Abstract

In this study, we investigated the changes in quality and antioxidant activity of sugar-snap cookies prepared with different blends of refined wheat (WHF) and oat flour (OAF). The crude protein contents of OAF and WHF were 12.24% and 7.17%, respectively, and the fiber contents of were 3.45% and 0.31%, respectively; both were increased by adding OAF. However, the total starch contents were decreased by adding OAF. The β-glucan content of the samples increased considerably upon the addition of OAF. The water-holding capacity was increased after adding OAF compared to WHF (79.21%). Water binding in wet gluten contents decreased on the addition of OAF. Final viscosity increased on the addition of OAF. Antioxidant activity and total phenolic acid were increased upon the addition of OAF. The thickness of cookies prepared with OAF, WHF, 20% of WHF with OAF (WOB20), and WOB40 were 11.28, 12.35, 9.74, and 9.81 mm, respectively. The hardness of cookies prepared with WHF and WOF20 did not differ significantly, and analysis of the appearance of cookies showed that the cookies were increasingly cracked as the OAF content increased. Therefore, substituting WHF with OAF improved the quality and nutrient value of the cookies.

Keywords: blends, refined wheat, oat flour, cookie quality, antioxidant activity

INTRODUCTION

Consumers are increasingly concerned about their health. Also, consumers are also demanding novel foods that are rich in nutrition (wholesome), with acceptable organoleptic qualities and those which have traditional values (1).

The addition of functional ingredients to baked goods has become popular, as they may reduce the risk of chronic diseases in addition to their basic nutritional functions (2). Baked products range in complexity and include food stuffs such as breads, cakes, and biscuits (crackers and cookies); these products generally contain wheat flour as the main ingredient (3). However, the majority of wheat flour is consumed as refined flour, in which carbohydrates are the primary energy source.

Oat, a type of whole grain, has gained increasing popularity, as it contains components such as bran and β-glucan, which are sources of dietary fiber for healthy food formulation (4). Moreover, oat is a commonly used grain and contains many phytochemicals that exhibit antioxidant activity, such as tocols, flavonoids, phytic acid, and phenolic acids (5,6). β-Glucan together with other phytochemicals are concentrated in the bran layer of oat grain that provide functional properties to the bran (7). Oats are consumed in whole-grain products including breakfast cereals, infant foods, porridge, and specialty breads (8). Therefore, oat represents a healthy alternative to starch-based ingredients (7).

Cookies and crackers have become one of the most popularly consumed snacks owing to their low manufacturing cost, convenience, long shelf-life, and ability to serve as a vehicle for important nutrients (9). Cookies are generally made using refined wheat flour, fat, egg, sugar, and baking agents (10). These ingredients make cookie dough a high-fat, high-sugar product with a relatively low water activity (11). However, they can be a major source of energy in the diet.

The objectives of this study were to determine the physicochemical properties of blends of refined wheat and oat flour, as well as the changes in quality of sugar-snap cookies made with different oat flour blends.

MATERIALS AND METHODS

Sample preparation

The refined low protein wheat flour was obtained from the Department of Rice and Winter Cereal Crop, National Institute of Crop Science (Wanju, Jeonbuk, Korea). Oat flour (OAF) was purchased from local store in Jeongeup, Korea. Crude protein content of OAF was 12.24%. The blends were mixed with oat and wheat flour. Oat flour added into low protein containing refined wheat flour at concentration of 0% (WHF), 20% (WOB20), and 40% (WOB40) (w/w), respectively. The sample was blended twice using a sieve.

Determination of the proximate composition, total starch, and β-glucan contents of samples

The proximate composition (e.g., water, ash, and crude protein) of samples was analyzed using the official methods of the American Association of Cereal Chemists using 44-15A, 08-01, and 46-12, respectively (12). Total crude fiber content was determined with a dietary fiber analyzer (Dosi-fiber, J.P Selecta s.a, Barcelona, Spain). β-Glucan and total starch content was analyzed using Megazyme assay kit (K-RSTAR; Megazyme, Wicklow, Ireland). Total starch content was measured using AOAC Official Method 996.11 (13).

Water-holding capacity, pasting profiles, and gluten properties of the samples

The water-holding capacity (WHC) of the samples was measured using the method of Medcalf and Gilles (14), with slight modifications (15). The samples (1 g) were mixed with 40 mL of distilled water, stirred at room temperature for 1 h, and centrifuged at 2,000 g for 30 min. The WHC was expressed by moisture absorption per g of samples.

Pasting properties of the starch suspension (3.0 g sample in 25 mL water) were determined with a Rapid Visco analyzer (RVA4, Newport Scientific Ltd., Warriewood, Australia). The peak viscosity, final viscosity and setback viscosity of the samples were determined using the pasting curve.

The gluten index, wet gluten content, and water binding in wet gluten of the samples were measured using a Glutomatic system (Perten Instruments AB, Hägersten, Sweden).

Preparation of cookies

Cookie preparation was carried out as previously described using cookie flour (12). Creamed mass was prepared using sugar, shortening, sodium bicarbonate, skim milk powder, ammonium chloride, and sodium chloride into a micro-mixer bowl and mixed for 3 min using a mixer (5k5ss; KitchenAid Europa Inc., Bever, Belgium). The sample was divided into three portion for the creamed mass and mixed for 3 min to make dough. The dough was then evenly spread on a cookie sheet, cut with a cookie cutter, baked for 11 min at 190°C, and allowed to cool for 30 min at room temperature.

Evaluation of sugar-snap cookies quality

The quality of cookies was analyzed by examining the thickness, diameter, spread factor, and hardness of cookies. The color values of the cookie were measured with a spectrophotometer (CM-5; Konica Minolta Inc., Tokyo, Japan) and expressed by L value, a value, and b value, respectively. The thickness and diameter of cookies was measured using a Model G Peacock dial thickness gauge (Ozaki Mfg. Co., Ltd., Tokyo, Japan). Cookie spread factor was calculated by dividing the diameter by the height. The hardness of the samples was analyzed using a texture analyzer (TA1; Lloyd Instruments Ltd., Chichester, UK). The samples were compressed up to 62.5% and evaluated using stainless steel probe of 5 mm diameter.

Total phenolic acids and antioxidant activity

Total phenolic contents were measured using the Folin-Ciocalteau colorimetric method (16). The total phenolic content was expressed as gallic acid equivalents.

Antioxidant activity was examined using 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity and 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid di-ammonium salts)(ABTS) radical scavenging activity. DPPH radical scavenging activity was estimated according to the method of Blois (17) with some modification. The scavenging activity of the DPPH radicals in percentage points was calculated by absorbance of the sample relative to the absorbance of the blank. ABTS radical cation was measured using the method of Zhao et al. (18) with slight modifications. The Trolox calibration curve was plotted as a function of the percentage of ABTS radical scavenging activity. The final results were expressed as micromoles of Trolox equivalents/g.

Statistical analysis

Data are shown as the mean and standard deviation. The differences between mean values were analyzed using ANOVA with SAS software (version 7.0; SAS Institute Inc., Cary, NC, USA). The probability value was identified at the 5% probability level using Duncan’s post hoc tests.

RESULTS AND DISCUSSION

Proximate composition, total starch content, β-glucan content, and gluten properties of samples

The proximate composition of the samples, which includes the water, ash, crude protein, crude fiber, total starch, and β-glucan content, is presented in Table 1. The crude protein contents of OAF and WHF were 12.24% and 7.17%, respectively; the fiber contents of OAF and WHF were 3.45% and 0.31%, respectively. The β-glucan content of OAF (4.57%) was higher than that of other samples. The β-glucan content of WHF was 0.17%, which increased significantly upon the addition of OAF to proportions of up to 1.95% (P<0.05). The ash, protein, crude fiber, and β-glucan contents of blends increased after the substitution of WHF with OAF. However, the total starch contents of WOB40 were lower than those of WHF. Mancebo et al. (19) reported that fine-grained flour had a lower protein content than coarse-grained flours and that the water-holding and water-binding properties are primarily dependent on starch content. Morales-Polanco et al. (9) reported that the increase in the protein content in oat/pea protein isolate crackers flour could be attributed to a blend of dehulled oat grain flour and pea flour protein isolate. Duta and Culetu (7) reported that the incorporation of oat bran increased protein weakening and decreased the stability of gelatinized starch. Our results showed the wet gluten contents of WHF and WOB20 were 28.40% and 21.70%, respectively. Water binding in wet gluten contents decreased upon the addition of OAF. Moreover, water binding percentages in wet gluten contents were 18.40% and 13.35% for WHF and WOB20, respectively, and the gluten index of WOB20 (97.68) was increased compared with that of OAF (94.72; data not shown).

Table 1.

Proximate composition, total starch, and β-glucan content of blends with refined wheat and oat flour

| Samples | Water contents (%) | Ash contents (%) | Crude protein contents (%) | Crude fiber contents (%) | Total starch content (%) | β-glucan content (%) |

|---|---|---|---|---|---|---|

| OAF | 5.16±0.16d | 1.73±0.03a | 12.24±0.06a | 3.45±0.23a | 49.46±0.11d | 4.57±0.07a |

| WHF | 13.66±0.06a | 0.31±0.01d | 7.17±0.08d | 0.31±0.02d | 77.50±0.01a | 0.17±0.01d |

| WOB20 | 12.75±0.06b | 0.77±0.03c | 10.57±0.13c | 0.82±0.11c | 73.17±0.31b | 0.96±0.01c |

| WOB40 | 10.48±0.02c | 1.16±0.04b | 11.24±0.07b | 1.65±0.01b | 67.64±0.48c | 1.95±0.03b |

Different letters (a–d) within the same column differ significantly (P<0.05).

OAF, oat flour; WHF, refined wheat flour; WOB20, blends that replaced 20% of wheat with oat flour; WOB40, blends that replaced 40% of wheat with oat flour.

WHC and pasting properties of samples

As the proportion of OAF increased in place of WHF, the WHC value increased significantly (P<0.05). The WHC of WHF, WOB20, and WOB40 were 79.21%, 82.89%, and 90.32%, respectively, and the WHC of WHF increased following the addition of OAF compared to that of WHF (79.21%) (Table 2). Additionally, samples which had lower starch content and higher protein, fiber, and β-glucan contents had higher WHC.

Table 2.

Water-holding capacity (WHC) and pasting properties of blends with refined wheat and oat flour

| Samples | WHC (%) | Peak viscosity (RVA) | Final viscosity (RVA) | Setback viscosity (RVA) |

|---|---|---|---|---|

| OAF | 137.03±3.79a | 125.77±1.17c | 281.97±2.23a | 156.20±3.40a |

| WHF | 79.21±1.99c | 151.52±2.64b | 199.39±0.47c | 47.88±2.17c |

| WOB20 | 82.89±0.68c | 167.60±1.46a | 215.02±2.87b | 47.43±1.41c |

| WOB40 | 90.32±2.33b | 162.25±4.45a | 219.42±0.18b | 57.17±4.63b |

Different letters (a–c) within the same column differ significantly (P<0.05).

OAF, oat flour; WHF, refined wheat flour; WOB20, blends that replaced 20% of wheat with oat flour; WOB40, blends that replaced 40% of wheat with oat flour.

The peak viscosities of OAF and WHF were 125.77 and 151.52 RVA, respectively (Table 2). Final viscosity of the samples increased following the addition of OAF, but was lower than OAF alone (281.97 RVA). The peak and final viscosity of WOB20 and WOB40 did not differ significantly (P>0.05). The setback viscosities of WHF and WOB40 were 47.88 and 57.17 RVA, respectively. However, setback viscosity of the WHF and WOB20 scores were lower than those for OAF or WOB40, although the difference was not significant (P>0.05). Inglett et al. (20) reported that the trends in whole oat flour, oat bran concentrate, and Nutrim WHC were related to their β-glucan contents, suggesting that β-glucan may be an important factor affecting WHC. The addition of oat β-glucan significantly increased water absorption and dough development time (21). Larrea et al. (22) reported that dietary fiber may interact with water through polar and hydrophobic interactions, hydrogen bonding, and physical enclosure. Mancebo et al. (19) reported positive correlations between damaged starch and hydration properties, including WHC, water binding capacity, and swelling volume, through correlation analysis. The pasting viscosities of blends with oat and amaranth composites were similar to that of amaranth flour alone and were all higher than that of wheat flour (20). Moreover, high setback viscosity is a characteristic of oat starch and leads to the onset of a thick gel (23).

Total phenolic contents and antioxidant activities of samples

The total phenolic content of WHF, WOB20, and WOB40 was 30.86, 40.86, and 61.57 ppm, respectively, as it increased upon the addition of OAF (Table 3). The antioxidant activity was measured based on DPPH and ABTS radical scavenging activity. The DPPH radical scavenging activity of OAF, WHF, WOB20, and WOB40 were 70.48, 13.10, 28.04, and 40.56%, respectively. Antioxidant activity was similar to the results of total phenolic content which was also increased by the addition of OAF. Similar to our findings, Değirmencioğlu et al. (24) reported that the total phenolic content gradually increased with oat flour supplementation and that DPPH scavenging capacity was not always linearly related to ABTS radical scavenging capacity. However, according to our results, the DPPH and ABTS radical scavenging activities were similar among samples. Sharma and Gujral (25) reported that antioxidant activity, total phenolic content, metal chelating activity, and reducing power increased as the proportion of barley flour increased by replacing wheat flour. Ragaee et al. (26) demonstrated that breads enriched with whole-grain flours exhibited improved DPPH scavenging capacity, with a 2-fold increase compared to the control recipe without enrichment. The antioxidant potential of the wheat and oat flour blends is enhanced, as oats have a higher total phenolic and flavonoid content and higher reducing power (27).

Table 3.

Total phenolic acid and antioxidant activity of blends with refined wheat flour and oat flour

| Samples | Total phenolic acid (ppm) | DPPH radical scavenging activity (%) | ABTS radical scavenging activity (mM, Trolox) |

|---|---|---|---|

| OAF | 149.36±6.16a | 70.48±0.01a | 0.100±0.01ns |

| WHF | 30.86±4.04c | 13.10±0.44d | ND1) |

| WOB20 | 40.86±2.02c | 28.04±0.76c | 0.022±0.01 |

| WOB40 | 61.57±3.03b | 40.56±0.82b | 0.090±0.07 |

Different letters (a–d) within the same column differ significantly (P<0.05).

OAF, oat flour; WHF, refined wheat flour; WOB20, blends that replaced 20% of wheat with oat flour; WOB40, blends that replaced 40% of wheat with oat flour.

ND, not detected.

Not significant.

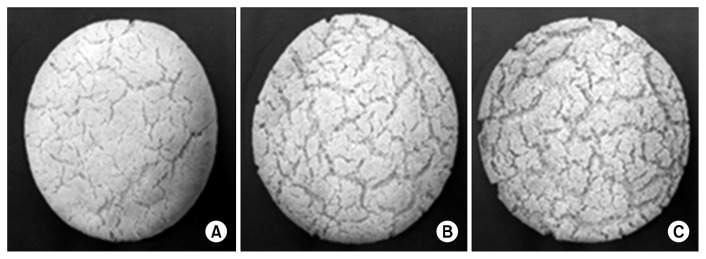

Changes in the quality and appearance of sugar-snap cookies made from blends of WHF and OAF

The sugar-snap cookies were prepared with blends of WHF and OAF. The color values, thicknesses, diameters, spread factors, and hardness of the cookies are shown in Table 4. The L values of cookies made with OAF and WHF were 44.15 and 57.53, respectively, and were decreased by the addition of OAF. The a and b value of sample was similar tendency with L value of cookie. The thickness of cookies made with OAF, WHF, WOB20, and WOB40 were 11.28, 12.35, 9.74, and 9.81 mm, respectively. The hardness of cookies prepared with WHF and WOB20 was lower than other samples, but was not significantly different (P>0.05). In our study, the spread factor and hardness of cookies was increased by the replacement of WHF with OAF. The appearance of cookies was observed, and they were found to be cracked as the OAF content increased (Fig. 1). Heiniö et al. (28) reported that bran or whole-grain flour often caused decreased spread and changes in biscuit structure owing to its high WHC. Similarly, Chauhan et al. (29) reported that amaranth flour cookies showed the highest spread ratio, followed by wheat flour cookies. Chung et al. (30) also observed an increase in spread factor when wheat flour was substituted with white rice flour or brown rice flour. Morales-Polanco et al. (9) reported that oat and pea protein isolates exhibited lower hardness (19.04 N) and gumminess (4.07 N) and higher cohesiveness. In contrast to our findings, Sharma and Gujral (25) reported that the spread factor of cookies decreased as the proportion of barley flour increased, whereas the snap force and water activity increased significantly. The decrease in hardness with rice flour substitution in cookies could be attributed to changes in gluten and moisture contents (30). However, Inglett et al. (20) reported that amaranth-oat cookies were acceptable in color, flavor, and texture, with no significant differences in sensory qualities compared with wheat flour cookies. Morales-Polanco (9) reported that crackers formulated with dehulled oat grain flour and pea protein showed improved texture properties (hardness, resilience, cohesiveness, springiness, gumminess, and chewiness) and higher levels of certain nutraceutical components, such as total dietary fiber. In our results, substituting WHF with OAF increased the fiber content, β-glucan content, and hardness of cookies made from WOB20 was not different compared with WHF (P<0.05). Consequently, low protein containing refined wheat and oat blends could be used to improve the quality and nutrient values of cookies, which could be useful for the manufacture of healthier products.

Table 4.

Color value, thickness, diameter, spread factor, and hardness of sugar-snap cookie made with blends with low-protein containing refined wheat and oat flour

| Samples | L value | a value | b value | Thickness of cookie sheet (mm) | Diameter of cookie sheet (mm) | Spread factor | Hardness of cookie (N) |

|---|---|---|---|---|---|---|---|

| OAF | 44.15±0.86c | 12.59±0.08c | 27.71±0.38d | 11.28±0.39b | 94.89±0.80b | 8.42±0.36b | 41.58±4.41a |

| WHF | 57.53±1.32a | 16.02±0.26a | 38.16±0.36a | 12.35±0.53a | 88.22±1.00c | 7.15±0.36c | 25.13±2.10b |

| WOB20 | 57.18±1.86a | 10.99±0.07b | 34.98±0.09b | 9.74±0.27c | 95.67±0.73ab | 9.83±0.29a | 30.85±4.59b |

| WOB40 | 53.36±0.26b | 12.82±0.18c | 33.06±0.07c | 9.81±0.20c | 97.27±0.97a | 9.92±0.28a | 45.81±6.75a |

Different letters (a–d) within the same column differ significantly (P<0.05).

OAF, oat flour; WHF, refined wheat flour; WOB20, blends that replaced 20% of wheat with oat flour; WOB40, blends that replaced 40% of wheat with oat flour.

Fig. 1.

Diagram of sugar-snap cookies made of blends with low protein containing refined wheat and oat flour. (A) Cookie made from wheat flour only. (B) Cookie made from blends of wheat and oat flour 20%. (C) Cookie made from blends of wheat and oat flour 40%.

ACKNOWLEDGEMENTS

This work was carried out with the support of the Cooperative Research Program for Agriculture Science and Technology Development (Project No. PJ01027104), Rural Development Administration, Republic of Korea.

Footnotes

AUTHOR DISCLOSURE STATEMENT

The authors declare no conflict of interest.

REFERENCES

- 1.Cheng YF, Bhat R. Functional, physicochemical and sensory properties of novel cookies produced by utilizing underutilized jering (Pithecellobium jiringa Jack.) legume flour. Food Biosci. 2016;14:54–61. doi: 10.1016/j.fbio.2016.03.002. [DOI] [Google Scholar]

- 2.Eswaran S, Muir J, Chey WD. Fiber and functional gastrointestinal disorders. Am J Gastroenterol. 2013;108:718–727. doi: 10.1038/ajg.2013.63. [DOI] [PubMed] [Google Scholar]

- 3.Lai HM, Lin TC. Bakery products. In: Hui YH, editor. Bakery Products: Science and Technology. Blackwell Publishing; Oxford, UK: 2006. pp. 3–68. [DOI] [Google Scholar]

- 4.Zhu F. Structures, properties, modifications, and uses of oat starch. Food Chem. 2017;229:329–340. doi: 10.1016/j.foodchem.2017.02.064. [DOI] [PubMed] [Google Scholar]

- 5.Peterson DM. Oat antioxidants. J Cereal Sci. 2001;33:115–129. doi: 10.1006/jcrs.2000.0349. [DOI] [Google Scholar]

- 6.Inglett GE, Chen D. Antioxidant and pasting properties of oat β-glucan hydrocolloids. Food Nutr Sci. 2012;3:827–835. [Google Scholar]

- 7.Duta DE, Culetu A. Evaluation of rheological, physicochemical, thermal, mechanical and sensory properties of oat-based gluten free cookies. J Food Eng. 2015;162:1–8. doi: 10.1016/j.jfoodeng.2015.04.002. [DOI] [Google Scholar]

- 8.Tester RF, Karkalas J. Swelling and gelatinization of oat starches. Cereal Chem. 1996;73:271–277. [Google Scholar]

- 9.Morales-Polanco E, Campos-Vega R, Gaytán-Martínez M, Enriquez LG, Loarca-Piña G. Functional and textural properties of a dehulled oat (Avena sativa L) and pea (Pisum sativum) protein isolate cracker. LWT-Food Sci Technol. 2017;86:418–423. doi: 10.1016/j.lwt.2017.08.015. [DOI] [Google Scholar]

- 10.Rao BD, Kulkarni DB, Kavitha C. Study on evaluation of starch, dietary fiber and mineral composition of cookies developed from 12 sorghum cultivars. Food Chem. 2018;238:82–86. doi: 10.1016/j.foodchem.2016.12.069. [DOI] [PubMed] [Google Scholar]

- 11.Pareyt B, Delcour JA. The role of wheat flour constituents, sugar, and fat in low moisture cereal based products: a review on sugar-snap cookies. Crit Rev Food Sci Nutr. 2008;48:824–839. doi: 10.1080/10408390701719223. [DOI] [PubMed] [Google Scholar]

- 12.AACC International. Approved methods of analysis. 10th ed. AACC International; St. Paul, MN. USA: 2000. Method 44-15A, 08-01, 46-12. [Google Scholar]

- 13.AOAC. Official methods of analysis of AOAC international. Association of Official Analytical Chemists; Rockville, MD, USA: 1986. AOAC Official method 996.11. [Google Scholar]

- 14.Medcalf DG, Gilles KA. Wheat starches. I. Comparison of physicochemical properties. Cereal Chem. 1965;42:558–568. [Google Scholar]

- 15.Kim WS, Shin M. The properties of rice flours prepared by dry- and wet-milling of soaked glutinous and normal grains. Korean J Food Cook Sci. 2007;23:908–918. [Google Scholar]

- 16.Yu L, Haley S, Perret J, Harris M. Comparison of wheat flours grown at different locations for their antioxidant properties. Food Chem. 2004;86:11–16. doi: 10.1016/j.foodchem.2003.08.037. [DOI] [Google Scholar]

- 17.Blois MS. Antioxidant determinations by the use of a stable free radical. Nature. 1958;181:1199–1200. doi: 10.1038/1811199a0. [DOI] [Google Scholar]

- 18.Zhao H, Dong J, Lu J, Chin J, Li Y, Shan L, Lin Y, Fan W, Gu G. Effects of extraction solvent mixtures on antioxidant activity evaluation and their extraction capacity and selectivity for free phenolic compounds in barley (Hordeum vulgare L.) J Agric Food Chem. 2006;54:7277–7286. doi: 10.1021/jf061087w. [DOI] [PubMed] [Google Scholar]

- 19.Mancebo CM, Picón J, Gómez M. Effect of flour properties on the quality characteristics of gluten free sugar-snap cookies. LWT-Food Sci Technol. 2015;64:264–269. doi: 10.1016/j.lwt.2015.05.057. [DOI] [Google Scholar]

- 20.Inglett GE, Chen D, Liu SX. Physical properties of gluten-free sugar cookies made from amaranth-oat composites. LWT-Food Sci Technol. 2015;63:214–220. doi: 10.1016/j.lwt.2015.03.056. [DOI] [Google Scholar]

- 21.Wang L, Ye F, Li S, Wei F, Chen J, Zhao G. Wheat flour enriched with oat β-glucan: A study of hydration, rheological and fermentation properties of dough. J Cereal Sci. 2017;75:143–150. doi: 10.1016/j.jcs.2017.03.004. [DOI] [Google Scholar]

- 22.Larrea MA, Chang YK, Martinez-Bustos F. Some functional properties of extruded orange pulp and its effect on the quality of cookies. LWT-Food Sci Technol. 2005;38:213–220. doi: 10.1016/j.lwt.2004.05.014. [DOI] [Google Scholar]

- 23.Kumar L, Brennan M, Zheng H, Brennan C. The effects of dairy ingredients on the pasting, textural, rheological, freeze-thaw properties and swelling behavior of oat starch. Food Chem. 2018;245:518–524. doi: 10.1016/j.foodchem.2017.10.125. [DOI] [PubMed] [Google Scholar]

- 24.Değirmencioğlu N, Gürbüz O, Herken EN, Yıldız AY. The impact of drying techniques on phenolic compound, total phenolic content and antioxidant capacity of oat flour tarhana. Food Chem. 2016;194:587–594. doi: 10.1016/j.foodchem.2015.08.065. [DOI] [PubMed] [Google Scholar]

- 25.Sharma P, Gujral HS. Cookie making behavior of wheat-barley flour blends and effects on antioxidant properties. LWT-Food Sci Technol. 2014;55:301–307. doi: 10.1016/j.lwt.2013.08.019. [DOI] [Google Scholar]

- 26.Ragaee S, Guzar I, Dhull N, Seetharaman K. Effects of fiber addition on antioxidant capacity and nutritional quality of wheat bread. LWT-Food Sci Technol. 2011;44:2147–2153. doi: 10.1016/j.lwt.2011.06.016. [DOI] [Google Scholar]

- 27.Gujral HS, Sharma P, Gill BS, Kaur S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013;138:1400–1406. doi: 10.1016/j.foodchem.2012.09.115. [DOI] [PubMed] [Google Scholar]

- 28.Heiniö RL, Noort MWJ, Katina K, Alam SA, Sozer N, de Kock HL, Hersleth M, Poutanen K. Sensory characteristics of wholegrain and bran-rich cereal foods–a review. Trends Food Sci Technol. 2016;47:25–38. doi: 10.1016/j.tifs.2015.11.002. [DOI] [Google Scholar]

- 29.Chauhan A, Saxena DC, Singh S. Total dietary fibre and antioxidant activity of gluten free cookies made from raw and germinated amaranth (Amaranthus spp.) flour. LWT-Food Sci Technol. 2015;63:939–945. doi: 10.1016/j.lwt.2015.03.115. [DOI] [Google Scholar]

- 30.Chung HJ, Cho A, Lim ST. Utilization of germinated and heat-moisture treated brown rices in sugar-snap cookies. LWT-Food Sci Technol. 2014;57:260–266. doi: 10.1016/j.lwt.2014.01.018. [DOI] [Google Scholar]