Abstract

Vaccinium bracteatum Thunb, have been widely used in various traditional medicines and food products. The narrow and uniform particle size distribution in V. bracteatum Thunb leaves (VBTL) can be achieved through a new emerging type of foodstuff processing and superfine grinding. The VBTL powders were subjected to four particle sizes as followed: 300–125, 125–75, 75–40, and <40 μm. The VBTL powders were observed to be with smaller size and bulk density, greater surface area, tapped density and the angle of repose. Water solubility index, water holding capacity and total flavonoid extraction increased slightly with the decrease in particle size. Differential scanning calorimetry showed that the VBTL exhibiting particle size of <40 μm had the lowest peak temperature; whereas, powder with a particle size of 125–300 μm displayed the largest endothermic enthalpy. Our results of the properties of VBTL superfine powder supplied the basis for VBTL in potential industrial applications of foods.

Keywords: Vaccinium bracteatum Thunb, Superfine grinding, Particle size, Physicochemical properties

Introduction

Vaccinium bracteatum Thunb, a traditional Chinese herb, also called Wufanshu belonging to the same genus as blueberry, is cultivated extensively across China as well as widely spread throughout the world [1]. Pigment from VBTL is available as a natural dying material for protein, hair, starch and white vinegar. VBTL juice is used to stain and cook rice, which then turns black by possible interactions of rice proteins with hydrophobic and hydrogen interactions [2]. In April every year, individuals living in the rural areas of China to the south of Yangtze River, e.g., Anhui Province and Jiangsu Province, customarily collect Wufanshu leaves and extract the pigments to make ‘Wufan’ with rice and other cereals, which has been developed into a well-known local tourist food [3]. Pigment from VBTL is available as a natural dying material for protein, hair, starch and white vinegar [4]. Previous report suggested that flavones from VBTL could ameliorate glucose level in blood and lipid level in plasma [5] and their polysaccharide were observed to acquire a potential hypoglycemic effect in diabetic mice model [1]. VBTL have many physiological functions such as anti-fatigue, digestion resistibility as well as antioxidant activity (accessible source of natural antioxidants and as a possible supplement of synthetic antioxidants), have been reported in the Compendium of Materia Medica. The retina protection, anti-fatigue and antimicrobial of VBTL have recently been confirmed [6, 7].

Superfine grinding process serves as an tool for making superfine powder with better dispersibility and solubility [8]. Superfine grinding technology has shown potential for production of nutraceuticals and functional foods [9]. Size is known to make a noticeable impact on the physicochemical attributes of a powder. The decrease in size of ultrafine powder surface leads to various alterations, which result into unique properties of bulk materials. Till date, this process technology has found applications in applied in ceramics, electrics, chemicals and paper manufacturing fields and in the pharmaceutical companies, but it is rarely in known in food industry. It is well known that this technique may not be suitable for many aspects due to the limitation which lead to the damage of active ingredients [10, 11]. Previous studies revealed that superfine ginger powder is known to exhibit good fluidity, water solubility index, water holding capacity and protein solubility [8]. Jin and Chen (2006) found that the cellulose accessibility of superfine grinding rice straw powder had positive relations in enzymatic hydrolysis [12]. Also, superfine chitin was observed to be a better substrate for the fungal deacetylase [13].

Till date, a limited knowledge is available for the effect of the particle size of VBTL powders and their physicochemical properties. In our previous study, thermal, emulsifying and rheological properties of polysaccharides sequentially extracted from V. bracteatum Thunb leaves were reported [14]. Therefore, to further evaluate the application of this technology on VBTL and particular surface area, bulk density, tapped density, angle of repose, water solubility index and water holding capacity solubility of different sized VBTL powders, present research was carried out. Thus, we targeted the characteristics of four powders on the basis of their particle size distributions and the physicochemical properties.

Materials and methods

Materials

V. bracteatum Thunb. leaves (VBTL) were obtained from West Anhui University, Anhui Province, China followed by drying at 40 °C to obtain the water content below 5% (w/w). The AACC method no. 44-19 [15] was used to determine the water content. A disc-mill was used to obtain the coarse particles of dried VBTL powder which was passed through sieves of different sizes (60 Mesh, GB/T6003.1-1997) to separate the granules to separate the granules (d < 300 μm). The AO table type micro ionizer (Qingxin Powder Machinery Company, Yixing, Jiangsu, China) was used and powders were subdivided through different sized sieves (120, 200 and 350 mesh, GB/T6003.1-1997) [2].

Particle size analysis

During this analysis, the particle sizes of obtained VBTL powders were determined by laser particle size analyzer (Mastersizer 2000 E, Malvern instrument Ltd., UK). Through this instrument, the following parameters such as volume weighed size distributions, the particle size parameters such as the volume median diameter (d50), De Brouckere mean diameter (d43 = ∑nid4i/∑nid3i), and Sauter mean diameter (d32 = ∑nid3i/∑nid2i) were targeted.

The population is subjected into two equal halves through Median diameter. On the other hand, De Brouckere mean diameter represents the volume or mass mean diameter of the particles, and Sauter mean diameter corresponds to the surface area weighted mean diameter of the particles [16].

Scanning electron microscopy (SEM)

The SEM Quanta 200FEG-SEM (FEI Co. Netherlands) (150 kV accelerated voltage and 10–15 mm working distance) was used for morphological characterization of the VBTL powders. The samples were prepared by using platinum (10 nm thick) for conductivity [17].

Color difference analysis

The color differences corresponding to ‘L’, ‘a’ and ‘b’ as indicators of the VBTL powders, were distinguished by using WB-2000IX A-automatic color difference meter (Shanghai Exact Science Instrument Ltd, Shanghai, China).

Bulk density and tapped density

For the estimation of the bulk density of VBTL powders, the samples were allowed to dry with an aim to reach a constant weight at 40 °C. Afterwards, the VBTL powders were filled to the mark of a 10 mL in volumetric flask (W1) and then weighed (W2). The bulk density of the ginger powders was calculated [18] as follows:

| 1 |

where total weight of the VBTL powders and the flask was denoted by W1 and W2 represents the weight of flask only.

The tapped density was determined as per the method given by Chen et al. and it was calculated using the following formula [2]:

| 2 |

Here, M denotes the total weight of the VBTL powder, V0 is the unsettled apparent volume and V1 is the tapped volume. All the tests were repeated thrice.

Test procedure for the angle of repose

The repose angle was determined according to the method reported by Chen et al. [2]. The maximum angle subtended by the surface of a heap of powder against the plane which supports the plane denotes the angle of repose (α) [19]. In brief, the filler was adjusted so that distance of glass plane from the outlet of filler (H) is adjusted to 1 cm. Further, the VBTL powders were separately poured into the filler so the tip of the powder cone touched the outlet of the filler. The radius (R) of cone was calculated for all powder type. The following formula for angle of repose (α) is presented as:

| 3 |

Test procedure for water solubility index (WSI)

The percentage of dry material obtained after the supernatant is evaporated from the water absorption determination represents water solubility index (WSI) [20] and it was determined by using the method of Zhao et al. [8].

The different sized samples (S1) were weighed. And then the samples (S1) were soaked in water (S2) with a ratio of S1:S2 = 0.02:1 at room temperature. Subsequently, the mixture was put into the centrifuge tubes placed in a water bath at 80 °C and stirred for different time intervals of 10, 20, 30, 40, 50 and 60 min, respectively, followed by centrifugation at 6000 rpm for 10 min and then supernatant solution was drained off by evaporation. Further, drying at 105 °C and weighing were followed in the final steps (S3). The formula to calculate water solubility index (WSI) is as follows:

| 4 |

Test procedure for water holding capacity (WHC)

The quantity of water bound to the fibers without the application of any external force (except for gravity and atmospheric pressure) represents water holding capacity [21]. In brief, the weights of the empty centrifuge tubes (M) and different sized VBTL powders (M1) were calculated followed by soaking into water (Mw) according to M1:Mw = 0.05:1 at 20 °C in a centrifuge tube (M). The tubes were kept at 60 °C for 60 min and then placed into cold water for 30 min, followed by centrifugation for 15 min at 5000 rpm. The centrifuge tubes with the powders (M3) were weighed after the supernatant removal step [22]. The water holding capacity (WHC) was calculated as the following formula:

| 5 |

Extraction and determination of total flavonoid

The extraction of flavonoids were carried out using the method reported by Chen et al. [2]. In brief, 3 g of VBTL powders were poured into an Erlenmeyer flask (100 mL) containing 30 mL diethyl ether solvent and stored for 12 h to remove the lipophilic impurities. Suction filtration was used to remove the ether by addition of 60, 70, 80, 90% ethanol (liquid to solid ratio 50:1, mL/g) to the Erlenmeyer flask, respectively followed by sonication in an ultrasonic cleaning bath for 2 h at 60 °C. Before subjected to determination of flavonoids, extract was filtered with filter paper (Xinhua, Medium102, China) and then concentrated by rotary evaporator to obtain the evaporated filtrate.

The colorimetric method was used to determine the total flavonoid content of sample as described by Zhang et al. [23]. Firstly, 1 mL of sample solution was mixed with 0.3 mL of 5% NaNO2 solution and incubated for 6 min followed by addition of 0.3 mL of 10% Al(NO3)3 solution which was allowed to stand for 6 min, followed by further adding of 4 mL of 1 mol/L NaOH solution to the mixture. Lastly, the final volume was adjusted to 10 mL with 30% (v/v) ethanol and mixture was allowed to stand for 15 min at room temperature and further subjected for the determination of absorbance of the solution at 510 nm using a UV752 spectrophotometer. The total flavonoid content was determined as described above and it was presented in milligrams of rutin equivalents per gram of VBTL powders extract.

Differential scanning calorimetric (DSC) analysis

The thermal properties of VBTL powders were investigated through differential scanning calorimetry (DSC). Approximately, 5 mg of dried sample was accurately weighed and subsequently placed in an aluminum pot prior to sealing, using an empty pot as a reference. DSC thermograms were obtained in the range of 40–300 °C in a nitrogen atmosphere at rate of 10 °C/min. The thermal analysis graphs were plotted as heat flow versus temperature [24].

Statistical analysis

All the data were presented in triplicates to calculate the mean ± SD and to be analyzed statistically by analysis of the variance. One-way analysis of variance (ANOVA) was performed using the Origin 8.0 software.

Results and discussion

Surface properties

In the present study, the particle size distribution was found to be associated to a Gaussian distribution and correspondent to normal distribution. The VBTL powders with different size displayed different surface properties (Table 1). With the increase in mesh number, the size of VBTLP powder decreased. Particularly, the increase of mesh number, the D (2, 3) values decreased from 61.101 to 8.411 μm and D (3, 4) from 215.736 to 15.996 μm, whereas, the specific surface area increased from 0.098 to 0.713. The VBTL powder with the smallest volume median diameter (13.734 μm) had the largest specific surface area. Meanwhile, the VBTL powder with the largest volume median diameter (212.326 μm) was considered to have the smallest specific surface (Table 1). The VBTL powders could ultimately be pulverized to finer particles by superfine grinding technology. Finer particles showed a better capability for achieving homogeneity when mixed with the active pharmaceutical ingredients and other powder additives, because they tended to have more particles per unit weight [25]. The adsorption capacity of the particles was improved gradually with the increase of the specific surface area. So that the moisture can be penetrated easily in tablets with the finer particles. Tablets or granules tended to disintegrate rapidly with the improvement of the ratio of moisture penetration. The larger specific surface area could accelerate indirectly the drug dissolution from solid dosage forms [23].

Table 1.

Physical characteristics of the VBTL powder particles obtained from the laser diffraction method

| Mesh number | Equivalent diameter particles accounted for by measuring the proportion (μm) | Specific surface area (m2/g) | ||||

|---|---|---|---|---|---|---|

| D10 | D50 | D90 | D(3,2) | D(4,3) | ||

| 60 | 2.855 ± 0.144 | 212.326 ± 9.985 | 363.629 ± 17.353 | 61.101 ± 2.863 | 215.736 ± 9.652 | 0.098 ± 0.004 |

| 120 | 17.11 ± 0.795 | 127.495 ± 6.128 | 213.295 ± 9.472 | 37.844 ± 1.652 | 134.847 ± 5.427 | 0.159 ± 0.007 |

| 200 | 4.193 ± 0.198 | 22.031 ± 0.983 | 55.716 ± 2.147 | 10.531 ± 0.425 | 26.505 ± 1.105 | 0.570 ± 0.021 |

| 350 | 3.739 ± 0.181 | 13.734 ± 0.691 | 31.568 ± 1.306 | 8.411 ± 0.385 | 15.996 ± 0.679 | 0.713 ± 0.032 |

Values were mean ± SD of three determinations. D50: volume median diameter, D(2, 3): Sautermena diameter, D(4, 3): De Brouckere mean diameter, D10: It signifies the 10% of the distribution below this value, D90: It signifies the 90% of the distribution below this value

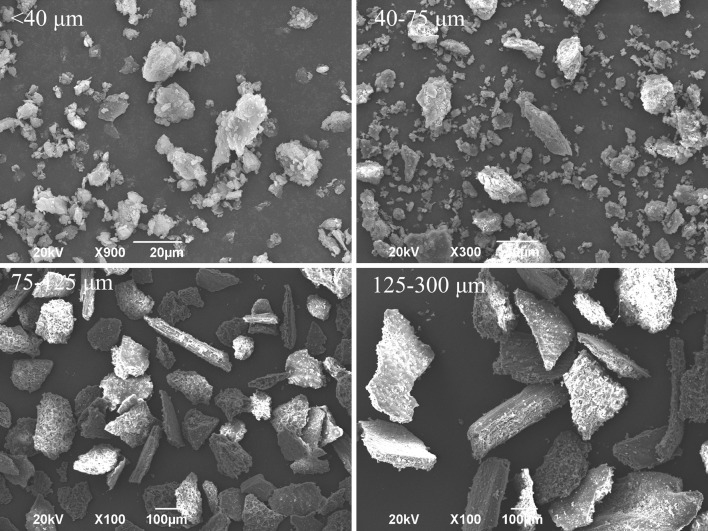

Microphotographs of VBTL powder

The morphology of fragmented VBTL granules was observed by means of the scanning electron microscope (Fig. 1). As the particle size decreased, the shape of the particles changed. The largest sized presented a more polygonal scheme, whereas the smallest particles seemed more spherical. The shape of the superfine powders (<40 and 40–75 μm) by the mill was uniform, and its surface was comparatively smooth [26]. At the beginning of crack propagation and fracture, the aggregation of VBTL particles might result into an increase in size. Particle would be finer when the effect of fracture overweighed the effect of aggregation [8]. The smaller particles conduced to the amorphous domains, some of which may more easily solubilize during heat/moisture treatment. The VBTL powders underwent a transformation from an ordered structure to an amorphous structure by means of the breakage intermolecular bonds. The morphology changed to obvious levels via mini-grinding, which had significant impact on physicochemical properties of VBTL powders [26].

Fig. 1.

SEM images of different particle size VBTL powders at magnifications (×900, ×300, ×100, ×100)

Color difference analysis

The color difference of the VBTL powders were presented in Table 2. As known, CIELAB represents “L, a, b” color space, which could express the colors. “L” could express lightness and “a and b” were the chromaticity coordinates. Where, +a is the red direction, −a is a green direction, +b is the yellow direction, and −b is the blue direction [27]. Different sized VBTL particles varied slightly in color, with L varying from 24.67 to 34.02, a value from 3.96 to 5.02, and b value from 14.66 to 18.64. The L value has no difference with 125–300 and 75–125 particle size group whereas, a value showed no difference with particle size group. On the other hand, b value signified that there was no difference with 125–300 and 75–125 group, 75–40 and <40 group (Table 2). VBTL powders showed a decrease in L value in particle size, while a and b values increased slightly. In other words, VBTL powders of smaller particle size were relatively darker, more reddish and more yellowish in color. As the internal material was exposed easily with decreased particles, the color of the powder was changed accordingly. The color is an important parameter of most foodstuffs, which is well considered by consumers when they evaluate and select goods. Therefore, our study could summarize that the particle size had significantly affected the VBTL powders. The result is consistent with the research investigated by Chen et al. [28].

Table 2.

Color difference of the VBTL powders

| VBTL particles (μm) | L | a | b |

|---|---|---|---|

| 125–300 | 34.02 ± 1.233c | 3.96 ± 0.754a | 14.66 ± 0.885a |

| 75–125 | 32.68 ± 0.698c | 4.23 ± 1.024a | 15.15 ± 1.374a |

| 75–40 | 28.43 ± 1.134b | 4.87 ± 0.589a | 16.98 ± 0.668b |

| <40 | 24.67 ± 0.955a | 5.02 ± 0.717a | 18.64 ± 0.431b |

Values were mean ± SD of three determinations. The lower case letters of a–c are significantly different in the same column, P < 0.05

Bulk density, tapped density and angle of repose

The bulk density and tapped density of the four particle sized VBTL powders were shown in Fig. 2(A), (B), respectively. Our study depicted that the bulk density reduced from 0.411 to 0.276 g/mL with the decrease of particle size of VBTL powder (Fig. 2(A)), whereas the tapped density of VBTL powders increased from 0.451 to 0.613 g/mL (Fig. 2(B)). The properties of the bulk and tapped densities are considered as a measure of inter-particulate interactions in VBTL powders, which have significant effect on the powder flow. It was useful for the VBTL powder to fill tablets or capsule products with the increase of tapped density [2].

Fig. 2.

Effect of particle size on the physicochemical properties of VBTL powders. (A) bulk density, (B) tapped density, (C) angle of repose, (D) water solubility index, WSI, (E) water holding capacity, WHC

The angle of repose is regarded as a measure of the angle of inclination of the free surface to the horizontal of a bulk solid pile. The property shows the inter-particulate friction and has been used to characterize the flow behavior of powders and granular materials with respect to flow ability [29]. The VBTL powders indicated different fluidity as shown in Fig. 2(C). With the decreased of the particle size of VBTL powder, the angle of repose increased from 35.97° to 49.08°. The VBTL powder with a particle size of <40 μm had the largest angle of repose, while the VBTL powder with the particle size of 125–300 μm had the lowest angle of repose. It is commonly reported that the angle of repose decreases with increasing particle size. As the decrease of angle of repose, the VBTL powder indicated a better fluidity of the granular bulk [30].

The water solubility index (WSI) and water holding capacity (WHC)

Soaking time had significant effect on the water solubility index (WSI) of four sized VBTL powders and the result was shown in Fig. 2(D). As the size of VBTL particles decreased and the soaking time was lengthened, the WSI values of VBTL powders with different sizes increased slightly. The WSI values of VBTL powders with different sizes ranged from 17.46 to 22.04%, 18.25 to 22.98%, 20.20 to 23.54%, 20.48 to 24.70% and 21.77 to 25.35% for 20, 30, 40, 50 and 60 min, respectively. As shown in Fig. 2(E), the WHC also increased with decrease in size of VBTL powder particles. The WHC values of VBTL powders with different sizes ranged from 2.681 to 2.881 g/g, 2.718 to 2.909 g/g, 2.816 to 2.998 g/g and 2.928 to 3.081 g/g for 10, 20, 30, 40 min, respectively. As the increase of soaking time and the decrease of particle size, the WSI and WHC values of VBTL powder decreased accordingly. It was speculated that the surface area of VBTL powders increased via superfine grinding, which brought about the increase in dispersibility and solubility of superfine powder. Therefor, the change of the surface of VBTL powders resulted in the increase of WSI value. Furthermore, since the hydrophilic groups in the polysaccharide content of the VBTL powder had been exposed, the particles could integrate with water easily, and the value of WHC increased eventually [8].

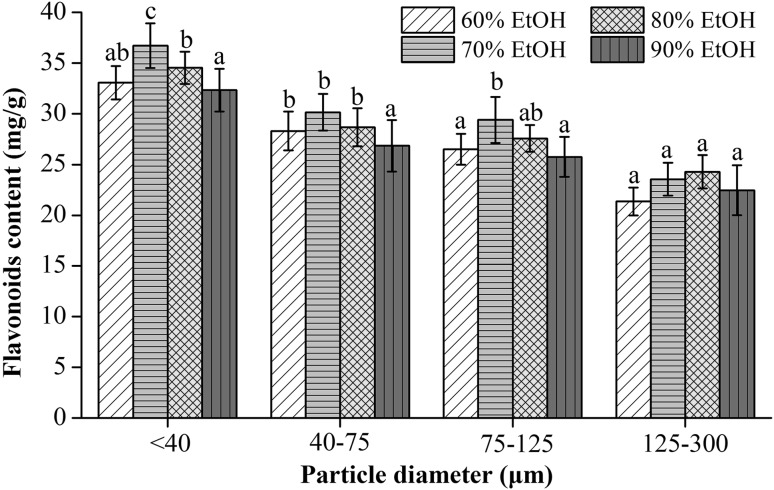

The effects on total flavonoid extract

The flavonoid concentration of VBTL powder was measured using rutin with different concentration as a standard. The calibration curve fitted from data of testing (y = − 0.010 + 6.836x), where y represents the absorbance at 510 nm of the sample and x represents rutin concentration which ranged from 0.008 to 0.040 mg/mL (R2 = 0.991). The effects of ethanol concentration on total flavonoid extract were showed in Fig. 3. As the particle size decreased, the solubility of flavonoid increased. The flavonoids content of VBTL powders with different sizes ranged from 21.36 to 33.06, 23.55 to 36.72, 24.28 to 34.52 and 22.46 to 32.33 mg/g for 60, 70, 80, 90% ethanol, respectively. Compared with other ethanol concentration, 70% ethanol witnessed to be the best concentration for the extraction of flavonoid and the flavonoid solubility of VBTL powder with particle sizes of <40 μm reached 36.72 mg/mL. The ethanol concentration could affect the extraction of flavonoid only to the lesser extent. With the decreased particle size, the solubility of flavonoids increases as shown in Fig. 3 and the ethanol concentration had significant effect on solubility of flavonoid. Whereas, with the increasing size the effect of ethanol concentration diminished. It might be due to the fact that the superfine powder had a higher specific surface area, which could result in the increase of solubility of flavonoid at all the four concentrations of ethanol.

Fig. 3.

The change of the percentage of flavonoids of different particle size VBTL powders. The lower case letters of a–c are significantly different in the VBTL powder with the same particle size, P < 0.05

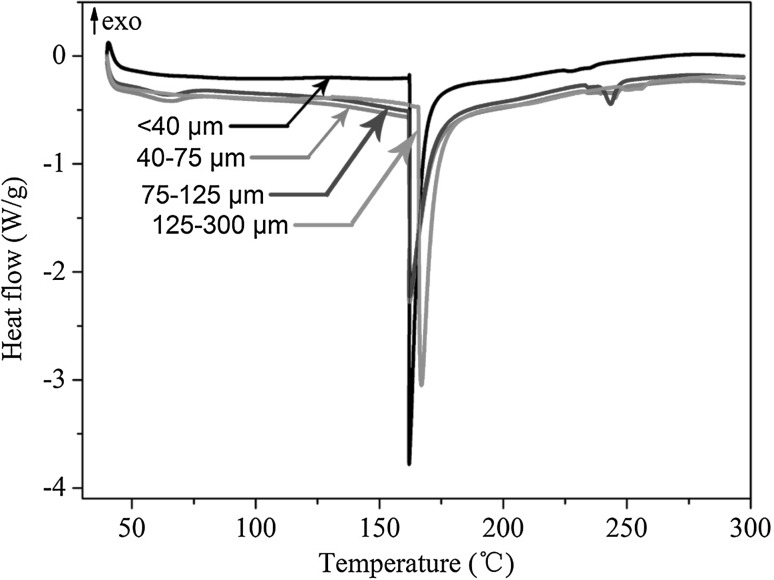

Thermal characteristics of VBTL powders

The heat flow properties of the four particle sized VBTL powders were shown in Fig. 4. The peak temperatures were 156.46, 162.78, 162.78 and 162.00 °C for <40, 40–75, 75–125 and 125–300 μm, respectively. The endothermic enthalpy change (ΔH) required to melt 1 g of <40, 40–75, 75–125 and 125–300 μm, was 78.38, 70.39, 75.78 and 89.44, respectively. The VBTL powder with a particle size of <40 μm had the lowest peak temperature. And the VBTL powder with a particle size of 125–300 μm had the largest endothermic enthalpy. The endothermic enthalpy is a measure of the required energy for disrupting hydrogen bonds within the junction zones [24]. It is speculated that with increasing size of VBTL powder particles, the more energy for disrupting hydrogen bonds was consumed. It is also due to the fact that the intense and prolonged grinding brought about by high temperature led to change of endothermic enthalpy of samples [23].

Fig. 4.

The thermal characteristics of different particle size VBTL powders

Acknowledgements

This study was supported by the Major Projects of Science and Technology in Anhui Province (15czz03115), the grants from the National Natural Science Foundation of China (31272111), the Key projects of Natural Science Research of Anhui Province (KJ2016A575) and the Special Fund for Agro-scientific Research in the Public Interest of China (201403064).

Compliance with ethical standards

Conflict of interest

The authors declare no conflict of interest.

Contributor Information

Li Jiang, Email: jiangli@ustc.edu.cn.

Qi-Xin Xu, Email: 369856938@qq.com.

Mu Qiao, Email: 1098485560@qq.com.

Fei-Fei Ma, Email: 519012671@qq.com.

Kiran Thakur, Email: kumarikiran@hfut.edu.cn.

Zhao-Jun Wei, Phone: 86-551-62901539, Email: zjwei@hfut.edu.cn.

References

- 1.Wang L, Zhang Y, Xu M, Wang Y, Cheng S, Liebrecht A, Qian H, Zhang H, Qi X. Anti-diabetic activity of Vaccinium bracteatum Thunb. leaves’ polysaccharide in STZ-induced diabetic mice. Int. J. Biol. Macromol. 2013;61:317–321. doi: 10.1016/j.ijbiomac.2013.07.028. [DOI] [PubMed] [Google Scholar]

- 2.Wang Y, Li Y, Liu Y, Chen X, Wei X. Extraction, characterization and antioxidant activities of Se-enriched tea polysaccharides. Int. J. Biol. Macromol. 2015;77:76–84. doi: 10.1016/j.ijbiomac.2015.02.052. [DOI] [PubMed] [Google Scholar]

- 3.Xu C, Ma Y, Chen H. Technique of grafting with Wufanshu (Vaccinium bracteatum Thunb.) and the effects on blueberry plant growth and development, fruit yield and quality. Sci. Hortic.-Amsterdam. 176: 290–296 (2014)

- 4.Wang L, Yao HY. Purification of black pigment from Vaccinium bracteatum Thunb leaves by resin. Nat. Prod. Res. Dev. 2006;18:20–24. [Google Scholar]

- 5.Wang L, Zhang XT, Zhang HY, Yao HY, Zhang H. Effect of Vaccinium bracteatum Thunb. leaves extract on blood glucose and plasma lipid levels in streptozotocin-induced diabetic mice. J Ethnopharmacol. 2010;130:465–469. doi: 10.1016/j.jep.2010.05.031. [DOI] [PubMed] [Google Scholar]

- 6.Wang L, Xu Y, Zhou S, Qian H, Zhang H, Qi X, Fan M. Interaction between Vaccinium bracteatum Thunb. leaf pigment and rice proteins. Food Chem. 2016;194:272–278. doi: 10.1016/j.foodchem.2015.08.006. [DOI] [PubMed] [Google Scholar]

- 7.Wang L, Xu HN, Yao H, Zhang H. Phenolic Composition and Radical Scavenging Capacity of Vaccinium bracteatum Thunb. Leaves. Int. J. Food Prop. 2011;14:721–725. doi: 10.1080/10942910903374106. [DOI] [Google Scholar]

- 8.Zhao X, Yang Z, Gai G, Yang Y. Effect of superfine grinding on properties of ginger powder. J. Food Eng. 2009;91:217–222. doi: 10.1016/j.jfoodeng.2008.08.024. [DOI] [Google Scholar]

- 9.Sun C, Liu R, Wu T, Liang B, Shi C, Zhang M. Effect of superfine grinding on the structural and physicochemical properties of whey protein and applications for microparticulated proteins. Food Sci. Biotechnol. 2015;24:1637–1643. doi: 10.1007/s10068-015-0212-y. [DOI] [Google Scholar]

- 10.Zhao XY, Ao Q, Yang LW, Yang YF, Sun JC, Gai GS. Application of superfine pulverization technology in Biomaterial Industry. J. Taiwan Inst. Chem. E. 2009;40:337–343. doi: 10.1016/j.jtice.2008.10.001. [DOI] [Google Scholar]

- 11.Song LL, Fan BY, Jiang SZ, Zhang DL. Probe into Characteristics of Taraxacum mongolicum Ultramicro-power. China J. Chinese Mater. Med. 2002;27:12–15. [PubMed] [Google Scholar]

- 12.Jin S, Chen H. Superfine grinding of steam-exploded rice straw and its enzymatic hydrolysis. Biochem. Eng. J. 2006;30:225–230. doi: 10.1016/j.bej.2006.05.002. [DOI] [Google Scholar]

- 13.Win NN, Stevens WF. Shrimp chitin as substrate for fungal chitin deacetylase. Appl. Microbiol. Biot. 2001;57:334–341. doi: 10.1007/s002530100741. [DOI] [PubMed] [Google Scholar]

- 14.Xu QX, Shi JJ, Zhang JG, Li L, Jiang L, Wei ZJ. Thermal, emulsifying and rheological properties of polysaccharides sequentially extracted from Vaccinium bracteatum Thunb leaves. Int. J. Biol. Macromol. 2016;93:1240–1252. doi: 10.1016/j.ijbiomac.2016.09.098. [DOI] [PubMed] [Google Scholar]

- 15.AACC A A o C C. Approved Methods of the AACC Method 44-19, 9th ed. St. Paul, MN, USA (1995)

- 16.Protonotariou S, Drakos A, Evageliou V, Ritzoulis C, Mandala I. Sieving fractionation and jet mill micronization affect the functional properties of wheat flour. J. Food Eng. 2014;134:24–29. doi: 10.1016/j.jfoodeng.2014.02.008. [DOI] [Google Scholar]

- 17.Chen Y, Zhang BC, Sun YH, Zhang JG, Sun HJ, Wei ZJ. Physicochemical properties and adsorption of cholesterol by okra (Abelmoschus esculentus) powder. Food Funct. 2015;6:3728–3736. doi: 10.1039/C5FO00600G. [DOI] [PubMed] [Google Scholar]

- 18.Bai YX, Li YF. Preparation and characterization of crosslinked porous cellulose beads. Carbohyd. Polym. 2006;64:402–407. doi: 10.1016/j.carbpol.2005.12.009. [DOI] [Google Scholar]

- 19.Taser OF, Altuntas E, Ozgoz E. Physical Properties of Hungarian and Common Vetch Seeds. J. Appl. Sci. 2005;5:323–326. doi: 10.3923/jas.2005.323.326. [DOI] [Google Scholar]

- 20.Jin Z, Hsieh F, Huff HE. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995;22:185–194. doi: 10.1016/0733-5210(95)90049-7. [DOI] [Google Scholar]

- 21.Raghavendra SN, Rastogi NK, Raghavarao KSMS, Tharanathan RN. Dietary fiber from coconut residue: effects of different treatments and particle size on the hydration properties. Eur. Food Res. Technol. 2004;218:563–567. doi: 10.1007/s00217-004-0889-2. [DOI] [Google Scholar]

- 22.Zhang M, Zhang CJ, Shrestha S. Study on the preparation technology of superfine ground powder of Agrocybe chaxingu Huang. J. Food Eng. 2005;67:333–337. doi: 10.1016/j.jfoodeng.2004.04.036. [DOI] [Google Scholar]

- 23.Zhang LH, Xu HD, Li SF. Effects of micronization on properties of Chaenomeles sinensis (Thouin) Koehne fruit powder. Innov. Food Sci. Emerg. 2009;10:633–637. doi: 10.1016/j.ifset.2009.05.010. [DOI] [Google Scholar]

- 24.Shi JJ, Zhang JG, Sun YH, Qu J, Li L, Prasad C, Wei ZJ. Physicochemical properties and antioxidant activities of polysaccharides sequentially extracted from peony seed dreg. Int. J. Biol. Macromol. 2016;91:23–30. doi: 10.1016/j.ijbiomac.2016.05.082. [DOI] [PubMed] [Google Scholar]

- 25.Riley CK, Adebayo SA, Wheatley AO, Asemota HN. Surface properties of yam (Dioscorea sp.) starch powders and potential for use as binders and disintegrants in drug formulations. Powder Technol. 2008;185:280–285. doi: 10.1016/j.powtec.2007.10.028. [DOI] [Google Scholar]

- 26.Zhao X, Du F, Zhu Q, Qiu D, Yin W, Ao Q. Effect of superfine pulverization on properties of Astragalus membranaceus powder. Powder Technol. 2010;203:620–625. doi: 10.1016/j.powtec.2010.06.029. [DOI] [Google Scholar]

- 27.Liu K. Particle size distribution of distillers dried grains with solubles (DDGS) and relationships to compositional and color properties. Bioresour. Technol. 2008;99:8421–8428. doi: 10.1016/j.biortech.2008.02.060. [DOI] [PubMed] [Google Scholar]

- 28.Chen Q, Koh HK, Park JB. Color Evaluation of Red Pepper Powder. T. Asaebe. 1999;42:749–754. doi: 10.13031/2013.13237. [DOI] [Google Scholar]

- 29.Zhou YC, Xu BH, Yu AB, Zulli P. An experimental and numerical study of the angle of repose of coarse spheres. Powder Technology. 2002;125:45–54. doi: 10.1016/S0032-5910(01)00520-4. [DOI] [Google Scholar]

- 30.Ileleji KE, Zhou B. The angle of repose of bulk corn stover particles. Powder Technol. 2008;187:110–118. doi: 10.1016/j.powtec.2008.01.029. [DOI] [Google Scholar]