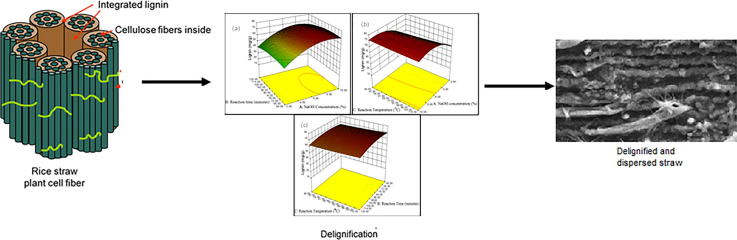

Graphical abstract

Keywords: Rice straw, Delignification, Alkali treatment, Optimization, Central composite design

Highlights

-

•

Rice straw was delignified for use in free-radical grafting as a roofing material.

-

•

NaOH concentration, reaction time and temperature on delignification were studied.

-

•

Delignification of rice straw was optimized by central composite design approach.

.

-

•

Alkali concn.7.59%, time 75.11 min and temperature 40 °C were best optimized conditions.

-

•

Lignin extraction concentration was found to be 70.3 mg/g.

Abstract

The present investigation deals with process optimisation of delignification of rice straw towards its micro-porous structural enhancement for its utilization in polymer grafting. The individual effect of influential parameters viz. sodium hydroxide concentration (1–12%, w/v), reaction time (30–126 min), and temperature (20–150 °C) on delignification were studied in a single mode batch process. The process parameters were further optimized with Central composite design (CCD) approach of response surface methodology in Design expert software. Delignification of rice straws was observed to follow quadratic equation. Analysis of variance (ANOVA) study suggested the equation to be significant for the process with major impact of sodium hydroxide concentration on the delignification process than reaction time and temperature. The optimized parametric conditions of delignification are: alkali concentration 7.59%, reaction time 75.11 min, and reaction temperature 40 °C. The software predicted lignin extraction concentration to be 72.4 mg/g, which upon experimentation was found to be 70.03 mg/g. Instrumental analysis of the delignified rice straw demonstrated porous structure and change in surface chemistry due to lignin removal. Therefore, the delignified rice straw obtained under optimized conditions were found to be appropriate for grafting of polymers which improved its resilience for variable usages.

Introduction

In tropical countries, rice straw is a commonly found agricultural by-product which is produced annually in large quantities remains vastly under-utilized [1]. In India and in other countries, rice straws are alternatively used as precursor in paper and pulp industries. Although, rice straws are alternatively used as animal fodder, fuel for cooking, house heating, packing material, organic fertilizer etc., but still a significant amount of it remains unutilized. Finding no such profitable use of rice straw, farmers usually burn them in open field to obtain heat; also, it serves as a way of ultimate disposal. This is considered to be a part of agricultural activity which is practised worldwide in countries like China, India, Philippine, and Thailand [2], [3]. Such activity leads to global warming because of greenhouse gas emission which includes carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), particulate matter (PM), and other toxic polycyclic aromatic hydrocarbons (PAHs) [4], [5] resulting from incomplete incineration process. Undesirable incidents like haze and traffic accidents due to poor visibility, health hazards are some of the unavoidable consequences which occur as a result of increase in particulate matters in the atmosphere. Out of 731 MT of paddy which is cultivated each year globally, a major portion of it viz., 28.7% and 19.5%, respectively, are produced in India and China [6]. For practical purposes, these rice straws are used as packing material and animal fodder which consumes 74 million tons approximately. Consequently, a larger percentage of this agricultural leftover are dumped, which in turn creates environmental nuisance. Efforts have been made to utilise this agricultural waste but the value of this product has not been high enough to make it worthwhile for farmers to collect and transport straw. However, it can be used as a cheap roofing material but normally it biodegrades and has a risk of inflammation from accidental fires in villages. This adds to the distress of the poverty stricken villagers and farmers considerably. Therefore, an initiative has been made in the present study to overcome the above stated crisis which rises from using untreated rice straws as roofing material. Therefore, the untreated rice straws were delignified followed by structural development via grafting.

Rice straw comprises polysaccharides, crystalline cellulose (33–48%), amorphous hemicellulose (18–28%) and non-sugar lignin (6–25%) along with silica and water [7]. Delignification involves subtraction of lignin along with disruption in cellulose crystals. For better grafting of polymer onto paddy straw, delignification imparts a prominent role which facilitates either partial or complete removal of lignin via chemical or physical agents without tampering much of its cellulose skeleton [8], [9]. In oxidative treatment, the chemicals affect lignin degradation while hydrolytic tools cleave the lignin-carbohydrate bonds. On the other hand, combination of both hydrolysis and oxidative treatment delivers better delignification efficacy [10]. Thus, for successful grafting porous structural benefits are required which can be accomplished with removal of lignin from rice straws. Therefore, the porous structure developed is occupied by the polymeric substance. This forms a strong covalent bond between the C2O4−• of the initiator system and Ph-OH group of the polymeric substrate (that is rice straw in the present study) which polymerises to give a grafted copolymer. Delignification generates micropores or hollow spaces on the surface of rice straw which acts as active sites on the surface for grafting of the polymer. This results in a cross-linked network which upon heating forms an insulative carbonaceous barrier on the surface, thereby inhibiting degradation of rice straw.

For the past few decades, rigorous investigations are being experimented to develop effective delignification methods for rice straws. Among them, the common most prevalent chemical treatments comprise sodium chlorite process [11], [12], [13], alkali pre-treatment [9], [14], [15], alkaline-peroxide pre-treatment [15], [16], ammonia pre-treatment [8], [9] and organogold technique [16], [17], [18]. Some of these methods require higher degree of temperature, lengthier retention time, and pressure and multiple usages of organic solvents. Alkaline pre-treatment is one such approach which has several potential benefits compared to other pre-treatment processes due to its low operation cost, abridged degradation of holo-cellulose and successive formation of inhibitors for downstream processing [9]. NaOH is a strong alkali and requires much less water to dissolve at a lower reaction temperature [19]. NaOH pre-treatment studies have already been reported for wheat straw, miscanthus, and cotton stalk exhibiting its impact on delignification and enzymatic hydrolysis [20], [21], [22]. The major parametric elements affecting lignin extraction are NaOH concentration, reaction temperature and reaction rate. Hence, standardization of such variables are quite essential for effective delignification. In general, parametric optimization includes variation of single parameter at a period when other parameters remain constant. Hence, limitation incorporated with such classical technique is its incapability in optimizing the overall process in lesser time. As a result, inadequacies could be eliminated via computed standardization viz., Response surface methodology (RSM). Numerous works have been stated on delignification of various plant species with central composite design for production of biodiesel, pulp, glucose etc. [23], [24], [25], [26]. So far, no works have been reported on Central composite design (CCD) based optimization of process parameters associated with delignification of rice straw for its use in polymer grafting.

Therefore, the present investigation deals with application of response surface methodology based Central composite design (CCD) for optimization of parametric variables involved in delignification of rice straw in order to obtain the optimum delignifying conditions. The findings of the present work also emphasizes on the structural changes of delignified rice straws and its applicability in grafting in order to increase its durability and flame retardancy so as to sustain its commercial usability.

Material and methods

Sample preparation

Freshly harvested rice straw (Oryza sativa) of same variety was collected from near-by rice field as post-harvest waste. After removal of leaves and nodal parts, these were chopped into 2–5 mm stalks and finally sieved through 2 mm screen (8 mesh, British standard). The rice straws were washed thoroughly under running tap water, followed by sun-drying for removal of moisture for its subsequent use in further studies. The delignification was done with sodium hydroxide (NaOH) (purchased from Merck, Mumbai, India). Deionized water obtained from deionizer (Sartorius A. G., Gottingen, Germany) was employed in preparing solutions for each study. Chopped rice straws were stored in moisture free plastic bags at room temperature for further use. Glasswares used for this experimental study was purchased from Borosil, Kolkata, India.

Batch delignification of rice straws

All experiments were executed batch wise to determine the effect of various operating parameters over lignin removal from rice straw. The range used for optimization of process parameters viz., NaOH percentage (w/v), temperature and contact time were set at 1–12%, 20–150 °C and 30–126 min. The following procedure was adopted for each set of experimental run with 15.0 g of chopped rice straw (2–5 mm) of same variety keeping in a 1000 mL Erlenmeyer flask. 300 mL of NaOH solution of predetermined concentration was poured into Erlenmeyer flask containing dried rice straw. The Erlenmeyer flask was placed in a hot air oven (Digitech Systems, Kolkata, India) to attain the desired temperature and thereafter, the time was counted. At regular interval, the flasks were shaken manually for proper mixing of the rice straw with NaOH. At the end of each batch, Erlenmeyer flask was taken out from the hot air oven and cooled at room temperature. Solid residue was first separated from the liquor by ordinary mesh filter followed by fine filtration via filter paper (Whatmann series 41) purchased from Filtroll India, West Bengal, India. Lastly, the filtrate was used for measurement of lignin concentration by UV–Visible spectrophotometer (Shimadzu Spectrophotometer, UV-1800, Toshvin Analytical, Bangalore, India) at specified wave length within six hours of experiment. Liquid sample should be stored in a refrigerator for a maximum of two weeks at 4 °C if the analysis is supposed to be performed later. The initial colour of the filtrate in most cases was yellow which gradually changed to deep brown with increase in concentration of lignin.

Proximate analysis of untreated rice straws

Proximate analysis helps in determining the moisture, ash, volatile matter content and overall fixed carbon content percentage of a given sample. Therefore, the untreated rice straws used in our present study were initially investigated for proximate analysis using Laboratory Analytical Procedures LAP-001(23) and LAP-005(24) [27], [28].

Raw rice straws were cut into uniform small pieces and it was used for the following analysis:

Determination of moisture content

A 2 g of rice straw was weighed and dried in a hot air oven (S.C. Dey Instruments Manufacturer, Kolkata, India) for 1 h at 105 °C. The weight loss was calculated from Eq. (1):

| (1) |

where M represents moisture content in percentage, W1 represents weight of empty crucible in g, W2 interprets weight of empty crucible and sample before heating in g and W3 represents weight of empty crucible and sample after heating in g.

Determination of ash content

Similarly, 2 g of sample was taken and dried in a muffle furnace (Servotronics DIC: 9681, Kolkata, India) at 850 °C for 1 h and the change in weight was calculated with Eq. (2):

| (2) |

where A interprets ash content in percentage.

Determination of volatile matter content

A 2 g of rice straw was taken into a lid covered crucible, heated at 915 °C for 10 min after which the sample was analysed for weight loss using Eq. (3):

| (3) |

where V represents volatile matter content in percentage.

Determination of fixed carbon content

Percentage of fixed carbon (FC) content was calculated form Eq. (4):

| (4) |

Lignin content in the raw and alkali treated rice straw

Lignin content in raw and alkali treated rice straw were recorded according to the standard of LAPs. Amount of lignin in the rice straw was calculated as a summation of acid soluble and insoluble lignin. Acid insoluble and acid-soluble lignin contents were determined using methods adapted from NREL CAT Task Laboratory Analytical Procedure [29]. A 0.3 g of raw and delignified rice straw sample was taken into two different beakers and 3.0 mL of 72% w/w H2SO4 (Merck, Mumbai, India) was added into the beaker. The sample was thoroughly mixed using a glass-stirring rod. The beakers were placed in a hot water bath (Daihan Labtech, New Delhi, India) at 30 °C for 2 h and stirring was made at every 15 min interval. The hydrolysate was transferred into a conical flask and diluted to a 4.0% acid concentration by adding 84.0 mL of ultrapure water. The conical flask was stoppered and tightly sealed using aluminium foil before boiling it for 1 h at 121 °C and at 15 psi pressure. The flasks were then cooled at room temperature followed by separation of the liquid. The filtrate was then diluted 7× with ultrapure water before it was subjected for UV analysis at 282 nm with 4% H2SO4 as blank. This analysis quantified the acid soluble lignin present in rice straw.

On the other hand, the solid residue was washed with hot water until the washed straws were acid free. The acid free residue was transferred into a pre-weighed crucible then dried at 105 °C until constant weight was achieved and finally the dried mass was weighed. Materials containing crucible was placed in a muffle furnace at 575 °C for 3 h. This was removed from the furnace and placed in a desiccator for cooling and then weighed. This analysis measured the acid insoluble lignin present in the rice straw. Therefore, the percentage of delignification was calculated from Eq. (5):

| (5) |

where m1 is the initial mass of lignin present in solid sample in g, m2 is the final mass of lignin present in solid sample in g.

Scanning electron microscope (SEM) imaging of rice straw

Changes in surface morphology of untreated and delignified rice straws were examined under scanning electron microscope (JEOL-JSM-6030, India). Before analysis the samples were dried and straddled on “stubs” at a height of 10 mm. Carbon tape was used as a non-conducting adhesive for the samples. In order to increase the conductivity of the samples, all three types of rice straws were subjected to 8 mm coating of palladium via sputter coating for 30 s (JOEL-JFC 1600, India). Coating of the samples was carried out at 30 mA in order to maximize its conductivity.

Energy dispersive X-ray analysis (EDAX) of elemental variation of rice straw

Elemental analysis of the two samples was investigated via energy dispersive X-ray analysis or EDAX (Fischer Measurement Technologies Pvt. Ltd., New Delhi, India). Dispersion of energy for individual elements is discrete in nature which, in turn, develops different peaks representing variance in elemental make-up of the sample, thus delivering the percentage constituent of each element.

Fourier-transform infrared analysis (FT-IR) of rice straw

Characterization of functional groups of untreated rice straws and their consequent changes due to delignification were documented via Fourier-transform infrared spectroscopy (Smart Omni-Transmission IS 10, Thermo Fisher Scientific, India). For preparation of sample, analytical grade potassium bromide (KBr) was used for preparation of pellets. Initially, the KBr powder was dried for 3 h followed by mixing of 0.25 mg of finely powdered rice straws (obtained from kitchen grade grinder) in a 12:1 ratio. The ingredients were then finely mixed using a motor and pestle in order to obtain a homogenous mixture. The mixture was then subjected to pelletization in a mould by applying a pressure of 6 tons. The pellets were then scanned from 500 cm−1 to 4500 cm−1 to determine the possible functional groups present in the three different types of rice straws.

Polymer grafting of delignified rice straws

Polymerisation of the delignified rice straws was conducted with acrylonitrile accompanied with sodium silicate. For the current study, acrylonitrile was chosen as a monomer because of its higher limiting oxygen index of 27% and durable nature [30]. Reactivity of acrylonitrile is high with low cost and easy availability making it flexible in complexing with the rice straw. This makes it an understandable choice since it can be easily grafted onto starch and cellulose in the presence of a number of different initiating systems.

In this process, sodium lauryl sulphate was employed as surfactant and potassium permanganate and oxalic acid were used as the grafting initiators. 500 mL of deionised water taken in a vat along with 7 mL of acrylonitrile (C3H3N), 5 g of sodium lauryl sulphate (NaC12H25SO4) and 5 g of oxalic acid (C2H2O4) which was then made into a homogenized solution. The air dried delignified rice straw (22.764% of lignin present) were then kept immersed in the above solution for 1 h at room temperature followed by consecutive dipping in 0.1% potassium permanganate solution (KMnO4). All the above chemicals used for polymer grafting were purchased from Merck, Mumbai, India. The rice straws were maintained in this condition for 2 h at 50 °C followed by sun drying until these were completely dried. Finally, the percentage of grafting of the dried treated rice straws was determined with Eq. (6) [31]:

| (6) |

where G% is the grafting percentage, Ws denotes the amount of polymer grafting on the rice straws in g and W0 interprets the amount of rice straw used for the analysis in g.

Durability analysis of polymer grafted rice straws

Biological oxygen demand (BOD) and chemical oxygen demand (COD) were used as investigating tools for determining the durability of the modified rice straws. Both treated and untreated rice straws were subjected to natural degradation by considering the natural degrading agents viz., sunlight, moisture and humidity. BOD of the rice straws was determined via Winkler’s technique and COD of the samples was analysed in a COD digester (Hanna Instrument, HI 839800, COD Reactor, Kolkata, India).

Flame retardancy analysis of polymer grafted rice straws

Non-flammability of the polymer grafted rice straws were analysed by determining their flame retardant efficacy. Therefore, the criterion used for analysis was its oxygen proportion in an oxygen (O2): nitrogen (N2) mixture which will allow it to burn for 3 min or burn 5 cm of the sample if placed vertically. Thus, the following equation (Eq. (7)) was used to determine the limiting oxygen index of the modified rice straws:

| (7) |

Cone calorimeter (IMO-LIFT, Jupiter Integrated Sensor System Private Limited, Mumbai, India) was used to determine the limiting oxygen index of the sample. Here the amount of heat produced from burning of mass was proportionate to the amount of oxygen incurred for burning. Mass loss during combustion was calculated from burning by placing the rice straws on loader cell, where it was heated via radiant electrical heater and ignited with electrical spark [30], [32].

Results and discussion

Proximate analysis of untreated rice straws

Proximate analysis provides an insight into the moisture, volatile matter and ash content of a sample which eventually estimates the overall fixed carbon of the particular sample. As a result, the rice straw used in the present work was analysed where it was observed that the moisture content was found to be 2.00%. In general, any carbonaceous material which has got greater percentage of moisture content produces hindrance towards combustibility of the substance [33]. Again, ash content provides an opportunity on the effectivness of a sample in terms of its disposal. The ash content in the present study was observed to be 10.18% which lies within the normal range of 5–12% as compared to other reported work on rice straw [33]. Similarly, presence of higher percentage of volatile matter content suggests versatility of active sites present on the substance. Volatile matter content was found to be 71.71% which can be used as an opportunity in surface modification of these rice-straws. Therefore, a carbon content of 16.11% ensures an appreciable carbon network which might help in surviving of the sample after delignification.

Surface morphological and chemical investigation of rice straws at various stages

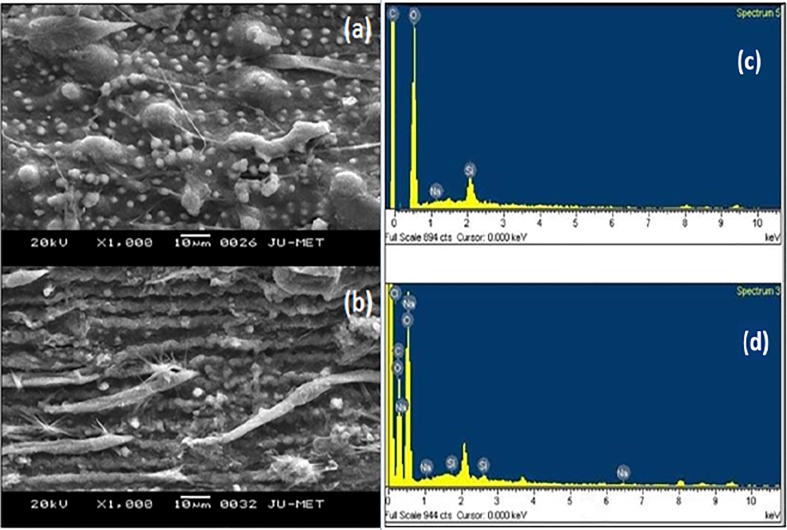

SEM imaging of rice straws

Delignification of rice straw and its corresponding superficial microstructural changes have been pictorially documented via scanning electron microscope as illustrated in Fig. 1. As it can be seen in Fig. 1a, the surface of rice straws seems to maintain uniformity in its structure without any distortion in its fibre alignment. Again the same fibre bundle was found to be loosely packed due to delignification which has caused delinking of carbon bonds. This is properly visible in Fig. 1b where the delignification have resulted in some unaltered fragmented fibre bundles with segregated sections and even in some places some portion of the rice are washed away creating hole-like structure. This alteration in structure is proved to be effective if this delignified rice straws are to be used for any kind of chemical modification as it can be found effectual in case of polymer grafting.

Fig. 1.

(a-b) SEM images of untreated rice straw and delignified rice straw. Spherical elevated structures found in untreated rice straw which after NaOH treatment are found to diminish; (c-d) EDAX spectrum of untreated rice straw and delignified rice straw. Differences in elemental configuration due to delignification is evident from the spectrums.

EDAX analysis of rice straws

Elemental analysis of raw and delignified rice straw have been enlisted in Table 1. Paddy plants use up water, nutrients and various other metal ions for their growth. Therefore, elemental analysis via EDAX provides a structural idea of raw and delignified rice straw as illustrated in Fig. 1c and d. In case of raw rice straw, carbon, oxygen and silica were found to be the dominant constituents along with other elements. Carbon and oxygen form thenaturally occurring fibres of rice straw. On the other hand, percentage of carbon, oxygen and silica decreased after alkaline pre-treatment. Among these, the percentage of oxygen decreased comparatively more than carbon. This can be attributed to the fact that carbon forms the structural unit of cellulose and hemicelluloses. Again the amount of silica was found to be lesser in delignified rice straw than un-treated rice straw. As reported in earlier works, such differences found were postulated as complex linking of silica with lignin where delignification has lowered silica concentration along with lignin.

Table 1.

Elemental analysis of untreated and treated rice straws.

| Untreated Rice straw |

Treated Rice straw |

|||

|---|---|---|---|---|

| Elements | Weight (%) | Atomic (%) | Weight (%) | Atomic (%) |

| C K | 44.81 | 50.66 | 27.65 | 33.84 |

| O K | 47.02 | 44.59 | 71.33 | 65.56 |

| Na K | – | – | 0.61 | 0.38 |

| Si K | 8.16 | 4.74 | 0.27 | 0.14 |

| Cl K | – | – | 0.14 | 0.06 |

| Ca K | 0.01 | 0.01 | – | – |

| Total | 100 | 100 | ||

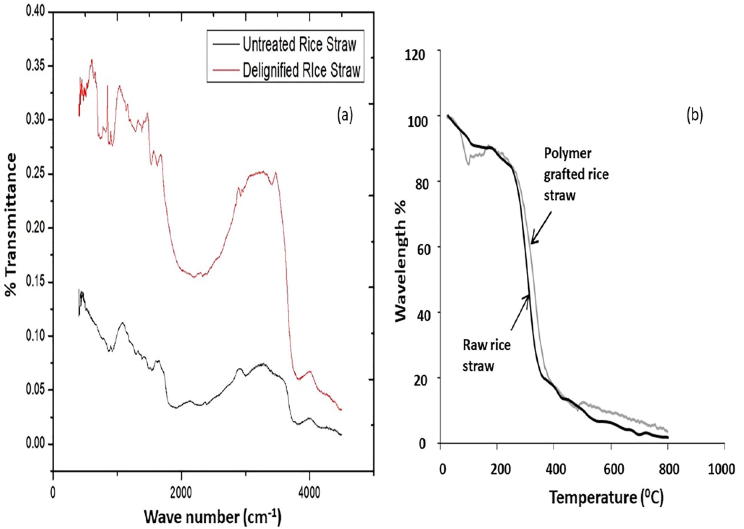

FTIR analysis

Functional group of untreated and delignified rice straws are demonstrated in Fig. 2a. The band at 1266 cm−1 indicates the presence of methoxy group as shown in Fig. 2a which is an important ingredient of lignin. The intensity of this band decreased after delignification (as shown in Fig. 2a) due to nucleophilic interaction between NaOH and the methoxy group of lignin. This data confirms structural deformation of delignified rice straw. In case of untreated rice straw, several other ingredients viz., cellulose and hemicellulose were confirmed from the bands at 1383 cm−1, 3421 cm−1 and 3422 cm−1 which represent functional groups like —OH and C—H. The intensity of these bands in Fig. 2a is found to decrease after alkali treatment due to loosening of hydrogen bonds. Xylans were typically represented with the bands 1116 cm−1 and 1000 cm−1 corresponding to the variation in functional groups which makes up the complicated xylan structure. Association of lignin with hemicellulose was confirmed from the peak formed at 1606 cm−1 as it been seen both before and after alkali treatment. Breaking of cellulose bond after delignification was confirmed from the disappearance of the band at 1156 cm−1 along with C—O—C vibration which occurred in hemicellulose due to alkaline treatment on the rice straw. Therefore, it can be concluded that the present treatment for lignin removal from rice straws was proved to be an effective tool.

Fig. 2.

(a) FT-IR spectra of untreated and delignified rice straw. Shifting of bands and differences in transmittance percentage confirms alteration of functional groups occurred due to NaOH treatment; (b) TGA thermogram of raw and polymer grafted rice straws depicting percentage weight loss at different temperature.

Thermo-gravimetric analysis

The thermal behaviour of raw rice straw and polymer grafted rice straw was determined by the TGA analysis (DTA-TG Apparatus (Shimadzu-00290, Japan) at a heating rate 10 °C min−1 in an inert atmosphere of dry nitrogen and a flow rate 50 mL/min under non-isothermal condition and the thermograms are plotted in Fig. 2b. The TGA curve of both raw and grafted rice straw show three degradation steps. At lower temperature an initial small mass loss occurred below 100 °C which is due to the evolution of adsorbed moisture being more prominent in the raw rice straw fibre. At a temperature of 200–360 °C, the second step of thermal degradation happens and is mainly assigned to the degradation of cellulosic material like hemicellulose and cellulose which decomposes yielding predominantly volatile products such as CO2, CO, condensable vapours and char. Due to the degradation of non-cellulosic substances like lignin the third step weight loss of rice straw takes place at 360–550 °C. From the thermogram it is evident that in grafted rice straw, the initial and maximum temperature of decomposition is greater than raw rice straw. The radical chain scission and radical chain mechanism are the two basic mechanisms through which the thermal degradation of polymer takes place. The amplification in thermal stability of grafted straw could be attributed due to late decomposition of polyacrylonitrile.

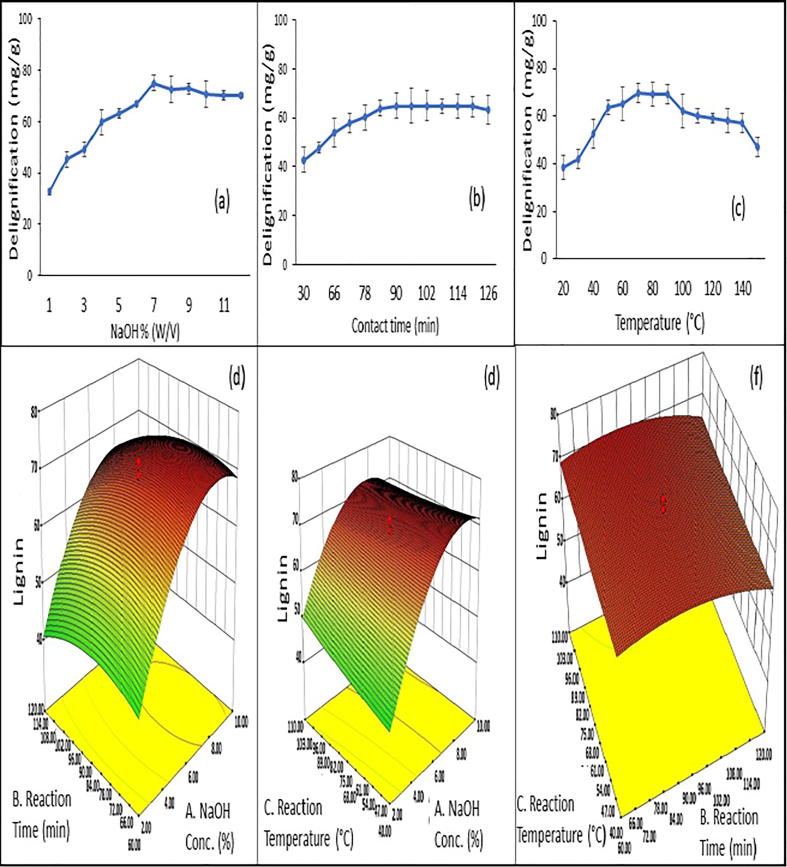

Impact of individual parameter on delignification

Impact of NaOH percentage over delignification

The process of delignification depends largely on the amount of delignifying agent to be used. Lignin being complex in nature requires intensified activity in order to break down the complex bonding. Therefore, in the present study the rice straws were treated with varied percentage of NaOH. As it can be seen in Fig. 3a, delignification of rice straws increased with rise in NaOH percentage. The rate of delignification increased gradually from 1% to 7% of delignifying agent. This may be attributed to the fact that the amount of rice straw present in the vat was able to use NaOH for complete removal of lignin from it, beyond which the delignifying agent causes no further degradation. When the amount of NaOH was further increased beyond 7%, not only lignin was removed from rice straw but also it led to the degradation of the texture of rice straw. This might be because of the vulnerability of the rice straws to corrosive agents (as in the present case is NaOH) due to the removal of lignin, since it forms the structural support to the plant. As a result, delignification of rice straw was well within 7% of NaOH.

Fig. 3.

Parametric impact and optimization of (a) NaOH concentration (b) Reaction time (c) Reaction temperature on delignification of rice straw; 3-dimenssional analysis of combined effect of (d) NaOH concentration versus reaction time (e) NaOH concentration versus reaction temperature (f) Reaction time versus reaction temperature on delignification of rice straw obtained from central composite design.

Impact of contact time over delignification

Apart from delignifying agent, breaking of complex bonds and its removal rely largely on the experiment time. As it can be seen in Fig. 3b, with rise in contact time the administrated amount of NaOH gradually increased the rate of removal percentage of lignin from rice straws. This may be due to the fact that with gradual escalation in contact time, the delignifying agent could have the desired time in order to execute breaking more of lignin bond without changing NaOH concentration thus creating comparatively more hollow spaces on the surface of rice straw. It has already been reported earlier that with increase in contact time the delignifying agent tends to have greater opportunity towards its interaction with lignin [24]. Even in case of other technologies, time plays an important role in delignification due to the complex nature of lignin. In this present study it was found that maximum removal of lignin was obtained after 90 min of incubation beyond which there was no significant increase in delignifying of rice straws.

Impact of reaction temperature over delignification

One of the intriguing facts in this process is the role of temperature in delignification. This may be due to the fact that temperature accelerates the process to a faster rate with increase in temperature. As illustrated in Fig. 3c that escalation in temperature from 20 up to 70 °C, there was an exponential increase in delignification. This can be attributed to the fact that at higher temperature, the level of activation energy decreases which not only reduces the overall time spent in it but at the same time it will increase the amount of lignin subtraction from rice straws. Although temperature plays an important role towards delignification but a decreasing pattern was observed when the temperature was increased beyond 100 °C. This may be due to the fact that at higher temperature, there has been a decrease in water volume which eventually has lowered the percentage removal of lignin from the rice straws.

Statistical analysis of the governing parameters viz., reaction time, temperature and NaOH concentration over delignification of rice straw are tabulated in Table 5, where it can be seen that they contributes significant involvement in the process. Therefore, from the above findings, the suitable ranges were taken into consideration towards process optimization of delignification of rice straws using response surface methodology (RSM).

Table 5.

Statistical analysis of process parameters.

| Source of variation | Degree of freedom | Sum of squares | Mean squares | F-value | P-value |

|---|---|---|---|---|---|

| Statistical analysis of delignification of rice straw | |||||

| NaOH concentration | 14 | 2129.606 | 177.472 | 1.018 | <0.01 |

| Time | 12 | 580.169 | 44.675 | 0.8591 | <0.031 |

| Temperature | 13 | 815.714 | 58.265 | 2.406 | <0.024 |

| Total | 39 | 3525.489 | 280.412 | – | – |

| Statistical analysis of polymer grafting percentage on rice straw | |||||

| Monomer concentration | 4 | 524.63 | 131.16 | 22.70 | <0.001 |

| Time | 4 | 2613.55 | 653.39 | 37.64 | <0.001 |

| Temperature | 5 | 1756.63 | 315.31 | 63.85 | <0.001 |

| Total | 13 | 4894.81 | 1099.86 | – | – |

Optimization of rice straw delignification

Use of alkaline solution which includes sodium hydroxide (NaOH), potassium hydroxide (KOH), lithium hydroxide (LiOH) and calcium hydroxide [Ca(OH)2] have already been reported. Among these, NaOH exhibited greater effectiveness than the rest. Literature investigation claimed that liquor-to-solid ratio, NaOH percentage, reaction period and reaction temperature are the dominating factors towards delignification. In the present simulation, in order to evade complexity of experimental design, three major factors viz., reaction temperature, NaOH concentration, reaction time were considered after fixating its solid-to-liquor ratio. Permutation of varied experimental conditions were prepared in central composite design of Response Surface Methodology from Design Expert software 10 (Stat-Ease, Inc, Minneapolis, USA). The parameters were defined within the range: NaOH concentration 2–10% (w/v); delignification time: 60–120 min; delignification temperature 40–110 °C where the air dried rice straw to delignifying solution ratio was maintained at 1:20 (w/v).

Experimental design for rice straw delignification

Computed and mathematical method was tooled to resolve the multivariate calculation from calculable experimental data towards lignin extraction from rice straw. It optimizes parametric conditions in an array of testing method with the benefit of condensed experimental runs, reduced time consumption, interactive dependency within different variables and efficient prediction of global optimum [34]. Other design matrices provided in RSM include Central Composite Design (CCD) [35], Box-Behnken Design (BBD) [36] and two-level full factorial proposal [36] among which CCD embedded in RSM was used since it interprets through three vital steps viz., statistically designed experimental run, assessment of coefficients in a mathematical model via regression and prophecy of response along with the model authentication. The overall investigational conclusions are subjected mostly to the figures of parameters to be reconnoitred in the process and its association with axial, factorial, and replicate trials which can be represented as Eq. (8) [37], [38]:

| (8) |

In Eq. (8), n represents the number of independent factors and nc depicts the number of replicates. In this investigation, three different variables viz., NaOH concentration, period, and temperature of reaction were studied and the extracted solution were used to determine the response. Thus, an experimental matrix was developed which includes 8 factorial points, 6 axial and 6 replicate points altogether with 20 experimental runs. The simulation produced experimental runs at five coded levels: (−α), −1, 0, +1 and (+α) where the high and low level values interpret independent factors involved in the process (as shown in Table 2). The high and low values were maintained at +1.682 and −1.682, respectively. However, it is worthwhile to mention that CCD works only with coded value for actual variables and the transformation of these coded value can be conveyed mathematically as shown in Eq. (9):

| (9) |

where Xac represents actual value of the ith factor in actual units, Xavg represents average of the low and high values for the ith factor, Xh and Xl interprets extreme values for the ith factor. With the help of Table 2, Eq. (9) was used to produce the experimental design comprising 20 runs for the process of lignin removal. Runs were performed with actual parametric value for actual responses. The functional association between the independent variables and response was modelled via an empirical quadratic equation consisting of a linear, quadratic and cross product terms as vividly represented in Eq. (10) [39]:

| (10) |

where β0 represents constant coefficient; βi interprets linear coefficient; βii represents quadratic coefficient and βij determines interactive coefficient. Each of the factors was examined for single and interactive effect over the response. Eq. (10) can be further extended for three separate variables in the following quadratic Eq. (11):

| (11) |

Table 2.

Factors and their levels as used in the design of rice straw delignification.

| Factors |

Levels |

||||||

|---|---|---|---|---|---|---|---|

| Coded Parameters | Uncoded Parameters | Unit | −α | −1 | 0 | +1 | +α |

| A | NaOH | % (w/v) | 0.73 | 2 | 6 | 10 | 12.73 |

| B | Reaction time | min | 39.55 | 60 | 90 | 120 | 140.45 |

| C | Reaction temperature | °C | 16.45 | 40 | 75 | 110 | 133.86 |

Accuracy of the developed computed model was reinvestigated via analysis of variance (ANOVA) technique. The significant terms in the model equation were determined in terms of p and F value and accuracy of the model was evaluated from its regression analysis R2 and the lack of fit test. Response surfaces and optimum conditions for the delignification were obtained through this model.

Combined parametric interaction towards delignification of rice straws

Assessment of the connections among multiple participating factors in a process is crucial for multi-variant optimization [40]. The software identifies and enumerates these relations as three-dimensional (3D) response plots. These plots exhibit alteration of response in simultaneous correlation with two other variables. The pattern of these plots is crucial as they signify the impact of a single parameter over mutual interactions of independent factors [41].

Interpretation of the parametric interaction among the factors was evaluated as combined effect of: NaOH concentration and contact time; NaOH concentration and reaction temperature; reaction temperature and time. As it can be seen in Fig. 3 varied range of interactions was observed among the parameters. In case of NaOH concentration, it was clearly visible that its effect on delignification varied appreciably. At lower alkaline concentration, the amount of lignin extracted from the rice straws was very less although the contact time was increased to the maximum level. This may be due to the fact that reactivity of NaOH was limited around 40% which did not increase with time. Again when the concentration of alkali increased, it was found that reactivity of the delignifying agent played considerable role till its reactivity has exhausted. It can be seen in Fig. 3d that at extreme NaOH concentration percentage of extracted lignin did not increase with time since the available lignin was already extracted at a lower optimum NaOH concentration of 7%. On the other hand, different trend was observed when effect of NaOH was tested against reaction temperature towards delignification. Fig. 3e shows that with increase in temperature the amount of delignification increased due to lowering of activation energy, since the energy required for breaking of complex lignin bond was accomplished preferably at higher temperature. Similarly, the role of reaction time and temperature were investigated simultaneously over delignification from rice straws. As illustrated in Fig. 3f it can be seen that their impact is comparably inferior as compared to NaOH. Conversely, when the rice straws were immersed in delignifying agent for a longer period of time at higher temperature it was found that the amount of delignification decreased. As stated earlier that at higher temperature water tends to evaporate leaving lesser scope for NaOH to interact with rice straws, thus, it provides lesser scope for reaction time to impart profitable impact on the delignification process. Therefore, both time and temperature played significant role at lower to moderate condition rather than at higher temperature and time.

Development of regression model equation for delignification

RSM enables evaluation of an empirical mathematical association with anticipated responses and the variables inflicting the course via regression procedure without considering the complexity of the process. The relation among the factors and their responses are depicted by quadratic equation (Eq. (12)). The statistical association of alkaline delignification of paddy straw was established by with three separate parameters viz., reaction temperature, reaction time and NaOH concentration in correlation with one dependent variable or response i.e., mg of lignin extracted from per unit of dried paddy straw. Model equation tooled to evaluate lignin extraction from its corresponding process parameters is depicted as follow:

| (12) |

Statistical data examination and authentication of model of lignin removal process

Statistical analysis of the present delignification study was performed with ANOVA in order to examine the impact of various parameters towards validation of the regression model. Statistical analysis was classified accordingly into F-test or Fisher’s test and P or probability. In such case, if the value of F is larger than its corresponding coefficient, it is considered as significant; whereas smaller the value of P greater is its significant. Along with the significance F and P, sum of squares was also considered as an important factor since higher value of it signifies greater importance of the corresponding parameters. Herein, the value of alkaline concentration was found to be a maximum of 196.82 followed by reaction time and temperature as 5.25 and 2.45 °C, respectively. Therefore, the impact of alkaline concentration played major role towards delignification than the other two factors. Among the three parameters, only NaOH concentration and reaction time was within the range (P < 0.05) except for reaction temperature whose value exceeded beyond 0.05 making it non-significant. Sum of squares also substantiated the finding with a maximum output of 2010.61 for NaOH concentration followed by reaction time and temperature. The Lack of Fit F-value of 4.69 suggests error formation which might occur due to noise. Thus, the model suggests applicability of the model towards delignification of rice straws as demonstrated in Table 3.

Table 3.

Statistical analysis for computed rice straw delignification.

| ANOVA for quadratic equation model developed for rice straw delignification | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F Value |

P-value Prob > F |

|

| Model | 4180.04 | 9 | 464.45 | 45.46 | <0.0001 | Significant |

| A-Conc. | 2010.61 | 1 | 2010.61 | 196.82 | <0.0001 | |

| B-Time | 53.65 | 1 | 53.65 | 5.25 | 0.0449 | |

| C-Temperature | 24.98 | 1 | 24.98 | 2.45 | 0.1489 | |

| AB | 5.35 | 1 | 5.35 | 0.52 | 0.4860 | |

| AC | 66.59 | 1 | 66.59 | 6.52 | 0.0287 | |

| BC | 0.22 | 1 | 0.22 | 0.022 | 0.8851 | |

| A2 | 1875.48 | 1 | 1875.48 | 183.59 | < 0.0001 | |

| B2 | 190.79 | 1 | 190.79 | 18.68 | 0.0015 | |

| C2 | 3.89 | 1 | 3.89 | 0.38 | 0.5512 | |

| Residual | 102.16 | 10 | 10.22 | |||

| Lack of Fit | 84.20 | 5 | 16.84 | 4.69 | 0.0576 | Not significant |

| Pure Error | 17.96 | 5 | 3.59 | |||

| Cor Total | 4282.20 | 19 | ||||

| Other statistical parameters | ||||||

| Std. Dev. | 3.20 | R-Squared | 0.9761 | |||

| Mean | 58.98 | Adj R-Squared | 0.9547 | |||

| C.V.% | 5.42 | Pred R-Squared | 0.8444 | |||

| PRESS | 666.50 | Adeq Precision | 24.962 | |||

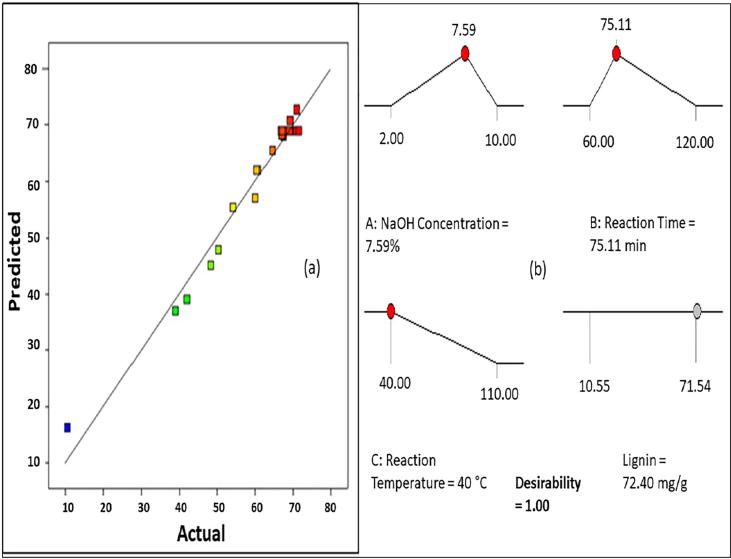

Interrelation between actual versus predicted values have been illustrated in Fig. 4a and tabulated in Table 3. The predicted values were generated from computed simulation whereas the actual values were obtained from the experimented data. The R2 value was found to be 0.9761 with an adjusted and predicted R2 value of 0.9547 and 0.8444, respectively which makes a difference less than 0.2. The adequate (Adeq.) precession value came around 24.962 which denote the ratio between signal and noise. The value is considered to be desirable if the value goes beyond 4 which in the present study was found to be highly desirable.

Fig. 4.

(a) Graphical representation of actual versus predicted delignification graph obtained from central composite design; (b) Optimum delignification conditions derived from computed parametric optimization of rice straw via central composite design.

Validation of optimum parametric conditions

The aim for optimization in this present investigation was to achieve maximum amount of lignin under optimized parametric conditions. The numerical ranges as aided to the software were used to develop the optimum condition for our purpose. As a result, the system offered an array of options for each factor which includes maximum, minimum, targeted, within range and null for better output from each parameter from the optimization process. Optimum desirability along with maximum delignification was obtained from numerical optimization method from the options provided by the system. As compared to other reported works maximum amount of lignin extraction from rice straws was obtained from 7.59% of NaOH (w/v), for a reaction time of 75.11 min at a reaction temperature of 40 °C as tabulated in Table 4. At this condition 72.4 mg/g of lignin can be extracted from the aforesaid condition with a desirability of 1.00 as predicted by the system (Fig. 4b). Further investigation was conducted using the predicted conditions in triplicates (as shown in Table 4) were it was found that delignification percentage came around 70.03 mg/g which was almost same as predicted by the system.

Table 4.

Experimental validation of experimental parameters and its comparative analysis with other reported works.

| Experimental validation of experimental parameters |

|||||

|---|---|---|---|---|---|

| Optimum Parameters |

Delignification (mg/g) | ||||

| NaOH Concentration (%w/v) | Reaction Time (min) | Temperature (°C) | |||

| Predicted | 7.59 | 75.11 | 40 | 72.4 | |

| Replica 1 | 7.59 | 75.11 | 40 | 70.03 | |

| Replica 2 | 7.59 | 75.11 | 40 | 70.03 | |

| Replica 3 | 7.59 | 75.11 | 40 | 70.03 | |

| Comparative analysis of delignification with other reported works | |||||

| Parameter selection range |

|||||

| Plant parts | Delignifying agent (%w/v) | Reaction time (h) | Reaction temperature (°C) | Lignin removed | Reference |

| Pressed palm oil seed | 2–6 | 1–5 | 30–120 | 55.29% | [25] |

| Corn-cobs | 76–92 | 50–70 | 1.5–7.5 | 71.16% | [26] |

| Palm oil trunk | 8–20 | 30–60 | 50.80 | – | [30] |

| Rice straw | 2–5 | 85–155 | 61–89 | 42.98 mg/g | [24] |

| Rice straw | 2–10 | 60–120 | 40–110 | 70.03 mg/g | [Present study] |

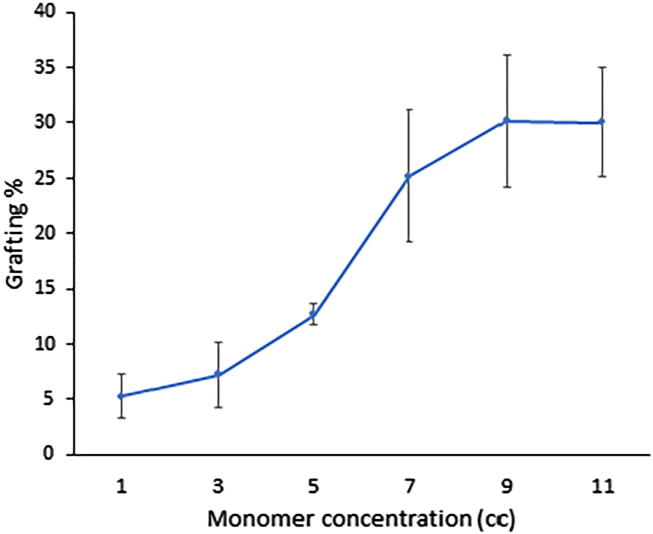

Polymer grafting of delignified rice straws

Impact of monomer reactivity towards grafting of delignified rice straws has been illustrated in Fig. 5. As it can be seen that the porous structure obtained at the optimum experimental condition due to delignification has produced sufficient space for polymerization. In Fig. 5, it can be seen that with increase in monomer condition, grafting percentage also increased. This investigation was conducted for 60 min at a reaction temperature of 70 °C. In the following sections a vivid explanation has been provided to substantiate the delignification process and how it has affected the grafted phenomenon. Influence of the governing parameters viz., reaction time, reaction temperature and monomer concentration over polymer loading were statistically analysed for determining the significance of each factor. As it can be seen in Table 5 there is a significant difference in the mean values among the different levels of monomer concentration, reaction time and temperature.

Fig. 5.

Determination of grafting percentage of delignified rice straws at different monomer concentration.

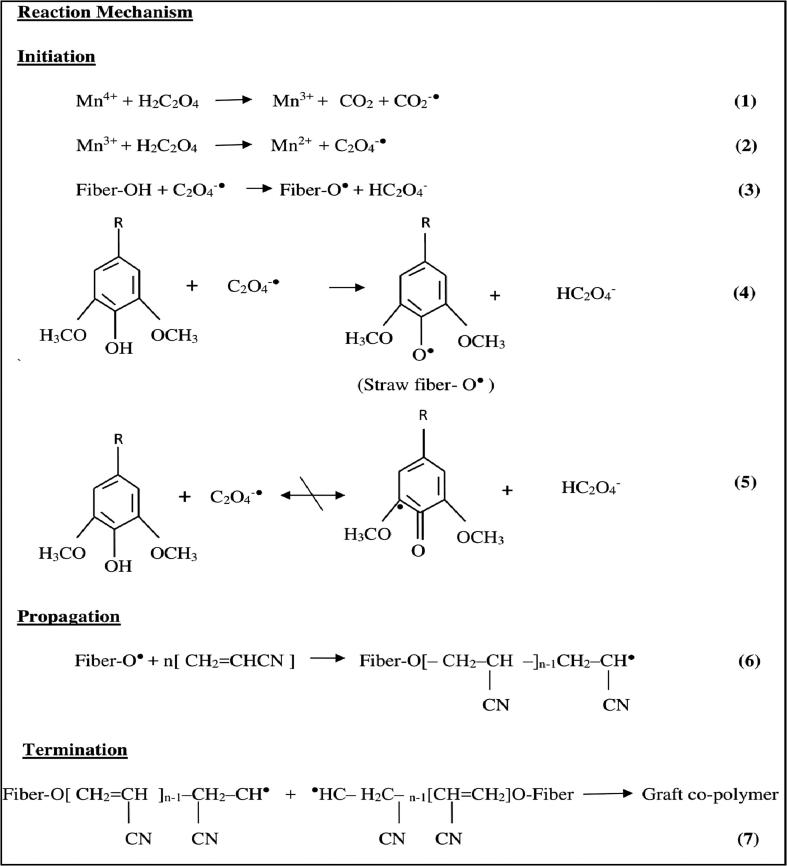

Proposed polymerization mechanism

In general, grafting mechanism is initiated by oxalic acid (C2H2O4) which decomposes to produce free radical species (C2O4−•) depicted in reaction 2 of Fig. 6. Usually chemical initiation method or radiation technique is generally used for the generation of reactive sites on the cellulosic polymeric backbone. The process is accelerated by the addition of MnO4- as co-catalyst. The radical species is expected to be reactive in the redox initiation of graft copolymerization by hydrogen abstraction from lignin of straw fibre (reaction 3 and 4) to produce a free radical on it known as phenoxy radical, thereby creating an active site for grafting copolymerization [42]. The FT-IR spectrum under our experimental condition revealed that no quinoid structure is formed thereby reducing the possibility of reaction (5). The next step is the propagation where the free radical initiated chain reacts with the monomer acrylonitrile to yield grafted co-polymer as revealed in reaction 6. The last and final step is the termination in which large straw fibre-acrylonitrile free radical combine to give graft co-polymer as indicated in reaction 7.

Fig. 6.

Proposed interaction between lignin and acrylonitrile occurring during polymer grafting.

Durability of polymer grafting of delignified rice straws

One of the major concerns of the present optimization study was to investigate the optimum condition which will accommodate greater grafting of polymers thus increasing its durability and simultaneously decreasing its flammable ability. Therefore, biodegradability index was used to determine the durability of the grafted rice straws along with the untreated rice straws. This was conducted by comparing its COD and BOD values obtained from a series of time interval as represented in Table 6. In general, the ratio between BOD and COD interprets the durability. As reported earlier that a substance is considered to be highly biodegradable if the ratio falls beyond 0.6. Again, the substance is chemically degradable if the ratio falls within 0.3–0.6 and if the ratio falls below 0.3 then it can be considered to be highly non-biodegradable due to the presence of multiple non-combustible agents. The polymer grafted rice straw in the present study prepared from delignified rice straw was found to be 0.2 which falls below the degradable range making it usable for roofing purpose. Therefore, this polymer grafted rice straw could withstand the change in weather condition due to its higher durability.

Table 6.

Durability analysis of untreated and treated rice straw.

| Days | Weight of untreated rice straw (g) | Lose/gain in weight (%) | Weight of treated rice straw (g) | Lose/gain in weight (%) |

|---|---|---|---|---|

| 0 | 5.86 | – | 8.63 | – |

| 15 | 5.36 | 8.16 | 8.36 | 3.14 |

| 30 | 5.18 | 3.87 | 8.03 | 0.36 |

| 45 | 5.1 | 2.01 | 7.08 | 0.14 |

| 60 | 5.00 | 1.19 | 6.04 | 0.09 |

Flame retardancy of polymer grafted rice straws

Limiting oxygen index or LOI was used to determine the flame retardancy of the aforementioned rice straw. In general, air contains 21% of oxygen which is sufficient for combustion of any combustible substance. Therefore, any polymeric substance possessing LOI above 21% is categorized as self-combustible substance which requires exposure to external energy for a prolonged period before it catches fire. On the other hand, any polymeric substance whose LOI falls under 21% is considered as self-combustible substance since its surface chemistry could be ignited easily. As the result, the polymer grafted rice straw thus produced was found to have LOI of 27% which is beyond the combustible limit thus retarding its ability to catch fire. Therefore, the rice straws grafted with polymers developed after its delignification treatment was found to have greater fire retardancy properties as compared to untreated rice straws.

Conclusions

Alkali treatment for delignification of rice straws obtained from process optimization with CCD showed potential applicability. With a minimum dose of 7.59%, sodium hydroxide was able to remove 70.03 mg/g of lignin over a reaction time of 75.11 min at 40 °C as optimum reaction temperature. Simulation and optimization of the delignification process via central composite design (CCD) was successfully achieved, where it was found that the concentration of sodium hydroxide had comparatively major role than reaction time and temperature. The system suggested the delignification process to follow quadratic equation. The optimum conditions as suggested by the system were found to be appropriate for delignification with a difference of 0.2. Instrumental analysis suggested that the alkaline treatment was able to remove lignin from the rice straw which produced numerous pores on its surface. Polymer grafting with acrylonitrile increased both of its durability and flame retardancy. Thus, the delignified rice straws obtained from alkaline treatment was found to be an efficient treatment towards its fruitful commercial utility.

Conflict of interest

The authors have declared no conflict of interest.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Acknowledgement

The authors are indebted for the financial support from Ministry of Science and Technology, Govt. of India through research project ST/P/S&T/1G-9/2011. Also, the authors express their gratitude to Mr. Sumit Dhawane and Miss. Madhumanti Mondal, research fellow of NIT Durgapur, West Bengal, India for their cooperation during experimentation of the assignment.

Footnotes

Peer review under responsibility of Cairo University.

References

- 1.Padkho N. A new design recycles agricultural waste materials for profitable use rice straw and maize husk in wall. Proc Eng. 2012;32:1113–1118. [Google Scholar]

- 2.Polthanee A., Tre-loges V., Promsena K. Effect of rice straw management and organic fertilizer application on growth and yield of dry direct-seeded rice. Paddy Water Environ. 2008;6:237–241. [Google Scholar]

- 3.Gadde B., Bonnet S., Menke C., Garivit S. Air pollutant emissions from rice straw open field burning in India, Thailand and the Philippines. Environ Pollut. 2009;157:1554–1558. doi: 10.1016/j.envpol.2009.01.004. [DOI] [PubMed] [Google Scholar]

- 4.Leminx P.M., Lutes C., Santoiann D.A. Emissions of organic air toxics from open burning: a comprehensive review. Prog Energy Combust Sci. 2004;30:1–32. [Google Scholar]

- 5.Duan F.K., Liu X., Yu T., Cachier H. Identification and estimate of biomass burning contribution to the urban aerosol organic carbon concentrations in Beijing. Atmos Environ. 2004;38:1275–1282. [Google Scholar]

- 6.Binod P., Sindhu R., Singhania R.R., Vikram S., Devi L., Nagalakshmi S. Bioethanol production from rice straw: an overview. Bioresour Technol. 2010;101:4767–4774. doi: 10.1016/j.biortech.2009.10.079. [DOI] [PubMed] [Google Scholar]

- 7.Saha B.C. Hemicellulose bioconversion. J Ind Microbiol Biotechnol. 2003;30:279–291. doi: 10.1007/s10295-003-0049-x. [DOI] [PubMed] [Google Scholar]

- 8.Kim J.W., Kim K.S., Lee J.S., Park S.M., Cho H.Y., Park J.C. Two-stage pretreatment of rice straw using aqueous ammonia and dilute acid. Bioresour Technol. 2011;102:8992–8999. doi: 10.1016/j.biortech.2011.06.068. [DOI] [PubMed] [Google Scholar]

- 9.Mosier N., Wyman C., Dale B., Elander R., Lee Y.Y., Holtzapple M. Features of promising technologies for pretreatment of lignocellulic biomass. Bioresour Technol. 2005;96:673–686. doi: 10.1016/j.biortech.2004.06.025. [DOI] [PubMed] [Google Scholar]

- 10.Patel M.M., Bhatt R.M. Optimisation of the alkaline peroxide pretreatment for the deligni cation of rice straw and its applications. J Chem Technol Biotechnol. 1992;53:253–263. [Google Scholar]

- 11.Callow H.J. Delignification of jute with sodium chlorite. J Text Inst Trancs. 2008;43:247–249. [Google Scholar]

- 12.Herbst H.E. The preparation of chlorite holocellulose. Can J Chem. 1952;30:668–978. [Google Scholar]

- 13.Ahlgrena P.A., Goring D.A.I. Removal of wood components during chlorite delignification of black spruce. Can J Chem. 1971;49:1272–1275. [Google Scholar]

- 14.Cheng Y.S., Zheng Y., Yu C.W., Dooley T.M., Jenkins B.M., Gheynst J.S.V. Evaluation of high solids alkaline pretreatment of rice straw. Appl Biochem Biotechnol. 2010;162:1768–1784. doi: 10.1007/s12010-010-8958-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Sun R., Tomkinson J., Mao F.C., Sun X.F. Physiochemical characterization of lignin from rice straw by hydrogen peroxide treatment. J Appl Polymr Sci. 2001;79:719–732. [Google Scholar]

- 16.Minu K., Jiby K.K., Kishore V.V.N. Isolation and purification of lignin and silica from the black liquor generated during the production bioethanol from rice straw. Biomass Bioenergy. 2012;39:210–217. [Google Scholar]

- 17.Pan X.J., Sano Y., Ito T. Atmospheric acetic acid pulping of rice straw II; behaviour of ash and silica in rice straw during atmospheric acetic acid pulping and bleaching. Holzforchung. 1999;53:49–55. [Google Scholar]

- 18.Sinha A.S.K., Singh M., Singh S.P. Acetic acid pulping and ECF bleaching of rice straw and effect of acid concentration on pulp characteristics. Ippta. 2012;24:151–157. [Google Scholar]

- 19.Sun R., Lawther J.M., Banks W.B. Effects of pretreatment temperature and alkali concentration on the composition of alkali-soluble lignins from wheat straw. J Appl Polym Sci. 1996;62:1473–1481. [Google Scholar]

- 20.Bjerre A.B., Olesen A.B., Fernqvist T., Ploger A., Schimdt A.S. Pretreatment of wheat straw using combined wet oxidation and alkaline hydrolysis resulting in convertible cellulose and hemicellulose. Biotechnol Bioeng. 1996;49:568–577. doi: 10.1002/(SICI)1097-0290(19960305)49:5<568::AID-BIT10>3.0.CO;2-6. [DOI] [PubMed] [Google Scholar]

- 21.de Vrige T., de Haas G.G., Tan G.B., Keijsers E.R.P., Classen P.A.M. Pretreatment of Miscanthus for hydrogen production by Thermotoga elfii. Inter J Hydrog Ener. 2002;27:1381–1390. [Google Scholar]

- 22.Silverstein R.A., Chen Y., Sharma-Shirappa R.R., Boyette M.D., Osberne J. A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour Technol. 2007;98:3000–3011. doi: 10.1016/j.biortech.2006.10.022. [DOI] [PubMed] [Google Scholar]

- 23.Punsuvon V. Optimization of delignification and enzyme hydrolysis of steam exploded oil palm trunk for ethanol production by response surface methodology. In: Chandel AK, Silva SS, editors. Sustainable degradation of lignocellulosic biomass- techniques, application and commercialization. InTech; 2013. p. 157–78.

- 24.Dutta S.K., Halder G.N., Mandal M.K. Modeling and optimization of bi-directional delignification of rice straw for production of bio-fuel feedstock using central composite design. Energy. 2014;71:579–587. [Google Scholar]

- 25.Hii KL, Mastitah MD. Optimisation of pressed pericarp fibre delignification for glucose recovery using response surface methodology Inter J Environ Eng 2014;6. http://doi.org/10.1504/IJEE.2014.062157.

- 26.Huang R.L., Qi W., Su R.X., He Z.M. The optimization of fractionating lignocellulose by formic acid using response surface methodology. Energy Sources, Part A. 2010;32:1282–1292. [Google Scholar]

- 27.Ehraman T. Chemical analysis & testing task: Standard Method for Determination of Total Solids in Biomass (LAP- 001), Gold Co. USA; NREL; 1994.

- 28.Ehraman T. Chemical Analysis & testing task: standard method for determination of ash in biomass (LAP- 005), Gold Co. USA; NREL; 1994.

- 29.Templeton D, Ehraman T. Chemical analysis and testing task: determination of acid-insoluble lignin in biomass (LAP-003), Gold Co. NREL; 1995.

- 30.Laoutid F., Bonnaud L., Alexandre M., Lopez-Cuesta J.M., Dubois P. New prospects in flame retardant polymer materials: from fundamentals to nanocomposites. Mat Sci Eng R: Rep. 2009;63:100–125. [Google Scholar]

- 31.Cabuk M., Yavuz M., Unal H.I. Electro kinetic properties of biodegradable conducting polyaniline-graft chitosan copolymer in aqueous and non-aqueous media. Colloids Surfs, A. 2014;460:494–501. [Google Scholar]

- 32.Enright P.A., Fleischmann C.M. Uncertainty of heat release rate calculation of the ISO5660-1. Cone calorimeter standard test method. Fire Technol. 1999;35:153–169. [Google Scholar]

- 33.Liu Z., Xu A., Zhao T. Energy from combustion of rice straw: status and challenges to China. Energy Power Eng. 2011;3:325–331. [Google Scholar]

- 34.Fang H., Zhao C., Song X. Optimization of enzymatic hydrolysis of steam-exploded corn stover by two approaches; Response surface methodology or using cellulose from mixed cultures of Trichoderma reesei RUTC30 and Aspeglus niger NL02. Bioresour Technol. 2010;101:4111–4119. doi: 10.1016/j.biortech.2010.01.078. [DOI] [PubMed] [Google Scholar]

- 35.Bhatti M.S., Kapoor D., Kalia R.K., Reddy A.S., Thukral A.K. RSM and ANN modelling for electrocoagulation of copper from simulated waste water multi objective optimization using genetic algorithm approach. Desalination. 2011;274:74–80. [Google Scholar]

- 36.Baskan M.B., Pala A. A statistical experiment design approach for arsenic removal by coagulation process using aluminium sulphate. Desalination. 2011;254:42–48. [Google Scholar]

- 37.Gottopati R., Mishra S. Process optimization of adsorption of Cr (VI) on activated carbons prepared from plant precursors by a two-level full factorial design. Chem Eng J. 2010;160:99–107. [Google Scholar]

- 38.Chen W.H., Chen Y.C., Lin J.G. Evaluation of biobutanol production from non-pretreated rice straw hydrolysate under non-sterile environmental conditions. Bioresour Technol. 2013;135:262–268. doi: 10.1016/j.biortech.2012.10.140. [DOI] [PubMed] [Google Scholar]

- 39.Brown J.N., Brown R.C. Process optimization of an auger pyrolyzer with heat carrier using response surface methodology. Bioresour Technol. 2010;103:405–414. doi: 10.1016/j.biortech.2011.09.117. [DOI] [PubMed] [Google Scholar]

- 40.Bayhan M., Onel K. Optimization of reinforcement content and sliding distance for AlSi7Mg/SiCp composites using response surface methodology. Mater Des. 2010;31:3015–3022. [Google Scholar]

- 41.Zhu M.Y., Wang C.J., Wang X., Chen S., Zhu H. Extraction of polysaccharides from Morinda officinalis by response surface methodology and effect of the polysaccharides on bone-related genes. Carbohydr Polym. 2011;85:23–28. [Google Scholar]

- 42.Bhattacharya A., Misra B. Grafting: a versatile means to modify polymers techniques, factors and application. Prog Polym Sci. 2004;29:767–814. [Google Scholar]