Abstract

Effects of processing parameters such as creaming time, dough mixing time, cookie thickness, baking temperature, time and principal ingredients viz. sugar, fat and water on quality of sugar snap cookies were investigated using the Response Surface Methodology. Shorter mixing time (100 s) along with higher creaming time (400 s) was desirable for producing softer cookies with tender bite and higher spread factor. Cookie baked at 190 °C had superior quality in terms of hardness and spread factor as compared with those baked either at lower or at higher temperature. At lower baking temperature, hardness of cookie increased as the baking time was decreased below 14 min. Hardness also increased significantly with increase in water content at all levels of sugar concentration in the formula. Optimum cookie quality was obtained with creaming time of 400 s and mixing time 100 s to make cookie dough containing 59.65% sugar, 46.68% fat and 14% water. Cookie thickness 11 mm, baking temperature 190 °C and baking time of 16 min 30 s resulted in best cookies.

Keywords: Processing parameters, Ingredients, Cookie, Hardness, Spread factor

Introduction

Dough for cookie is composed of three principal components, other than flour it contains fat, sugar and water. Dough and final product (cookie) quality is characterized by the nature and quantity of ingredient composition (Panghal et al. 2011a). The behavior of ingredients used in cookie may differ when they are used in combination. Dough ingredients also influenced the processing parameters predominately. Soft wheat flour is usually preferred for cookie making as it produces cookies with desired spread and surface characteristics with greater tenderness and softer bite. Dough of good cookies making flour flows much faster in comparison to made from poor cookies quality flour. Greater spread factor and larger cookie diameter are considered as suitable and most desirable cookie quality characteristics (Panghal et al. 2011b). The rate of dough flow, expansion and setting time after the dough expansion during baking regulates the final cookie spread factor and diameter. The amount of ingredients used in the cookie formulation and their interaction affect the dough viscosity and hence the rate of spread (Singh et al. 2002; Hoseney and Rogers 1994). However, conflicting results have been reported by researchers regarding effects of ingredients on the quality of cookies. Sugars have little effect on sugar-snap cookie spread (Abboud et al. 1985); however contradictory results were also reported (Drewnowski et al. 1998). The water amount in formulation had slight or no effect on final cookie spread factor and diameter (Miller et al. 1997). Finished product quality is regulated by processing treatments and heating temperature is an important aspect (Panghal et al. 2009). Processing conditions such as creaming time, mixing time, thickness of cookies, baking time and temperature also affect cookie quality substantially. Creaming and mixing are the initial steps in cookie making process and these operations allow the mixing of flour, fat, sugar, water and other ingredients to form coherent mass. The mechanical behavior of dough have a significant effect on handling the dough during processing and thus quality attributes of finished products (Khatkar and Schofield 2002). The findings by various researchers on the effects of principal ingredients and processing parameters on final quality of various types of cookies (Chevallier et al. 2002; Cronin and Preis 2000; Manohar and Rao 1997; Singh et al. 2002) appear to be conflicting. Moreover, no study has planned and reported so far on the cumulative effect of basic ingredients and process parameters on cookie quality characteristics. A good understanding of various formula ingredients behavior in cookie baking and effect of process parameters should provide an opportunity to understand the factors regulating the quality of cookies. Therefore, present research was conducted to study the effect of formula ingredients (flour, fat, sugar and water) and process parameters (creaming time, dough mixing time, dough sheeting, thickness of cookies, baking temperature and time) using Response Surface Methodology.

Materials and methods

Procurement of raw material and milling

Sound grains of wheat variety ‘Sonak’ were obtained from CCS Haryana Agriculture University, Hisar, Haryana, India. Shortening and sugar were purchased from local area market and sugar was ground coarsely in laboratory grinder.

Cleaned wheat grains were conditioned with moisture content 14.5% for 24 h and additional 0.5% moisture was increased 30 min prior milling to facilitate the bran separation (Panghal et al. 2011a). The tempered grains were milled in a laboratory mill Chopin laboratory Flour and Semolina Mill (Model CD 1, France) to get flour. Flour sample was stored at − 20 °C and used after proper thawing of 2 h at room temperature.

Physical analysis of grain

General grain characteristics like kernel length, width, kernel weight and test weight of the sample were determined to evaluate grain quality. The kernel length and width of the sample were determined using digital Vernier caliper (Mitutogo Corporation, Model CD-6 BS). Thousand kernel weight (g) of grains was measured by using seed counter (Dexter et al. 1984). Hectolitre weight of the sample was measured as mentioned in Panghal et al. 2017 and was expressed as kg/hL.

Physicochemical analysis

Chemical characteristics like ash, moisture, protein, and sodium dodecyl sulphate (SDS) sedimentation volume were analyzed as per approved methods of American Association of Cereal Chemists (AACC 2000). Dough was prepared in one chamber of glutomatic instrument (Perten) and dough was washed with 2% NaCl solution resulting in removal of water and salt soluble proteins. Gluten obtained was dried using gluten dryer (Adhesive Drier Device CE, Max Egger Laborgerte, Austria). All results were observed in triplicates.

Experimental design

To optimize different variables viz., experiment design, selection of variables level range in different formulations, fitting of mathematical models and optimized levels selection of variables with respect to optimized responses, was done by using Design Expert 10. RSM (response surface methodology) is a statistical technique used to design experiments that yield the relevant information with minimum cost in the shortest time. The effect of processing parameters Creaming Time (120–540 s), Mixing Time (80–200 °C), Baking temperature (128–250 °C), baking time (6–18 min), thickness (5–11 mm) on cookie hardness and spread was studied. The impact of ingredients, sugar (29.8–80.2 g), fat (13.2–46.8 g), water (13.2–46.8 ml) on cookie texture and spread factor were studied. Central composite design was used for selection of variable combination levels in each experiment. The independent variables optimized were creaming time (X1), mixing time (X2), cookie thickness(X3), baking temp (X4) and baking time (X5) for dependent response variable Y1 (spread ratio) and Y2 (cookie hardness). The actual values of the variables for each experiment along with the measured response value have been represented in Table 1. The variables were standardized to simplify computation and deduce their relative effect of variables on the responses. The magnitude of the coefficients in second order polynomial shows the effect of that variable on the response.

where b0 is the value for the fixed response at the central point of the experiment; and bi, bii and bij are the linear, quadratic and cross-product coefficients, respectively.

Table 1.

Experimental design for process parameters and their effect on cookie quality

| Creaming time (s) | Mixing time (s) | Baking temp ( °C) | Baking time (s) | Thickness (mm) | Compression force (g) | Spread factor (Diameter/thickness) |

|---|---|---|---|---|---|---|

| 240 | 80 | 165 | 14 | 7 | 2610 | 10.71 |

| 240 | 150 | 220 | 9 | 7 | 3150 | 10.39 |

| 330 | 115 | 193 | 12 | 9 | 2200 | 8.83 |

| 420 | 80 | 220 | 9 | 7 | 2300 | 10.71 |

| 330 | 115 | 193 | 6 | 9 | 2601 | 8.70 |

| 330 | 115 | 128 | 12 | 9 | 3800 | 8.52 |

| 330 | 40 | 193 | 12 | 9 | 3402 | 8.14 |

| 330 | 115 | 193 | 12 | 9 | 2200 | 8.83 |

| 240 | 80 | 220 | 9 | 7 | 2500 | 10.57 |

| 240 | 80 | 220 | 14 | 11 | 3200 | 7.52 |

| 330 | 115 | 193 | 17 | 9 | 2097 | 8.91 |

| 420 | 150 | 165 | 14 | 11 | 3500 | 7.55 |

| 240 | 150 | 165 | 14 | 7 | 3100 | 10.24 |

| 420 | 150 | 220 | 9 | 7 | 2900 | 10.47 |

| 420 | 150 | 165 | 9 | 11 | 4200 | 7.43 |

| 240 | 80 | 165 | 9 | 7 | 2817 | 10.47 |

| 330 | 115 | 250 | 11 | 9 | 4000 | 8.64 |

| 420 | 150 | 165 | 14 | 7 | 2800 | 10.67 |

| 330 | 115 | 193 | 16 | 9 | 1761 | 8.94 |

| 420 | 80 | 165 | 14 | 11 | 2860 | 7.73 |

| 420 | 80 | 220 | 14 | 11 | 2970 | 7.61 |

| 120 | 115 | 193 | 12 | 9 | 3100 | 8.83 |

| 240 | 80 | 165 | 9 | 11 | 3400 | 7.48 |

| 540 | 115 | 193 | 12 | 9 | 2640 | 8.91 |

| 420 | 80 | 165 | 14 | 7 | 2100 | 10.96 |

| 330 | 115 | 193 | 14 | 9 | 2067 | 8.92 |

| 240 | 150 | 220 | 9 | 11 | 4100 | 7.43 |

| 240 | 150 | 165 | 14 | 11 | 4200 | 7.57 |

| 420 | 150 | 220 | 14 | 11 | 3600 | 7.43 |

| 240 | 80 | 220 | 14 | 7 | 3105 | 10.61 |

| 240 | 80 | 165 | 14 | 11 | 3167 | 7.66 |

| 420 | 80 | 220 | 14 | 7 | 2800 | 10.71 |

| 420 | 80 | 165 | 9 | 7 | 2600 | 10.76 |

| 330 | 115 | 193 | 15 | 9 | 1962 | 8.94 |

| 420 | 150 | 165 | 9 | 7 | 3427 | 10.47 |

| 330 | 115 | 193 | 13 | 9 | 1863 | 8.91 |

| 240 | 80 | 220 | 9 | 11 | 3726 | 7.53 |

| 330 | 115 | 193 | 18 | 9 | 2772 | 8.91 |

| 240 | 150 | 165 | 9 | 7 | 3672 | 10.54 |

| 420 | 150 | 220 | 9 | 11 | 3960 | 7.43 |

| 240 | 150 | 220 | 14 | 7 | 3960 | 10.43 |

| 330 | 200 | 193 | 12 | 9 | 3897 | 8.52 |

| 420 | 80 | 220 | 9 | 11 | 3510 | 7.61 |

| 420 | 150 | 220 | 14 | 7 | 3510 | 10.53 |

| 240 | 150 | 165 | 9 | 11 | 4500 | 7.48 |

| 240 | 150 | 220 | 14 | 11 | 3800 | 7.43 |

| 330 | 115 | 193 | 12 | 14 | 3800 | 6.31 |

| 330 | 115 | 193 | 12 | 9 | 2067 | 8.89 |

| 420 | 80 | 165 | 9 | 11 | 3096 | 7.55 |

| 330 | 115 | 193 | 12 | 5 | 2115 | 13.66 |

The regression analysis was performed using central composite design to optimize five process parameters (independent variables) i.e. creaming time, mixing time, baking temperature, baking time and cookie thickness for cookie making. The optimized process parameters were used to study the effect of principal ingredients sugar (A); fat (B); and water (C) on spread factor and hardness of cookies.

Cookie preparation

Cookie dough was prepared according to AACC method using different combinations of process parameters (Table 1). The dough was sheeted to different thickness with the help of dough sheeter (Model SF 600, Italy). The cookie dough pieces were cut with a cookie die of 60 mm diameter as described in AACC method and transferred to baking tray. The cookies were baked at different time and temperature conditions in baking oven (Model BX2-640 classic, Mono Equipment’s Ltd., UK). The optimized conditions were used to study the effects of principal ingredients (in different combinations as shown in Table 2).

Table 2.

Experimental design for principal ingredients and their effect on cookie quality

| Sugar (g) | Fat (g) | Water (ml) | Compression force (g) | Spread factor (Diameter/thickness) |

|---|---|---|---|---|

| 55 | 13.2 | 30 | 2155.25 | 5.071429 |

| 40 | 40 | 20 | 913.33 | 8.1111 |

| 80.2 | 30 | 30 | 1940.33 | 10.375 |

| 70 | 20 | 20 | 2874 | 7.6 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 70 | 20 | 40 | 1402.33 | 5.8148 |

| 55 | 46.8 | 30 | 1461.5 | 7.77 |

| 55 | 30 | 13.2 | 2234.2 | 7.467 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 40 | 20 | 20 | 2417.6 | 5.387 |

| 29.8 | 30 | 30 | 2031.5 | 6.027 |

| 40 | 20 | 40 | 553.25 | 4.667 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 55 | 30 | 46.8 | 522 | 5.0556 |

| 70 | 40 | 40 | 1003 | 8.169 |

| 55 | 30 | 30 | 2155.25 | 6.199 |

| 40 | 40 | 40 | 1147 | 6.4167 |

| 70 | 40 | 20 | 1431 | 10.63 |

Cookie properties

The baked cookies were observed for spread factor and hardness.

Spread factor

The cookie diameter measured by placing seven cookies edge to edge and thickness by stacking one above the other, respectively. The cookies were rearranged and restacked to obtain the average measurements.

Cookie texture

The cookie hardness was recorded, as force required to cut/break the cookie using Texture analyzer (Model TA-XT 2i) with software Texture Expert Exceed (version 2.61), Stable Micro Systems, U.K. The cookie hardness was recorded as the force required for breaking the cookie with Knife Edge with Slotted Insert (HDP/BS) using 5 kg load cell Heavy Duty Platform (HDP/90). This peak force (g) at breaking point was represented hardness of cookie (Panghal et al. 2011b). The cookies were rearranged and restacked to obtain the average measurements. Ten measurements per replication were taken and average values are reported.

Statistical analysis

The data obtained from the experimental trials was analysed for analysis of variance (ANOVA) and regression models using statistical Design expert 8.0.4.1 software (State Ease Inc., Minneapolis, USA). A second order polynomial was fitted to data to obtain regression equations and was evaluated for significance. The significance of the models was analyzed using model analysis and coefficient of determination (R2) value (Weng et al. 2001). Coefficient of determination, ratio of explained variation to the total variation, explains the model fitness.

Analysis of data

Multiple regression equation was used to fit the model as suggested by Yadav et al. (2008). The mapping of fitted response was achieved using Design Expert 10 software. The contour graphs for model were plotted as function of two variables, while keeping other one at optimum level.

Results and discussion

Physical analysis

Length and breadth of grain were 7.1 ± 0.08 and 3.5 ± 0.11 mm respectively. The L/B ratio for Sonak was 2.03 ± 0.13. Thousand kernel weight of wheat grains was 41.0 ± 0.45 g and hectoliter weight was 84.0 ± 0.33 kg/L.

Proximate analysis

The proximate analysis showed that flour has moisture (13.4 ± 0.16%), protein (10.4 ± 0.08%), ash content (0.45 ± 0.02%), SDS-sedimentation volume (32 ± 1.20 ml), and falling number (540 ± 1.00 s). Wet and dry gluten contents were found 29 ± 0.80% and 9.6 ± 0.24%.

Optimization of creaming and mixing time

The mixing time had a significant effect on both the cookie hardness and spread factor. This was observed that on increasing the mixing time from 80 to 150 s, the diameter of cookies decreased from 88.3 to 68.3 mm (Table 1) leads to spread factor reduction from 10.96 to 10.67 and hardness increase from 2100 to 2800 g keeping other parameters constant. By kneading the dough continously enough gluten network was developed resulting in tough dough, thus restricting the flow of dough. This behaviour is also supported by other researchers also. Panghal et al. 2006 suggested that wheat proteins control the special dough properties and the quality of the processed food products like cookie spread factor.

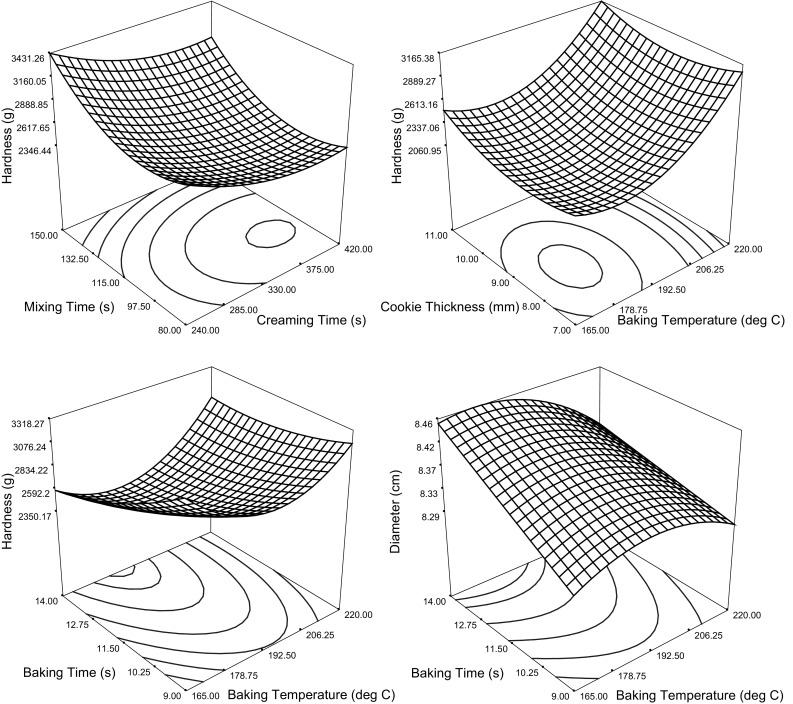

The gluten network also results in hard texture cookies. Dough with longer mixing time produced thicker and harder cookies that needed more force to puncture, indicating lower crispness (Table 1). The optimum creaming time for good spread factor and lesser hardness obtained from the RSM was 400 s. This was observed that on increasing the creaming time from 120 to 400 s, the spread factor was increased from 8.83 to 10.96 and hardness decreased from 3100 to 2100 g. The results in Table 1 and Fig. 1 clearly depicted that proper creaming is essential to reduce gluten network and produce good quality cookies. Mixing time had adverse effect on the hardness of cookies that can be reduced to some extent by proper creaming of basic ingredients, thus restricting gluten network. However, independently the creaming time did not show any substantial effect on the hardness of cookies. The shorter mixing time (< 100 s) in combination with longer creaming time (> 350 s) is desirable for producing softer cookies with tender bite (Fig. 1).

Fig. 1.

Effect of processing parameters on cookie quality

Optimization of cookie thickness

The results clearly depicts that with increase in thickness of the cookies there was an increase in the spread factor (Fig. 1), suggesting more speedily flow of the cookies dough during baking. The rate of cookie dough flow in the oven increased with increase in thickness because of gravitational forces. On the other hand, cookies hardness had positive correlation with thickness at different processing parameters, confirming weight hardness relationship among cookies (Sharma et al. 2016).

Optimization of baking temperature

The chemical conversion in cookie dough during baking are very complex involving fat melting, loss of starch granular structure, protein denaturation, maillard reactions, dough expansion by thermal expansion of gases and water evaporation (Chevallier et al. 2002). All these changes depend on the baking temperature of cookies. Cookie baked at 190 °C had superior quality with respect to hardness and spread factor as compared with those baked either at lower (128 °C) or higher temperature (250 °C). On increasing the baking temperature (> 190 °C), spread factor decreased. In the oven, the sugars and fat melt that causes the spread of cookies dough. However, at higher baking oven temperature (> 190 °C), the viscosity of the dough increases rapidly due to early starch gelatinization and protein coagulation which stops the spread of cookie dough. Higher oven temperature also leads to an early escape of gases and vapors from dough due to stress hardening of dough that makes the cookies more denser and harder (Table 1).

Optimization of baking time

The optimum baking time allows proper drying and development of open porous structure thus influencing the cookie quality. When baking time is reduced, cookies with less spread factor and hardness were produced. The browning of cookie surface due to maillard reaction and sugar caramalisation is the final step of baking. In the present study, at lower baking temperature the cookie spread factor increased with increase in baking time but at higher baking temperature the change in baking time did not affect the spread factor due to an early setting of cookie dough. Hardness of cookie increased as the baking time was decreased below 14 min at low baking temperature.

Optimization of formula ingredients

Sugar

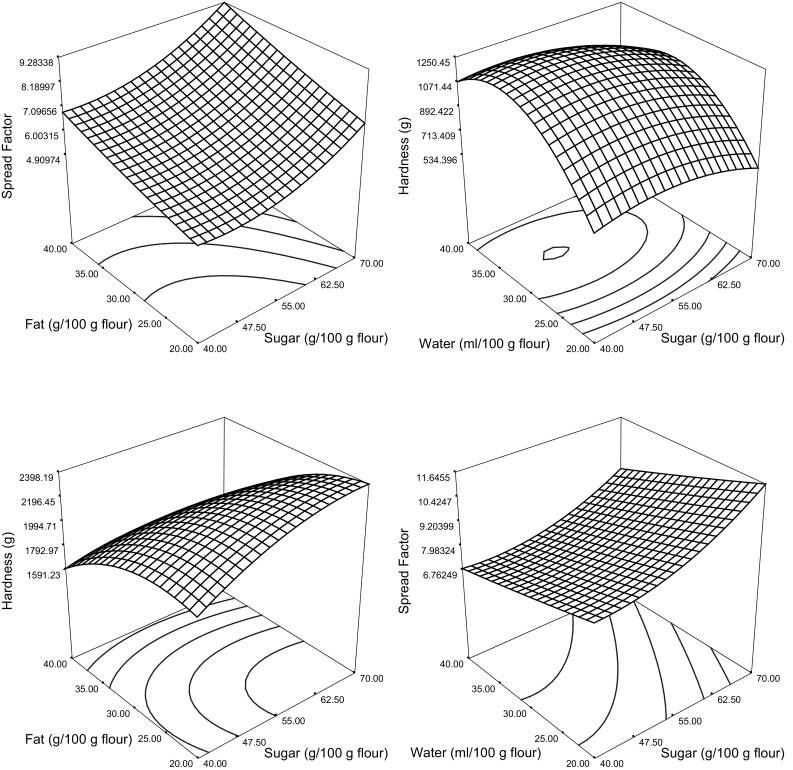

The results in Fig. 2 show a positive correlation between sugar content and spread factor. On increasing sugar content, spread factor was also increased. Sugar increases the dough flow during baking and spread more under function of gravity. Effect of increase in sugar proportion on spread was enhanced with increase in fat level (Fig. 2). The increase in spread factor of cookie with addition of sugar improved with increase of fat content. Sugar influenced the hardness of cookies (Fig. 2); an increase in its concentration at lower fat content was directly reflected in an increase in hardness which gave an indication of cohesion of cookie structure. This might be due to stronger bonding between particles after crystallisation resulting in cohesion of cookies structure. Similar results was also reported by other researcher as well (Rezzoug Maache et al. 1998).

Fig. 2.

Effect of principal ingredients on cookie quality

Fat

The presence of fat in the formula favoured increase in spread factor of cookies (Fig. 2). Increased levels of fat with higher sugar levels resulted in improved cookies with desirably softer texture and greater spread factor. Hardness of the end product was closely related with the fat content. Increasing fat contents was found associated with reduction in hardness of the cookies (Fig. 2). The incearse in the fat content produced more friable cookies. This might be due to the fat encapsulation by the flour particles, thereby isolating them from each other and hence produces friable cookies. Fat coating of flour particles also prevents development of gluten proteins network during mixing. Similar results have been reported by Jacob and Leelavathi (2007).

Water

The experimental data indicate that water has no significant effect on the spread factor of the cookies at lower levels of sugars (Fig. 2). At higher levels of sugar spread factor decreased slightly with increase in water content in the formula. Overall, the effect of water content on spread factor characteristics of cookies was less marked than that recorded with sugar and fat. Hardness of cookies increased significantly with increase in water content at all levels of sugar concentration in the formula.

Model equation

The quadratic model equations between dependent variables and independent variables along with their interactive effects were:

A, B and C in the above equations are sugar, fat and water, respectively. R2 values of the model was sufficiently high, indicating the validity of the analysis.

Regression analysis of processing variables modeling were used for obtained best optimum conditions for the desired values of responses such as spread factor and hardness of cookies. Validation of model was done by analyzing various significant statistical aids such as F-value and coefficient of determination (R2). All these terms revealed the statistical adequacy of model. The experimental and predicted values were in agreement with each other.

Conclusion

The RSM approach was used to optimize the process parameter and principal ingredients in the cookies production using hardness, diameter and spread factor as responses. The results demonstrate clearly that the developed models are suitable and can describe the effect of process conditions like creaming time, dough mixing time, cookie thickness, baking temperature and time along with principal ingredients. The model also explains the impact of sugar, shortening, and water on cookie characteristics. The process conditions and principal ingredients were optimized by numerical methods and the optimum product quality in terms of hardness (1520 g) and spread factor (10.98) were obtained at creaming time 400 s; mixing time 100 s; cookie thickness 11 mm; baking temperature 190 °C and baking time 16 min 30 s with cookie dough formulation containing sugar 59.65/100 g flour, fat 46.68/100 g flour and water 14 ml/100 g flour.

References

- AACC . Approved methods of American Association of Cereal Chemists. 10. Minnesota: St Paul; 2000. [Google Scholar]

- Abboud AM, Hoseney RC, Rubenthaler GL. Effect of fat and sugar in sugar-snap cookies and evaluation of tests to measure cookie flour quality. Cereal Chem. 1985;62:124–129. [Google Scholar]

- Chevallier S, Valle GD, Colonna P, Broyart B, Trystram G. Structural and chemical modifications of short dough during baking. J Cereal Sci. 2002;35:1–10. doi: 10.1006/jcrs.2001.0388. [DOI] [Google Scholar]

- Cronin K, Preis C. A statistical analysis of biscuit physical properties as affected by baking. J Food Eng. 2000;46:217–225. doi: 10.1016/S0260-8774(00)00053-4. [DOI] [Google Scholar]

- Dexter JE, Preston KR, Matsuo RR, Tipples KH. Development of a high extraction flow for the grl pilot mill to evaluate Canadian wheat potential for the Chinese market. Can Inst J Food Sci Tech. 1984;17:253. doi: 10.1016/S0315-5463(84)72567-3. [DOI] [Google Scholar]

- Drewnowski A, Nordensten K, Dwyer J. Replacing sugar and fat in cookies: impact on product quality and preference. Food Qual Prefer. 1998;9(1):13–20. doi: 10.1016/S0950-3293(97)00017-7. [DOI] [Google Scholar]

- Hoseney RC, Rogers DE. Mechanism of sugar functionality in cookies. In: Faridi H, editor. The science of cookie and cracker production. New York: AVI; 1994. [Google Scholar]

- Jacob J, Leelavathi K. Effect of fat-type on cookie dough and cookie quality. J Food Eng. 2007;79:299–305. doi: 10.1016/j.jfoodeng.2006.01.058. [DOI] [Google Scholar]

- Khatkar BS, Schofield JD. Dynamic rheology of flour dough. II. Assessment of dough strength and bread making quality. J Sci Food Agric. 2002;82:823–826. doi: 10.1002/jsfa.1111. [DOI] [Google Scholar]

- Manohar RS, Rao PH. Effect of mixing period and additives on the rheological characteristics of dough and quality of biscuits. J Cereal Sci. 1997;25:197–206. doi: 10.1006/jcrs.1996.0081. [DOI] [Google Scholar]

- Miller RA, Hoseney RC, Morris CF. Effect of formula water content on the spread of sugar-snap cookies. Cereal Chem. 1997;74:669–671. doi: 10.1094/CCHEM.1997.74.5.669. [DOI] [Google Scholar]

- Panghal A, Khatkar BS, Singh U. Cereal proteins and their role in food industry. Indian Food Ind. 2006;25(5):58–62. [Google Scholar]

- Panghal A, Khatkar BS, Singh U. Applications of cereal starches in food processing. Indian Food Ind. 2009;28(2):37–44. [Google Scholar]

- Panghal A, Navnidhi CV, Khatkar BS. Effect of minor ingredients on quality of cookies. Ann Agri-Bio Res. 2011;16(1):79–84. [Google Scholar]

- Panghal A, Navnidhi CV, Khatkar BS. Effect of enzymes on cookies quality. Ann Agri-Bio Res. 2011;16(1):75–78. [Google Scholar]

- Panghal A, Chhikara N, Khatkar BS. Characterisation of Indian wheat varieties for chapatti (flat bread) quality. J Saudi Soc Agric Sci. 2017 [Google Scholar]

- Rezzoug Maache Z, Bouvier JM, Allaf K, Patras C. Effect of principal ingredients on rheological behaviour of biscuit dough and on quality of biscuits. J Food Eng. 1998;35:23–42. doi: 10.1016/S0260-8774(98)00017-X. [DOI] [Google Scholar]

- Sharma S, Singh N, Katyal M. Effect of gelatinized-retrograded and extruded starches on characteristics of cookies, muffins and noodles. J Food Sci Technol. 2016;53(5):2482–2491. doi: 10.1007/s13197-016-2234-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh N, Gupta S, Sodhi NS, Singh RP. Effect of additives on dough and cookie making properties of flour. Int J Food Prop. 2002;5:547–562. doi: 10.1081/JFP-120015491. [DOI] [Google Scholar]

- Weng W, Liu W, Lin W. Studies on the optimum models of the dairy product Kou Woan Lao using response surface methodology. Asian Australas J Anim. 2001;14(10):1470–1476. doi: 10.5713/ajas.2001.1470. [DOI] [Google Scholar]

- Yadav DN, Patki PE, Mahesh C, Sharma GK, Bawa AS. Optimisation of baking parameters of chapati with respect to vitamin B1 and B2 retention and quality. Int J Food Sci Technol. 2008;43(8):1474–1483. doi: 10.1111/j.1365-2621.2008.01712.x. [DOI] [Google Scholar]