Abstract

Jaggery (Gur) is a natural sweetener made by concentration of sugarcane juice, contains all minerals and vitamins present in sugarcane juice. In order to utilise jaggery in place of sugar, muffins were prepared by replacing 84% sugar with 42, 63 and 84% jaggery. Different levels of eggs namely 42, 63 and 84% were also tried for jaggery muffins. The results showed that muffins prepared with 84% each of jaggery and eggs had acceptable quality characteristics. Effect of jaggery in comparison with sugar on the pasting characteristics of wheat flour, physico-sensory and storage characteristics of muffins were studied. Addition of jaggery and sugar increased pasting temperature and peak viscosity. Higher increase in pasting temperature with jaggery and in peak viscosity with sugar were observed indicating differential influence on pasting characteristics of wheat flour. The muffins with jaggery had lower pH, overall quality score and higher aw than muffins with sugar. During 21 days storage period, pH and aw decreased and titratable acidity increased for both the muffins. Even though the muffins with jaggery were less soft, showed lower overall quality score than the muffins with sugar, muffins with jaggery were acceptable and both the muffins were found to be microbiologically safe, as shown by the microbial load (total mesophilic count and yeast and mold count) in the range of 66–89 CFU/g. Hence, it can be concluded that it is possible to replace sugar with jaggery in muffins without affecting the properties of the product.

Keywords: Jaggery, Sugar, Muffins, Rheological characteristics, Storage studies

Introduction

Jaggery or gur is a solid/semi-solid form of sugar obtained by concentration of sugarcane juice in an open pan. The present production of sugar and jaggery in India are 27.7 and 6.6 million metric tonnes, respectively (Sugar Production Annual Report, USDA 2017). Jaggery is important in Indian diet, which is consumed either directly or used in preparation of various sweet based foods (Verma and Narain 1990). Jaggery is generally called as “medicinal sugar” because of its use in Ayurveda as well as its comparison with honey (The Agricultural and Processed Food Products Export Development, APEDA, 2016). According to Food Safety and Standards Authority of India (FSSAI), the cane jaggery is the product achieved from sugarcane juice (Saccharum officinarum) by boiling or processing. The limit of permissible quality characteristics of jaggery are moisture—7%, sucrose—70%, total sugars—90%, reducing sugars—20%, ash—4% and acid insoluble ash—0.3%.

The parameters important for high market value and consumer’s acceptability of the jaggery are colour, flavour and shelf life. Hussain et al. (2012) studied the preservation of colour, flavour and shelf life of the jaggery. In order to get light coloured jaggery, sulphur dioxide (SO2) is used as juice clarificant during its preparation, hence, light golden colour jaggery is injurious to health (Uppal et al. 2005) and therefore it is advisable to consume jaggery which is darker in colour.

The granular jaggery is rich in minerals (0.6–1%) as it contains 9 mg% calcium, 4 mg% phosphorous and 12 mg% iron (Singh et al. 1978). Jaggery which is far more complex than sugar, as it is made up of longer chains of sucrose with traces of mineral salts, iron and some fiber is digested slower than sugar and releases energy slowly and not instantaneously (Patil et al. 1985).

Jaggery is generally used for preparation of various traditional sweet dishes, such as payasam, obbattu (holige), Hurakki holige stuffing, Karadantu, Madeli, Godhi huggi, Gudagana huggi, Allittu and unday (Inamdar et al. 2005). Tidke et al. (2017) have used jaggery for the development of peanut and chickpea nut Chikki. Other value added products of sugarcane juice are jaggery chocolate, vinegar, gazak, reori, chikki and ramdana (Shahi 1999). Nath et al. (2015) reviewed the value addition of jaggery based products and stated that the jaggery industry is the leading unorganised sector in the country. Sahu and Saxena (1994) have reported study on health benefits of jaggery and found that jaggery can help for prevention of damage to lung in rats. Manufacturing of jaggery is mainly carried out with minimum capital investment by sugarcane growers, which help rural people by giving them employment. Value addition to jaggery in bakery products could fetch higher prices in the market, even globally which could improve the crop cultivation and increase the basic income of the sugarcane growers.

Sucrose is one of the main ingredients in sweet based bakery products. A decrease in the sugar content is accompanied by significant changes in the processing properties of batter/dough, product texture, colour, taste and shelf life (De Souza et al. 2013). Torley et al. (2004) pointed out that individual starch gelatinization characteristic differs in their response to partial or complete substitution of various sugars. Several authors have tried to replace sugar for the production of sugar free muffins and low calorie muffins. Zahn et al. (2013) reported that it is possible to replace 30% sucrose in muffins by steviol glycoside (sweet natural compound from stevia rebaudiana Bertoni leaves) in combination with fibres such as apple, oat, pea and wheat. Manisha et al. (2012) carried out studies on interaction between stevioside, liquid sorbitol, hydrocolloids and emulsifiers for replacement of sugar in cakes. The authors concluded that acceptable quality sugar-free fenugreek cake can be produced by using combination of stevioside, liquid sorbitol, xanthan, polysorbate-60 and debittered fenugreek seed powder.

The microbiological shelf life of high moisture bakery products is related to their pH and water activity (aw). Bakery products, like many processed foods, are subject to physical, chemical and microbiological spoilage (Smith et al. 2004). While physical and chemical spoilage limits the shelf life of low and intermediate moisture bakery products, microbiological spoilage by bacteria, yeast and molds is the concern in high moisture products i.e., products with a water activity aw > 0.85. Smith and Simpson (1995) reported water activity of cakes in the range of 0.91–0.96. There are no reports available on the complete replacement of sugar with jaggery in muffins. There is a scope for complete replacement of sugar with jaggery along with the improved nutritional benefits.

Keeping in view the above, the effects of replacement of sugar with jaggery on the rheological characteristics of wheat flour, physico-sensory and storage characteristics of muffins were studied.

Materials and methods

Materials

Commercial refined wheat flour, sugar, eggs and jaggery were purchased from the local market. Shortening procured from Bunge India Pvt. Ltd, Mumbai, India. Rex Baking powder (Hindustan Lever Ltd.), vanilla essence (Bush Boake Allen Ltd., Chennai, India), plate count agar, E. coli agar, potato dextrose agar media (HiMedia Mumbai, India) and petroleum ether (Merck chemicals, Mumbai, Maharashtra, India) were used for the studies. Sodium hydroxide and phenolphthalein pH indicator used for titratable acidity analysis were purchased from Merck Specialities Pvt. Ltd., Mumbai and SD Fine Chem limited, Mumbai. Calcium propionate and acetic acid were purchased from Sisco Research Laboratories Pvt. Ltd., Mumbai.

Methods

The proximate analysis of wheat flour such as moisture, fat, ash and total sugar contents were analyzed by using AACC International methods 44-19.01, 30-25.01, 08-01.01 and 80-60.01, respectively (AACC 2000). Protein content of samples was analyzed by using N-protein analyzer (Thermo Flash 2000, Waltham, MA, USA). The sugar powder and jaggery powder were subjected for moisture content, ash content and total sugar content estimation according to AACC International methods 44-19.01, 08-01.01 and 80-60.01, respectively (AACC 2000). Amylograph characteristics of wheat flour as influenced by the addition of sugar and jaggery were studied in triplicate according to AACC International method 22-10.01 (AACC 2000) using Micro-visco amylograph (Model 803201, Brabender, Germany) equipped with 300 cm g sensitivity cartridge and at a temperature profile of 30–92 °C. Titratable acidity of muffins expressed as lactic acid (mg/100 mL) was determined according to AOAC standard method (AOAC 1990). The water activity (aw) of muffins was measured by using water activity meter (Pawkit Water Activity Meter, Pullman, Washington). The pH of muffin samples were measured by using a pH meter (Eutech Instruments pH 510, Ayer Rajah Crescent, Singapore) by dissolving 10 g of sample with 10 mL of distilled water and readings were noted.

Muffins formulation and processing conditions

Muffins with sugar (Table 1) were prepared according to the method described by Jyotsna et al. (2004). Wheat flour, salt, baking powder, calcium propionate were sieved thrice for uniform mixing. Sugar powder and margarine were creamed for 1 min at 58 rpm, 1 min at 112 rpm and 5 min at 173 rpm in a Hobart mixer (Model N-50, Hobart, GmbH, Offenburg, Germany) to get uniform mixture. Simultaneously, egg and essence were whipped at 173 rpm for 7 min. The whipped egg mixture was added to the cream in three additions and mixed for 1 min at 58 rpm then 2 min at 112 rpm to prevent the cake batter from curdling or separating. Wheat flour, water, acetic acid were added to the sugar, margarine, egg and essence mixture and was mixed at 112 rpm for 2 min to get a homogeneous mix. The cake batter was transferred into a cake pan, baked at 180 °C for 25 min using the oven (APV, Queensland, Australia), cooled for 2 h and were later packed in sterile polypropylene until further utilization. All cake baking experiments were carried out in triplicates and results are the average of three readings.

Table 1.

Formulation of muffins with sugar, different levels of egg and jaggery

| Ingredients g) | Muffins with sugar | Muffins with jaggery | |||||

|---|---|---|---|---|---|---|---|

| Variation in egg | Variation in jaggery | ||||||

| (A) 42% | (B) 63% | (C) 84% | (D) 42% | (E) 63% | (F) 84% | ||

| Maida | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Sugar | 84 | – | – | – | – | – | – |

| Jaggery | – | 84 | 84 | 84 | 42 | 63 | 84 |

| Margarine | 84 | 84 | 84 | 84 | 84 | 84 | 84 |

| Egg | 84 | 42 | 63 | 84 | 84 | 84 | 84 |

| Baking powder | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 |

| Vanilla (mL) | 1.5 mL | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Calcium propionate | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Acetic acid | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Water | Variable | ||||||

Bold values are variables of egg and jaggery

A 42% egg, B 63% egg, C 84% egg, D 42% jaggery, E 63% jaggery, F 84% jaggery

Muffins with jaggery

In order to replace sugar (84%) completely with jaggery and find out the amount of egg and jaggery required, muffins were prepared with 42, 63 and 84% jaggery. Different levels of eggs namely 42, 63 and 84% were also tried for jaggery muffins (Table 1). The processing conditions followed were similar to the cake preparation with sugar. Jaggery was used in place of sugar. Jaggery powder was used in the form of thick solution by adding water in the ratio of 1:2. The other ingredients such as margarine, baking powder, preservatives and vanilla essence were kept constant for preparation of muffins. The muffins prepared with these variations of egg and jaggery were denoted as A, B, C, D, E and F, respectively.

Batter-specific gravity

The specific gravity of muffins batter at (28 ± 2 °C) was calculated by dividing the weight of a standard measure of the batter by the weight of an equal volume of water. The average of two readings is reported.

Muffins loaf volume

The volume of the muffins was measured by rapeseed displacement method reported by Pierce and Walker (1987) using the standard volume-measuring apparatus (National Manufacturing Co., Lincoln, NE). The calibration of apparatus was carried out initially with a standard block of 400 mL. The muffin sample was placed at the end in bottom chamber of the volume-measuring apparatus along with the block. After closing the instrument, the slit plate located at the end of the shaft was moved, and the volume was read from the height of the rapeseed collected in the shaft. The muffin volume was calculated by subtracting the volume of the block plus the cake and standard block (Vanhamel et al. 1991). The moisture of the cakes was determined by placing the sample for 1 h in a hot air oven (Model H014DF, Serve well Instruments Pvt ltd, Bengaluru, India) maintained at 130 °C. Loss in weight in percentage was reported as % moisture content on dry basis.

Textural measurement

Texture analyser (Model TA-XDi, Stable Micro Systems, UK) fitted with a cylindrical aluminium probe of 36 mm diameter was used to measure the firmness of muffins crumb. Maximum force required for 25% compression of the muffins was recorded. The results recorded as an average of three replicates. Texture determinations were carried out after removing the crust from the cake surface and drilling out uniform crumb with the help of a cylindrical vessel of diameter 30 mm.

Color measurement

The colour of muffins was measured in terms of lightness (L) and colour (+ a: red, − a: green, + b: yellow, − b: blue) using Hunter Lab Colour Measuring system (Colour measuring Labscan XE system, USA). A standard white board made from barium sulphate (100% reflectance) was used as a perfectly white object for setting the instrument with illuminant D65 lamp. Muffin samples were placed in the sample holder and the reflectance was auto-recorded for the wavelength ranging from 360 to 800 nm. Each value represents the mean of three readings.

Sensory evaluation

The sensory quality of muffins was evaluated by ten panellists of age between 25 and 50 years, including six male and 4 females, who have expertise in sensory evaluation of bakery products. They were further oriented in four sessions, including 2 h of training in each session. The muffin samples were evaluated under ambient temperature and light conditions for colour for the maximum score of 10, shape of crust (10), crumb colour (10), grain (10), texture (10), eating quality (10) and overall quality score (60), which is the combined score of all these parameters.

Storage of muffins

For storage studies, muffins with sugar; muffins with jaggery prepared with egg (84%) and jaggery (84%) were cooled, packed separately in polypropylene pouches (150 gauge) and heat sealed. Muffins were stored at room temperature (27 ± 2 °C) and relative humidity (65 ± 5%) for 21 days. The muffin samples were subjected to objective evaluation such as moisture, texture, water activity, pH, titratable acidity, sensory evaluation as described earlier on 0, 7th, 14th and 21st day.

Microbiological analysis of muffins

Total mesophilic (total viable bacterial counts), fungi counts (yeast and mould counts), Salmonella and E. coli counts of jaggery and sugar muffins were analysed over 21 days storage period. The samples were withdrawn weekly for analysis for 4 weeks. Muffin samples were prepared by mashing and mixing in peptone water. Subsequently, samples were diluted decimally and 0.1 mL aliquots were inoculated on Plate Count Agar (PCA), Potato Dextrose Agar (PDA) via pour plate technique for the enumeration of aerobic bacteria and yeast and mold, respectively. EMB broth with inverted Durhams tubes and Rappaport—Vassiliadis R10 Broth was inoculated with the samples for detection coliforms and Salmonella, respectively (Ijah et al. 2014). All inoculated plates and tubes were incubated at 37 °C for 24–48 h except for PDA plates which were incubated at room temperature (28 ± 2 °C) for 3–5 days. The colonies were then counted and expressed as colony forming units per gram (CFU/g) of samples. Broth inoculated cultures for detection of E. coli and Salmonella were observed for gas formation and colour change, respectively.

Statistical analysis

All the experiments were carried out in triplicates and statistically analyzed using Duncan’s new multiple range tests (DMRT) with the different experimental group using statistica software version 7.0 of Stat Soft Incorporation, Tulsa, OK, USA as per the method of Steel and Torrie (1960). The significant level was established at p ≤ 0.05.

Results and discussion

Physico-chemical characteristics of wheat flour, sugar and jaggery

The wheat flour used for the studies had 10.25% moisture, 10.12% protein, 2.33% fat, 0.48% ash and 0.46% total sugars. The sugar and jaggery powder had 0.81 and 6.90% moisture, ash (0.2 and 1.56%) and total sugar (96 and 69.23%). These results show that the jaggery is rich in minerals. The moisture and total sugar contents of jaggery are within the limits specified by FSSAI (2017).

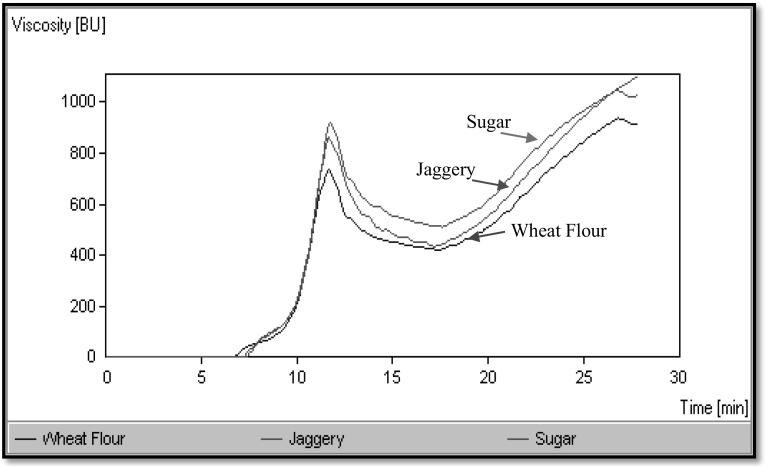

Effect of sugar and jaggery on amylograph characteristics of wheat flour

The effect of addition of sugar and jaggery on the amylograph characteristics of wheat flour is presented in Fig. 1. Addition of sugar and jaggery increased the pasting temperature, peak viscosity, hot paste viscosity, cold paste viscosity, set back and breakdown values of wheat flour. However the increase in peak viscosity, hot and cold paste viscosity values were higher for sugar than jaggery, and pasting temperature, break down and set back values were higher for jaggery than sugar. It is reported that the delay in the gelatinisation temperature of starch in the presence of sugar is due to antiplasticisation by sugar-water co-solvents as compared to water alone. It is clear from the results that jaggery exhibited more antiplasticisation effect than sugar. The increase in viscosity values during heating, cooking and cooling shows that addition of sugar or jaggery increased the swelling capacity of the starch granules during heating, resistance of swollen starch granules against break down, re-association of starch granules during cooling, however the increasing effect is more with sugar than jaggery.

Fig. 1.

Effect of sugar and jaggery on amylograph characteristics of wheat flour

Manisha et al. (2012) reported an increase in amylograph peak viscosity of wheat flour paste during heating and cooling with addition of sugar, whereas, replacement of sugar with sorbitol at different levels showed decrease in amylograph viscosities. Struck et al. (2016) had studied replacement of sucrose in muffins with a combination of rebaudioside A and wheat, apple or pea fibers. Protein denaturation and starch gelatinization occurred during strain oscillatory measurements of muffin batter were delayed with increase in replacement of sucrose by fiber.

Effect of different levels of egg and jaggery on quality of jaggery muffins

The specific gravity is a very important physical property for muffins batter, since, it represents total air holding capacity of the batter during mixing. Low specific gravity is associated with better aeration of the batter, indicating a high capacity of the batter to retain air bubbles during beating (Kahlil 1998). The volume of muffins not only depends on the amount of air incorporated inside the batter but also its capacity to retain air during baking (Frye and Setster 1991).

Effect of replacement of sugar with jaggery on specific gravity of muffins batter is presented in Table 2. The specific gravity of muffins batter prepared with 42, 63 and 84% egg were 0.76, 0.78, 0.79 g/cc and with jaggery it was 0.82, 0.81 and 0.79 g/cc respectively, when compared to 84% sugar (0.80 g/cc). It is reported that the air incorporation depends not only on the aeration process but also on the physico-chemical properties of the batter (Sahi and Alava 2003). The quality of an aerated baked product depends on the batter viscosity. The viscosity of muffins batter is important for retention of gas during the primary stages of baking but slows down the gas diffusion rate (Ronda et al. 2005). Psimouli and Oreopoulou (2012) observed specific gravity of cake batter prepared with replacement of sugar with oligofructose, lactitol and maltitol within the range of 0.85–0.99, which is slightly higher than the specific gravity results of the present study.

Table 2.

Effect of different percentages of egg and jaggery on the quality characteristics of muffins

| Muffins | Batter specific gravity (g/cc) | Volume (mL) | Texture (g) | Colour | OQS (60) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Crumb | Crust | |||||||||

| L | a | b | L | a | b | |||||

| With sugar | 0.80c ± 0.01 | 150c ± 0.25 | 1200a ± 5.50 | 72.0f ± 0.4 | 0.9a ± 0.1 | 16.4a ± 0.3 | 52.2e ± 02 | 12.2b ± 0.2 | 72.0f ± 0.4 | 54e ± 0.25 |

| A | 0.76a ± 0.01 | 130b ± 0.35 | 1380c ± 7.50 | 59.2b ± 0.2 | 6.0f ± 0.1 | 35.0c ± 0.4 | 50.3d ± 0.5 | 9.2a ± 0.2 | 59.2b ± 0.2 | 39b ± 0.35 |

| B | 0.78b ± 0.02 | 135b ± 0.20 | 1350c ± 4.55 | 61.1d ± 0.2 | 5.6e ± 0.1 | 35.9d ± 0.3 | 46.3b ± 0.4 | 13.8d ± 0.2 | 61.1d ± 0.2 | 43c ± 0.50 |

| C | 0.79b ± 0.02 | 150c ± 0.30 | 1300b ± 2.55 | 61.9e ± 0.2 | 5.3d ± 0.1 | 36.1d ± 0.2 | 44.4a ± 0.5 | 14.3e ± 0.3 | 61.9e ± 0.2 | 50d ± 0.45 |

| D | 0.82e ± 0.01 | 125a ± 0.35 | 1630e ± 3.55 | 58.5a ± 0.5 | 3.5b ± 0.1 | 34.4b ± 0.2 | 50.6d ± 0.5 | 12.8c ± 0.3 | 58.5a ± 0.5 | 32a ± 035 |

| E | 0.81d ± 0.02 | 135b ± 0.25 | 1430d ± 5.05 | 60.5c ± 0.5 | 4.4c ± 0.1 | 35.0c ± 02 | 48.7c ± 0.5 | 13.0c ± 0.2 | 60.5c ± 0.5 | 40c ± 0.25 |

| F | 0.79b ± 0.01 | 150c ± 0.30 | 1300b ± 5.55 | 61.9e ± 0.5 | 5.3d ± 0.2 | 36.1d ± 0.4 | 44.4a ± 0.5 | 14.3e ± 0.2 | 61.9e ± 0.5 | 50d ± 0.45 |

A 42% egg, B 63% egg, C 84% egg, D 42% jaggery, E 63% jaggery, F 84% jaggery

OQS overall quality score

Values in the row with the same letter in superscript are not significantly different from each other at p ≤ 0.05. Values are means of three replicates ± standard deviation

The quality characteristics of muffins with sugar and jaggery are shown in Table 2. There was not much variation in the weight of the muffins (53–54 g) with different percentages of jaggery and egg, while the muffins prepared with 84% egg and jaggery showed highest volume that is 150 mL which was similar to the muffins made using sugar. The softness of muffins was observed to increase with an increase in jaggery and egg contents. This may be due to foaming, coagulation, emulsification, and binding properties of egg (Agrahar-Murugkar et al. 2016). The muffins prepared with 84% egg and jaggery showed more softness among all other muffins samples. However, the sugar muffins showed highest softness when compared to jaggery muffins. The L, a and b values indicating the lightness, redness and yellowness for crust and crumb of muffins respectively, are shown in the Table 2. The lightness of muffins crumb increased with increase in egg and jaggery percentages. It can be seen from the table that the redness of the jaggery muffins crumb slightly increased with an increase in jaggery percentages, while there was not much difference in the yellowness of the crumb. The lightness value of crust of jaggery muffins was reduced with an increase in egg and jaggery concentration, while redness of muffins crust was increased. An increase in the lightness value of crumb of muffins was observed from 59.2 to 61.9, when the egg content increased from 42 to 84%. Similarly an increase in the lightness value of crumb of muffins from 58.5 to 61.9 was observed. It can be concluded from these results that the jaggery muffins showed lower value for lightness, higher values for redness and yellowness than sugar muffins.

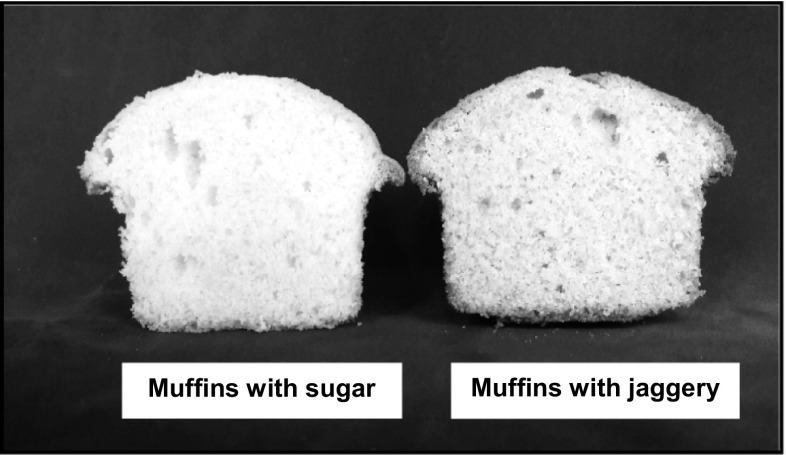

The sensory evaluation of jaggery muffins showed that the crust colour of jaggery muffins with different levels of egg was brown, crust shape was normal and crumb colour was brownish white (Fig. 2). With increase in egg from 42 to 84%, the crumb grain improved from medium fine to fine uniform, texture from medium soft to soft, eating quality from slight residue formation to clean mouthfeel with optimum sweetness and perceptible jaggery taste. With increase in jaggery from 42 to 84%, the crust colour improved from dull brown to brown, crust shape from normal curved shape with cracks on the top surface to normal shape with smooth top surface, crumb colour from dull brown to brownish white, closed compact crumb grain to fine uniform grain, slightly hard texture to soft texture, slightly powdery mouthfeel, less sweet to clean mouthfeel with optimum sweetness and perceptible jaggery taste. These improvements are indicated with the increase in the overall quality score from 39 to 50 and 32 to 50 with increase in egg and jaggery contents from 42 to 84% respectively. The overall quality score of sugar muffins was 54 for the maximum score of 60 (Table 2). Hence, it could be concluded that for the preparation of jaggery muffins having quality characteristics closer to sugar muffins, the amount of egg and jaggery required is 84% for 100 g of wheat flour. Ronda et al. (2005) have reported highest overall acceptability for the cakes prepared with xylitol instead of sucrose.

Fig. 2.

Photograph of muffins with sugar and jaggery

Physico-chemical, sensory characteristics of muffins

The results of the evaluation of physico-chemical characteristics of both the muffins showed that the moisture content of muffins prepared with jaggery was higher (21.8%) than muffins prepared with sugar (19.6%) due to presence of invert sugar, mineral salts which are hygroscopic in nature and also higher moisture content present in the jaggery (Mandal et al. 2006). The protein and fat contents were slightly lower (6.38 and 30.93%) in muffins with jaggery than muffins with sugar (6.58 and 33.33%). The ash content of muffins was higher in muffins with jaggery (1.21%) than muffins with sugar (0.82%). The sugar content in muffins with jaggery muffins was found to be 27.8%, which is considerably lower than the muffins with sugar (32.4%). The increase in ash and decrease in sugar contents in muffins with jaggery than muffins with sugar is due to the presence of higher amount of minerals like iron, calcium, phosphorous and lower amount of sucrose in jaggery when compared to sugar (Jagannadha Rao et al. 2007).

Effect of storage on the quality of muffins

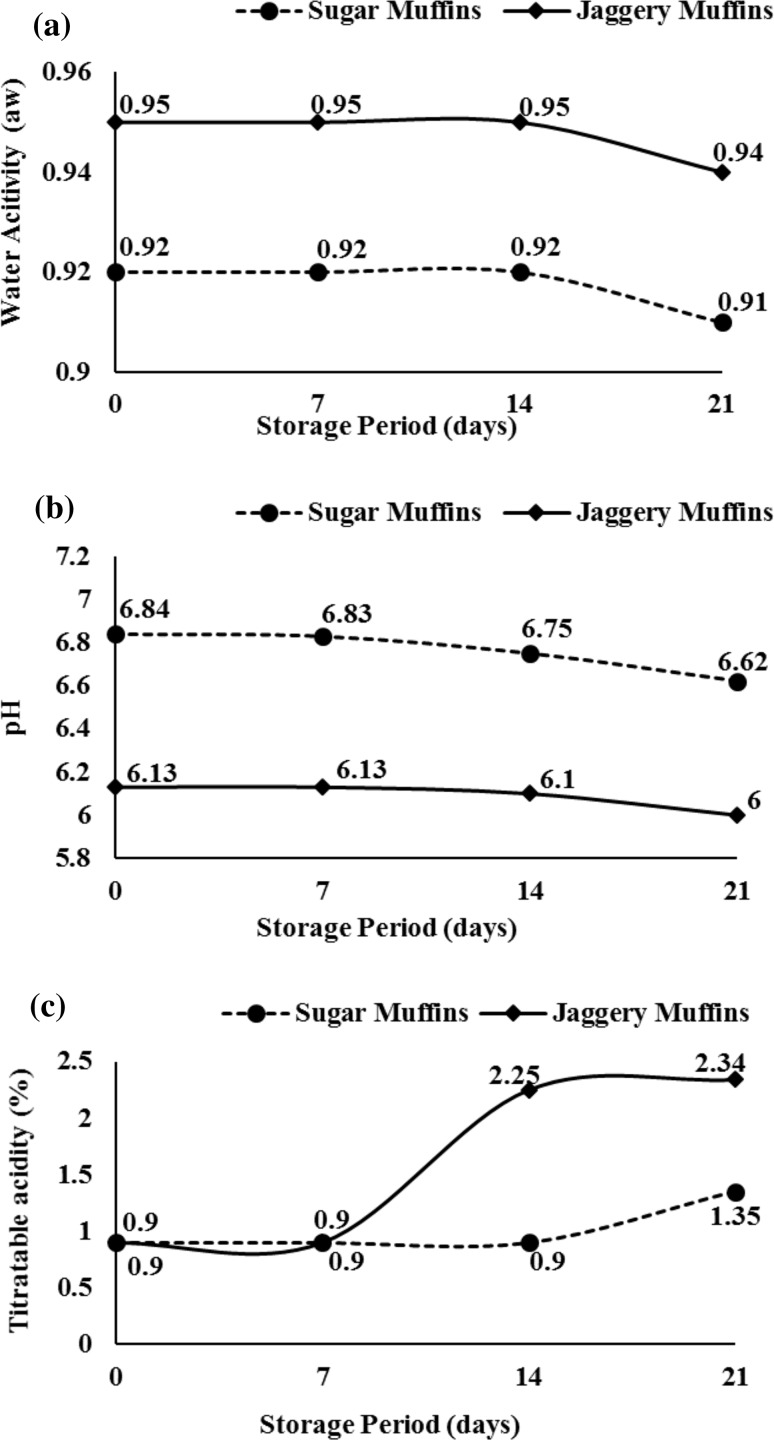

Changes in various quality parameters of muffins with jaggery when compared to muffins with sugar during storage for 21 days are presented in Table 3 and Fig. 3.

Table 3.

Effect of storage on the quality of muffins

| Muffins | Storage period (days) | Moisture (%) | Texture (g) | Overall quality score (60) |

|---|---|---|---|---|

| Sugar muffins | 0 | 19.6a ± 0.2 | 1200a ± 5.5 | 54d ± 0.5 |

| 7 | 19.2a ± 0.4 | 1920c ± 6.5 | 53d ± 0.6 | |

| 14 | 18.8a ± 0.5 | 2060e ± 7.5 | 51c ± 0.8 | |

| 21 | 18.8a ± 0.3 | 2250g ± 6.0 | 50c ± 0.4 | |

| Jaggery muffins | 0 | 21.8b ± 0.2 | 1300b ± 5.5 | 48b ± 0.5 |

| 7 | 21.8b ± 0.3 | 2115d ± 3.5 | 47b ± 0.4 | |

| 14 | 21.3b ± 0.3 | 2200f ± 4.5 | 46b ± 0.3 | |

| 21 | 20.9b ± 0.4 | 2385h ± 2.5 | 45a ± 0.4 |

Values in the row with the same letter in superscript are not significantly different from each other at p ≤ 0.05. Values are means of three replicates ± standard deviation

Fig. 3.

Effect of storage period on water activity (aw), pH and titratable acidity of muffins with sugar and jaggery

It can be seen from the Table 3 that the jaggery based muffins showed higher moisture content as compared to sugar based muffins initially as well as over storage period of 21 days. The softness of muffins with sugar and jaggery was found to reduce with an increase in storage period, while the muffins with jaggery showed lesser softness than sugar muffins throughout the storage period. These results indicate that the retrogradation rate in muffins with jaggery is higher than muffins with sugar which accounted for lesser softness throughout storage for muffins with jaggery. The higher amylograph setback value with jaggery also confirms higher retrogradation rate of starch in the presence of jaggery than sugar.

It can be seen from the Fig. 3a that the jaggery muffins were observed to have higher water activity (aw) of 0.95 than muffins with sugar (0.92). With increase in storage period from 0 to 21 days, the aw even though decreased it practically remained constant up to 14 days and slightly decreased on 21st day of storage. Similar results were observed for water activity in muffins prepared with different fibers and stevia as sugar replacement by Zahn et al. (2013).

The pH of sugar and jaggery muffins was found to decrease slightly from 6.84 to 6.62 and 6.13 to 6.0, respectively (Fig. 3b). Sugar based muffins showed higher pH values when compared with jaggery based muffins. The titratable acidity of sugar and jaggery muffins was found to increase from 0.90 to 1.35 and 0.90 to 2.34. The titratable acidity of jaggery muffins was observed to increase after 7 days of storage, while in the case of sugar muffins the titratable acidity was increased at the end of storage period. These results are similar to as reported by Jariyawaranugoon (2013) who reported a decrease in water activity, pH and increase in titratable acidity during storage of cakes with sugar and honey.

The effect of storage period on sensory characteristics of sugar and jaggery muffins was observed. The moisture content of muffins even though decreased it was not significant. The softness decreased as shown by the increase in the crumb firmness values from 1200 to 2250 g for muffins with sugar and from 1300 to 2385 g for muffins with jaggery. The crust colour, crust shape, crumb colour, crumb grain did not change for both the muffins. The crumb firmness increased with increase in storage period from 0 to 21 days. The muffins with jaggery showed higher firmness value throughout the storage period when compared to muffins with sugar. The muffins with sugar jaggery showed clean mouthfeel without any residue formation, no off flavour, optimum sweetness throughout the storage period. However, the muffins with jaggery were more acceptable as it showed wholesome taste and perceptible jaggery flavour till 21 days of storage. Psimouli and Oreopoulou (2012) reported similar results in terms of sensory evaluation of cakes prepared with replacement of sugar with oligofructose, lactitol and maltitol. Muffins were prepared with tagatose as a replacement of sucrose at 3–6% and no significant difference were observed in flavour and sweetness of the muffins (Armstrong et al. 2009). Lin et al. (2003) had studied the formulation of chiffon cake with partial replacement of sucrose with erythritol (75%) and found similar quality characteristics like cake prepared with 100% sucrose.

The results of microbial analyses of muffins performed as a part of storage studies showed that the muffins with sugar and jaggery were stable at ambient room temperature and humidity when packed in air tight polypropylene bags, may be due to use of calcium propionate and acetic acid in the preparation of muffins. Microbial analysis has shown that E. coli and Salmonella were not detected in both the muffin samples. The total mesophilic count, yeast and mold count for muffins with sugar increased from < 10–79 CFU/g and < 10–66 CFU/g and for muffins with jaggery (< 10–89 CFU/g and < 10–68 CFU/g) respectively with increase in storage period from 0 to 21 days. These results of total mesophilic count, yeast and mold count of the muffins were found to be within the recommended limits set by FSSAI (2016). The microbial load was higher in jaggery muffins as compared to sugar based muffins over a storage period of 21 days. There was considerable increase seen in fungi and bacteria in the third week. Hence, it can be concluded that the muffins stored for 21 days was microbiologically safe and should be consumed before the end of that period.

Conclusion

The jaggery powder had higher moisture, ash content and lower total sugar when compared to sugar. The amylograph pasting temperature and peak viscosity of wheat flour were observed to increase with addition of sugar and jaggery. The jaggery muffins showed lower value for lightness, higher values for redness and yellowness than sugar muffins. For the preparation of jaggery muffins having quality characteristics closer to sugar muffins, the amount of egg and jaggery required was 84% for 100 g of wheat flour. The overall quality score of muffins with jaggery was lower than the muffins with sugar. The jaggery muffins had higher moisture, ash, lower protein, fat and total sugar contents when compared to muffins with sugar. Even though there was difference in aw, pH, titratable acidity, texture characteristics and overall quality score for the muffins with jaggery when compared to muffins with sugar during storage for 21 days. Both the muffins had the microbial load within the acceptable limits for 21 days. Hence, it can be concluded that Jaggery can be used for the total replacement sugar on equal weight basis in various bakery products in future.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

References

- Agrahar-Murugkar D, Zaidi A, Kotwaliwale N, Gupta C. Effect of egg-replacer and composite flour on physical properties, color, texture and rheology, nutritional and sensory profile of cakes. J Food Qual. 2016;39:425–435. doi: 10.1111/jfq.12224. [DOI] [Google Scholar]

- American Association of Cereal Chemists (AACC) (2000) Approved methods of American Association of Cereal Chemists (9th ed.), Moisture (44-19.01), Ash (08-01.01), fat (30-25.01), total sugar (80-60.01) and modified amylograph (22-10.01) method. AACC International, St. Paul Minnesota, USA

- AOAC (1990) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Virginia, Washington DC, pp 805–845

- Armstrong LM, Luecke KJ, Bell LN. Consumer evaluation of bakery product flavour as affected by incorporating the prebiotic tagatose. Int J Food Sci Technol. 2009;44:815–819. doi: 10.1111/j.1365-2621.2009.01909.x. [DOI] [Google Scholar]

- De Souza VR, Pereira PAP, Pinheiro ACM, Bolini HMA, Borges SV, Queiroz F. Analysis of various sweeteners in low-sugar mixed fruit jam: equivalent sweetness, time intensity analysis and acceptance test. Int J Food Sci Technol. 2013;48:1541–1548. doi: 10.1111/ijfs.12123. [DOI] [Google Scholar]

- Frye AM, Setster CS. Optimising texture of reduced calorie sponge cakes. Cereal Chem. 1991;69:338–343. [Google Scholar]

- FSSAI . Manual of methods of analysis of foods microbiological testing. New Delhi: Food Safety and Standards Authority of India, Ministry of health and Family Welfare, Government of India; 2016. [Google Scholar]

- FSSAI . Standards for Gur or jaggery, sodium saccharin and calcium saccharin. New Delhi: Food Safety and Standards Authority of India, Ministry of health and Family Welfare, Government of India; 2017. p. 5. [Google Scholar]

- Hussain Z, Islam M, Mohammad Z, Khan KM, Perveen S, Afzal M. The effect of pre-treatment of juice on the properties and composition of jaggery. Sugar Techol. 2012;14:291–294. doi: 10.1007/s12355-012-0154-0. [DOI] [Google Scholar]

- Ijah UJJ, Auta HS, Aduloju MO, Aransiola SA. Microbiological, nutritional, and sensory quality of bread produced from wheat and potato flour blends. Int J Food Sci. 2014 doi: 10.1155/2014/671701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Inamdar V, Chimmad BV, Naik R. Nutrient composition of traditional festival foods of North Karnataka. J Hum Ecol. 2005;18:43–48. doi: 10.1080/09709274.2005.11905805. [DOI] [Google Scholar]

- Jagannadha Rao PVK, Das Madhusweta, Das SK. Jaggery—a traditional Indian sweetener. Indian J Tradit Knowl. 2007;6:95–102. [Google Scholar]

- Jariyawaranugoon U. Combined effect of honey and oxygen absorber packaging on storage quality of chocolate sponge cake. J Food Sci Technol. 2013;5(3):236–243. [Google Scholar]

- Jyotsna R, Prabhasankar P, Indrani D, Venkateswara Rao G. Improvement of rheological and baking properties of cake batters with emulsifier gels. J Food Sci. 2004;69:16–19. doi: 10.1111/j.1365-2621.2004.tb17880.x. [DOI] [Google Scholar]

- Kahlil AH. The influence of carbohydrate-based fat replacers and with and without emulsifiers on the quality characteristics of low fat cake. Plant Foods Human Nutr. 1998;52:299–311. doi: 10.1023/A:1008096031498. [DOI] [PubMed] [Google Scholar]

- Lin SD, Hwang CF, Yeh CH. Physical and sensory characteristics of chiffon cake prepared with erythritol as replacement for sucrose. J Food Sci. 2003;68:2107–2110. doi: 10.1111/j.1365-2621.2003.tb07027.x. [DOI] [Google Scholar]

- Mandal D, Tudu S, Mitra SR, De GC. Effect of common packing materials on keeping quality of sugarcane jaggery during monsoon season. Sugar Tech. 2006;8:137–142. doi: 10.1007/BF02943648. [DOI] [Google Scholar]

- Manisha G, Soumya C, Indrani D. Studies on interaction between stevioside, liquid sorbitol, hydrocolloids and emulsifiers for replacement of sugar in cakes. Food Hydrocoll. 2012;29:363–373. doi: 10.1016/j.foodhyd.2012.04.011. [DOI] [Google Scholar]

- Nath A, Dutta D, Kumar Pawan, Singh JP. Review on recent advances in value addition of jaggery based products. J Food Process Technol. 2015;6:4–7. [Google Scholar]

- Patil JR, Wandre SS, Gojar DG (1985) Kakavi quality in relation to sterilization and preservatives. In: Proceedings of National-Seminar-cum group discussion on jaggery manufacture and storage, Lucknow, p 84

- Pierce MM, Walker CE. Addition of sucrose fatty acid ester emulsifiers to sponge cake. Cereal Chem. 1987;64:222–225. [Google Scholar]

- Psimouli V, Oreopoulou V. The effect of alternative sweeteners on batter rheology and cake properties. J Sci Food Agric. 2012;92:99–105. doi: 10.1002/jsfa.4547. [DOI] [PubMed] [Google Scholar]

- Ronda F, Gomez M, Blanco CA, Caballero PA. Effects of polyols and nondigestible oligosachharides on the quality of sugar-free sponge cakes. Food Chem. 2005;90:549–555. doi: 10.1016/j.foodchem.2004.05.023. [DOI] [Google Scholar]

- Sahi SS, Alava JM. Functionality of emulsifiers in sponge cake production. J Sci Food Agric. 2003;83:1419–1429. doi: 10.1002/jsfa.1557. [DOI] [Google Scholar]

- Sahu AP, Saxena AK. Enhanced translocation of particles from lungs by jaggery. Environ Health Perspect. 1994;102:211–214. doi: 10.1289/ehp.94102s5211. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shahi HN. Sustainability of jaggery and khandsari industry in India. In: Singh J, editor. Status, problems and prospects of jaggery and khandsari industry in India. Lucknow: Indian Institute of Sugarcane Research; 1999. pp. 19–27. [Google Scholar]

- Singh M, Bharadwaj KM, Agrawal ML. Storage of jaggery. Co-oper Sugar. 1978;3:14–17. [Google Scholar]

- Smith JP, Simpson BK. Modified atmosphere packaging of bakery and pasta products. In: Farber JM, Dodds KL, editors. Principles of modified atmosphere and sous vide product packaging. Lancaster: Technomic Publishing Company; 1995. p. 207. [Google Scholar]

- Smith JP, Daifas DP, El-Khoury W, Koukoutsis J, El-Khoury A. Shelf life and safety concerns of bakery products—a review. Critical Rev Food Sci Nutr. 2004;44(1):19–55. doi: 10.1080/10408690490263774. [DOI] [PubMed] [Google Scholar]

- Steel RGD, Torrie JH. Principles and procedures of statistics. New York: McGraw-Hill; 1960. [Google Scholar]

- Struck S, Gundel L, Zahn S, Rohm H. Fiber enriched reduced sugar muffins made from iso-viscous batters. LWT Food Sci Techol. 2016;65:32–38. doi: 10.1016/j.lwt.2015.07.053. [DOI] [Google Scholar]

- Tidke B, Sharma HK, Kumar N. Development of peanut and chickpea nut brittle (Chikki) from the incorporation of sugar, jaggery and corn syrup. Int Food Res J. 2017;24:657–663. [Google Scholar]

- Torley PJ, Rutgersb RPG, Arcya BD, Bhandar BR. Effect of honey types and concentration on starch gelatinization. Lebensm Wiss Technol. 2004;37:161–170. doi: 10.1016/j.lwt.2003.08.002. [DOI] [Google Scholar]

- Uppal SK, Thind KS, Gill RS. Relative performance of sugarcane genotypes for jaggery (gur) quality and storage. Sugar Tech. 2005;7(4):136–140. doi: 10.1007/BF02950598. [DOI] [Google Scholar]

- Vanhamel S, Vandenende L, Darius PL, Delcouri JA. A volumeter for breads prepared from 10 grams of flour. Cereal Chem. 1991;68:170–172. [Google Scholar]

- Verma VK, Narain M. Moisture absorption isotherms of jaggery. J Stored Prod Res. 1990;26:6146–6147. doi: 10.1016/0022-474X(90)90001-9. [DOI] [Google Scholar]

- Zahn S, Forker A, Krugel L, Rohm H. Combined use of rebaudioside A and fibres for partial replacement in muffins. LWT Food Sci Technol. 2013;50:695–701. doi: 10.1016/j.lwt.2012.07.026. [DOI] [Google Scholar]