7.34–9.12) added with tomato powder (0–1.5%), reported by Kim et al. (2011). They attributed the values to the yellow carotenoids such as -carotene, cryptoxanthine and lycopene present in tomato. On the other hand, a* values of Vienna-type sausages were positives (redness) and decrease as the concentration of SDFC increase in the mixture, which could be due to a decrease in the concentration of red color nitrosomyoglobin complex which is the principal pigment responsible for the coloration of meat products (Bazan-Lugo 2008).

Selection, chemical and physical properties of Vienna sausages

The optimized Vienna sausages formulated with SDFC were selected according to the lowest residual nitrite value (< 21.98 mg/kg) calculated by numerical optimization. Also, the other optimized values of chemical and physical characteristics such a minimum of 4.2 g GAE/kg of polyphenol content and 63.0% of moisture, and a maximum of 6.2% of shrinkage and 13.94 N of shear force, as well as values of 62.59, 10.00 and 20.0 for L*, a* and b* color parameters, respectively, were taken in account for selection of optimized sausages. According to this, three optimized Vienna-type sausages formulations (OVS) added with SDFC were obtained with the following ternary mixture composition: OVS1 = 38.3% pork meat/53.3% turkey meat/8.4% SDFC; OVS2 = 68.75% pork meat/23.75% turkey meat/7.5% SDFC; OVS3 = 23.75% pork meat/68.75% turkey meat/7.5% SDFC.

The proximate chemical composition and physical characteristics of the three optimized formulations is shown in Table 5. There were no significant differences among OVS2 and OVS3 samples in moisture, ash, protein and fat contents (Table 5), probably due to their same proportion of SDFC (7.5%) in the mixture regardless of the proportion of pork and turkey meat. In turn, the OVS1 formulation showed lower moisture, protein and fat contents than OVS2 and OVS3 formulations, but OVS1 had the highest total (17.79%) and soluble (7.21%) DF contents, maybe by its higher proportion of SDFC (8.4%). As nutritional facts, the OVS1, OVS2 and OVS3 formulations contain 5.87, 3.64 and 4.04 g of DF per serving size (33 g product), respectively, according to their total DF content (Table 5). Therefore, OVS1 can carry the claim as food item of “high fiber”, while OVS2 and OVS3 can be claims as food item of “good source of fiber”, according to the current regulations (“high fiber”: 5 g or more fiber and “good source”: 2.5 to 4.9 g of fiber per serving) (Li and Komarek 2017). Thus, one serving size optimized Vienna sausages formulated with SDFC, especially OVS1 can contribute to the daily recommended DF intake for the consumer (28–36 g/day for adult person) (Mehta et al. 2015).

Table 5.

Chemical and physical characteristics of optimized Vienna sausages (OVS) formulated with SDFC

| Parameter | OVS1 | OVS2 | OVS3 |

|---|---|---|---|

| Moisture (% FW) | 63.86 ± 0.27b | 65.20 ± 0.27a | 66.09 ± 0.39a |

| Ash (% DW) | 3.26 ± 0.6a | 2.65 ± 0.20b | 2.80 ± 0.39b |

| Proteins (% DW) | 43.42 ± 0.52b | 46.59 ± 0.21a | 46.06 ± 0.44a |

| Fat (% DW) | 35.82 ± 0.84a | 39.75 ± 0.24b | 38.90 ± 0.35b |

| Total dietary fiber (% DW) | 17.79 ± 0.49a | 11.04 ± 1.37c | 12.24 ± 0.96b |

| Insoluble dietary fiber (% DW) | 10.58 ± 1.26a | 10.85 ± 0.18a | 11.23 ± 1.61a |

| Soluble dietary fiber (% DW) | 7.21 ± 0.77a | 1.5 ± 0.00b | 1.01 ± 0.69b |

| Polyphenols (g GAE/kg DW) | 5.3 ± 0.1a | 4.3 ± 0.2b | 4.4 ± 0.03b |

| Antioxidant capacity (µmol TE/g DW) FRAP assay |

71.10 ± 1.73a | 64.26 ± 2.75a | 53.25 ± 4.20b |

| Antioxidant capacity (µmol TE/g DW) ABTS assay |

298.21 ± 0.24a | 232.75 ± 0.2b | 196.21 ± 14.81c |

| Residual nitrites (mg/kg FW) | 22.22 ± 0.83c | 25.7 ± 0.22a | 24.13 ± 0.32b |

| Shrinkage (%) | 3.24 ± 0.21a | 5.29 ± 0.73b | 6.14 ± 0.64b |

| Shear force (N) | 13.28 ± 1.10a | 12.10 ± 0.23a | 11.4 ± 0.50a |

| Hardness (N) | 37.22 ± 5.76a | 28.45 ± 1.65b | 28.30 ± 3.66b |

| Cohesivity | 0.37 ± 0.10b | 0.34 ± 0.07b | 1.42 ± 1.70a |

| Gumminess (N) | 21.92 ± 8.44a | 17.66 ± 5.68a | 17.04 ± 1.82a |

| Elasticity (mm) | 0.88 ± 0.33a | 0.91 ± 0.29a | 1.63 ± 0.11a |

| Masticability (N/mm) | 21.92 ± 8.44a | 17.68 ± 5.68a | 17.56 ± 1.70a |

| L* | 60.12 ± 2.81a | 62.47 ± 1.32a | 59.31 ± 0.23a |

| a* | 8.84 ± 0.90a | 9.0 ± 1.2a | 9.45 ± 0.95a |

| b* | 19.95 ± 2.21a | 15.98 ± 2.64a | 18.58 ± 1.36a |

Results are the mean ± SD from triplicate analysis. Means in rows with different superscript letters are significantly different by Fisher’s LSD method (p < 0.05). OVS1 = 38.3% pork meat/53.3% turkey meat/8.4% SDFC; OVS2 = 68.75% pork meat/23.75% turkey meat/7.5% SDFC; OVS3 = 23.75% pork meat/68.75% turkey meat/7.5% SDFC

FW fresh weight, DW dry weight

The range content of total DF (11.04–17.7%), protein (43.43–46.06%) and fat (35.82–39.75%) determined in the three optimized Vienna-type sausages formulated with SDFC (Table 5), especially in OVS1 is higher than those reported (0.88–3.20%, 11.51–13.32% and 18.01–21.10% DW, respectively) in bolognas sausages prepared with date flesh paste in different proportions (5–15%) (Sánchez-Zapata et al. 2011).

On the other hand, OVS1 showed the highest (p < 0.05) polyphenol content and antioxidant capacity (ABTS assay) and the lowest (p < 0.05) residual nitrite content (Table 5) compared to the OVS2 and OVS3 samples. This product had a reduced residual nitrite content (46.41%) respect to the Vienna-type sausages of pork or turkey meat without SDFC (Table 2), which is desirable because nitrites are considered toxic for the human health, since they can form carcinogenic nitrosamines in acidic environmental conditions of stomach (Honikel 2008).

Regarding the physical properties of optimized Vienna sausages, the higher proportion of SDFC in the OVS1 and its higher DF content favored the lowest shrinkage and the highest hardness with a high cohesiveness value compared to OVS2 and OVS3 (Table 5). This could be attributed to the higher functional properties of DF such as water retention (Sánchez-Zapata et al. 2011). The shear force values presented in the three optimized products were slightly higher (27.19–41.75%) than those without SDFC (Table 3). However, there were no significant differences among the values of shear force, gumminess, elasticity and masticability of the three optimized sausages, neither the color parameters (L*, a* and b*), but it could noted a yellowness (positives value of b*) of sausages.

Sensory evaluation of Vienna-type sausages

Selection and training of sensory panel assessors

Twelve persons aged between 20 and 40 years old (eight women and four men) were evaluated to form the sensory panel assessors. The odour recognition test was favourable and there was 85% of correct answers, while the recognition test of basic flavours had a 93% of the correct answers for the assessors. The test of the intensity evaluation resulted that assessors generated up to 90% of the correct answers.

After the evaluation of assessors, ten panelists were selected (6 woman and 4 man of 22–40 years old) and training. Triangular test showed that the 12 assessors were able to identify the differences between the evaluated sausages. Finally, the panellists generated 13 descriptors for sausages, 5 descriptors relating to flavour (salty, sour) and odour (meat, smoke, garlic), 2 descriptors relating to color (intensity and homogeneity) and 4 descriptors relating to texture (hardness, gumminess, fibrous, juiciness).

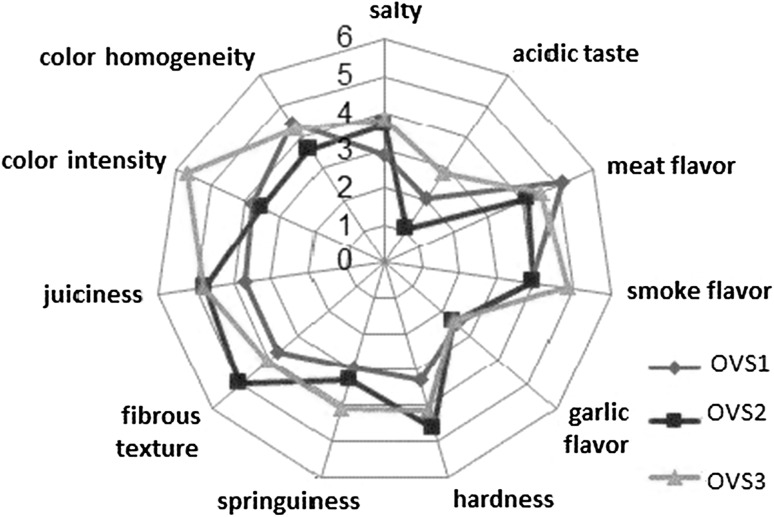

Flash profile analysis and consumer acceptability test of Vienna sausages

The results of the Flash Profile to describe the sensory attributes of the optimized sausages are shown in a radial graphic (Fig. 2). There were no significant differences in all the attributes between the three optimized sausages except in color intensity which was higher (p < 0.05) in sausage with the highest proportion of SDFC (8.4%) maybe by its higher yellow color. Panelists no detected differences (p > 0.05) in the hardness and fibrous texture between any optimized sausages. Three optimized sausages were describe with low acidic taste and moderately salty, and the meat flavor was no decreased in the formulation with the highest concentration of SDFC (OVS1).

Fig. 2.

Results of the consumer acceptability of optimized Vienna sausages formulated with SDFC

There was no significant difference in the sensory consumer acceptance between OVS1 and OVS2 formulations which showed the highest acceptability; these samples had an average values of 7.05 ± 0.70 and 7.18 ± 0.85, respectively, which correspond to “I like” in the hedonic scale; while the OVS3 had lower (p < 0.05) acceptability of 6.92 ± 0.95 (“I like a little”) than OVS2. This could be due to the higher proportion of turkey meat in the OVS3 (68.75%) than OVS1 and OVS2. Therefore, Vienna sausages formulated with high proportion (7.5 or 8.5%) of SDFC in mixture with pork meat at a minimum of 38.3% proportion and turkey meat until up 53.3% of proportion were sensory acceptable for the consumers.

Conclusion

The SDFC in mixture with pork or turkey meats have a binary synergistic effect contributing to a significant reduction in nitrite content, moisture, shrinkage and shear force, and an increase in polyphenol content in Vienna-type sausages. The optimization provided Vienna-type sausages formulated with a ternary mixture of pork/turkey meat and high SDFC proportion (7.4–8.4%) which had high total DF content up to 17–79%, polyphenols with antioxidant activity, reduced residual nitrite content (46.41%), low shrinkage values and red color. Also, they had good taste, color and texture attributes, and was sensory acceptable to the consumer. This study demonstrated that enrichment of Vienna-type sausages with SDFC in mixture with pork and turkey meat is a way to obtain potential functional meat products reduced in nitrites with high content of DF and antioxidant polyphenols, sensory acceptable to the consumer, and improved in their physical properties that could contributes to the daily recommended intake levels of fiber.

Acknowledgements

The authors thank to Tecnológico Nacional de México for the financial support of the Project 5938.16-P.C-P “Red para el Aprovechamiento de Derivados Nutracéuticos para el Control de enfermedades crónico degenerativas”. Also, we are grateful to Consejo Nacional de Ciencia y Tecnología-CONACYT for the financial support to Red Temática en Seguridad Alimentaria Valorización de Residuos Agroindustriales y Disminución de Pérdidas y Desperdicios de Alimentos (PDA), and for the Master in Food Science scholarship of Solano-Barrera.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

References

- American Association of Cereal Chemist (AACC) International (2009) Approved methods of analysis, 11th edn. Method 32-07.01. Soluble, insoluble, and total dietary fiber in foods and food products (final approval 10-16-91). AACC International Press, St. Paul

- Association of Official Analytical Chemists (AOAC) (2005). In: Horwitz W, Latimer GW (eds) Official methods of analysis, 18th edn. AOAC International, Gathersburg

- Bazan-Lugo E. Nitritos y Nitratos: Su uso, control y alternativas en embutidos cárnicos. Nacameh. 2008;2(2):160–187. [Google Scholar]

- Bravo L, Saura-Calixto F. Characterization of the dietary fiber and the in vitro indigestible fraction of grape pomace. Am J Enol Vitic. 1998;49:135–141. [Google Scholar]

- Brewer S. Technological quality of meat for processing, chapter 2. In: Toldrá F, editor. Handbook of meat processing. 1. Hoboken: Blackwell Publishing; 2010. pp. 25–42. [Google Scholar]

- Díaz-Vela J, Totosaus A, Héctor B, Escalona-Buendía M, Pérez-Chabela L. Influence of the fiber from agro-industrial co-products as functional food ingredient on the acceptance, neophobia and sensory characteristics of cooked sausages. J Food Sci Technol. 2017;54(2):379–385. doi: 10.1007/s13197-016-2473-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Honikel KO. The use and control of nitrate and nitrite for the processing of meat products. Meat Sci. 2008;78:68–76. doi: 10.1016/j.meatsci.2007.05.030. [DOI] [PubMed] [Google Scholar]

- Jiménez-Colmenero F, Delgado-Pando G. Fiber-enriched meat products. In: Delcour JA, Poutanen K, editors. Fiber-rich and wholegrain foods. Oxford: Woodhead Publishing Limited; 2013. pp. 329–347. [Google Scholar]

- Kim IS, Jin SK, Mandal PK, Kang SN. Quality of low-fat pork sausages with tomato powder as color and functional additive during refrigerated storage. J Food Sci Technol. 2011;48(5):591–597. doi: 10.1007/s13197-010-0182-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ktari N, Smaoui S, Trabelsi I, Nasri M, Salah RB. Chemical composition, techno-functional and sensory properties and effects of three dietary fibers on the quality characteristics of Tunisian beef sausage. Meat Sci. 2014;96:521–525. doi: 10.1016/j.meatsci.2013.07.038. [DOI] [PubMed] [Google Scholar]

- Li YO, Komarek AR. Dietary fiber basics: health, nutrition, analysis, and applications. Food Qual Saf. 2017;1(1):47–59. doi: 10.1093/fqsafe/fyx007. [DOI] [Google Scholar]

- Li L, Shao J, Zhu X, Zhou G, Xu X. Effect of plant polyphenols and ascorbic acid on lipid oxidation, residual nitrite and N-nitrosamines formation in dry-cured sausage. Int J Food Sci Technol. 2013;48:1157–1164. doi: 10.1111/ijfs.12069. [DOI] [Google Scholar]

- Mehta N, Ahlawat SS, Sharma DP, Dabur RS. Novel trends in development of dietary fiber rich meat products: a critical review. J Food Sci Technol. 2015;52(2):633–647. doi: 10.1007/s13197-013-1010-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nisa AU, Zahra N, Hina Sajila, Masood S, Javed A, ManzarInam S. Development of meat-based functional foods: a review. J Appl Biol Biotechnol. 2017;5(03):086–092. [Google Scholar]

- Norma Oficial Mexicana (2002) NOM-213-SSA1-2002. Productos y Servicios. Productos cárnicos procesados. Especificaciones Sanitarias. Métodos de Prueba. Dirección General de Normas (in Spanish)

- O’Shea N, Arendt EK, Gallagher E. Dietary fiber and phytochemicals characteristics of fruit and vegetable by-products and their recent applications as novel ingredients in food products. Innov Food Sci Emerg Technol. 2012;16:1–10. doi: 10.1016/j.ifset.2012.06.002. [DOI] [Google Scholar]

- Pantaleón-Velasco MR, Ruiz-López II, Pérez-Silva A, Bravo-Clemente L, Mateos R, Ruiz-Espinosa H, Vivar-Vera MA. Antioxidant and functional properties of a high dietary fiber powder from carambola (Averrhoa carambola L.) pomace. Int J Food Sci Technol. 2014;49(9):2101–2110. doi: 10.1111/ijfs.12519. [DOI] [Google Scholar]

- Pulido R, Bravo L, Saura-Calixto F. Antioxidant activity of dietary polyphenols as determined by a modified ferric reducing/antioxidant power assay. J Agric Food Chem. 2000;48(8):3396–3402. doi: 10.1021/jf9913458. [DOI] [PubMed] [Google Scholar]

- Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med. 1999;26(9):1231–1237. doi: 10.1016/S0891-5849(98)00315-3. [DOI] [PubMed] [Google Scholar]

- Sánchez-Zapata E, Fernández-López J, Peñaranda M, Fuentes-Zaragoza E, Sendra E, Sayas E, Pérez-Alvarez JA. Technological properties of date paste obtained from date by-products and its effect on the quality of a cooked meat product. Food Res Int. 2011;44(7):2401–2407. doi: 10.1016/j.foodres.2010.04.034. [DOI] [Google Scholar]

- Sharma K, Bansal S, Mangal M, Dixit AK, Gupta RK, Mangal AK. Utilization of food processing by-products as dietary, functional, and novel fiber: a review. Crit Rev Food Sci Nutr. 2016;56:1647–1661. doi: 10.1080/10408398.2013.794327. [DOI] [PubMed] [Google Scholar]

- Verma AK, Banerjee R. Dietary fiber as functional ingredient in meat products: a novel approach for healthy living: a review. J Food Sci Technol. 2010;47(3):247–257. doi: 10.1007/s13197-010-0039-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Viuda-Martos M, Ruiz-Navajas Y, Fernández-López J, Pérez-Álvarez JA. Effect of adding citrus fiber washing water and rosemary essential oil on the quality characteristics of a bologna sausage. LWT Food Sci Technol. 2010;43:958–963. doi: 10.1016/j.lwt.2010.02.003. [DOI] [Google Scholar]