Abstract

Emulsifiers are a large category of compounds considered as surface active agents or surfactants. An emulsifier acts by reducing the speed of chemical reactions, and enhancing its stability. Bioemulsifiers are known as surface active biomolecule materials, due to their unique features over chemical surfactants, such as non-toxicity, biodegradability, foaming, biocompatibility, efficiency at low concentrations, high selectivity in different pH, temperatures and salinities. Emulsifiers are found in various natural resources and are synthesized by Bacteria, Fungi and Yeast. Bioemulsifier’s molecular weight is higher than that of biosurfactants. Emulsion’s function is closely related to their chemical structure. Therefore, the aim of this paper was to study the various bioemulsifiers derived from microorganisms used in the drug and food industry. In this manuscript, we studied organisms with biosurfactant producing abilities. These inexpensive substrates could be used in environmental remediation and in the petroleum industry.

Keywords: Bioemulsifiers, Emulsion stability, Biosurfactants, Microorganism

Introduction

As it is clear, oil and water are incompatible. The mixture of oil and water lead to the production of an emulsion. When an emulsion stays still for a while, oil droplets begin to separate from water. In this regards, emulsifiers are used to stop this process. In fact, emulsifiers are used to prevent the emulsion from breaking. Examples of emulsions currently used in the food industry include milk, butter, margarine, mayonnaise and ice cream. Emulsifiers are a large category of compounds also known as surface active agents or surfactants. The word surfactant is used for molecules that migrate to the surface between phases.1-6

Bioemulsifiers are higher in molecular weight compared to biosurfactants since they are complex mixtures of heteropolysaccharides, lipopolysaccharides, lipoproteins and proteins.7 Emulsifiers have double lipophilic and hydrophilic properties. On the other hand, emulsions are either oil-in-water (O/W) or water-in-oil (W/O). In oil emulsions, small droplets of oil form the dispersed phase and discrete in water, while in water emulsions, they are distrebuted as small droplets of water in oil.8,9 Adding an emulsifier to an unmixable compound, reduces surface tension between the two phases and prevents it from separating. Therefore, the two liquids are able to form an emulsion. Since an emulsion consists of water-soluble and oil-soluble fragments, an emulsifier is placed on the surface of the area where the two liquids (water and oil) are connected. The water-soluble fragment ambulates towards the water fragment and the fat-soluble fragment places near the oil.4,6,9-12

Emulsifiers are substances that increase the uniformity of nutrients, such as fatty acids, fat-soluble vitamins, and amino acids. The function of emulsions is closely related to its chemical structure.9 Physiologically, in animal’s digestive system, the presence of bile salts, benefits fat absorption. Emulsifiers are surfactant materials widely used in food products.9,13 Hydrophilic characteristics (water-friendliness) and lipophilic (lipid-friendliness) emulsifiers are sometimes referred as hydrophilic/lipophilic equilibrium (HLB), indicating the rate of emulsifier’s inclination towards water or oil.14-16 Emulsifiers are embedded in fat droplets and prevent the protein layer from collapsing. Other functions of emulsifiers in the food industry include:

1) Starch reaction: most emulsifiers have a lean fatty acid layer in their molecule which form an amylose mixture. This feature is very important in delaying bread and bakery products staling and reducing their adhesion to staple products such as potato puree and pasta.10,11,17,18

2) Generating interactions with proteins: emulsifiers have ionic structure which react with proteins in food products and produce a modifiable structure. For example, they respond to the gluten present in wheat and increase protein elasticity, thereby increasing bakery products volume.10,14,19

3) Adhesion correction: some emulsifiers are added to food products containing sugar crystals that are scattered in fat and, by coating on glucose crystals, reduce adhesion. This feature affects the fluidity of molten chips and prevent fat appearance on the surface of chocolate.11,20-22

4) Creating foam: emulsifiers with saturated fatty acids stabilize the bottommost surface of aqueous solutions. Therefore, it is an important factor in creating foam in raw instant desserts.4,11,21

5) Tissue modification is a complex process that is performed on starch and reduces breakdown. For example, homogeneity usually occurs in pasta, bread and bakery products.2,11

6) Modifying the dispersion of liquids in another liquid in order to formulate clear solutions: many greed and colors require emulsifiers for solving.11,14

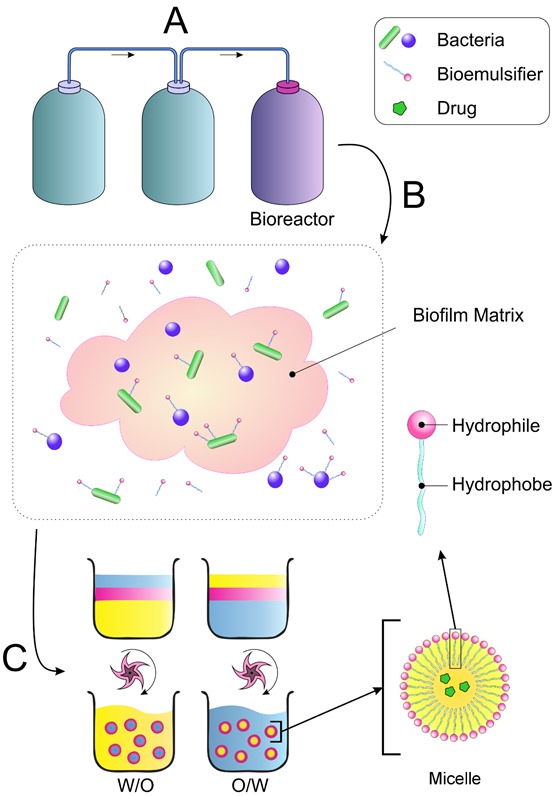

Today, due to emulsifier effect on human health and limited resources as well as expensivity, researchers have produced emulsifiers using natural resources, especially microorganisms.19 According to findings, many microorganisms are able to produce compounds with emulsifying properties.10 A number of these bioemulsifiers have been licensed by the International Organization for Animal Health, including WHO; but most of these compounds have been studied from a nutritional point of view. A large number of biomolecules are also used in the oil, food, drug and chemical industries.11,17 The schematic and mechanism of action of important emulsifiers produced by microorganisms using biotechnological processes are presented in Figure 1.

Figure 1.

The schematic and mechanism of action of bioemulsifiers in emulsion systems. A: The cultivation, preparation, purification and isolation of microorganisms producing bioemulsifiers. B: Bioemulsifiers produced by microorganisms. C: Emulsion production, adding bioemulsifiers to emulsion systems and assessing their stability.

Bioemulsifiers derived from yeast and fungi

Mannoprotein

Mannoprotein bioemulsifier is a glycoprotein with a molecular weight of about 14,000 to 15,800 Dalton. Within the cellular wall of Saccharomyces spp. and Kluyveromyces marxianus of yeast, mannoprotein molecules are present in glucan, networks, and released from the cell wall of yeast using pressurized heat treatments. This bioemulsifier is able to stabilize oil-in-water emulsions (O/W). According to researchers, bioemulsifiers can be used for producing mayonnaise along with carboxymethyl cellulose (CMC), instead of using expensive ingredients such as ginseng for mayonnaise formulation. Bakery's yeast (Saccharomyces cerevisiae) is an affordable, inexpensive and non-toxic source used for producing this bioemulsifier. Mannoprotein is stable in pH = 3-11. Removing mannoprotein molecules from bakery yeast cell is possible using thermal and enzymatic processes (β-1 and 3 glucanases). Mannoprotein molecules are formed from a polypeptide chain with short and long mannose links. When the protein portion of the mannoprotein molecule is detached by the protease enzyme, the mannoprotein emulsifier disappears. In an industrial scale, this bioemulsifier is active at concentrations equal to or greater than 5% sodium chloride.10-12,19,23,24

Liposan

Liposan bioemulsifier is a water-soluble emulsifier obtained from extracting organic solvents fermented by Candida lipolytica yeast. Liposan is produced in the extracellular layer and consists of 83% carbohydrate and 17% protein. The presence of protein fractions in the bioemulsifier polymer molecule is essential for its emulsifying properties. The carbohydrate part is a heteropolysaccharide, composed of glucose, galactose, galactose-amine and galacturonic acid molecules. The maximum liposomal properties of liposan are observed at pH = 2-5. Liposan is resistant to temperatures less than 70 °C, but after heating at 100 °C for one hour, 60% of its emulsifiable strength reduces. Liposan causes the stability of various types of emulsions in oil, such as hydrocarbons, vegetable oils including cottonseed, soybean, sunflower, corn, ground, safflower and olive oil.10,25-30

Candida tropicalis yeast

During the fed-batch process, Candida yeast species produce an extracellular bioemulsifier. This bioemulsifier is very effective in fixing emulsions of many types of hydrocarbons, especially aromatic compounds. The amount of emulsifier produced and its activity increases during fermentation by limiting nitrogen (N) source. Extracting this bioemulsifier from Candida tropicalis cells using hot water shows better results in terms of increasing emulsion strength.11,14,17,31-34

Rhodotorula yeast

This bioemulsifier is an extracellular emulsifier produced by the Rhodotorula glutinis yeast. It is formulated during fed-batch fermentation and glucose utilization under limited nitrogen conditions at 30 °C and pH = 4.32,33,35-37

Phaffia yeast

Phaffia rhodozyma is a basidiomycetous pink yeast. It has been known as a natural source of astaxanthin and many other nutrients. Also, it is currently being used as an ingredient in feeds. It grows on carbohydrate, hydrocarbon and a mixture of carbohydrate and lipid polymers. Fermentation is accomplished in a culture medium chain with sucrose as the carbon source for 3 days at 22 °C and centrifuged at 150 rpm. Experiments have shown that adding sodium citrate, stimulates bioemulsifiers production.10,11,38,39 Table 1 and 2 show bioemulsifiers produced by yeast and fungi.

Table 1. List of bioemulsifiers producing yeast .

| Microorganism’s | Bioemulsifiers | Ref. |

| Torulopsis petrophilum | Sophorolipids | 40 |

| Torulopsis apicola | Sophorolipids | 41 |

| Pseudozyma rugulosa | Mannosylerythritol lipids | 42 |

| Pseudozyma aphidis | Mannosylerythritol lipids | 43 |

| Kurtzmanomyces sp. | Mannosylerythritol lipids | 44 |

| Kurtzmanomyces sp. I-11 | Mannosylerythritol lipids | 45 |

| Debaryomyces polymorphus | Carbohydrate protein-lipid complex | 32 |

| Saccharomyces cerevisiae | Mannoprotein | 23 |

| Kluyveromyces marxianus | Mannoprotein | 12 |

| Rhodotorula glutinis | Polymeric bioemulsifier | 46 |

Table 2. List of bioemulsifiers producing fungi .

| Microorganism’s | Bioemulsifiers | Ref. |

| Candida tropicalis | Mannan-fatty acid | 47 |

| Candida lipolytica Y-917 | Sophorous lipid | 39 |

| Candida utilis | NDA | 39 |

| Candida ingens | Fatty acids | 48 |

| Candida lipolytica UCP0988 | Carbohydrate-protein-lipid complex | 49 |

| Candida tropicalis | Liposan | 28 |

| Candida bombicola | Sophorolipids | 50 |

| Candida (torulopsis) apicola | Sophorolipids | 51 |

| Candida lipolytica ATCC 8662 | Carbohydrate-protein complex | 52 |

| Penicillium chrysogenum | Polyketide derivative | 53 |

| Yarrowia lipolytica IMUFRJ 50682 | Carbohydrate-protein complex | 27,54 |

| Yarrowia lipolytica NCIM 3589 | Bioemulsifier | 54 |

| Yarrowia lipolytica IMUFRJ 50682 | Yansan | 55 |

| Ustilago maydis | Cellobiose lipids | 56 |

| Candida sphaerica UCP0995 | Sophorolipids | 57 |

| Candida. glabrata UCP0995 | Sophorolipids | 58 |

| Pseudomonas. aeruginosa | Rhamnolipids | 59 |

Bioemulsifiers derived from bacteria

Lauryl fructose

This bioemulsifier is produced by the lipase enzyme obtained from Pseudomonas spp.60 in a culture media containing dry pyridine. This bioemulsifier has emulsification properties for a variety of hydrocarbons, edible oils, and oil based oils such as margarine and shortening. In a water-containing environment, Laura fructose reduces surface tension from 72 to 29 (MN / m). Also, it reduces the intermolecular reaction of water and hydrocarbons from 50 to 6 when combined with water-insoluble oil compounds.10,11,61-63 In Table 3, bio-emulsifiers produced by bacteria are presented.

Table 3. List of bioemulsifiers producing bacteria .

| Microorganism’s | Bioemulsifiers | Ref. |

| Pseudomonas fluorescens | Viscosin | 71 |

| Pseudomonas aeruginosa | Rhamnolipids | 72 |

| Pseudomonas fluorescens | Carbohydrate-lipid complex | 39 |

| Bacillus amyloliquefaciens, | Surfactin/Iturin | 73 |

| Bacillus subtilis | Subtilisin | 74 |

| Bacillus subtilis | Lichenysin | 75 |

| Bacillus licheniformis K51, Bacillus subtilis | Peptide lipids | 76 |

| Bacillus pumilus A1 | Rhamnolipids | 77 |

| Bacillus sp. AB-2 | Hydrocarbon-lipid-protein | 78 |

| Acinetobacter calcoaceticus | Emulsan | 79 |

| Acinetobacter radioresistens | Alasan | 39 |

| Acinetobacter calcoaceticus RAG1 | Emulsan | 80 |

| Rhodococcus erythropolis | Glycoprotein | 81 |

| Rhodococcus sp. 33 | Uronic acids | 82 |

| Cyanobacteria | Trehalose dicorynomycolate | 83 |

| Clostridium pasteurianum | Polysaccharide | 84 |

| Debaryomyces polmorphus | Whole cell | 85 |

| Halomonas eurihalina | Carbohydrate-lipid complex | 86 |

| Halomonas | Emulsifier HE39 & HE67 | 87 |

| Lactobacillus paracasei | Glycoprotein | 88 |

| Leuconostoc mesenteriods | Dextran | 89 |

| Serratia marcescens, Serrated rubidea | Serrawettin | 90 |

| Bacillus pseudomycoides BS6 | Lipopeptide | 91 |

| Pseudomonas. cepacia CCT6659 | Rhamnolipids | 92 |

| Bacillus. licheniformis R2 | Lipopeptide | 93 |

Alasan or E-KA53

Alasan is a biomolecular bacterium produced by the Acinetobacter radioresistant bacteria. The molecular composition of this complex bioemulsifier consists of polysaccharides and proteins with high molecular weight (100,000 - 230,000 Daltons). If the protein portion is damaged and digested using proteolytic enzymes, the bioemulsifier polymer turns into a thick polysaccharide and loses its emulsifying properties. Heating with alcohol at 50 °C may lead to 2.5 times increase in polysaccharide concentration, while the protein portion and the emulsifying properties of the molecule remain unchanged. Heating at 60-90 °C reduces viscosity and increases emulsifying activity as much as 5.8 times than the initial value. The emulsifying properties of alasan are affected by pH and magnesium ion concentrations. This bioemulsifier is an extracellular product and is used extensively in the food industry. Alasan is produced during Acinetobacter bacterium fermentation in a fed-batch fermentation system. The ultimate product consists of 2.2 g of emulsifier per liter of culture fluid. Alcohols stabilize a wide range of oil-in-water (O/W) emulsions, such as n-alkanes, alkaline compounds, liquid paraffin, soybean oil, coconut oil and raw oils. The emulsifying activity of alasan increase approximately 2-3 times, when heated at 100 °C under neutral or alkaline conditions. This bioemulsifier is completely active in pH = 3.3-9.2 and its maximum emulsifier activity is at pH = 5. Magnesium ions increase the activity of emulsifiers both at lower (3.3-4.5) and higher pH (5.5-9.3) than that of the optimal pH. Alasan activity is higher in an environment containing 20 mL citrate than that of same concentrations of acetate or Tris-HCl. According to studies, we can indicate that this bioemulsifier is a high molecular weight anion heteropolysaccharide combined with a protein component such as alanine.10,11,21,64-70

Emulsan

Emulsan is an extracellular poly-anionic bioemulsifier produced by Acinetobacter calcoaceticus RAG 1 bacteria. In fact, emulsan is a lipoheteropolysaccharide polymer containing D-galactose-amine produced during the stationary phase. This bioemulsifier is a poly-anionic and amphiphilic compound which is able to stabilize the hydrocarbon emulsion in water by creating a very thin layer between the hydrocarbon droplets and water. Maximum concentration is obtained when culture media containing 12 carbon-based fatty acids are used as the carbon source. Emulsan production is possible with fermentation methods such as batch, chemo-stat, immobilized cell system and self-cycling fermentation (SCF). Based on SCF methods, bioemulsifier production could increase about 50 times compared to the batch method. Another type of emulsan considered as bio-emulsion is produced by Acinetobacter calcoaceticus, which is used in the formulation and production of soft cheese and ice creams as well as creams and skin-protecting materials. Different types of emulsions produced from these bacteria include alpha-amyloemulsan, Apo-alpha-oleo-emulsan, and beta-emulsan, which are used for treating skin infections are widely used in the food industry. These compounds are mostly poly-anionic lipoheteropolysaccharides that are produced by different species of Acinetobacter venetianus rag-1t ATCC 31012- and Streptomyces NRRL.B- 15615, NRRL.B-15847 or ATCC 31926 and few other species.7,70,94-98

Cyanobacteria

A variety of cyanobacteria (Genus phormidium, ATCC 39161) (Oscillatoriales) bacterium produce bioemulsifiers that can be used for producing hydrocarbon and oil emulsions in a fluid environment such as water. This bacterium is obtained from using precise separation methods from riverside water, which subsequently grow on a suitable culture medium under favorable conditions and produce an extracellular bioemulsifier sphincter. The molecular weight of this polymeric bioemulsifier is more than 200,000 Dalton. According to chemical tests, it contains sugars, fatty acids, and a protein fractions. Also, more accurate tests using IR spectrophotometry have shown that it is contains amide, carboxylic and amino groups. This bioemulsifier is used for producing various types of oil-in-water emulsions (O/W).99-101

Pseudomonas cepacia bacteria

This bioemulsifier which in terms of molecular characteristics, is considered as a mixture of glycolic acid, is produced after Pseudomonas cepacia bacteria growth and propagation on sunflower oil (as the carbon source) medium. The production of this bioemulsifier is carried out by Pseudomonas cepacia bacteria by adding 1.7 % of sunflower oil per liter of culture medium when oxygen and nitrogen levels are controlled. This bioemulsifier is used as a natural source of disintegrating agents used for decomposing and neutralizing polychlorinated biphenyls, especially polychlorinated biphenyls. Polychlorinated biphenyls are toxic and with carcinogenic compounds produced by pesticides during various chemical processes which are able to contaminate industrial wastewater and cultivated soils.102-105

Bacillus stearothermophilus

During growth, Bacillus stearothermophilus VR-8 produces an extracellular bioemulsifier on a medium containing 4% crude oil. The optimum temperature for producing this bioemulsifier is 50 °C, which at this temperature, 0.6 gr/L bioemulsifier is produced. This emulsifier is purified by acetone and dialysis and contains 46% protein, 16% carbohydrate and 10% fat. Its emulsifier activity is stable over a wide range of temperatures, i.e. 50-80 °C, and pH = 2-8, and salt concentrations (5% chlorine, 5% calcium chloride or 1% chlorine magnesium). The emulsifying properties of this bioemulsifier are related to its stability in a wide range of pH (liposomal at pH = 2-5 and a maximum of 70 °C) and temperatures. This emulsifier is used for removing crude oil from reservoirs and eliminating the remaining oil of crude oil tanks. Hereby, recovery of crude oil, increases by complete scouring of oil remained on storage chamber.9,106-110

Sphingomonas bacteria

Presence of polycyclic aromatic hydrocarbons (PAH) in water resources due to their low solubility, is somewhat problematic. When the molecular weight of these compounds (PAH) are reduced, available microorganisms metabolize them. A number of degrading bacteria have been isolated from multi-ring aromatic hydrocarbons of contaminated soils, which produce bioemulsifiers and active compounds, most notably strain No. 107 of Sphingomonas bacteria. This bacterium grows on culture media containing a variety of aromatic hydrocarbon compounds and create clear spots on the medium. Also in liquid culture media, this bacterium uses aromatic hydrocarbons as the main source of energy and carbon. Notably, this bioemulsifier has emulsifying properties similar to high molecular weighting polycyclic hydrocarbons.111-114

Discussion

Biosurfactants have received great attention due to their safety and biodegradable properties. Although biosurfactants have various functions,their practical application is limited. Biosurfactants worldwide production was approximately 17 million tons in 2000 and is expected to have a growth rates of 3-4% per year globally. Biosurfactants have many advantages in comparison to synthesized components, such as, biodegradability (easily decomposed by microorganism), low toxicity (Effective Concentration =50), availability of raw materials (produced from cheap materials), physical factors (components which are not affected by temperature, pH and ionic strength tolerances), surface and interface activity (lower surface tension) ,biocompatibility and digestibility, commercial laundry detergents, bio pesticide, medical function (antimicrobial activity, anti-cancer activity, anti-adhesive agents, immunological adjuvants, antiviral activity, gene delivery), food processing industry, cosmetic industry and increasing oil recovery. Considering, biosurfactants applications and their affect on nutrient, micronutrient and environmental factors, their production still remains a challeng. It is expected that in the near future, a new strain of microorganisms will be developed for using as biosurfactants in industries.

Conclusion

Nowadays, emulsifiers are widely used in the food and drug industry. Therefore, using emulsifiers derived from natural resources are preferred to synthetic emulsifiers because of their nutritional benefits. As a result, using bioemulsifiers derived from microbial sources are beneficial and may be a significant alternative for synthesized emulsifiers. Thus, they can be used efficiently in the food and drug industry in acceptable and recommended quantities.

Acknowledgments

This review was conducted at Tabriz University of Medical Sciences, Tabriz, Iran.

Compliance with Ethical standards.

Ethical Issues

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of Interest

The authors declare no conflict of interests.

References

- 1.Hasenhuettl GL, Hartel RW. Food emulsifiers and their applications. USA: Springer; 2008. [Google Scholar]

- 2.Whitehurst RJ. Emulsifiers in food technology. United Kingdom: John Wiley & Sons; 2008. [Google Scholar]

- 3.Krog N. Functions of emulsifiers in food systems. J Am Oil Chem Soc. 1977;54(3):124–31. [Google Scholar]

- 4.Krog NJ, Sparso FV. Food emulsifiers and their chemical and physical properties. New York: Marcel Dekker Inc; 1997. [Google Scholar]

- 5. Hasenhuettl GL. Synthesis and commercial preparation of food emulsifiers. Food emulsifiers and their applications: Springer; 2008. 11-37.

- 6.Lauridsen JB. Food emulsifiers: Surface activity, edibility, manufacture, composition, and application. J Am Oil Chem Soc. 1976;53(6):400–7. [Google Scholar]

- 7.Uzoigwe C, Burgess JG, Ennis CJ, Rahman PK. Bioemulsifiers are not biosurfactants and require different screening approaches. Front Microbiol. 2015;6:245. doi: 10.3389/fmicb.2015.00245. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Calvo C, Manzanera M, Silva-Castro GA, Uad I, Gonzalez-Lopez J. Application of bioemulsifiers in soil oil bioremediation processes. Future prospects. Sci Total Environ. 2009;407(12):3634–40. doi: 10.1016/j.scitotenv.2008.07.008. [DOI] [PubMed] [Google Scholar]

- 9.Calvo C, Toledo FL, Pozo C, Martínez-Toledo MV, González-López J. Biotechnology of bioemulsifiers produced by micro-organisms. J Food Agric Environ. 2004;2(3):238–43. [Google Scholar]

- 10.Shepherd R, Rockey J, Sutherland IW, Roller S. Novel bioemulsifiers from microorganisms for use in foods. J Biotechnol. 1995;40(3):207–17. doi: 10.1016/0168-1656(95)00053-s. [DOI] [PubMed] [Google Scholar]

- 11.Nitschke M, Costa S. Biosurfactants in food industry. Trends Food Sci Tech. 2007;18(5):252–9. [Google Scholar]

- 12.Lukondeh T, Ashbolt NJ, Rogers PL. Evaluation of kluyveromyces marxianus fii 510700 grown on a lactose-based medium as a source of a natural bioemulsifier. J Ind Microbiol Biotechnol. 2003;30(12):715–20. doi: 10.1007/s10295-003-0105-6. [DOI] [PubMed] [Google Scholar]

- 13.Bach H, Gutnick D. Potential applications of bioemulsifiers in the oil industry. Stud Surf Sci Catal. 2004;151:233–81. [Google Scholar]

- 14.Zajic J, Panchal C, Westlake D. Bio-emulsifiers. CRC Crit Rev Microbiol. 1976;5(1):39–66. doi: 10.3109/10408417609102309. [DOI] [PubMed] [Google Scholar]

- 15.Sineriz F, Hommel R, Kleber H. Production of biosurfactants. Argentina: Encyclopedia of life support systems, semanticscholar; 2001. [Google Scholar]

- 16.Satpute SK, Banpurkar AG, Dhakephalkar PK, Banat IM, Chopade BA. Methods for investigating biosurfactants and bioemulsifiers: A review. Crit Rev Biotechnol. 2010;30(2):127–44. doi: 10.3109/07388550903427280. [DOI] [PubMed] [Google Scholar]

- 17.Campos JM, Stamford TL, Sarubbo LA. Production of a bioemulsifier with potential application in the food industry. Appl Biochem Biotechnol. 2014;172(6):3234–52. doi: 10.1007/s12010-014-0761-1. [DOI] [PubMed] [Google Scholar]

- 18.Mnif I, Besbes S, Ellouze R, Ellouze-Chaabouni S, Ghribi D. Improvement of bread quality and bread shelf-life by bacillus subtilis biosurfactant addition. Food Sci Biotechnol. 2012;21(4):1105–12. [Google Scholar]

- 19.Torabizadeh H, Shojaosadati S, Tehrani H. Preparation and characterisation of bioemulsifier fromsaccharomyces cerevisiaeand its application in food products. LWT-Food Sci Technol. 1996;29(8):734–7. [Google Scholar]

- 20.Mnif I, Ghribi D. Glycolipid biosurfactants: Main properties and potential applications in agriculture and food industry. J Sci Food Agric. 2016;96(13):4310–20. doi: 10.1002/jsfa.7759. [DOI] [PubMed] [Google Scholar]

- 21.Kosaric N, Sukan FV. Biosurfactants: Production: Properties: Applications. Canada: CRC Press; 2010. [Google Scholar]

- 22.Gutierrez T, Rhodes G, Mishamandani S, Berry D, Whitman WB, Nichols PD. et al. Polycyclic aromatic hydrocarbon degradation of phytoplankton-associated arenibacter spp. And description of arenibacter algicola sp. Nov., an aromatic hydrocarbon-degrading bacterium. Appl Environ Microbiol. 2014;80(2):618–28. doi: 10.1128/AEM.03104-13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Cameron DR, Cooper DG, Neufeld R. The mannoprotein of saccharomyces cerevisiae is an effective bioemulsifier. Appl Environ Microbiol. 1988;54(6):1420–5. doi: 10.1128/aem.54.6.1420-1425.1988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Barriga JA, Cooper DG, Idziak ES, Cameron DR. Components of the bioemulsifier from s. Cerevisiae. Enzyme Microb Tech. 1999;25(1):96–102. [Google Scholar]

- 25.Cirigliano MC, Carman GM. Purification and characterization of liposan, a bioemulsifier from candida lipolytica. Appl Environ Microbiol. 1985;50(4):846–50. doi: 10.1128/aem.50.4.846-850.1985. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Cirigliano MC, Carman GM. Isolation of a bioemulsifier from candida lipolytica. Appl Environ Microbiol. 1984;48(4):747–50. doi: 10.1128/aem.48.4.747-750.1984. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Amaral P, Da Silva J, Lehocky M, Barros-Timmons A, Coelho M, Marrucho I. et al. Production and characterization of a bioemulsifier from yarrowia lipolytica. Process Biochem. 2006;41(8):1894–8. [Google Scholar]

- 28.Sarubbo L, Porto A, Campos-Takaki G. The use of babassu oil as substrate to produce bioemulsifiers by candida lipolytica. Can J Microbiol. 1999;45(5):423–6. doi: 10.1139/w99-025. [DOI] [PubMed] [Google Scholar]

- 29.Souza F, Salgueiro A, Albuquerque C. Production of bioemulsifiers by yarrowia lipolytica in sea water using diesel oil as the carbon source. Braz J Chem. 2012;29(1):61–7. [Google Scholar]

- 30. Fracchia L, Cavallo M, Martinotti MG, Banat IM. Biosurfactants and bioemulsifiers biomedical and related applications–present status and future potentials. Bio Sci Eng Technol 2012.

- 31.Batista RM, Rufino RD, Luna JM, de Souza JE, Sarubbo LA. Effect of medium components on the production of a biosurfactant from candida tropicalis applied to the removal of hydrophobic contaminants in soil. Water Environ Res. 2010;82(5):418–25. doi: 10.2175/106143009x12487095237279. [DOI] [PubMed] [Google Scholar]

- 32.Amaral PF, Coelho MAZ, Marrucho IM, Coutinho JA. Biosurfactants from yeasts: Characteristics, production and application. Adv Exp Med Biol. 2010;672:236–49. doi: 10.1007/978-1-4419-5979-9_18. [DOI] [PubMed] [Google Scholar]

- 33.Campos-Takaki GM, Sarubbo LA, Albuquerque CDC. Environmentally friendly biosurfactants produced by yeasts. Adv Exp Med Biol. 2010;672:250–60. doi: 10.1007/978-1-4419-5979-9_19. [DOI] [PubMed] [Google Scholar]

- 34.Accorsini FR, Mutton MJR, Lemos EGM, Benincasa M. Biosurfactants production by yeasts using soybean oil and glycerol as low cost substrate. Braz J Microbiol. 2012;43(1):116–25. doi: 10.1590/S1517-838220120001000013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Satpute SK, Banat IM, Dhakephalkar PK, Banpurkar AG, Chopade BA. Biosurfactants, bioemulsifiers and exopolysaccharides from marine microorganisms. Biotechnol Adv. 2010;28(4):436–50. doi: 10.1016/j.biotechadv.2010.02.006. [DOI] [PubMed] [Google Scholar]

- 36.Mnif I, Ghribi D. High molecular weight bioemulsifiers, main properties and potential environmental and biomedical applications. World J Microbiol Biotechnol. 2015;31(5):691–706. doi: 10.1007/s11274-015-1830-5. [DOI] [PubMed] [Google Scholar]

- 37.Eliwa E-S, El-Hofi M. Β-galactosidase (β-gal) from the yeast rhodotorula ingeniosa and its utilization in ice milk production. Biotechnol. 2010;13(1):02. [Google Scholar]

- 38.Feng H-f, DU Q-j, LUAN J, SUN Y-m. Biosurfactant production by ochrobactrum sp. With alkane as carbon source. J Ind Microbiol. 2015;3:011. [Google Scholar]

- 39.Shekhar S, Sundaramanickam A, Balasubramanian T. Biosurfactant producing microbes and their potential applications: A review. Crit Rev Environ Sci Technol. 2015;45(14):1522–54. [Google Scholar]

- 40.Cooper DG, Paddock DA. Torulopsis petrophilum and surface activity. Appl Environ Microbiol. 1983;46(6):1426–9. doi: 10.1128/aem.46.6.1426-1429.1983. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Rau U, Hammen S, Heckmann R, Wray V, Lang S. Sophorolipids: A source for novel compounds. Ind Crop Prod. 2001;13(2):85–92. [Google Scholar]

- 42.Morita T, Konishi M, Fukuoka T, Imura T, Kitamoto D. Discovery of pseudozyma rugulosa nbrc 10877 as a novel producer of the glycolipid biosurfactants, mannosylerythritol lipids, based on rdna sequence. Appl Microbiol Biotechnol. 2006;73(2):305. doi: 10.1007/s00253-006-0466-7. [DOI] [PubMed] [Google Scholar]

- 43.Rau U, Nguyen LA, Schulz S, Wray V, Nimtz M, Roeper H. et al. Formation and analysis of mannosylerythritol lipids secreted by pseudozyma aphidis. Appl Microbiol Biotechnol. 2005;66(5):551–9. doi: 10.1007/s00253-004-1672-9. [DOI] [PubMed] [Google Scholar]

- 44.Konishi M, Morita T, Fukuoka T, Imura T, Kakugawa K, Kitamoto D. Production of different types of mannosylerythritol lipids as biosurfactants by the newly isolated yeast strains belonging to the genus pseudozyma. Appl Microbiol Biotechnol. 2007;75(3):521. doi: 10.1007/s00253-007-0853-8. [DOI] [PubMed] [Google Scholar]

- 45.Kakugawa K, Tamai M, Imamura K, Miyamoto K, Miyoshi S, Morinaga Y. et al. Isolation of yeast kurtzmanomyces sp. I-11, novel producer of mannosylerythritol lipid. Biosci Biotechnol Biochem. 2002;66(1):188–91. doi: 10.1271/bbb.66.188. [DOI] [PubMed] [Google Scholar]

- 46.Johnson V, Singh M, Saini VS, Adhikari DK, Sista V, Yadav NK. Bioemulsifier production by an oleaginous yeastrhodotorulaglutinis iip-30. Biotechnol lett. 1992;14(6):487–90. [Google Scholar]

- 47.Miura Y. Mechanism of liquid hydrocarbon uptake by microorganisms and growth kinetics. Adv Biochem Eng. 2017;9:31–56. doi: 10.1007/BFb0048090. [DOI] [Google Scholar]

- 48.Amezcua-Vega C, Poggi-Varaldo HM, Esparza-Garcia F, Rios-Leal E, Rodriguez-Vazquez R. Effect of culture conditions on fatty acids composition of a biosurfactant produced by candida ingens and changes of surface tension of culture media. Bioresour Technol. 2007;98(1):237–40. doi: 10.1016/j.biortech.2005.11.025. [DOI] [PubMed] [Google Scholar]

- 49.Rufino R, Sarubbo L, Campos-Takaki G. Enhancement of stability of biosurfactant produced by candida lipolytica using industrial residue as substrate. World J Microb Biot. 2007;23(5):729–34. doi: 10.1007/s11274-006-9278-2. [DOI] [Google Scholar]

- 50.Cavalero DA, Cooper DG. The effect of medium composition on the structure and physical state of sophorolipids produced by candida bombicola atcc 22214. J Biotechnol. 2003;103(1):31–41. doi: 10.1016/s0168-1656(03)00067-1. [DOI] [PubMed] [Google Scholar]

- 51.Hommel R, Weber L, Weiss A, Himmelreich U, Rilke O, Kleber H-P. Production of sophorose lipid by candida (torulopsis) apicola grown on glucose. J Biotechnol. 1994;33(2):147–55. doi: 10.1016/0168-1656(94)90107-4. [DOI] [Google Scholar]

- 52.Huang L, Zhang B, Gao B, Sun G. Application of fishmeal wastewater as a potential low-cost medium for lipid production by lipomyces starkeyi hl. Environ Technol. 2011;33(15-16):1975–81. doi: 10.1080/09593330.2011.562551. [DOI] [PubMed] [Google Scholar]

- 53.Gao SS, Li XM, Du FY, Li CS, Proksch P, Wang BG. Secondary metabolites from a marine-derived endophytic fungus penicillium chrysogenum qen-24s. Mar Drugs. 2010;9(1):59–70. doi: 10.3390/md9010059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Zinjarde SS, Pant A. Emulsifier from a tropical marine yeast, yarrowia lipolytica ncim 3589. J Basic Microbiol. 2002;42(1):67–73. doi: 10.1002/1521-4028(200203)42:1<67::AID-JOBM67>3.0.CO;2-M. [DOI] [PubMed] [Google Scholar]

- 55.Coelho M, Amaral P, Belo I. Yarrowia lipolytica: An industrial workhorse. Appl Microbiol Microb Biotechnol. 2010;2:930–40. [Google Scholar]

- 56.Teichmann B, Linne U, Hewald S, Marahiel MA, Bolker M. A biosynthetic gene cluster for a secreted cellobiose lipid with antifungal activity from ustilago maydis. Mol Microbiol. 2007;66(2):525–33. doi: 10.1111/j.1365-2958.2007.05941.x. [DOI] [PubMed] [Google Scholar]

- 57.Ben Belgacem Z, Bijttebier S, Verreth C, Voorspoels S, Van de Voorde I, Aerts G. et al. Biosurfactant production by pseudomonas strains isolated from floral nectar. J Appl Microbiol. 2015;118(6):1370–84. doi: 10.1111/jam.12799. [DOI] [PubMed] [Google Scholar]

- 58.Luna JM, Rufino RD, Sarubbo LA, Rodrigues LR, Teixeira JA, de Campos-Takaki GM. Evaluation antimicrobial and antiadhesive properties of the biosurfactant lunasan produced by candida sphaerica UCP 0995. Curr Microbiol. 2011;62(5):1527–34. doi: 10.1007/s00284-011-9889-1. [DOI] [PubMed] [Google Scholar]

- 59.Gusmão CAB, Rufino RD, Sarubbo LA. Laboratory production and characterization of a new biosurfactant from Candida glabrata UCP1002 cultivated in vegetable fat waste applied to the removal of hydrophobic contaminant. World J Microb Biot. 2010;26(9):1683–92. doi: 10.1007/s11274-010-0346-2. [DOI] [Google Scholar]

- 60.Santos CA, Bezerra MS, Pereira HS, Santos ES, Macedo GR. Production and recovery of rhamnolipids using sugar cane molasses as carbon source. J Chem Eng Chem Eng. 2010;4(11):27. [Google Scholar]

- 61.Mohammadi S, Abbasi S, Scanlon M. Development of emulsifying property in persian gum using octenyl succinic anhydride (osa) Int J Biol Macromol. 2016;89:396–405. doi: 10.1016/j.ijbiomac.2016.04.006. [DOI] [PubMed] [Google Scholar]

- 62.Kiran GS, Selvin J, Manilal A, Sujith S. Biosurfactants as green stabilizers for the biological synthesis of nanoparticles. Crit Rev Biotechnol. 2011;31(4):354–64. doi: 10.3109/07388551.2010.539971. [DOI] [PubMed] [Google Scholar]

- 63. dos Santos SC, Fernandez LG, Rossi-Alva JC, de Abreu Roque MR. Evaluation of substrates from renewable-resources in biosurfactants production by pseudomonas strains. Afr J Biotechnol 2010;9(35).

- 64.Hames EE, Vardar-Sukan F, Kosaric N. 11 patents on biosurfactants and future trends. Biosurfactants: Production and Utilization Processes, Technologies, and Economics. USA: CRC press, Taylor & Francis group; 2014. [Google Scholar]

- 65.Perfumo A, Smyth T, Marchant R, Banat I. Production and roles of biosurfactants and bioemulsifiers in accessing hydrophobic substrates. Germany: Springer; 2010. [Google Scholar]

- 66.Jagtap S, Yavankar S, Pardesi K, Chopade B. Production of bioemulsifier by acinetobacter species isolated from healthy human skin. Indian J Exp Biol. 2010;48(1):70–6. [PubMed] [Google Scholar]

- 67.Cameotra SS, Makkar RS, Kaur J, Mehta SK. Synthesis of biosurfactants and their advantages to microorganisms and mankind. Adv Exp Med Biol. 2010;672:261–80. doi: 10.1007/978-1-4419-5979-9_20. [DOI] [PubMed] [Google Scholar]

- 68.Ron E, Rosenberg E. Role of biosurfactants. Handbook of hydrocarbon and lipid microbiology: Germany; 2010. [Google Scholar]

- 69.Vijayakumar S, Saravanan V. Biosurfactants-types, sources and applications. Res J Microbiol. 2015;10(5):181–92. [Google Scholar]

- 70.Foght JM, Gutnick DL, Westlake DW. Effect of emulsan on biodegradation of crude oil by pure and mixed bacterial cultures. Appl Environ Microbiol. 1989;55(1):36–42. doi: 10.1128/aem.55.1.36-42.1989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Banat IM, Franzetti A, Gandolfi I, Bestetti G, Martinotti MG, Fracchia L. et al. Microbial biosurfactants production, applications and future potential. Appl Microbiol Biotechnol. 2010;87(2):427–44. doi: 10.1007/s00253-010-2589-0. [DOI] [PubMed] [Google Scholar]

- 72.Jadhav M, Kalme S, Tamboli D, Govindwar S. Rhamnolipid from pseudomonas desmolyticum ncim-2112 and its role in the degradation of brown 3rel. J Basic Microbiol. 2011;51(4):385–96. doi: 10.1002/jobm.201000364. [DOI] [PubMed] [Google Scholar]

- 73.Arguelles-Arias A, Ongena M, Halimi B, Lara Y, Brans A, Joris B. et al. Bacillus amyloliquefaciens ga1 as a source of potent antibiotics and other secondary metabolites for biocontrol of plant pathogens. Microb Cell Fact. 2009;8(1):63. doi: 10.1186/1475-2859-8-63. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 74.Abriouel H, Franz CM, Omar NB, Gálvez A. Diversity and applications of bacillus bacteriocins. FEMS Microbiol Rev. 2010;35(1):201–32. doi: 10.1111/j.1574-6976.2010.00244.x. [DOI] [PubMed] [Google Scholar]

- 75.Yakimov MM, Golyshin PN. Coma-dependent transcriptional activation of lichenysin a synthetase promoter in bacillus subtilis cells. Biotechnol Prog. 1997;13(6):757–61. doi: 10.1021/bp9700622. [DOI] [PubMed] [Google Scholar]

- 76.Begley M, Cotter PD, Hill C, Ross RP. Identification of a novel two-peptide lantibiotic, lichenicidin, following rational genome mining for lanm proteins. Appl Environ Microbiol. 2009;75(17):5451–60. doi: 10.1128/AEM.00730-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 77.Banat IM, Makkar RS, Cameotra SS. Potential commercial applications of microbial surfactants. Appl Microbiol Biotechnol. 2000;53(5):495–508. doi: 10.1007/s002530051648. [DOI] [PubMed] [Google Scholar]

- 78.Banat IM. Biosurfactants production and possible uses in microbial enhanced oil recovery and oil pollution remediation: A review. Bioresour Technol. 1995;51(1):1–12. doi: 10.1016/0960-8524(94)00101-6. [DOI] [Google Scholar]

- 79.Rosenberg E, Barkay T, Navon-Venezia S, Ron E. Role of acinetobacter bioemulsans in petroleum degradation. Novel approaches for bioremediation of organic pollution. USA: Springer; 1999. [Google Scholar]

- 80.Kim S-Y, Oh D-K, Kim J-H. Biological modification of hydrophobic group in acinetobacter calcoaceticus RAG-1 emulsan. J Biosci Bioeng. 1997;84(2):162–4. doi: 10.1016/S0922-338X(97)82548-2. [DOI] [Google Scholar]

- 81.Hirrlinger B, Stolz A, Knackmuss H-J. Purification and properties of an amidase from rhodococcus erythropolis mp50 which enantioselectively hydrolyzes 2-arylpropionamides. J Bacteriol. 1996;178(12):3501–7. doi: 10.1128/jb.178.12.3501-3507.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 82.Aizawa T, Neilan BA, Couperwhite I, Urai M, Anzai H, Iwabuchi N. et al. Relationship between extracellular polysaccharide and benzene tolerance of rhodococcus sp. 33. Actinomycetologica. 2005;19(1):1–6. doi: 10.3209/saj.19.1. [DOI] [Google Scholar]

- 83.Nerurkar AS, Hingurao KS, Suthar HG. Bioemulsifiers from marine microorganisms. J Sci Ind Res. 2009;68(4):273–7. [Google Scholar]

- 84.Mortenson LE. Ferredoxin and atp, requirements for nitrogen fixation in cell-free extracts of clostridium pasteurianum. Proc Natl Acad Sci U S A. 1964;52:272–9. doi: 10.1073/pnas.52.2.272. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 85.Yang Q, Yediler A, Yang M, Kettrup A. Decolorization of an azo dye, reactive black 5 and mnp production by yeast isolate: Debaryomyces polymorphus. Biochem Engine J. 2005;24(3):249–53. doi: 10.1016/j.bej.2004.12.004. [DOI] [Google Scholar]

- 86.Ates O, Oner ET, Arga KY. Genome-scale reconstruction of metabolic network for a halophilic extremophile, chromohalobacter salexigens dsm 3043. BMC Syst Biol. 2011;5(1):12. doi: 10.1186/1752-0509-5-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 87.Gutierrez T, Mulloy B, Black K, Green DH. Glycoprotein emulsifiers from two marine halomonas species: Chemical and physical characterization. J Appl Microbiol. 2007;103(5):1716–27. doi: 10.1111/j.1365-2672.2007.03407.x. [DOI] [PubMed] [Google Scholar]

- 88.Gudina EJ, Teixeira JA, Rodrigues LR. Isolation and functional characterization of a biosurfactant produced by lactobacillus paracasei. Colloids Surf B Biointerfaces. 2010;76(1):298–304. doi: 10.1016/j.colsurfb.2009.11.008. [DOI] [PubMed] [Google Scholar]

- 89.Sarwat F, Ul Qader SA, Aman A, Ahmed N. Production & characterization of a unique dextran from an indigenous leuconostoc mesenteroides cmg713. Int J Biol Sci. 2008;4(6):379–86. doi: 10.7150/ijbs.4.379. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 90.Wei YH, Lai HC, Chen SY, Yeh MS, Chang JS. Biosurfactant production by serratia marcescens ss-1 and its isogenic strain smδr defective in spnr, a quorum-sensing luxr family protein. Biotechnol lett. 2004;26(10):799–802. doi: 10.1023/b:bile.0000025881.95596.23. [DOI] [PubMed] [Google Scholar]

- 91.Li J, Deng M, Wang Y, Chen W. Production and characteristics of biosurfactant produced by Bacillus pseudomycoides BS6 utilizing soybean oil waste. Int Biodeter Biodegr. 2016;112:72–9. doi: 10.1016/j.ibiod.2016.05.002. [DOI] [Google Scholar]

- 92.Silva RCFS, Rufino RD, Luna JM, Farias CBB, Filho HJB, Santos VA. et al. Enhancement of biosurfactant production from Pseudomonas cepacia CCT6659 through optimisation of nutritional parameters using response surface methodology. Tenside Surfact Det. 2013;50(2):137–42. doi: 10.3139/113.110241. [DOI] [Google Scholar]

- 93.Joshi SJ, Desai AJ. Bench-scale production of biosurfactants and their potential in ex-situ MEOR application. Soil Sediment Contam. 2013;22(6):701–15. doi: 10.1080/15320383.2013.756450. [DOI] [Google Scholar]

- 94.Fondi M, Orlandini V, Emiliani G, Papaleo MC, Maida I, Perrin E. et al. Draft genome sequence of the hydrocarbon-degrading and emulsan-producing strain acinetobacter venetianus rag-1t. J Bacteriol. 2012;194(17):4771–2. doi: 10.1128/JB.01019-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 95.Mousavian S, Rahimi K. Emulsan production by acinetobacter calcoaceticus rag-1 ATCC-31012. FSCT. 2010;7(26):117–25. [Google Scholar]

- 96.Goldman S, Shabtai Y, Rubinovitz C, Rosenberg E, Gutnick DL. Emulsan in acinetobacter calcoaceticus rag-1: Distribution of cell-free and cell-associated cross-reacting material. Appl Environ Microbiol. 1982;44(1):165–70. doi: 10.1128/aem.44.1.165-170.1982. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 97.Rubinovitz C, Gutnick DL, Rosenberg E. Emulsan production by acinetobacter calcoaceticus in the presence of chloramphenicol. J Bacteriol. 1982;152(1):126–32. doi: 10.1128/jb.152.1.126-132.1982. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 98.Pines O, Gutnick D. Role for emulsan in growth of acinetobacter calcoaceticus rag-1 on crude oil. Appl Environ Microbiol. 1986;51(3):661–3. doi: 10.1128/aem.51.3.661-663.1986. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 99. Shilo M, Fattom A. Cyanobacterium-produced bioemulsifier composition and solution thereof. Google Patents; 1987. No. 4,693,842.

- 100. Susilaningsih D. Biosurfactant properties of extracellular pink pigment produced by a freshwater cyanobacterium, oscillatoria sp. Microbiol Indones 2010;1(3).

- 101.Shete A, Wadhawa G, Banat I, Chopade B. Mapping of patents on bioemulsifier and biosurfactant: A review. J Sci Ind Res. 2006;65:91–115. [Google Scholar]

- 102.Kanaly RA, Harayama S. Biodegradation of high-molecular-weight polycyclic aromatic hydrocarbons by bacteria. J Bacteriol. 2000;182(8):2059–67. doi: 10.1128/jb.182.8.2059-2067.2000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 103.Fiebig R, Schulze D, Chung J-C, Lee S-T. Biodegradation of polychlorinated biphenyls (pcbs) in the presence of a bioemulsifier produced on sunflower oil. Biodegradation. 1997;8(2):67–75. [Google Scholar]

- 104.Aislabie J, Lloyd-Jones G. A review of bacterial-degradation of pesticides. Aust J Soil Res. 1995;33(6):925–42. doi: 10.1071/SR9950925. [DOI] [Google Scholar]

- 105.Van Dyke MI, Lee H, Trevors JT. Applications of microbial surfactants. Biotechnol Adv. 1991;9(2):241–52. doi: 10.1016/0734-9750(91)90006-H. [DOI] [PubMed] [Google Scholar]

- 106.Gurjar M, Khire J, Khan M. Bioemulsifier production by bacillus stearothermophilus vr‐8 isolate. Lett Appl Microbiol. 1995;21(2):83–6. doi: 10.1111/j.1472-765X.1995.tb01012.x. [DOI] [Google Scholar]

- 107.Rosenberg E, Ron EZ. High- and low-molecular-mass microbial surfactants. Appl Microbiol Biotechnol. 1999;52(2):154–62. doi: 10.1007/s002530051502. [DOI] [PubMed] [Google Scholar]

- 108.Rosenberg E, Ron EZ. Bioemulsans: Microbial polymeric emulsifiers. Curr Opin Biotechnol. 1997;8(3):313–6. doi: 10.1016/s0958-1669(97)80009-2. [DOI] [PubMed] [Google Scholar]

- 109.Ilori MO, Amobi CJ, Odocha AC. Factors affecting biosurfactant production by oil degrading aeromonas spp. Isolated from a tropical environment. Chemosphere. 2005;61(7):985–92. doi: 10.1016/j.chemosphere.2005.03.066. [DOI] [PubMed] [Google Scholar]

- 110.de Acevedo GT, McInerney MJ. Emulsifying activity in thermophilic and extremely thermophilic microorganisms. J Ind Microbiol. 1996;16(1):1–7. doi: 10.1007/BF01569914. [DOI] [Google Scholar]

- 111.Willumsen PA, Karlson U. Screening of bacteria, isolated from pah-contaminated soils, for production of biosurfactants and bioemulsifiers. Biodegradation. 1996;7(5):415–23. doi: 10.1007/BF00056425. [DOI] [Google Scholar]

- 112.Ron EZ, Rosenberg E. Biosurfactants and oil bioremediation. Curr Opin Biotechnol. 2002;13(3):249–52. doi: 10.1016/S0958-1669(02)00316-6. [DOI] [PubMed] [Google Scholar]

- 113.Dagher F, Deziel E, Lirette P, Paquette G, Bisaillon JG, Villemur R. Comparative study of five polycyclic aromatic hydrocarbon degrading bacterial strains isolated from contaminated soils. Can J Microbiol. 1997;43(4):368–77. doi: 10.1139/m97-051. [DOI] [PubMed] [Google Scholar]

- 114.Leys NM, Ryngaert A, Bastiaens L, Top EM, Verstraete W, Springael D. Culture independent detection of sphingomonas sp. Epa 505 related strains in soils contaminated with polycyclic aromatic hydrocarbons (pahs) Microb Ecol. 2005;49(3):443–50. doi: 10.1007/s00248-004-0011-0. [DOI] [PubMed] [Google Scholar]